Pipeline for delivering engine waste gas post-processing medium

A technology for exhaust gas after-treatment and conveying pipelines, which is used in engine components, machines/engines, pipeline protection, etc., and can solve the problem that the exhaust gas after-treatment system cannot be put into work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

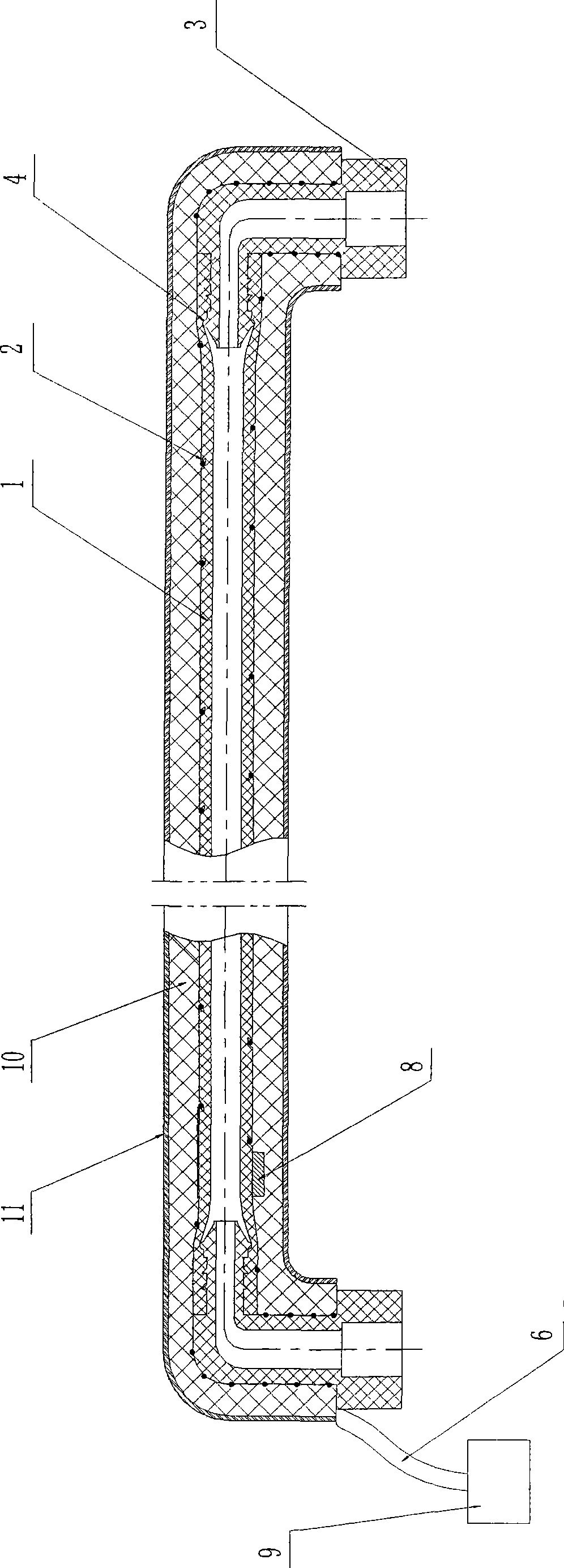

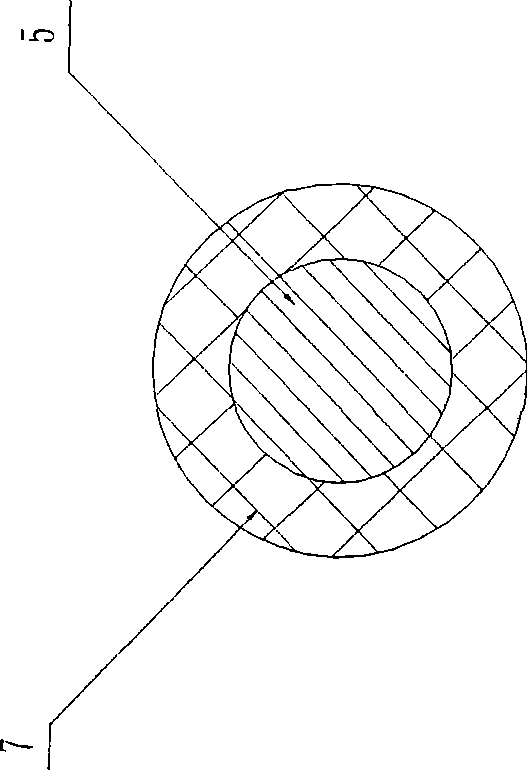

[0011] see figure 1 with figure 2 , The delivery pipe (1) of the present invention is made of polytetrafluoroethylene material, which has the characteristics of high and low temperature resistance, acid and alkali corrosion resistance, non-stick, self-lubricating, and excellent dielectric properties. The length of the conveying pipe (1) is designed according to the actual installation requirements. Its surface is provided with equally spaced spiral grooves (2) with a depth of about 0.5mm from one end to the other. The distance between the grooves (2) can be determined according to The resistance, resistivity, length, diameter and other requirements of the heating material are set. The heating wire (5) is covered with an insulating layer (7) made of polytetrafluoroethylene material to prevent the occurrence of a short circuit when the heating wire (5) is staggered, and also to prevent the heating wire (5) from being stored and working. oxidized and corroded. Before winding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com