Plaster-shape regenerated rubber and preparation method thereof

A reclaimed rubber and paste technology, which is applied in the field of paste reclaimed rubber and its production, achieves the effect of reducing costs, deducting kneading and refining processes after desulfurization, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

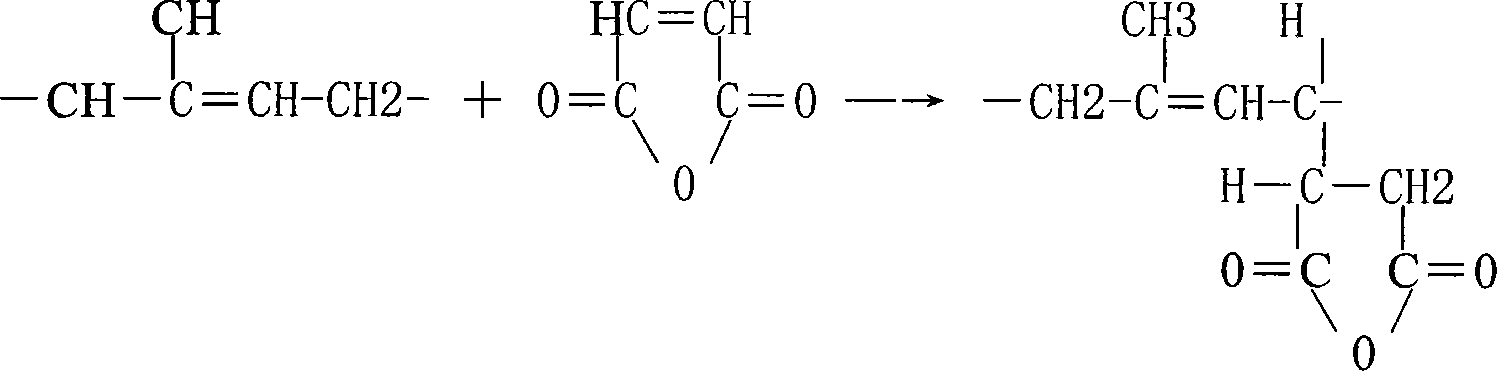

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] After the waste rubber tires are pulverized, 30 mesh vulcanized rubber powder is obtained,

[0040] Take the following recipe:

[0041] 30 mesh vulcanized rubber powder: 100kg

[0042] Solvent:

[0043] Paraffin oil 70kg

[0044] Solid Coumarone 22kg

[0045] Catalyst and co-catalyst

[0046] Phthalic anhydride 3kg

[0047] Formaldehyde solution 4.5kg

[0048] Resorcinol 0.5kg

[0049] Total; 200kg

[0050] Craftsmanship

[0051] Put 100kg of vulcanized rubber powder into the vertical depolymerizer, add solvent paraffin oil, solid coumarone, catalyst and co-catalyst phthalic anhydride, formaldehyde aqueous solution, resorcinol in sequence, close the feeding port, stir and heat up To 180°C, control the pressure at 0.5 MPa, react for 2.5 hours, cool down and let off the residual gas, then discharge the material, filter with a 100-mesh metal screen to obtain a paste-like regenerated rubber.

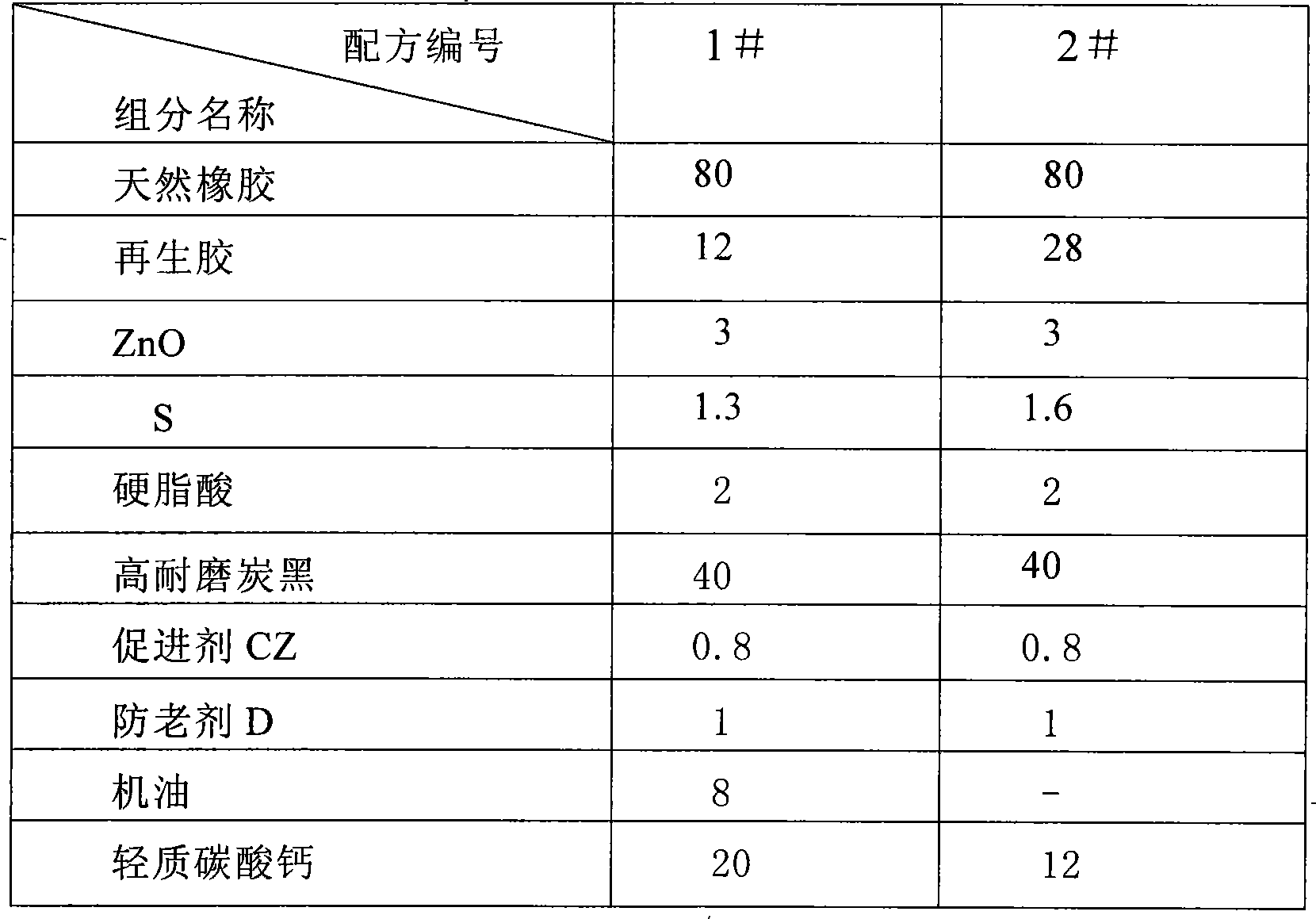

[0052] Combine the obtained paste regenerated rubber with synthetic rub...

Embodiment 2

[0069] After the waste rubber tires are pulverized, 30 mesh vulcanized rubber powder is obtained,

[0070] Take the following recipe:

[0071] 30 mesh vulcanized rubber powder: 100kg

[0072] Solvent:

[0073] Paraffin oil 80kg

[0074] Solid Coumarone 20kg

[0075] Catalyst and co-catalyst

[0076] Phthalic anhydride 5kg

[0077] Formaldehyde solution 4.3kg

[0078] Resorcinol 0.3kg

[0079] Total; 200kg

[0080] Craftsmanship

[0081] Put 100kg of vulcanized rubber powder into the vertical depolymerizer, add solvent paraffin oil, solid coumarone, catalyst and co-catalyst phthalic anhydride, formaldehyde aqueous solution, resorcinol in sequence, close the feeding port, stir and heat up To 160°C, control the pressure at 0.6MPa, react for 2.5 hours, cool down and let off the residual gas, then discharge the material, filter with a 100-mesh metal screen to obtain a paste-like regenerated rubber.

[0082] Combine the obtained paste regenerated rubber with natural rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com