Sealing device

A technology for sealing devices and sealing components, which is applied in the directions of engine sealing, bearing assembly, transportation and packaging, etc. It can solve the problems of no radial interference, achieve small sliding torque, excellent sealing performance, and good resistance to muddy water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

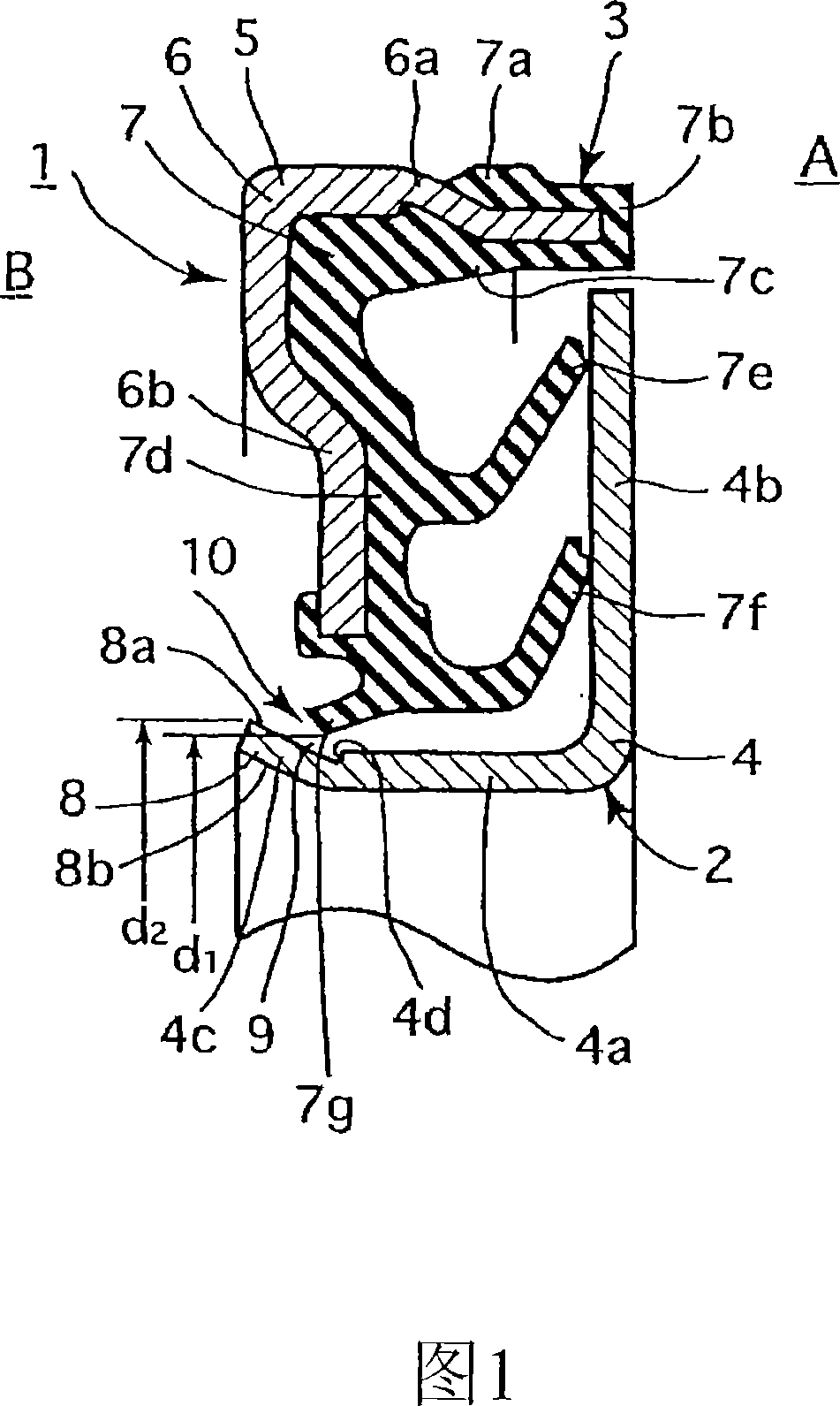

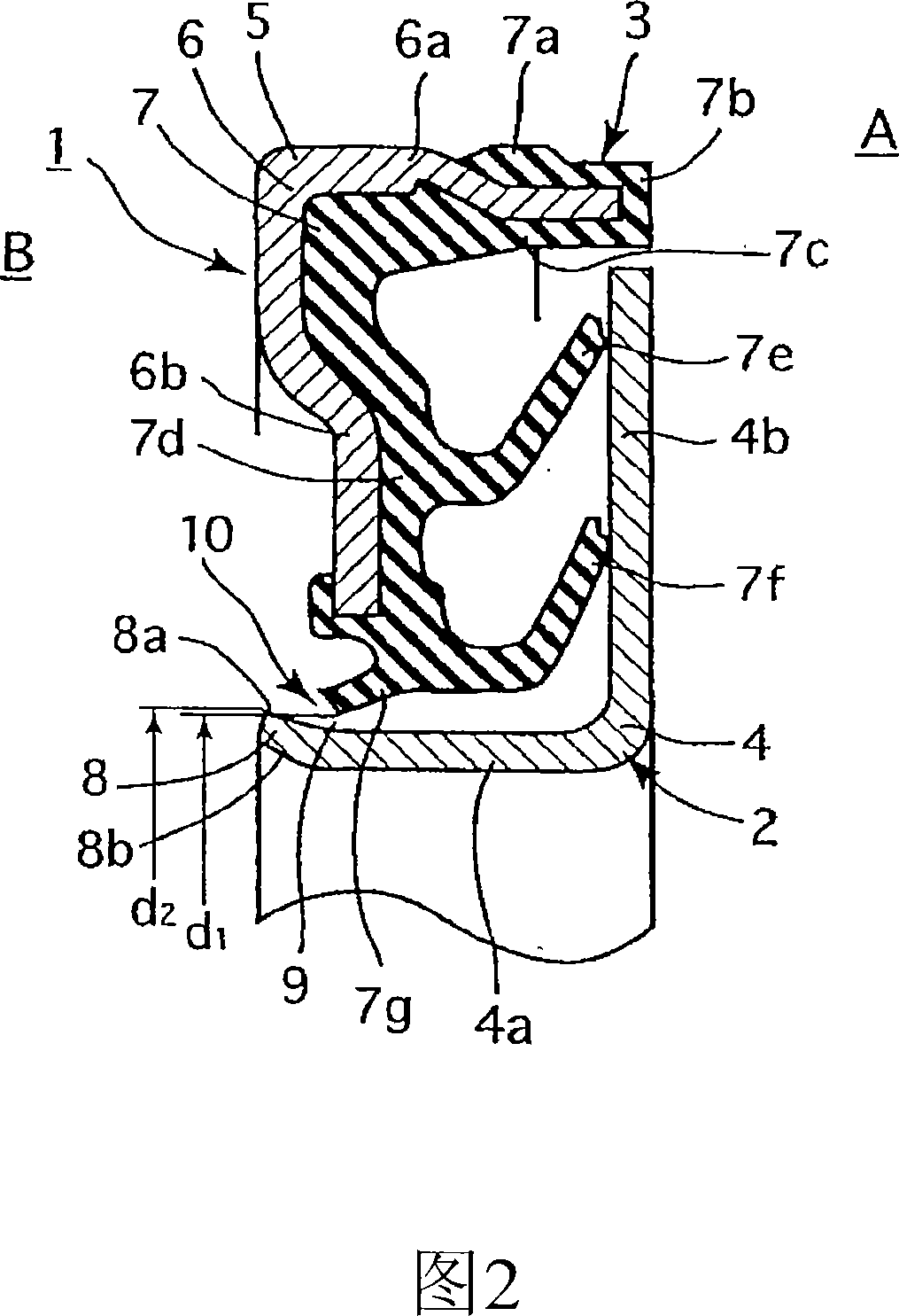

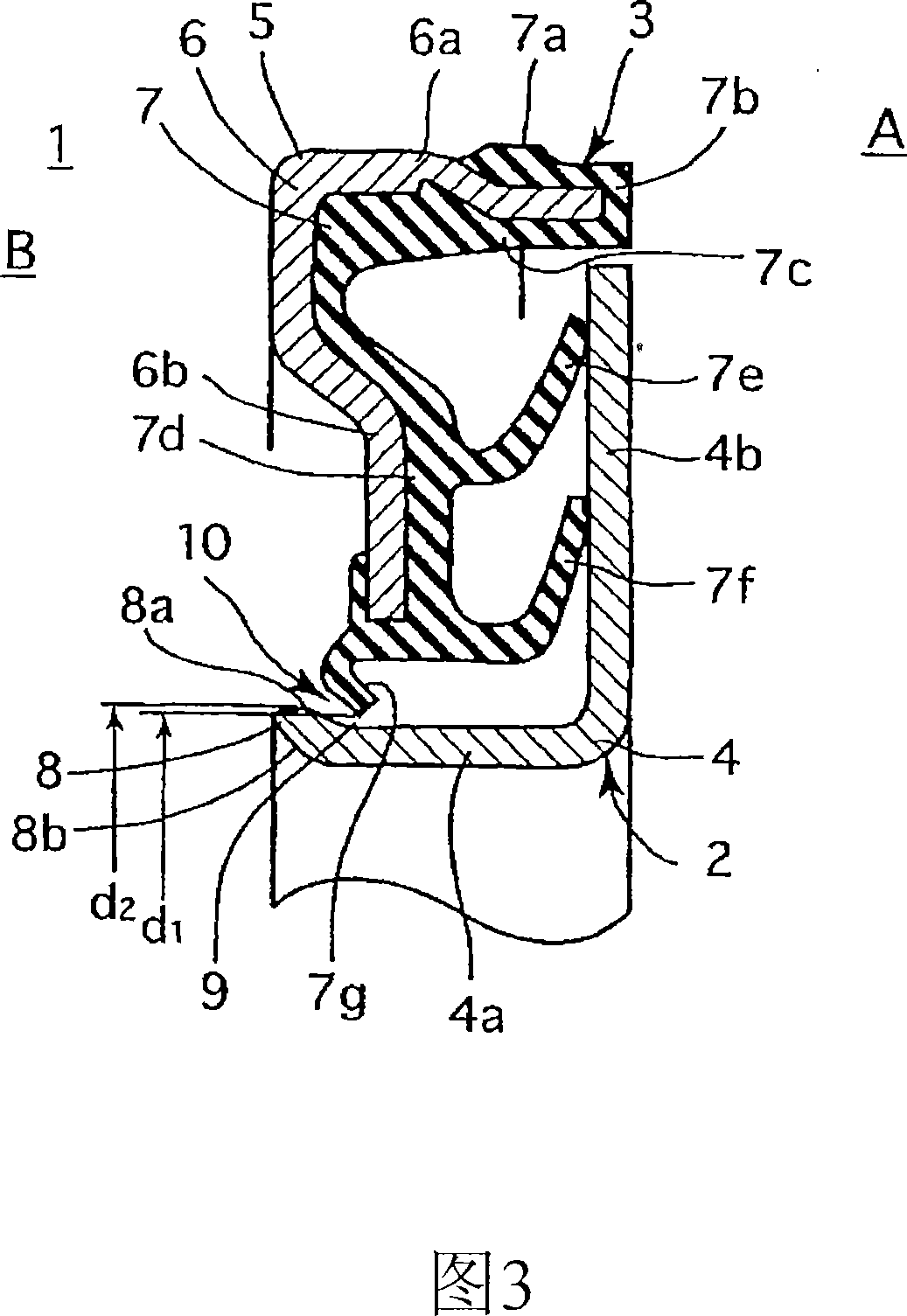

[0052] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0053]FIG. 1 shows a cross section of a main part of a sealing device 1 according to an embodiment of the present invention. The sealing device 1 of this embodiment is used as a hub bearing seal (hub seal) in the field of automobiles, and is configured as follows.

[0054] That is, first, this sealing device 1 has an inner bearing inner ring (an inner peripheral side mounting member, not shown in the figure) that is one of two members that rotate relatively, and rotates together with the inner ring of the bearing. a peripheral side seal member 2; and a non-rotatable outer peripheral side seal member 3 installed in a bearing outer ring (outer peripheral side mounting member, not shown in the figure) which is the other of the two members.

[0055] The inner peripheral side seal member 2 is composed of an oil slinger member (hereinafter simply referred to as an oil slinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com