Antibacterial and moisture-proof car cushion

A technology of car seat cushions and antibacterial materials, applied in the direction of thigh cushions, conjugated synthetic polymer artificial filaments, etc., can solve the problems of easy water absorption and mold growth, inconvenient maintenance, and bacteria breeding, etc., to achieve good comfort and long retention time , the effect of preventing the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

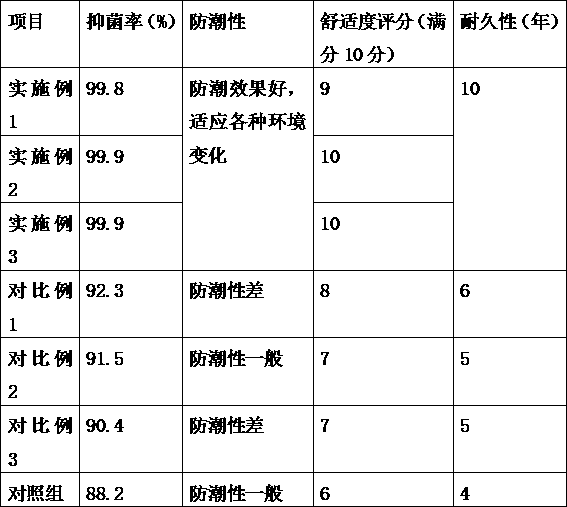

Examples

Embodiment 1

[0015] An antibacterial and moisture-proof automobile seat cushion is prepared by blending hydrophobic spinning raw materials and antibacterial materials, and the amount of antibacterial materials added is 0.2% of the spinning raw materials, and the spinning raw materials used include polypropylene resin and polyethylene resin , polyamide resin, the preparation method of antibacterial material comprises the following steps:

[0016] (1) Mix the prepared nano-zinc oxide into the electrical insulating ceramic powder, the mixing ratio is 1:120, add 15 times the volume of water and stir, stir at room temperature at 1200 rpm for 30 minutes, and let stand for 3 Hour;

[0017] (2) Raise the temperature of the system to 80°C, add cetyltrimethylammonium bromide aqueous solution with a mass concentration of 20% in 10% of the volume of the system dropwise, stir at a speed of 600 rpm, and maintain 75-85°C Range of temperature reaction for 2.0 hours;

[0018] (3) After the reaction, cool...

Embodiment 2

[0023] An antibacterial and moisture-proof automobile seat cushion is prepared by blending hydrophobic spinning raw materials and antibacterial materials, and the amount of antibacterial materials added is 0.25% of the spinning raw materials, and the spinning raw materials used include polypropylene resin and polyethylene resin , polyamide resin, the preparation method of antibacterial material comprises the following steps:

[0024] (1) Mix the prepared nano-zinc oxide into the electrical insulating ceramic powder, the mixing ratio is 1:125, add 18 times the volume of water and stir, stir at 1250 rpm at room temperature for 35 minutes, and let stand for 3.5 Hour;

[0025] (2) Raise the temperature of the system to 82°C, add dropwise an aqueous solution of cetyltrimethylammonium bromide with a mass concentration of 22% accounting for 12% of the volume of the system, stir at a speed of 700 rpm, and maintain 75-85°C Range of temperature reaction for 2.2 hours;

[0026] (3) Aft...

Embodiment 3

[0031] An antibacterial and moisture-proof automobile seat cushion is prepared by blending hydrophobic spinning raw materials and antibacterial materials, and the amount of antibacterial material added is 0.3% of the spinning raw materials, and the spinning raw materials used include polypropylene resin and polyethylene resin , polyamide resin, the preparation method of antibacterial material comprises the following steps:

[0032] (1) Mix the prepared nano-zinc oxide into the electrical insulating ceramic powder, the mixing ratio is 1:130, add 20 times the volume of water and stir, stir at 1300 rpm at room temperature for 40 minutes, and let stand for 4 Hour;

[0033] (2) Raise the temperature of the system to 85°C, add dropwise an aqueous solution of cetyltrimethylammonium bromide with a mass concentration of 25% accounting for 15% of the volume of the system, stir at a speed of 800 rpm, and maintain 75-85°C Range of temperature reaction for 2.5 hours;

[0034] (3) After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com