Environment-friendly water-based sapphire cutting fluid

A cutting fluid, sapphire technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of difficult rinsing of processed parts, inability to comply with RoHS standards, etc., and achieve good environmental protection benefits, good anti-corrosion and anti-rust functions, The effect of less foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

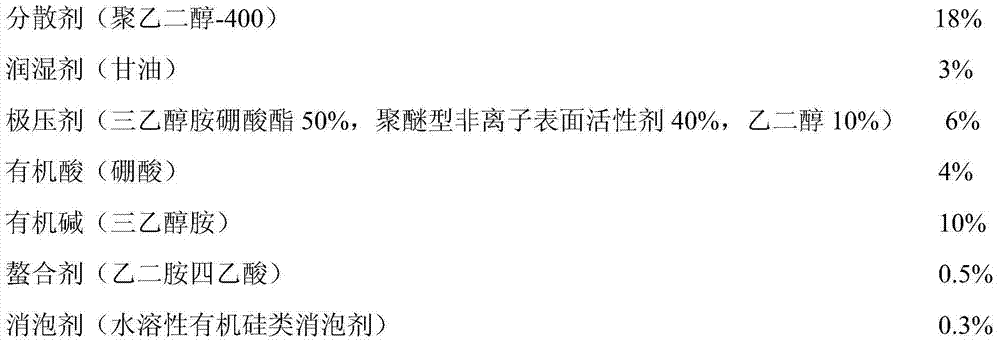

[0025] An environment-friendly water-based sapphire cutting fluid is made from the following raw materials in parts by weight:

[0026]

[0027]

[0028] Preparation method: first prepare the extreme pressure agent according to the ratio of the three components in the extreme pressure agent, and then mix the above ten components to obtain the cutting fluid of the present invention.

[0029] In the present invention, the dispersant polyethylene glycol has good water solubility, and can also be used as a solvent, auxiliary agent, and suspending agent in the cutting fluid system; Flow away quickly. Moreover, the molecular weight of polyethylene glycol-400 is small, and it has good wetting ability to the processed cut surface during high-speed frictional movement, and its thermal stability is excellent. In the present invention, the used triethanolamine borate has good extreme pressure anti-wear properties, wettability, and good reactivity, and the extreme pressure agent co...

Embodiment 2

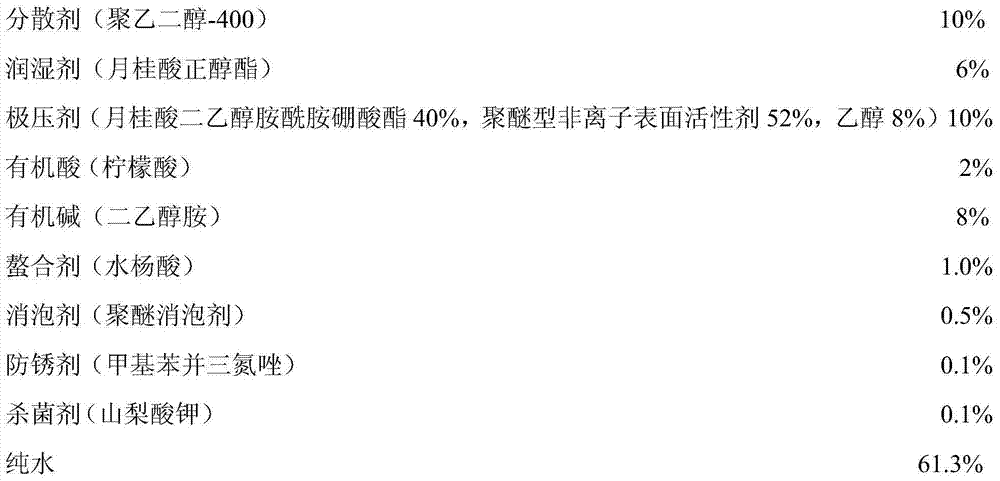

[0031] An environment-friendly water-based sapphire cutting fluid is made from the following raw materials in parts by weight:

[0032]

[0033] This embodiment and embodiment 1 also provide a kind of environment-friendly water-based sapphire cutting fluid with similar effects, and the finished cutting fluid produced is transparent and clear, non-toxic, non-irritating smell, and has good chemical stability; It is not easy to deteriorate, does not corrode processing tools and machine tools, has low probability of skin allergies, excellent lubricating and cooling performance, excellent processing stability, and the processed parts used for cutting are easy to clean. The waste liquid after use of the cutting fluid has good biodegradability and easy chemical treatment.

Embodiment 3

[0035] An environment-friendly water-based sapphire cutting fluid is made from the following raw materials in parts by weight:

[0036]

[0037] This embodiment and embodiment 1 also provide a kind of environment-friendly water-based sapphire cutting fluid with similar effects, and the finished cutting fluid produced is transparent and clear, non-toxic, non-irritating smell, and has good chemical stability; It is not easy to deteriorate, does not corrode processing tools and machine tools, has low probability of skin allergies, excellent lubricating and cooling performance, excellent processing stability, and the processed parts used for cutting are easy to clean. The waste liquid after use of the cutting fluid has good biodegradability and easy chemical treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com