Method for manufacturing nanometer antibacterial ceramic glaze layers

An antibacterial ceramic and glaze technology is applied in the preparation of nanometer antibacterial ceramic glaze and the preparation of antibacterial and antivirus ceramic glaze. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

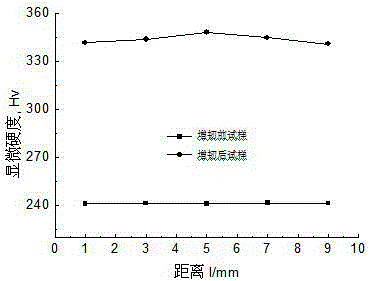

[0024] The best embodiment of the present invention is given below: the precursor chemical composition of in-situ generation nano antibacterial ceramic glaze layer ultrafine powder is: silicon oxide, aluminum oxide, calcium oxide, zinc oxide, copper oxide, magnesium oxide, titanium dioxide and oxide Silver, of which SiO 2 : 45~60%, Al 2 o 3 10-14%, CaO: 7-10%, ZnO: 5-7%, CuO: 2-5%, MgO: 3-6%, TiO 2 : 1~3%, Ag 2 O: 0.2 to 2%. Put the precursor composite powder prepared in proportion and capable of producing ultrafine powder of the nano-antibacterial ceramic glaze layer into a graphite container, under the protection of argon atmosphere and the temperature of 1250°C-1400°C, keep it warm for 120min-240min to synthesize, and then add The absolute ethanol is mechanized ball milled in a ball mill for 24 hours to obtain an ultrafine precursor composite powder with a grain size of 30-80 nm. The chemical composition of in-situ generated nano-antibacterial ceramic glaze layer ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com