Production process of antibacterial, anti-pilling, anti-wrinkle and wear-resistant wool fabric

A production process and anti-pilling technology, which is applied in the treatment of wear-resistant fibers, textile materials, and elongation of fabrics, and can solve problems such as rough craftsmanship, poor fabric shaping, and non-irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

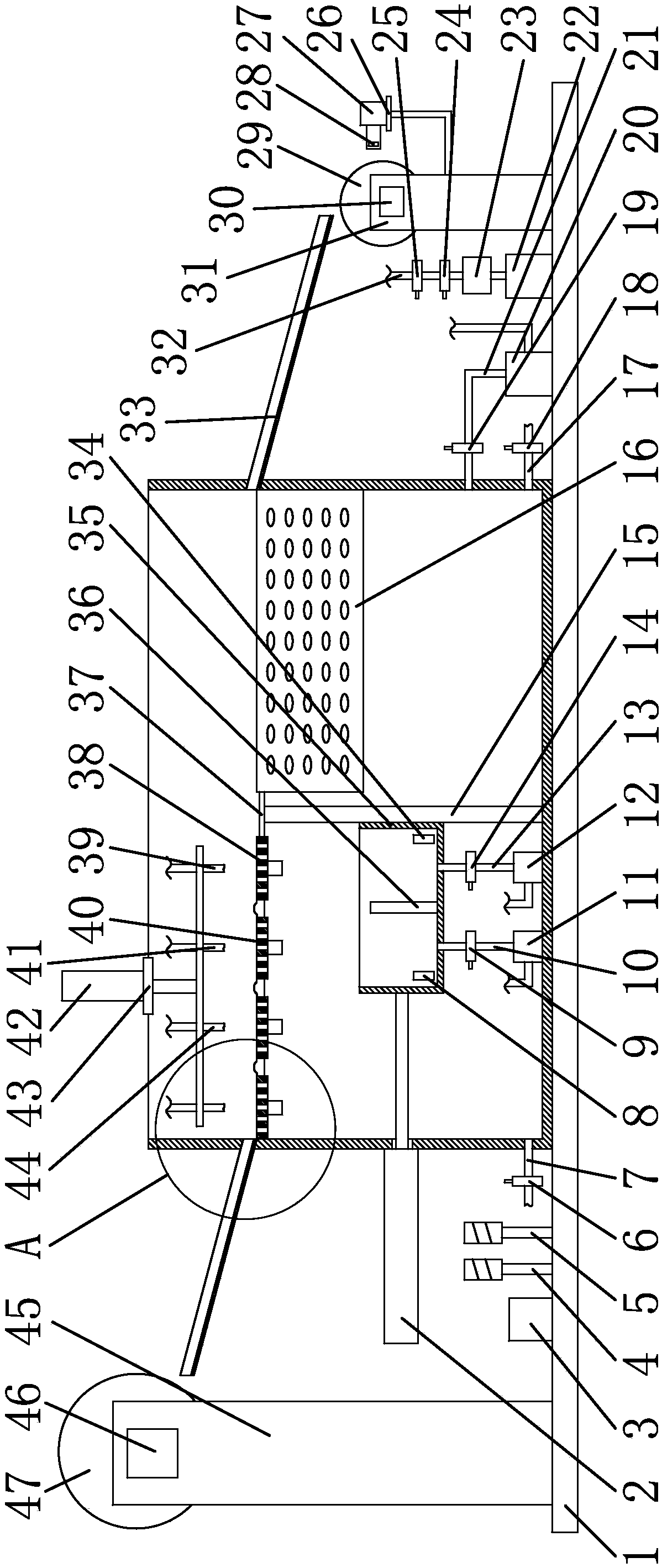

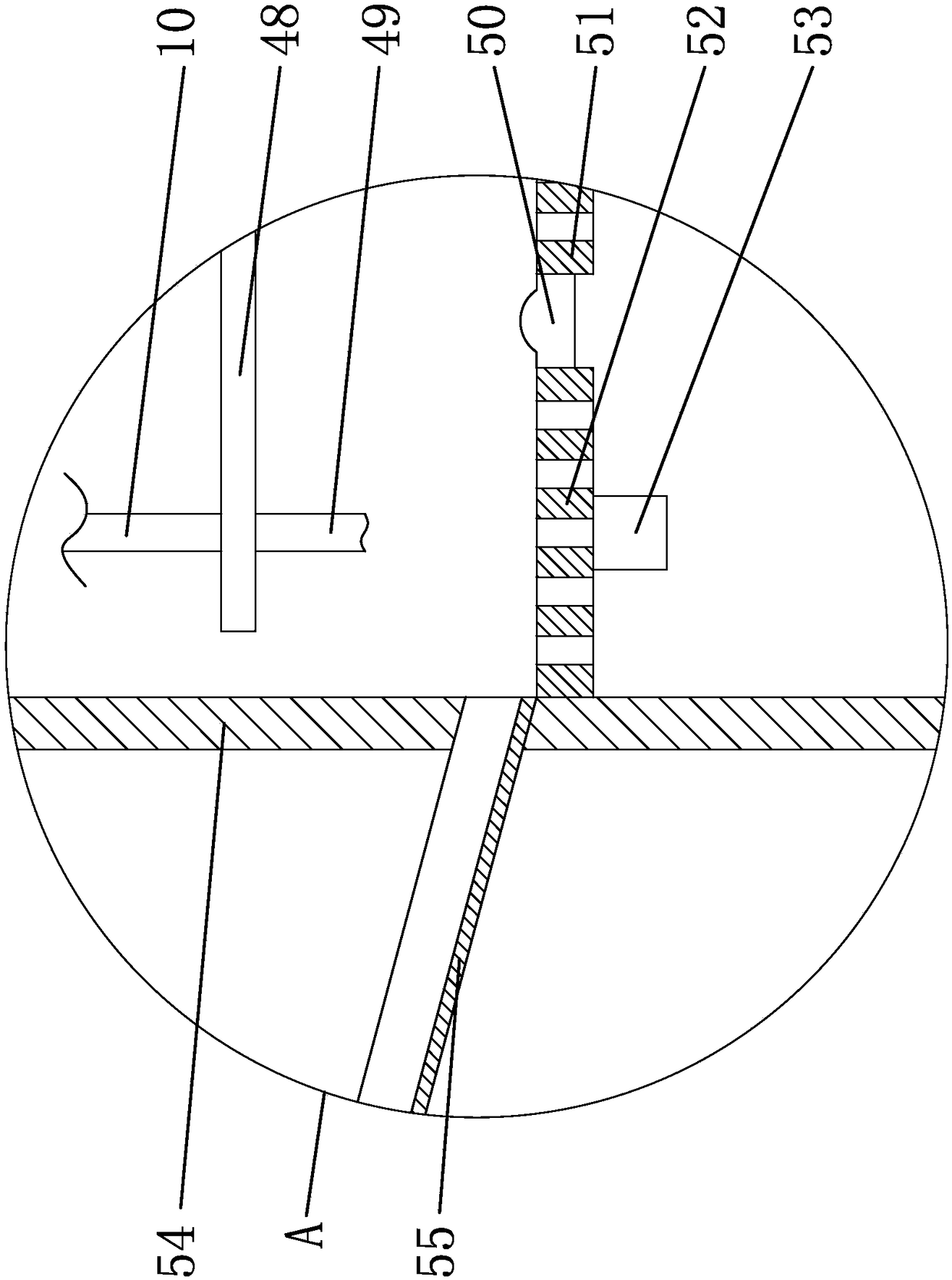

[0068] Below are specific embodiments of the present invention and in conjunction with accompanying drawing, technical scheme of the present invention is described further, but the present invention is not limited to these embodiments.

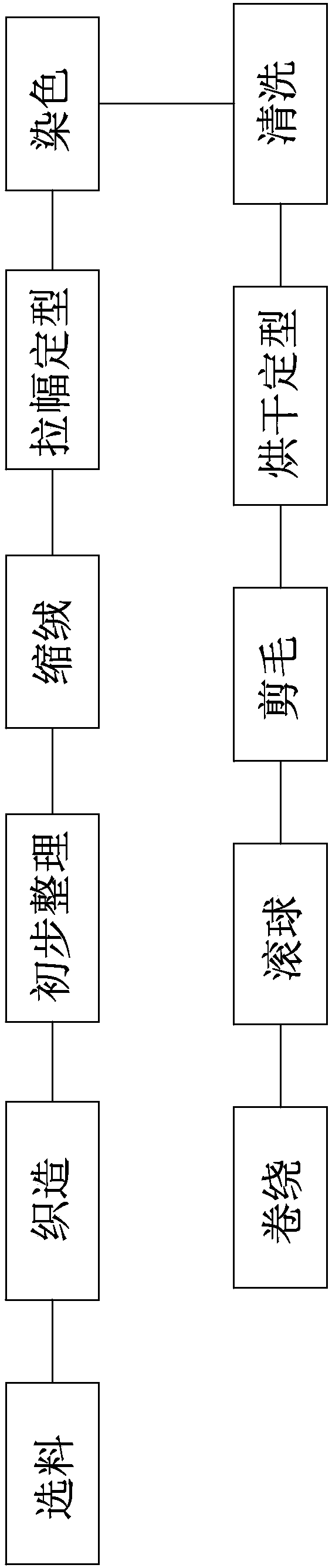

[0069] Such as figure 1 As shown, the production process of the anti-bacterial, anti-pilling, anti-wrinkle and wear-resistant wool fabric, the production process comprises the following steps:

[0070] S1, material selection: wool fiber, cashmere fiber and polyester fiber are put into the fiber mixer by weight to obtain mixed fiber, then the mixed fiber is combed into tops; existing products available for purchase;

[0071] S2. Weaving: the wool top made by combing in S1 is made into yarn through pre-spinning, spinning, winding, doubling, two-for-one twisting, and steaming, and the yarn is respectively put into the rapier loom as warp yarn and weft yarn Carry out weaving, obtain wool fabric gray cloth; In the present embodiment, rapier loom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com