Dyeing and finishing processing method of acetate fiber/polyester fiber blended fabric

A technology of blended fabrics and processing methods, applied in the direction of dyeing method, fiber type, fiber treatment, etc., can solve the problems of large dyeing temperature difference between acetate fiber and polyester fiber, etc., achieve dimensional stability, excellent fastness, and small loss of strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

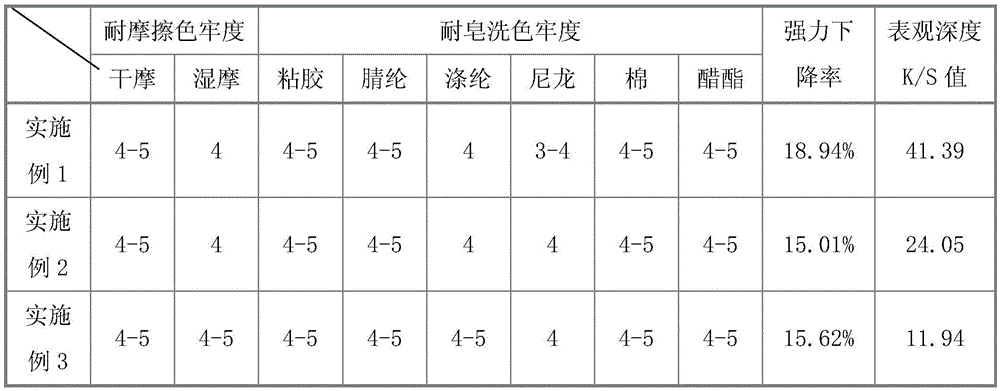

Examples

Embodiment 1

[0033] Fabric sample: Acetate / polyester blended fabric (Teijin Co., Ltd.) Component: 60 / 40 Gram weight: 110g / m 2

[0034] The above-mentioned cloth sample is processed through the following steps:

[0035] 1) Prepare 100ml of scouring solution containing NaOH: 2.0% by weight; degreaser HomectolLYS (purchased from Clariant Chemicals): 1.5% by weight, sodium bicarbonate: 1.0% by weight, and heat up to 80°C to treat 5g of the above-mentioned cloth samples for 20 minutes. wash;

[0036] 2) Prepare 100ml of Accophony DP-FFC aqueous solution with a concentration of 40g / L, soak the cloth sample twice and scour it twice, and then bake it at 130°C for 60s.

[0037] 3) Preparation containing Yatelong black SW-VIP: 5.6% by weight, Yatelong emerald blue SW-GL: 2.0% by weight, Yatelong yellow SW-GG: 0.8% by weight and leveling agent PEL (purchased from BASF ): 3g / L, PH5.0 acetic acid-sodium acetate buffer: 100ml of 40g / L water dyeing solution, put the cloth sample treated with Accord DP-F...

Embodiment 2

[0041] Fabric sample: Acetate / polyester interwoven fabric (Japan Teijin Company) Component: 25 / 75 Gram Weight: 200g / m 2

[0042] The above-mentioned cloth sample is processed through the following steps:

[0043] 1) Prepare 100ml of scouring solution containing NaOH: 4.0% by weight; HomectolLYS (purchased from Clariant Chemicals): 2.5% by weight, sodium bisulfite: 2.0% by weight, heat up to 90°C, treat 5g of the above cloth sample for 45 minutes, and wash with water;

[0044] 2) Prepare 100ml of Accophony DP-FFC aqueous solution with a concentration of 40g / L, soak the cloth sample twice and scour it twice, and then bake it at 140°C for 45s.

[0045] 3) Prepare 100ml of dyeing solution containing Yatrom blue SW-B: 3.5%, leveling agent PEL (purchased from BASF): 2g / L, pH4.0 acetic acid-sodium acetate buffer: 40g / L, and put in The fabric sample treated with DP-FFC can be dyed, and the temperature is raised to 130°C at 2°C / min, then kept for 90 minutes, and then cooled to 80°C; ...

Embodiment 3

[0049] Fabric sample: Acetate / polyester interwoven fabric (Japan Teijin Company) Component: 80 / 20 Gram weight: 170g / m 2

[0050] The above-mentioned cloth sample is processed through the following steps:

[0051] 1) Prepare 100ml of scouring solution containing NaOH: 1.5% by weight; degreaser Yajierui TSC-E: 1.5% by weight, heat up to 65°C, treat 5g of the above cloth sample for 15 minutes, and wash with water;

[0052] 2) Prepare 100ml of Accophony DP-FFC aqueous solution with a concentration of 40g / L, dip and roll the scoured cloth samples, and bake them at 140°C for 45s.

[0053] 3) Prepare 100ml of dye solution containing Yatelong Golden SW-RW: 1.8%, leveling agent PEL (purchased from BASF): 1g / L, pH5.5 acetic acid-sodium acetate buffer: 40g / L, and put it into Yatelong The fabric sample treated with DP-FFC can be dyed, and the temperature is raised to 110°C for 45 minutes at 2°C / min, and then cooled to 80°C;

[0054] 4) Prepare 100ml of reducing cleaning solution contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com