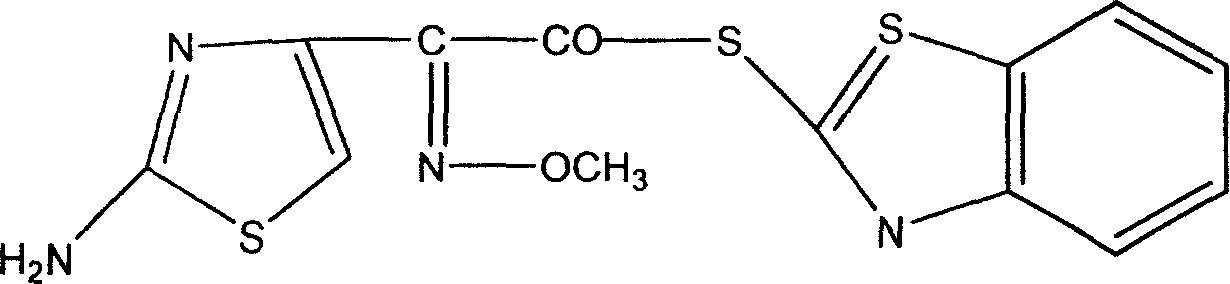

New technique for catalytic synthesis of AE active ester

A new technology, active ester technology, applied in the production process field of key intermediate - AE-active ester, can solve the problems of mild production and operation conditions, achieve the effect of mild production and operation conditions, reduce operation intensity, and reduce operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

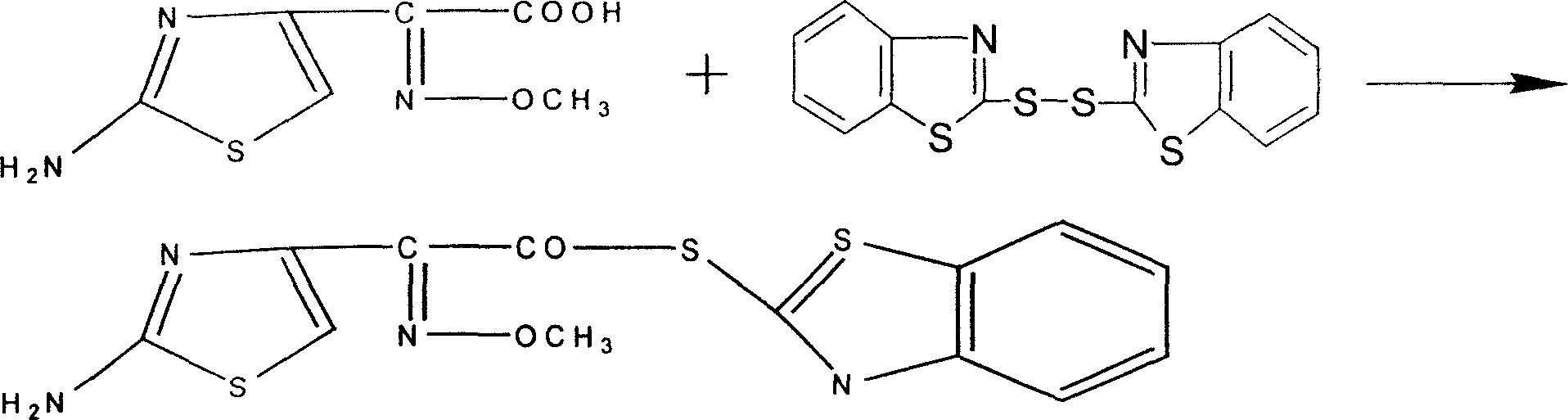

Method used

Image

Examples

Embodiment 1

[0021] Raw material ratio: 200 kg of aminothioxamic acid

[0022] Dibenzothiazole disulfide 250 kg

[0023] Pyridine 1.5 kg

[0024] Mixed solvent 1600 liters

[0025] Wherein the volume ratio of mixed solvent acetonitrile and dichloromethane is acetonitrile: dichloromethane=0.9:1

[0026] Triethylamine 80 kg

[0027] Phosphite triethyl ester 160 kg

[0028] 200 liters of mixed solvent in the rinse mother liquor

[0029] New acetonitrile 100 liters

[0030] New dichloromethane 200 liters

[0031] (1) Preparation of mixed solvent

[0032] Add 1,100 liters of new dichloromethane and 1,000 liters of new acetonitrile into a 3,000-liter well-sealed reactor, add 120 kg of phosphorus pentoxide under nitrogen protection, seal the reactor, heat up and distill, and collect at 80-110°C The distillate is placed in a dry and airtight storage tank for later use.

[0033] (2) Reaction

[0034] In the reaction kettle, first add 1600 liters of distilled mixed solvent, then add aminot...

Embodiment 2

[0038] Embodiment 2: according to the technique of embodiment 1, the proportioning of different raw materials is:

[0039] Aminothioxamic acid 200kg

[0040] Dibenzothiazole disulfide 250 kg

[0041] Pyridine 1 kg

[0042] Mixed solvent 1500 liters

[0043] Wherein the volume ratio of mixed solvent acetonitrile and dichloromethane is acetonitrile: dichloromethane=1.0:1

[0044] Triethylamine 82 kg

[0045] Phosphite triethyl ester 162 kg

[0046] The product yield is 91%.

Embodiment 3

[0047] Embodiment 3: according to the technique of embodiment 1, the proportioning of different raw materials is:

[0048] Aminothioxamic acid 200kg

[0049] Dibenzothiazole disulfide 255 kg

[0050] Pyridine 2 kg

[0051] Mixed solvent 1700 liters

[0052] Wherein the volume ratio of mixed solvent acetonitrile and dichloromethane is acetonitrile: dichloromethane=1.0:1

[0053] Triethylamine 80 kg

[0054] Phosphite triethyl ester 158 kg

[0055] The product yield is 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com