Method for recovering useful constituents in mixed waste solvent during glufosinate ammonium production process

A production process, glufosinate-ammonium technology, applied in chemical instruments and methods, organic chemistry, distillation purification/separation, etc., can solve the problems affecting the cost of glufosinate-ammonium, high energy consumption, high equipment cost and operating cost, and achieve savings Rectification column, the effect of reducing evaporation process, equipment cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

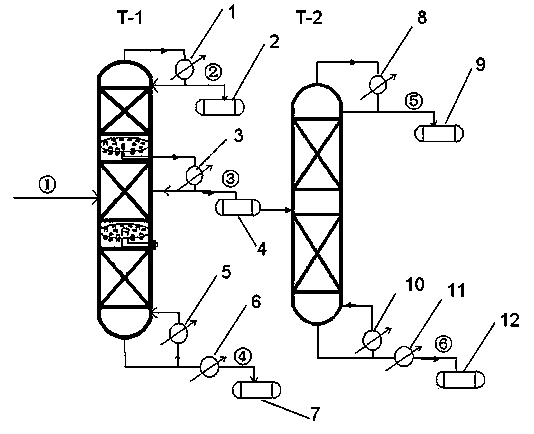

[0021] A method for integrated rectification recovery of tetrahydrofuran, diethyl methyl phosphite, triethyl phosphite, trimethylbenzene and other useful components in the mixed waste solvent produced in the production process of glufosinate-ammonium. The process flow is as follows figure 1 Shown, with reference to the process parameter shown in Table 1, the steps are as follows:

[0022] (1) Use the mixed waste solvent from glufosinate-ammonium production after preliminary treatment in the factory as the raw material, and pump it into the side rectification tower;

[0023] (2) Cut the distillate at 65~66°C from the top of the sideline rectification tower, control the reflux ratio, and take out the product as tetrahydrofuran from the top of the tower and enter the tetrahydrofuran storage tank;

[0024] (3) The middle side line of the side line rectification tower cuts the distillate at 120~158°C, after heat exchange by the heat exchanger, the reflux ratio is controlled, and th...

Embodiment 2

[0034] It is basically the same as in Example 1, but the overhead reflux ratio of side rectification column T-1 is controlled to be 3:1, and the overhead reflux ratio of rectification column T-2 is controlled to be 2:1.

Embodiment 3

[0036] It is basically the same as in Example 1, but the overhead reflux ratio of side rectification column T-1 is controlled to be 5:1, and the overhead reflux ratio of rectification column T-2 is controlled to be 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com