Bearing device for wheel

A technology for wheel bearings and outer components is applied in the field of wheel bearing devices to achieve the effects of preventing grease leakage, preventing corrosion and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

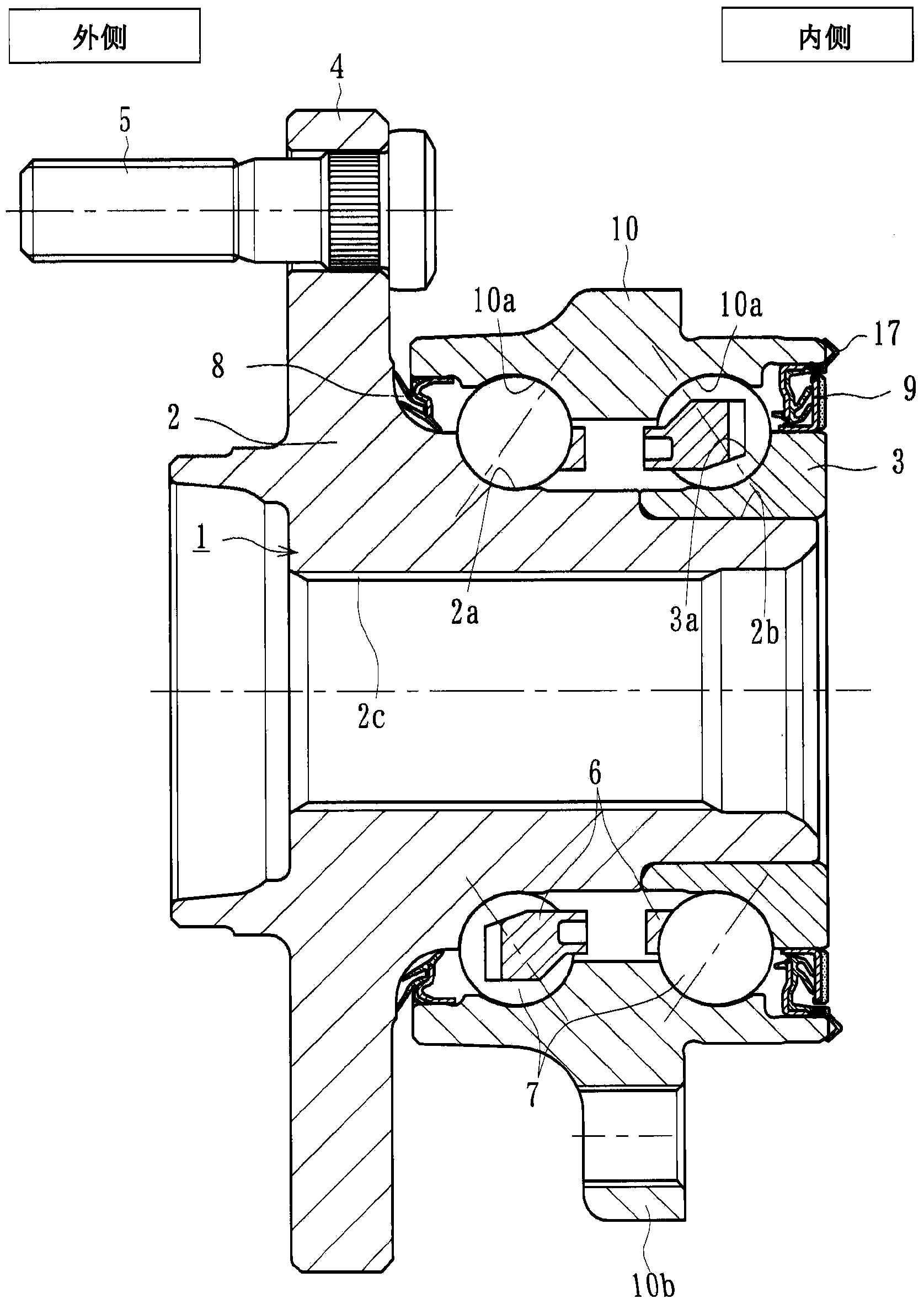

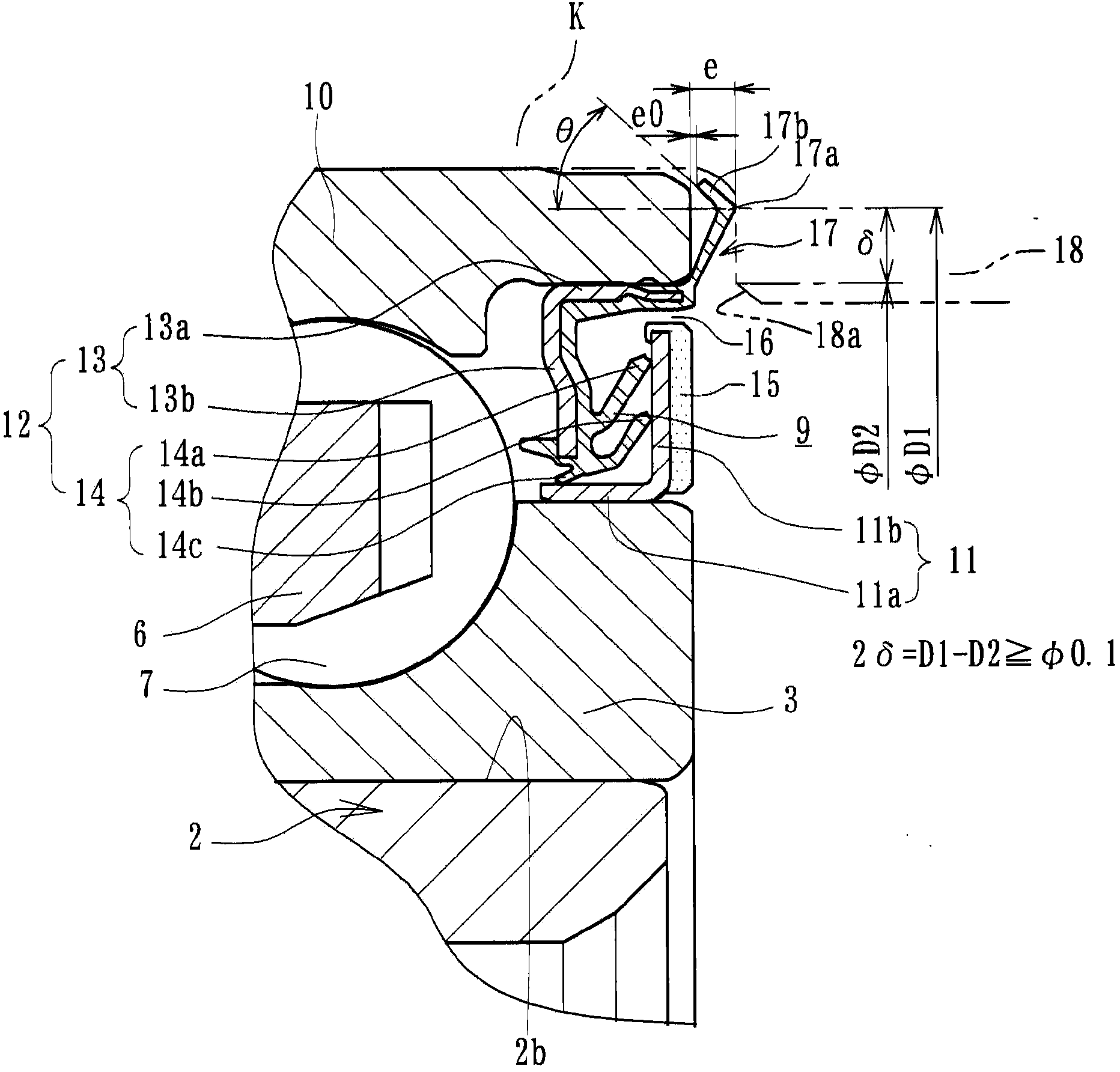

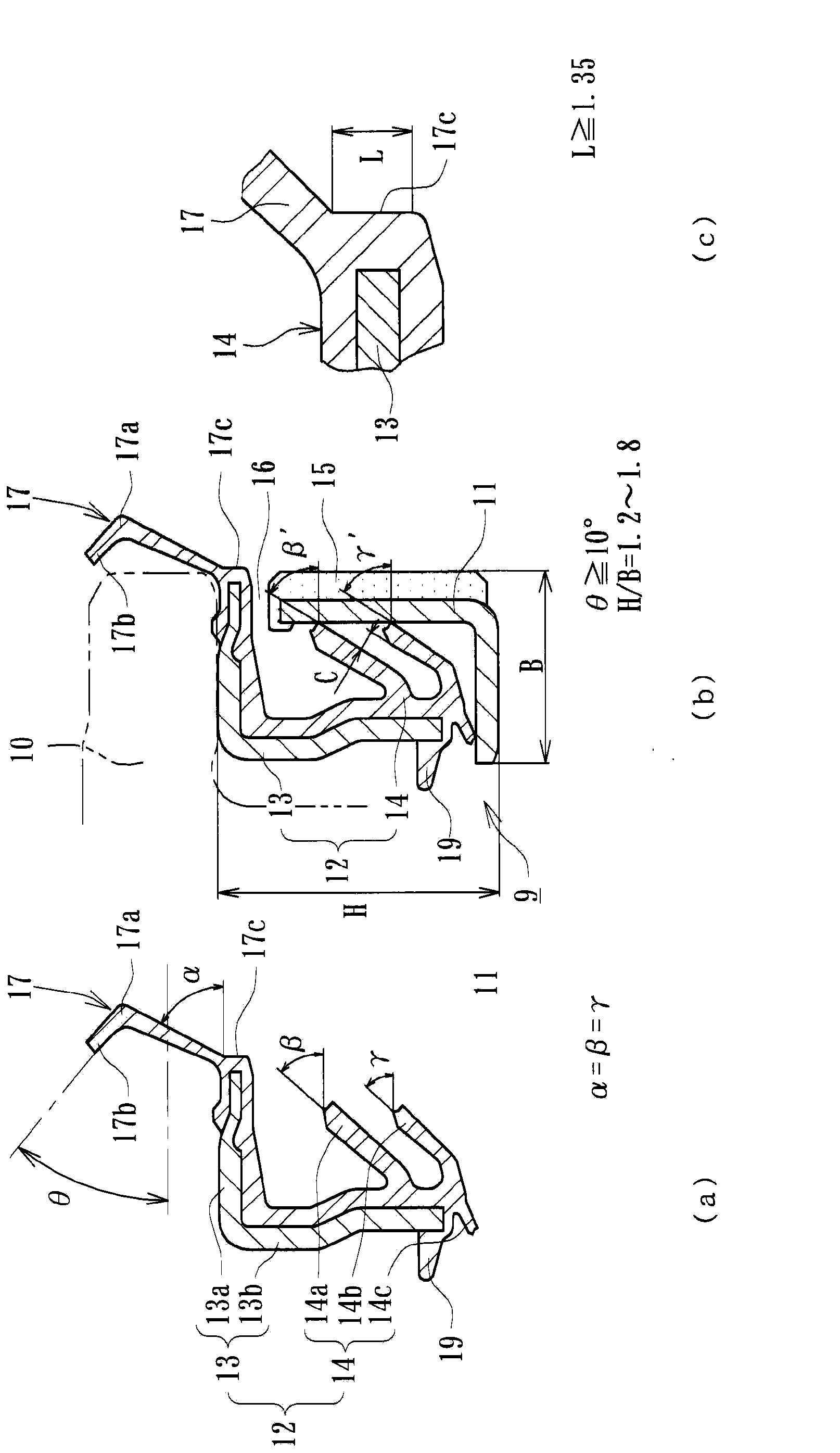

[0052] figure 1 is a longitudinal sectional view showing a preferred embodiment of the wheel bearing device of the present invention, figure 2 is shown figure 1 A partial enlarged view of the seal, image 3 (a) is only showing the figure 2 A partial enlarged view of the sealed plate, image 3 (b) is shown figure 2 A partial enlarged view of the sealed unit, Figure 4 (a) is an explanatory diagram showing a state in the process of assembling the wheel bearing device to the steering knuckle, Figure 4 (b) is an explanatory diagram showing a state after the wheel bearing device is assembled to the knuckle, Figure 5 is an explanatory diagram showing a stacked state of the sealing members of the present invention, Figure 6 is shown figure 2 A longitudinal sectional view of a variant of the seal, Figure 7 (a) is shown figure 2 A longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com