Patents

Literature

282results about How to "Won't decompose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyphenylene oxide/polystyrene blend alloy material, its preparation method and application

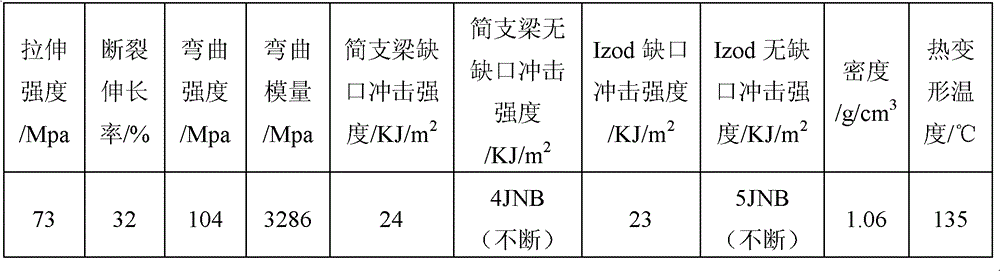

Belonging to the technical field of high polymer materials, the invention discloses a polyphenylene oxide / polystyrene blend alloy material, its preparation method and application. The polyphenylene oxide / polystyrene blend alloy material provided in the invention is prepared from the following components by weight: 36-90 parts of polyphenylene oxide, 10-50 parts of polystyrene, 0.2-0.7 part of a lubricant, 0.2-0.5 part of an antioxidant and 7.1-46.1 parts of an assistant. The preparation method of the polyphenylene oxide / polystyrene blend alloy material consists of the steps of: weighing 36-90 parts of polyphenylene oxide, 10-50 parts of polystyrene, 0.2-0.7 part of the lubricant, 0.2-0.5 part of the antioxidant and 7.1-46.1 parts of the assistant, mixing them uniformly at a high speed by a high-speed mixing machine, then pouring the mixture into a screw extruder, and carrying out strand pelletizing by the screw extruder, thus obtaining the product. The invention also discloses application of the polyphenylene oxide / polystyrene blend alloy material as an extrusion type profile material. The polyphenylene oxide / polystyrene blend alloy material provided in the invention can reduce cost and save energy, and realizes the purpose of substituting plastics for steel.

Owner:上海事升新材料有限公司

Lithium secondary battery additive, preparation method thereof, and application thereof

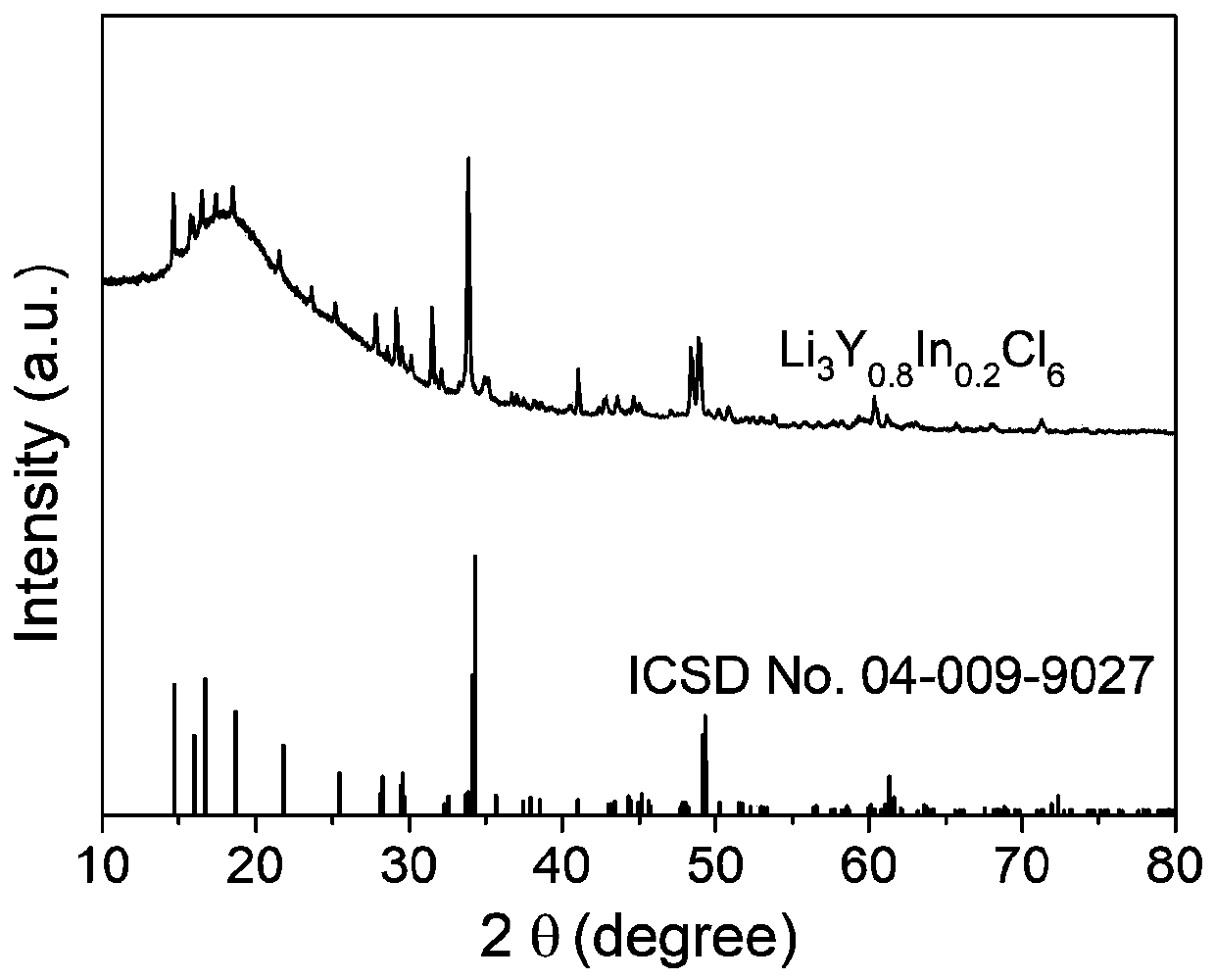

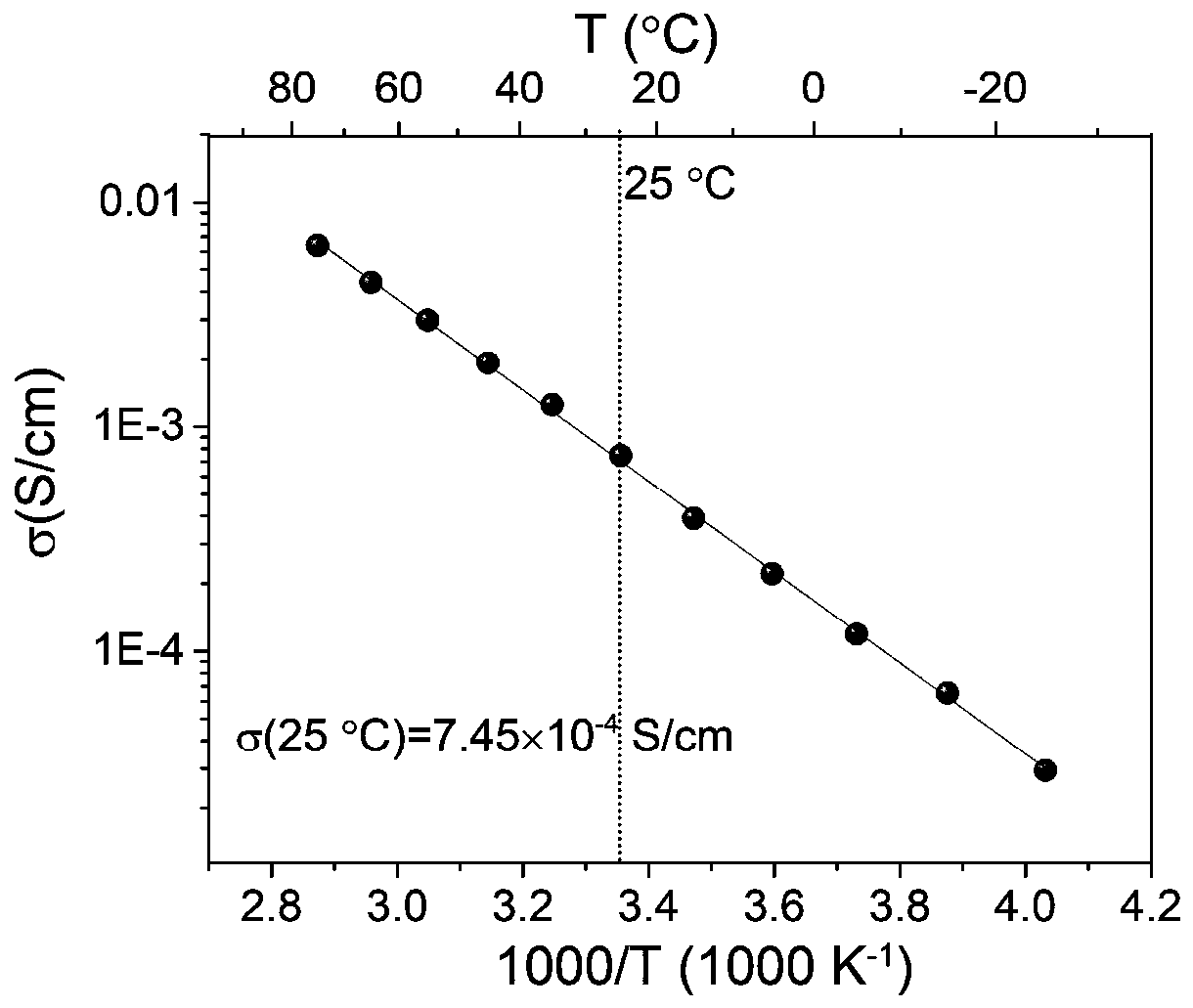

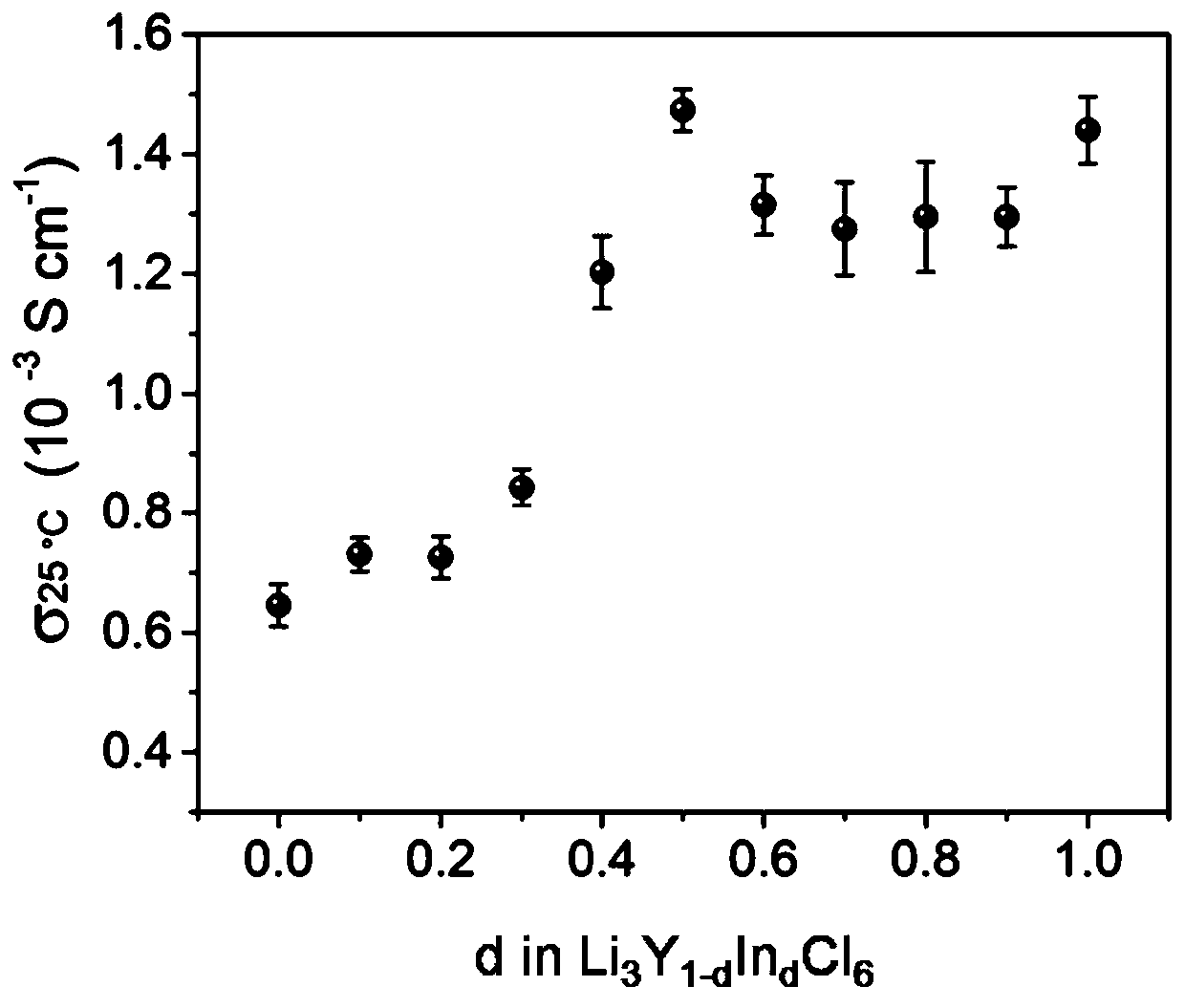

The invention relates to the technical field of lithium secondary battery additives and particularly relates to a lithium secondary battery additive, a preparation method thereof and application thereof. The additive is LibMaXc, M is B, Al, Ga, In, Y, Sc, Sb, Bi, Nb, Ta, Ti, Zr, V, Cr, Mo, W, Mn, Tc, Re, Fe, Co, Ni, Cu, Ag, Zn, Cd, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb or Lu, X isF, Cl, Br or I, b is larger than or equal to 0.2 and smaller than or equal to 6, a is larger than or equal to 0.1 and smaller than or equal to 3, and c is larger than or equal to 1 and smaller than or equal to 9. The lithium secondary battery additive has the advantages of high ionic conductivity and air stability, the rapid transmission of electrode ions can be improved, the electrode loading capacity and thickness are improved, and the energy density of the battery is improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

Inorganic thermal-insulation mortar used for building exterior walls of buildings and preparation method thereof

InactiveCN101863639AGood chemical stabilityGood weather resistanceSolid waste managementHigh resistanceWeather resistance

The invention relates to inorganic thermal-insulation mortar used for building exterior walls of buildings and a preparation method thereof. The invention is characterized in that the thermal-insulation mortar comprises the following components in part by weight: lightweight aggregate 100-150, binding material 100-150, fly ash 10-60, and additive 8.72-11.36. Compared with the prior art, the inorganic thermal-insulation mortar has the advantages of high weather resistance, high aging resistance, long service life, high fireproofing and flame-retarding performance, energy conservation and environment protection.

Owner:SHANGHAI MINJIANG TONG PROD

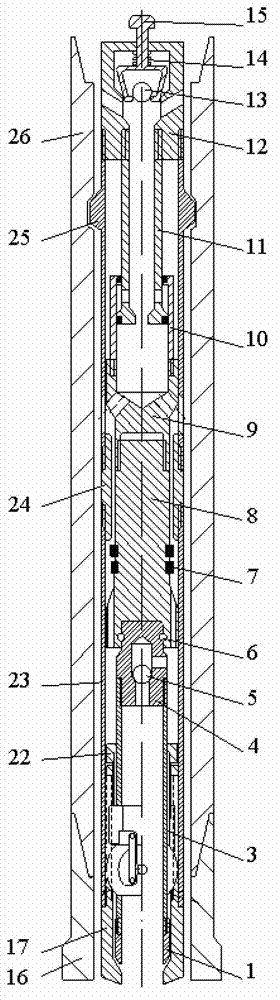

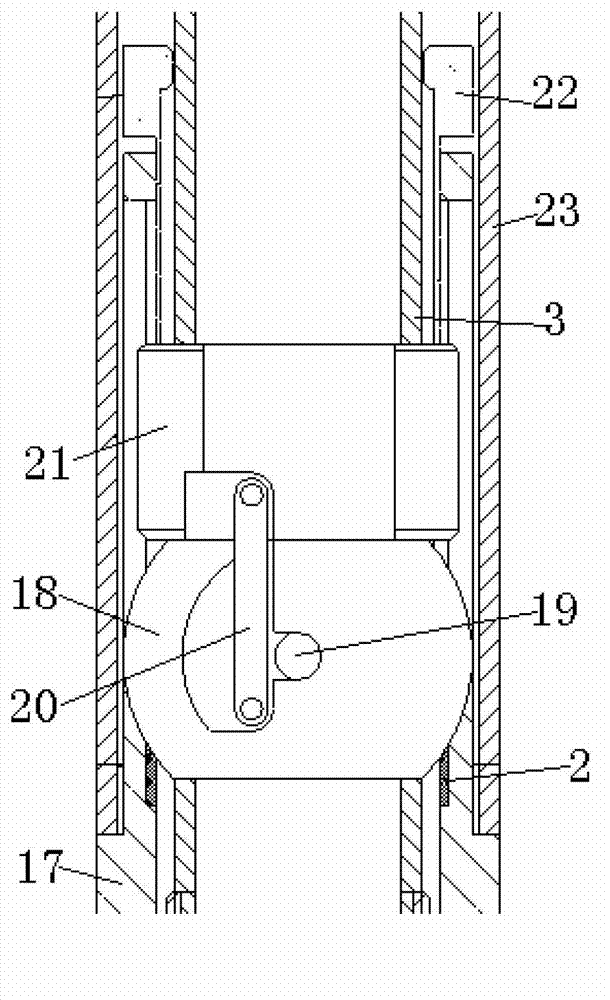

Gas hydrate pressure-retaining sampler

The invention relates to a gas hydrate pressure-retaining sampler at least comprising an external pipe assembly, a middle pipe assembly, an internal pipe assembly, a fishing part and a linkage mechanism. The external pipe assembly is arranged at the bottom part of a drill rod; the internal pipe assembly is positioned in the external pipe assembly; the middle pipe assembly is positioned between the external pipe assembly and the internal pipe assembly; the fishing part is positioned above the internal pipe assembly and the middle pipe assembly, and the bottom part of the fishing part is fixedly connected with the top parts of the internal pipe assembly and the middle pipe assembly. The internal pipe assembly of the gas hydrate pressure-retaining sampler is used for loading a rock core, the inner part of the middle pipe assembly forms a sealed cavity under the action of upper sealing and lower sealing when sampling is required, the pressure of the rock core sample positioned in the sealing cavity keeps unchanged, and finally the sampler except for the external pipe assembly is lifted to the ground surface through the fishing device; and with the sampler, decomposition of gas hydrate during sampling can be effectively avoided.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

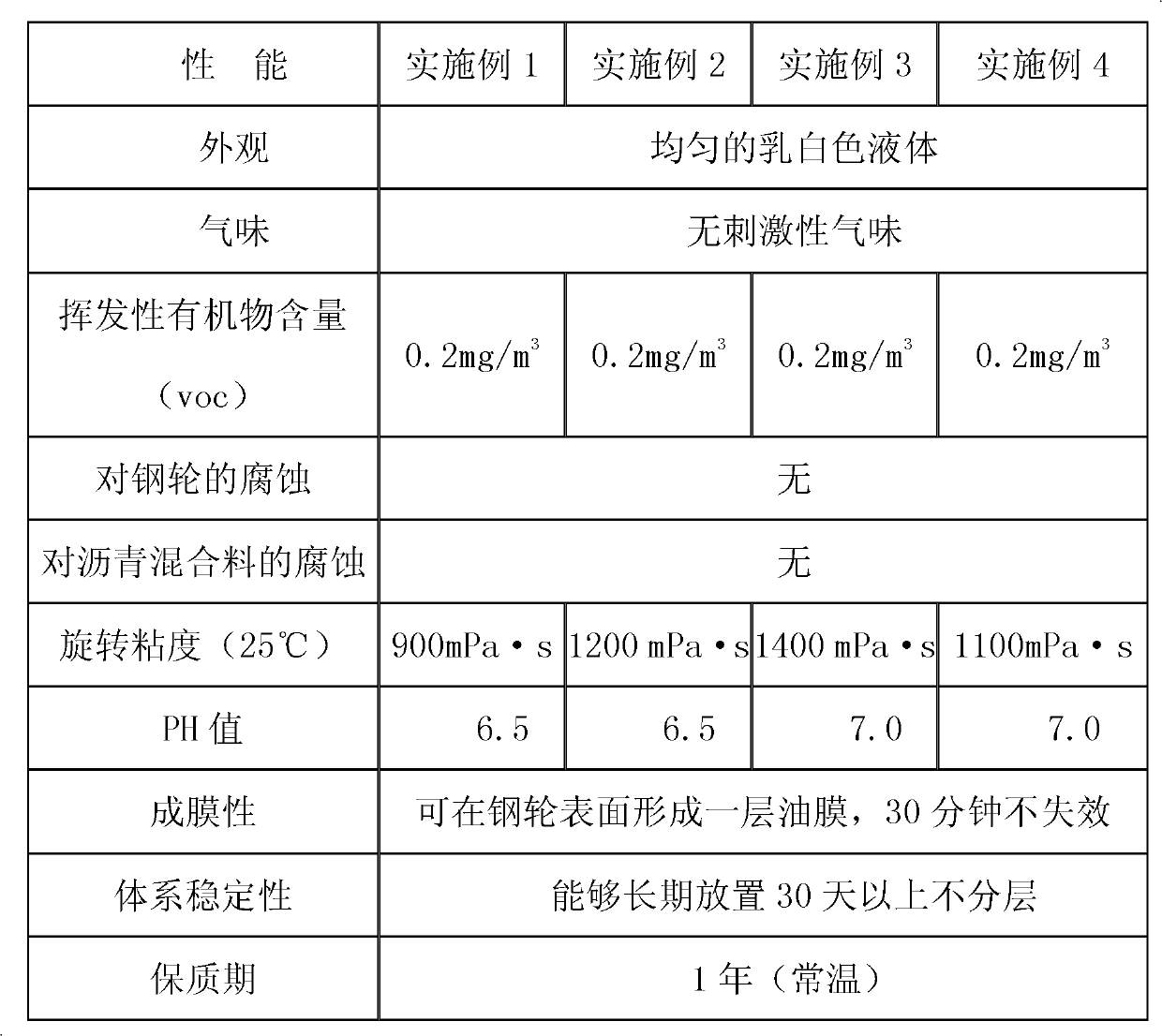

Insulator for low-temperature construction of asphalt pavement road roller and method for preparing same

ActiveCN102167939ANo pollution in the processNo chemical reactionClimate change adaptationCoatingsGreenhouseEngineering

The invention belongs to the technical field of preparation of insulators for the construction of asphalt pavement road rollers and relates to an insulator for the low-temperature construction of road rollers and a method for preparing the same. The insulator is mainly prepared by mixing silicone oil, compound emulsifier, glycerin, pH regulator, preserving agent and water. The insulator has the advantages of high chemical stability, high high-low temperature resistance, no corrosion to steel wheels, small amount of coating, lasting insulating effect, environment friendliness and the like. By using the insulator, the asphalt mixture pavement is guaranteed to be constructed at the ultralow temperature (15 DEG C below zero), so that the working season is greatly prolonged; and during normal-temperature construction, by using the insulator, the mixing temperature of the asphalt mixture is reduced to 15 to 20 DEG C under the condition of unchanging the compaction degree and the emitted greenhouse gases are reduced in the mixing process and the environment-friendly and energy saving requirements are met.

Owner:山西省交通科技研发有限公司

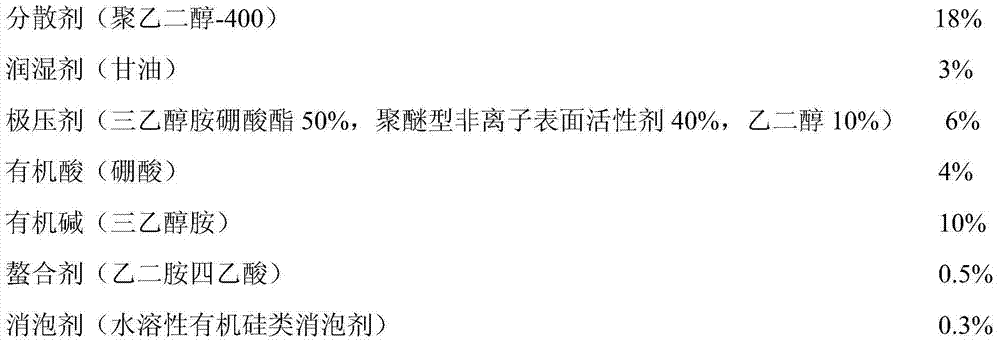

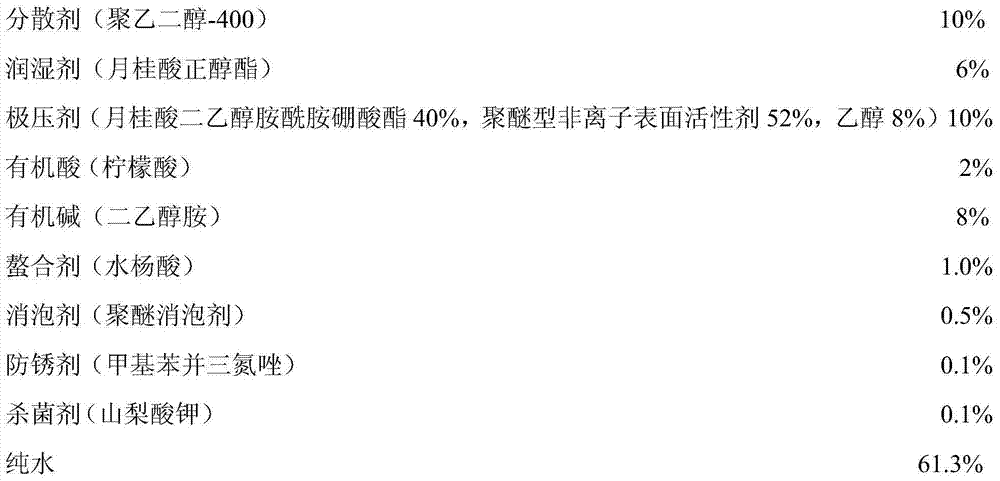

Environment-friendly water-based sapphire cutting fluid

The invention provides environment-friendly water-based sapphire cutting fluid. The cutting fluid comprises, by mass, 10-20% of dispersing agents, 3-8% of wetting agents, 6-12% of extreme pressure agents, 2-6% of organic acid, 6-10% of organic alkali, 0.02-2.0% of chelating agents, 0.01-1.0% of defoaming agents, 0.01-1.0% of antirust agents and 0.01-1.0% of sterilizing agents, wherein the dispersing agents are polyethylene glycol, the wetting agents are glycerin and / or lauric acid normal alcohol ester, the extreme pressure agents contain a boric acid ester compound and a polyether type nonionic surface active agent, and the antirust agents are benzotriazole and / or methyl benzotriazole. The environment-friendly water-based sapphire cutting fluid meets the production requirement and is low in cost, practical and environmentally friendly.

Owner:LENS TECH CHANGSHA

High toughness, high wearproof, and corrosion resistant nano-plastic floor

InactiveCN103450585AImprove toughnessWon't decomposeFlooringPolyvinyl chloridePolymethyl methacrylate

The invention discloses a high toughness, high wearproof, and corrosion resistant nano-plastic floor, which includes polyvinyl chloride, i.e. PVC, a polymethyl methacrylate-polybutadiene-polystyrene copolymer, chlorinated polyethylene, a stabilizer, a processing modifier, a plasticizer, and a lubricant. The improvement of the nano-plastic floor lies in that: it also includes an environment-friendly wear-resisting agent, a corrosion inhibitor, SiC nano-powder, a filler, an ultraviolet absorbent, and a pigment. The components can be combined together to endow the plastic floor with high strength, wear resistance and corrosion resistance so as to meet the long-term use requirements of outdoor sport fields.

Owner:TAIZHOU HUALI PLASTIC

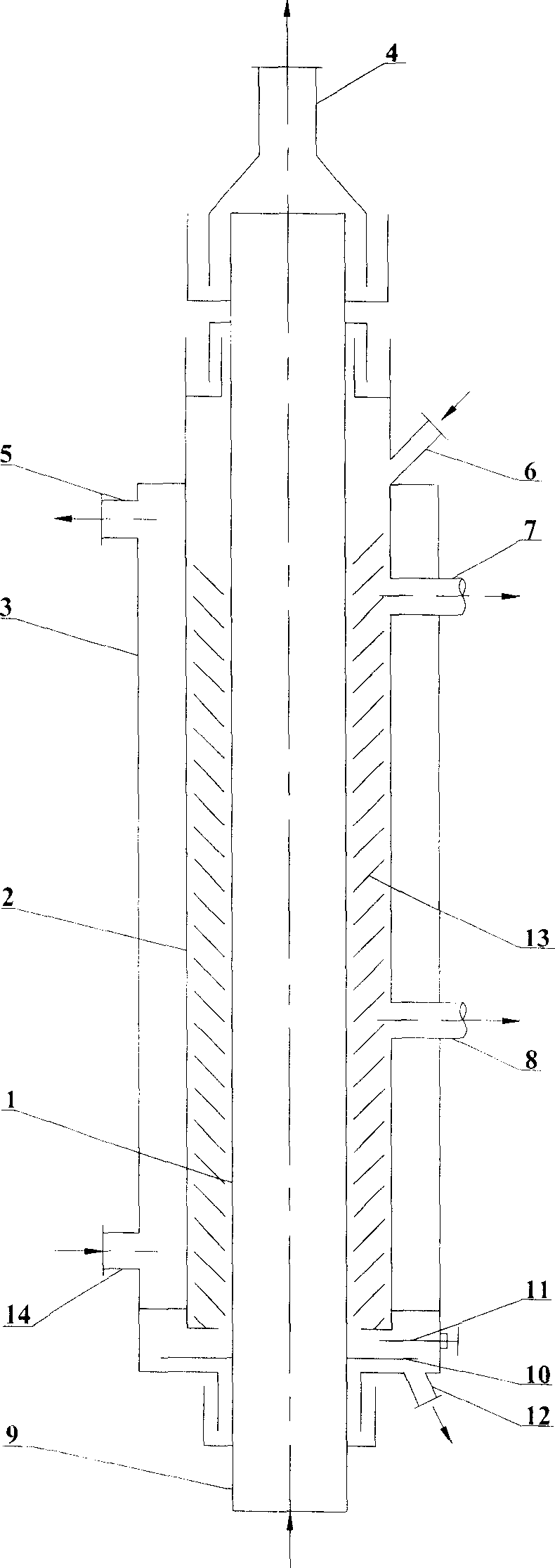

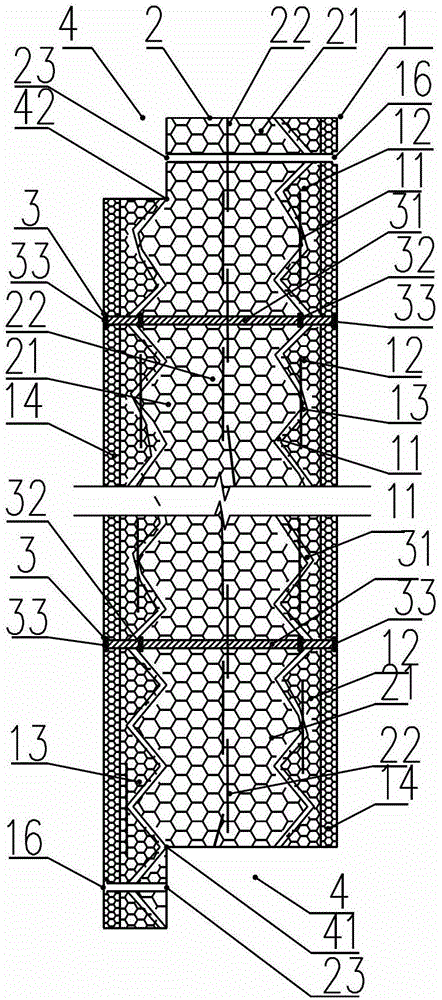

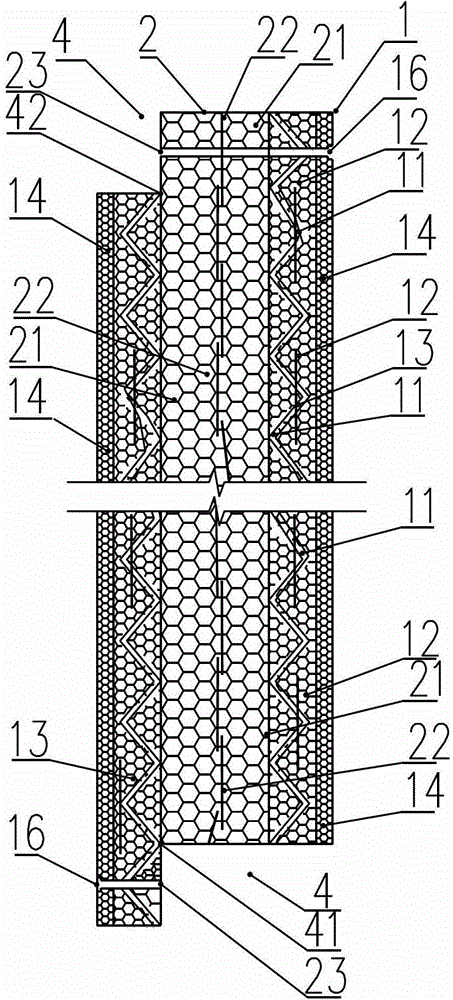

Low temperature distillation method and device for high volatile component weak viscosity coal

InactiveCN1865398AEvenly heatedAvoid stickingLiquid hydrocarbon mixture productionSpecial form destructive distillationWater vaporTar

The invention discloses a low-temperature retorting method of high-volatile flux fine particle, which is characterized by the following: the method adopts vertical pipe with inner, middle and outer concentric casing to move two sides of outer heat retort furnace, which produces char coal, gas and tar; the needed energy of retorting is provided by fine grain coal in the middle casing ring-shaped space from inner and outer casing high-temperature gas, which proceeds drying and charring steps; the steam and char volatile product are guided out of upper segment steam and lower segment char hole separately; the char coal falls in the char furnace chassis discharger, which is discharged from outlet.

Owner:FUZHOU UNIV

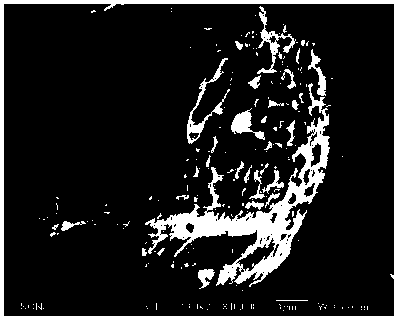

Method for manufacturing nanometer antibacterial ceramic glaze layers

The invention belongs to the field of inorganic nonmetal materials, particularly discloses a method for manufacturing nanometer antibacterial ceramic glaze layers, and relates to methods for manufacturing ceramic glaze layers. Antibacterial elements are added into ceramic glaze layer bases to carry out antibacterial disinfection on the ceramic glaze layers. Precursors for superfine powder of the nanometer antibacterial ceramic glaze layers comprise 45-60% of SiO<2>, 10-14%of Al<2>O<3>, 7-10% of CaO, 5-7% of ZnO, 2-5% of CuO, 3-6% of MgO, 1-3% of TiO<2> and 0.2-2% of Ag<2>O. The method includes filling graphite containers with the precursors for proportionally preparing the superfine powder of the nanometer antibacterial ceramic glaze layers; preserving heat for 120min-240min under argon atmosphere protection and the condition of temperatures of 1250-1400 DEG C to carry out synthesis; adding absolute ethyl alcohol into a ball-mill to carry out mechanical ball-milling for 24 hours so as to obtain the superfine precursor powder with crystal grain sizes of 30-80nm. The method has the advantages that metal grains of zinc, copper, magnesium and silver are fine and are uniformly distributed in glaze layers, the diameters of the metal grains are 30-80nm, and antibacterial elements can be quickly, durably and continuously released.

Owner:SHANDONG JIANZHU UNIV

Polymer composite film, preparation method thereof and lithium ion battery comprising same

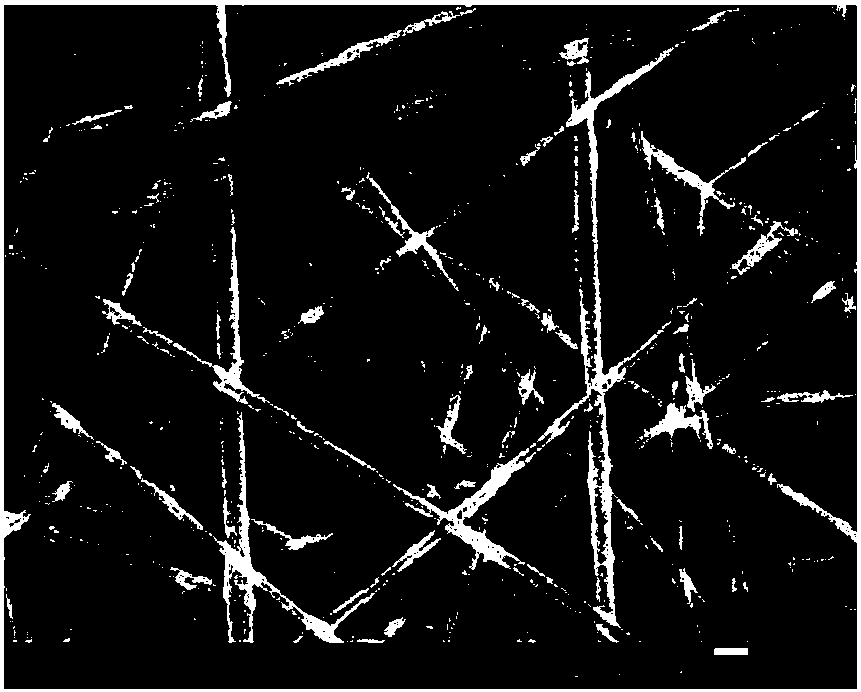

ActiveCN108242522AMeet porosity requirementsImprove securitySecondary cellsCell component detailsPorosityFiber

The invention discloses a polymer composite film, a preparation method thereof and a lithium ion battery comprising the polymer composite film. The polymer composite film comprises a porous base filmand a heat-resistant layer covering at least one side surface of the porous base film, wherein the heat-resistant layer comprises a heat-resistant macromolecular material and has a fibrous network structure, and the heat-resistant macromolecular material comprises one or more than one of poly (p-phenylene terephthalamide), polyisophthaloyl metaphenylene diamine, poly p-benzamide, poly-p-phenyleneben-zobisthiazole, polyphenylene benzobisthiazole, polybenzoxazole and polybenzimidazole. The polymer composite film disclosed by the invention has the advantages that a specific heat-resistant macromolecular material is adopted for forming the heat-resistant layer, high temperature (180 DEG C) stability of the polymer composite film can be beneficially improved while porosity requirement of the polymer composite film is met, lithium ion migration is facilitated, and safety performance of a battery is improved.

Owner:BYD CO LTD

Zirconium corundum heavy load strong abrasive band

ActiveCN101134300AImprove toughnessImprove grinding effectAbrasion apparatusHeavy loadMaterials science

The present invention relates to abrasive belt, and is especially one kind of powerful zirconia corundum supported abrasive belt comprising cloth base, adhesive and grinding material zirconia corundum adhered onto the cloth base. It features the adhesive comprising thermosetting phonetic resin 28-36 wt%, diphenol propane type epoxy resin 4-8 wt%, melamine resin 1-4 wt%, boron 0.2-0.6 wt%, dispersant 0.1-0.3 wt%, coupling agent 0.1-0.3 wt%, diluent 3-6 wt%, fluoride salt 45-60 wt%, fluoride of inert gas 0.5-1 wt%. The abrasive belt has high heat resistance high adhesion strength at high temperature, capacity of softening metal surface and lowering surface hardness, no damage to metal surface and high grinding efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

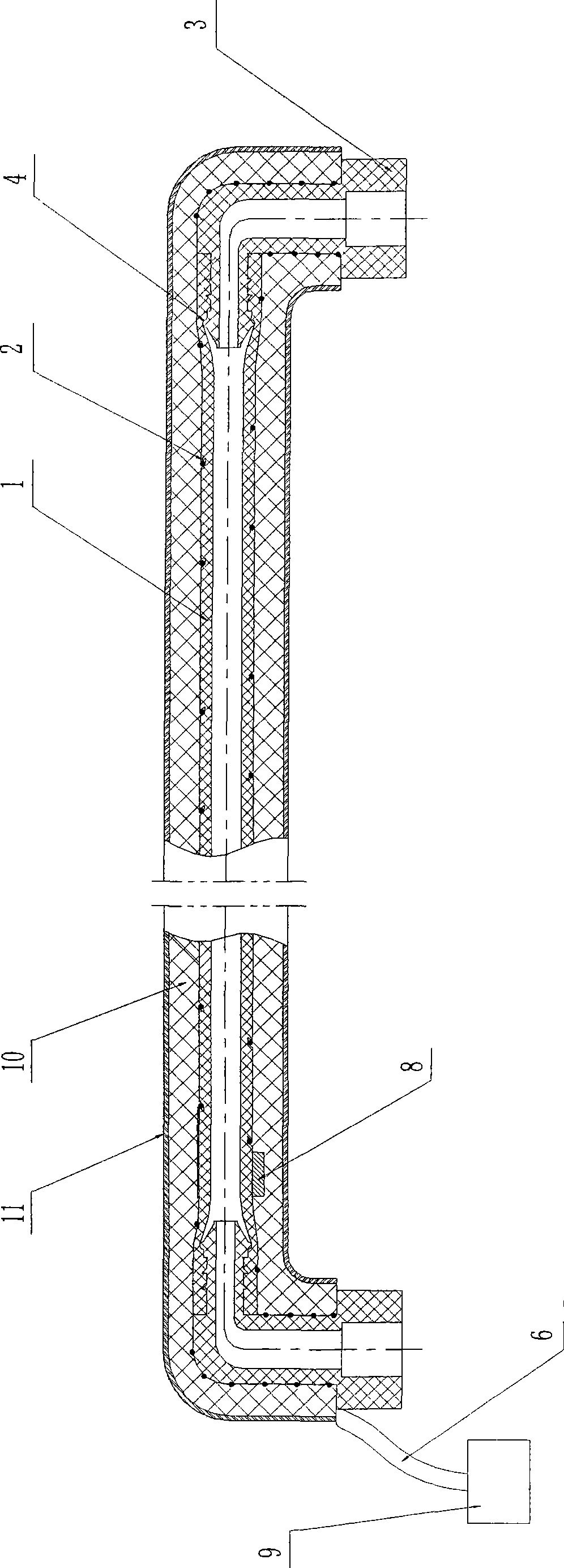

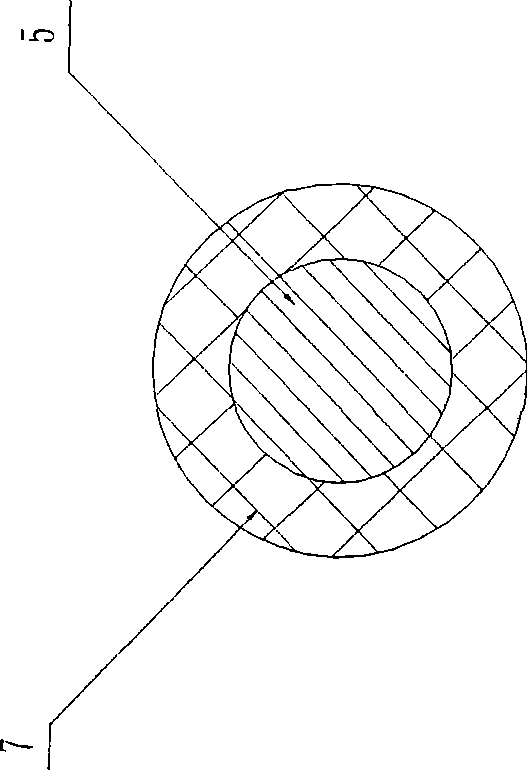

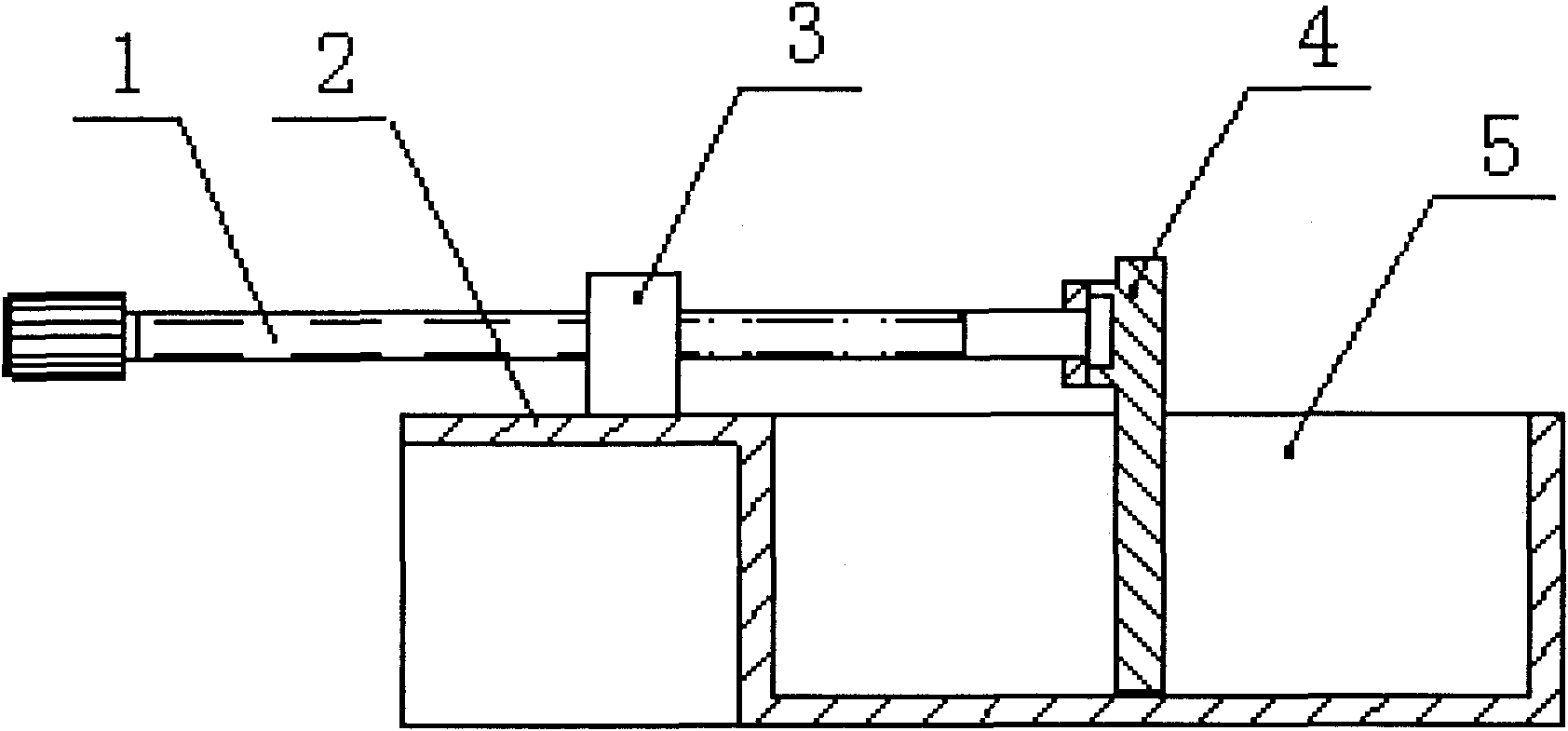

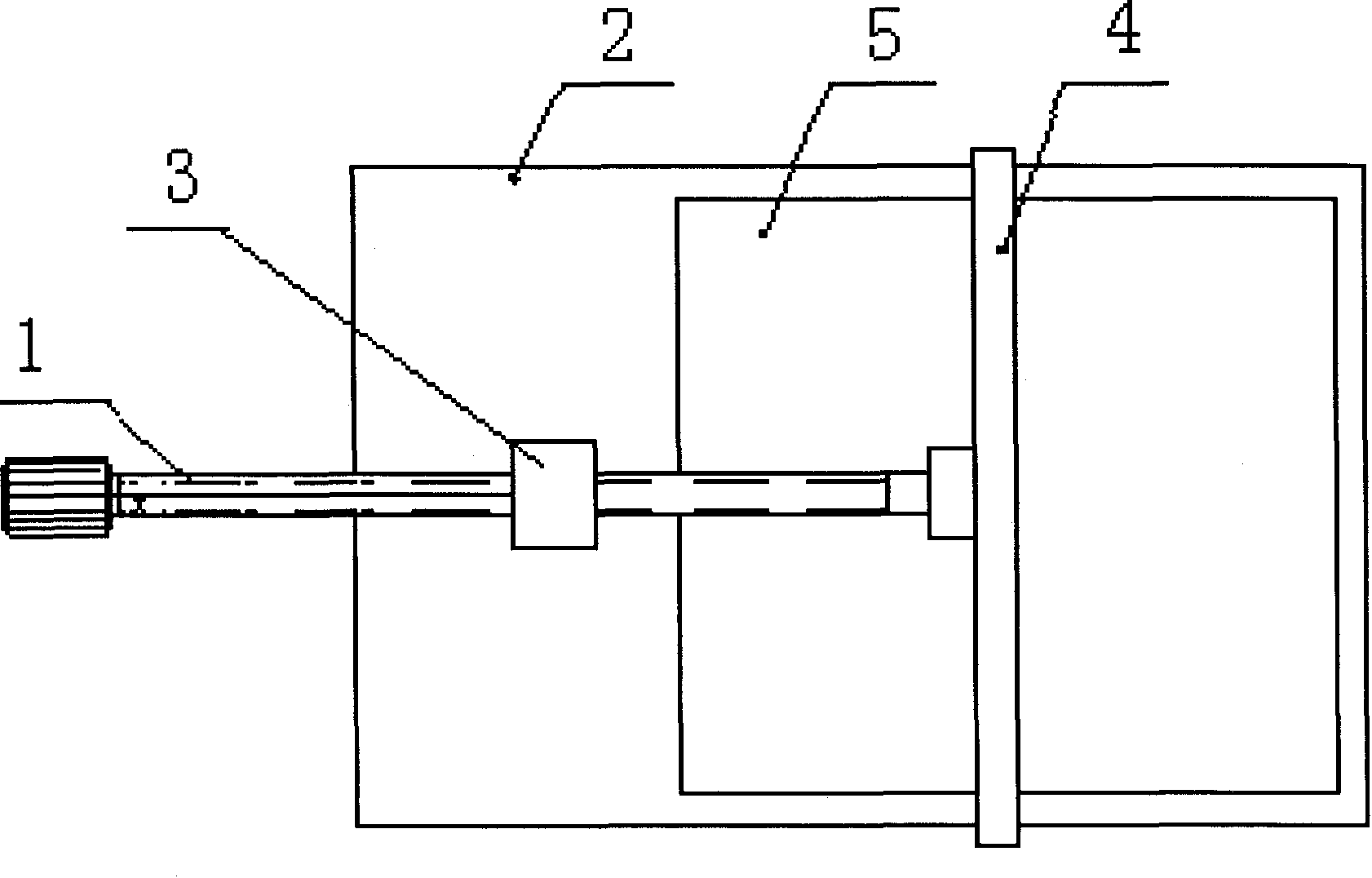

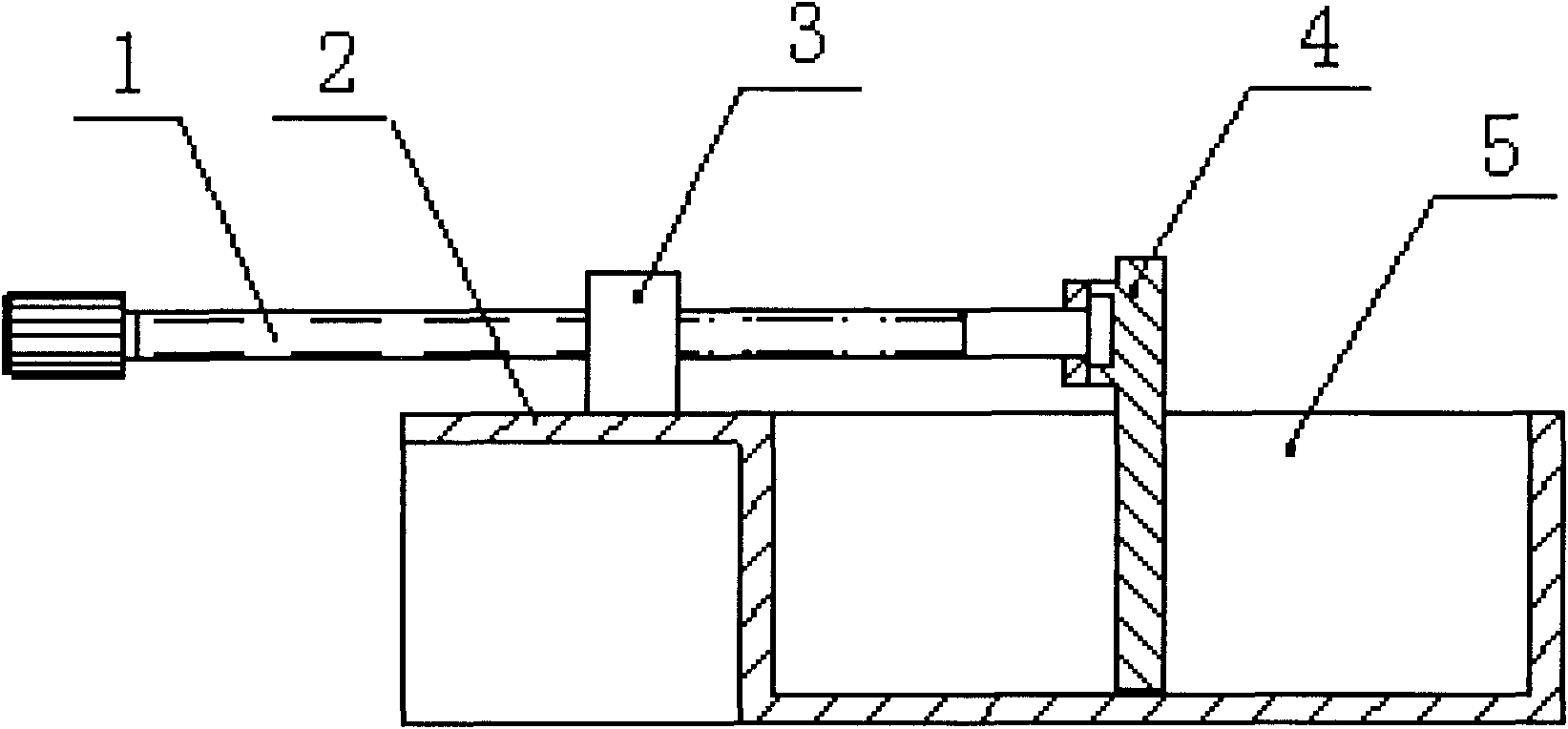

Pipeline for delivering engine waste gas post-processing medium

ActiveCN101476659AWon't decomposeSimple structureThermal insulationExhaust apparatusInterference fitHeating power

The invention relates to a conveying tube for conveying an exhaust post-treatment medium of an engine. The conveying tube comprises a conveying tube (1), joints (3), a heater strip (5), a lead wire (6), a wire connecting terminal (9) and an insulating layer (10), wherein a groove (2) used for assembling the heater strip (5) is arranged on the surface of the conveying tube (1); two joints (3) are connected with two ends of the conveying tube in an interference fit mode respectively; and the heater strip (5) is connected with the wire connecting terminal (9) through the lead wire (6). The conveying tube has the advantages of simple structural manufacture, long service life, accurate performance and high reliability, is particularly applicable to an exhaust post-treatment device of a diesel motor, not only has the function of conveying a urea solution, but also has the function of heating and melting the urea solution under the condition that the urea solution is refrigerated and iced, and can strictly control heating power and temperature so as to ensure that urea cannot be decomposed at a high temperature.

Owner:NANJING AOLIAN AE&EA

Preparation method of high performance halogen free environment-friendly extruded magnetic stripe made of rubber&plastic ferrite and magnetic stripe

InactiveCN102163496AReduce production stepsReduce energy consumptionMagnetsInductances/transformers/magnets manufactureAdhesiveFerrite powder

The invention discloses a preparation method of a high performance halogen free environment-friendly extruded magnetic stripe made of rubber&plastic ferrite. The method is characterized by comprising the following steps: (1) preparing raw material mixture, to be more specific, preparing uniform raw material mixture by mixing ferrite powder, the size of which is between 10 and 200 nanometers, cladding agent and adhesive; (2) extruding a sheet, to be more specific, setting a scope of extrusion thickness for an extruder, feeding the raw material mixture into the extruder, and successively extruding to obtain a plastic magnetic sheet; (3) cutting, to be more specific, cutting the plastic magnetic sheet into predetermined shape and dimension; (4) UV glazing, to be more specific, spraying UV oil polish on a surface of the magnetic sheet, thereby forming a protection film on the surface; (5) magnetizing, to be more specific, magnetizing by placing the magnetic sheet in a magnetic field to obtain a magnetic stripe. The invention also discloses an extruded magnetic stripe of high performance halogen free environment-friendly rubber&plastic ferrite prepared by the method. The invention can be widely applied to the manufacturing field of flexible rubber&plastic magnetic products.

Owner:广州高馨能生物科技有限公司 +1

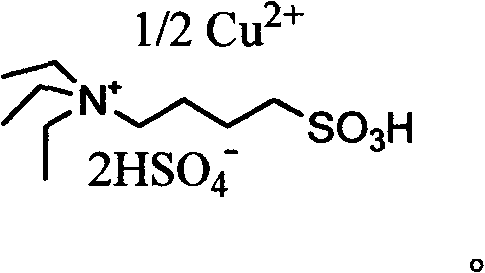

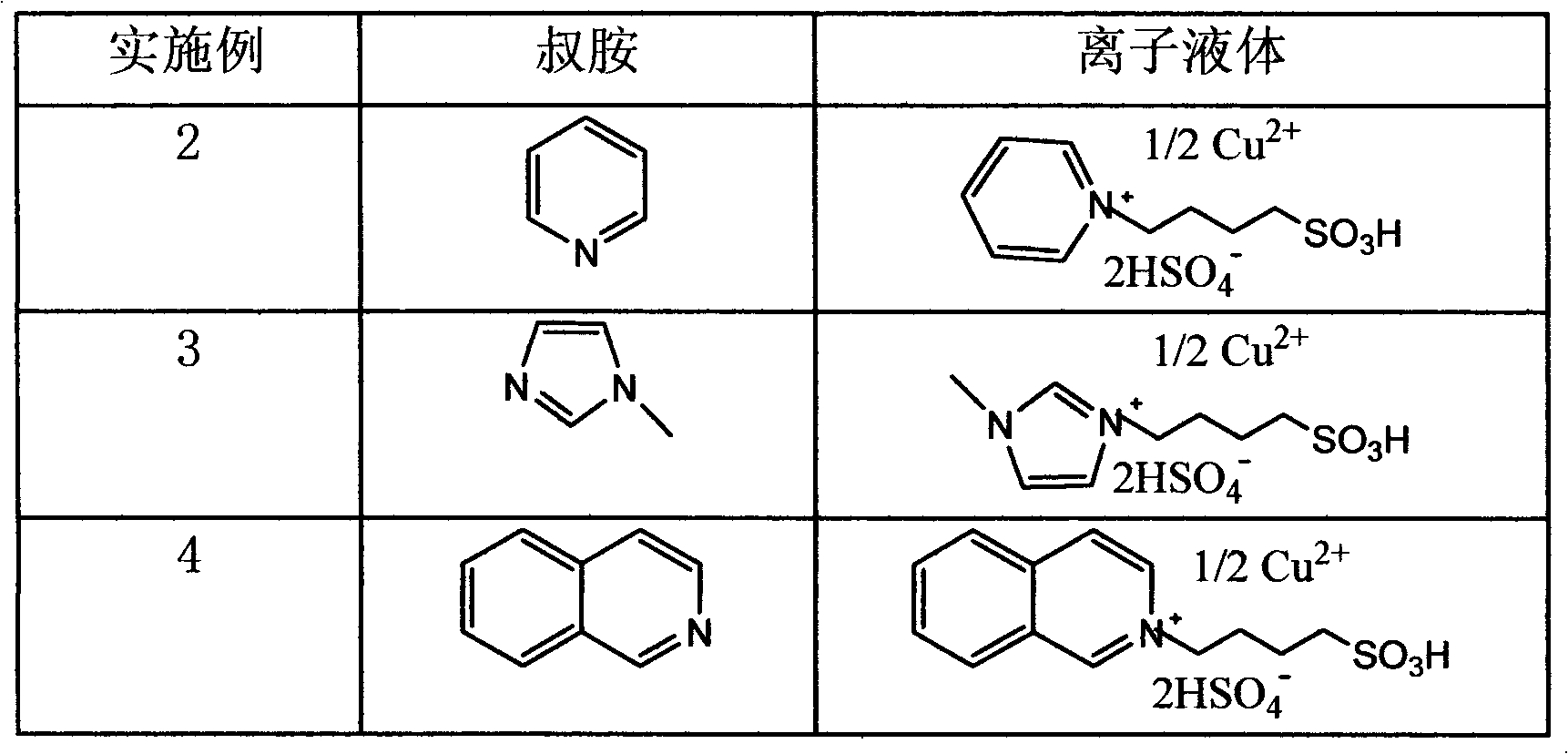

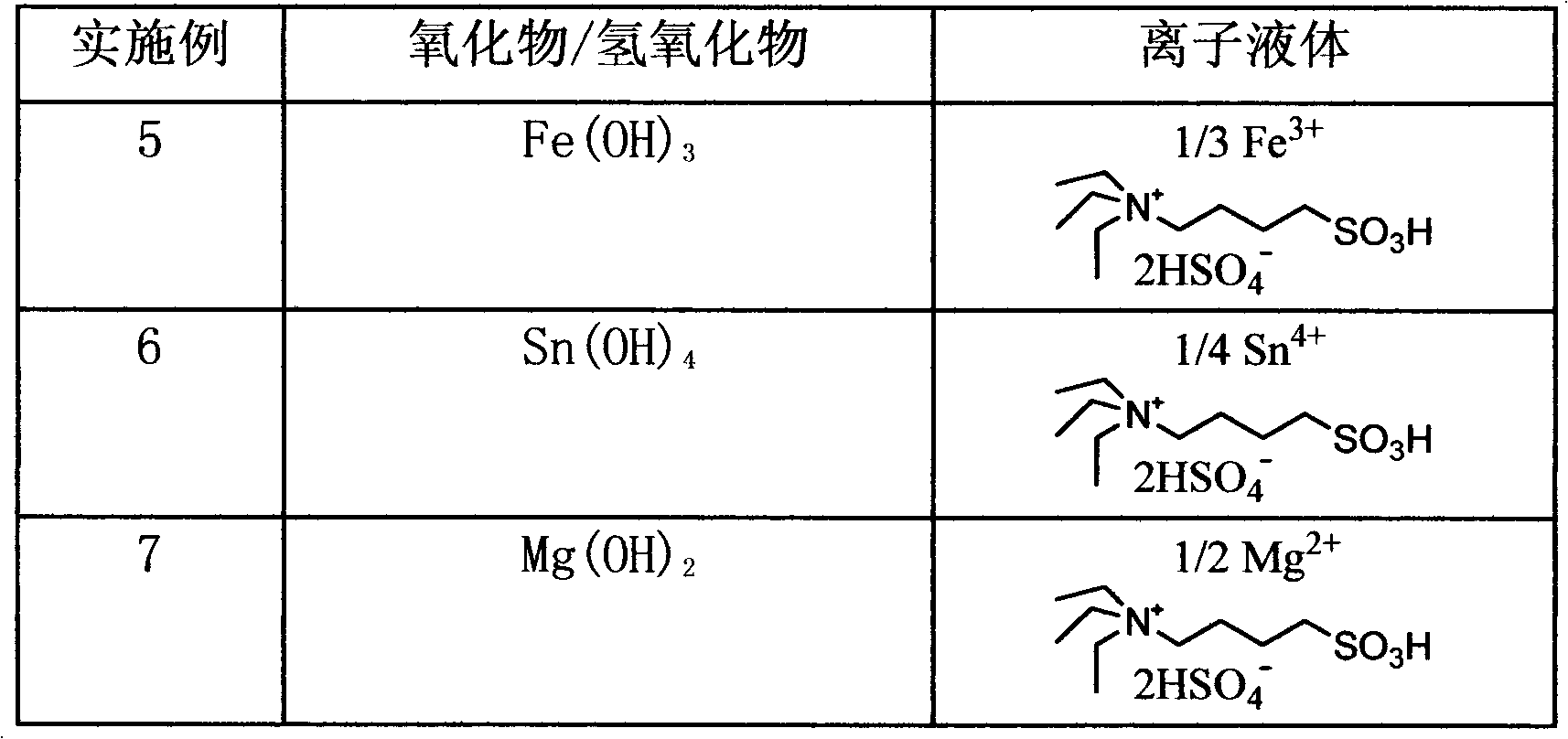

Ionic liquid combining B acid site and L acid site as well as preparation method and application thereof

InactiveCN102060738AImprove thermal stabilityRich varietyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisDecomposition

The invention discloses an ionic liquid combining a B acid site and an L acid site as well as a preparation method and application thereof, belonging to the technical field of organic chemistry synthesis. The preparation method is characterized by comprising the following steps of: reacting a tertiary amine compound with sultone to obtain the ylid salt of mucopolysaccharide radical; acidizing with sulfuric acid to obtain a sulfonic functionalized ion liquid of which the anion is bisulfate radical; reacting with metal oxide or hydroxide; and converting parts of hydrogen ion into the metal ion of the L acid site to prepare the ionic liquid combining the B acid site and the L acid site. The ionic liquid has the advantages of high thermal stability, varied acid types, good catalytic effect, combination of the B acid site and the L acid site, stability to water and no decomposition and the like, and a catalyst can be reused several times.

Owner:SHAOXING UNIVERSITY

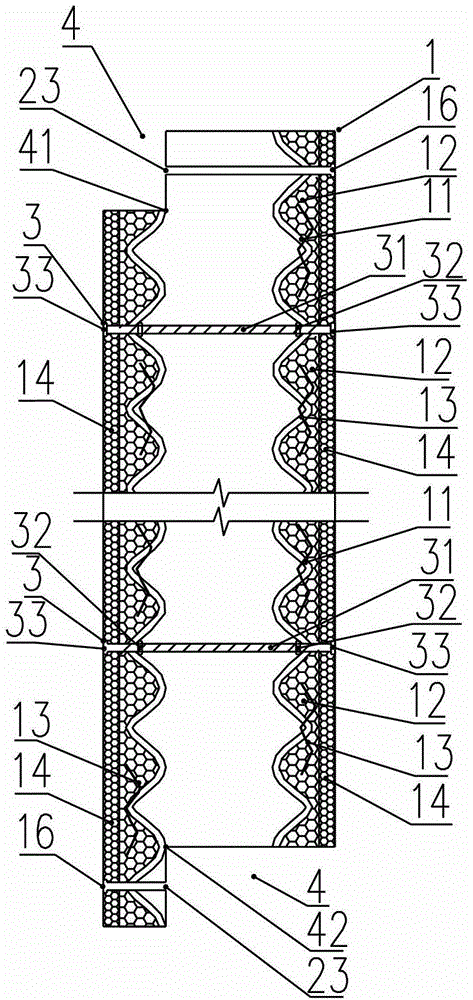

High-strength composite corrugated fiber foam cement heat insulation material

InactiveCN103334504AImprove sound insulation and noise reductionImprove thermal insulation performanceHeat proofingWater-setting substance layered productEnvironmental resistanceFiber

The invention discloses a high-strength composite corrugated fiber foam cement heat insulation material. Aiming at the defects that organic materials such as polyphenyl, extruded sheet and polyurethane, belonging to petroleum extractant, are complicated in structure, easy to age, inflammable, easy to crack, easy to seep and are short in service life, and inorganic materials such as a foam cement heat insulation board cannot reach the use strength of a wall body, the invention designs the high-strength composite corrugated fiber foam cement heat insulation material. The heat insulation material comprises corrugated fiber cement heat insulation material, composite foam cement heat insulation material, a fixed connecting support component, and concave-convex or male-female connecting mortise and tenon joints. The design purposes of meeting the use strength of a building outer wall and reducing the cost are realized by utilizing the performances of low heat conductivity coefficient, non-inflammability, high compression resistance and breaking strength of the foam cement, foamed ceramics and corrugated fiber cement plate and a pouring extrusion and foam technique. The high-strength composite corrugated fiber foam cement heat insulation material has the characteristics that the performances of heat preservation and insulation, non-inflammability and fireproofing, sound insulation and noise reduction, lightweight earthquake and acid rain resistance can be improved, and the material has the advantages on performance that the structure is simple, the material is saved, the mounting and dismounting are convenient, the construction efficiency is high, the service life is long, the cost is low, the material can be used as a finished wall body and recycled, and is energy-saving and environmental-protection.

Owner:BENXI NATURAL ICE PREPARATION ENG

Method for preparing high-performance halogen-free environment-friendly rubber-plastic NdFeB (neodymium, iron and boron) extruded magnetic strip and magnetic strip

InactiveCN102029394AReduce production stepsReduce energy consumptionInorganic material magnetismSheet filmAdhesive

The invention discloses a method for preparing a high-performance halogen-free environment-friendly rubber-plastic NdFeB (neodymium, iron and boron) extruded magnetic strip, which is characterized by comprising the following steps: (1) raw material mixture preparation: preparing an even raw material mixture of NdFeB powder, coating agents and adhesives, wherein the particle size of the even raw material mixture is 10-200 nanometers; (2) film extrusion: setting an extrusion thickness range of an extruder, feeding the raw material mixture into the extruder, and carrying out continuous extrusion on the raw material mixture so as to obtain a plastic-magnetic film; (3) cutting: cutting the plastic-magnetic film according to the preset shape and size; (4) UV glazing: painting UV gloss oil on the surface of the obtained magnetic strip so as to form a layer of protective film on the surface of the magnetic strip; and (5) magnetization: putting the magnetic strip into a magnetic field to be magnetized, thereby obtaining a finished magnetic strip. The invention also discloses a high-performance halogen-free environment-friendly rubber-plastic NdFeB extruded magnetic strip prepared by the method. The invention can be widely used for manufacturing flexible rubber-plastic magnetic products.

Owner:广东高鑫信息股份有限公司 +1

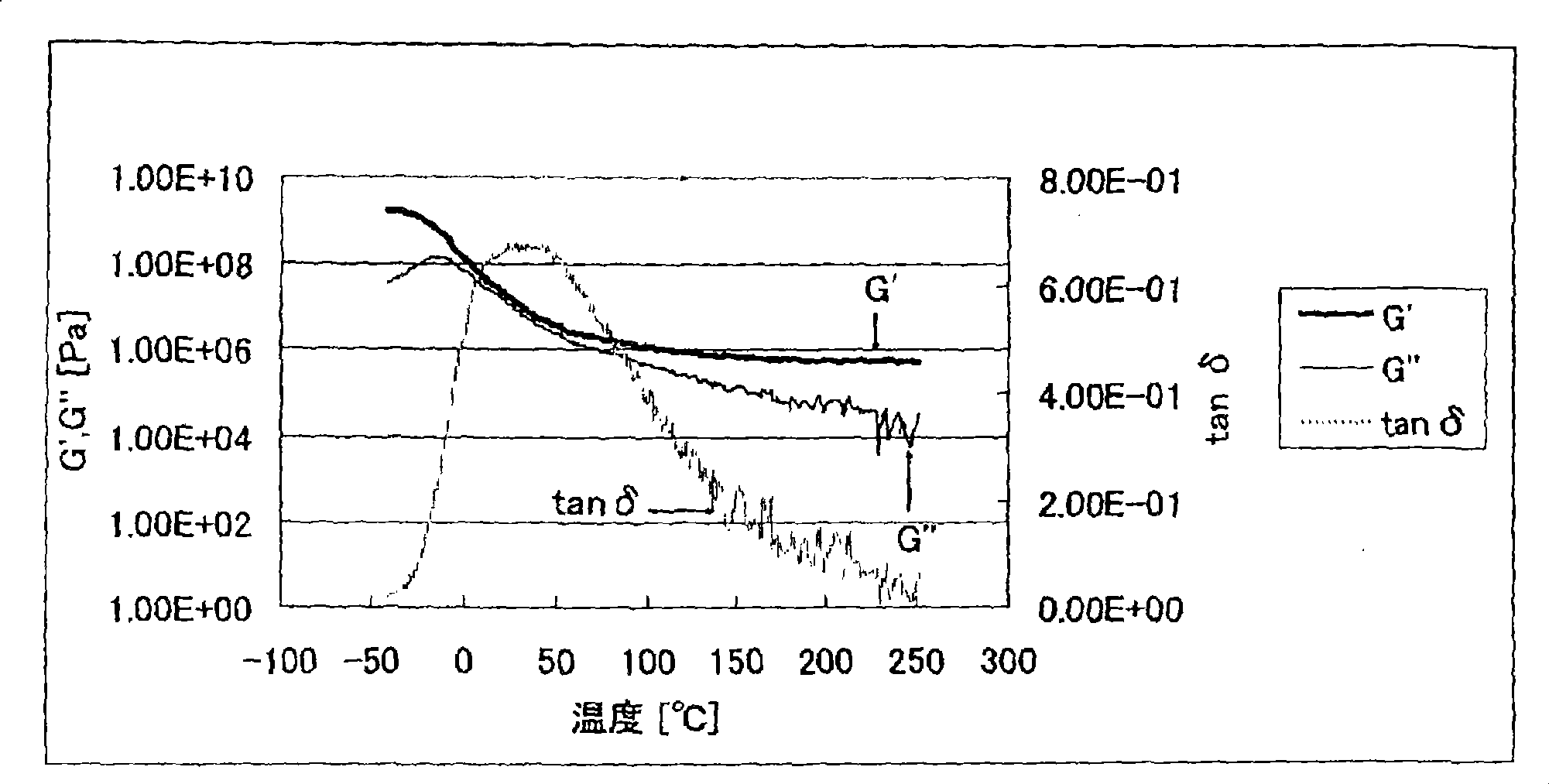

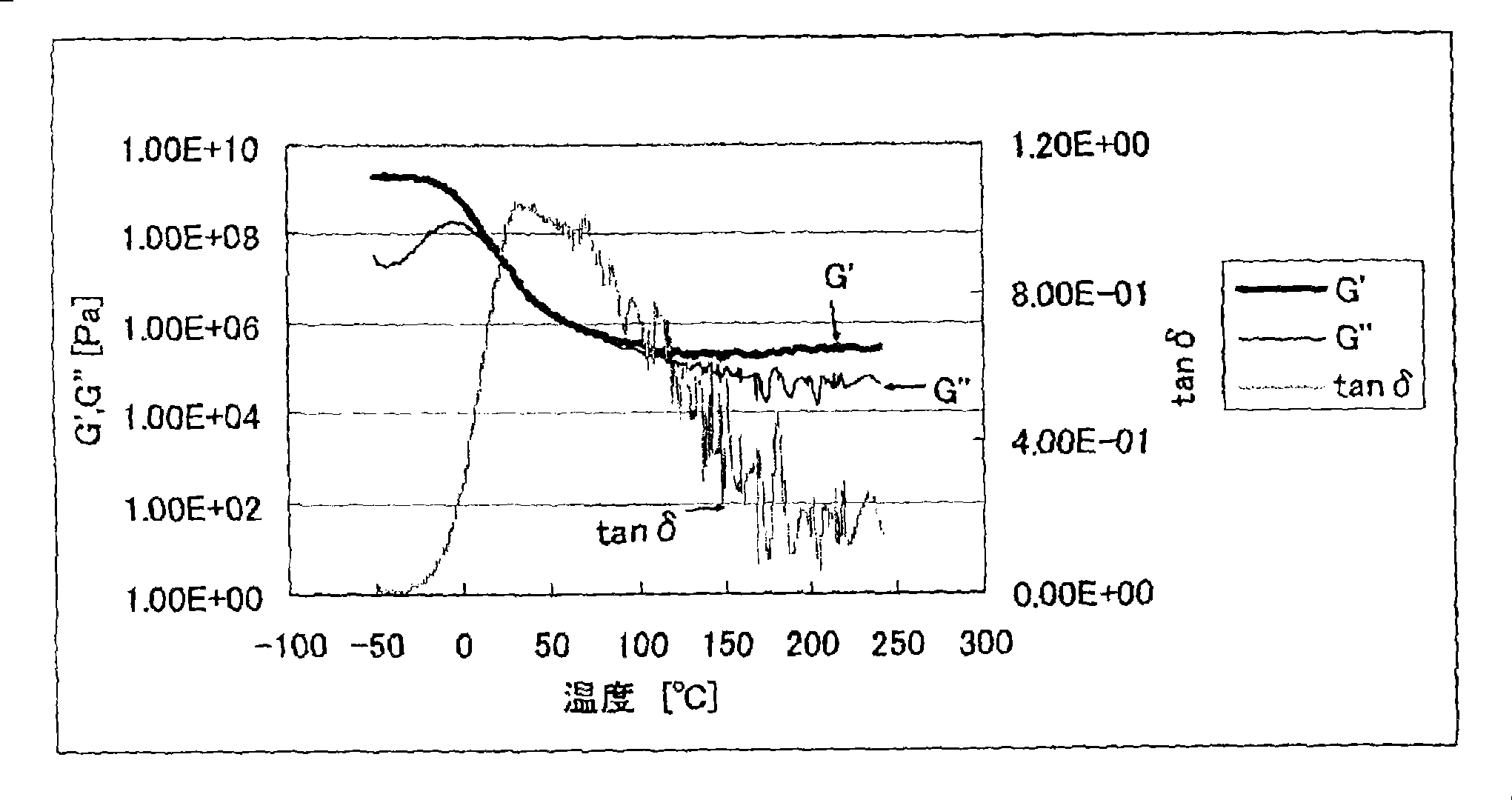

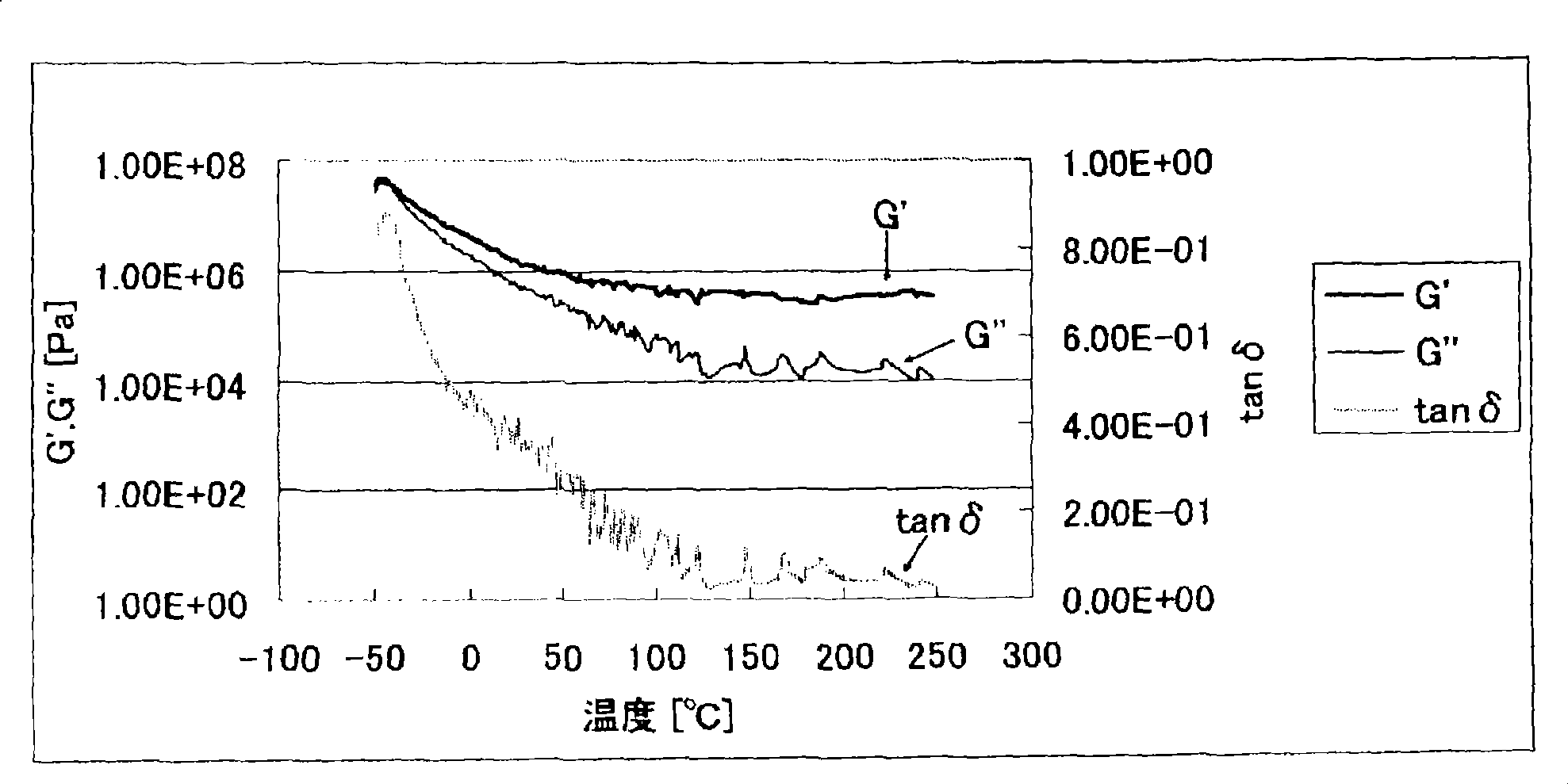

Thermosetting polyimide resin composition and cured product thereof

Owner:MITSUBISHI GAS CHEM CO INC

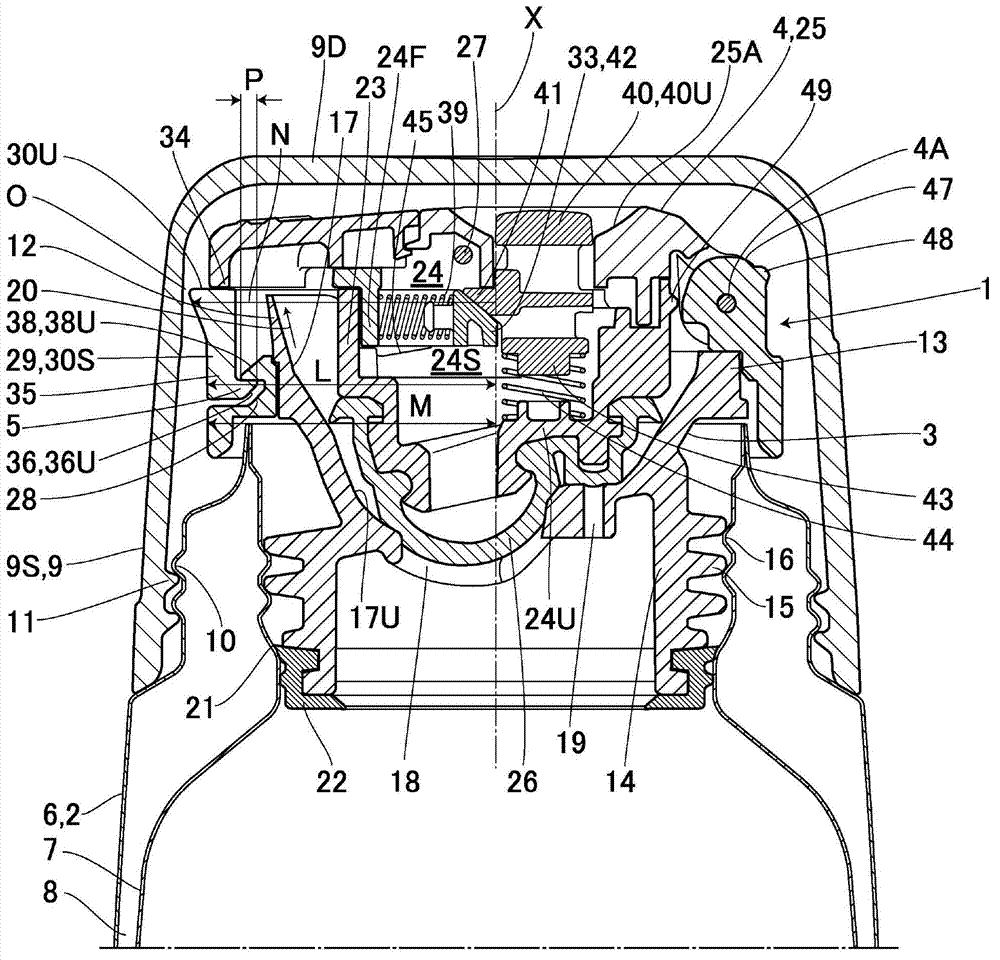

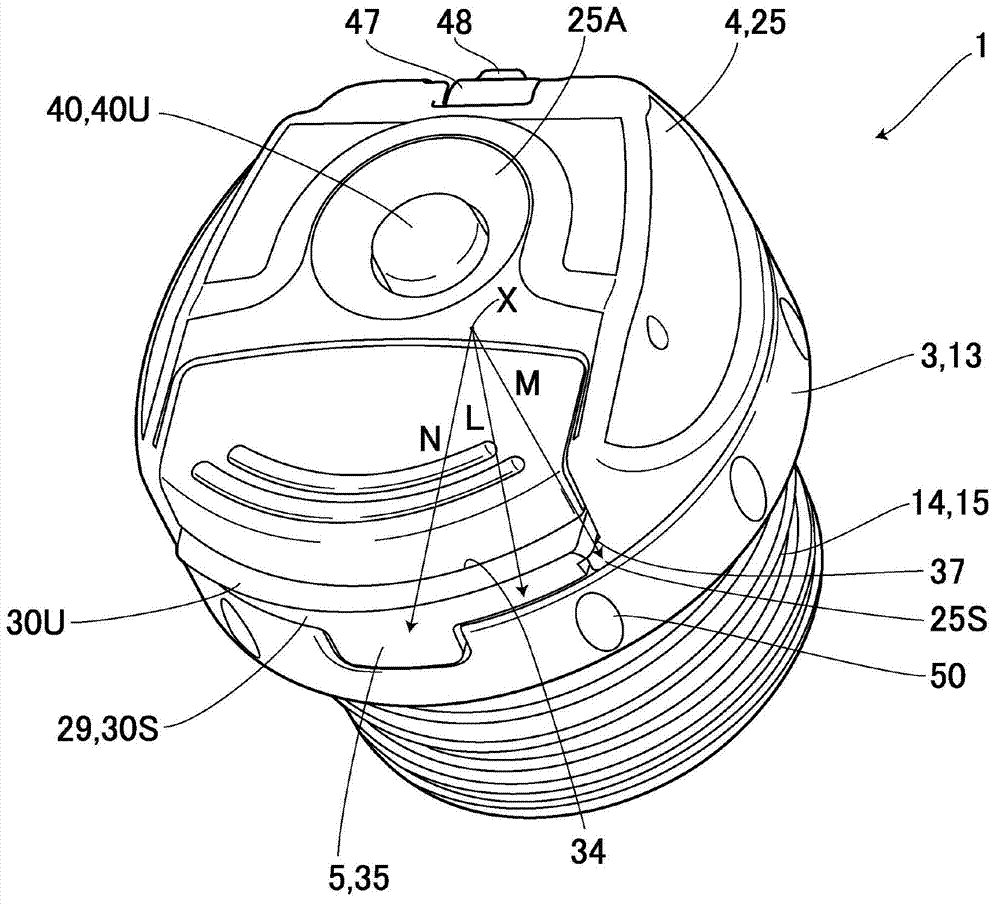

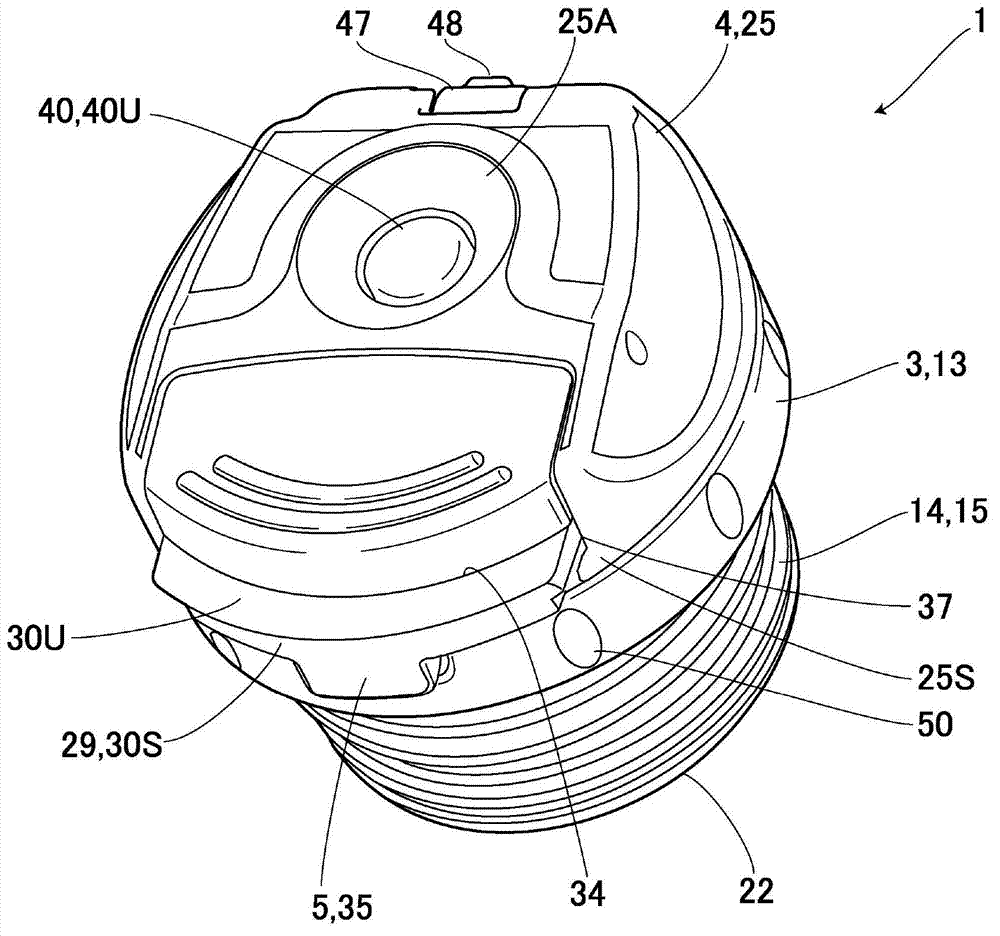

Intermediate pour stopper of portable beverage container

ActiveCN103086059AGood visual confirmationAccurateClosuresVenting meansEngineeringMechanical engineering

Owner:THERMOS CHINA HOUSEWARES +1

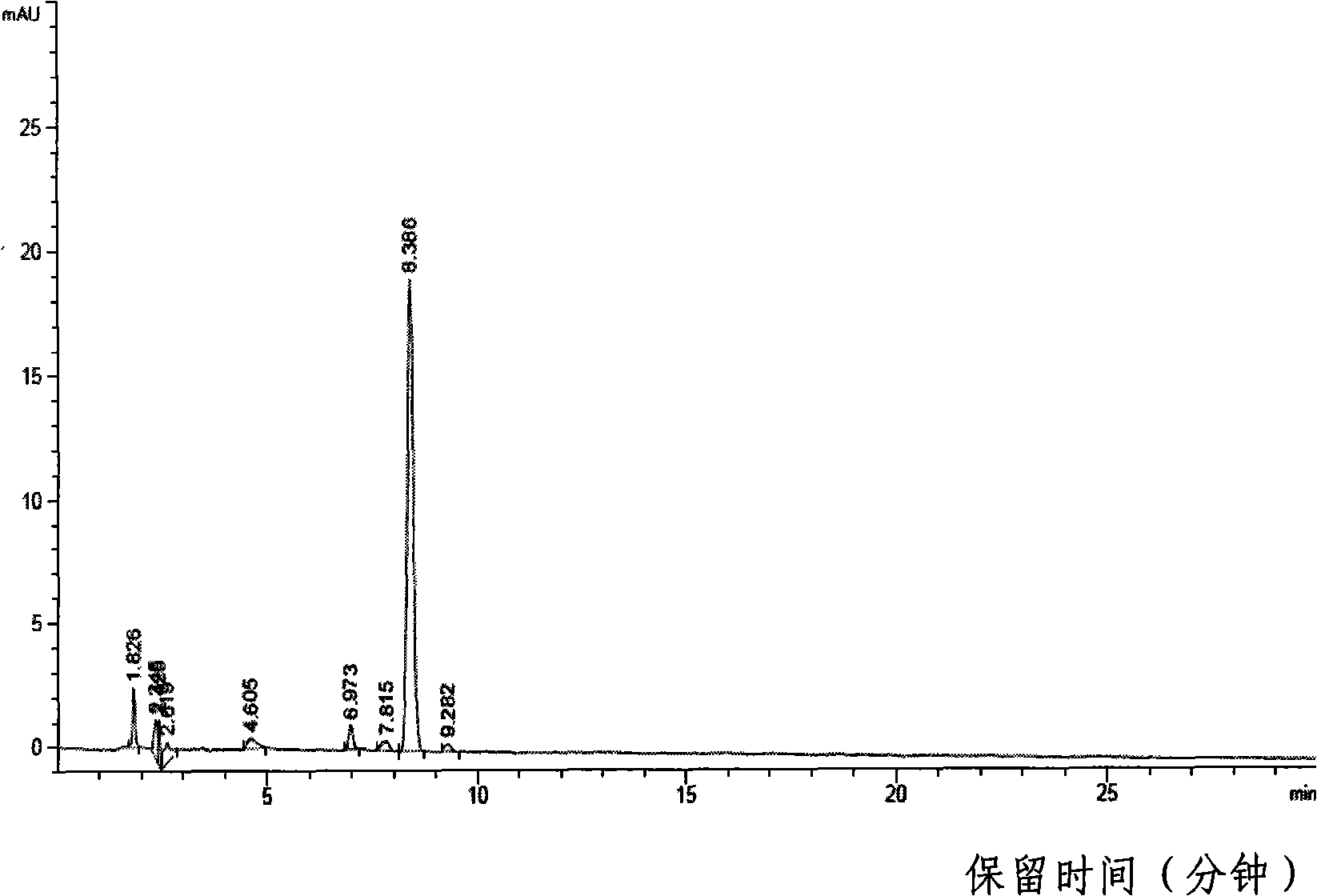

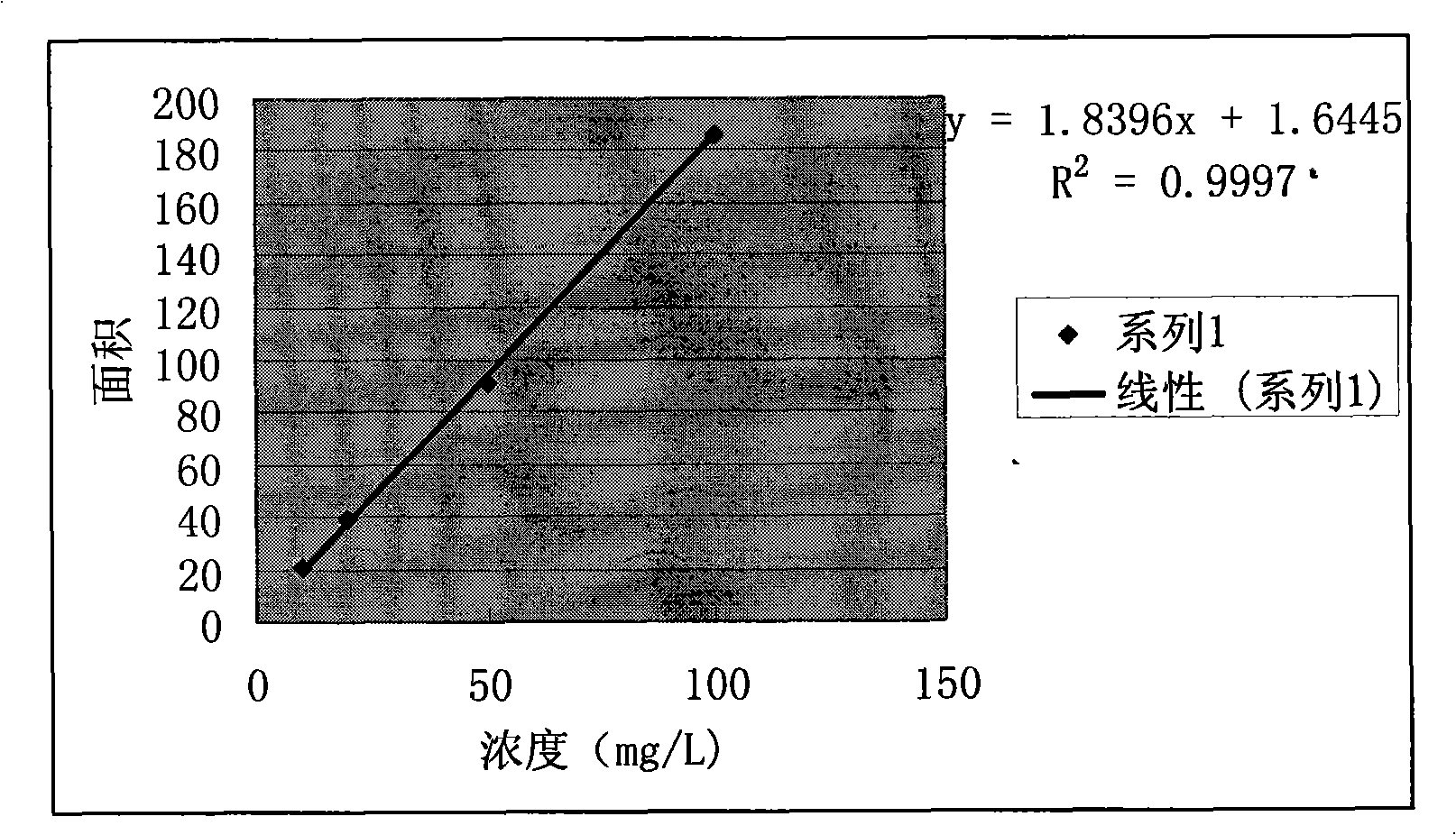

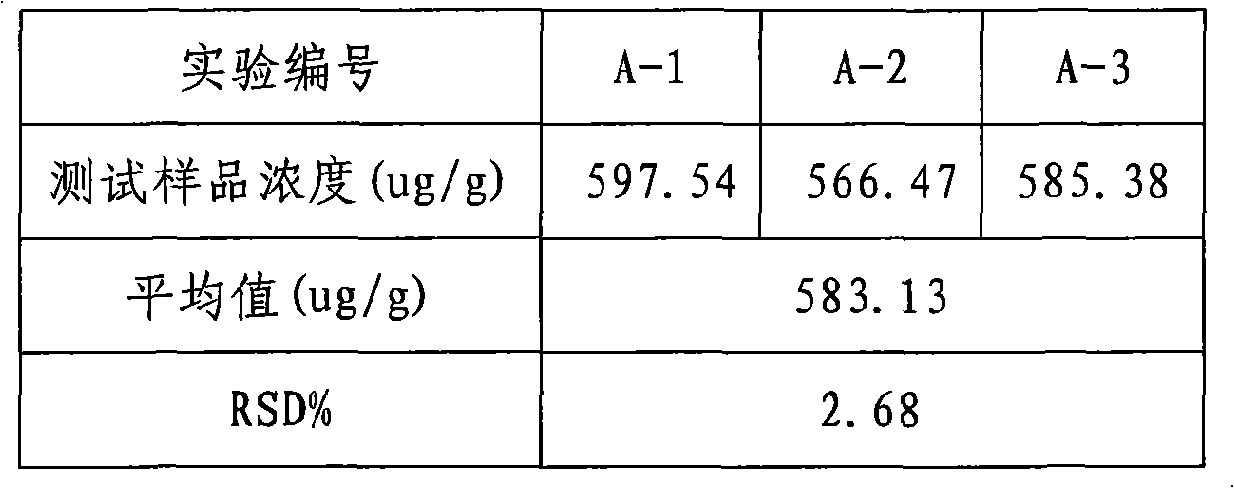

Method for detecting haloalkylphosphate by liquid phase chromatograph

InactiveCN101311721AReduce lossesSimple processing methodComponent separationInjection volumeAlkylphosphate

The invention relates to a detection method of halogenated alkyl phosphate and includes the following steps: samples are pre-treated with a Soxhlet extraction method or a supersonic extraction method; a high-performance liquid phase color spectrometer which connects diode array detectors is used for detecting the halogenated alkyl phosphate, and the proportions of the organic flow phases of the spectrometer are set from 50 to 100 percent, and the proportions of the inorganic flow phases are set from 0 to 50 percent, and the flow rates are set from 0.5 to 1.0ml per minute and the injection volume is set from 10 to 40ul and an anti-phase chromatographic column is selected as the chromatographic column; the samples pre-treated are brought into the chromatographic column by the flow phases of the high performance liquid phase color spectrometer, and the temperature of a column temperature box is set from 20 to 40 DEG C and components of the samples are separated from the chromatographic column; the components of the samples separated by the chromatographic column enter the diode array detectors to be detected. The detection method of the invention can prevent the samples from decomposing and is accurate and secure in analysis method.

Owner:CENT TESTING INT GRP CO LTD

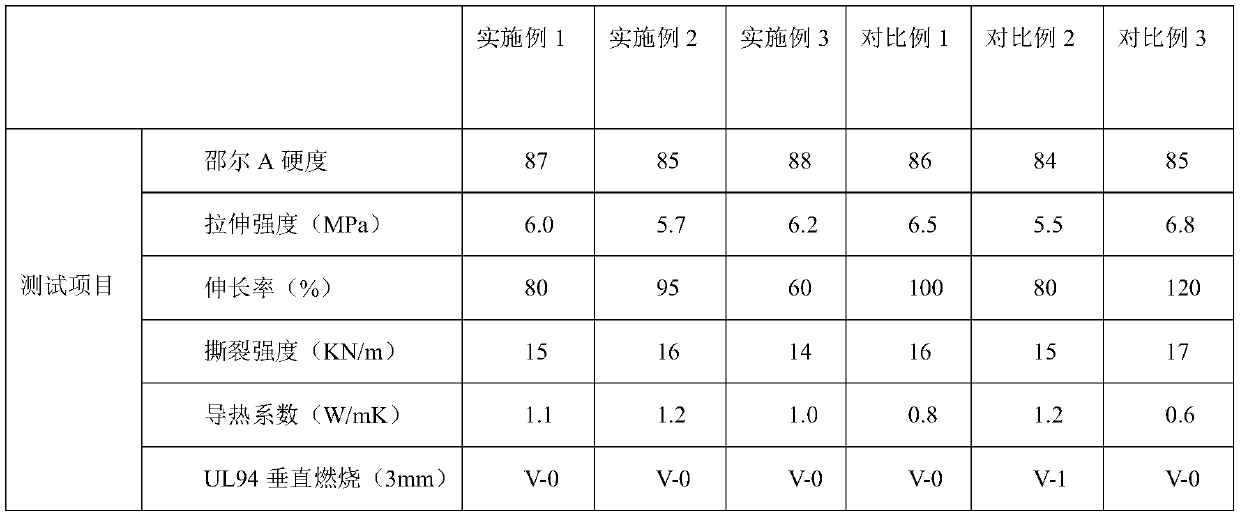

Silicone rubber for heat-conduction silicone sheet and preparation method of silicone rubber

InactiveCN109777114AImprove thermal conductivityImprove flame retardant performancePolymer scienceSilanes

The invention discloses silicone rubber for a heat-conduction silicone sheet. The silicone rubber for the heat-conduction silicone sheet specifically comprises the following raw materials: methyl vinyl raw silicone rubber, white carbon black, superconductive acetylene carbon black, silicon carbide, hydroxyl silicone oil, zinc stearate, vinyl trimethoxy silane, hydrogen-containing silicone oil andalcohol modified chloroplatinic acid catalyst. According to the invention, by reasonably designing the combination of the raw materials and the use amount and proportion, the product has excellent heat conductivity and flame retardance. A preparation method of the silicone rubber has simple production process, the quality is easy to control, and the silicone rubber is non-toxic and odorless at a normal temperature, has excellent mechanical property, can be processed into various molded products, and is suitable for being produced on a large scale.

Owner:GUANGDONG POLYSIL TECH CO LTD

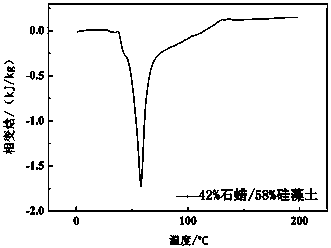

Preparation method of diatomite and paraffin composite phase change material

InactiveCN104194732ASimple preparation processLow costHeat-exchange elementsParaffin oilsPhase change

The invention relates to a preparation method of a diatomite and paraffin composite phase change material. The preparation method comprises the following steps: dissolving a phase change material paraffin in petroleum ether in a water domain at a certain temperature and stirring; then, adding a carrier diatomite with nanoscale porous structures, and continuously stirring, so that the porous structures of diatomite can be fully contacted with the phase change material to adsorb sufficient paraffin; and then, raising the temperature of the water domain to 75 DEG C, evaporating the solvent petroleum ether, then condensing and recovering the solvent petroleum ether and drying to obtain a powder composite energy storage material. The composite phase change material provided by the invention is not changed in shape in the phase change process, and paraffin is not leaked. Moreover, the composite phase change material is simple in preparation process, low in cost and energy-saving and environmentally friendly, and the solvent can be recycled.

Owner:TAIYUAN UNIV OF TECH

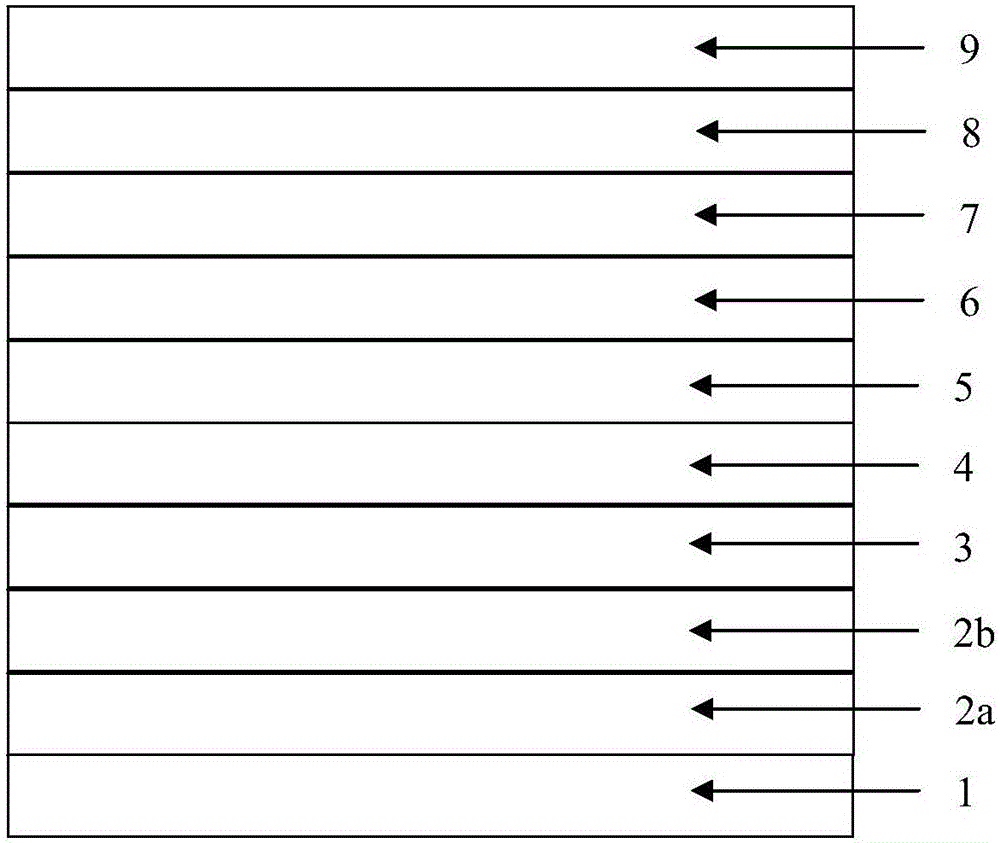

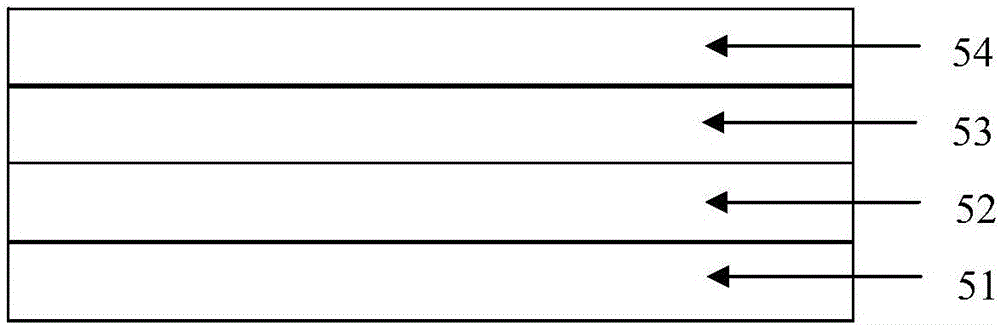

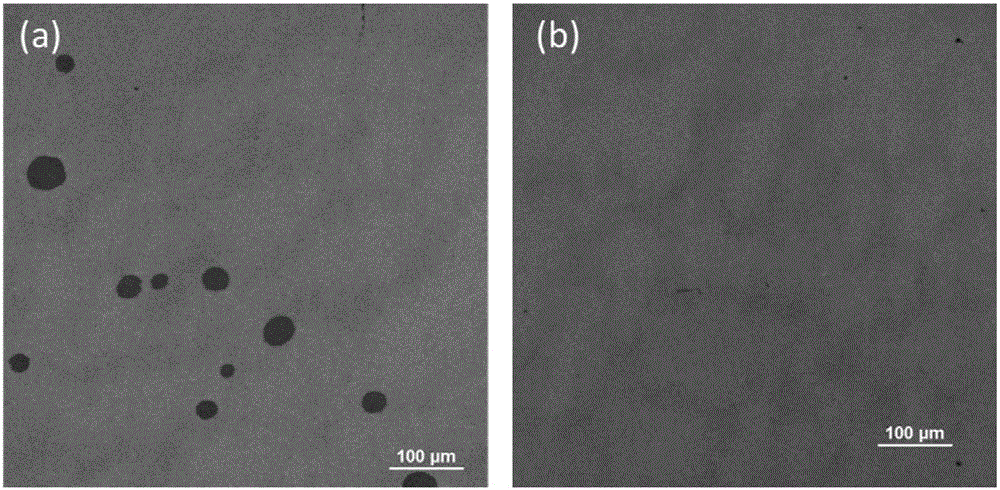

InGaN/GaN quantum well laser and manufacturing method thereof

ActiveCN106785919AEvenly distributedQuality improvementLaser detailsSemiconductor lasersOhmic contactLayer thickness

The invention discloses an InGaN / GaN quantum well laser, comprising a substrate and the following components sequentially arranged on the substrate: a low temperature GaN buffer layer, a high temperature n-type GaN layer and an n-type AlGaN light confinement layer; an n-type InGaN lower waveguide layer on the n-type AlGaN light confinement layer; an InGaN / GaN quantum well active region on the n-type InGaN lower waveguide layer; a u-type InGaN upper waveguide layer on the InGaN / GaN quantum well active region; a p-type AlGaN electron barrier layer on the u-type InGaN upper waveguide layer; a p-type AlGaN / GaN light confinement layer on the p-type AlGaN electron barrier layer; and a p-type GaN ohmic contact layer on the p-type AlGaN / GaN light confinement layer. The invention also discloses a manufacturing method for the InGaN / GaN quantum well laser. The invention adopts the InxGa1-XN of 1 to 2 single-atom layer thickness to be inserted into the cap layer so that the two-dimensional island-like surface of the InGaN quantum well surface becomes smooth, that the distribution of the In group becomes more uniform and that the subsequently formed GaN cap layer has a better quality in which the InGaN quantum well is not decomposed during the temperature rise and does not undergo thermal degradation during the subsequent high temperature growth of the p-type AlGaN / GaN light confinement layer.

Owner:杭州增益光电科技有限公司

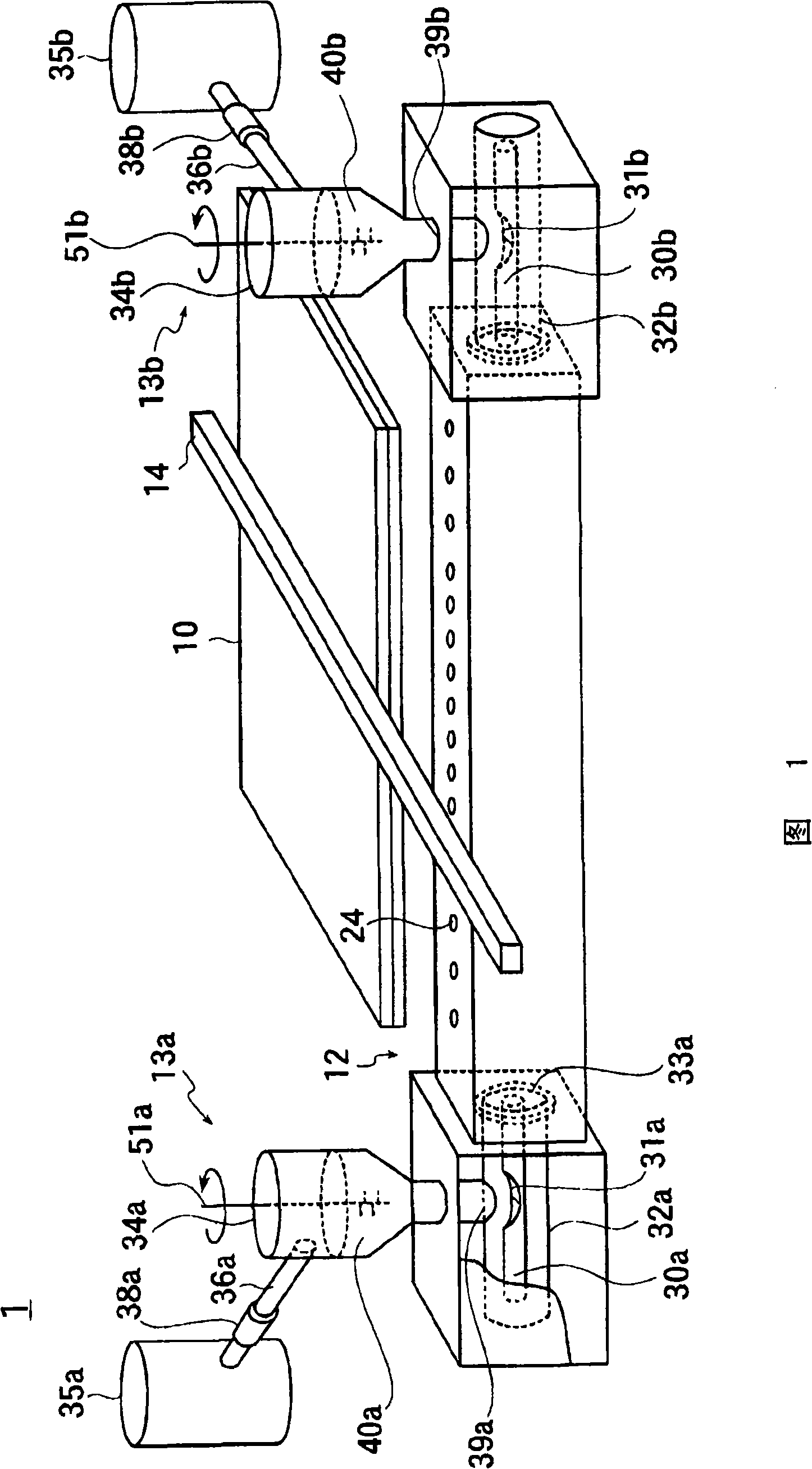

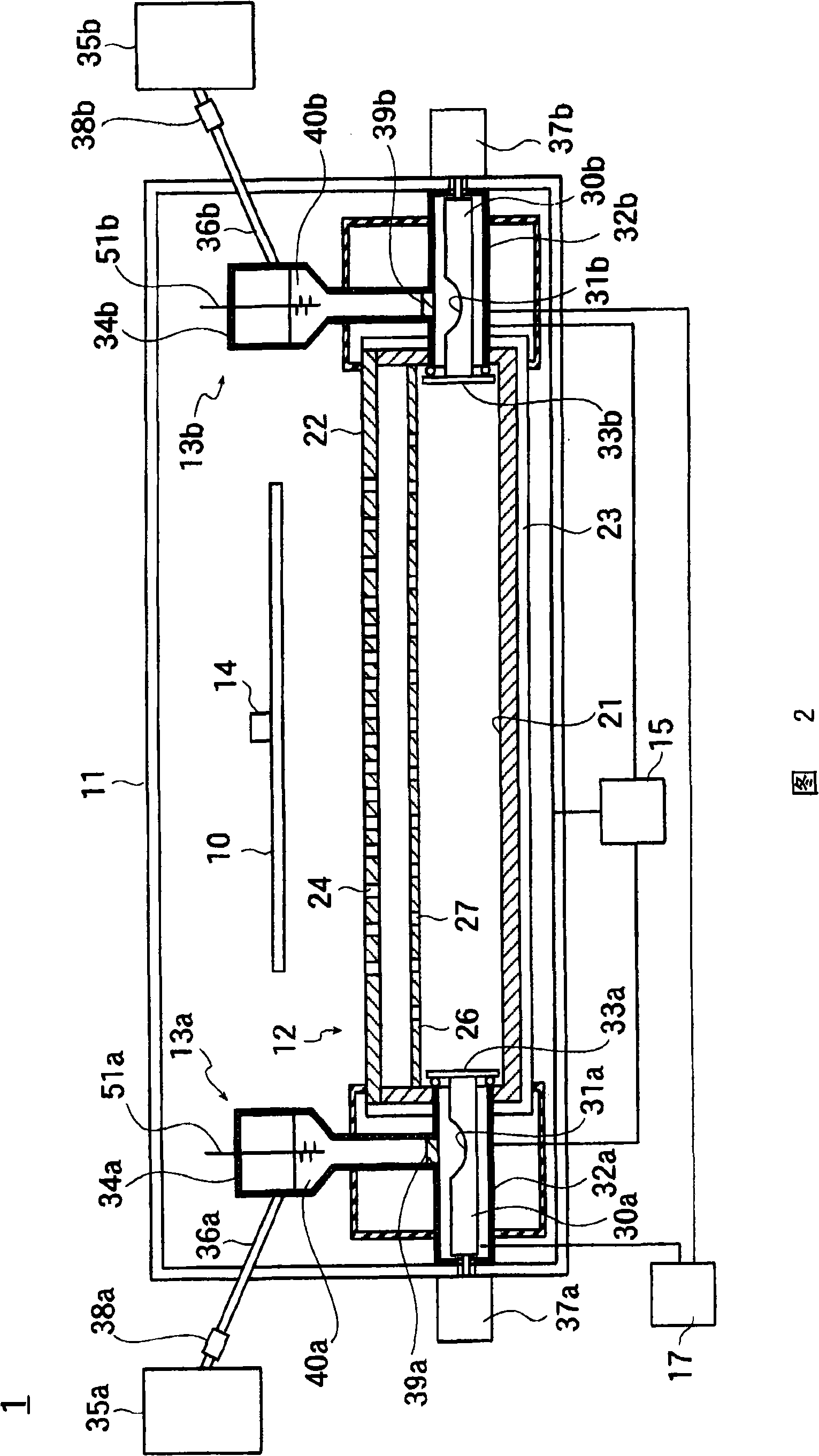

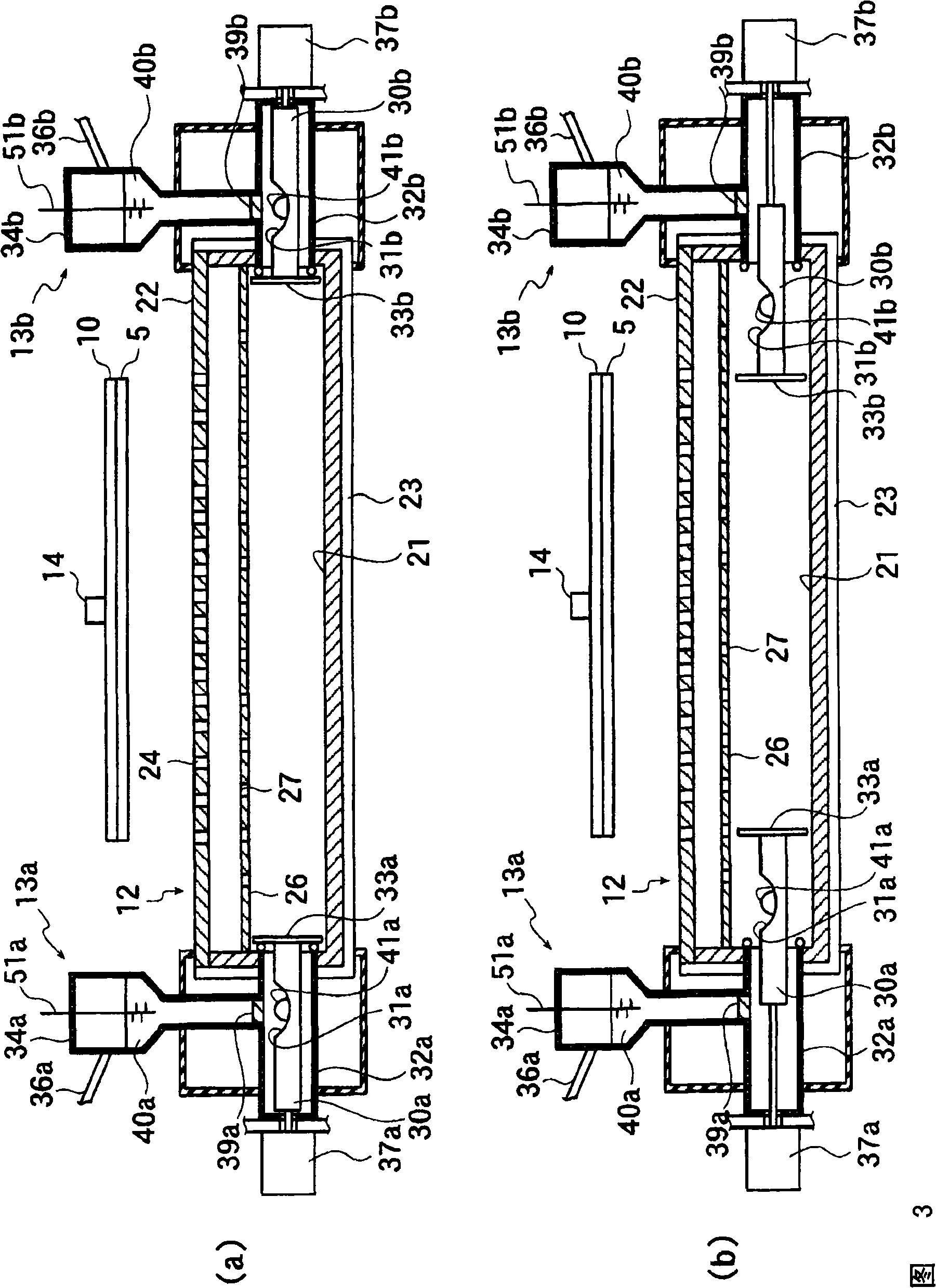

Vapor deposition apparatus for organic vapor deposition material and process for producing organic thin film

ActiveCN101356296AWon't decomposeWon't spoilElectroluminescent light sourcesSolid-state devicesDecompositionOrganic compound

The present invention provides a vapor deposition apparatus in which an organic vapor deposition material undergoes none of a compositional change, decomposition, and alteration. An organic vapor deposition material is put on a conveyor (30a) or (30b) in an amount corresponding to one substrate and introduced into a vapor deposition vessel (12) heated beforehand. The organic vapor deposition material is heated little by little for each substrate and disappears while emitting an organic-material vapor. Hence, the time period during which the material is being heated is short and the material is prevented from being decomposed or altered by water. Even when different organic compounds have been mixed, the mixture does not change in composition. Consequently, an organic vapor deposition material obtained by mixing a base material with a color former can be stored in a storage tank (34a) or (34b) and then put on the conveyor (30a) or (30b).

Owner:ULVAC INC

Method for extracting oil sample inside hydrocarbon inclusion in groups

The invention discloses a method for extracting an oil sample inside hydrocarbon inclusion in groups, which is applied to oil field reservoir stratum rock analysis. The method comprises the steps of washing tools, manufacturing and preparing a rock sample and extracting oil samples from the hydrocarbon inclusions of same period and particularly comprises the steps of: grinding the rock sample into a rock polished sheet with polished double surface and the thickness of 0.2-0.5cm and washing clean; fixing the rock polished sheet in a sample chamber, and adding a mixture liquid of chloroform and methanol into the sample chamber; and drilling up 90-300 hydrocarbon inclusions of the same period under a 35cm focal length objective lens, dissolving the oil in the hydrocarbon inclusions by the mixture liquid of the chloroform and the methanol and completing the oil sample extraction inside the hydrocarbon inclusions of the same period. Tests prove that the invention can satisfy the analysis magnitude of a chromaticness chromatograph, respectively extract the components of the hydrocarbon inclusions of different periods for testing, avoid the phenomenon of union dying of the hydrocarbon inclusions of different periods and guarantee no component loss and no decomposition of the hydrocarbon inclusions in the process of extraction, and has no requirements on the sizes of the hydrocarbon inclusions.

Owner:PETROCHINA CO LTD

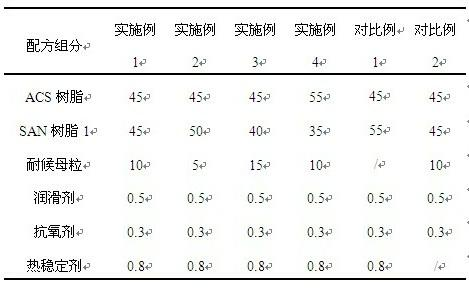

Acrylonitrile-chlorinated polyethylene-styrene resin composition and preparation method of acrylonitrile-chlorinated polyethylene-styrene resin composition

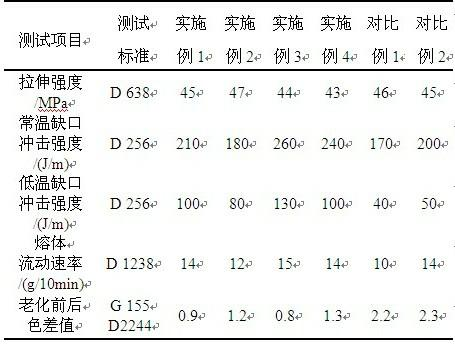

The invention discloses an acrylonitrile-chlorinated polyethylene-styrene resin composition and a preparation method of the acrylonitrile-chlorinated polyethylene-styrene resin composition. The composition comprises the following components in part by weight: 30 to 60 parts of acrylonitrile-chlorinated polyethylene-styrene grafting powder, 30 to 50 parts of SAN resin 1, 5 to 15 parts of weather resistance master batch, 0.3 to 3 parts of lubricant, 0.05 to 0.5 part of antioxidant and 0.5 to 1.5 parts of heat stabilizer. The composition is prepared by stirring and mixing the components except for the weather resistance master batch, adding the mixture from a main feed inlet of a double screw extrusion machine, adding the weather resistance master batch from a side feed inlet of the double screw extrusion machine and carrying out extrusion and granulation to obtain a sample. The obtained composition has excellent weather resistance, high low-temperature impact property and good antistatic property, size stability and processing property and is particularly suitable for the field of electrons, electrical appliances, communication, instruments, building materials, decorative materials,automobile parts and the like with high requirements on weather resistance, impact resistance and surface antistatic property.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

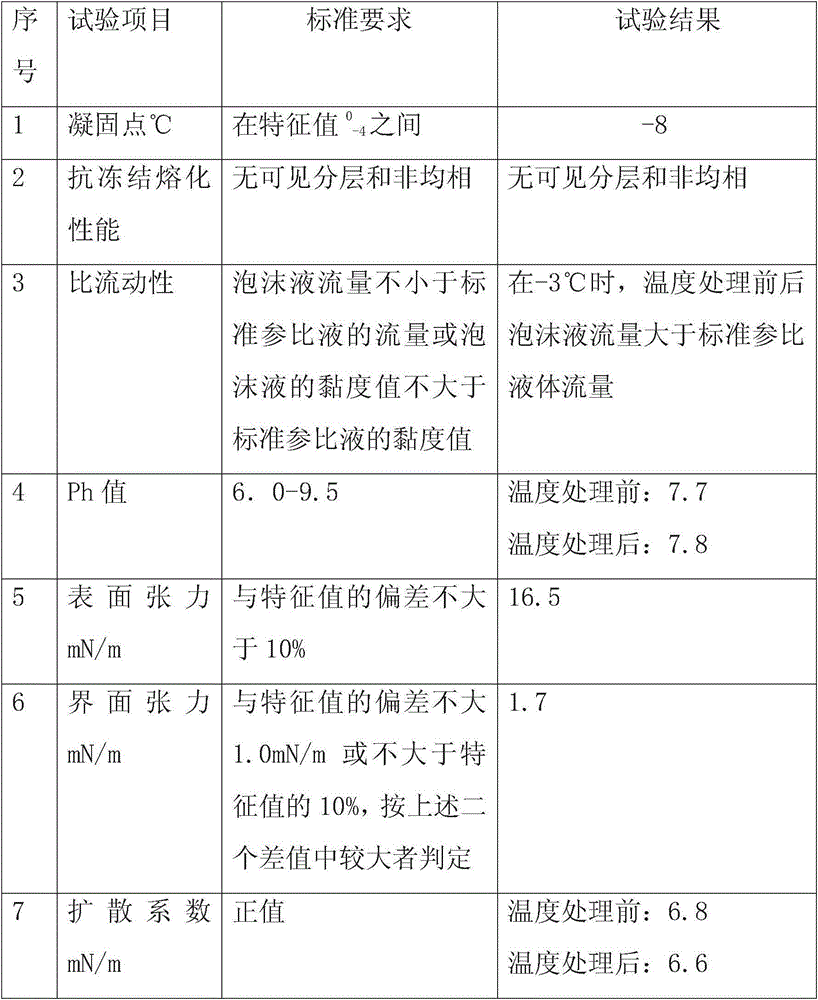

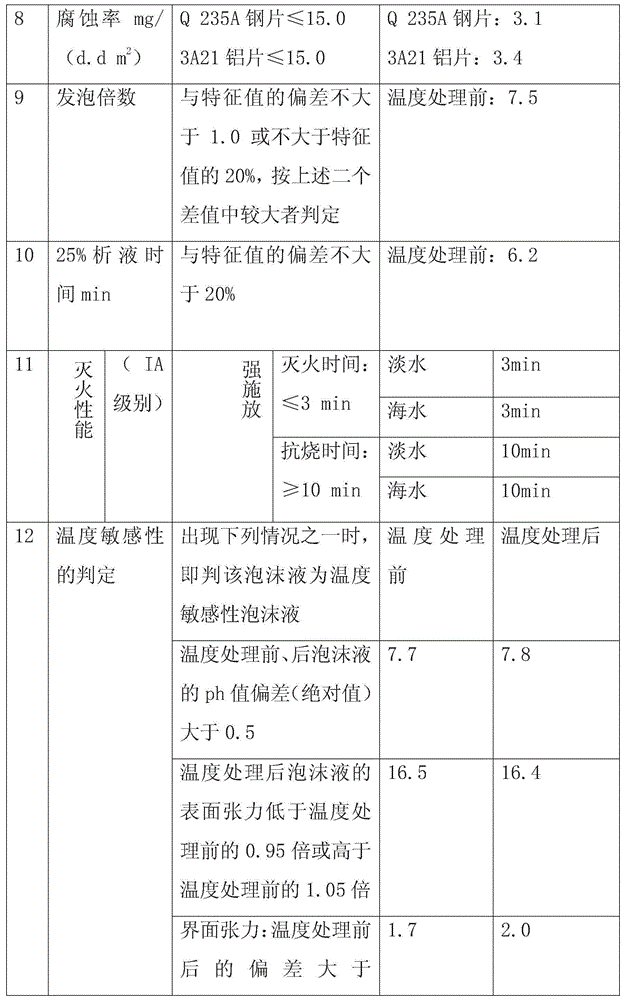

Foam extinguishing agent

The invention discloses a foam extinguishing agent. The foam extinguishing agent is composed of, by mass, 1-3% of perfluorinated betaine, 3-8% of fluorinated alkyl betaine, 1-5% of urea, 5-15% of Sodium alpha olefin sulfonate, 10-15% of lauryl sodium sulfate, 10-16% of alkyl polyglucoside (1412) and the balance water. The invention further discloses application of the foam extinguishing agent. The thickness and the stability of films generated by the foam extinguishing agent are high, the extinguishing speed is high, and the extinguishing effect is good.

Owner:厦门安港消防科技有限公司

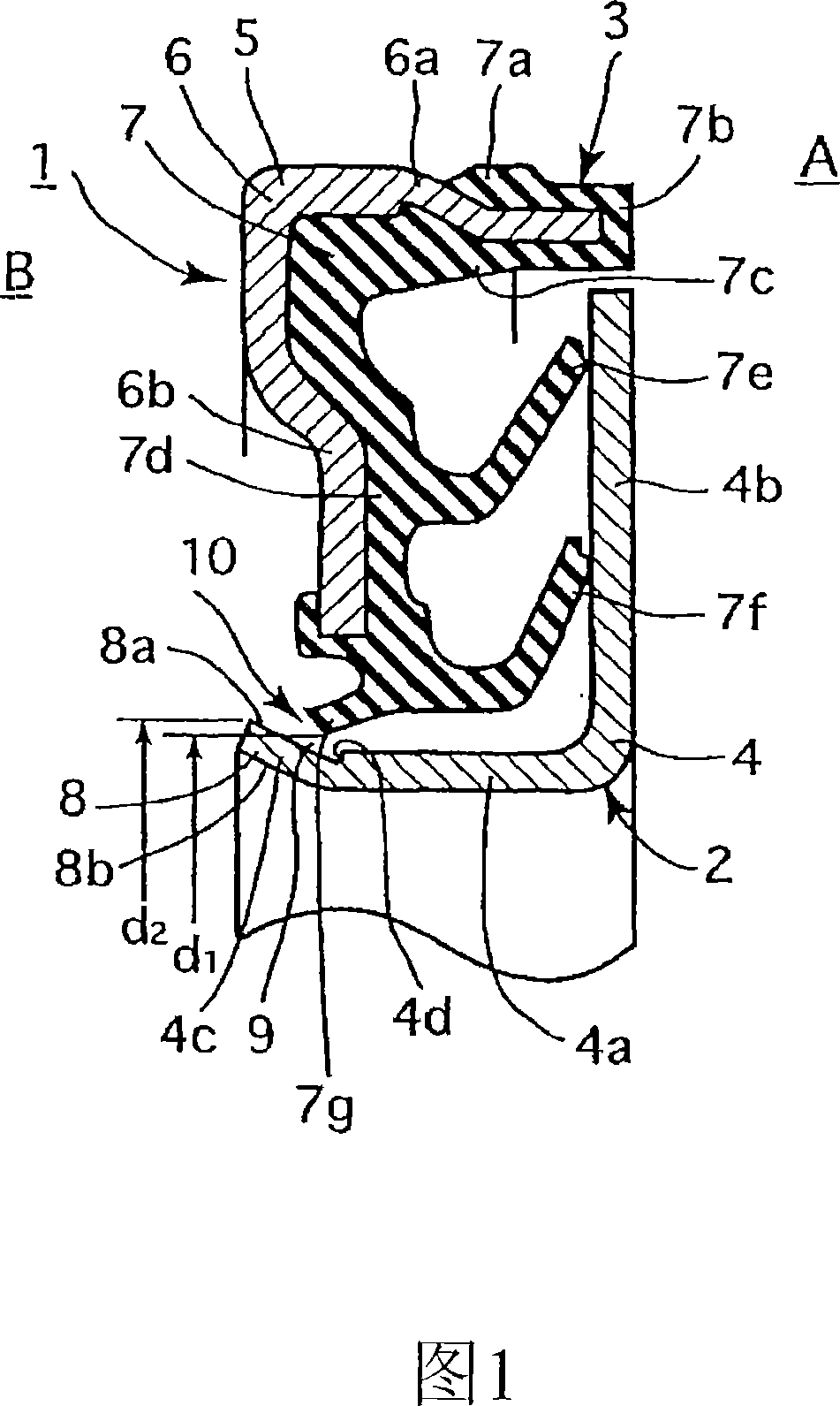

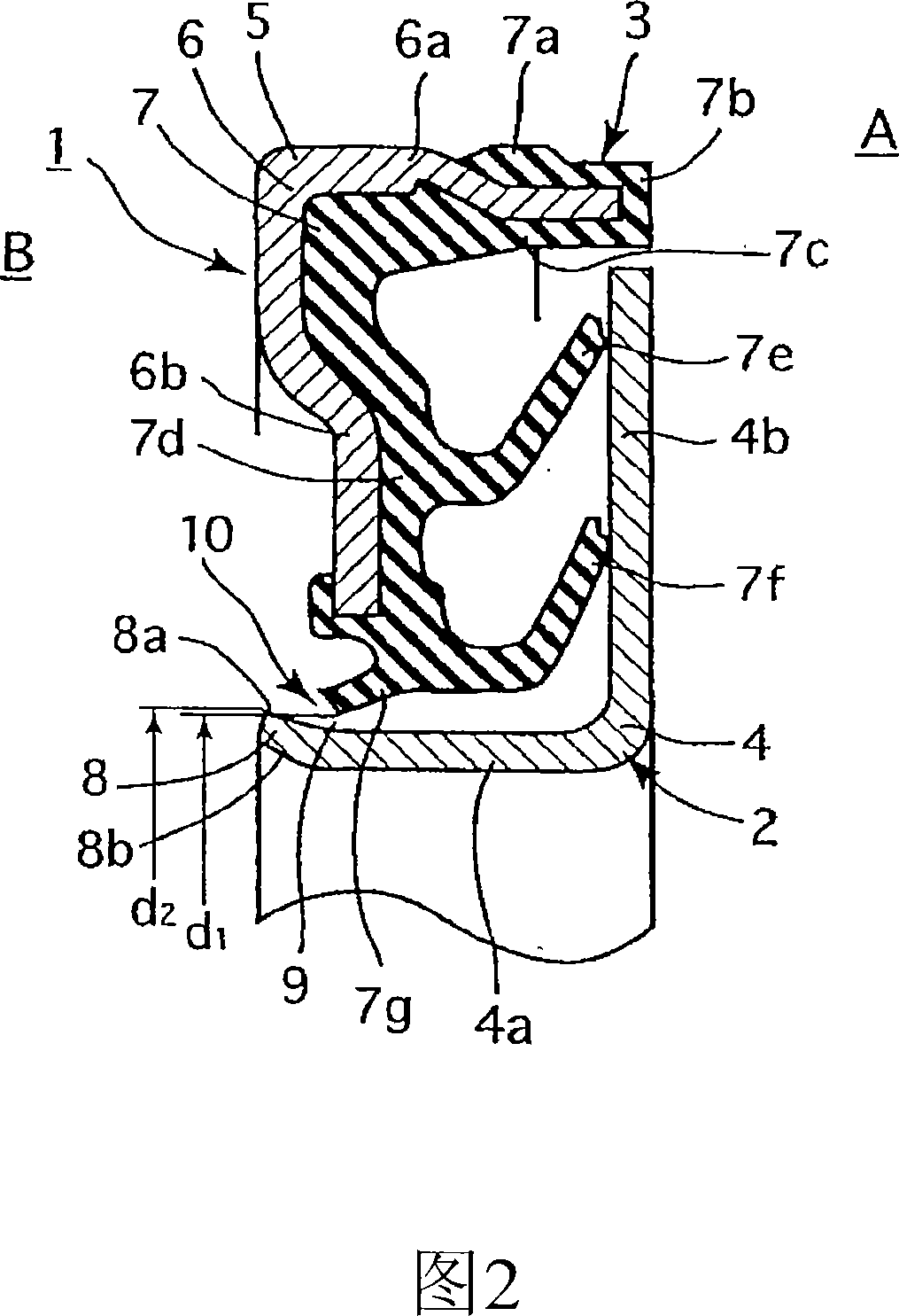

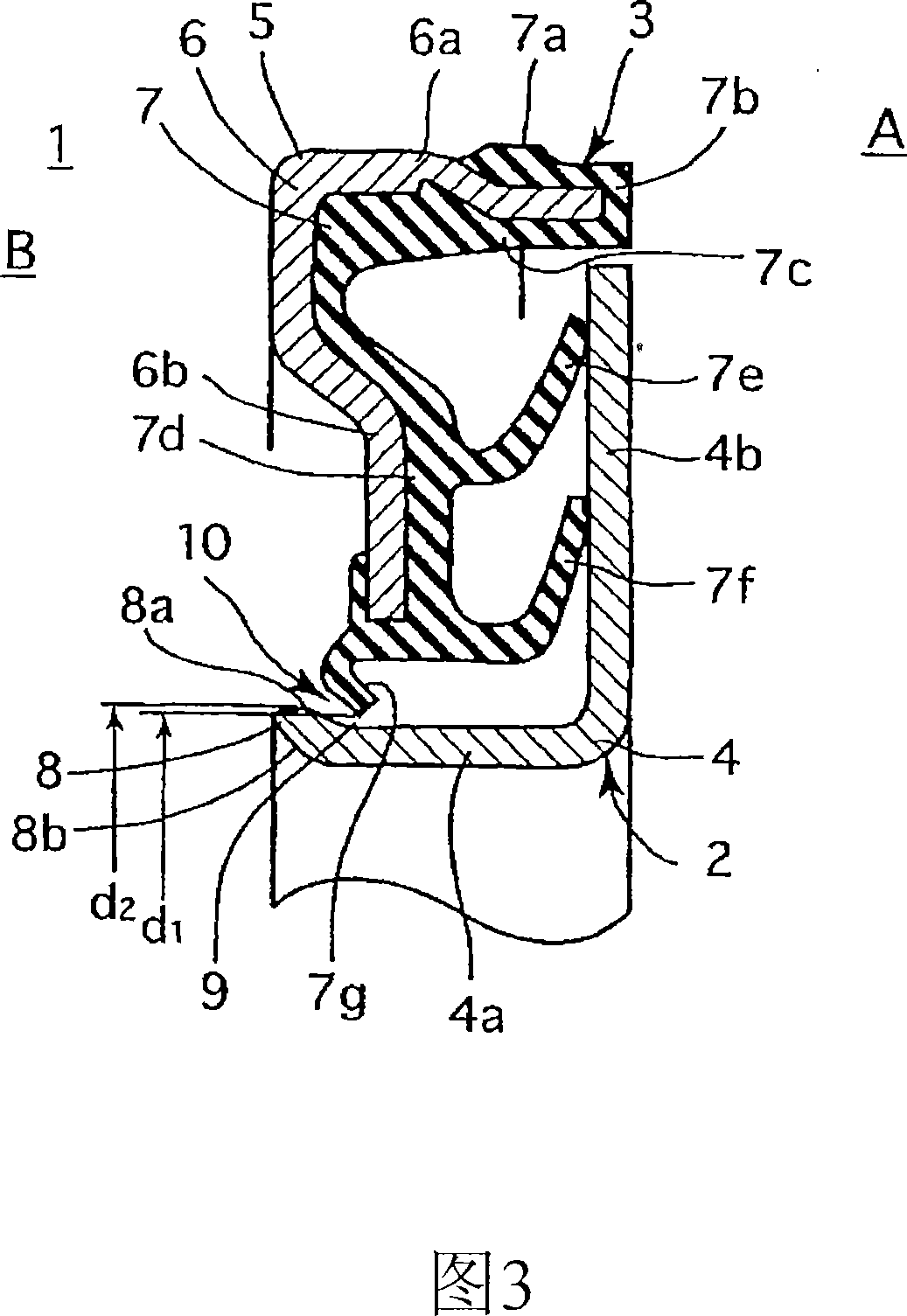

Sealing device

InactiveCN101208550AImprove mud and water resistanceSuppression of increase in slip torqueEngine sealsBearing assemblyEngineeringLip seal

A sealing device (1) formed by combining an inner peripheral sealing member (2) and an outer peripheral sealing member (3), where the inner peripheral sealing member (2) such as a slinger member is prevented from falling out in axially one direction from the outer peripheral sealing member (3) such as a lip seal member. The inner peripheral sealing member (2) has a metal ring (4) provided with a tubular section (4a) and a radially rising section (4b) integrally formed with the tubular section (4a) and extending radially outward from one end of the tubular section (4a). The outer peripheral sealing member (3) has side lips (7e, 7f) in slidable intimate contact with the radially rising section (4b) of the metal ring (4), and also has a radial lip (7g) provided without contact, on the outer peripheral side of the tubular section (4a) of the metal ring (4). The tubular section (4a) has an axial fall-out prevention section (8) having an outer diameter d 2 greater than the inner diameter d 1 of the radial lip (7g) and preventing the metal ring (4) from falling out in axially one direction from the outer peripheral sealing member (3).

Owner:NOK CORP

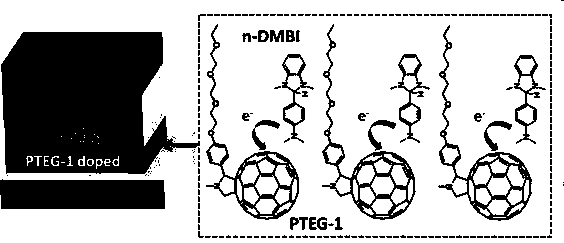

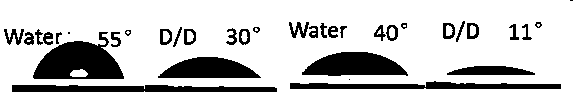

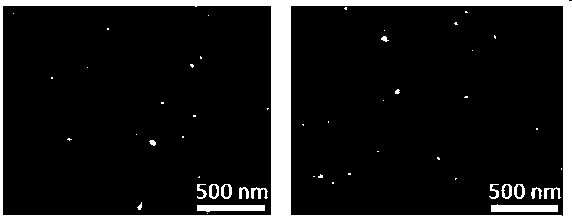

Preparation method of interface-enhanced high-light-heat-stabilized perovskite film

ActiveCN109585661AReduce defectsImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingDopantRoom temperature

The invention belongs to the technical field of photoelectric thin films, and discloses a preparation method of an interface-enhanced high-light-heat-stabilized perovskite film. The method comprises the following steps of: (1) dissolving the fullerene derivative and the N-type organic dopant in a non-polar solvent, wherein the concentration of the fullerene derivative in the non-polar solvent is 10-20 mg / mL, and by the mass percentage, the dosage of the N-type organic dopant is 1-5% of the dosage of the fullerene derivative; (2) spinning the solution obtained in the step (1) on the substrate for drying at the room temperature, and forming a fullerene derivative doped film in a self-assembling mode on the substrate; and (3) preparing a perovskite film on the fullerene derivative doped filmto obtain an interface-enhanced high-light-heat-stabilized perovskite film. The perovskite film greatly improves the film forming property and reduces the film defects, the grain size is increased, the interface-enhanced high-light-heat-stabilized perovskite film cannot be decomposed in the continuous illumination or high temperature environment, thereby greatly improving the performance of the solar cell.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com