Agranular type silver-based conductive ink and preparation method therefor and application thereof

A conductive ink, particle-free technology, applied in applications, inks, household appliances, etc., can solve the problems that restrict the commercial production of particle-free silver-based conductive ink, short shelf life, etc., to achieve easy industrial production, reduce heat treatment temperature, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

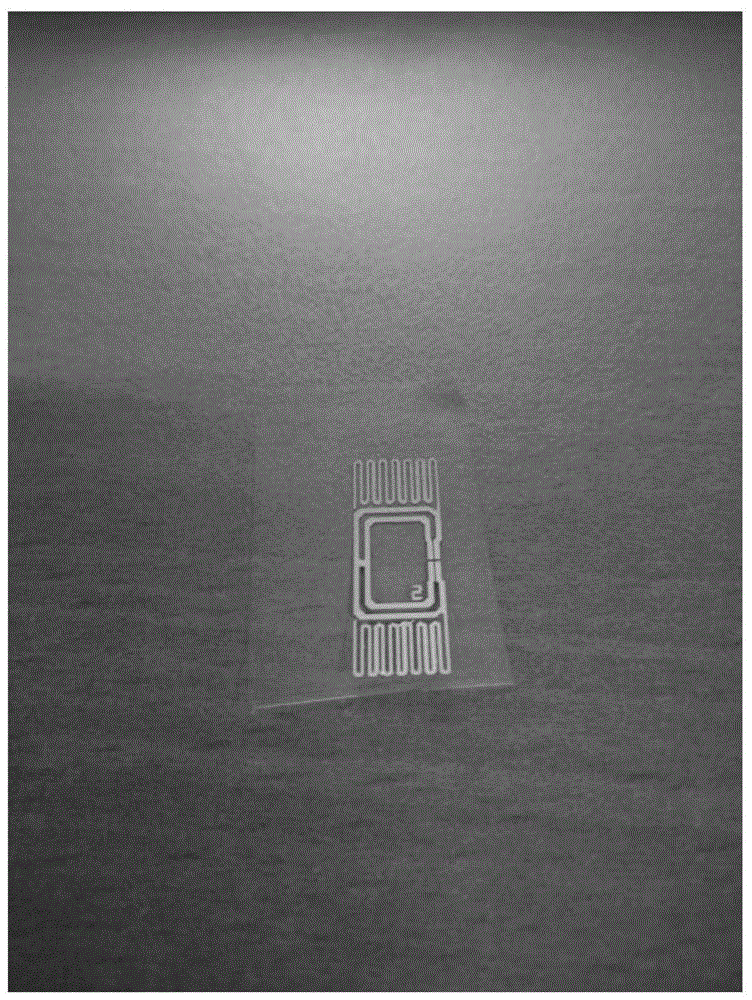

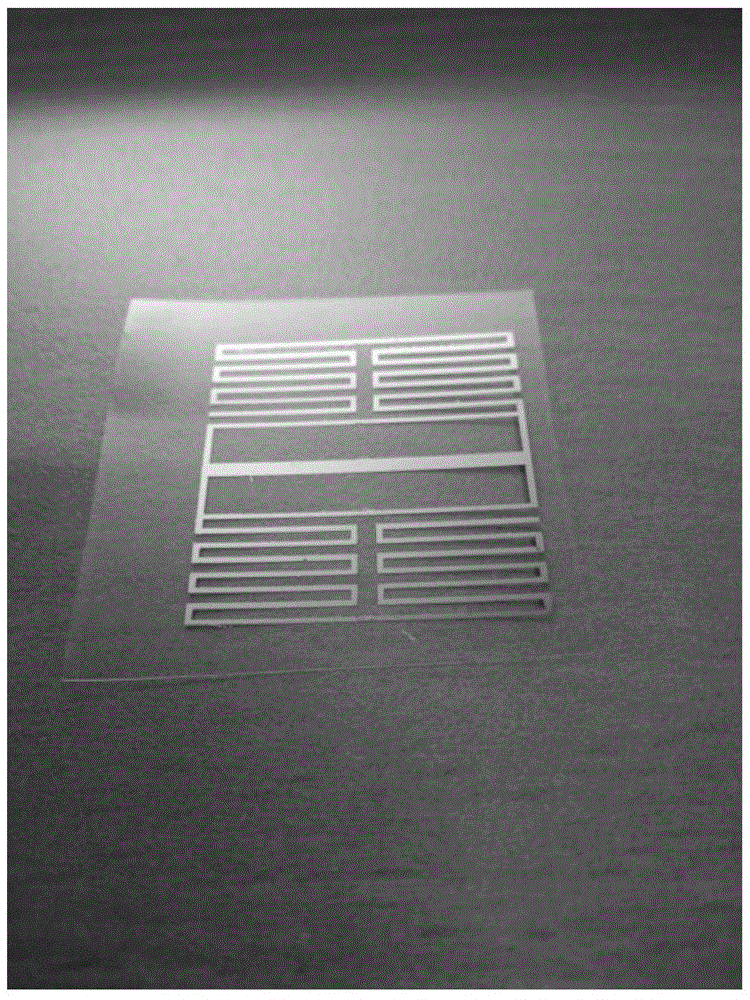

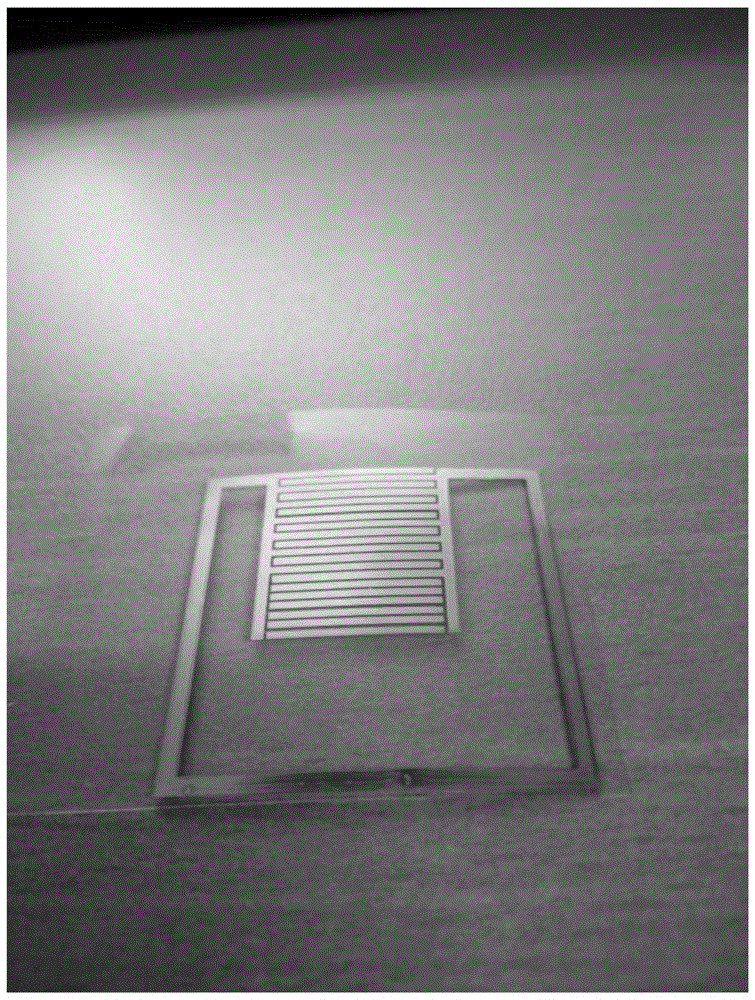

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation of particle-free silver-based conductive ink

[0034] The raw material is composed of: (by weight percentage)

[0035] Silver acetate 45.6%, methanol-N,N-dimethylethanolamine (1:2) 40%, formic acid 14%, curdlan 0.4%;

[0036] The preparation method is: weigh the raw materials according to the above ratio, place silver acetate in methanol-N,N-dimethylethanolamine (1:2), oscillate ultrasonically for 5 minutes, mix well, add formic acid under stirring conditions, and react for 30 minutes , and then add curdlan to adjust the viscosity and surface tension of the ink, and filter to obtain a particle-free silver-based conductive ink. Its viscosity is 11cp and its surface tension is 40mN / m.

Embodiment 2

[0037] Embodiment 2: the preparation of particle-free silver-based conductive ink

[0038] The raw material is composed of: (by weight percentage)

[0039] Silver citrate 20%, methanol-N,N-dimethylethanolamine (1:2) 50%, ascorbic acid 29.5%, sodium hydroxymethylcellulose 0.5%;

[0040] The preparation method is as follows: weigh the raw materials according to the above ratio, place silver citrate in methanol-N,N-dimethylethanolamine (1:2), oscillate ultrasonically for 5 minutes, mix well, add ascorbic acid under stirring condition, and react After 30 minutes, sodium hydroxymethylcellulose was added to adjust the viscosity and surface tension of the ink, and filtered to obtain a particle-free silver-based conductive ink. Its viscosity is 14cp and its surface tension is 45mN / m.

Embodiment 3

[0041] Embodiment 3: the preparation of particle-free silver-based conductive ink

[0042] The raw material is composed of: (by weight percentage)

[0043] Silver nitrate 55%, methanol-isopropanolamine (1:2) 30%, ascorbic acid 14.7%, curdlan 0.3%;

[0044] The preparation method is as follows: weigh the raw materials according to the above ratio, place silver citrate in methanol-N,N-dimethylethanolamine (1:2), oscillate ultrasonically for 5 minutes, mix well, add ascorbic acid under stirring condition, and react After 30 minutes, sodium hydroxymethylcellulose was added to adjust the viscosity and surface tension of the ink, and filtered to obtain a particle-free silver-based conductive ink. Its viscosity is 10cp and its surface tension is 50mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com