Environment-friendly diatom ooze composite material and production method for decorative plates

A composite material and decorative plate technology, which is applied in the production field of diatom mud environmental protection composite materials and environmental protection decorative plates, can solve the problems of single diatom mud texture, high price, and difficult to clean, and achieves diversified surface texture and easy cleaning. , the effect of strong air treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

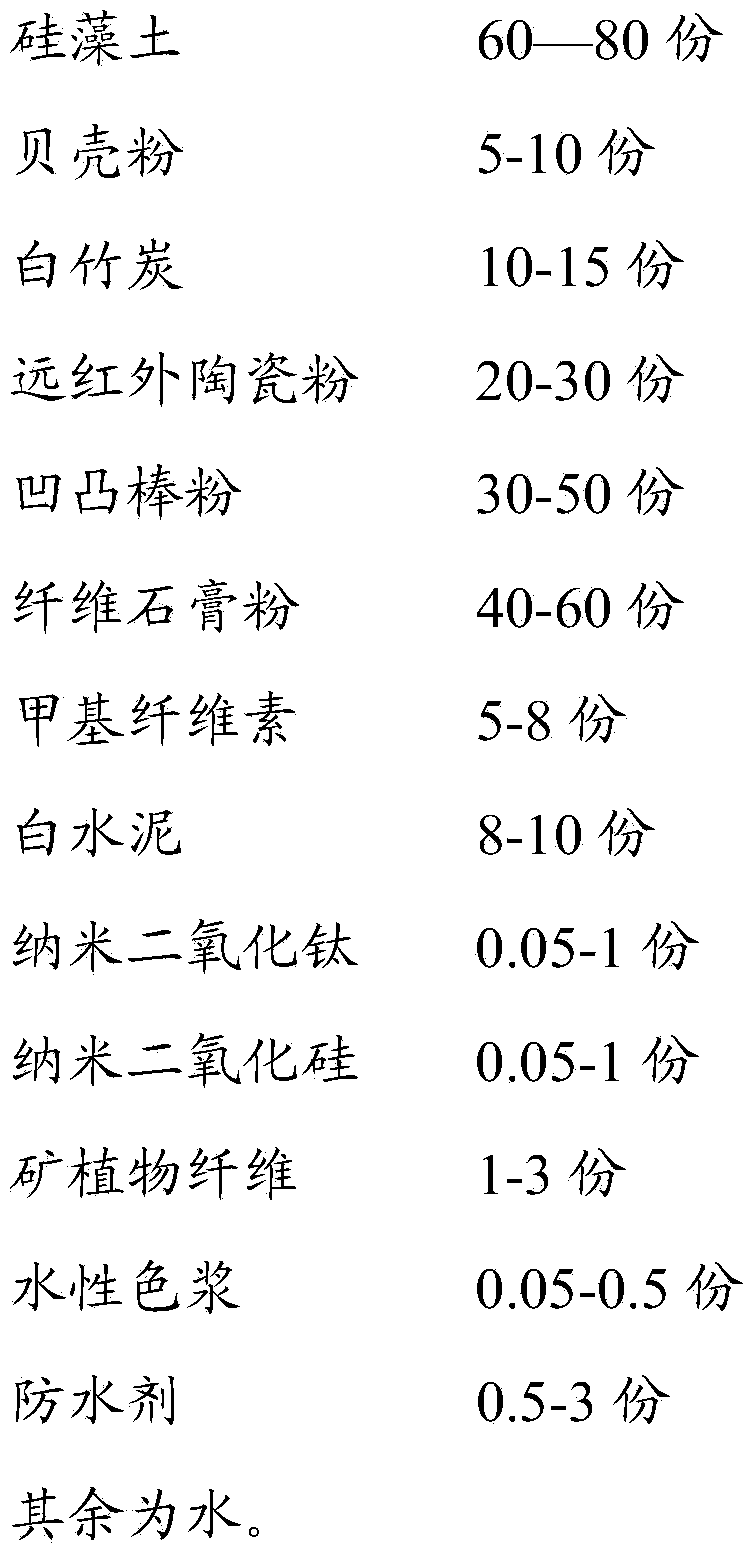

[0016] A kind of diatom mud environmental protection composite material, back up various raw materials according to the following parts by weight: 60 parts of diatomite, 5 parts of shell powder, 10 parts of white bamboo charcoal, 20 parts of far-infrared ceramic powder, 30 parts of attapulgite powder, 40 parts of Fiber gypsum powder, 5 parts of methyl cellulose, 8 parts of white cement, 0.05 parts of nano-titanium dioxide, 0.05 parts of nano-silicon dioxide, 1 part of mineral plant fiber, 0.05 parts of water-based color paste, 0.5 parts of waterproofing agent and an appropriate amount of water.

[0017] The method of utilizing the above-mentioned diatom mud environmental protection composite material to produce an environmental protection decorative plate is as follows: at room temperature, 60 parts of diatomite, 5 parts of shell powder, 10 parts of white bamboo charcoal, 20 parts of far-infrared ceramic powder, 30 parts of Attapulgite powder, 40 parts of fiber gypsum powder, 5...

Embodiment 2

[0019] A kind of diatom mud environmental protection composite material, back up various raw materials according to the following parts by weight: 80 parts of diatomite, 10 parts of shell powder, 15 parts of white bamboo charcoal, 30 parts of far-infrared ceramic powder, 50 parts of attapulgite powder, 60 parts of Fiber gypsum powder, 8 parts of methyl cellulose, 10 parts of white cement, 1 part of nano-titanium dioxide, 1 part of nano-silica, 3 parts of mineral plant fiber, 0.5 parts of water-based color paste, 3 parts of waterproofing agent and an appropriate amount of water.

[0020] The method for utilizing the above-mentioned diatom mud environmental protection composite material to produce an environmental protection decorative plate is: at room temperature, 80 parts of diatomite, 10 parts of shell powder, 15 parts of white bamboo charcoal, 30 parts of far-infrared ceramic powder, 50 parts of Attapulgite powder, 60 parts of fiber gypsum powder, 8 parts of methyl cellulose...

Embodiment 3

[0022] A kind of diatom mud environmental protection superposition material, back up various raw materials according to the following parts by weight: 70 parts of diatomite, 7.5 parts of shell powder, 12.5 parts of white bamboo charcoal, 25 parts of far-infrared ceramic powder, 40 parts of attapulgite powder, 50 parts of 1 part of fiber gypsum powder, 6.5 parts of methyl cellulose, 9 parts of white cement, 0.525 parts of nano-titanium dioxide, 0.525 parts of nano-silica, 2 parts of mineral plant fiber, 0.275 parts of water-based color paste, 1.75 parts of waterproofing agent and an appropriate amount of water.

[0023] The method for utilizing the above-mentioned diatom mud environmental protection composite material to produce an environmental protection decorative plate is as follows: at room temperature, 70 parts of diatomite, 7.5 parts of shell powder, 12.5 parts of white bamboo charcoal, 25 parts of far-infrared ceramic powder, 40 parts of Attapulgite powder, 50 parts of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com