Vapor deposition apparatus for organic vapor deposition material and process for producing organic thin film

A technology of evaporation materials and organic thin films, which is applied in lighting devices, vacuum evaporation plating, metal material coating technology, etc., and can solve the problems of different content ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described using the drawings.

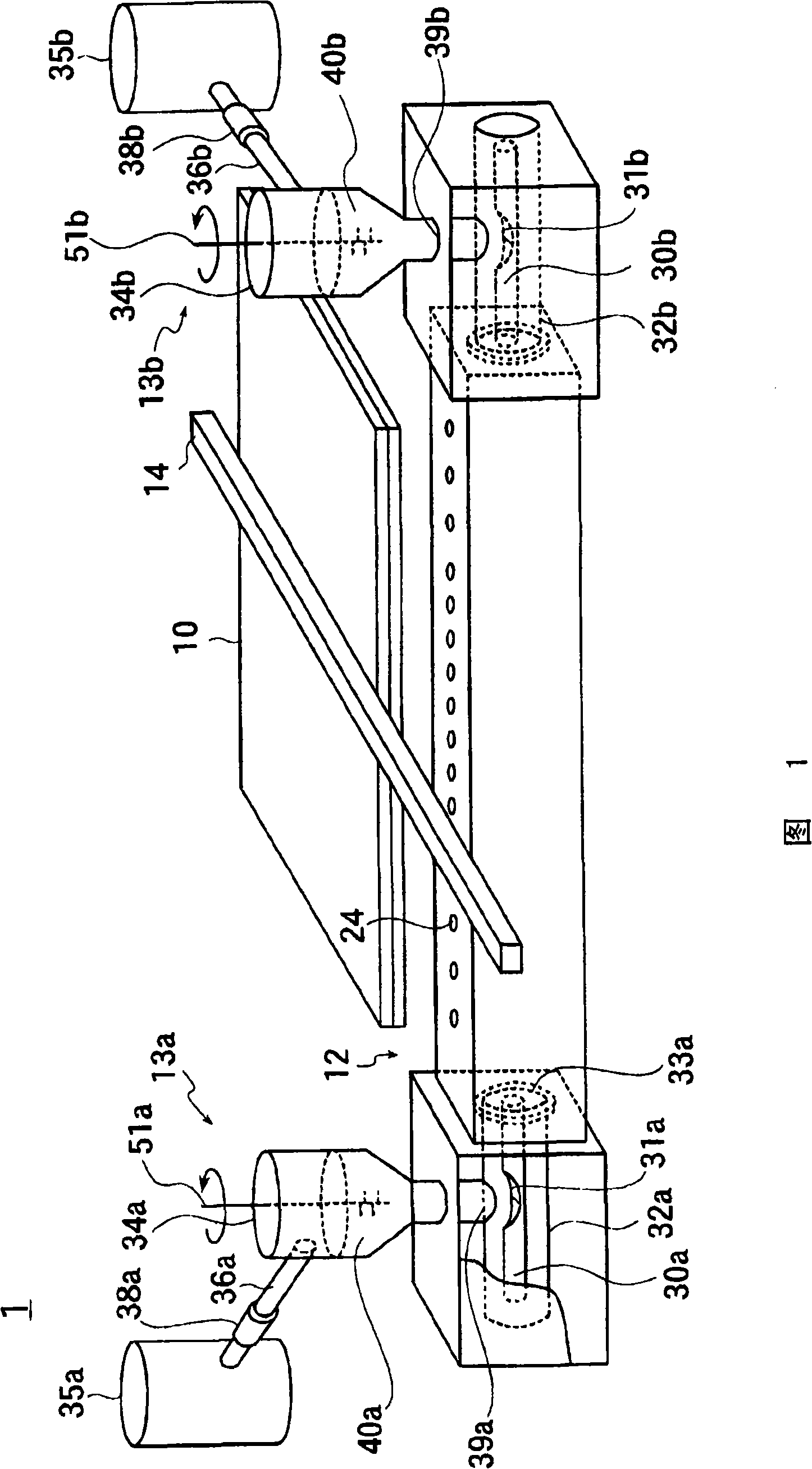

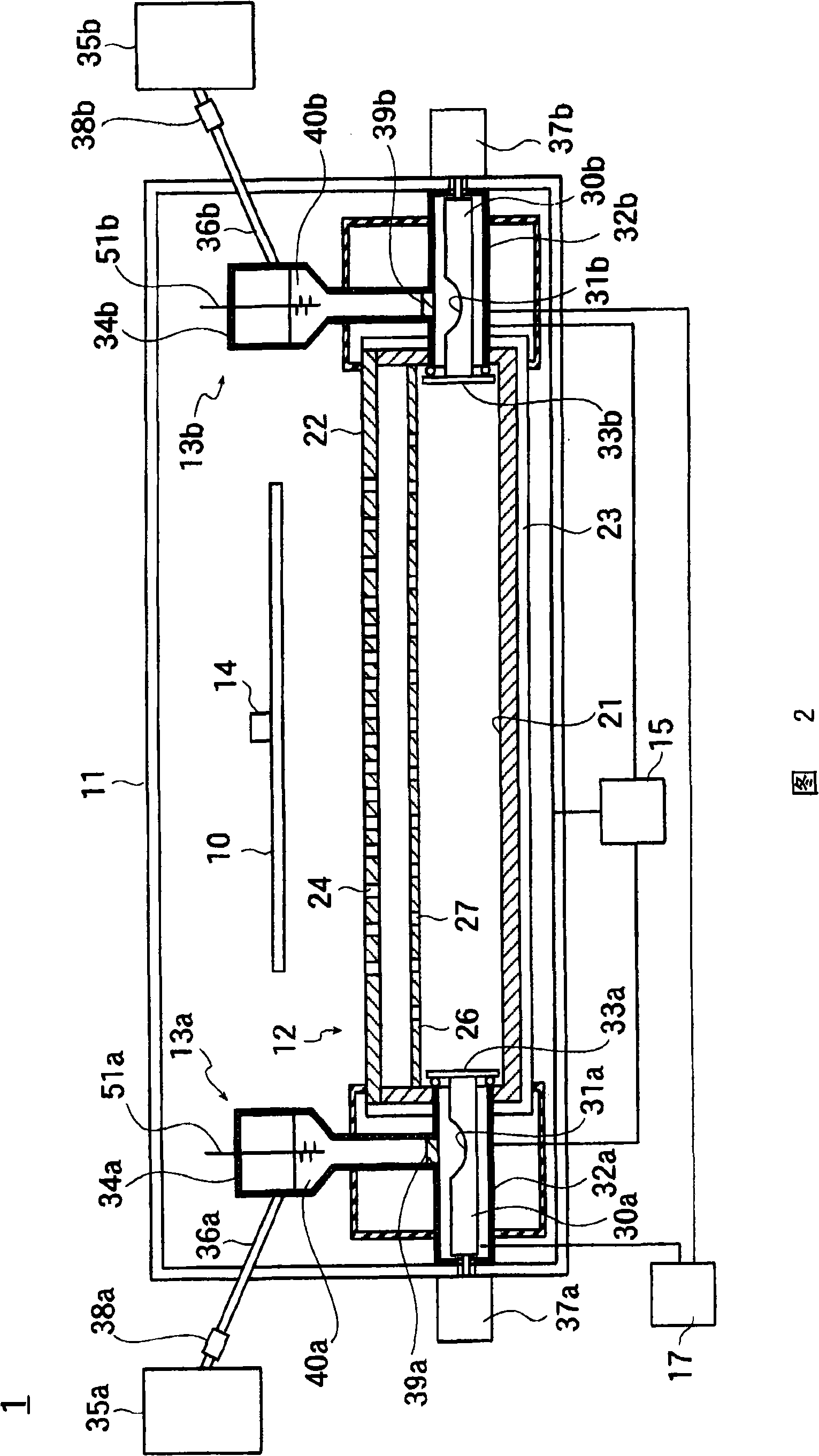

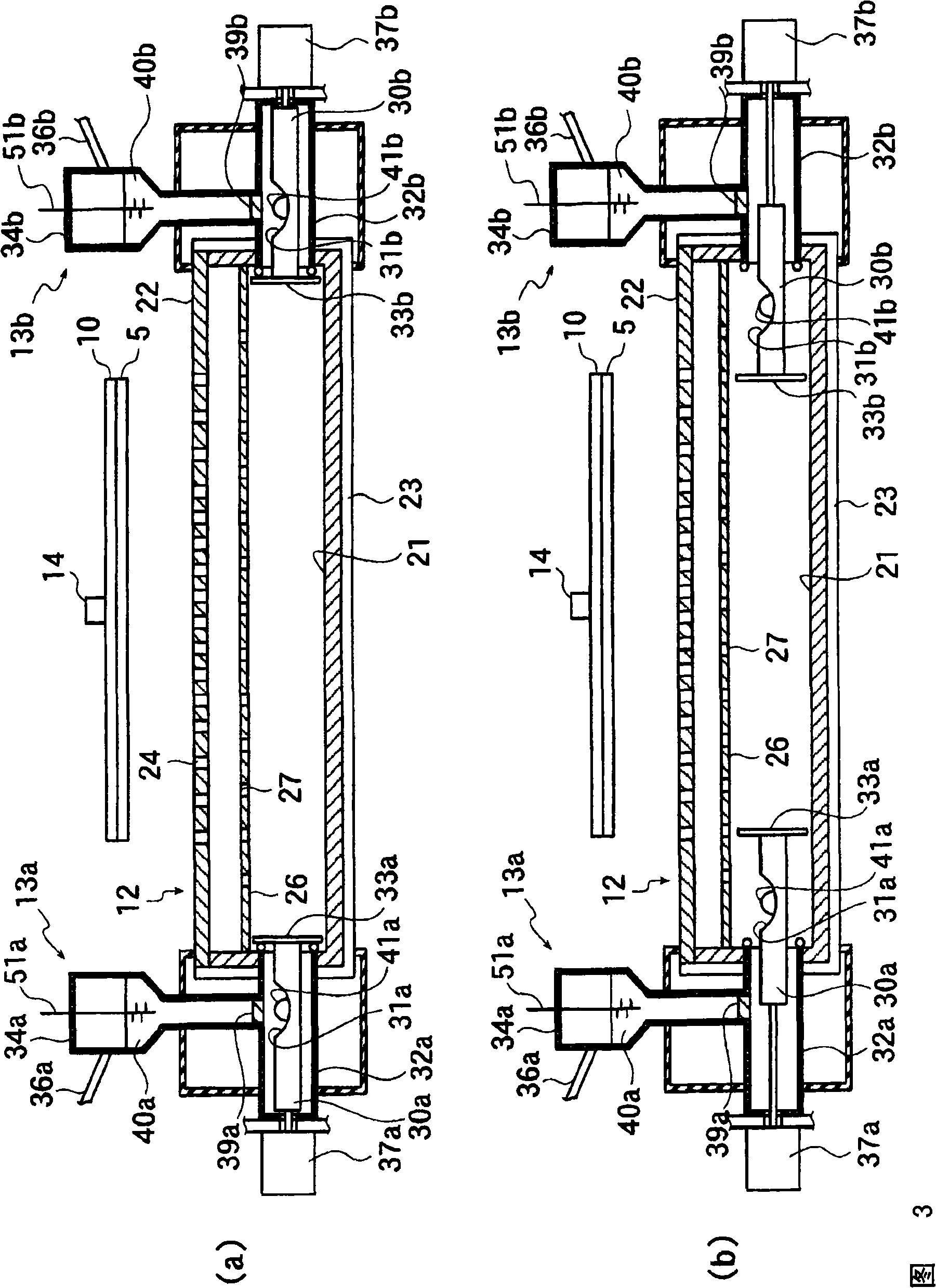

[0050] Reference numeral 1 in the perspective view of FIG. 1 and the schematic cross-sectional view in FIG. 2 is an embodiment of the present invention, and represents a vapor deposition apparatus of a first example for forming an organic thin film.

[0051] The vapor deposition apparatus 1 has a vacuum chamber 11, a vapor deposition container 12, and one or more supply devices 13a, 13b (the vacuum chamber 11 is omitted in FIG. 1).

[0052] The vapor deposition container 12 is arranged inside the vacuum chamber 11 .

[0053] The vapor deposition container 12 has an elongated container body 21 and an elongated plate-shaped lid 22 . The container main body 21 is covered by a lid part 22 .

[0054] One or more loading tanks 32 a and 32 b are connected to the vapor deposition container 12 . Here, there are two mounting grooves 32a and 32b, and the mounting grooves 32a and 32b are arranged at both ends in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com