Production method of triethyl phosphite

A technology of triethyl phosphite and production method, which is applied in chemical instruments and methods, compounds of elements of Group 5/15 of the periodic table, organic chemistry, etc., and can solve problems such as ammonia pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

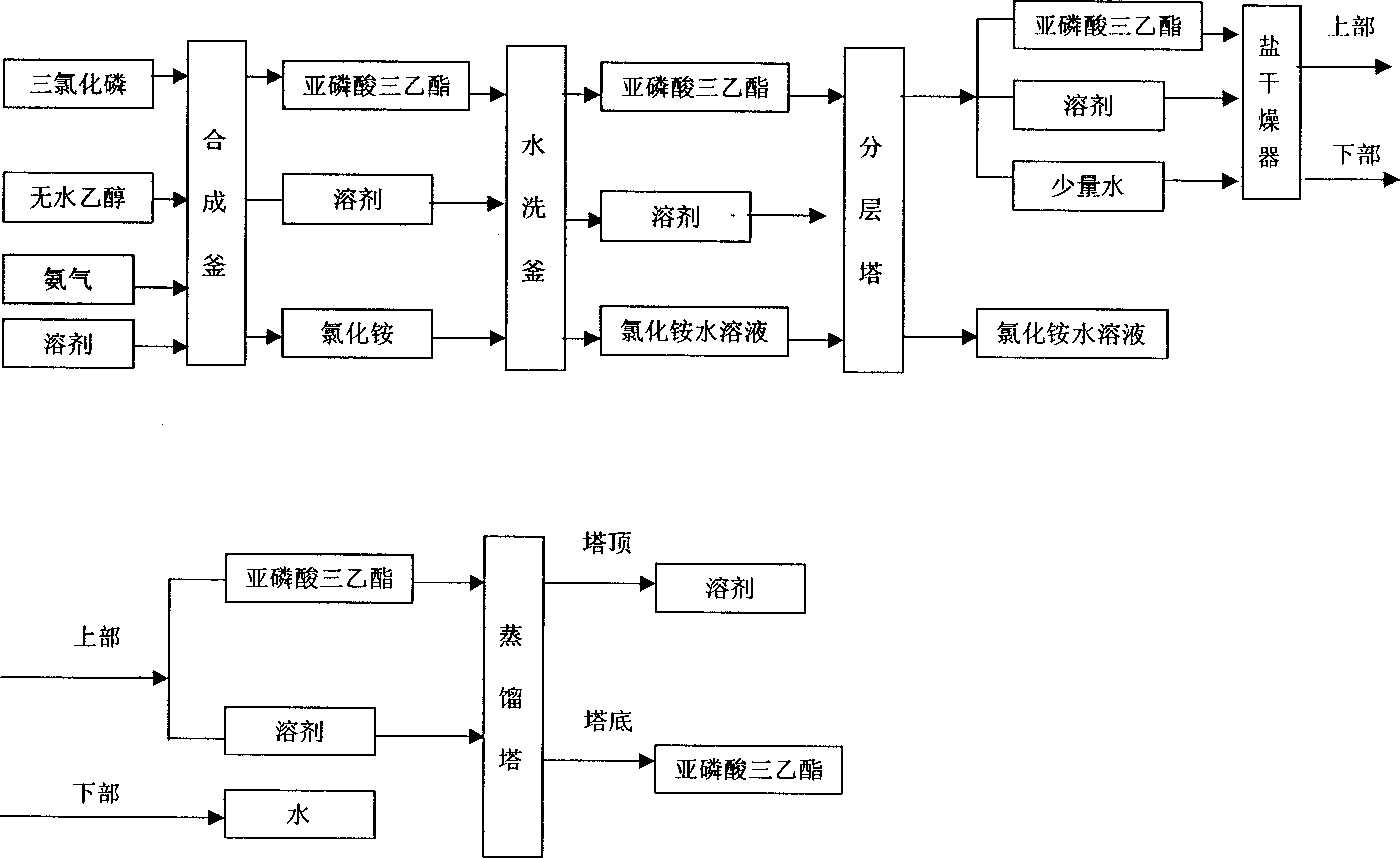

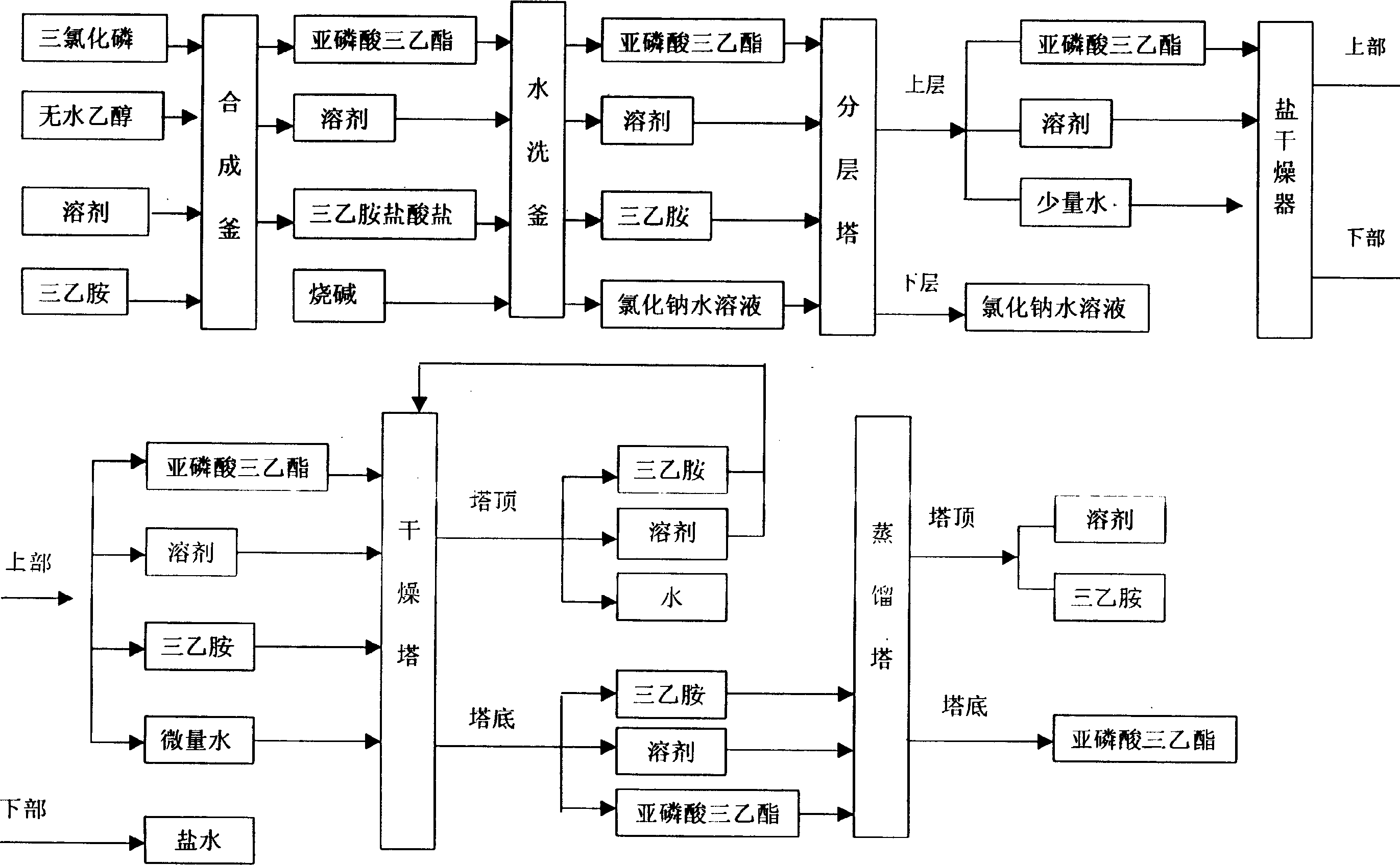

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with embodiment.

[0025] The raw materials phosphorus trichloride and dehydrated alcohol used for the metering synthesis, the solvent toluene and the acid-binding agent triethylamine. In order to prevent the insufficient protection of triethyl phosphite caused by the lack of triethylamine decomposed in the early stage of water washing, excessive triethylamine should be used. In consideration of avoiding unnecessary energy consumption in the production process, the excess of triethylamine is preferably controlled at no less than 0.2% of the reaction amount.

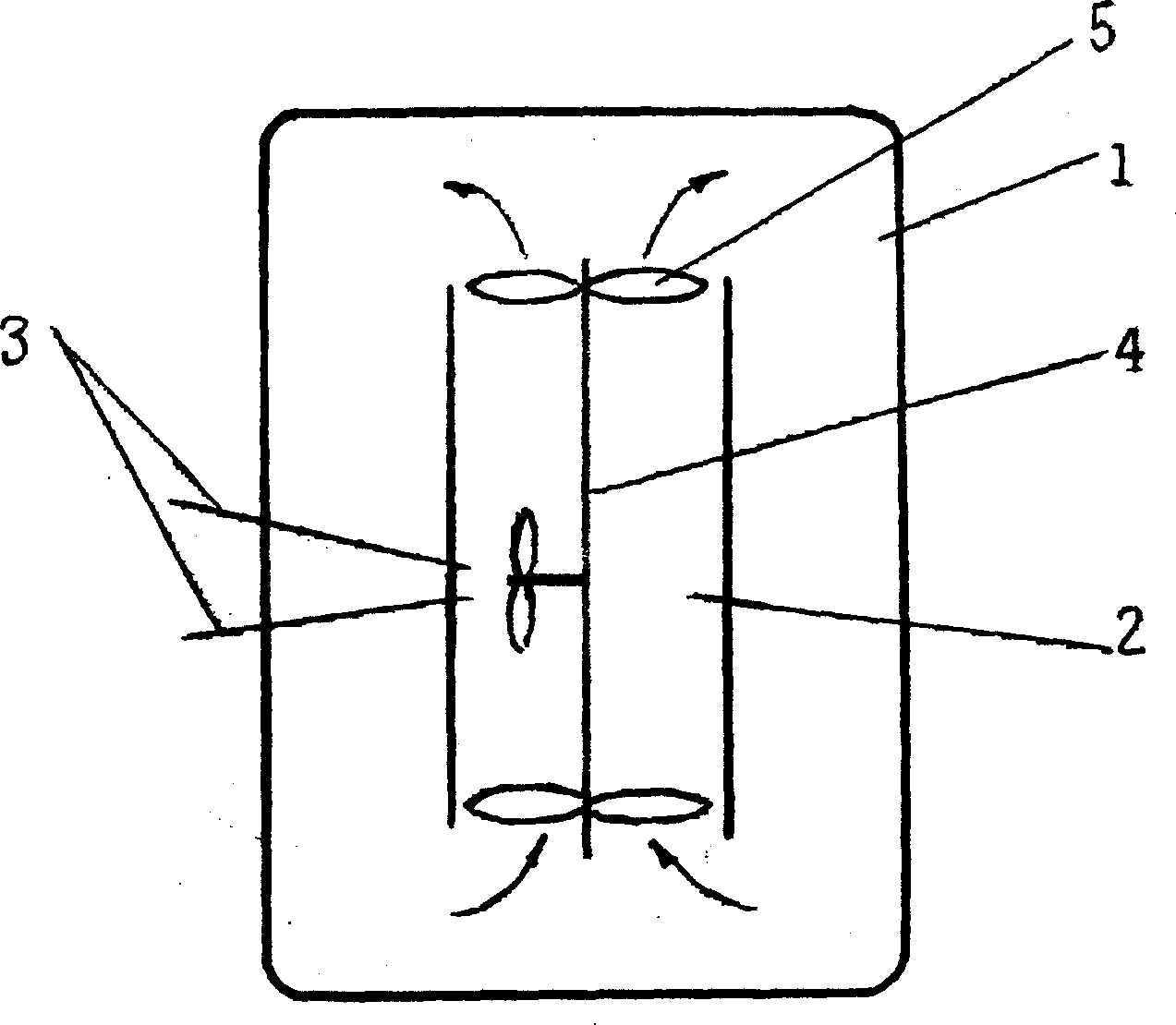

[0026] When synthesizing, anhydrous ethanol and triethylamine are well mixed in a solvent, and then phosphorus trichloride is reacted with the above mixture. In order to improve the yield, when the reaction takes place, measures should be taken to disperse the reactants in time and fully. This is because, if the reactant is not in a highly dispersed state, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com