Patents

Literature

132 results about "Methyl aldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formaldehyde (methyl aldehyde) Description. Formaldehyde is used in the manufacture of formaldehyde-based resins and plastics used in many industries, but mostly in the wood-products industry. Formaldehyde-based resins are also used as adhesives.

Methyl aldehyde adsorbing substance and preparation method thereof

ActiveCN101468305AGood hygroscopicityPromote enrichmentOther chemical processesDispersed particle separationMethyl aldehydeChemical reaction

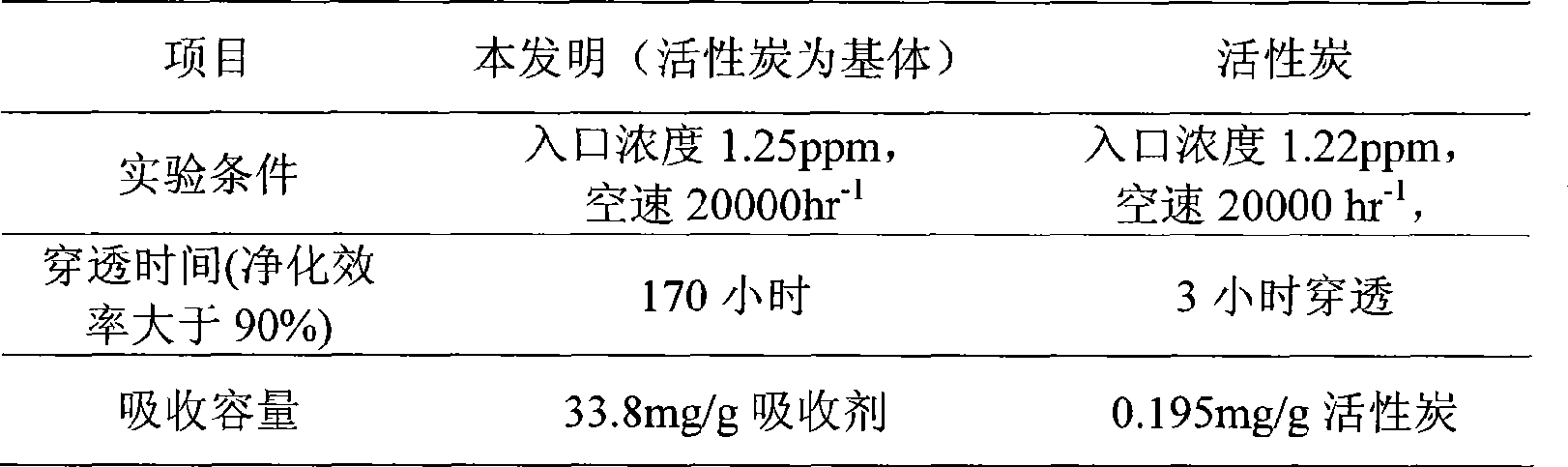

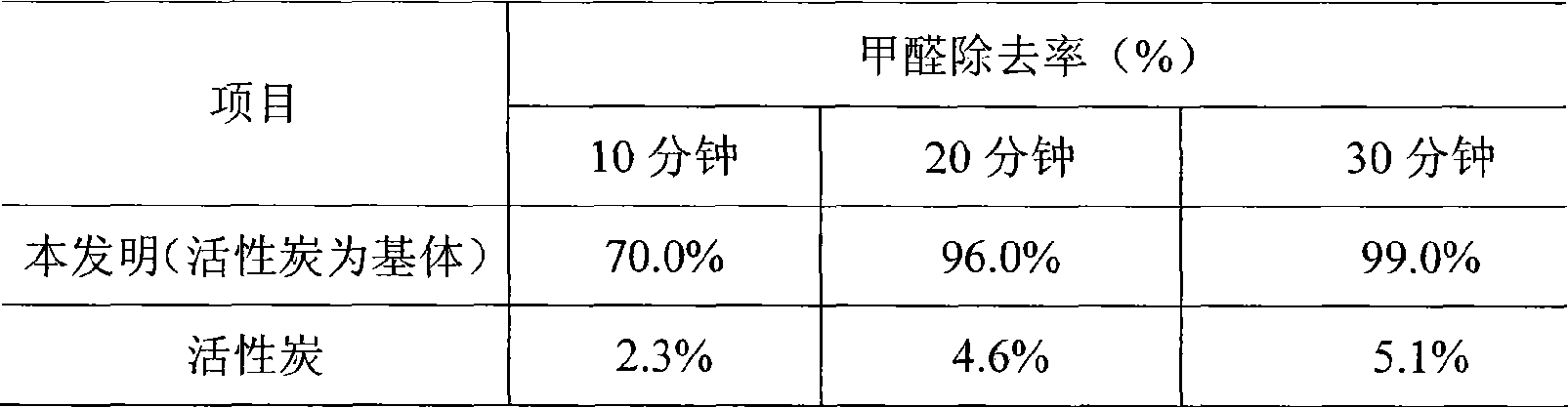

The invention relates to a formaldehyde adsorbent and a preparation method. The formaldehyde adsorbent consists of a basis material, a high molecular organic amine polymer and a polylol polymer, wherein the high molecular organic amine polymer and the polylol polymer account for 1 to 50 percent of the formaldehyde adsorbent, and the balance being the basis material. The preparation method for the formaldehyde adsorbent comprises steps of preparing formaldehyde reagent, preprocessing the basis material, solidifying and forming, and the like. When the formaldehyde adsorbent adsorbs formaldehyde, formaldehyde gas can quickly enrich on the surface of the formaldehyde adsorbent, and carries out chemical reaction to generate substances harmless to human body, so as to achieve the effect of uninterruptedly and thoroughly removing the formaldehyde; the adopted raw materials are nontoxic and harmless; the preparation technology has simple and easily controlled process; and the prepared formaldehyde adsorbent is safe and environment-friendly, and has no secondary pollution.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Low-release aldehyde adhesive and its preparation method and use

InactiveCN1670104AIncrease the degree of cross-linkingHigh strengthAldehyde/ketone condensation polymer adhesivesMethyl aldehydeThiourea

The invention discloses a low release aldehyde adhesive agent which comprises in the proportion of urea formaldehyde condensate of 100 shears, filler of 18-25 shears, curing agent of 1.0-2.0 shears, reinforcing agent P of 1.0-2.0 shears and curing accelerating agent Pa of 0.06-0.12 shear, wherein the reinforcing agent P is a water-soluble polyisocyanates and process art of low release aldehyde adhesive agent comprises the following steps: A, the preparation of thiourea resin, B, adding the said thiourea resin in a container, running the agitator and adding the filler slowly, intimate mixing and adding the curing agent, intimate mixing adding the accelerating agent dissolved using water, stirring, meter adding addition agent P slowly and stirring to get the low release aldehyde adhesive agent. The said low release aldehyde adhesive agent can be used in binding between wood and wood. In the invention, the content of methyl aldehyde is decreased in the preparation process.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

A sodium alginate and polyvinyl alcohol compound sponges material and preparation method thereof

InactiveCN101445636AGood tissue compatibilityImprove mechanical propertiesWater/sewage treatmentAbsorbent padsMethyl aldehydeWound dressing

The present invention provides sodium alginate and polyvinyl alcohol compound sponges material, wherein the component (wt) are as follows: sodium alginate 1-11%; polyvinyl alcohol 5-25%; inorganic acid 3-15%; methyl aldehyde 3-15%, aerating powder 1-5%; and distilled water 29-87% The preparation of the material are as following: heating sodium alginate, polyvinyl alcohol and distilled water for dissolving with heating temperature 80-100 DEG C; adding inorganic acid, methyl aldehyde and aerating powder for mixed stirring; heating mixed solution for forming with hot forming temperature 60-90 DEG C and hot forming time from 4 to 12 hours; And clean hot formed product. The present invention is provided with advantages like low cost, environment protection, simple process etc. The obtained material can be applied on wound dressing, vacuum sealing drainage, and hemostasia material etc. because of the good biocompatibility of polyvinyl alcohol and sodium alginate.

Owner:WUHAN UNIV OF TECH

Paper-surface plasterboard for quickly and efficiently removing methyl aldehyde and preparation method thereof

InactiveCN101549980AEfficient degradationLow costSolid waste managementCeramicwareFiberMethyl aldehyde

The invention discloses a paper-surface plasterboard for quickly and efficiently removing methyl aldehyde, which comprises the following components: 100 parts of calcined gypsum powder, 60-80 parts of clear water, 0.05-0.1 part of foaming agent, 0.5-1.2 parts of modified starch, 0.8-1.6 parts of wood fiber and 2-4 parts of methyl aldehyde elimination agent. The invention also discloses a method for preparing the paper-surface plasterboard for quickly and efficiently removing the methyl aldehyde, which comprises the following steps: (1) weighting the components; (2) putting the calcined gypsum powder and the modified starch in a mixer and separately and uniformly stirring the clear water, the wood fibers and the methyl aldehyde elimination agent and adding the clear water, the wood fibers and the methyl aldehyde elimination agent into the mixer; (3) foaming the foaming agent and the compressed air, adding the foaming agent and the compressed air into the mixer and uniformly stirring the components in the mixer; and (4) molding the uniformly stirred mixture by a forming machine and finally hardening and drying the mixture. The invention can quickly and efficiently degrade the methyl aldehyde in an environment without light or with weak light.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Plaster-shape regenerated rubber and preparation method thereof

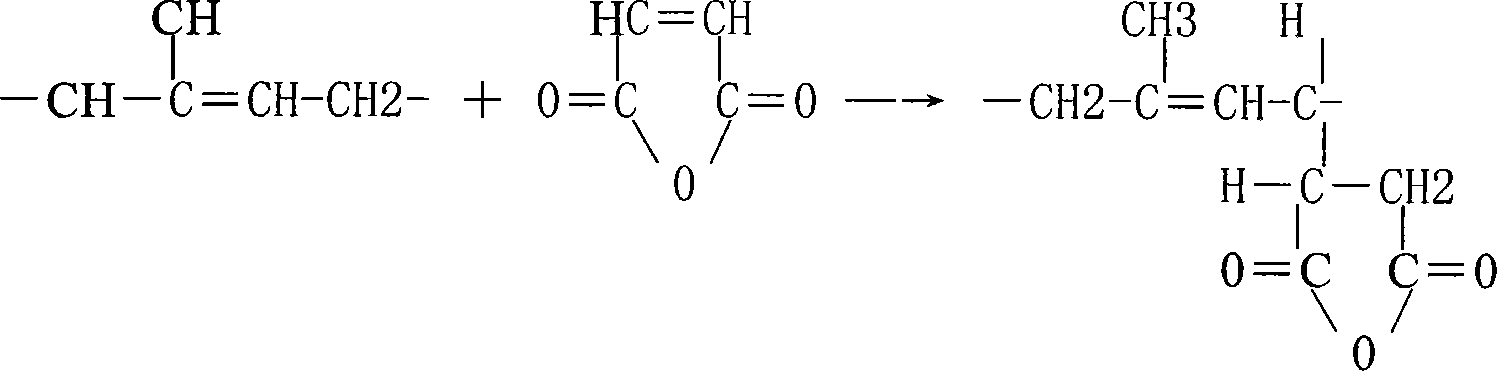

InactiveCN101100534ASimple processNo need to consume electricityPlastic recyclingFiberPolymer science

A creamed reclaimed rubber and its production are disclosed. It consists of 20-50 mesh vulcanized rubber powder 100 proportion, paraffin oil as solvent 70-90 proportion, solid coumarone 10-30 proportion as solvent, catalyst and catalyst accessory phthalic acid anhydride 2-5 proportion, methyl aldehyde aqueous solution 4-6 proportion, 1,3-benzenediol 0.2-0.5 proportion. The process is carried out by adding vulcanized rubber powder into vertical de-polymerizer, adding into solvent, catalyst and catalyst accessory successively, closing feeding open, agitating, raising temperature to 160-180 deg. C, controlling pressure to 0.5-0.7 MPa, reacting for 2-2.5 hrs, lowering temperature, releasing gas, discharging and filtering to obtain final product. It's simple, has stable quality, waterproof and antiseptic performances and no environmental pollution. It can be used to synthesize rubber with petrochemical asphalt and to paving road.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

Environment-friendly diatom ooze composite material and production method for decorative plates

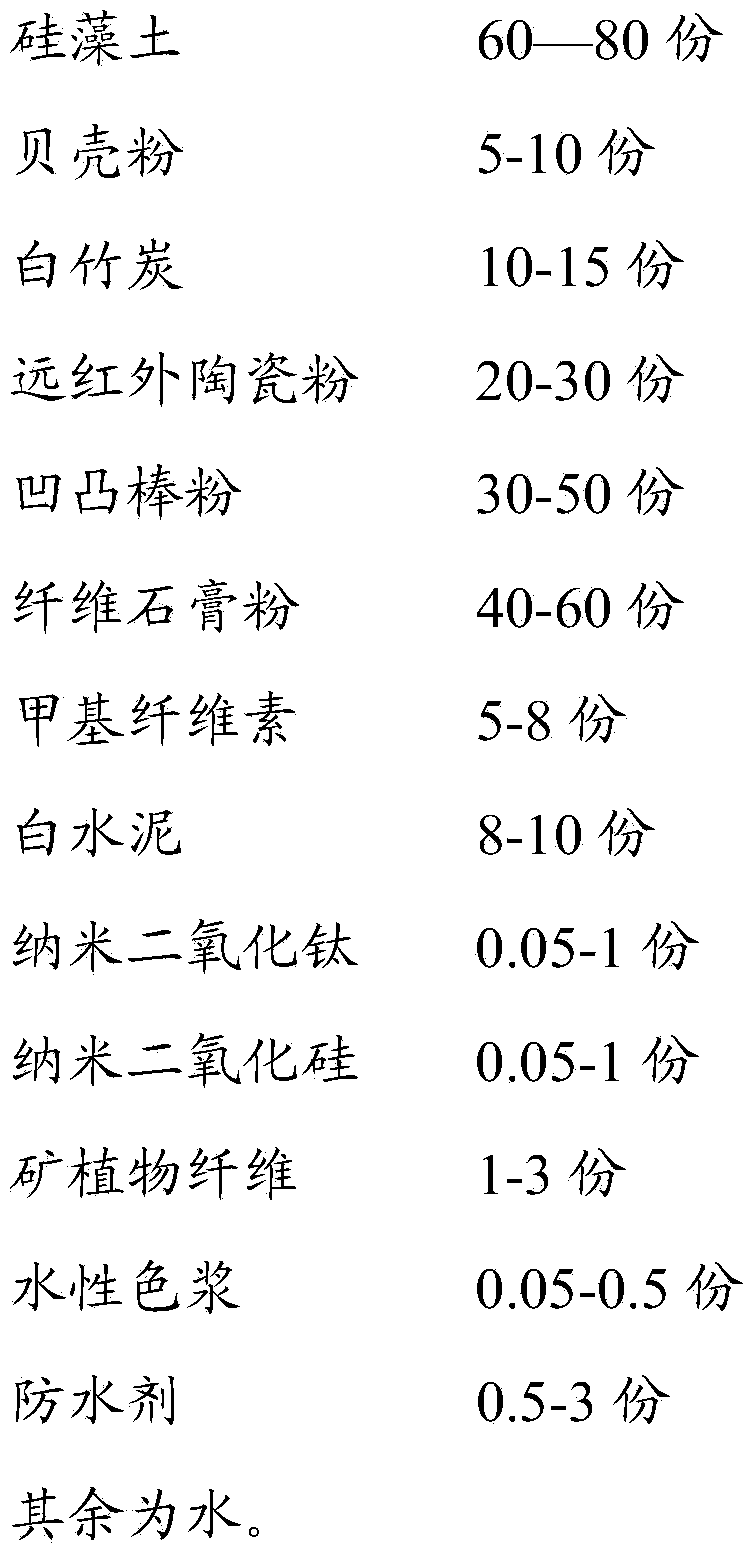

The invention discloses an environmental-friendly diatom ooze composite material which is a mixture including various components in weight part, including 60-80 parts of diatomite, 5-10 parts of shell powder, 10-15 parts of white bamboo charcoal, 20-30 parts of far infrared ceramic powder, 30-50 parts of attapulgite powder, 40-60 parts of fiber gypsum powder, 5-8 parts of methyl cellulose, 8-10 parts of white cement, 0.05-1 part of nano titanium dioxide, 0.05-1 part of nano silica, 1-3 parts of ore plant fiber, 0.05-0.5 part of water-based color paste, 0.5-3 parts of a waterproof agent, and the balance of water. The invention further discloses a method for producing decorative plates by utilizing the composite material. The environmental-friendly diatom ooze composite material formed by the mixture including various components is used for producing the environmental-friendly decorative plates by adopting the production method for environmental-friendly decorative plates, the decorative plates have high purification effects on methyl aldehyde, methylbenzene, ammonia gas and TVOC, can automatically adjust indoor humidity, continuously release negative oxygen ions, have the effects of deodorization, sterilization, heat insulation, water resistance, moisture protection, sound absorption and noise reduction, and have rich colors and textures, are attractive for decoration, easy to clean due to smooth surfaces, convenient to mount, and suitable for large-scale production.

Owner:徐伟

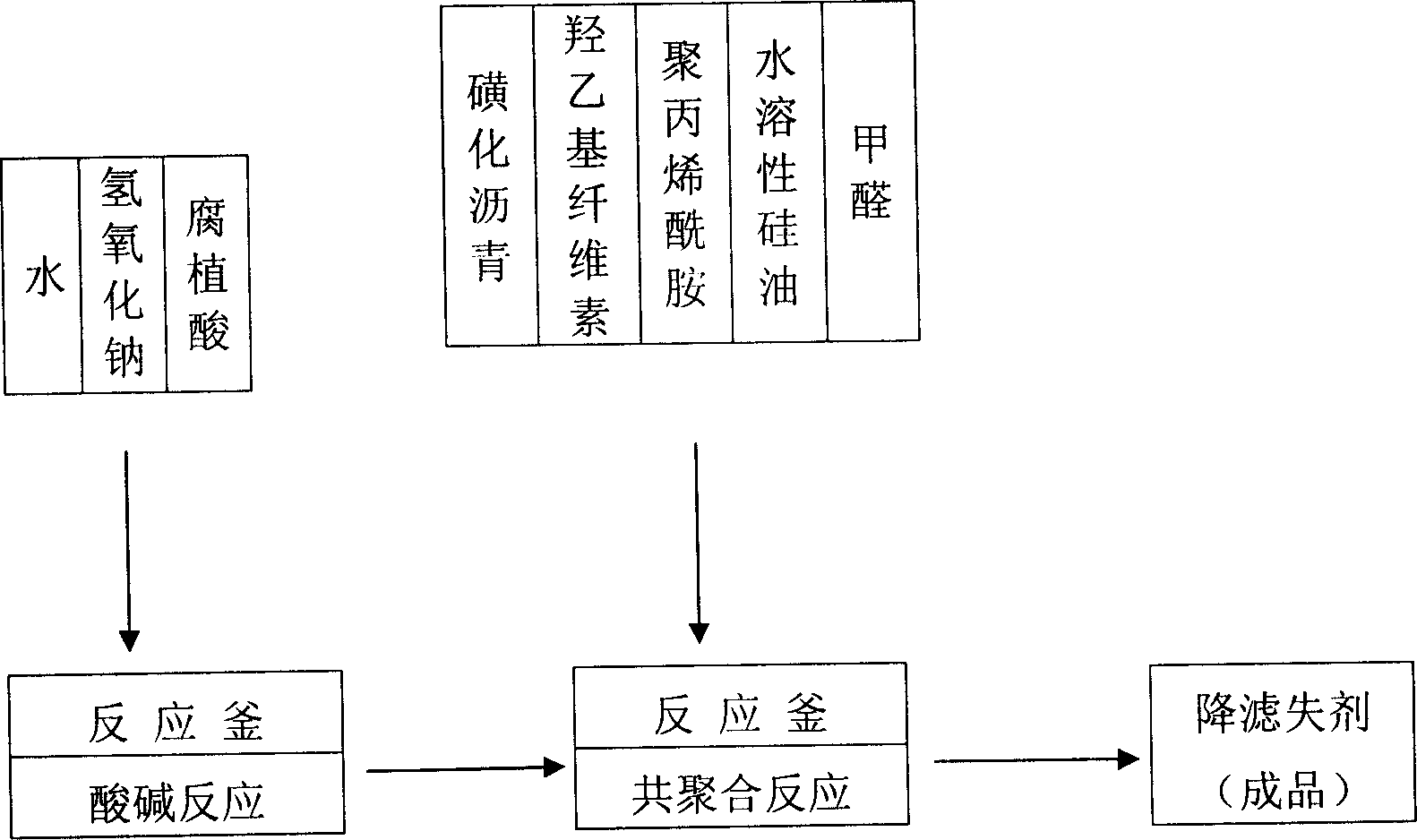

Fluid loss additive for boring fluid

The invention relates to a fluid loss control agent for drilling fluid, which is prepared through reacting natural humic acid with sodium-hydroxide to obtain humic sodium salts, then carrying out reduction copolymerization with sulfonated asphalt, hydroxyethyl cellulose, polyacrylamide, water-soluble silicon oil AND methyl aldehyde.

Owner:XINJIANG SANJING DERUN TECH

Bioengineering lacquer putty as well as preparation method and use thereof

InactiveCN101585982ASmooth circulationEnsure safetyCovering/liningsFilling pastesDiseaseMethyl aldehyde

The invention discloses a bioengineering lacquer putty as well as preparation method and use thereof. The bioengineering lacquer putty comprises: talcum powder, heavy calcium carbonate, emiaste, hydroxypropylmethylcellulose, adhesive, calcium stearate, tourmaline powder and bergmeal. the bioengineering lacquer putty of the invention has the sterilizing and deodorizing function, can automatically remove the harmful gas such as methyl aldehyde and the like, has no pollution, and ensure the safety of the human body and the animals and plants. The bioengineering lacquer putty of the invention has higher production amount of the negative ion and far infrared emissing ability, can prevent the electromagnetic radiation, can rapidly absorb and remove the abnormal flavour generated by the paint, the colloid and the like, absorb the smoke flavor for a long time, and has definite treating efficacy for the limbs ice-cold disease, shoulder pain, lumbago, physical pain, neuralgia and the like.

Owner:陈耕 +1

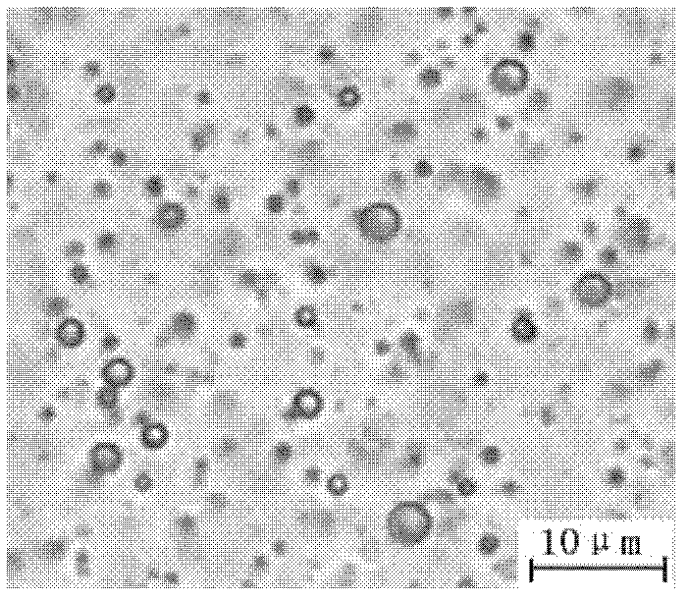

Method for preparing carbon nano tube reinforced epoxy resin self repairing microcapsule

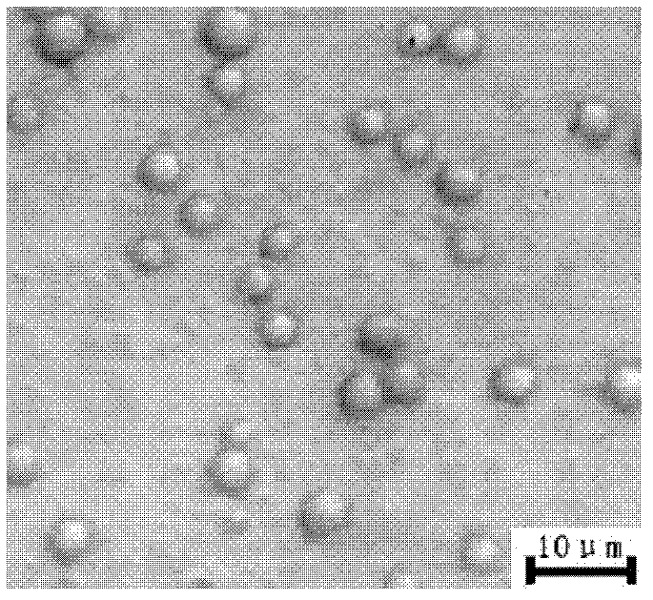

InactiveCN102240533AImprove performanceImprove self-healing abilityMicroballoon preparationMicrocapsule preparationWater bathsEpoxy

The invention provides a method for preparing a self repairing microcapsule by compounding epoxy resins and carbon nano tubes as a capsule core repairing agent, belonging to the field of organic composite materials. The method comprises the following steps of: preparing the epoxy resins into an epoxy emulsion with a compound surfactant by adopting a phase inversion method; adding carbon nano tubes in different mass fractions, stirring the emulsion and carrying out ultrasonic dispersion to obtain fine emulsion in which the carbon nano tubes and the epoxy resins are uniformly mixed; heating melamine and methyl aldehyde in a water bath kettle at the temperature of 60-80 DEG C to generate a capsule wall prepolymer solution; and mixing the epoxy-carbon nano tube emulsion and the melamine-methyl aldehyde prepolymer solution, and regulating to obtain an acid environment, thus the prepolymer further reacts to generate a capsule wall. The prepared micro capsules are uniform in particle size and are better distributed, and the contained carbon nano tubes can further enhance the repairing effect of the microcapsules and improve mechanical property.

Owner:UNIV OF SCI & TECH BEIJING +1

Production technology of methyl naphthalenesulfonic acid-methyl aldehyde condensation compound

InactiveCN101386587ALow impurity contentHigh sulfonation efficiencyOrganic chemistryOrganic dyesMethyl aldehydeSulfate

The present invention provides a method for preparing a condensation compound of methylol naphthalene sulphonic acid formaldehyde. The method comprises the following steps that methylnaphthalene is adopted as the material, and is sulfonated with 104.5 percent of fuming sulfuric acid in advance; the sulfonated product is condensed with formaldehyde; and, finally the pH is adjusted to between 6 and 9 by liquid alkali, and thus the methylol naphthalene sulphonic acid formaldehyde condensation compound is obtained. The method does not need to add an azeotrope former, and does not need to add and distill of sulfonated bodies every time. The process is simplified, the manufacturing cost is saved, and the impurity content in the product is reduced. Additionally, the 104.5 percent of fuming acid is adopted to sulfonate. Not only the efficiency of methylnaphthalene sulfuration is improved, but also the total acidity of the condensation reaction process is reduced. The subsequent process completely adopts liquid alkali. No calcium sulfate calcium offscum is produced. Compared with the adoption of concentrated sulfuric acid, the quality of the product is equivalent in dispersancy, calcium and magnesium ions are not produced, and the product is stable in heat resistance.

Owner:ZHEJIANG LONGSHENG GROUP +1

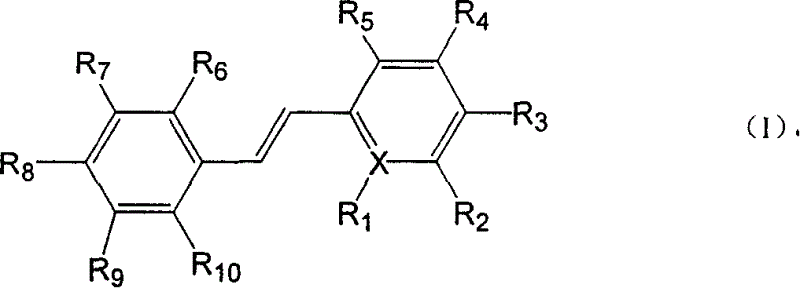

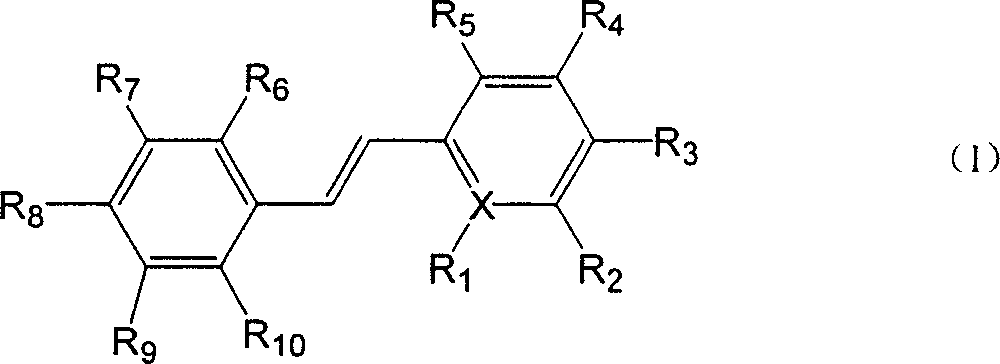

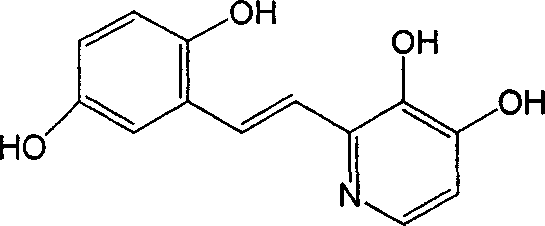

Polyhydroxy stilbenes compound preparation and uses as drugs for suppressing SARS

InactiveCN1736986AMeet the requirements of therapeutically effective doseOrganic chemistryHydroxy compound active ingredientsMethyl aldehydeTriethylphosphite

The invention provides a group of polyhydroxy stilbene compounds, their preparing process and use for suppressing and eradicating SARS coronavirus. The preparing process comprises, preparing phosphonic ester by reacting multi-alkyl substituted chloro (bromo) methoxyl or pyridine compounds with triethyl phosphate, then reacting phosphonate ester compound with multi-alkyl (oxy) phenylpyridine methyl aldehyde to obtain multi-alkyl (oxy) stilbene compounds. Finally acting with boron tribromide to obtain polyhydroxy stilbene compounds with substituent groups.

Owner:DALIAN UNIV OF TECH +1

Preparation process of dispersing dye microcapsule

InactiveCN1443807AFormaldehyde freeNo pollution in the processOrganic dyesMicroballoon preparationDisperse dyeMethyl aldehyde

The present invention relates to a technological process for preparing disperse dye microcapsule by utilizing double or polyisocyanate compound as monomer for forming microcapsule wall material, using disperse dye as core material and adopting interfacial polymerization. The polyurea finalkly formed by using said process has no methyl aldehyde, has no pollution, high strength, good slowly-releasing property and small dose of adjuvant. It is specially suitable for high-temp. high-pressure dyeing, thermosol dyeing and multiple transfer printing of polyester fabrics.

Owner:DONGHUA UNIV

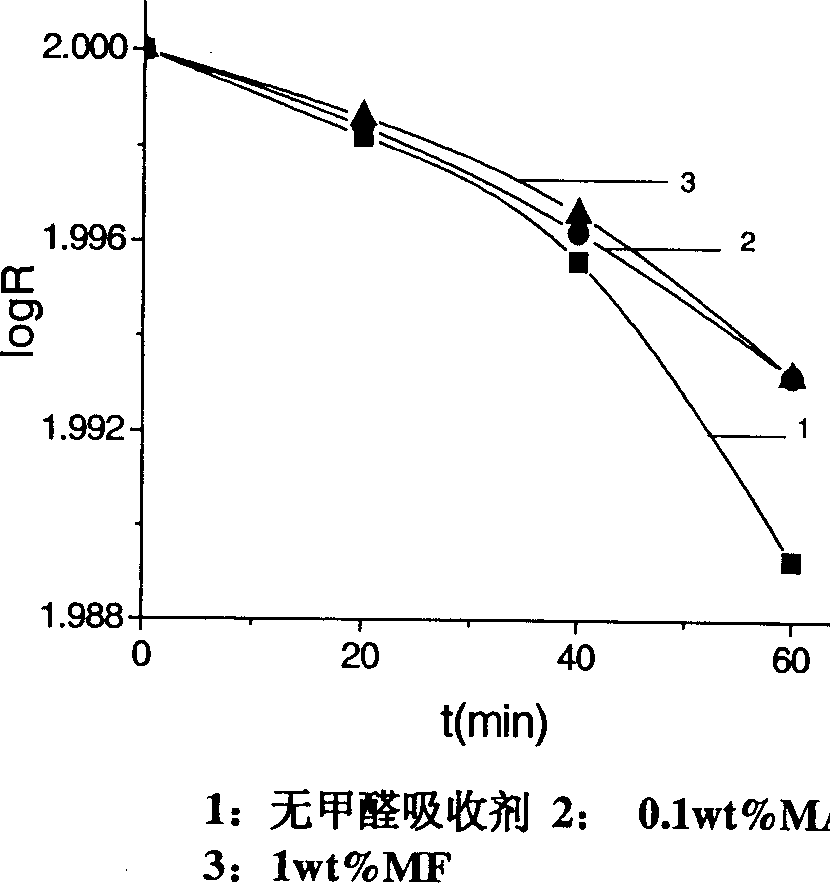

Disinfecting and foreign flavor removing sustained-release agent in small space

InactiveCN101194627AHigh removal rateImprove disinfection efficiencyBiocideDisinfectantsBenzeneMethyl aldehyde

The invention provides a small-space disinfecting and peculiar smell-removing slow release agent, which comprises chlorine dioxide liquid which is dissolved in the water, and is characterized in that solid adsorbent is filled in stable chlorine dioxide liquid whose thickness is set to form a gelatin system. The invention further comprises stabilizing agent and pH conditioning agent, wherein the stabilizing agent and pH conditioning agent can be citric acid and sodium percarbonate, and the solid adsorbent can be high water-absorbing resin. The invention has the advantage of solving the problems of dynamic constant disinfection, sterilization, and removing peculiar smell in small space, which has high disinfecting efficiency and plays a role in removing peculiar smell and bad odor momentarily, and the removing rate of harmful gases such as methyl aldehyde and benzene reaches more than 90%.

Owner:深圳市罗奇环保科技有限公司

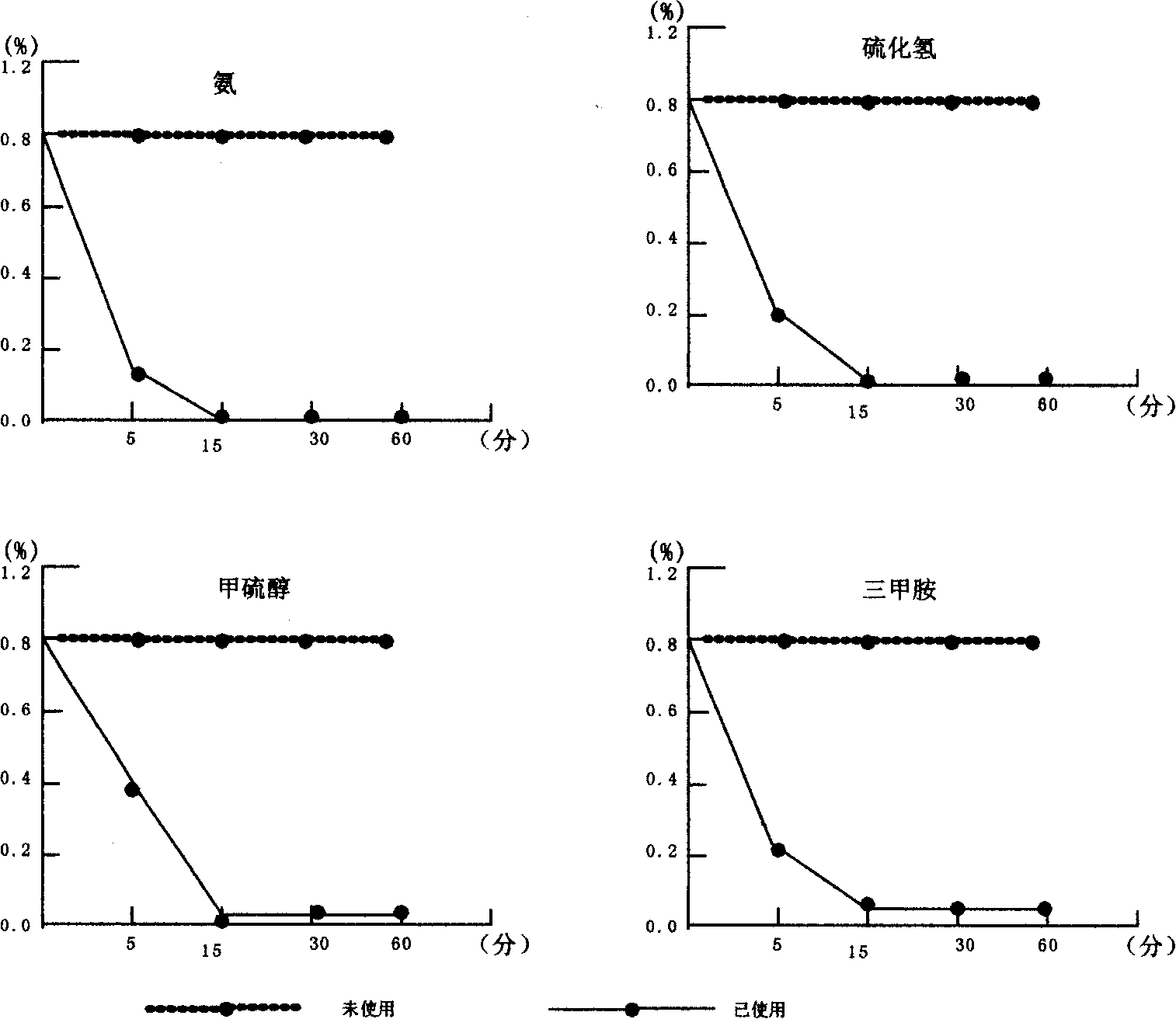

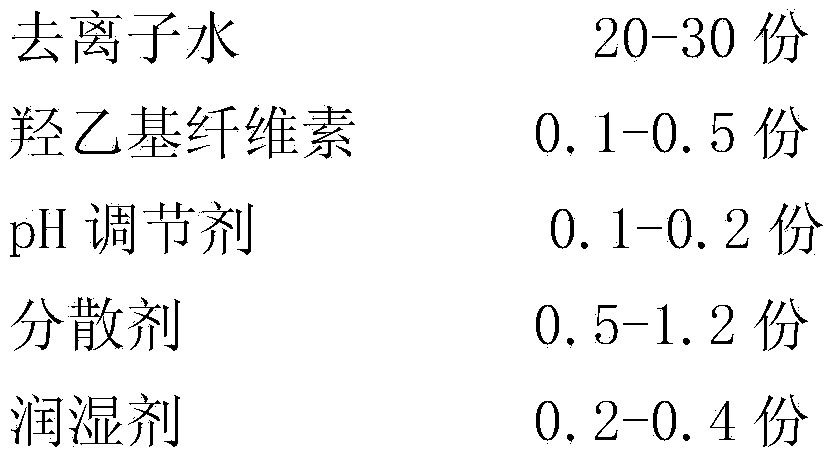

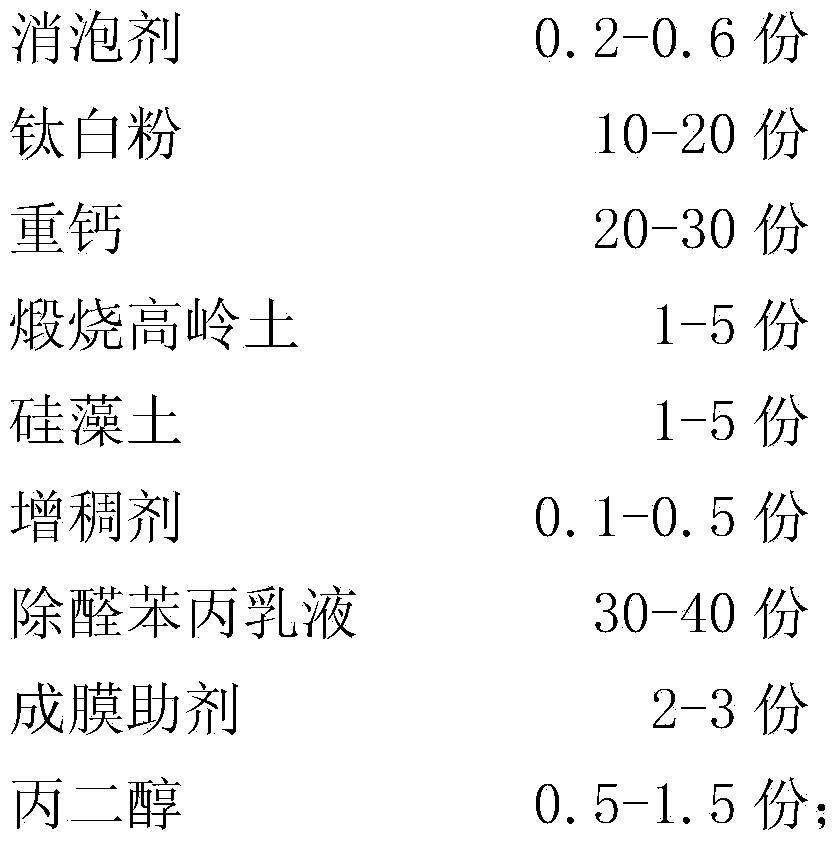

Building coating capable of removing methyl aldehyde and preparation method of building coating

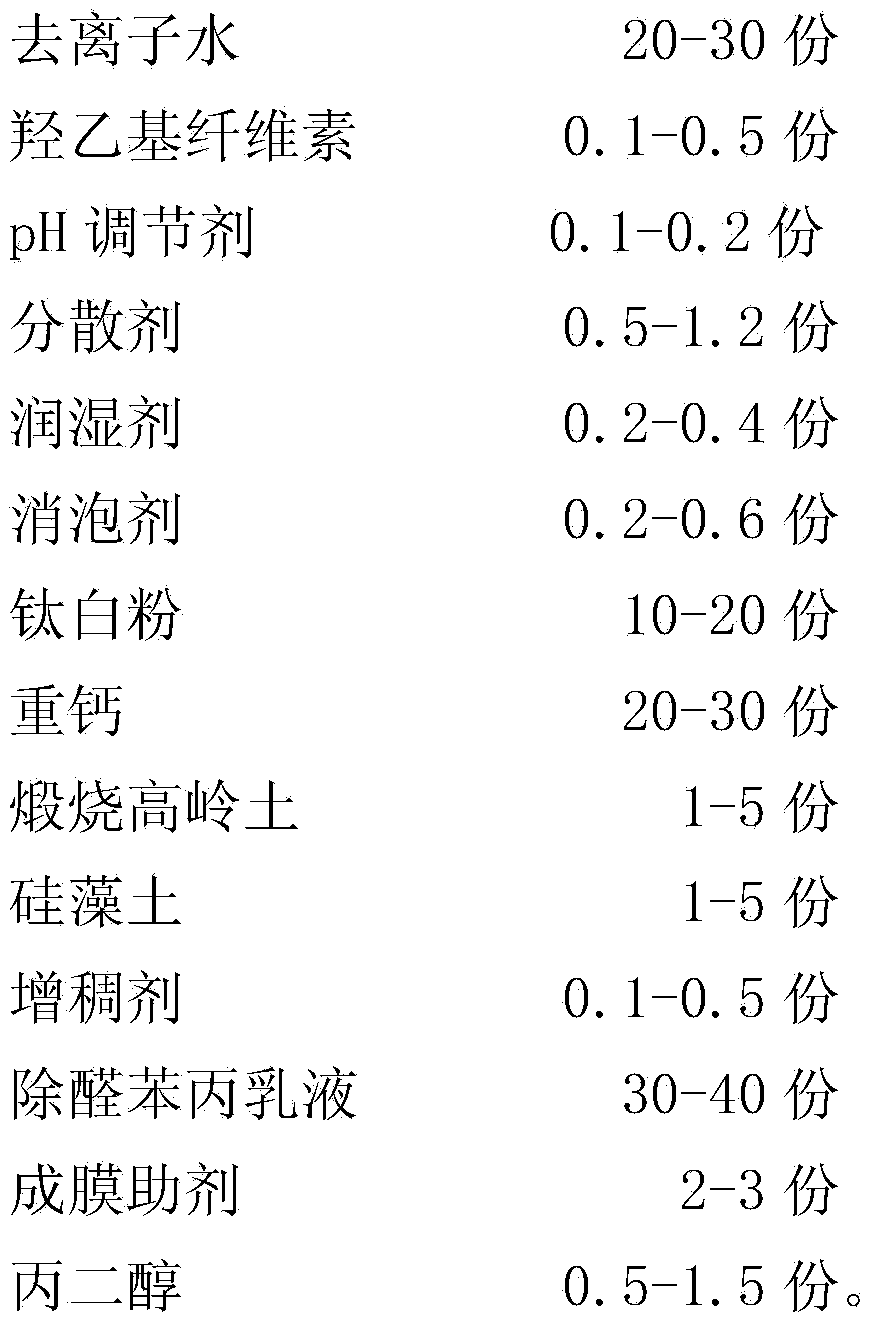

InactiveCN104046146AAchieve long-term effectAchieve stabilityCoatingsMethyl aldehydeDefoaming Agents

The invention relates to building coating capable of removing methyl aldehyde and a preparation method of the building coating. The building coating capable of removing methyl aldehyde is prepared from the following components in parts by weight: 20-30 parts of deionized water, 0.1-0.5 part of hydroxyethyl cellulose, 0.1-0.2 part of a pH regulator, 0.5-1.2 parts of a dispersing agent, 0.2-0.4 part of a lubricating agent, 0.2-0.6 part of a defoaming agent, 10-20 parts of titanium dioxide, 20-30 parts of calcium triple superphosphate, 1-5 parts of calcined kaolin, 1-5 parts of diatomite, 0.1-0.5 part of a thickening agent, 30-40 parts of aldehyde removal styrene-acrylic emulsion, 2-3 parts of a coalescing agent and 0.5-1.5 parts of propylene glycol. The prepared building coating capable of removing the methyl aldehyde has the advantage that an aldehyde removal function can be realized without adding a functional material later, and long-term and stable aldehyde removal effect of the prepared building coating is realized.

Owner:SKSHU PAINT

Melamine-urea-methyl aldehyde copolycondensation resin lumber adhesive and preparation thereof

ActiveCN101302412AStable storageImprove performanceAldehyde/ketone condensation polymer adhesivesWood veneer joiningPolymer scienceMethyl aldehyde

The invention relates to melamine-urea-formaldehyde copolycondensation resin (MUF) wood adhesives and a method for preparing the same, belonging to the wood processing and production technical field. The adhesives are formed by copolycondensation of melamine (M), urea (U) and formaldehydes (F) and are characterized in that: the formaldehydes are added at a time and the urea and the melamine are added for a plurality of times, and the amount of the formaldehydes is over 40 percent of the total amount of the urea and the melamine, wherein, the formaldehydes are added at a time during the initial reaction stage, and urea for the first time and melamine for the first time are added during the initial reaction stage; after the urea for the first time is added, the mole ratio of the formaldehydes and the urea is controlled to be over 2.9; melamine for the second time is added during the intermediate reaction stage; and urea for the second time is added during the late reaction stage. The melamine-urea-formaldehyde copolycondensation resin (MUF) wood adhesives have the advantages of good stability, excellent performance and so on, are used for producing hard boards and particularly high-performance hard boards, laminwood and so on, and also can be used for producing impregnated paper.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Colour development methyl aldehyde adsorption material and preparation method thereof

ActiveCN101468304AResponsivenessRapid pollutionMaterial analysis by observing effect on chemical indicatorOther chemical processesFormaldehyde productMethyl aldehyde

The invention discloses a chromogenic formaldehyde adsorbing material and a preparation method thereof. The adsorbing material consists of a carrier, a high molecular organic amine polymer, a polylol polymer and a formaldehyde reaction indicator, wherein the high molecular organic amine polymer and the polylol polymer account for 1 to 50 percent of formaldehyde adsorbent, the formaldehyde reaction indicator is little, and the balance being the carrier. The preparation method thereof comprises the following steps: mixing the high molecular organic amine polymer and the polylol polymer according to mass, adding deionized water to dilute the mixture so as to prepare formaldehyde reagent; mixing the formaldehyde reagent and the formaldehyde reaction indicator; and spraying or dipping the mixed solution onto the surface of the carrier, and drying the carrier and so on. The adsorbing material and the preparation method can quickly, thoroughly and continuously remove formaldehyde pollution in indoor air until the content of the formaldehyde is reduced to safe concentration, are nontoxic, pollution-free, safe and environment-friendly to use, and can intuitively show the reaction degree of the formaldehyde.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Preparation method of alpha-cyanacrylate

InactiveCN101096350AProcess safetyEasy to operateCarboxylic acid nitrile preparationOrganic compound preparationCyanoacrylateMethyl aldehyde

The invention discloses a condensation reaction without anhydrating agent and the preparing method of alpha-cyanacrylate without elasticizer in the alpha-cyanacrylate field. The method comprises the following steps: regarding cyanoacetate and methyl aldehyde solution or cavaform as the material; proceeding with the condensation reaction without anhydrating agent in the basic catalyst, 60+ -5Deg. C, 0.5-50mmHg vacuum condition; adding the inhibitor after completing dewatering; proceeding with cracking distillation without elasticizer at 0.5-25mmHg vacuum and 160-220Deg. C; getting high purity and production efficient alpha-cyanacrylate by distillation. The invention doesn't pollute the environment, which is provided with the wide application foreground and the apparent economy benefit.

Owner:北京科化新材料科技有限公司

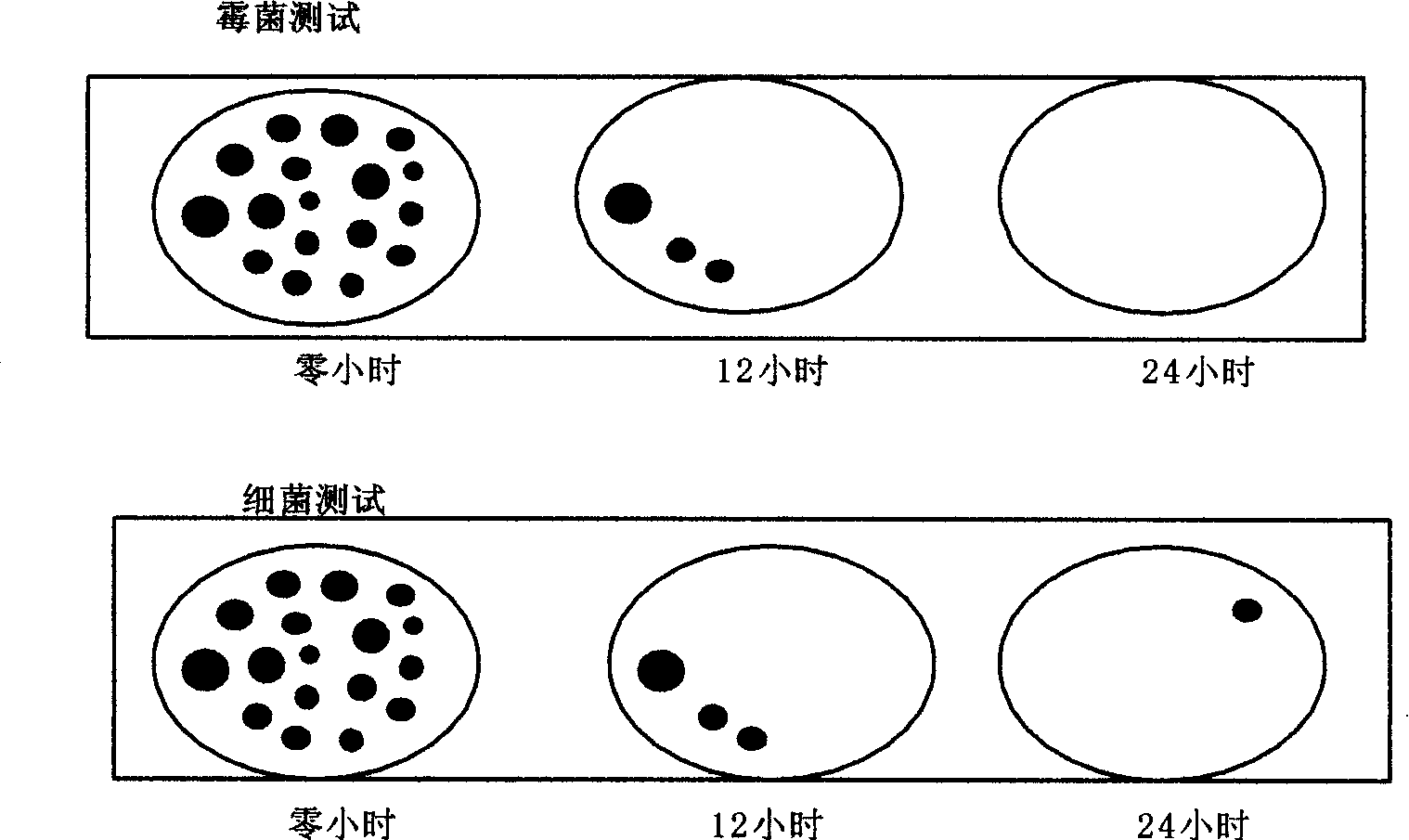

Composition for corpse specimen conservation and its preparing process

InactiveCN101011050AEfficient killingInhibition is effectiveDead animal preservationEducational modelsMethyl aldehydeAlcohol

The invention relates to a composite used to store the corpse specimen, which comprises fungus-proof active component, penetration adjuster and humectant, wherein, the fungus-proof active component is heterocyclic compound and quaternary ammonium salt; the penetration adjuster is one, two or the mixture of nitrate, sulfate, or hydrochlorate; the humectant is polyatomic alcohol. The invention also provides relative production. The invention can be used to store the corpse specimen, while the component has long fungus-proof time and high effect, without methyl aldehyde, with low cost.

Owner:WENZHOU MEDICAL UNIV

Chemical bronze plating liquid of mixing type non-formaldehyde reducer

ActiveCN1730724ANo pollution in the processGood deposition density (excellent backlight level)Liquid/solution decomposition chemical coatingHybrid typeMethyl aldehyde

The invention relates to a chemical bronze plating liquid of mixing type non-formaldehyde reducer for electronic printing circuit board, wherein the constituents include copper sulfate, EDTA, reducing agent and stabilizing agent, the reducing agent is prepared by mixing two non-formaldehyde reducing agents, which can be hypophosphites, glyoxylic acid and methyl aldehyde addition compound, any two of them can be combined. The advantages of the non-formaldehyde reducing agent include reduced environmental pollution, fast rate of deposition, high copper sedimentary deposit, and good copper deposition compactness.

Owner:GUANGDONG GUANGHUA SCI TECH +1

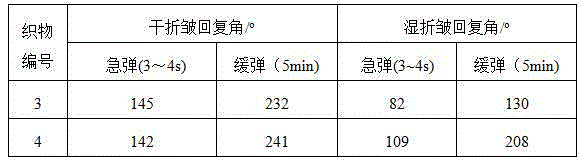

Pure cotton bright black adhesive interlining and production method thereof

ActiveCN105696375APrevent penetrationNo skippingWrinkle resistant fibresDyeing processCoated surfaceInterlining

The invention discloses a pure cotton bright black adhesive interlining and a production method thereof. The production method comprises the steps of edge turning, refining, dyeing, chemical shrink resistance finishing, black HDPE powder bright coating, mechanical preshrinking and the like. The adhesive interlining is bright black in coating surface; after the adhesive interlining and a colorful thin type garment material are fitted, the problem of bright white hot melt adhesive speckles will not be generated, and the garment quality is improved. The defects of leakage points, leakage coating and the like can be easily detected during appearance inspection, and it is ensured that a clothing enterprise will not generate degradation losses of products by using a defected adhesive interlining. The free and hydrolysis methyl aldehyde of the adhesive interlining is smaller than or equal to 35 mg / kg, and the warp and weft washing dimensional change rate ranges from -0.8% to +0.5%.The production method is easy to operate, environmentally friendly and excellent in product performance.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD

Silicone acrylic emulsion and application of silicone acrylic emulsion as textile finishing agent

The invention discloses silicone acrylic emulsion and the application of the silicone acrylic emulsion as a textile finishing agent. The silicone acrylic emulsion is manufactured by the following raw materials in parts by weight: 24-30 parts of butyl acrylate, 6-14 parts of methyl methacrylate, 0.15-1.0 part of initiator, 42.9-67.7 parts of deionized water, 1.2-6 parts of compound emulsifier, 0.3-0.6 part of pH buffer agent, 1-5 parts of vinyltriethoxysilane and 0.1-0.3 part of ammonium hydroxide. The silicone acrylic emulsion of the invention has the advantages that the composition is simple, the consumption of organosilicone monomer is low, the hydrolyzation of siloxane can be efficiently reduced through the matching of the silicone acrylic emulsion and seed emulsion, the polymerization process and the finally obtained emulsion are stable, and the emulsion is high in solid content, low in viscosity and convenient to use; the emulsion is used as the textile finishing agent so as to enable the textile to gain better weight increment and anti-wrinkle performance under the condition of keeping whiteness and intensity, no methyl aldehyde is realized during finishing, preservation and use, and the emulsion has the characteristics of remarkable effect, environmental protection and low cost.

Owner:SUZHOU UNIV

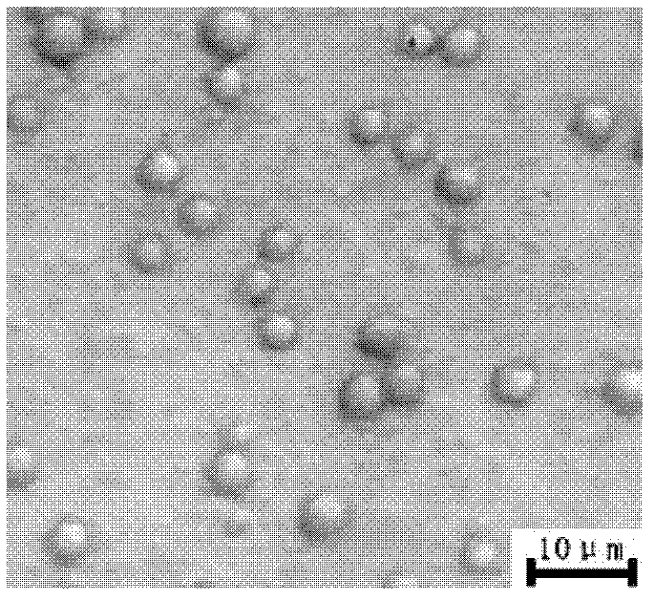

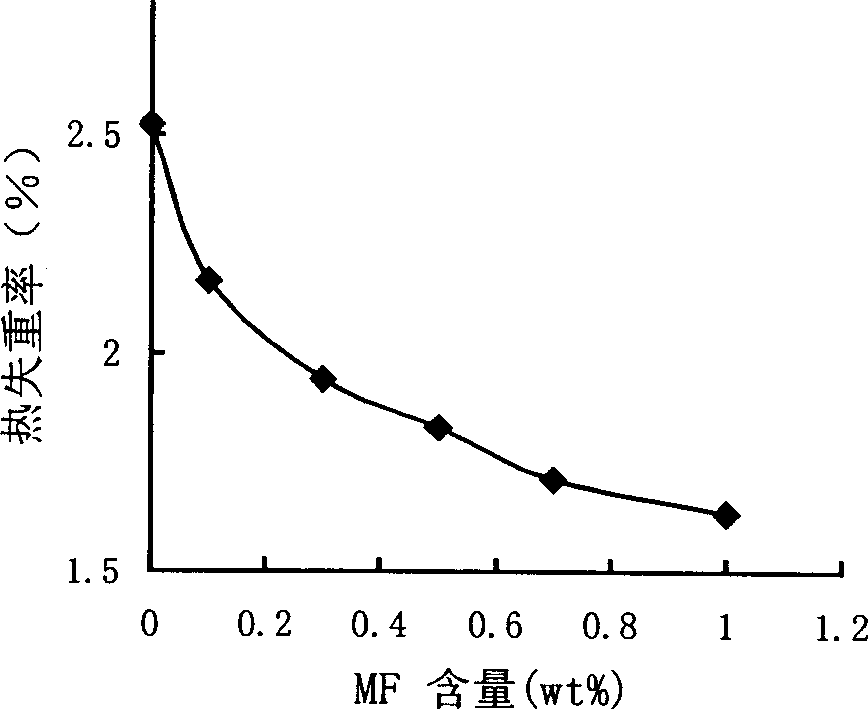

Dicyclopentadiene microcapsule with melamine methyl aldehyde coating and preparing method thereof

InactiveCN1927187AImprove water resistanceHigh mechanical strengthMicrocapsulesMethyl aldehydeResin-Based Composite

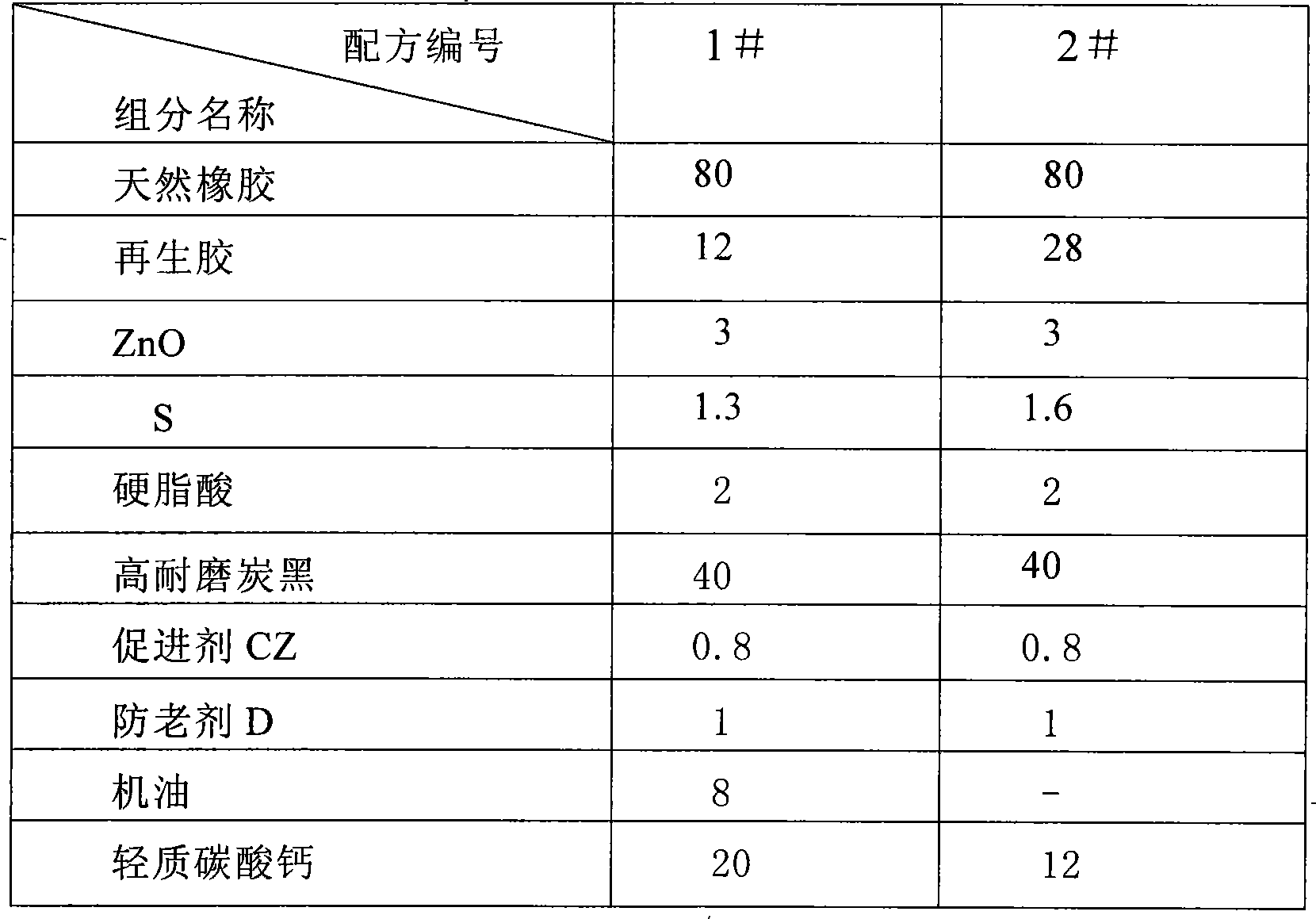

The invention involves a melamine formaldehyde coating dicyclopentadiene microcapsule and its preparation methods. Technical characteristics characterized in that: composition is: melamine and formaldehyde solution, dicyclopentadiene, polymerization inhibitor, water, surfactant and defoamer. preparation steps is: put the melamine, formaldehyde solution and water into the bottle, heat and use the lixivium to accommodate the solution, obtain the melamine formaldehyde prepolymer solution; again add emulsifier and defoamer water solution and stir, control the heating rate of the reaction system, preserve heat and end the reaction; wash the product several times, through vacuum filtering and drying microencapsulation products is obtained. Beneficial effect: relatively better heat resistance, excellent mechanical properties and good leak tightness of microcapsules, hoping that the Microencapsulation will be fit for self-repairing of the mid-high temperature shaping materials, after expansion can be used for self-repair of composite materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Thermostable metaformaldehyde containing condensate of melamine and formaldehyde, and its preparation method

The invention discloses a thermostable metaformaldehyde containing condensate of melamine and formaldehyde, and its preparation method, which consists of charging melamine and methyl aldehyde into a bottle with a stirrer, a temperature gage and a reflux condenser, charging composite disperser solution 5-15 weight parts at 60-75 deg C, adjusting pH to 6.3-6.5, elevating temperature to 80-95 deg C, reacting 0.5-1.5 hrs, adjusting pH to 6.8-7.2, stopping the reaction, washing and filtering the reactant, thus obtaining MF condensate and storing at low temperature, then charging polyoxymethylene resin 100 weight parts, melamine methylene oxide condensate 0.07-1.8 weight parts, anti-oxidizing agent 0.1-0.5 part, formic acid absorbent 0.05-0.5 weight part, lubricating agent 0.1-0.5 weight part into a high speed mixing machine, melting with exhaustion type double screw bolt extrusion machine for squeezing and granulating.

Owner:YUNNAN YUNTIANHUA +1

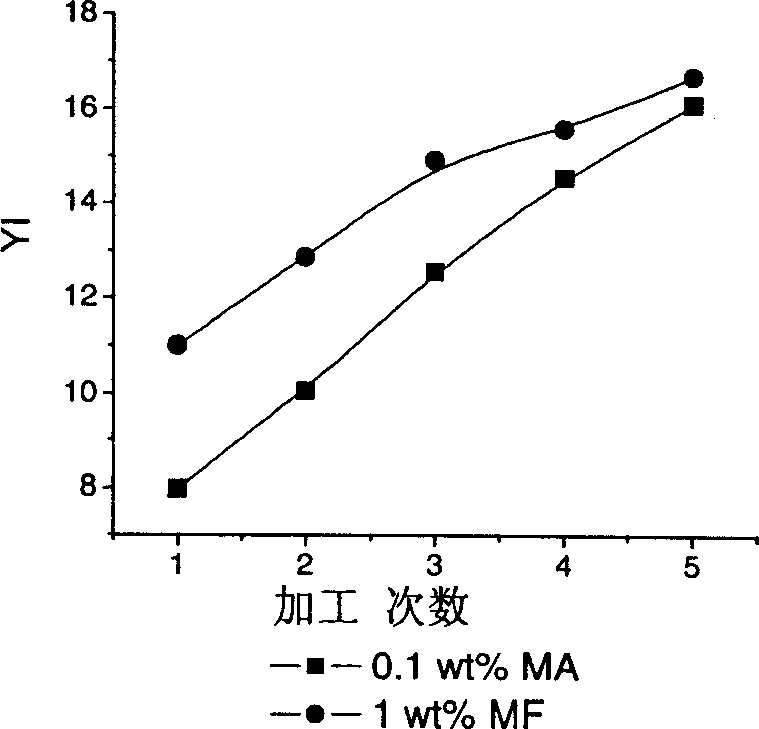

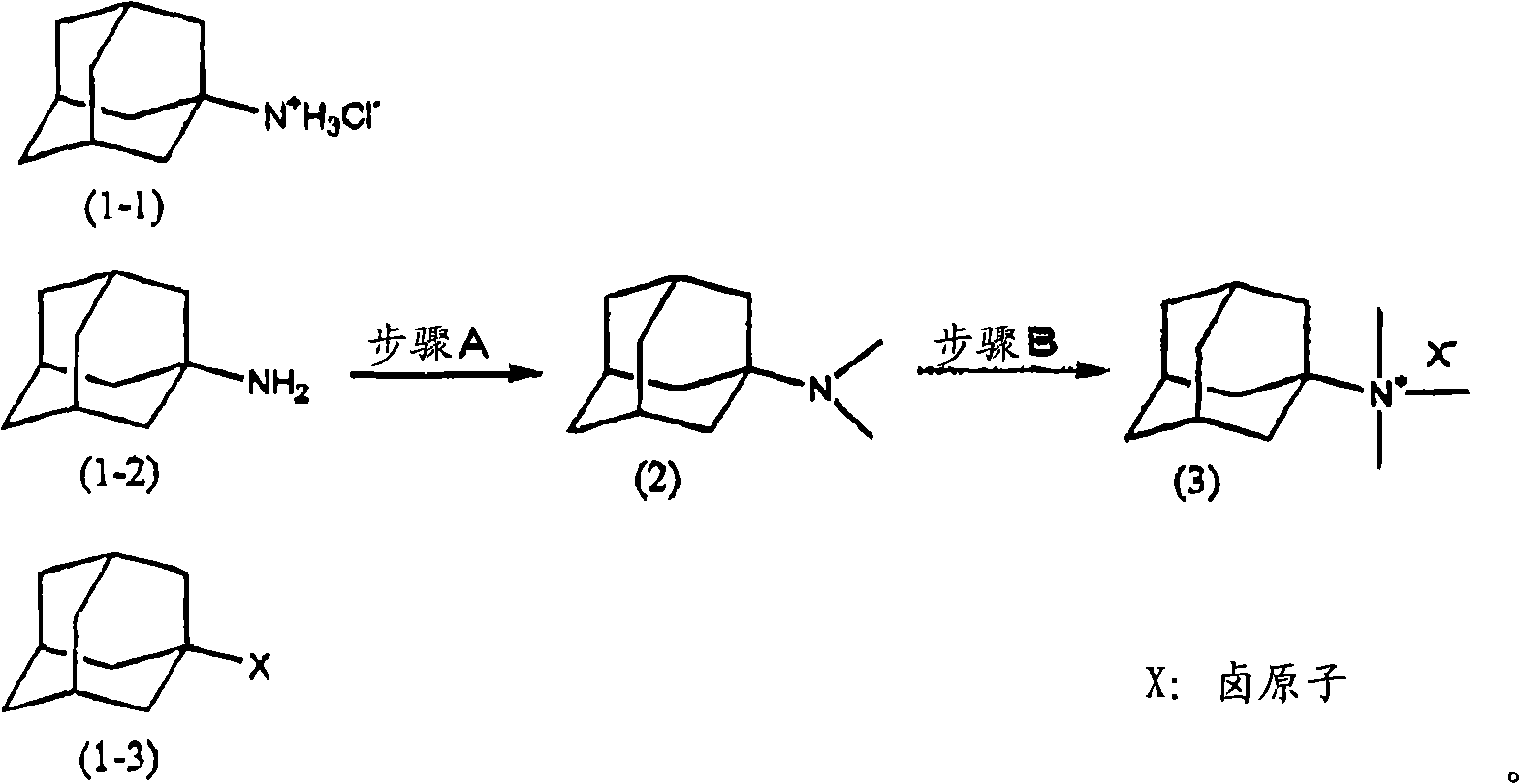

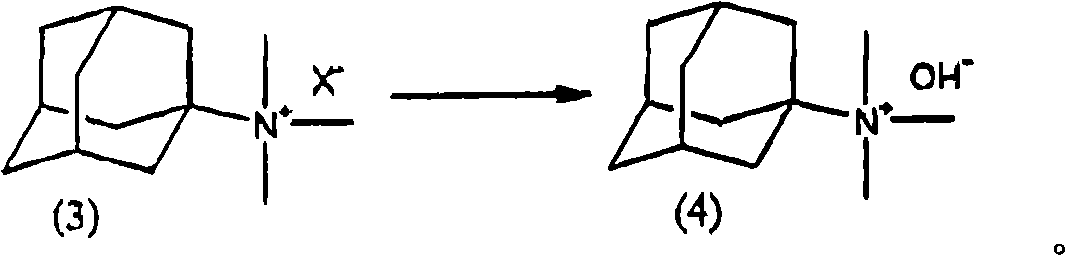

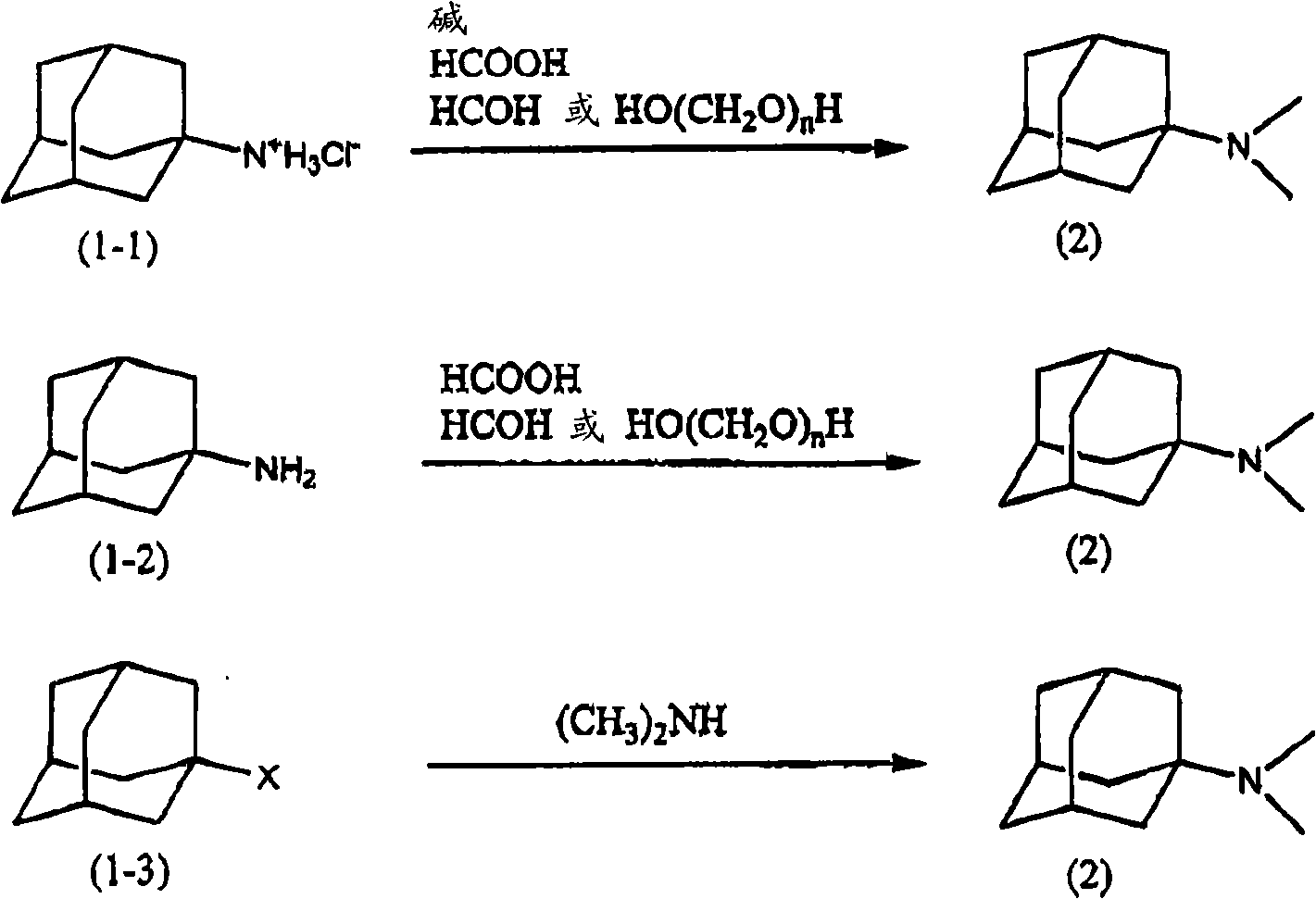

Method for preparing quaternary ammonium salt containing adamantine alkyl

InactiveCN101935286AEfficient manufacturingHigh yieldAmino preparation from aminesOrganic compound preparationQuaternary ammonium cationHalomethane

The present invention relates to a method for preparing a quaternary ammonium salt containing adamantine alkyl. By means of the method of the invention, it is possible to effectively in a short time and industrially high-yield and high -purity prepare the quaternary ammonium salt containing the adamantine alkyl. The method is characterized in that it includes a step A and a step B, step A: a step of preparing 1-adamantane dimethyl amine (formula (2)) selected from a step of reacting a reactant of an adamantane hydrochloric acid and a base metal hydroxide dissolved in a solvent (a) which relative inductivity is 10.0 to 20.0 with aminic acid and methyl aldehyde or paraformaldehyde, a step of reacting 1-amidogen adamantane dissolved in the solvent (a) with aminic acid and methyl aldehyde or paraformaldehyde, and a step of reacting 1-halogeno adamantane with dimethyl amine; step B: a step of preparing a 1-adamantane trimethyl halogenation aminium salt by reacting the 1-adamantane dimethyl amine of the step A dissolved in a solvent (b) with halomethane.

Owner:IDEMITSU KOSAN CO LTD

Preparation method of environment-friendly modified starch adhesive for cigarette

ActiveCN103242786AImprove liquidityHigh solid contentGraft polymer adhesivesBiotechnologyMethyl aldehyde

The invention discloses a preparation method of an environment-friendly modified starch adhesive for a cigarette, belonging to the technical field of an adhesive. The adhesive uses the starch as the main ingredient, is free of an organic solvent, is properly modified by adding a small amount of modifying agent, overcomes the inherent defects of the pure starch adhesive, such as low solid content, poor fluidity and poor storage stability, so that the product performance is improved greatly, and the product can meet production of a high-speed cigarette making machine, and is suitable for various cigarette adhesive joints, such as a cigarette holder and a connector. The auxiliary material used in the method is free from harmful substances such as methyl aldehyde and phthalic acid esters, under the premise of meeting the requirement on cigarette production, the sanitary and safe condition meets the sanitary standard of adhesive in China cigarette industry, and real environment-friendly property is realized.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Water-based epoxy terrace coating capable of releasing negative ions and preparation method for water-based epoxy terrace coating

The invention discloses a water-based epoxy terrace coating capable of releasing negative ions and a preparation method for the water-based epoxy terrace coating. The coating is a double-component emulsion coating and consists of a component A and a component B, wherein the component A comprises water-based epoxy resin emulsion, deionized water, a wetting dispersing agent, a defoaming agent, titanium white, a negative ion additive, quartz powder, precipitated barium sulphate, a thickening agent, a substrate wetting agent and water-based color paste; and the component B comprises a water-based epoxy hardener and the deionized water. Besides the advantages of the ordinary water-based epoxy terrace coating, the prepared water-based epoxy terrace coating has the functions of releasing the negative ions and emitting far infrared, can decompose and remove harmful gases such as methyl aldehyde and the like in air quickly and inhibit the survival of mycetes, and is long in valid period of construction and convenient to construct.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

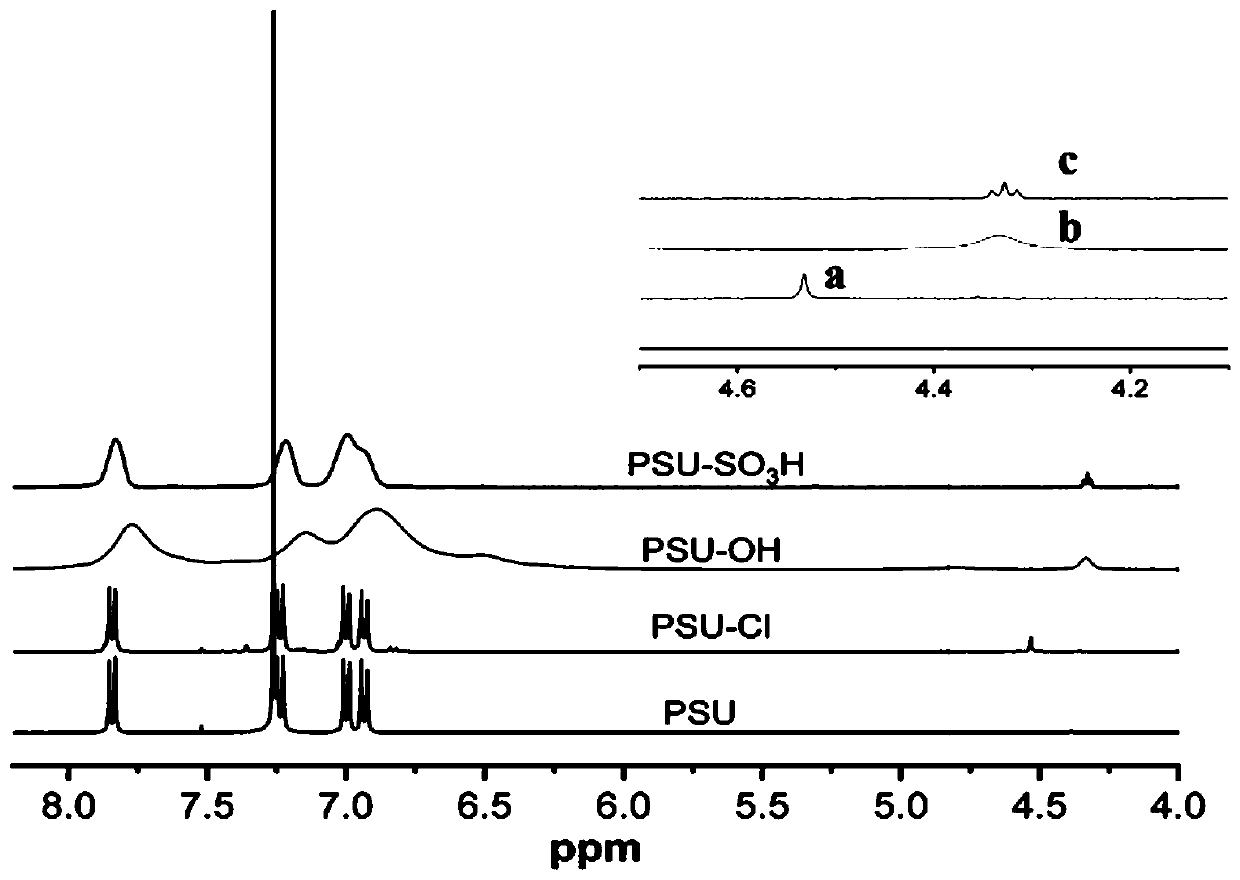

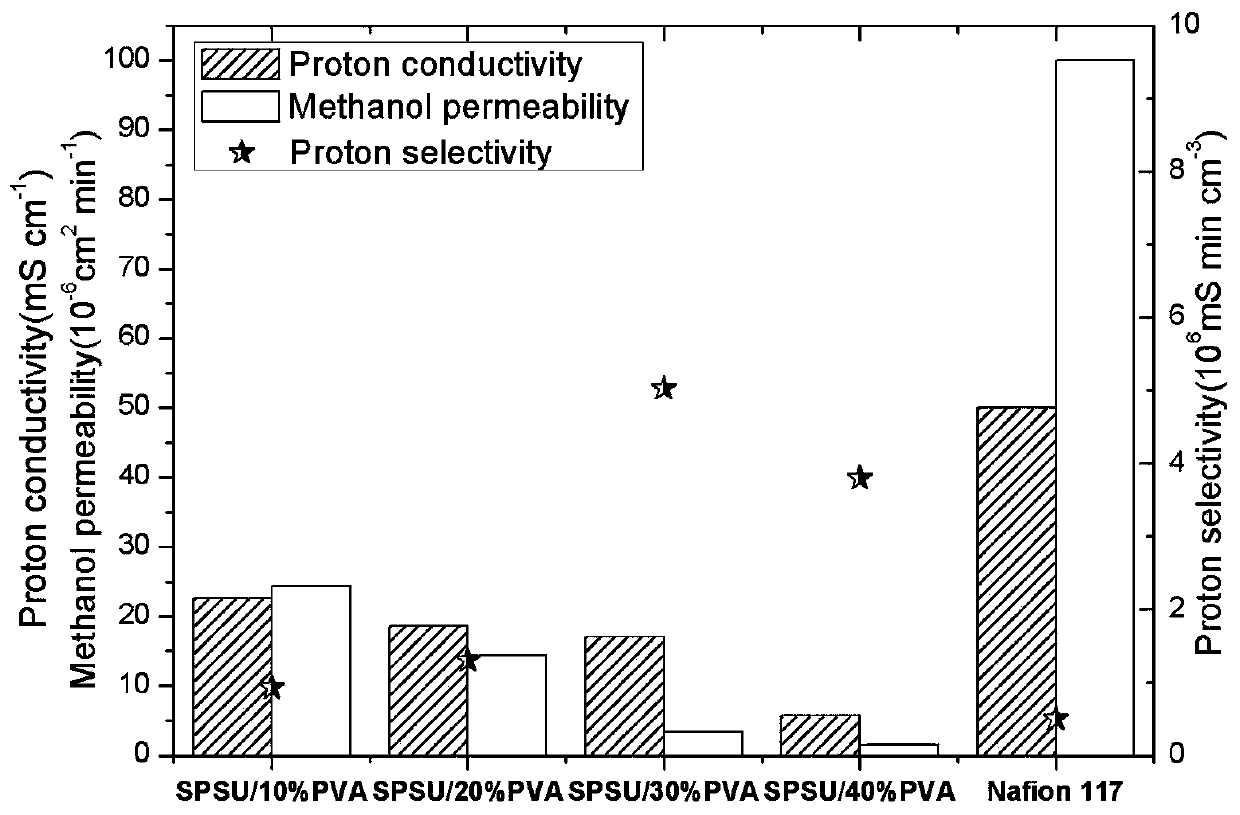

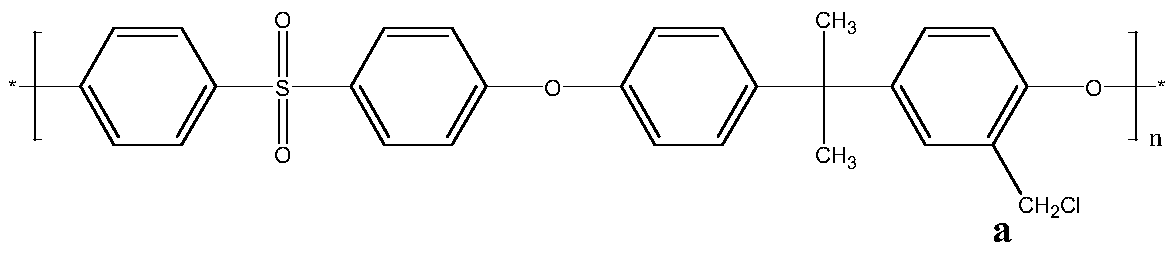

Side-chain sulfonated polysulfone/ polyvinyl alcohol proton exchange membrane and preparation method thereof

ActiveCN109904500AImprove proton conductivityGood chemical stabilityRegenerative fuel cellsMethyl aldehydeAlcohol

The invention discloses a side-chain sulfonated polysulfone / polyvinyl alcohol proton exchange membrane and a preparation method thereof. The proton exchange membrane is formed in a way that side-chain sulfonated polysulfone solution and polyvinyl alcohol solution are blended to carry out casting to form a membrane and then the membrane is subjected to crosslinking, wherein the mass ratio of the side-chain sulfonated polysulfone to the polyvinyl alcohol is 50:50-90:10. By use of the proton exchange membrane, the side-chain sulfonated polysulfone solution and polyvinyl alcohol solution are blended to form the membrane on a glass plate, the membrane is dried in vacuum, and the dried membrane is dipped in sulfuric acid aqueous solution containing methyl aldehyde or glutaraldehyde to be subjected to crosslinking to obtain the blended crosslinking proton exchange membrane. The proton exchange membrane has the advantages of high proton conductivity, low methyl alcohol permeability, wide material source, simple preparation instrument and low preparation cost.

Owner:SICHUAN UNIV

Black wattle light medium container cutting seedling method

InactiveCN103392576AImprove water absorptionImprove permeabilityCultivating equipmentsSoilless cultivationMethyl aldehydePlant roots

The invention discloses a black wattle light medium container cutting seedling method which comprises four steps of cutting medium preparation, scion wood collection and processing, cutting and management after cutting, wherein the medium is prepared by the following raw materials in volume percent: 45 to 55 percent of coco coir, 10 to 20 percent of carbonize saw dust, 15 to 30 percent of fermented tung bran, and 5 to 10 percent of perlite; the light medium is sterilized through 40 percent of methyl aldehyde before cutting; the cutting scion is processed by sterilizing agent and rooting agent after being soaked by clean water for 2 to 4 hours; the seedling is cultivated under the environmental condition that the water content of the medium is 50 to 70 percent, the temperature is 20 DEG C to 28 DEG C, and the relative humidity is above 85 percent. The method provided by the invention has the advantages that the physical behavior of the light medium is better, and is more suitable for the growth and development of plant root system; the light medium of the un-survived plant can be recycled, and the medium is light in weight, so that seedling cultivation cost, transportation cost and forestation cost are reduced; according to the cutting seedling method provided by the invention, survival rate is improved, and healthy plantlets with high quality are cultivated.

Owner:GUANGXI FORESTRY RES INST

Synthesis of amino-base resin-base polyurea polylol

Synthesis of amino-resin polyurea polyol is carried out by mixing melamine with methyl aldehyde, agitating, regulating pH value by alkali agent, adding into catalyst, heat reacting to obtain polyhydroxy-methyl-melamine solution, heat reacting the obtained solution with excessive methyl alcohol to obtain amino-resin solution, agitation mixing the obtained amino-resin solution with poly-ether polybasic alcohol with molecular weight 3000, depress distilling to remove small molecule, cooling to lower temperature, adding into paraffin solvent and tertiary amine catalyst, agitating, adding into isocyanate, heat reacting, decompressing and removing residual small molecules to obtain final product. It is simple, cheap, has lower acidity, higher oxygen index and no halogen, phosphor and antimony.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of melamine microcapsule

InactiveCN103506059AGuaranteed efficacyFormaldehyde residue reductionInorganic non-active ingredientsEssential-oils/perfumesPolyamine CompoundMethyl aldehyde

The invention relates to a manufacturing method of melamine microcapsule, comprising the following steps: adding melamine, formalin and basic hydroxide and adjusting the pH to 8 to 10, and adding polyamine compound having at least two amine groups for reaction to form a melamine-methyl aldehyde prepolymer; using the basic hydroxide to basify more than one resin selected from an ethylene-maleic acid copolymer resin and a styrene-maleic acid copolymer resin to form an emulgator; putting a sac core substance into the emulgator for stirring to form an oily / aquiform emulsion; mixing the melamine-methyl aldehyde prepolymer with oily / aquiform emulsion and reacting under 40 to 80 DEG C; putting into a product of the abovementioned reaction a compound that reacts with methyl aldehyde and reacting under 40 to 80 DEG C; and putting into the product of the abovementioned reaction a metal or a metal compound that reacts with methyl aldehyde and reacting under 40 to 80 DEG C.

Owner:株式会社大河曼泰克

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com