Addition-type silicone rubber latex and preparation method thereof and application product thereof

A silicone rubber emulsion and addition molding technology, applied in the field of material science, can solve the problems affecting the modification of chemical fiber cotton, poor compatibility of silicone rubber, and inapplicability to modified chemical fiber cotton composite materials, etc. The effect of excellent compression set resistance and water wash resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

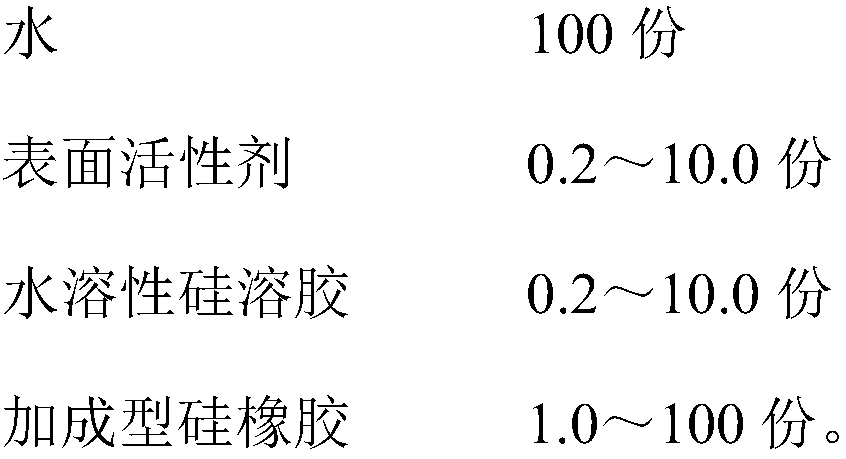

[0049] The preparation method of addition type silicone rubber emulsion of the present invention comprises the following steps:

[0050] a. Add surfactant and water-soluble silica sol into water, stir and dissolve evenly to obtain mixed solution;

[0051] b. Add addition-type silicone rubber into the mixture, and use high-shear mixing equipment to fully mix and emulsify.

[0052] The high-shear mixing equipment used in step b is a high-speed disperser, an intermittent high-speed homogenizer, a continuous high-speed homogenizer, a colloid mill, and the like. The mixing and emulsifying time should be adjusted according to the amount of emulsification. The standard of emulsification is fine and uniform, without large particles of silicone rubber or floating oil on the liquid surface.

[0053] In the application of the present invention, the chemical fiber cotton composite material is modified with the above-mentioned addition-type liquid silicone rubber emulsion:

[0054] (1) S...

Embodiment 1-6

[0079] The preparation method of embodiment 1-6 is as follows:

[0080] Add the surfactant and water-based silica sol into the water, and use a disc disperser to stir at a low speed for 1 minute to mix evenly. Mix the AB component of the addition-type silicone rubber evenly with a manual seasoning knife, and add it to the above-mentioned water dispersion. Intermittent high-speed homogenizer emulsifies at high speed for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com