Synthetic method of alpha-hydroxyl carbonyl compound

A technology of carbonyl compounds and hydroxycarbonyl compounds, which is applied in the field of synthesizing α-hydroxycarbonyl compounds, can solve the problems such as the narrow scope of application of substrates, and achieve the effects of easy industrial production, high yield and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

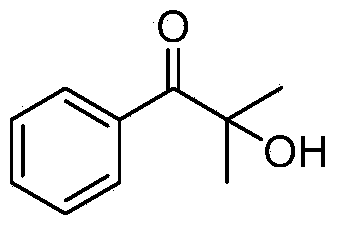

[0014] The synthesis of embodiment 12-hydroxyl-2-methyl-1-phenylacetone

[0015]

[0016] a): Take a 25mL Schlenk reaction tube, add 33mg of cesium carbonate, 74mg of 2-methyl-1-phenylacetone, 167mg of triethyl phosphite, 2mL of dimethyl sulfoxide, connect a 200mL oxygen balloon, and put it at room temperature Stir at 25°C for 24 hours. After the reaction was completed, 15 mL of ethyl acetate was added to quench the reaction, washed with 5 mL of brine, the organic phase was separated, the aqueous phase was extracted 3 times with ethyl acetate, the organic phases were combined, and separated by column chromatography to obtain 2-hydroxy-2-methyl- Pure 1-phenylacetone 71mg, yield 87%.

[0017] b): Take a 25mL Schlenk reaction tube, add 33mg of cesium carbonate, 74mg of 2-methyl-1-phenylacetone, 167mg of triethyl phosphite, 2mL of dimethyl sulfoxide, and stir at room temperature at 25°C under normal air pressure 48 hours. After the reaction was completed, 15 mL of ethyl acet...

Embodiment 2

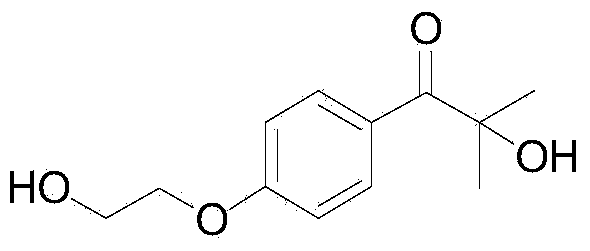

[0033] The synthesis of embodiment 22-hydroxyl-4'-(2-hydroxyethoxy)-2-methylpropiophenone

[0034]

[0035] Take a 25mL Schlenk reaction tube, add 33mg of cesium carbonate, 105mg of 4'-(2-hydroxyethoxy)-2-methylpropiophenone, 167mg of triethyl phosphite, 2mL of dimethyl sulfoxide, and connect a 200mL Oxygen balloon, stirred at room temperature 25°C for 24 hours. Add 15 mL of ethyl acetate to quench the reaction after the reaction is finished, add 5 mL of brine to wash, separate the organic phase, extract the aqueous phase with ethyl acetate for 3 times, combine the organic phases, and separate by column chromatography to obtain 2-hydroxy-4'-(2 -Hydroxyethoxy)-2-methylpropiophenone pure product 84mg, productive rate 75%.

[0036] 1 H NMR (400MHz, CDCl 3 ):δ7.97(d,J=8.8Hz,2H),6.84(d,J=8.0Hz,2H),4.04(t,J=4.4Hz,2H),3.88(t,J=4.0Hz,2H ),3.57(s,2H),1.52(s,6H); 13 CNMR (100MHz, CDCl 3 ): δ202.5, 162.4, 132.3, 126.1, 114.0, 75.9, 69.3, 60.8, 28.4 ppm; IR (neat): ν=3404.8, 2932...

Embodiment 3

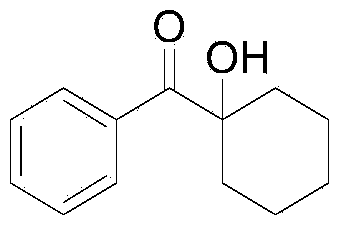

[0037] The synthesis of embodiment 3α-hydroxycyclohexyl benzophenone

[0038]

[0039] Take a 25mL Schlenk reaction tube, add 163mg cesium carbonate, 95mg cyclohexyl benzophenone, 167mg triethyl phosphite, 2mL dimethyl sulfoxide, connect a 200mL oxygen balloon, and stir at room temperature 25°C for 72 hours. Add 15 mL of ethyl acetate to quench the reaction after the reaction, add 5 mL of brine to wash, separate the organic phase, extract the aqueous phase with ethyl acetate for 3 times, combine the organic phases, and separate by column chromatography to obtain pure α-hydroxycyclohexylbenzophenone. Product 98mg, yield 96%.

[0040] 1 H NMR (400MHz, CDCl 3 ):δ8.00(d,J=7.6Hz,2H),7.53(t,J=7.2Hz,1H),7.43(d,J=8.0Hz,2H),3.40(s,1H),2.08-2.00 (m,2H),1.82-1.65(m,7H),1.39-1.29(m,1H); 13 C NMR (100MHz, CDCl 3 ): δ205.5, 135.1, 132.3, 129.4, 128.2, 78.6, 35.3, 25.3, 21.4ppm; IR (neat): ν=3460.2, 2930.8, 1675.4, 1261.9cm -1 ;MS(70ev):m / z(%):99.0(100),105(30),176.0(M + ,5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com