Composite active black dye with high levelling property

A reactive black and composite technology, applied in the direction of organic dyes, etc., can solve the problems of fabrics that cannot be reused after stripping, poor levelness and dye migration, and easy occurrence of color flowers, and achieves high dye dischargeability, high The effect of levelness and high jet blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

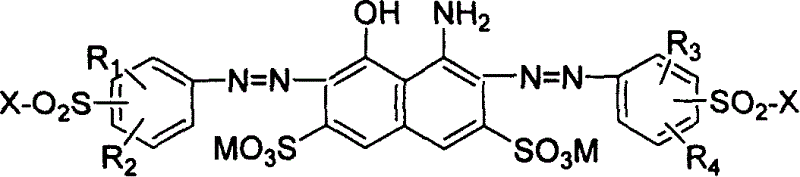

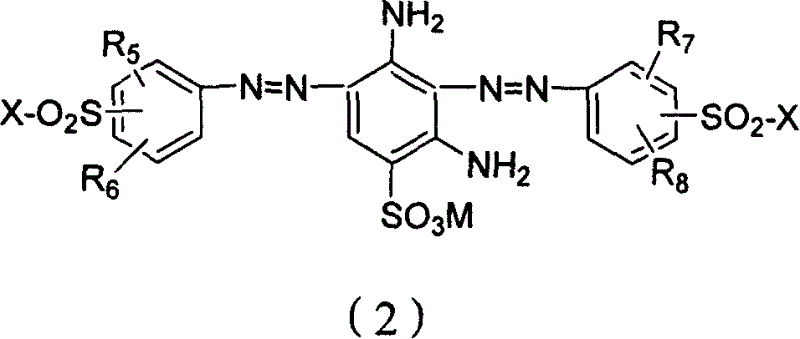

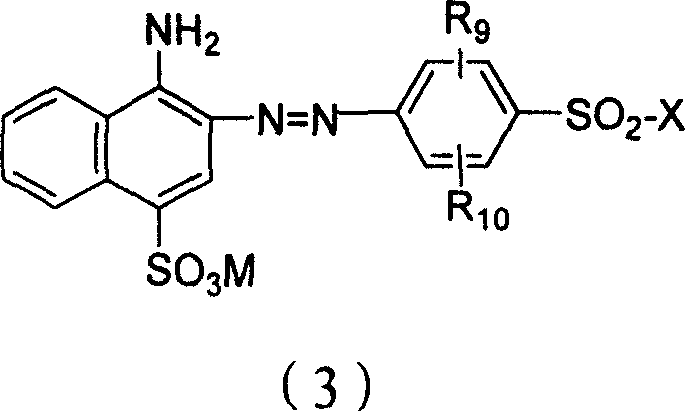

Method used

Image

Examples

example 1

[0041] 280kg of para-esterification, add appropriate amount of water and ice cubes, under high-speed stirring, add 90kg of industrial hydrochloric acid, then under good stirring, add 70kg of pure product with a weight percentage concentration of 30% sodium nitrite aqueous solution , keeping the reaction liquid for diazotization reaction on Congo red test paper blue, starch potassium iodide test paper light blue, 0~5°C for 2~3 hours. Then, 175 kg of H acid was added to keep the pH ≤ 2, and the acidic coupling reaction was carried out at 5-8° C. for 3-5 hours. Then, below 20°C, quickly add soda to adjust the pH of the reactant to 6.5-7, and carry out alkaline coupling for 2-3 hours to complete the reaction. Obtain about 600kg of dye A reactive black KN-B compound.

example 2

[0043]280kg of para-esterification, add appropriate amount of water and ice cubes, under high-speed stirring, add 90kg of industrial hydrochloric acid, and then under good stirring, add 70kg of sodium nitrite aqueous solution to keep the reaction liquid against Congo red test paper blue, starch potassium iodide The test paper is slightly blue, and the diazotization reaction is carried out at 0-5°C for 2-3 hours. Then, add 115 kg of m-diaminobenzenesulfonic acid, keep the pH ≤ 2, and carry out acidic coupling reaction at 5-8° C. for 2-4 hours. Then, below 20°C, quickly add soda to adjust the pH of the reactant to 6.5-7, and then carry out alkaline coupling for 2-4 hours to complete the reaction. Obtain dye B reactive yellow KN-RR about 450kg.

example 3

[0045] 140kg of para-esterification, add appropriate amount of water and ice cubes, under high-speed stirring, add 45kg of industrial hydrochloric acid, then under good stirring, add 35kg (pure product) sodium nitrite aqueous solution to keep the reaction solution against Congo red The test paper is blue, the starch potassium iodide test paper is blue, and the diazotization reaction is carried out at 0-5°C for 2-3 hours. Then, add 110kg of 1-amino-4-naphthalenesulfonic acid, keep the pH≤2, and carry out acidic coupling reaction at 5-8°C for 2-4 hours. Then, below 20°C, quickly add soda to adjust the pH of the reactant to 6.5-7.0 to complete the reaction, and obtain about 320kg of dye C reactive orange KN-R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com