Patents

Literature

251 results about "Triethylphosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triethylphosphite is an organophosphorus compound with the formula P(OCH₂CH₃)₃, often abbreviated P(OEt)₃. This colorless liquid is used as a ligand in organometallic chemistry and as a reagent in organic synthesis...

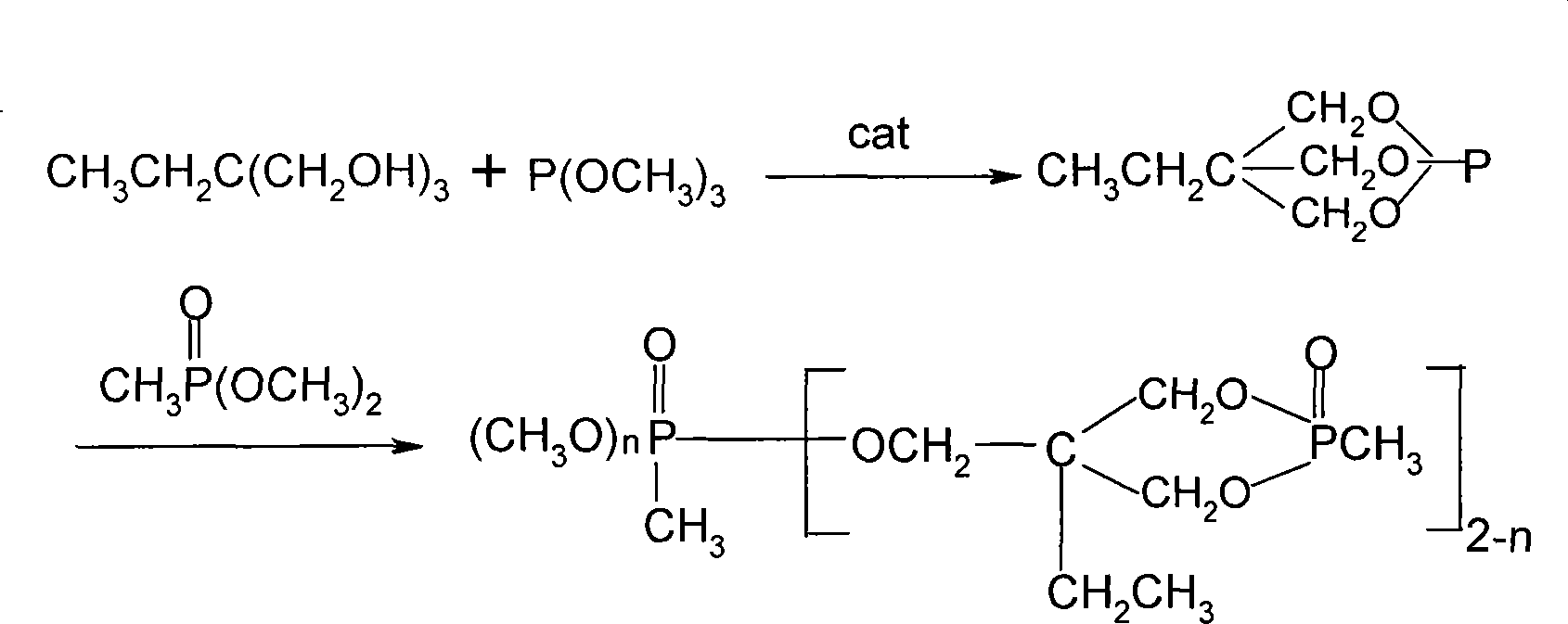

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

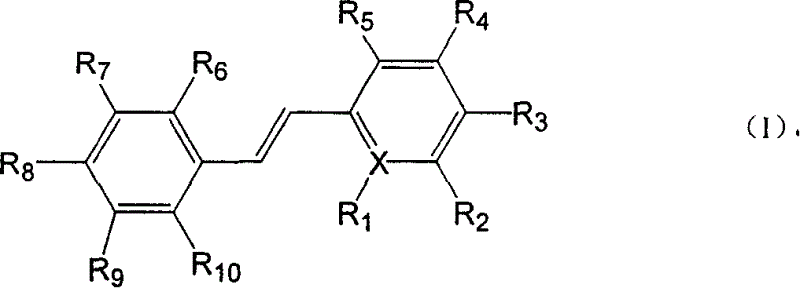

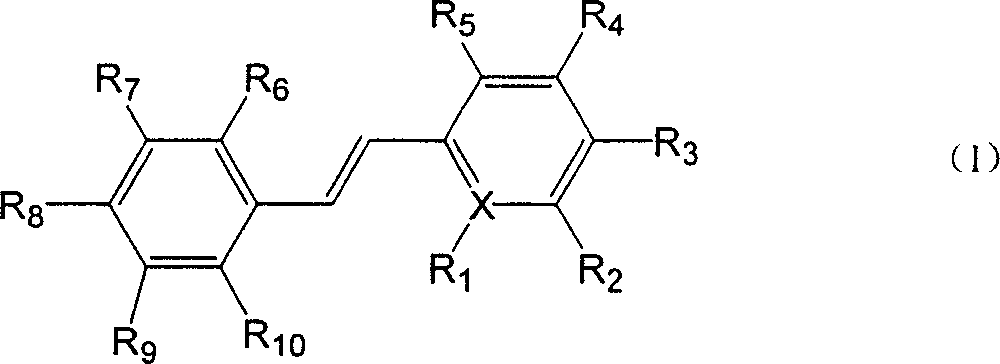

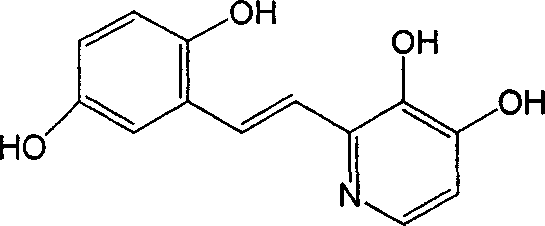

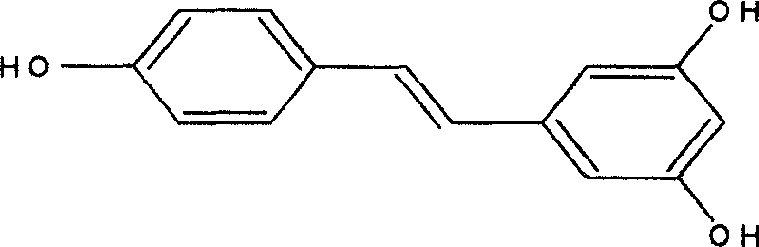

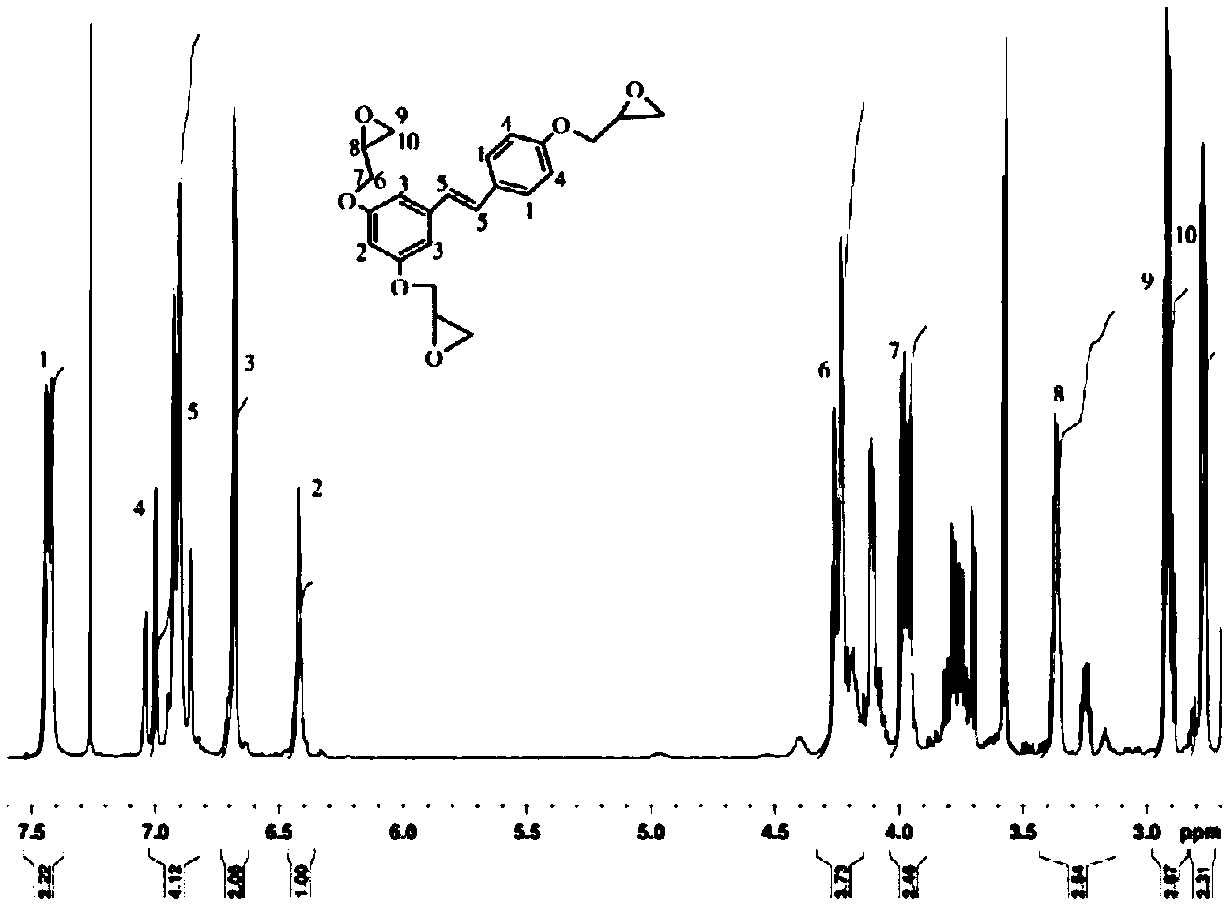

Polyhydroxy stilbenes compound preparation and uses as drugs for suppressing SARS

InactiveCN1736986AMeet the requirements of therapeutically effective doseOrganic chemistryHydroxy compound active ingredientsMethyl aldehydeTriethylphosphite

The invention provides a group of polyhydroxy stilbene compounds, their preparing process and use for suppressing and eradicating SARS coronavirus. The preparing process comprises, preparing phosphonic ester by reacting multi-alkyl substituted chloro (bromo) methoxyl or pyridine compounds with triethyl phosphate, then reacting phosphonate ester compound with multi-alkyl (oxy) phenylpyridine methyl aldehyde to obtain multi-alkyl (oxy) stilbene compounds. Finally acting with boron tribromide to obtain polyhydroxy stilbene compounds with substituent groups.

Owner:DALIAN UNIV OF TECH +1

Preparation method of 4-acetoxyl-2-methyl-2-butylenoic aldehyde

ActiveCN101723827AGood reaction selectivityHigh yieldOrganic compound preparationCarboxylic acid esters preparationTriethylphosphiteMethyl group

The invention discloses a preparation method of 4-acetoxyl-2-methyl-2-butylenoic aldehyde. In the traditional method, the yield is lower, the waste water amount is larger, and the requirements on equipment are higher. The preparation method comprises the following steps of: reacting 2-halogenated ethanol as a raw material with an acylating agent to obtain halogenated ester; then preparing phosphonate ester through the Arbuzov reaction between the halogenated ester and triethyl phosphite; preparing glutaraldehyde acetal through the Wittig-Horner reaction between the phosphonate ester and 1,1-dimethoxy acetone under the action of alkaline, and carrying out deprotection on the glutaraldehyde acetal under the acidic condition to obtain glutaraldehyde, namely, the 4-acetoxyl-2-methyl-2-butylenoic aldehyde. The invention has less three waste generation, good reaction selectivity, less by-products and higher yield.

Owner:SHANGYU NHU BIOCHEM IND

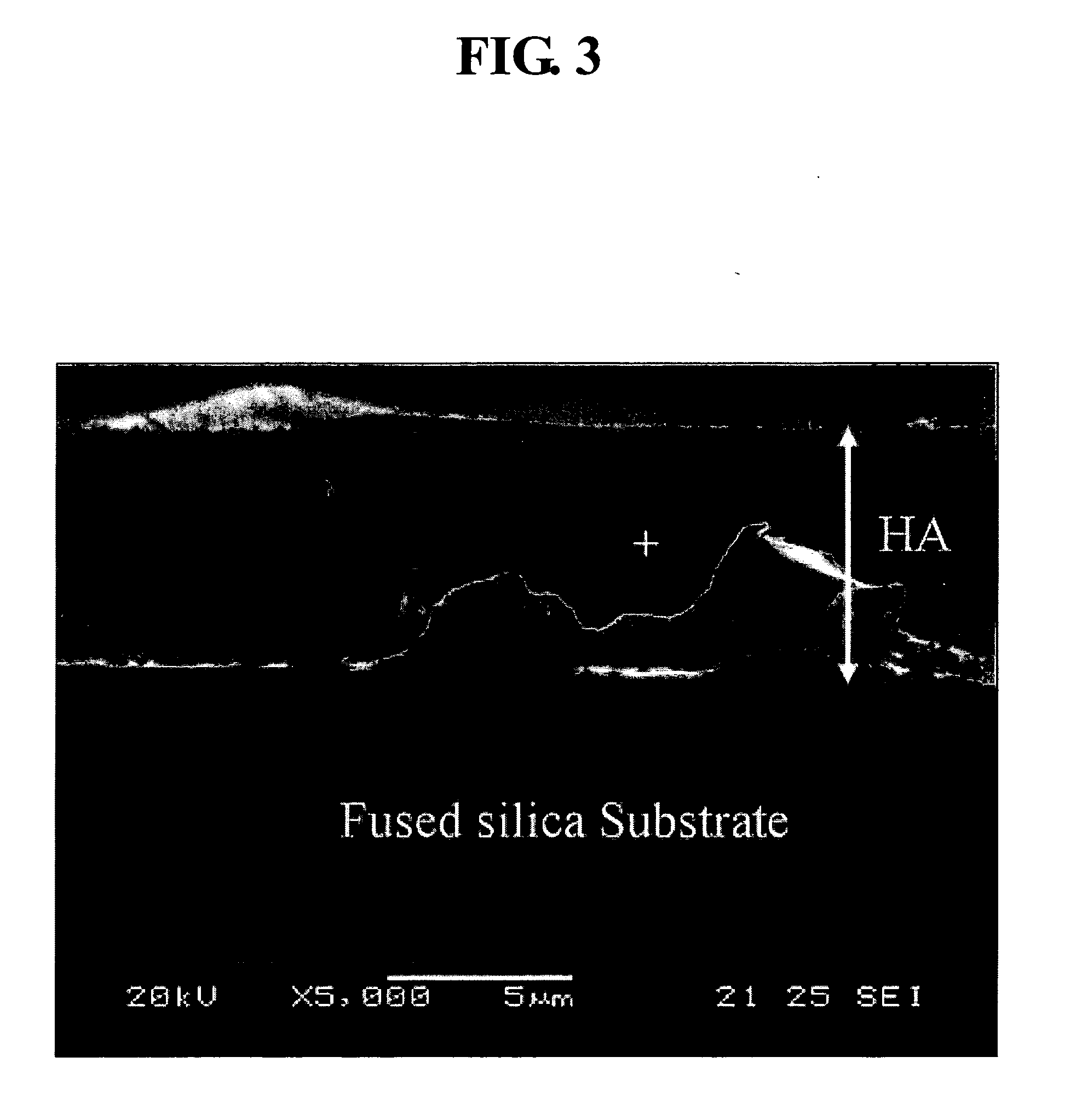

Method for producing polymeric sol of calcium phosphate compound and method for coating the same on a metal implant

ActiveUS20050158399A1Improve wettabilityExcellent bioactivityDental implantsBiocideTriethylphosphiteApatite

Disclosed is a method for producing a transparent and homogenized polymeric sol of a calcium phosphate compound, containing apatite and having excellent wettability and bioactivity, according to a sol-gel synthesis, and a method for coating the polymeric sol on a metal implant, in which the polymeric sol is coated on the metal implant and then heat-treated to form a dense coated layer strongly bonded to the metal implant. The polymeric sol is obtained by process of preparing a calcium salt solution, containing calcium ethoxide dissolved in organic acid, and a phosphate solution, containing triethyl phosphite or triethyl phosphate dissolved in the organic acid, mixing the calcium salt solution with the phosphate solution to produce a mixed solution, and aging the mixed solution.

Owner:SEOUL NAT UNIV R&DB FOUND

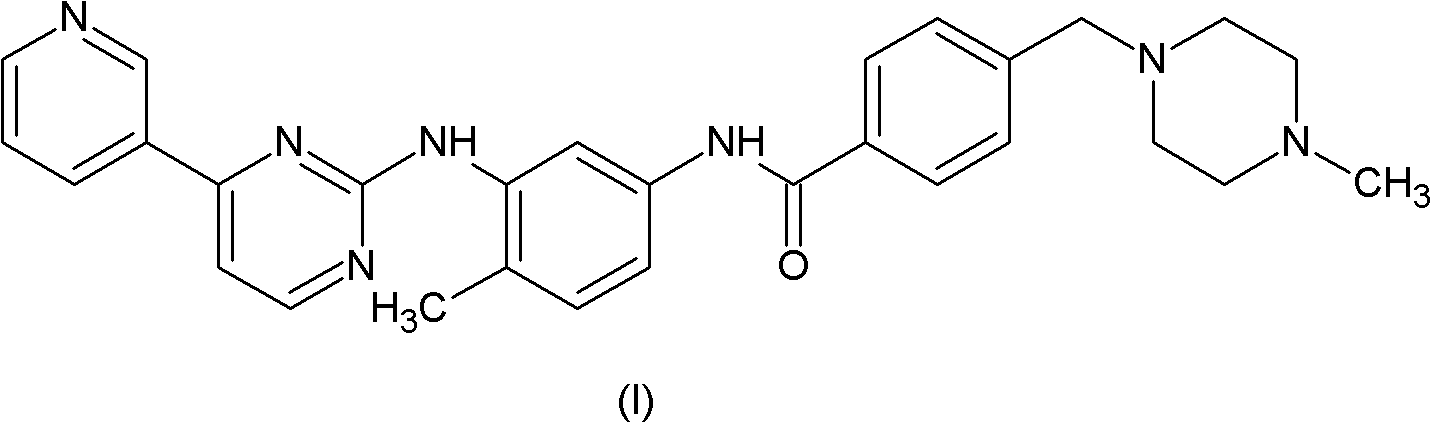

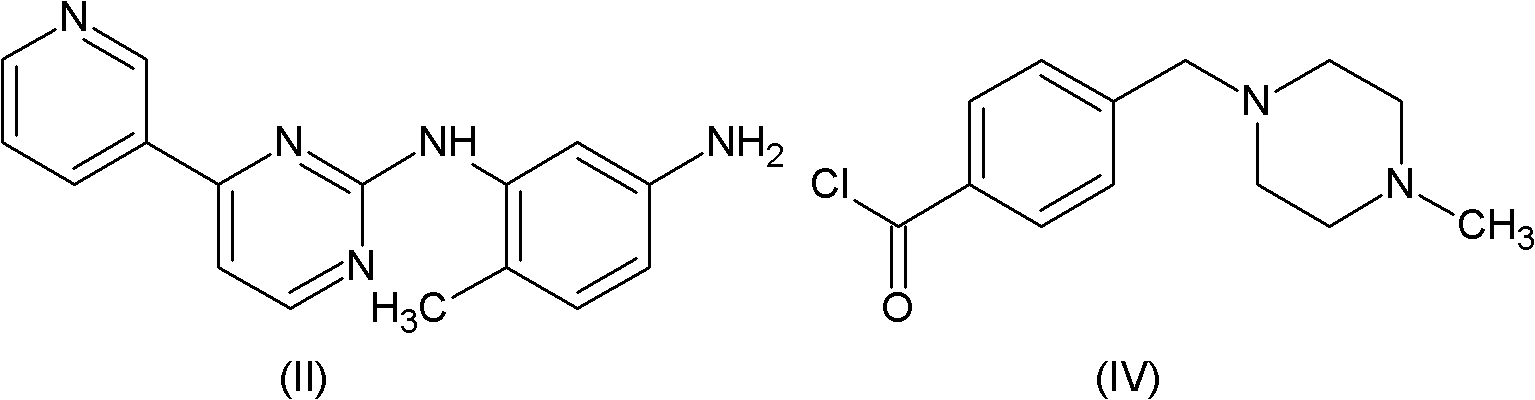

Method for preparing imatinib

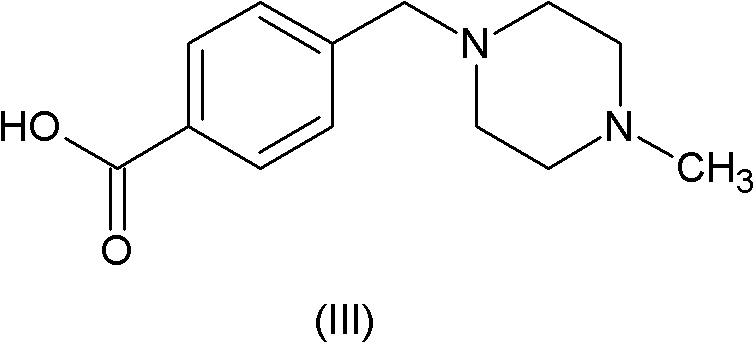

ActiveCN101921260AThe reaction steps are simpleShorten the production cycleOrganic chemistryBenzoic acidN dimethylformamide

The invention relates to a method for preparing imatinib, which comprises the following steps of: with a compound N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidineamine shown as the structural formula (II) and a compound 4-[(4-Methylpiperazin-l-yl)methyl]benzoic acid shown as the structural formula (III) as initial raw materials, dropwise adding phosphite ester at 50-90 DEG C for 1-2 hours inthe presence of a catalyst in an organic solvent; and continuously insulating and reacting at 50-90 DEG C to obtain the compound imatinib shown as the structural formula (I). The organic solvent is N,N-dimethylformamide, N,N-dimethylacetylamide or N-methylpyrrolidone. The catalyst is pyridine; and the phosphite ester is trimethyl phosphate, triethyl phosphate or triphenyl phosphate. The technical scheme of the invention has the advantages of simple reaction step, easy control of reaction, short production cycle, low toxicity of used raw materials, less pollution to the environment and higher product quality, and the yield can reach 95 percent, and the purity reaches 99.5 percent.

Owner:山东金城昆仑药业有限公司

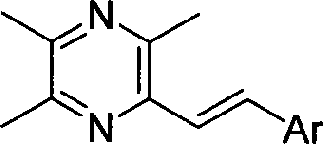

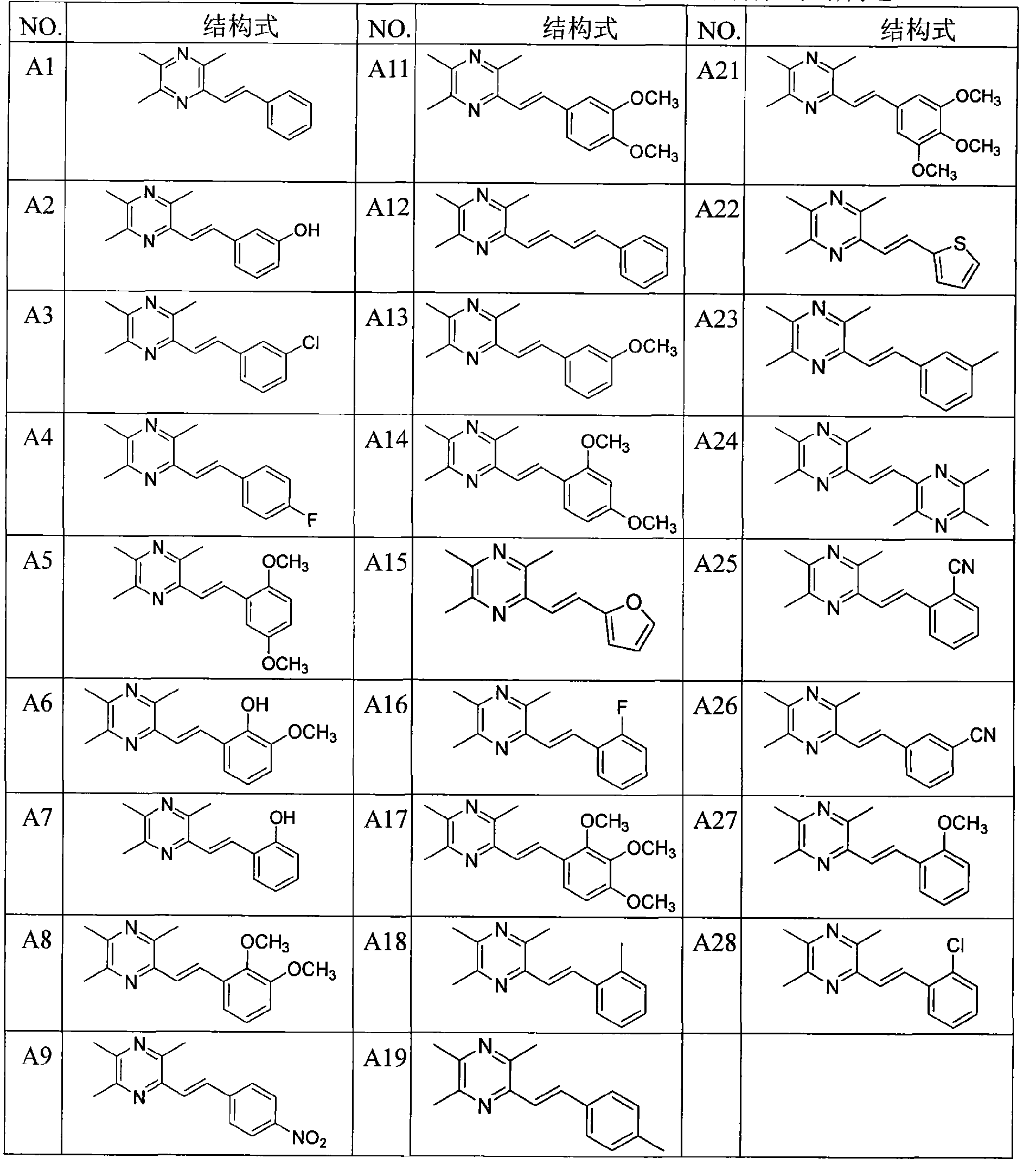

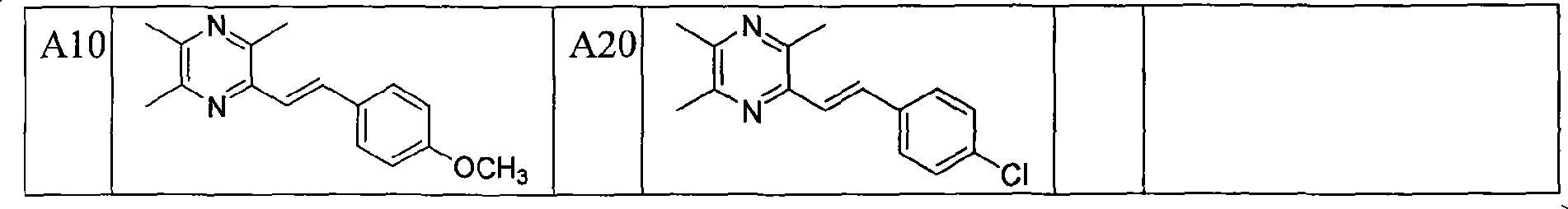

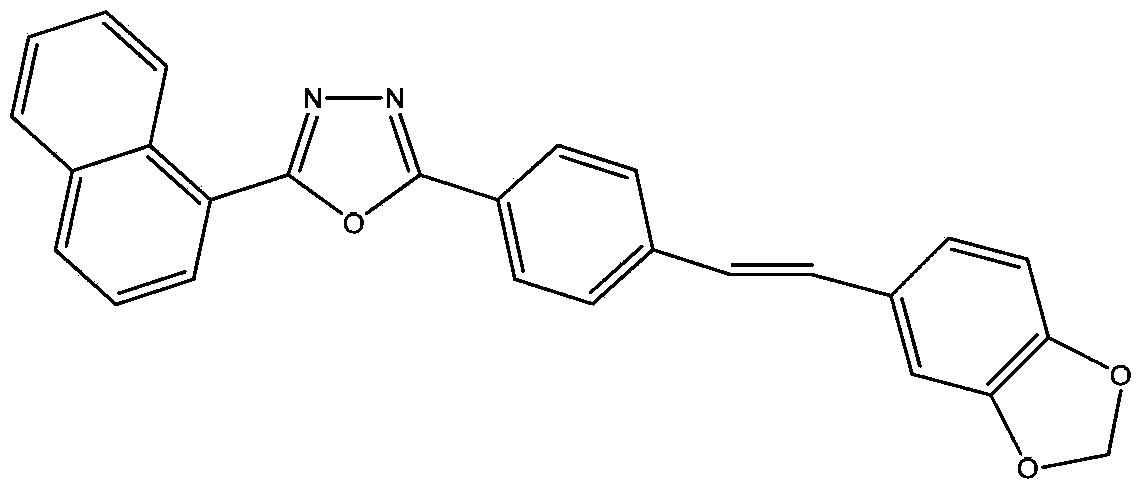

Ligustrazine stilbenoids derivatives, preparation method thereof, medicament composition and use

The invention relates to a kind of ligustrazine derivant, preparation method and medicinal compound and its application, belonging to chuanxiong rhizome derivant medicine technique. The structure general formula is as that: Ar is hydroxybenzene, fluorophenyl, chlorphenyl, methylbenzene, methoxybenzene, nitrobenzene, cyanobenzene, furan group, ligustrazine or thiofuran. Said preparation method comprises following steps: mixing intermediate 2- chloromethyl- 3, 5, 6- trimethyl pyrazine and halogenated benzyl, triethyl phosphite; heating and refluxing, adding waterless tetrahydrofuran and NaH at tetrahydrofuran bath condition, dropping mixing solution of aromatic aldchyde and waterless tetrahydrofuran, stirring, extracting, drying, filtering, steaming to remove disslovant, separating residues with fast column chromatography, recrystallizing with methanol, and getting ligustrazine derivant. Said product and medical findings can be used to produce medicinal compound, and medicine for preventing angiocardiopathy and cerebrovascular diseases such as ischemic disease, atherosclerosis and coronary disease.

Owner:SHANDONG UNIV

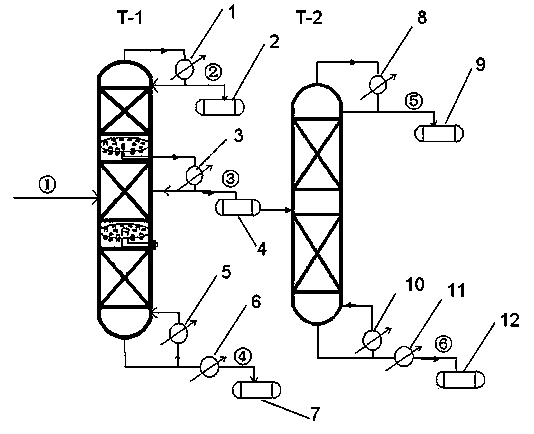

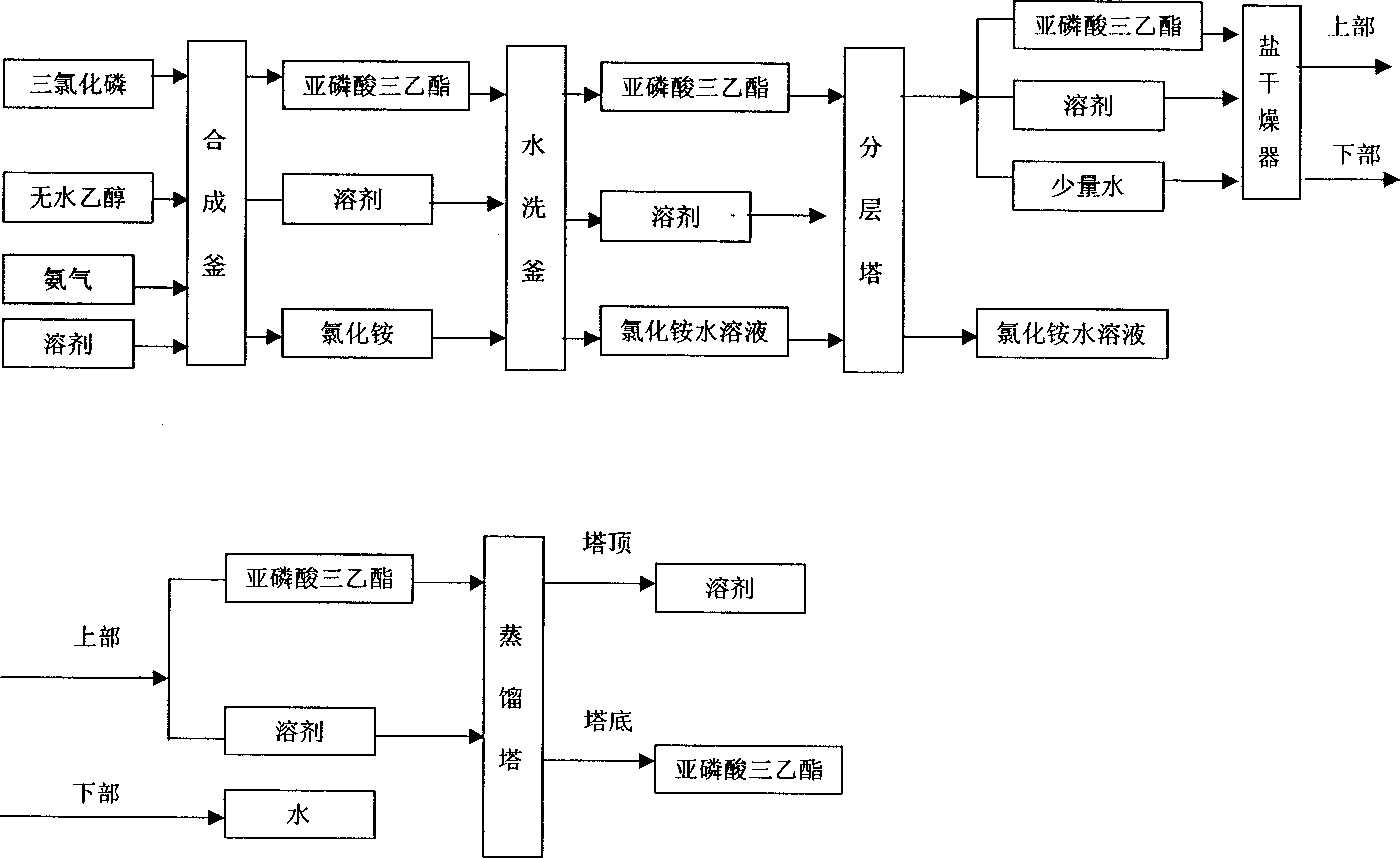

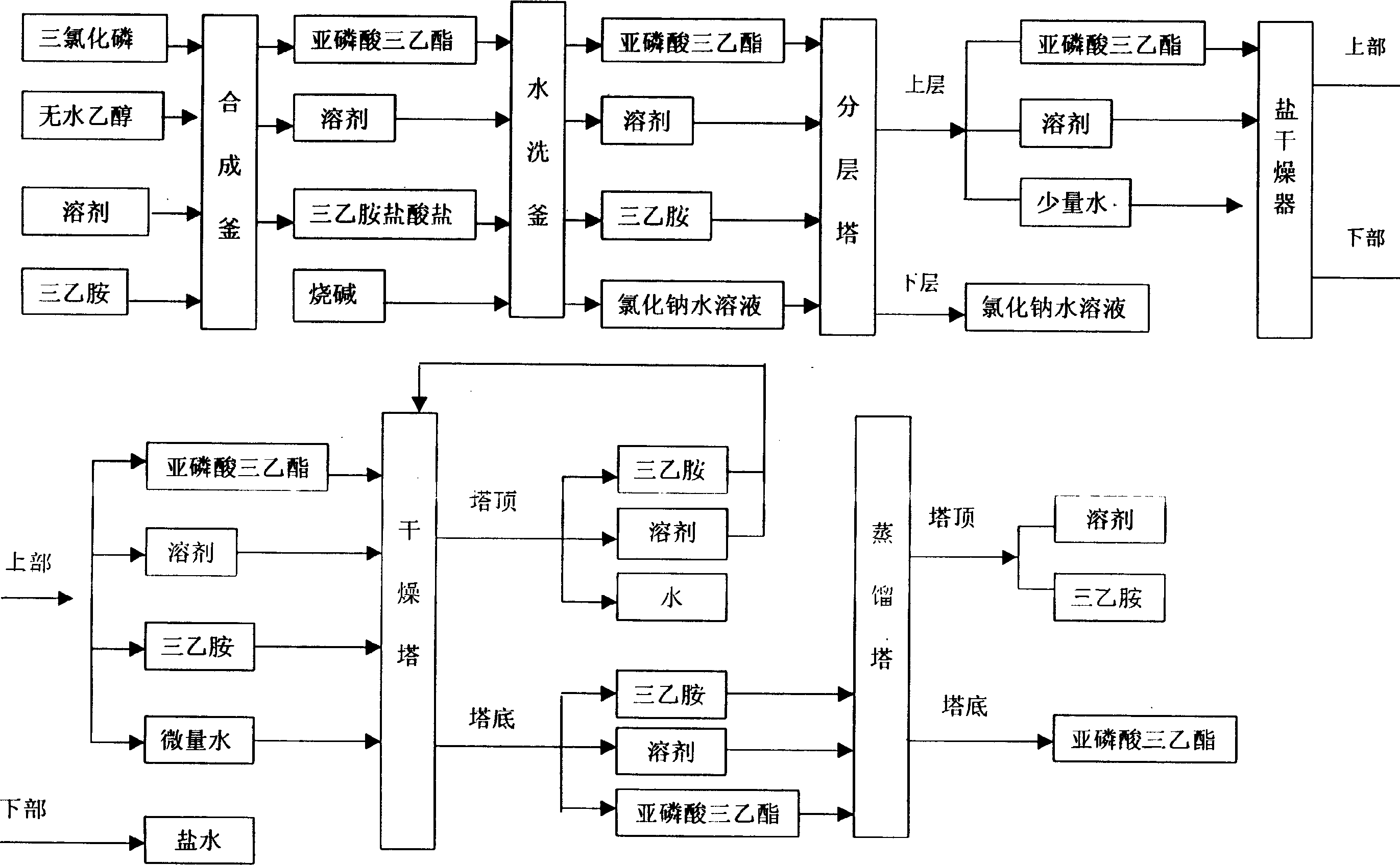

Production method of triethyl phosphite

ActiveCN101624400AIncrease production capacityImprove product qualityGroup 5/15 element organic compoundsAmmonium halidesTriethylphosphiteDistillation

The invention relates to a production method of triethyl phosphite, which belongs to the technical field of chemical production. Absolute ethyl alcohol, phosphorous trichloride are taken as main material, pure benzol is taken as solvent, triethylamine is taken as acid-binding agent, liquid ammonia is taken as reducing agent, and the triethyl phosphate is prepared through the processes of three-complex liquor preparing, synthetic reaction, water scrubbing reaction, layering, drying, crude distillation, rectifying, recovering and ammonia recovery and the like. The method adopts continuous production process of triethylamine, the material charging and the product discharging are continuous, the production capacity is strong, and the product quality is stable. With equal equipment and investment, the capacity of the method can be 6 to 7 times as the capacity of intermittent method. The method solves the problems of the prior production method that the production capacity is small, the production cycle of the product is long, the material consumption is large, the quality is unstable, the discharge amount of 'three wastes' is large, and the yield can not be guaranteed. The method has the advantages that the liquid ammonia is taken as reducing agent, the cost is low, the recovery factor of excess ammonia can reach more than 90 percent, the recovered ammonium chloride can be used as the crude product of ammonium fertilizer, the production cost is lowered, and the environmental pollution is reduced.

Owner:荆州三才堂化工科技有限公司

Process for synthesizing 6-quinazolinyl-ethyl-benzoyl and related antifolates

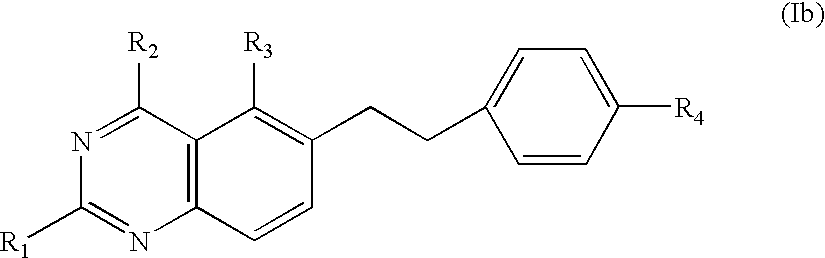

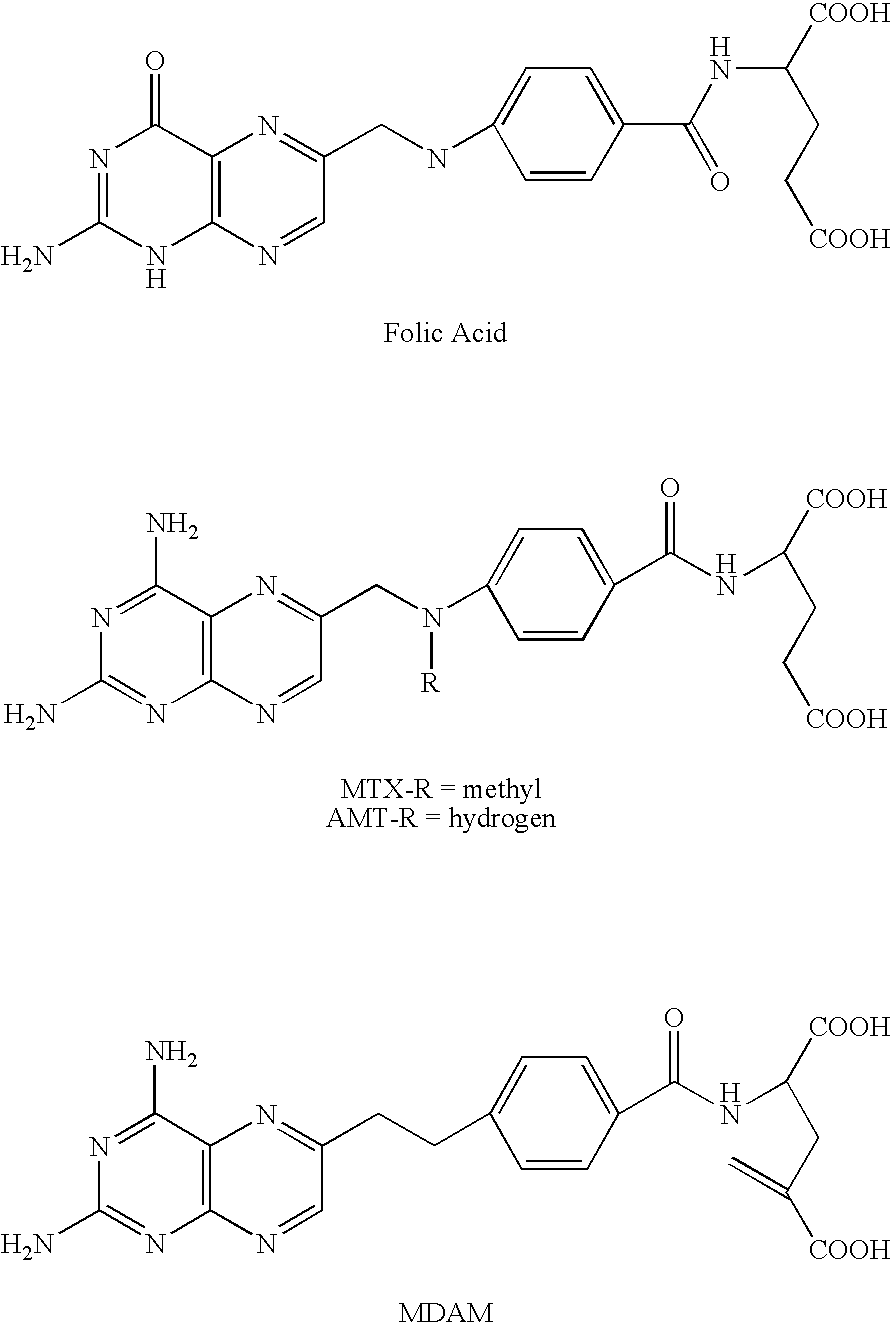

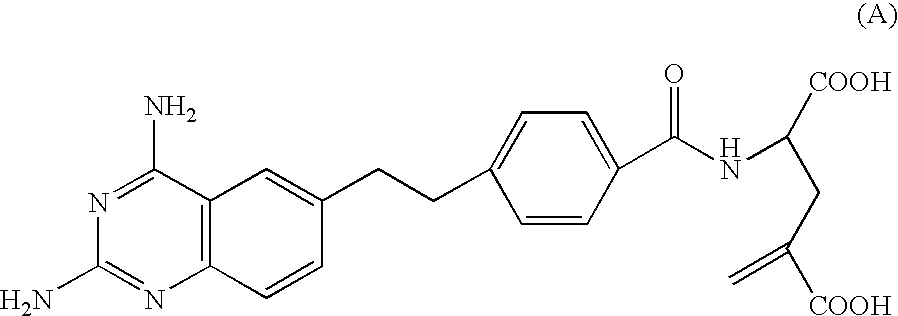

InactiveUS7060825B2Efficient and economicalEfficient and economical processOrganic chemistryBulk chemical productionBenzoic acidTriethylphosphite

The invention claimed herein relates to an improvement in a process for synthesizing a compound of formula Ib:wherein R1 and R2 are each individually amino or N-alkyl substituted amino; hydroxy; alkoxy; keto; lower alkyl; or a nitrogen or oxygen protecting group;R3 is hydrogen; hydroxy; alkoxy; trifluoromethyl alkoxy; halo; sulfhydryl or alkylthio;R4 is —C(O)—X;X is hydroxy; alkoxy; or an amino acid residue;in which process a 2-amino-5-nitro-benzonitrile starting reagent is cyclized to form 2,4-diamino-6-nitro-quinazoline, which is converted to 2,4,6-triamino-quinazoline, which is converted to 2,4-diamino-6-cyano-quinazoline, which is converted to 2,4-diamino-6-formyl-quinazoline;in which the improvement includes:reacting an R4-p-benzoic acid alkylene moiety with triethyl phosphite to form a 4-R4-carbonyloxyalkyl-phenyl-alkyldiethylphosphite; andreacting the 2,4-diamino-6-formyl-quinazoline with the 4-R4-carbonyloxyalkyl-phenyl-alkyldiethylphosphite to form the compound of formula Ib.

Owner:BIONUMERIK PHARMA INC

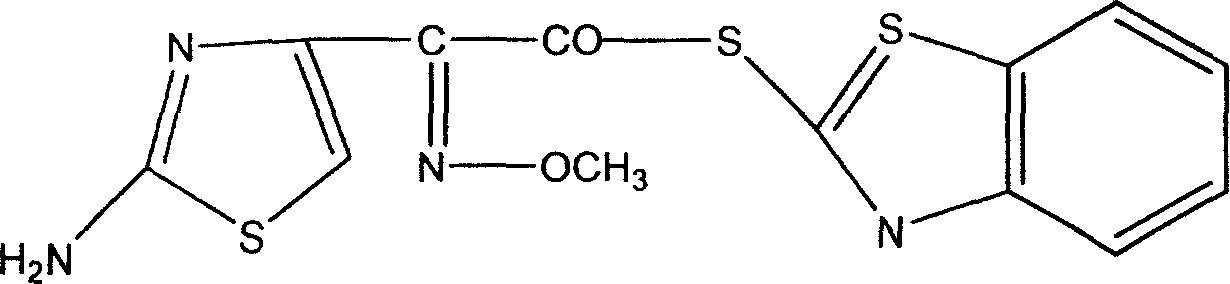

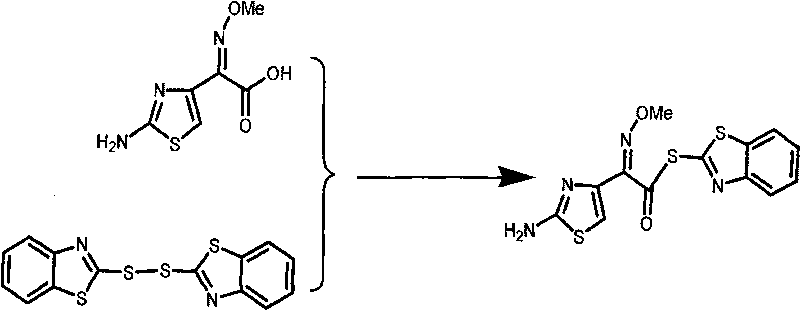

New technique for catalytic synthesis of AE active ester

ActiveCN101096364AHigh yieldMild operating conditions for productionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTriethylphosphiteDistillation

The invention discloses a new technology for synthesizing AE-active ester with accelerant, which is made by condensation reaction in the triethyl phosphate and triethylamine solvent. The invention is characterized by the following: introducing pyridine with high hydroscopicity as the accelerant in order to accelerate the reaction proceeding according to the forward direction based on the original technology; changing the reaction solvent system (the mixed solvent which is comprised by acetonitrile and carrene according to (0.9-1.0):1); avoiding the problem of water content which is introduced by the new solvent; improving the normal reaction temperature; reducing the operation difficult; reducing the strength; improving the product efficient to more than 92%. The invention also achieves the recycling of the solvent by distillation.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD +1

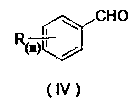

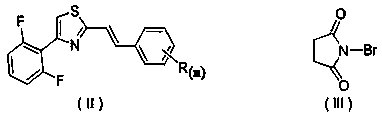

Distyrene compound containing bromothiazole ring as well as synthesis method and application thereof

ActiveCN108863977AEasy to makeModerate inhibitory activityBiocideAntimycoticsTriethylphosphiteThiazole

The invention discloses a distyrene compound containing a bromothiazole ring as well as a synthesis method and application thereof. The compound has the following synthesis process that firstly, 2-(brome methyl)-4-(2,6-difluorophenyl) thiazole and triethyl phosphite react in a backflow state; TLC monitoring is performed till reaction completion; concentration is performed to remove excessive triethyl phosphite; solvents DMF, sodium hydroxide and substituted benzaldehyde are added into the obtained concentrated solution; reaction is performed at room temperature; after the reaction is completed, post treatment is performed to obtain a distyrene compound containing a thiazole ring; next, the distyrene compound containing the thiazole ring and N-bromo-succinimide take bromo reaction in acetonitrile solvents at 0 to 100 DEG C; the distyrene compound containing the bromothiazole ring is obtained. By using the technology, a kind of novel (E)-5-brome-4-(2,6-difluorophenyl)-2-substituted styryl thiazole compounds can be obtained through synthesis. The preparation of the compound is simple; certain anticancer and anti-fungus activity is shown.

Owner:ZHEJIANG UNIV OF TECH +1

Method for synthesizing AE-active ester

ActiveCN101747291AImprove solubilityReduce solubilityOrganic chemistryTriethylphosphiteOrganic solvent

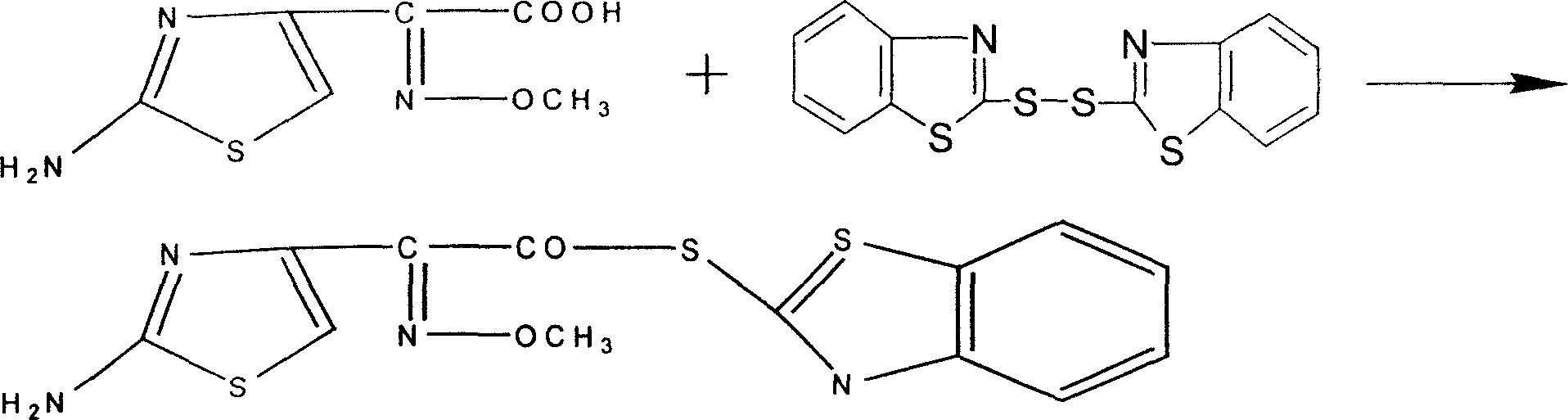

The invention discloses a method for synthesizing AE-active ester. The AE-active ester is prepared by taking aminothiazoly loximate and dithio-bisbenzothiazole as raw materials and carrying out condensation reaction in the presence of triethylamine and triethyl-phosphite. The method is characterized in that higher fatty acid with diffusion effect is introduced into the condensation reaction and a mixed solvent consisting of methylene dichloride and acetonitrile is adopted, wherein the volume ratio of the methylene dichloride to the acetonitrile is (1.2-1.6):1. On the basis of the traditional process, the invention introduces a dispersion agent with diffusion effect, overcomes the defects of unstable structure and short preservation time of the AE-active ester, ensures that products are easy to preserve, changes a reaction solvent system and improves the yield up to over 91 percent. In addition, the solvent can be recycled so as to reduce the production cost and has higher implementation benefit and economic benefit.

Owner:YIYUAN XINQUAN CHEM

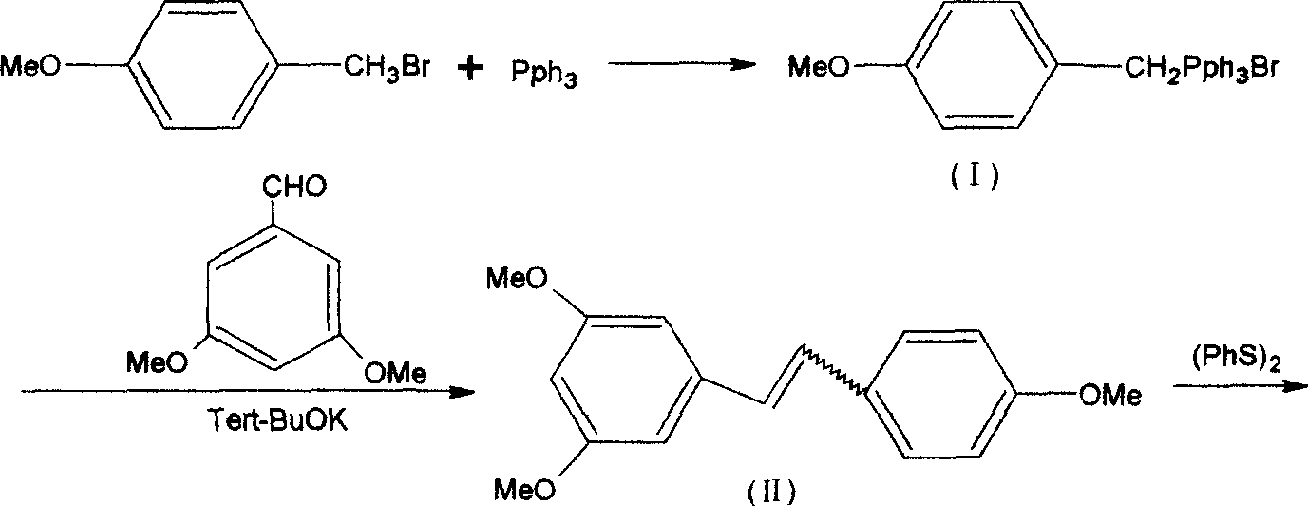

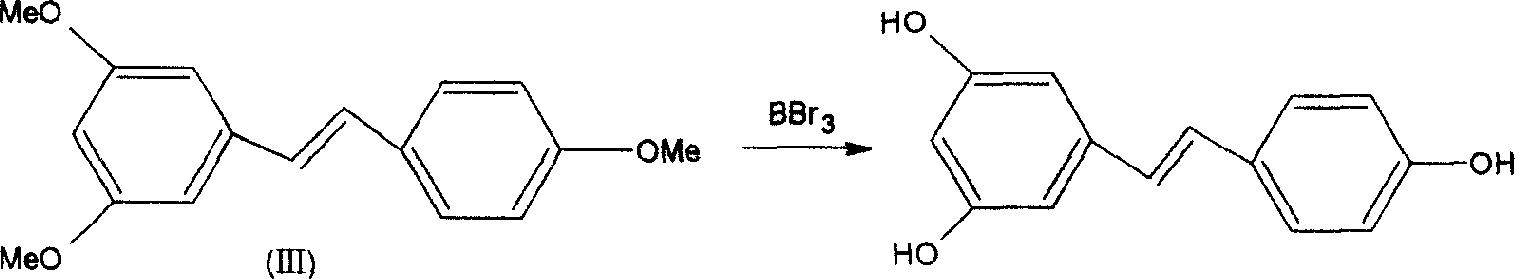

Method for synthesizing veratric alcohol

InactiveCN1907931AThe synthesis process is simpleThe synthesis process is easier to industrializeOrganic chemistryOrganic compound preparationDiethyl phosphateTriethylphosphite

The invention discloses a synthesis method for resveratrol, including (1) discharging hydrogen bromide gas to benzene solution of p-methoxy benzyl alcohol to obtain p-methoxy benzyl bromide, (2) carrying out reaction of p-benzyl bromide with triethyl phosphate to obtain diethyl p-methoxy benzyl phosphate, (3) carrying out reaction of diethyl p-methoxy benzyl phosphate with sodium amide and 3,5-dimethoxybenzaldehyde to obtain (E)-3, 4', 5-trimethoxystilbene, and (4) carrying out reaction of (E)-3, 4', 5- trimethoxystilbene with aluminum iodide to obtain the final product. The invention has the advantages of raw materials easy to get, lowered cost, mild reaction conditions, simplified operation, and enhanced yield.

Owner:JINAN UNIVERSITY

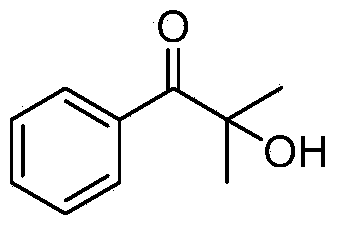

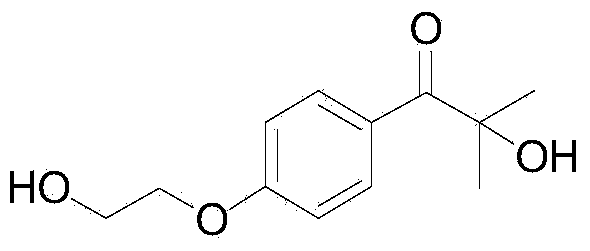

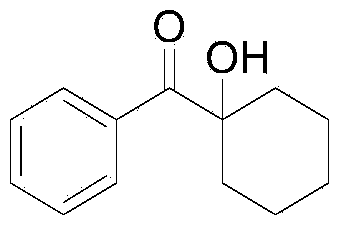

Synthetic method of alpha-hydroxyl carbonyl compound

InactiveCN103613478AWide range of substratesEmission reductionOrganic compound preparationCarboxylic acid esters preparationTriethylphosphiteCarbonate

The invention relates to a synthetic method of an alpha-hydroxyl carbonyl compound. The method is as below: mixing a carbonyl compound (I) with an organic phosphorus compound in an organic solvent; adding a catalyst cesium carbonate; and reacting under aerobic conditions to obtain the alpha-hydroxyl carbonyl compound (II). R1 is selected from the group consisting of hydrogen, alkyl, alkoxy, amino, aromatic base, substituted aromatic base and heterocyclic aromatic base; R2 is selected from alkyl, carbonyl, ester and phenyl; R3 is selected from alkyl, carbonyl, ester group and phenyl. Or, R1 combines with R2 to form naphthenic group or substituted cycloalkyl, benzo cycloalkyl base or substituted benzo cycloalkyl base, indole ring or substituted indole ring. Or, R2 combines with R3 to form the cycloalkyl or substituted cycloalkyl. The organic phosphorus compound is triphenylphosphine or triethyl phosphate. The organic solvent is dimethyl sulphoxide, N,N-dimethyl formamide, N,N-dimethyl acetamide or N-methyl pyrrolidone.

Owner:PEKING UNIV

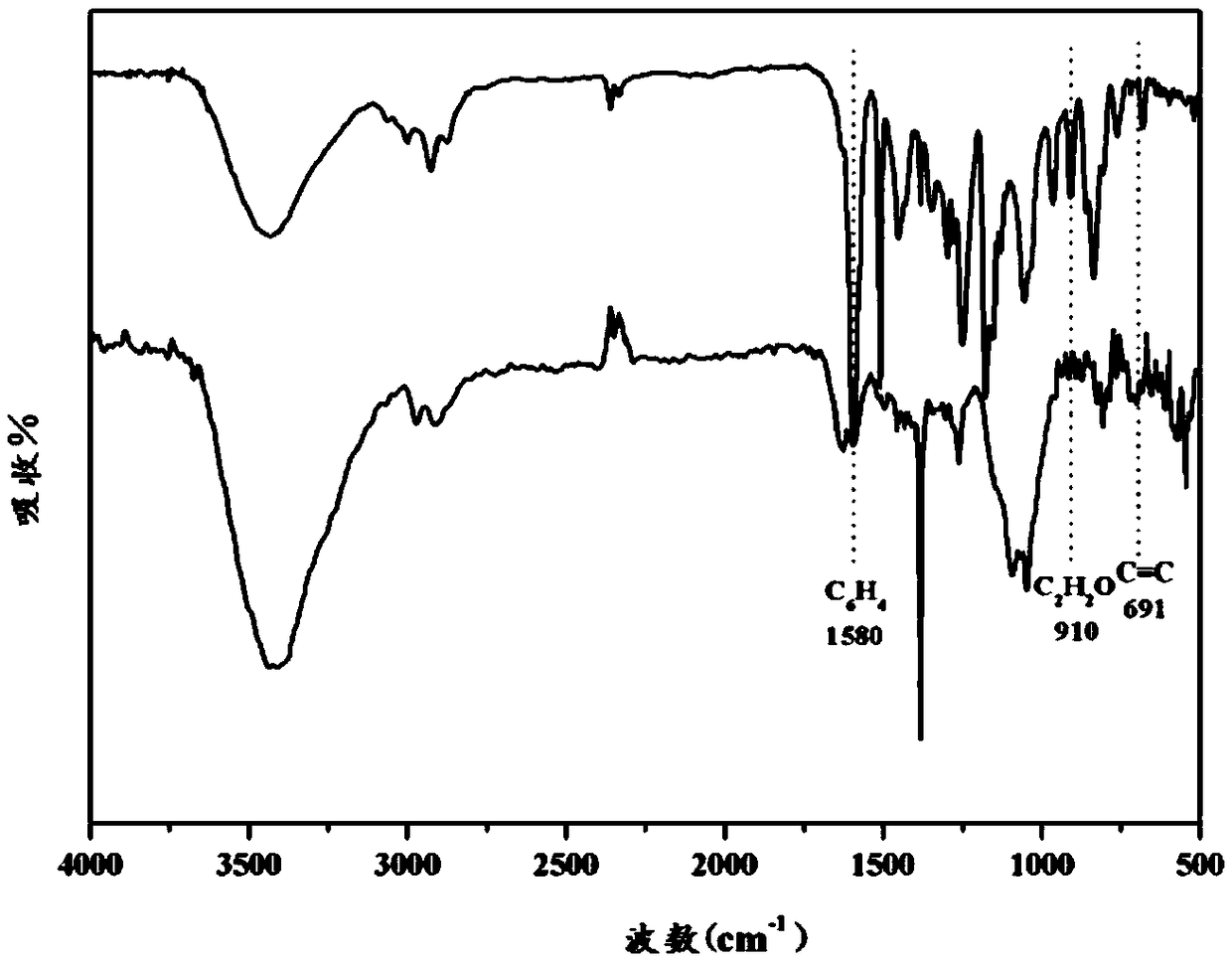

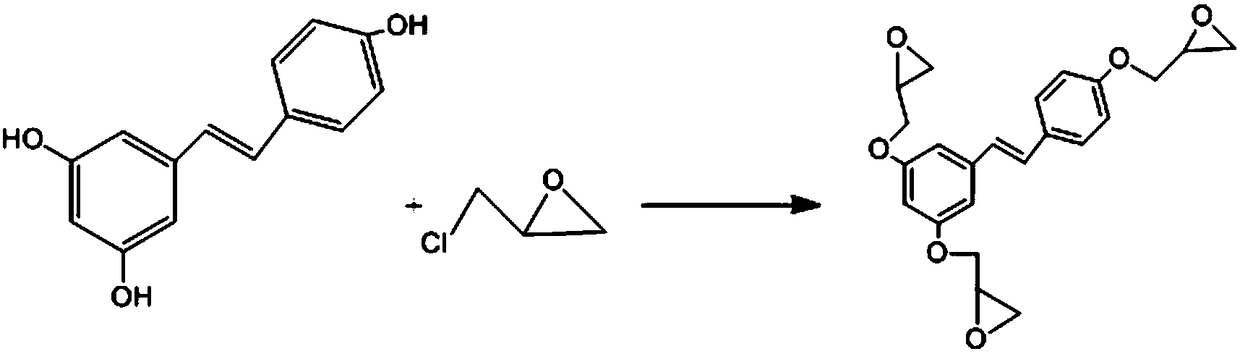

Resveratrol based flame retardance epoxy resin and preparation method thereof

The invention provides resveratrol based flame retardance epoxy resin. The fully bio-based epoxy resin with flame retardance is prepared by introducing triethyl phosphite and epoxy groups through hydroxyl on resveratrol to form a bio-based epoxy monomer capable of substituting bisphenol A (DGEBA (diglycidyl ether of bisphenol A)) generally used in the industry, synthesizing a higher activity bio-based curing agent, maleopimaric anhydride (MPA), and mixing the curing agent with the prepared epoxy monomer under certain conditions for curing. The epoxy resin is wide in raw material source, greenand environmentally friendly; a synthesis method is relatively simple; the flame retardance of the epoxy resin is good; a maximum limit oxygen index can reach 52%; and a maximum vertical burning gradecan reach V-0. The invention discloses a preparation method of the resin.

Owner:NANJING UNIV

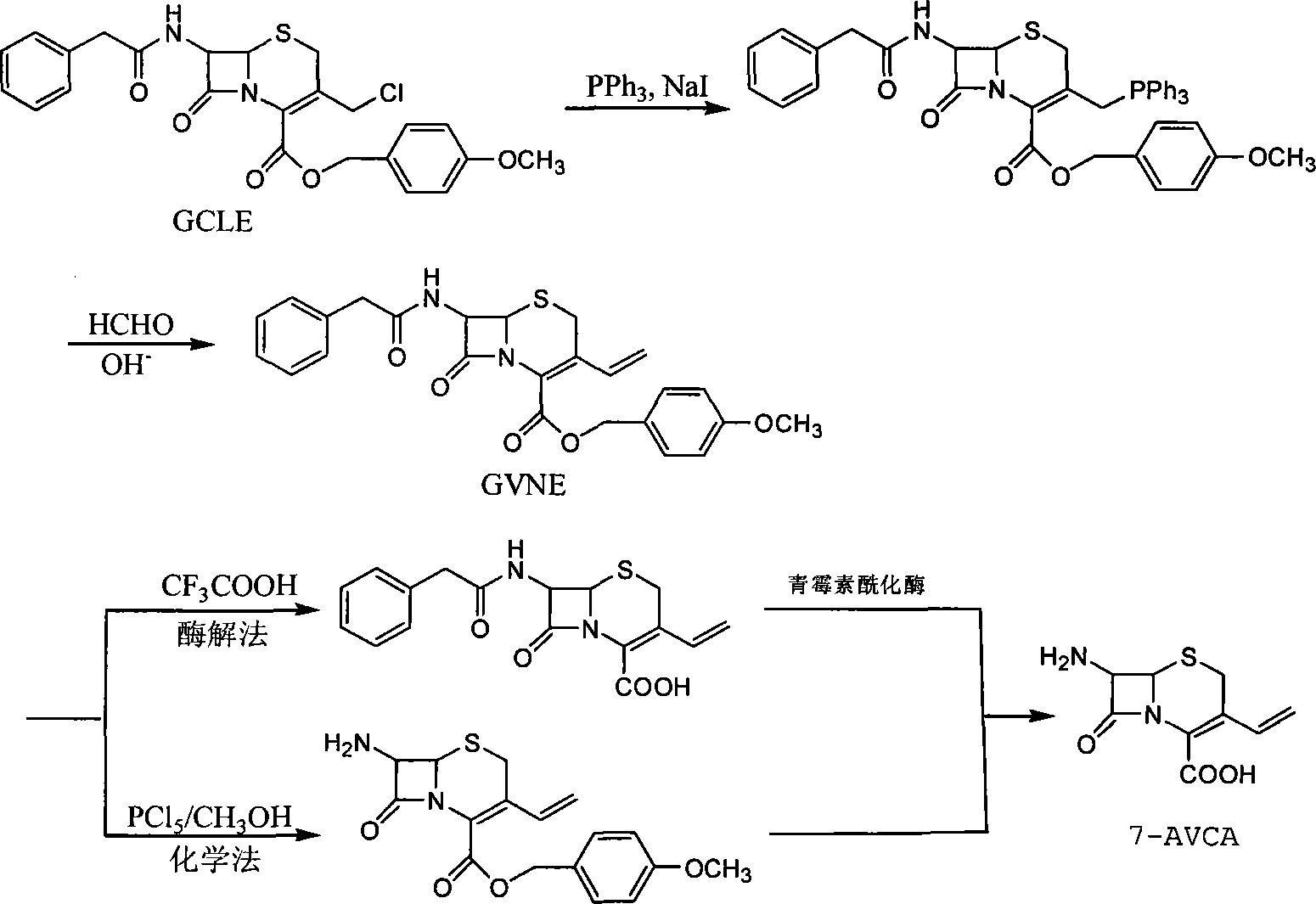

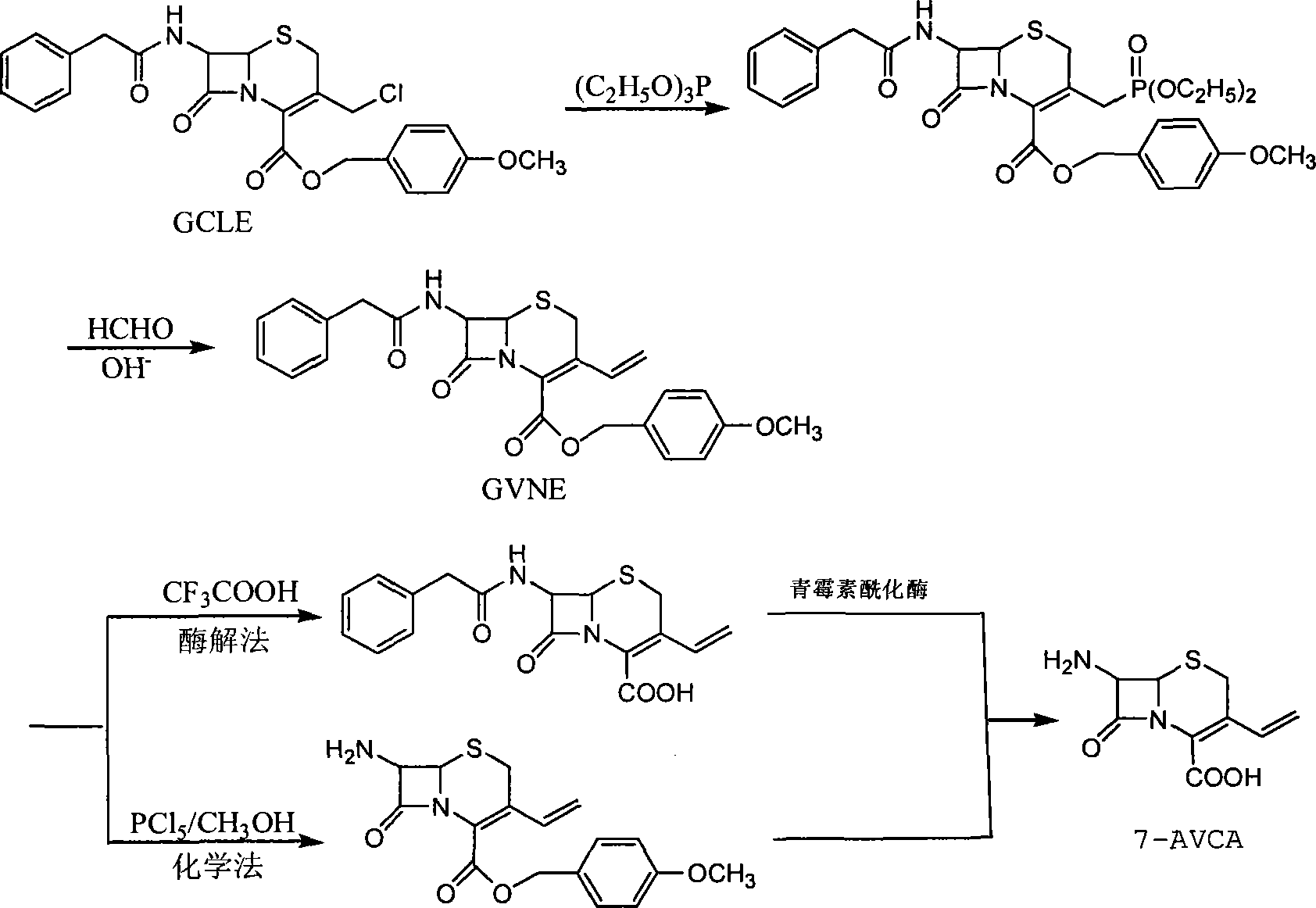

Method for preparing 7-amido-3-vinyl cethalosporanic acid

InactiveCN101182326ALow costSimple production methodOrganic chemistryWittig reactionTriethylphosphite

A method of preparing for 7-amido-3-ethylene cephalosporanic acid considers 7-phenylacetyl amino-3-chloromethyl cephalosporanic acid p-methoxybenzyl ester (GCLE) as a starting material and adopts the Wittig reaction. Ethylene is introduced on position 3 to obtain 7-phenylacetyl amino-3- ethylene-4- cephalosporanic acid p-methoxybenzyl ester, and a product GVNE is obtained. The GVNE is used to prepare for 7-amido-3-7 alkenyl cephalosporanic acid (7-AVCA). The present invention has the main technical characteristic that the triethyl phosphite with quite low price is used to replace triphenyl-phosphonium in the preparation of the GVNE to realize the purpose of introducing the ethylene on the position 3 of GCLE to prepare for the GVNE. The production method is simple; the cost of the main materials is low; the yield is high; the comprehensive benefit efficiency is high; the present invention is applicable to the large scale industrialized preparation of 7-AVCA.

Owner:SHANDONG JINCHENG PHARMA & CHEM

Inflaming retarding polyether polyol, combined polyether, polyurethane foam and preparation method of polyether polyol

InactiveCN104004175AImprove flame retardant performanceHigh oxygen indexGroup 5/15 element organic compoundsTriethylphosphiteDistillation

The invention discloses inflaming retarding polyether polyol, combined polyether, polyurethane foam and a preparation method of the polyether polyol. The preparation method of the polyether polyol includes the steps that first, under the inert atmosphere, diethanol amine, formalin and triethyl phosphite are mixed and reacted, reduced pressure distillation is conducted, and an initiator is obtained; second, the initiator, the polyol, cyanuric acid and a basic catalyst are mixed to obtain feed liquid B; or, the initiator, the polyol, the cyanuric acid and the basic catalyst are mixed to obtain the feed liquid B; or, the initiator, the polyol, the cyanuric acid, the basic catalyst and water are mixed to obtain the feed liquid B; third, the feed liquid B is mixed with epoxide, after the feed liquid B and the epoxide are reacted, feed liquid C is obtained, or dehydration is performed after reacting, and accordingly the feed liquid C is obtained; fourth, the feed liquid C is mixed with epoxide, and the polyether polyol can be obtained after the reaction. The polyether polyol is halogen-free nitrogen and phosphorus collaboration inflaming retarding polyether polyol, the obtained polyurethane foam has good flame retardation, and the preparation method is easy to operate, high in yield and suitable for large-scale industrial production.

Owner:SHANGHAI DONGDA POLYURETHANE

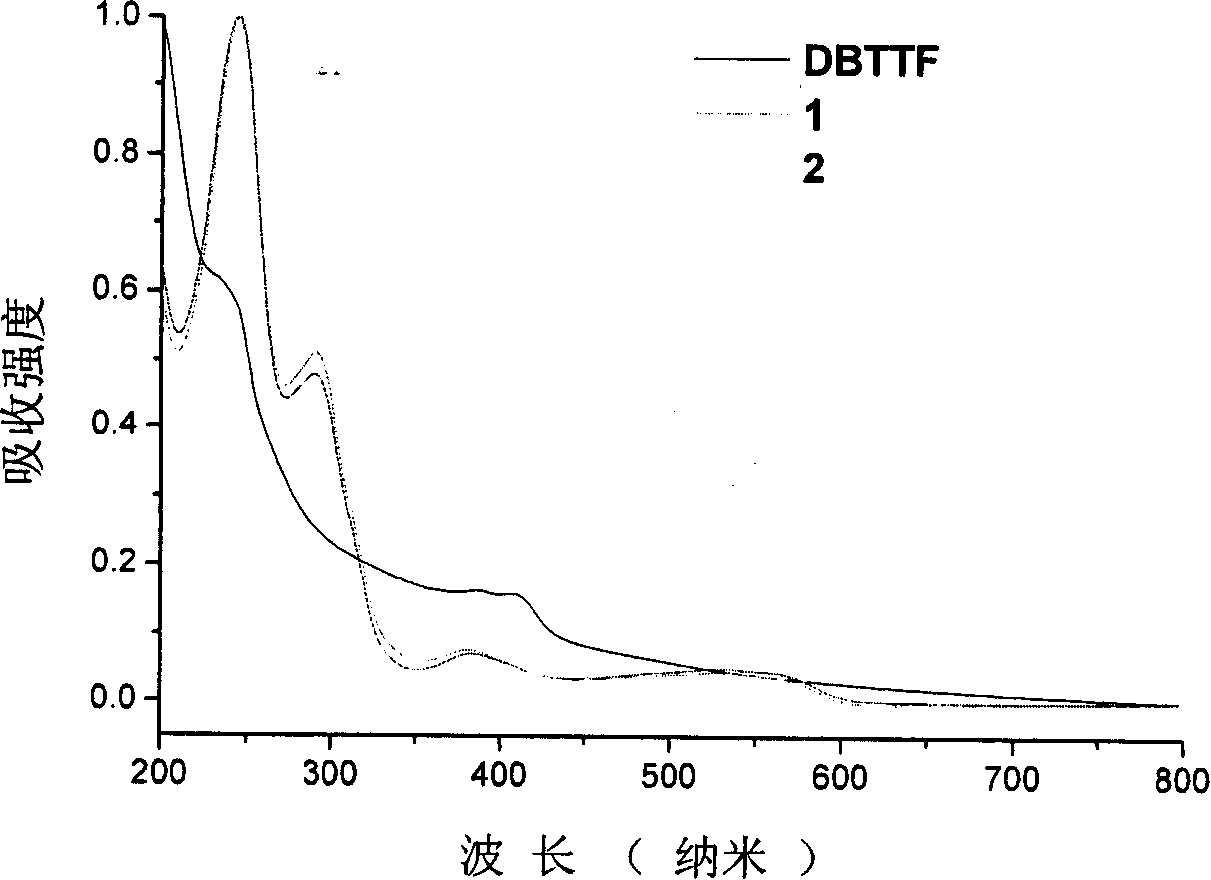

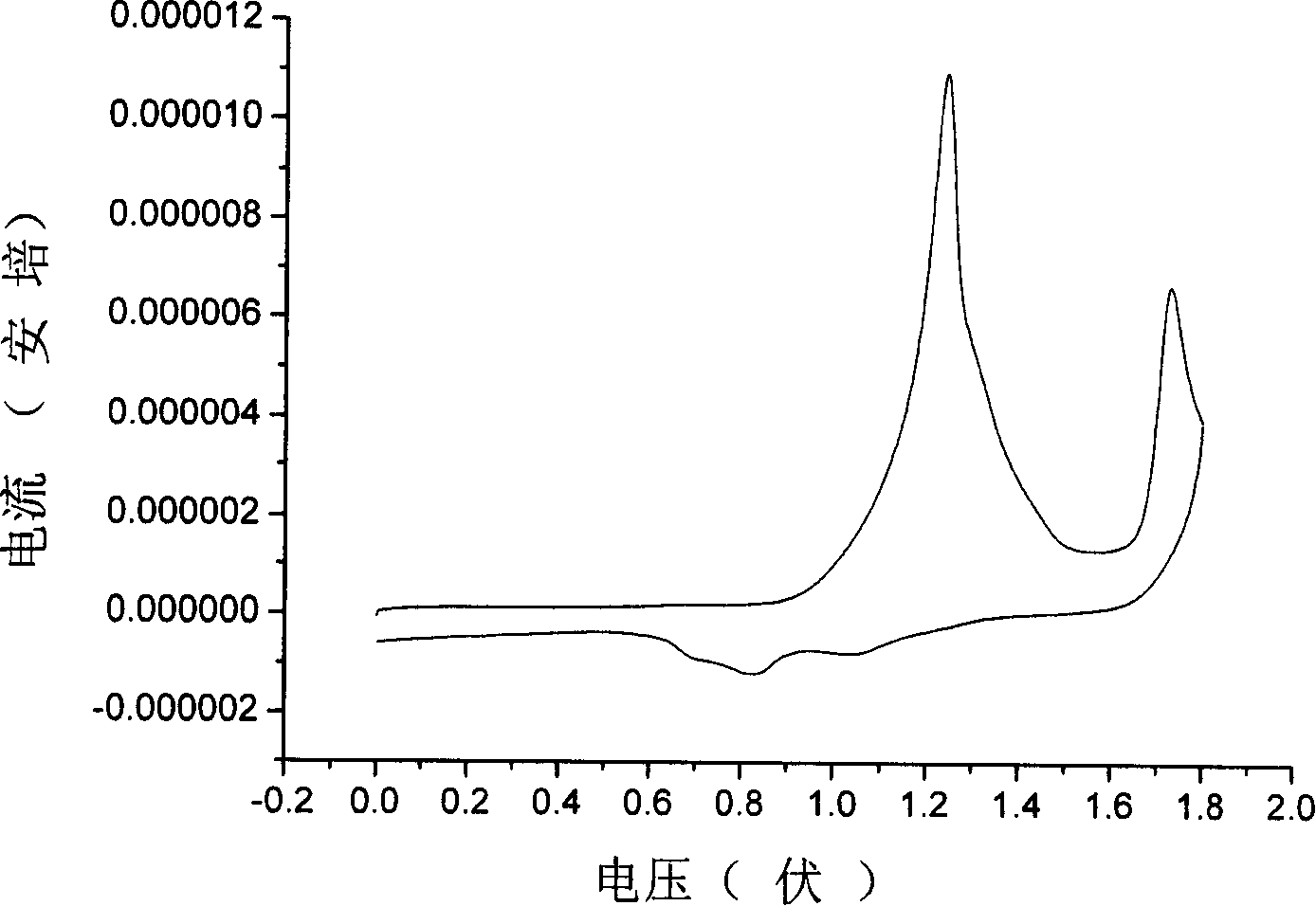

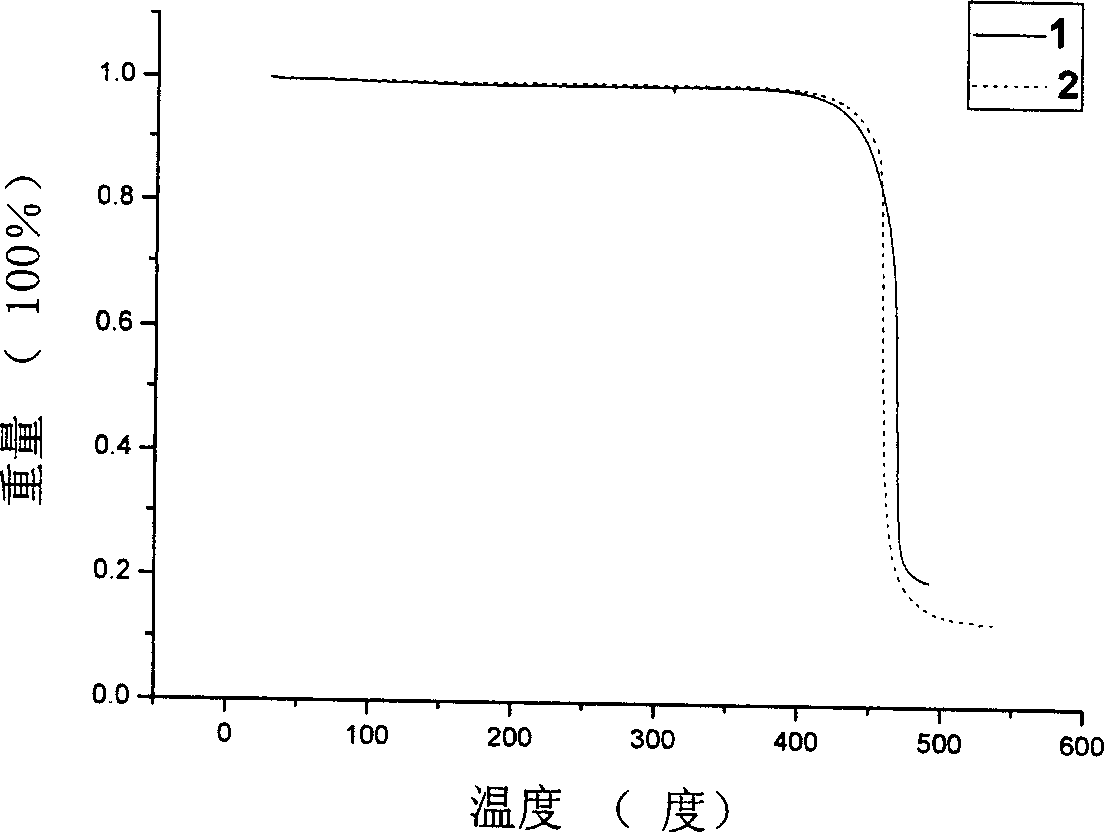

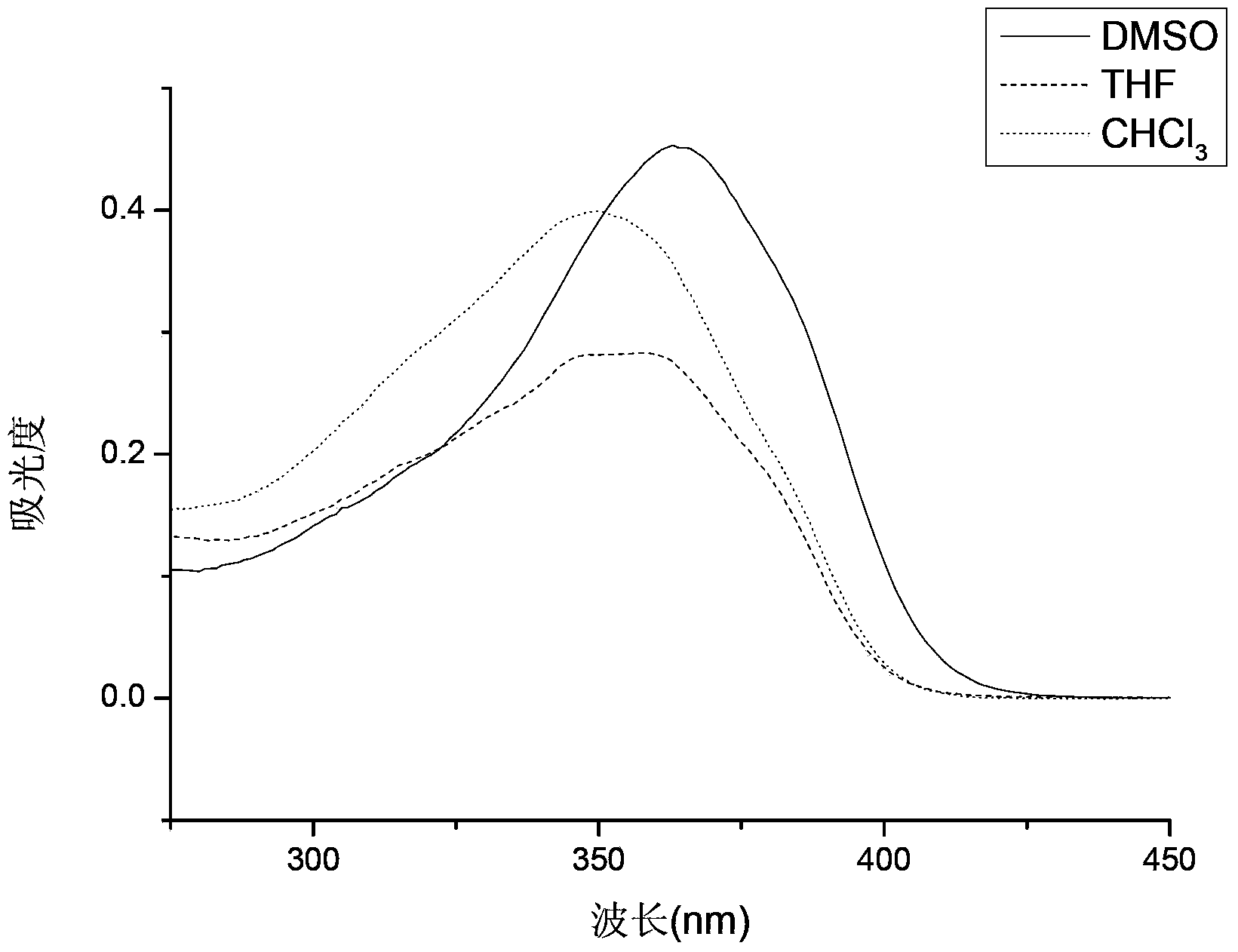

Dibenzo tetrathiafulvalene tetracarbonyl imide derivative and preparation method and uses thereof

InactiveCN101161656AImprove mobilityGood conjugationOrganic chemistryPropanoic acidTriethylphosphite

A derivative of dibenzo-tetrathiafulvalene-tetrahydroxy-succinimide is provided, which has the structure shown by the right formula, in which R represents an alkyl. The preparation method includes the following procedures that: A) a mixture of dichlorophthalic anhydride and amine with the molecular ratio of 1: 1.5-3 undergoes circumfluence in propionic acid under 140 DEG C to 160 DEG C for 2-4 hours, B) the products obtained in procedure A is mixed with benzyl mercaptan with the molecular ratio of 1:2-3 and then undergoes calefaction in dimethylacetamide under the condition with excessive dosage of K2CO3 under 60 DEG C to 80 DEG C and, C) the product obtained in procedure B is kept in dry toluene with excessive dosage of AlCl3 to undergo debenzylation, and then reacts with carbonyldiimidazole under 70 DEG C to 90 DEG C for 2-5 hours, wherein the molecular ratio between 4,5-[(diphenylmethyl)thio substituted]- phthalimide and the carbonyldiimidazole is 1:1-3 and, D) the product obtained in procedure C undergoes circumfluence in a mixture of toluene / triethyl phosphate, the molecular ratio of which is 2-3 / 1 to carry out the auto-coupling reaction for 2-5 hours, the product of which is cooled down and filtrated to obtain the target product.

Owner:INST OF CHEM CHINESE ACAD OF SCI

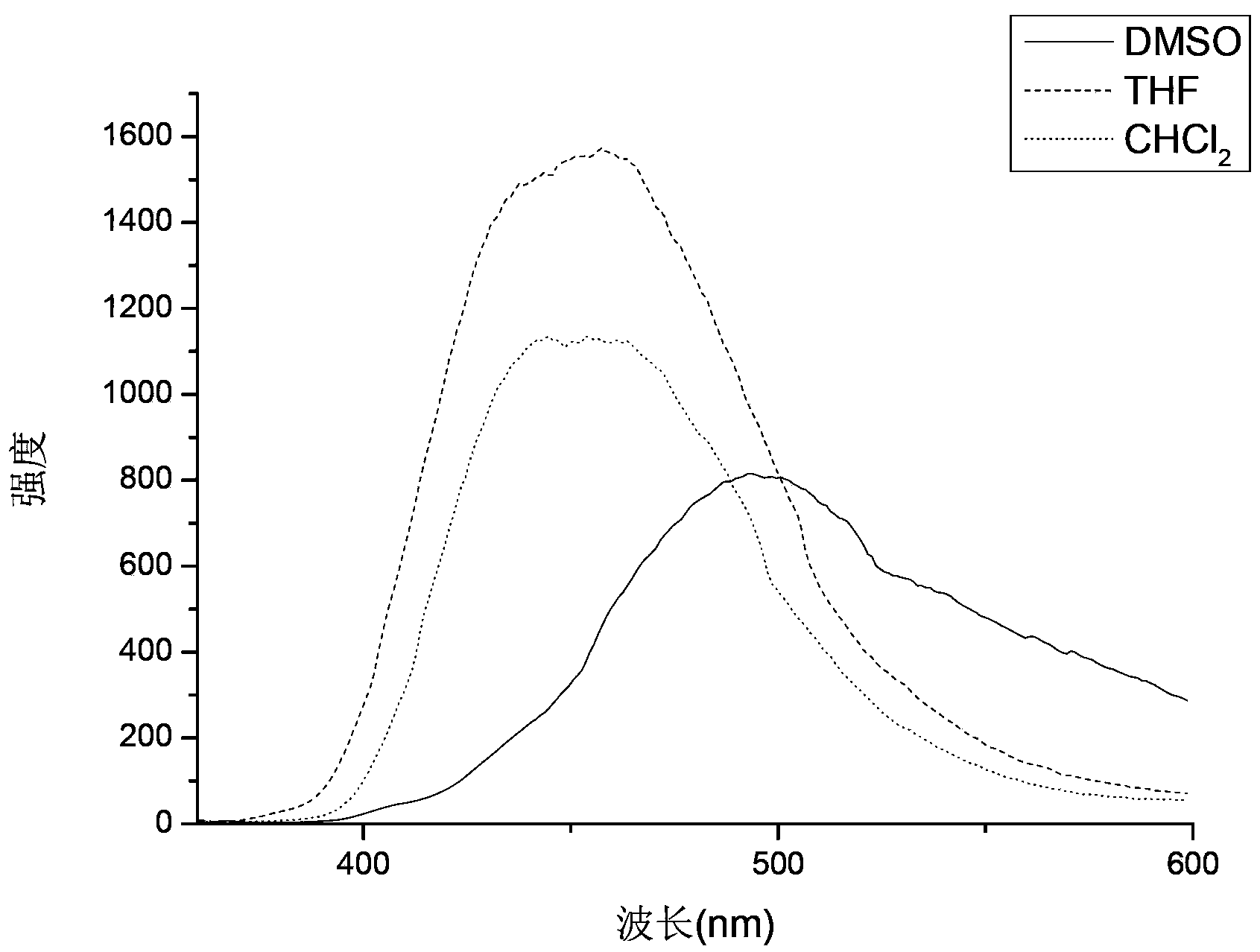

Stilbene fluorescent whitening agent, and preparation method and application thereof

InactiveCN103483328AHigh fluorescence intensityHas antibacterial propertiesStyryl dyesOrganic chemistryTriethylphosphiteWhitening Agents

The invention discloses a stilbene fluorescent whitening agent, and a preparation method and application thereof. The preparation method of the stilbene fluorescent whitening agent comprises the steps of esterification reaction of triethyl phosphite and Wittig-Horner reaction. The synthesis method has the advantages of mild reaction conditions and high yield, and is easy for separation and suitable for industrialization. The fluorescent whitening agent is a nonionic whitening agent using stilbene as a lightwave converter, has the properties of an optical whitening agent and antimicrobial and bactericidal actions, is green and environment-friendly, and has important application value for developing novel environment-friendly high-efficiency fluorescent whitening agents.

Owner:SOUTH CHINA UNIV OF TECH

Method for recovering useful constituents in mixed waste solvent during glufosinate ammonium production process

InactiveCN103880786AReduce one evaporation processLow costGroup 5/15 element organic compoundsDistillation purification/separationGlufosinate-ammoniumDiethyl phosphate

The invention discloses a method for recovering useful constituents such as tetrahydrofuran, methyl diethyl phosphate, triethyl phosphate and trimethylbenzene in a mixed waste solvent during a process of producing glufosinate ammonium by an integrated rectification process. The method comprises the following steps: using an integrated rectification process of discharging and rectifying in a single-tower side line and then connecting a single tower to rectify, directly extracting tetrahydrofuran from the top of the rectification tower in the side line and obtaining trimethylbenzene from the bottom of the tower; extracting the mixed solution of methyl diethyl phosphate and triethyl phosphate from the side line simultaneously, conveying the mixed solution to the rectification tower and carrying out single-tower separation, thereby obtaining methyl diethyl phosphate from the top of the tower and obtaining triethyl phosphate from the bottom of the tower. According to the method disclosed by the invention, the useful constituents in the mixed waste solvent during the glufosinate ammonium production process are recovered by the integrated rectification process, the total recovery rate of the mixed solvent exceeds 98%, and the quality achieves reuse standards. Compared with the conventional three-tower rectification method, the equipment cost and energy consumption of the method disclosed by the invention are obviously lowered.

Owner:江苏威格瑞斯化工有限公司

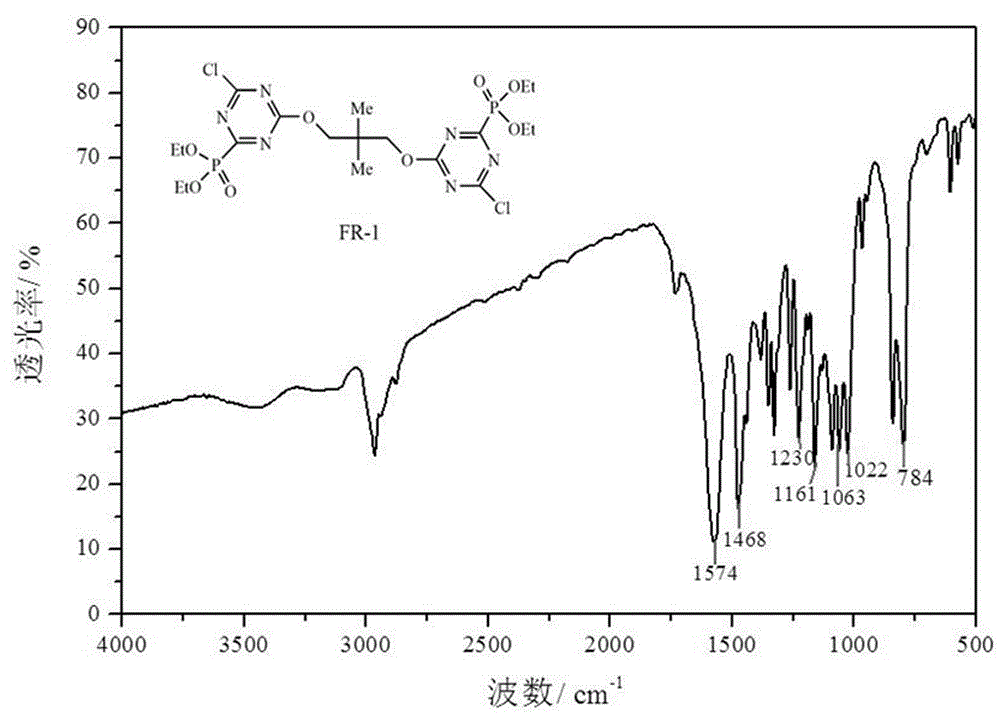

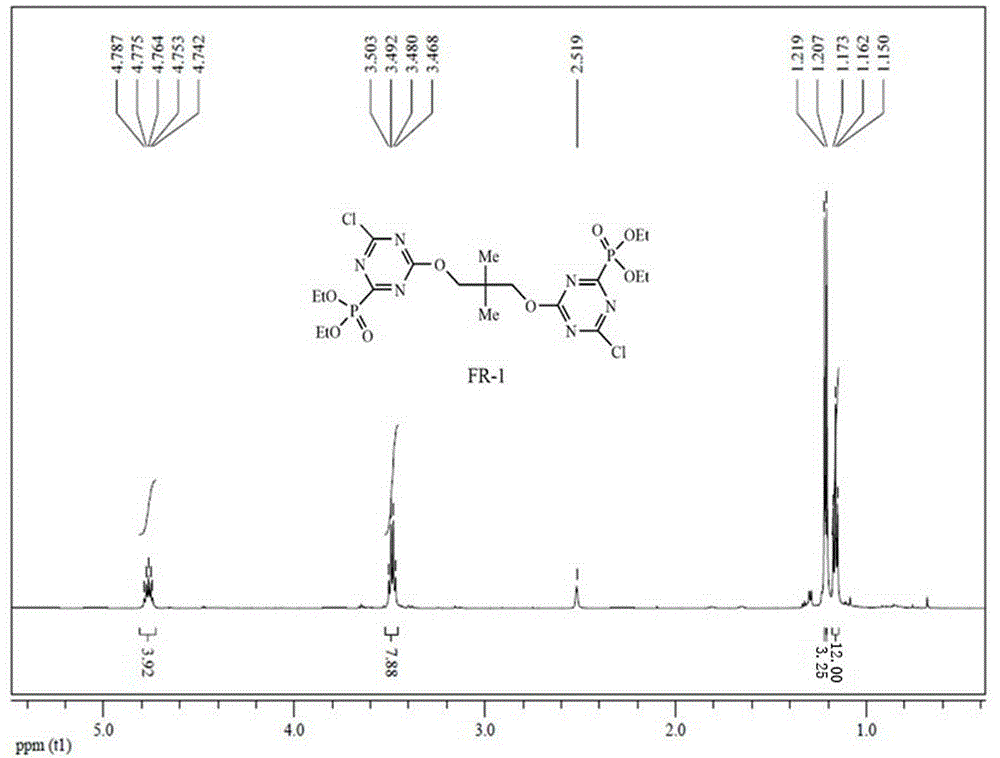

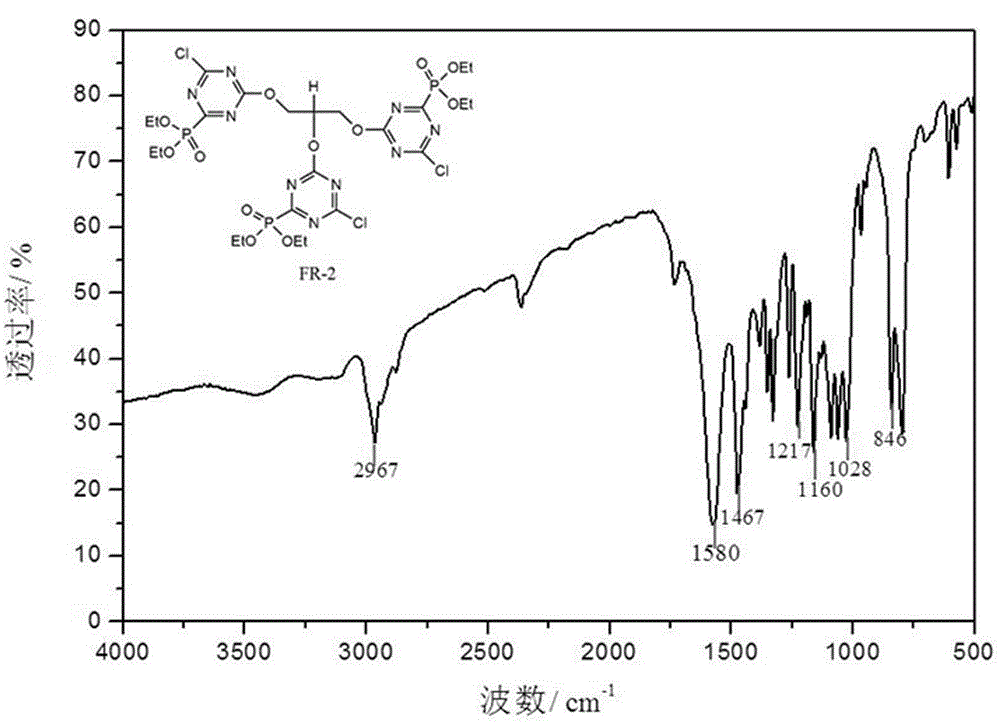

Compound with a plurality of active groups and preparation method of compound

InactiveCN103980314AImprove flame retardant performanceImprove thermal stabilityGroup 5/15 element organic compoundsElectrophilic additionPhosphorous acid

The invention relates to a reaction type phosphorus-nitrogen flame retardant and in particular to a compound with a plurality of active groups and a preparation method of the compound. The preparation method comprises the following steps: (1) weighing cyanuric chloride, dissolving cyanuric chloride into a first solvent, stirring till being completely dissolved, slowly heating to be 60 DEG C, preserving heat while continuously stirring to uniformly disperse reactant; and (2) in the presence of nitrogen, adding a phosphite ester solution which is dissolved in the first solvent, reacting for 4-6 hours, and keeping stirring in the reaction process. Compared with the prior art, the compound with the plurality of active groups has the beneficial effects that the compound is prepared from raw materials, namely, cyanuric chloride, phosphite ester compounds (trimethyl phosphate or triethyl phosphate) and polyhydric alcohol compounds (neopentyl glycol, glycerol or pentaerythritol) with quaternary carbon (or secondary carbon) atoms, through Michaelis-Arbuzov electrophilic addition reaction and nucleophilic substitution reaction.

Owner:ZHONGBEI UNIV

Apatite super-fine fiber material and its prepn. method

InactiveCN1751745ALarge specific surface areaPromote degradationInorganic material artificial filamentsPhosphorus compoundsTriethylphosphiteApatite

A superfine apatite fiber material used for repairing bone tissue is prepared through proportionally mixing triethyl phosphite with distilled water, hydrolyzing while stirring, adding the aqueous solution of calcium nitrate, stirring, ageing to obtain the gel solution, mixing it with alcohol, adding polyvinyl pyrrolidone to obtain the solution for electrospinning, electrospinning, drying and calcining. Its advantages are nano-class fineness, large specific surface area, high biodegradability and high affinity to cells.

Owner:TIANJIN UNIV

Hydrotalcite-tin maleate composite environmental protection stabilizer for PVC, and preparation method thereof

InactiveCN105295250APlay a role in thermal stabilityImprove heat resistancePolyesterPhosphorous acid

The present invention provides a hydrotalcite-tin maleate composite environmental protection stabilizer for PVC, wherein the hydrotalcite-tin maleate composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of tin maleate, 6-9 parts of lanthanum salicylate, 1-3 parts of triethyl phosphite, 3-6 parts of barium stearate, 2-4 parts of epoxidized soybean oil, 10-13 parts of poly(1,2-propylene glycol adipate), 2-3 parts of beta-diketone, 5-6 parts of isomaltitol, 2-3 parts of 2,4,6-tris(2'n-butoxyphenyl)-1,3,5-triazine, 1-3 parts of oxidized polyethylene wax, and 10-12 parts of celestine powder. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

Production method of triethyl phosphite

InactiveCN1724546ANo pollution in the processGroup 5/15 element organic compoundsAlcoholTriethylphosphite

The invention provides a process for preparing triethyl phosphate which comprises, using phsophorus trichloride and absolute alcohol as raw material, synthesizing in benzene solvents, then segregating the expected outcome yield, the synthesis is carried out at the presence of triethylamine. The invention has the advantages of increased yield and improved product purity.

Owner:罗方明 +1

Method for preparing endotoxin adsorbing agent

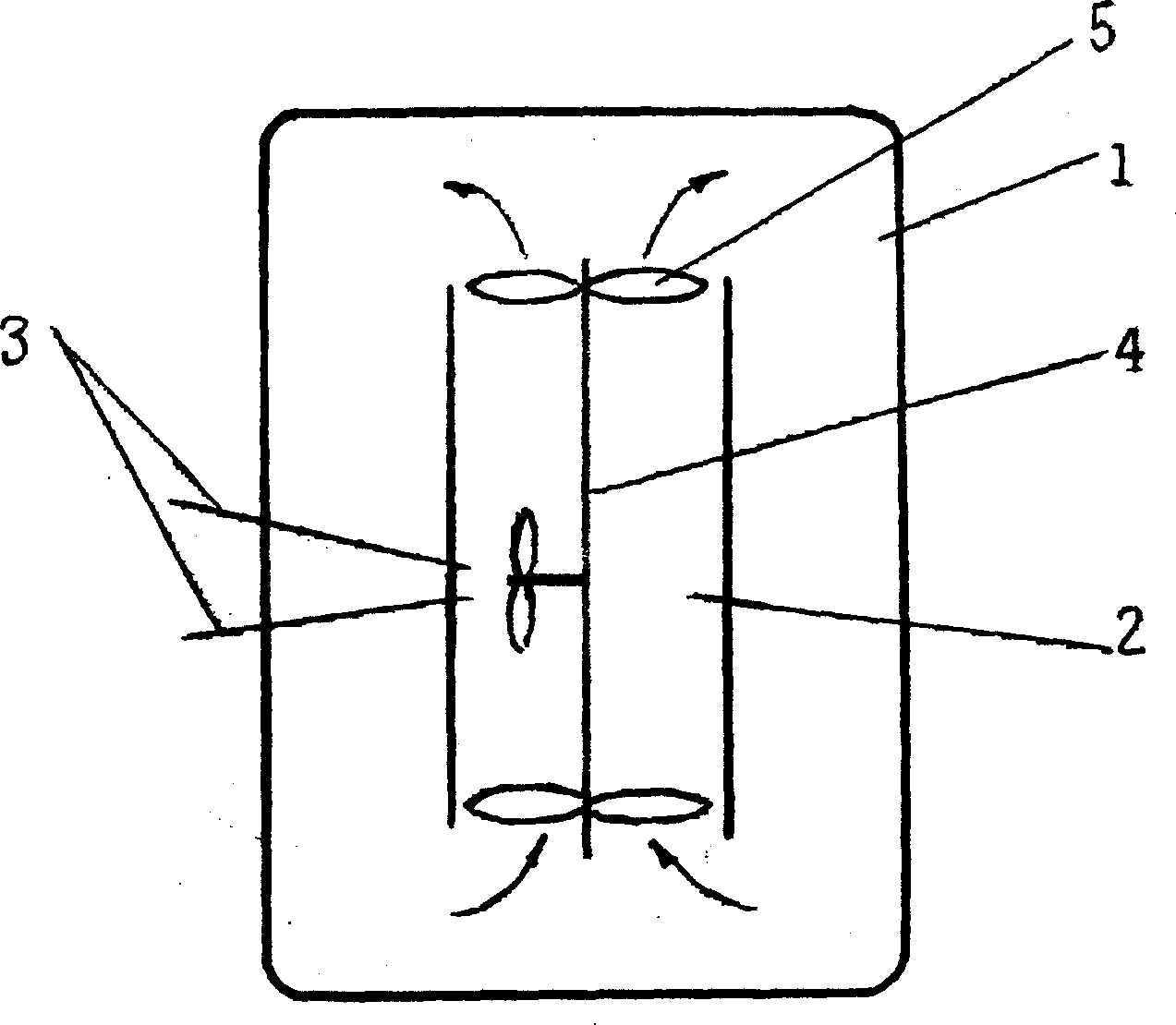

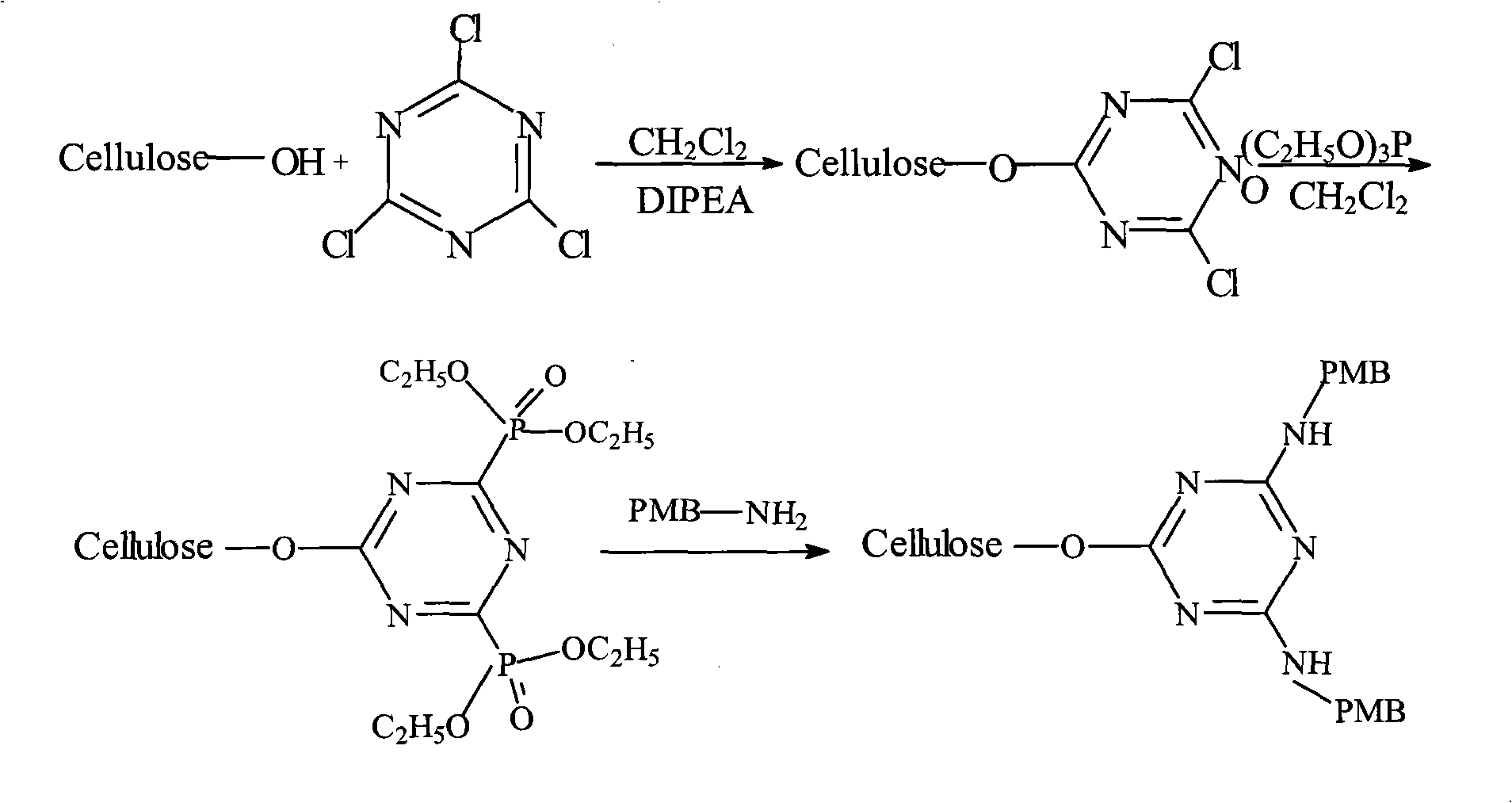

The invention relates to a preparation method of an endotoxin adsorbent. The spherical porous cellulose is taken as a carrier; the spherical porous cellulose is activated by triazine trichloride, coupled with triethyl phosphate, then immobilized polymyxin B, thus the endotoxin adsorbent is obtained. The endotoxin adsorbent obtained by the method has stable performance and good adsorption property.

Owner:JAFRON BIOMEDICAL

Production method of ethyl-phosphonic acid diethyl ester

InactiveCN101624402AImprove responseHigh transposition efficiencyGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsTriethylphosphiteDistillation

The invention relates to a production method of ethyl-phosphonic acid diethyl ester, which belongs to the technical field of chemical production. Triethyl phosphate is taken as the main material, alkylogen is taken as catalyst, and the ethyl-phosphonic acid diethyl ester is prepared through the processes of charging batch into a reaction kettle, heating up, heat preserving, sampling, cooling and distilling and the like. The equipment for the production of the ethyl-phosphonic acid diethyl ester is simple, and reaction and distillation can be accomplished in a kettle; the product yield is high, no sewage is discharged, and the impact on the environment is small. The method solves the problems that the prior production operating procedure of the ethyl-phosphonic acid diethyl ester is complex, the production cost is high, the environmental pollution is severe and the product yield is low. The invention adopts general chemical equipment, therefore the purchase and maintenance are very convenient. The production cycle is short, and the production of a batch can be accomplished in about 8 hours; the reaction is simple, the triethyl phosphate can be transferred into the final product in one step under the catalysis of the alkylogen, and the transfer efficiency can reach 95 percent.

Owner:湖北三才堂化工科技有限公司

Preparation method of triethyl phosphate

InactiveCN103374028AWon't decomposeNothing producedGroup 5/15 element organic compoundsTriethylphosphiteAlcohol

The invention relates to a preparation method of triethyl phosphate. The method specifically comprises the following steps of: first, with ammonia gas as an acid-binding agent and methyl red as an indicator, reacting phosphorus trichloride with absolute ethyl alcohol to generate triethyl phosphite; filtering out the byproduct ammonium chloride and then, introducing a certain amount of oxygen for oxidization; and finally, distilling and purifying at reduced pressure to obtain the target product triethyl phosphate. The method provided by the invention has the advantages that the yield is high, the unit consumption is low, and the byproduct ammonium chloride can be used as a fertilizer; and the method is simple in production process, the raw materials are easily available and the production safety is high.

Owner:JIANGSU DAMING TECH

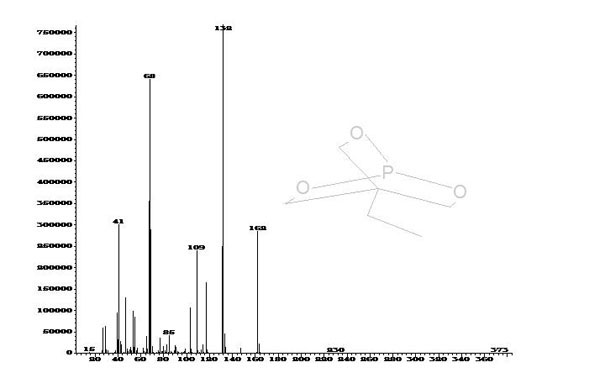

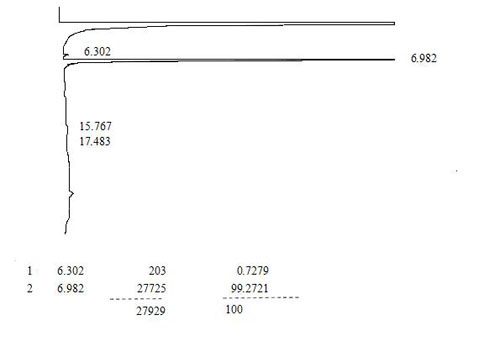

Method for catalytically synthesizing dicycloethyl phosphite ester by using ionic liquid

InactiveCN101792466AShort reaction timeGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsTriethylphosphitePhosphite ester

The invention discloses a method for catalytically synthesizing dicycloethyl phosphite ester by using ionic liquid, which relates to a method for synthesizing dicycloethyl phosphite ester and solves the problems of long reaction time and low yield during preparing the dicycloethyl phosphite ester by adopting triethylamine as a catalyst. The method comprises the following steps: mixing trimethylolpropane, triethyl phosphite and ionic liquid [Bmim] BF4, then thermostatically reacting the mixture for 1.5 to 5.5 hours under the protection of N2 at the temperature of between 78.4 and 100 DEG C, and distilling the reaction product for 0.5 to 1 hour under reduced pressure to obtain the dicycloethyl phosphite ester. The method for preparing the dicycloethyl phosphite ester has short reaction time, the yield can reach 98 percent, and the purity is 99.27 percent.

Owner:NORTHEAST FORESTRY UNIVERSITY

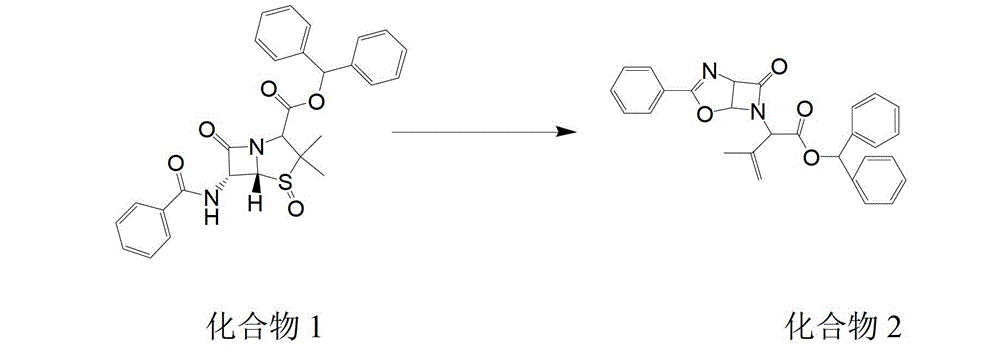

Latamoxef Sodium midbody synthetic method

The invention discloses a Latamoxef Sodium midbody synthetic method. The method comprises the following steps: a new desulfurizer-triethyl phosphite is adopted for dehydration reaction in toluene and then is subjected to concentrated crystallization to achieve the purpose of synthesizing [1R-[1a, 5a]]-3-methyl-2-(7-oxo-3-phenyl-4-oxa-2, 6-diazabicyclo [3.2.0] heptane-2-alkene-6-based)-3-butenoic acid methyl ester diphenyl. As the triethyl phosphite is selected as the desulfurizer, the technological process is simplified, the operation is simple and the equipment utilization ratio is high.

Owner:陕西思尔生物科技有限公司

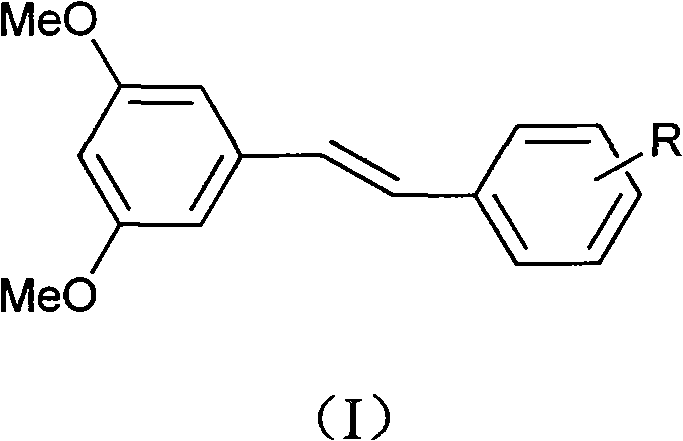

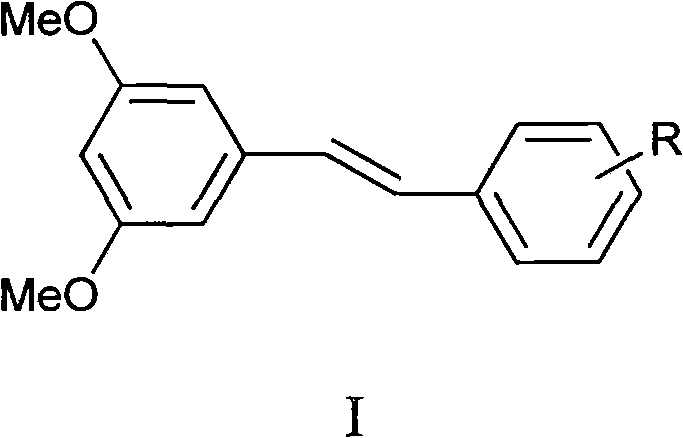

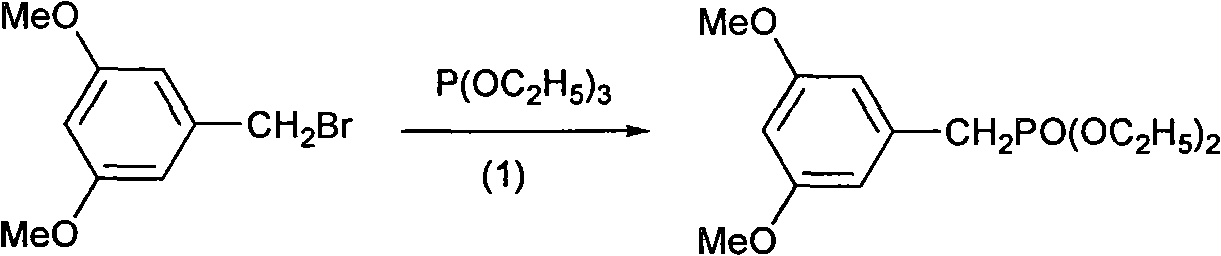

3,5-dimethoxystilbene derivative, preparation method and application thereof in anti-drug resistant bacteria

InactiveCN102001949ASimple reaction conditionsEasy to operateAntibacterial agentsOrganic compound preparationResistant bacteriaTriethylphosphite

The invention discloses a 3,5-dimethoxystilbene derivative, a preparation method and an application thereof, in particular relating to the synthesis of the 3,5-dimethoxystilbene derivative as shown in structural formula (1) and anti-drug resistant bacterial activity thereof. The preparation method comprises the following steps: firstly mixing 3,5-dimethoxybenzyl bromide with triethyl phosphate to obtain 3,5-dimethoxybenzyl phosphonate; and then carrying out Wittig-Honner reaction to obtain the 3,5-dimethoxystilbene derivative. The preparation method has the advantages of high yield, simple and convenient operation, low cost, good industrialization prospect and the like. A bacterial inhibiting test result shows that the synthesized 3,5-dimethoxystilbene derivative has obvious inhibition activity on drug resistant bacteria and is of great significance on research and development of a novel anti-drug resistant bacterial drug.

Owner:SOUTH CHINA UNIV OF TECH

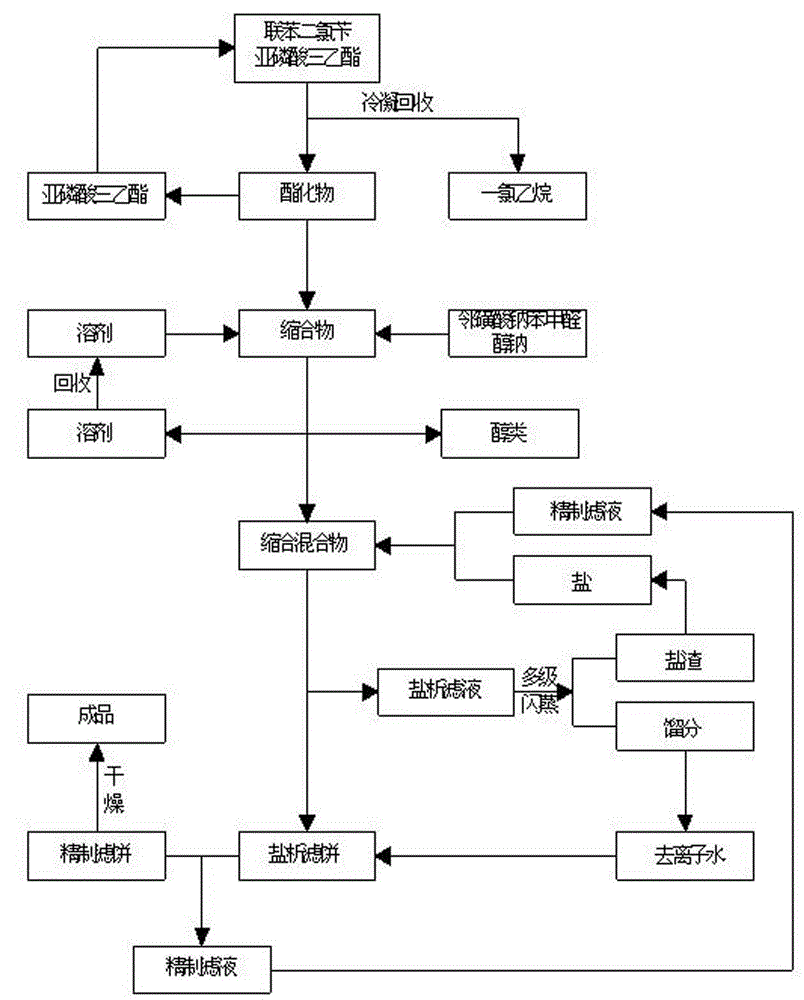

Environment-friendly preparation method of toluylene-based biphenyl type fluorescent brightener

The invention discloses an environment-friendly preparation method of toluylene-based biphenyl type fluorescent brightener, which belongs to the field of a preparation technique of high-grade fluorescent brightener used for washing powder, detergent, cosmetic and the like, and solves the problems of great pollution to the environment and difficulty in disposal in the prior art. The method comprises the steps of: heating and refluxing 4, 4'-bis(chloromethyl)-1, 1'-biphenyl and triethyl phosphite under the condition of N2, distilling to remove a part of triethyl phosphite and side products through vacuum distillation, condensing, and crushing to obtain an esterified product; reacting the esterified product and benzaldehyde-2-sulfonic acid sodium for 2-15 hours in a strong polar aprotic organic solvent and under the action of organic strong base to obtain a condensate; distilling the condensate, recycling the solvent, and recycling tail gases to obtain a condensed mixture; adding water and salt into the condensed mixture, cooling, performing pressure-filtering to obtain a salting-out filter cake, washing, and refining; and drying the refined cake to obtain the toluylene-based biphenyl type fluorescent brightener. According to the method provided by the invention, the recycling is convenient and the brightener can be used circularly; the problem of environmental pollution is solved and energy is saving and the environment is protected; and the used raw materials is convenient in source and low in cost.

Owner:山西青山化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com