Patents

Literature

35 results about "Silver citrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver citrate is a the salt of silver and citric acid, where silver exists in its ionic form. Silver citrate in the presence of citric acid (which, when sold as this preservative it's a blend of citric acid and silver citrate) is soluble in water.

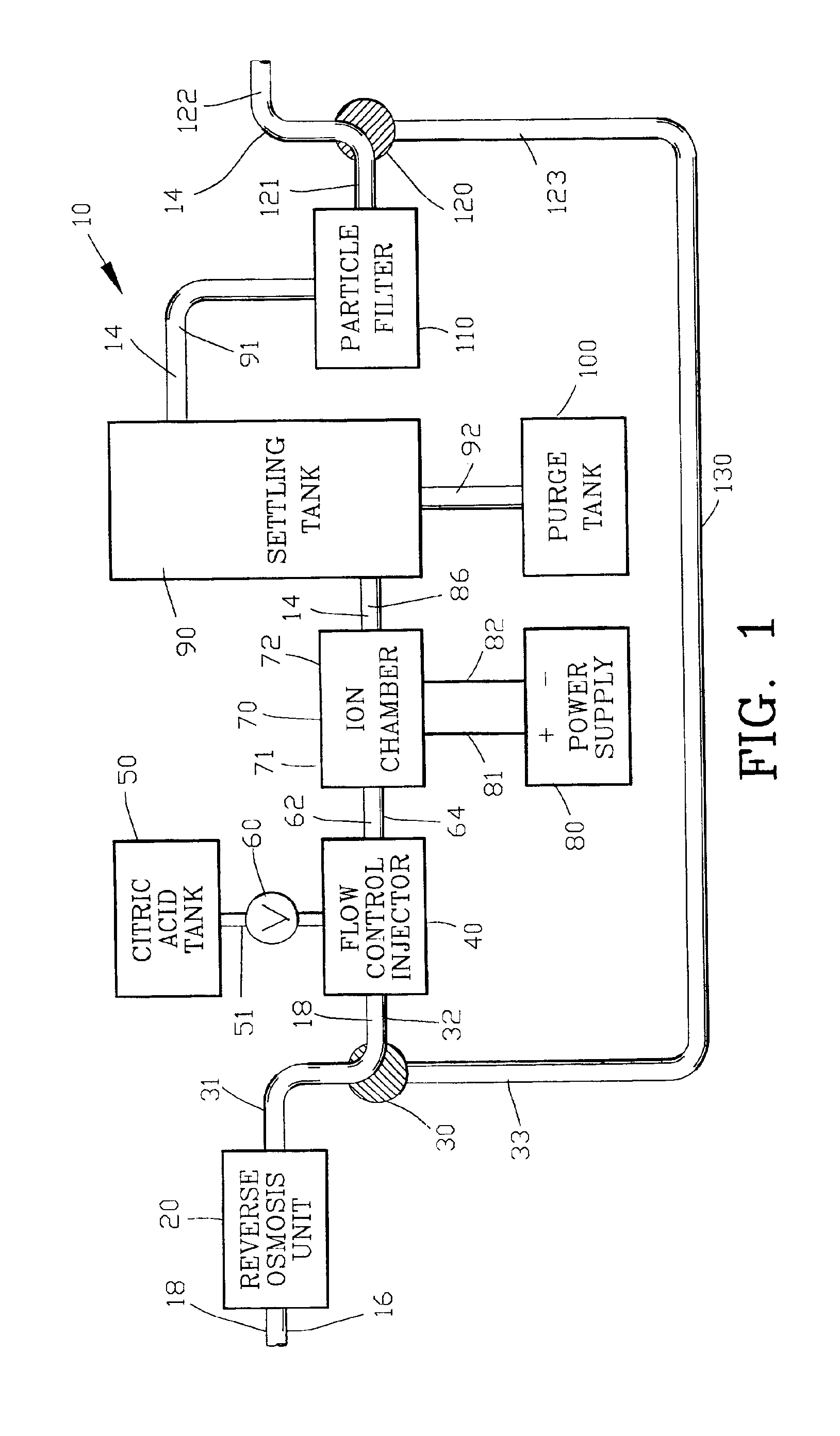

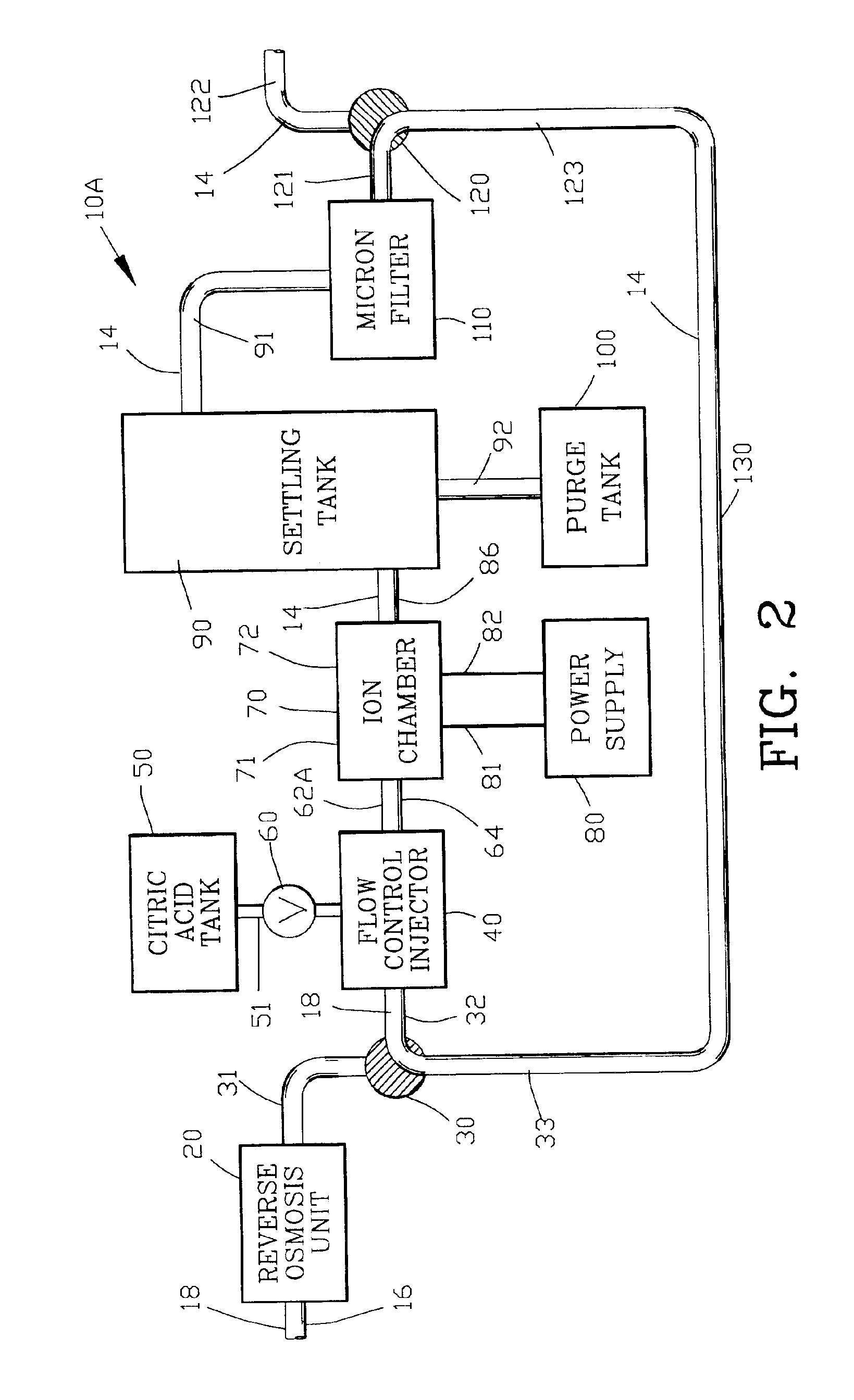

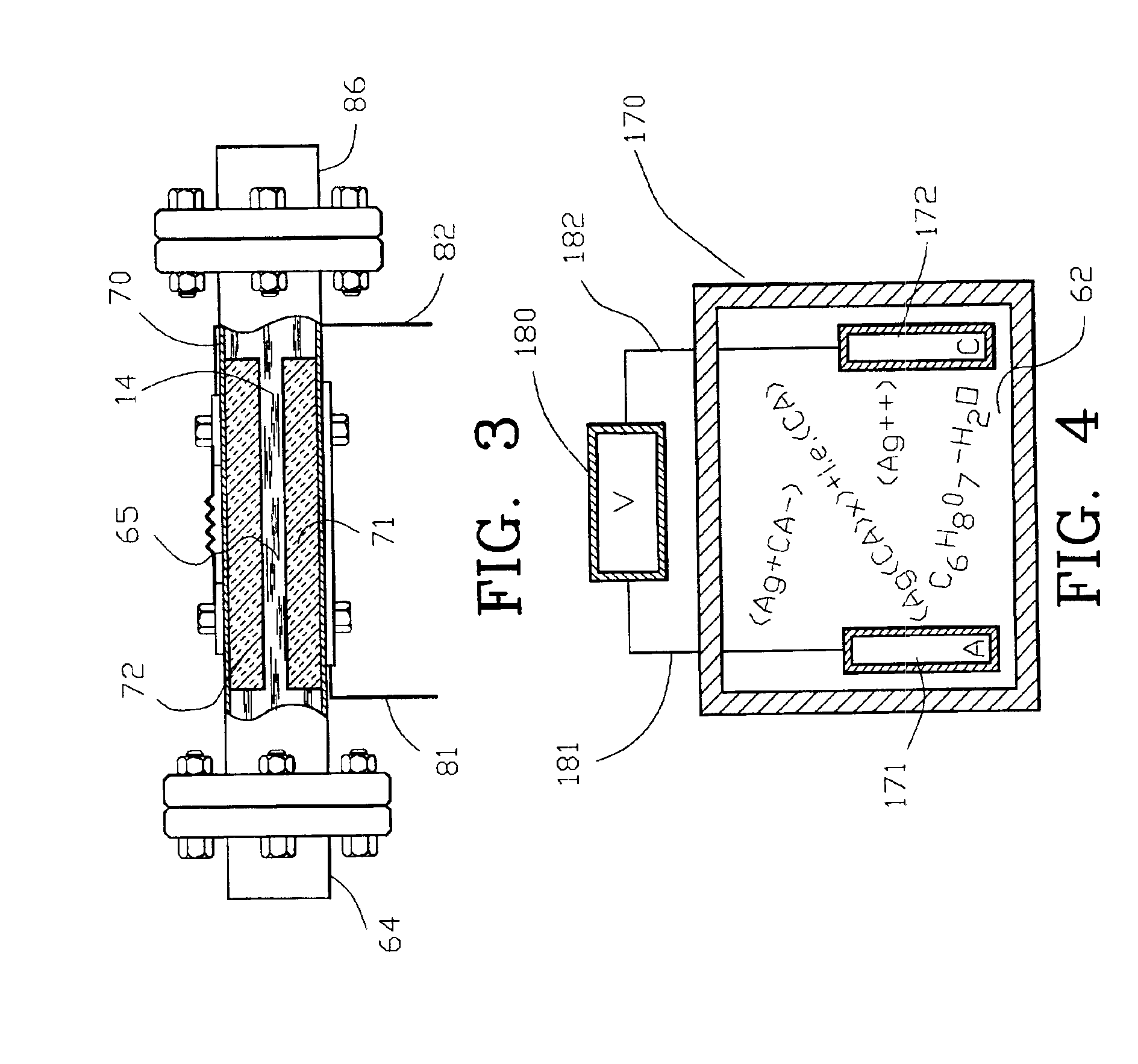

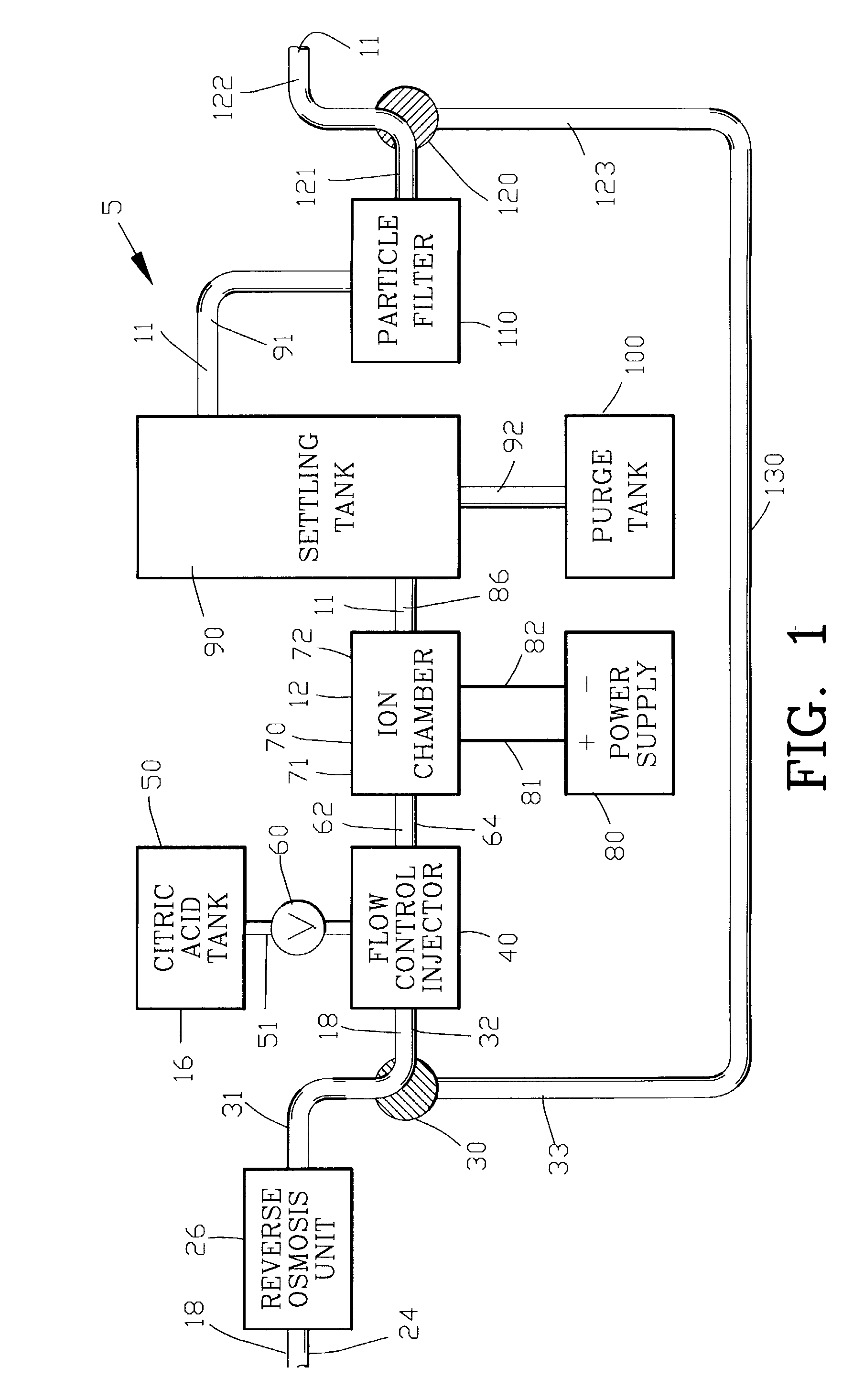

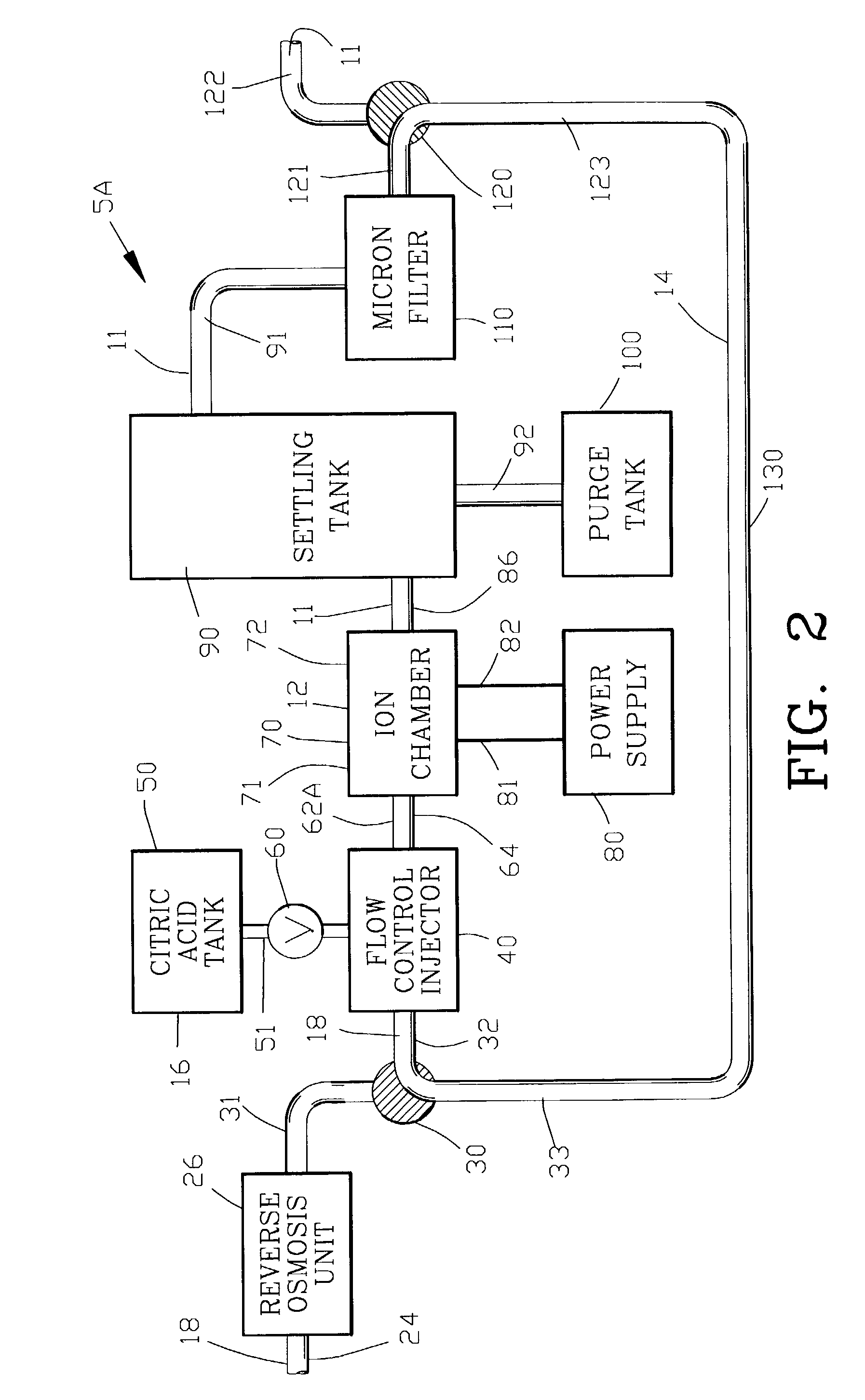

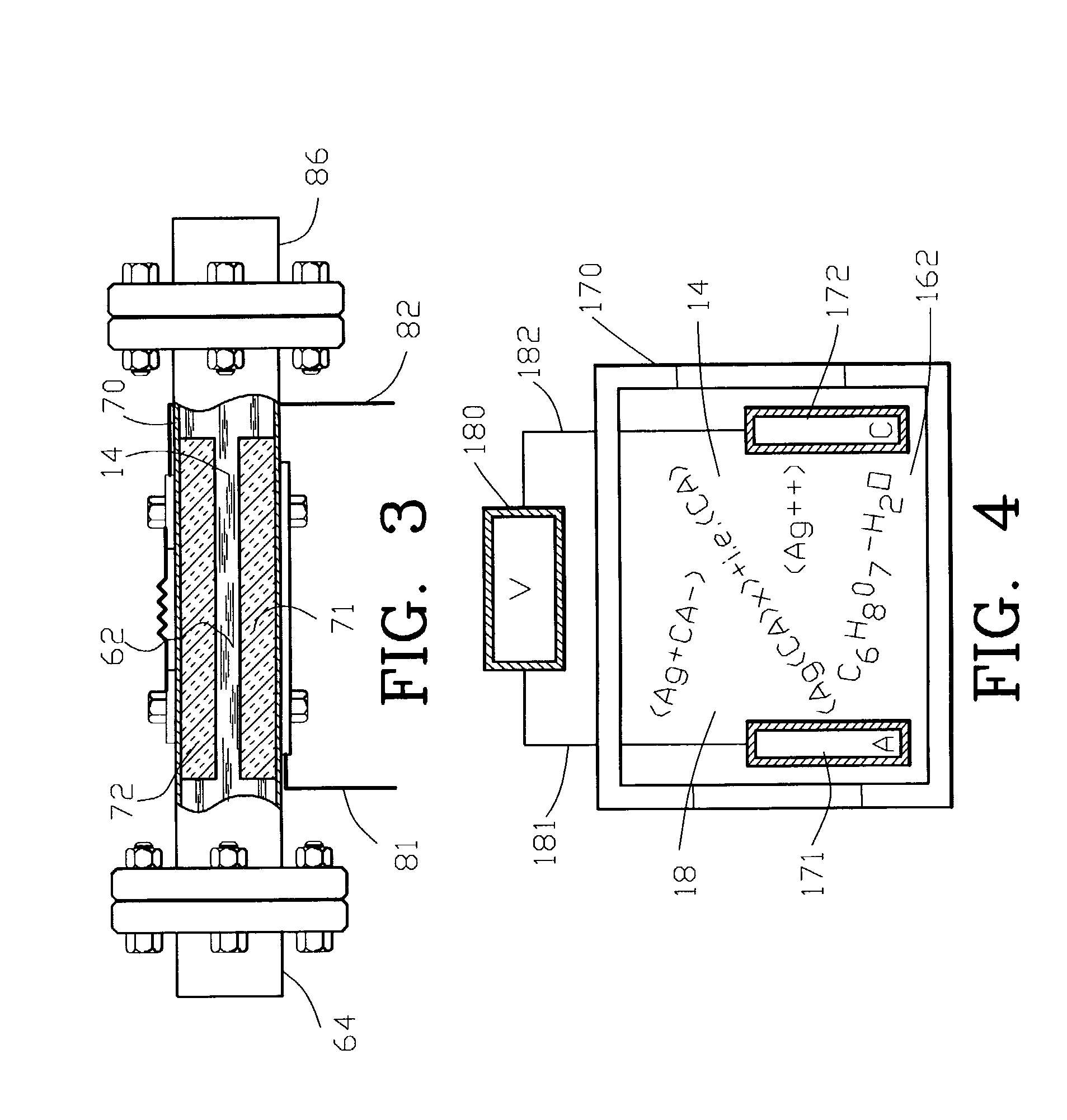

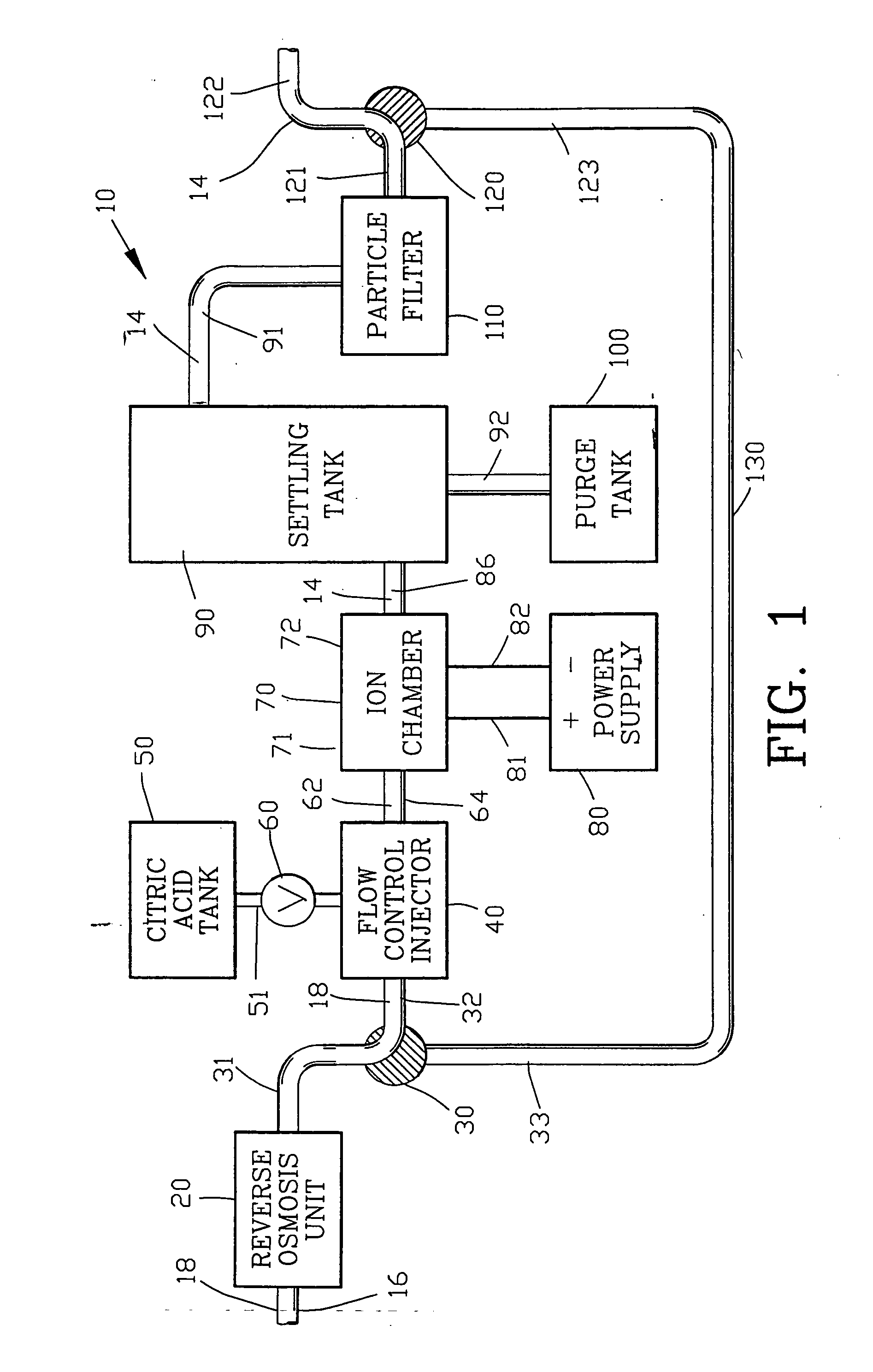

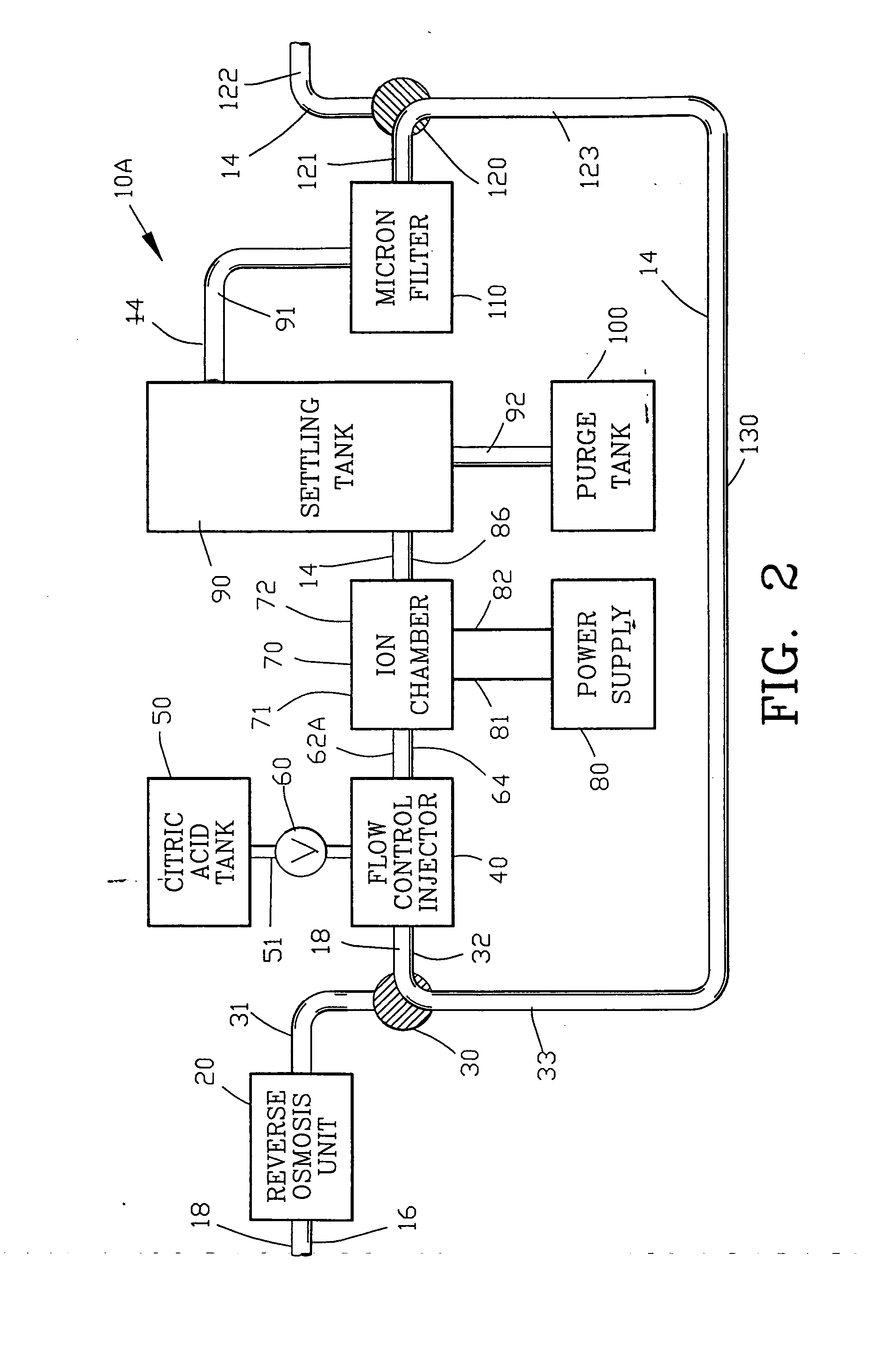

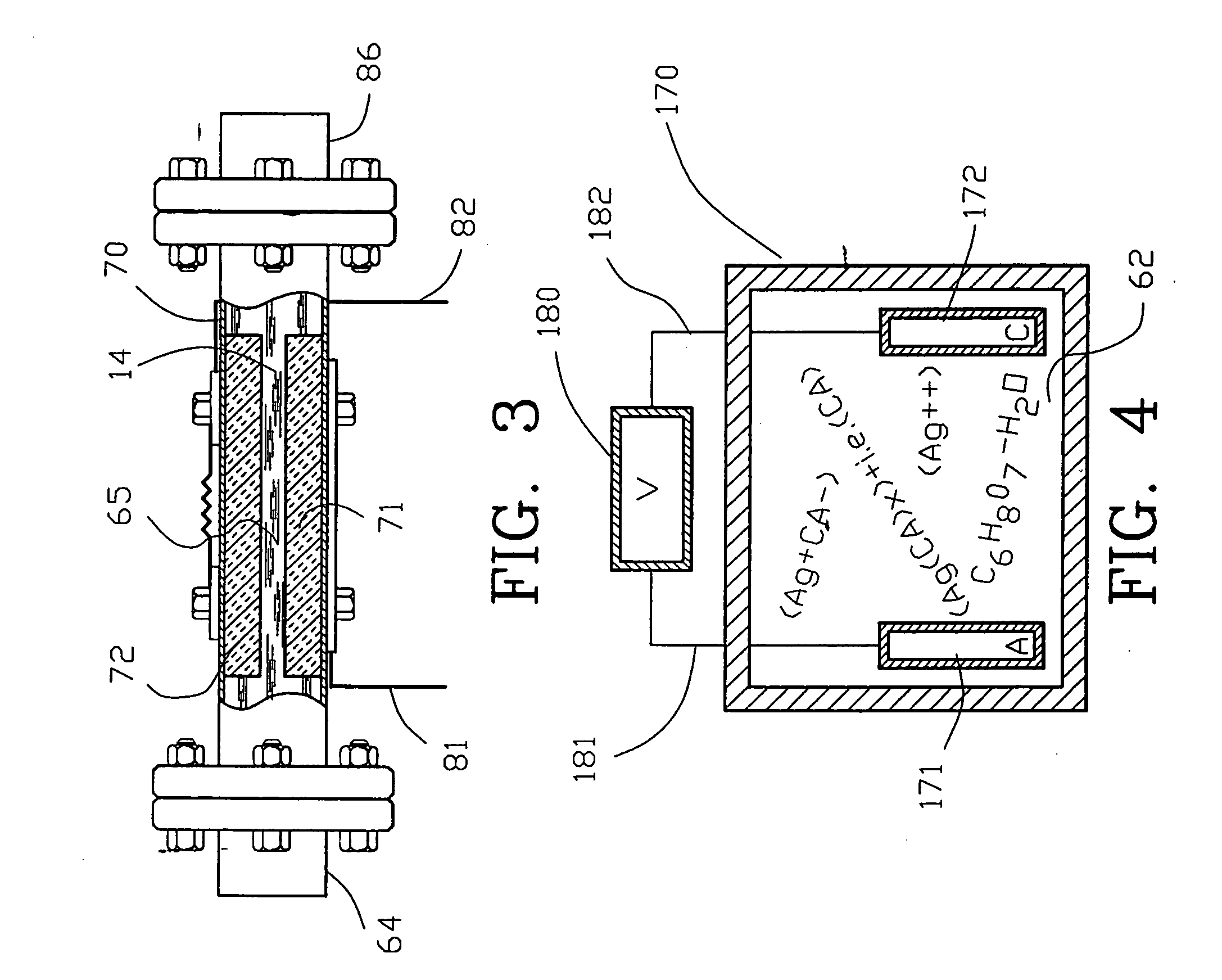

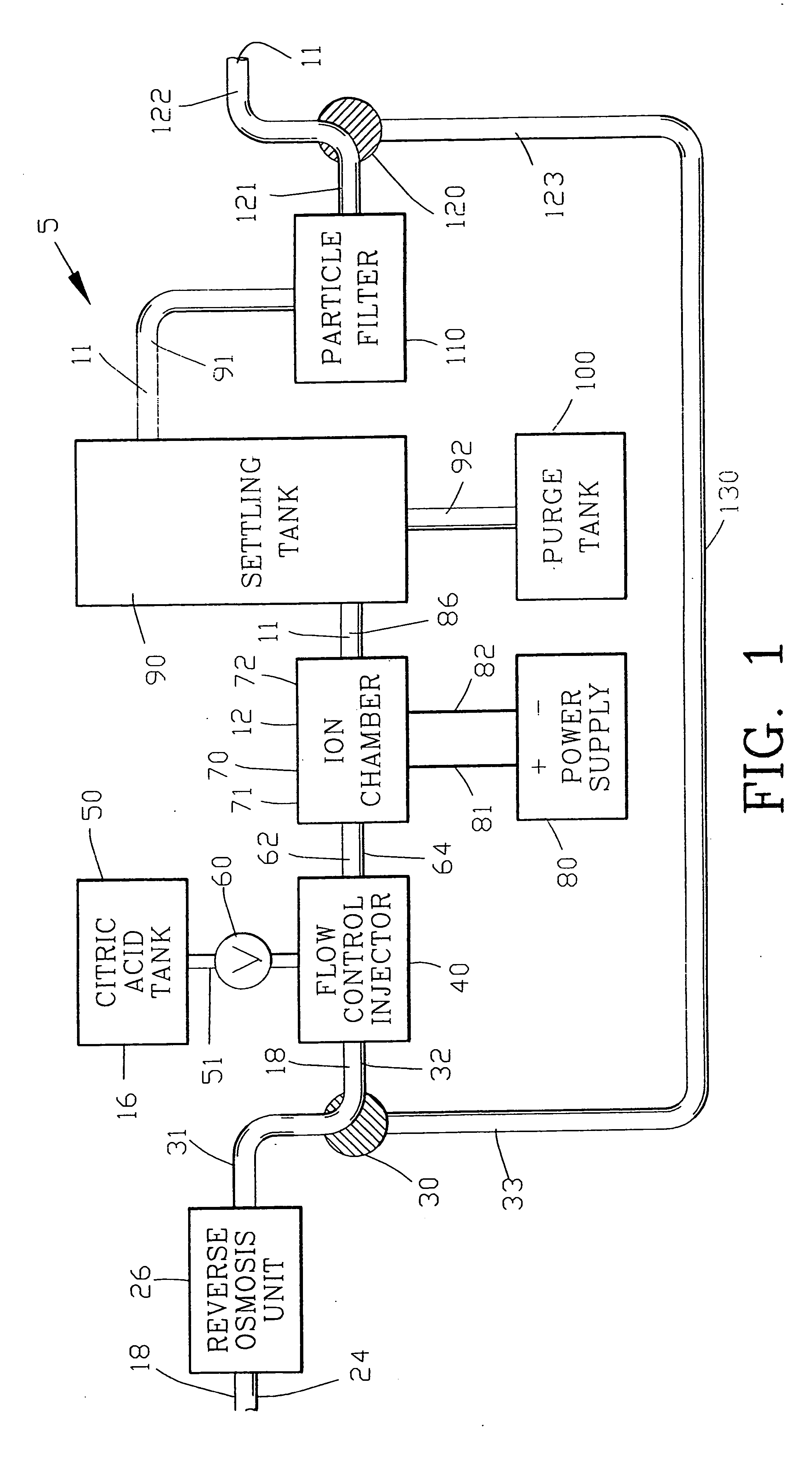

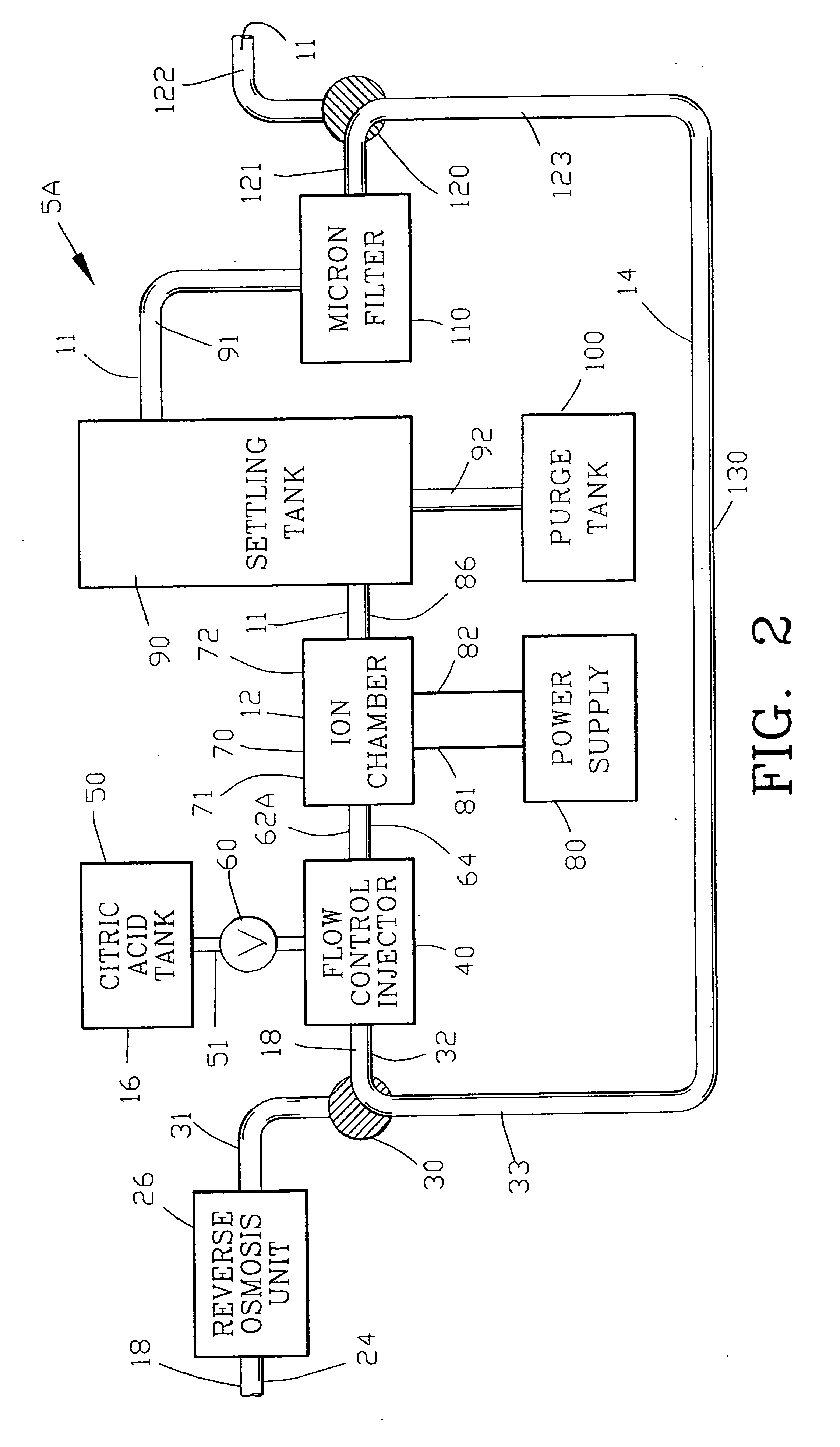

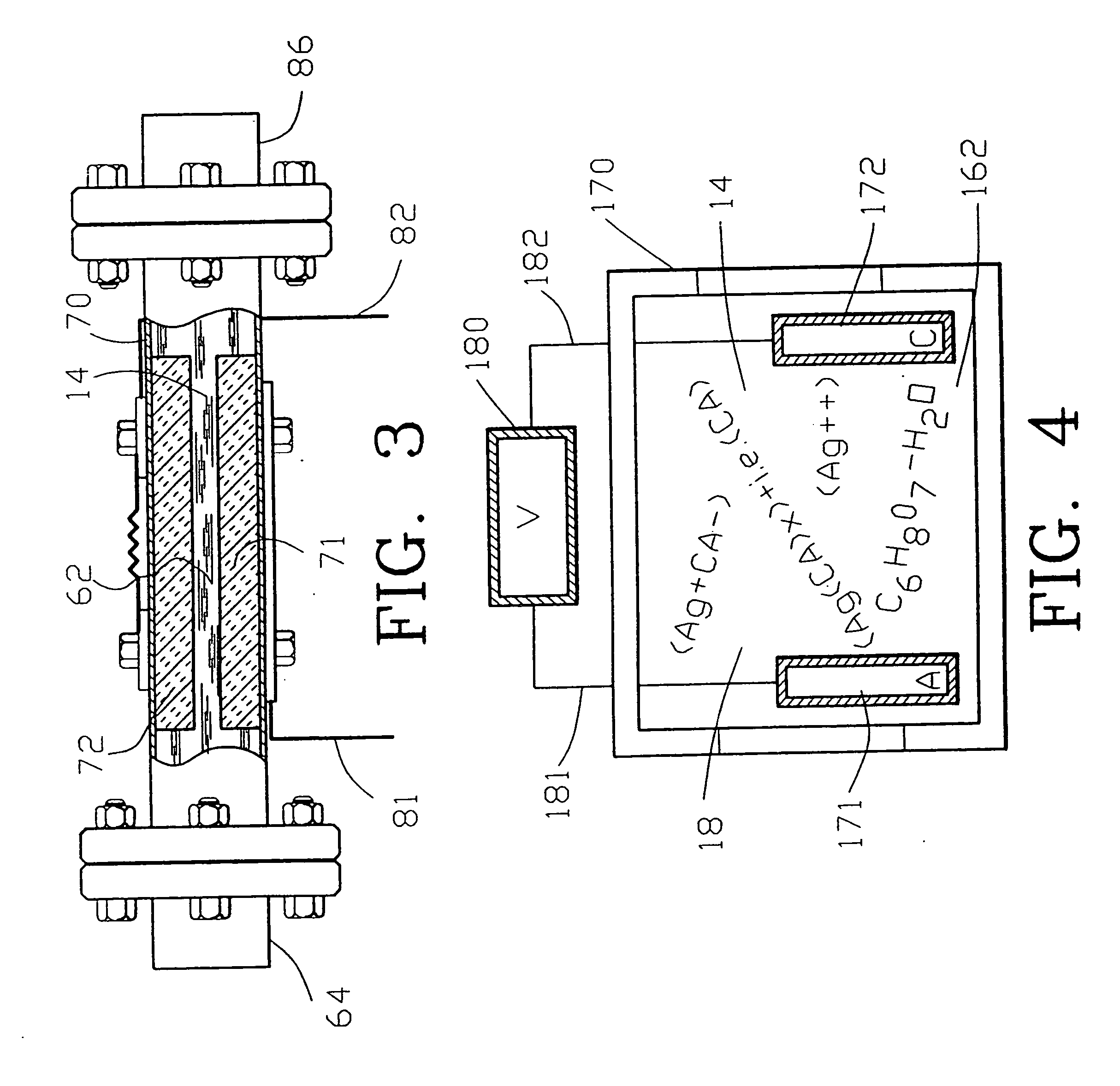

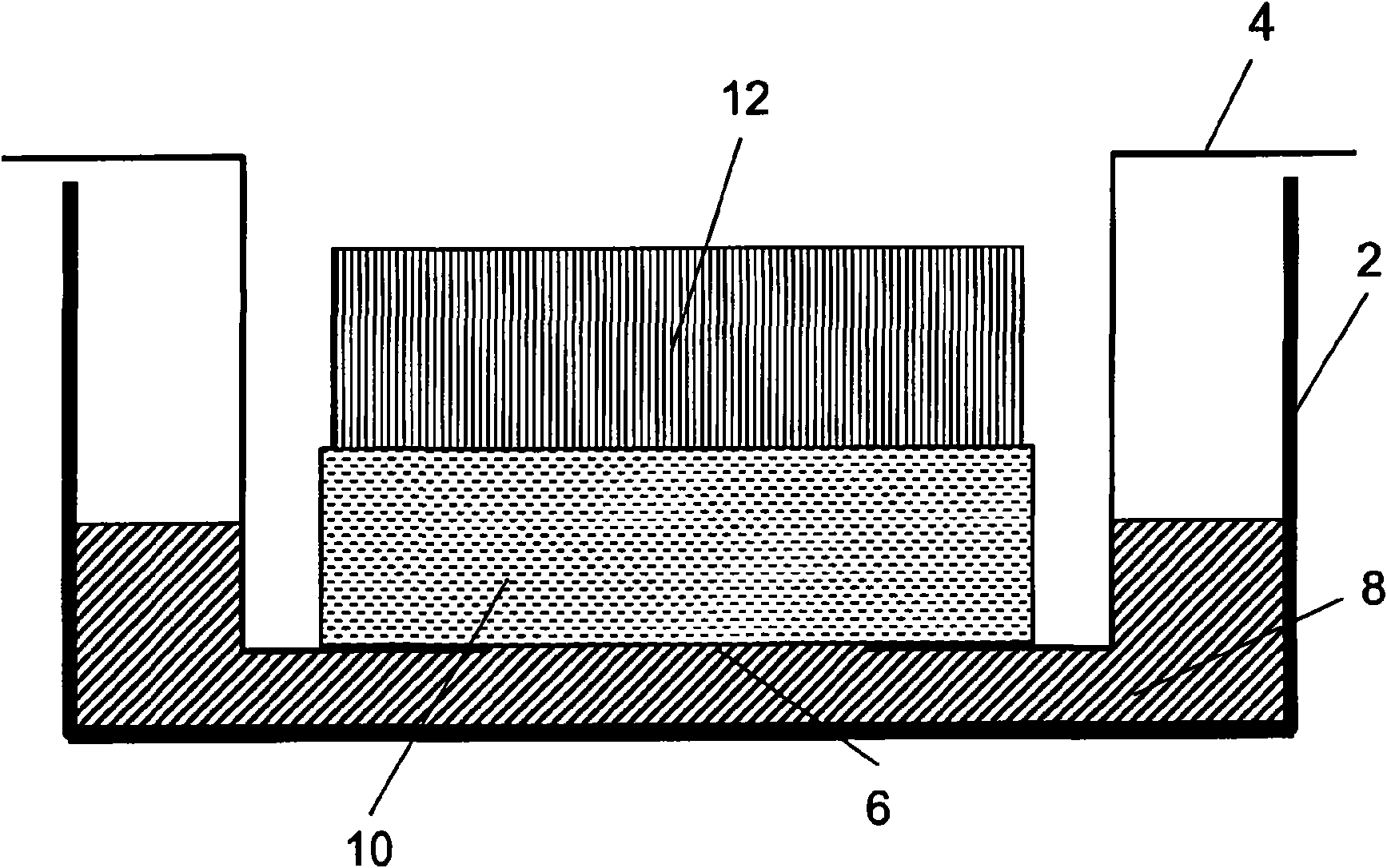

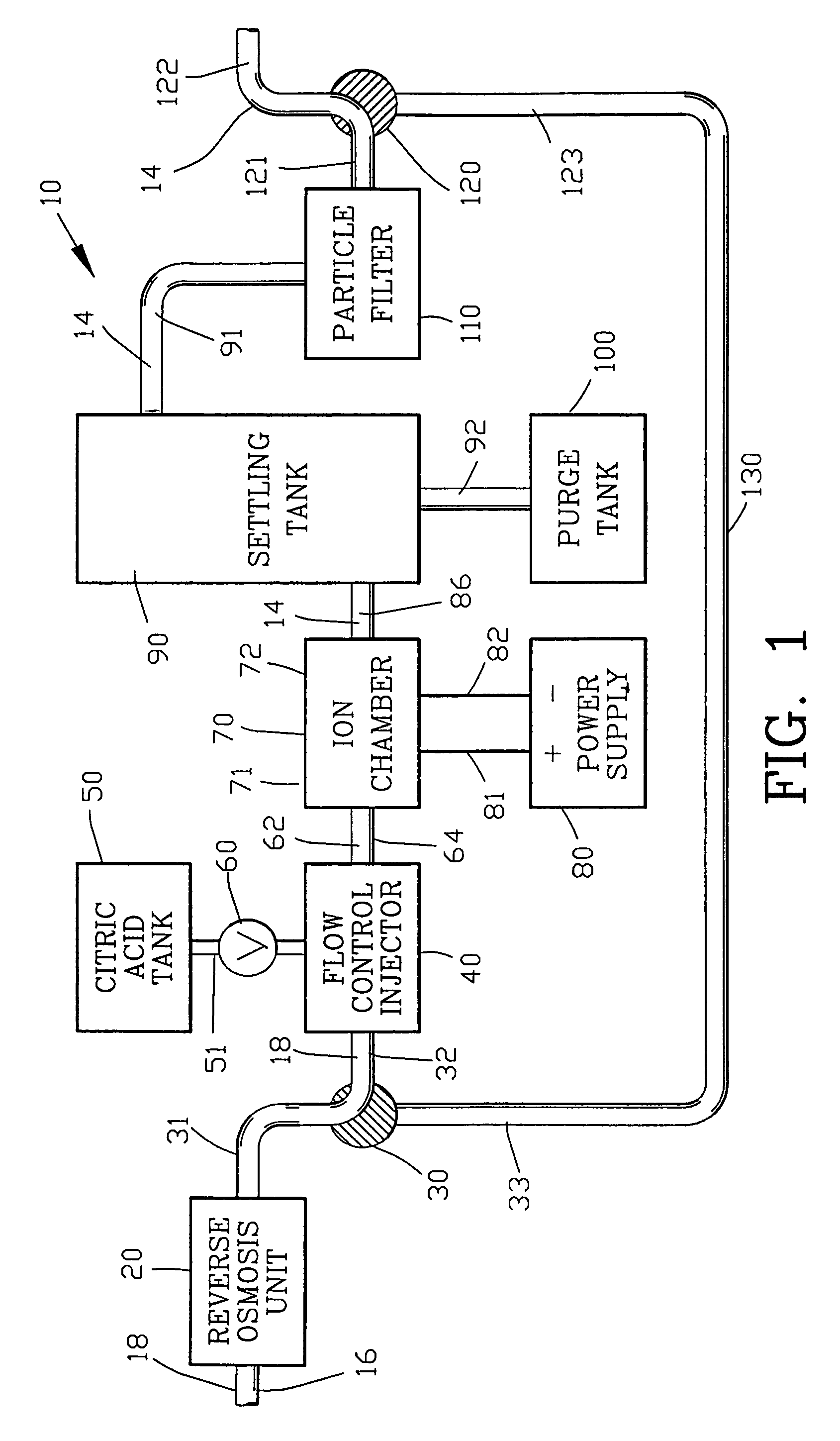

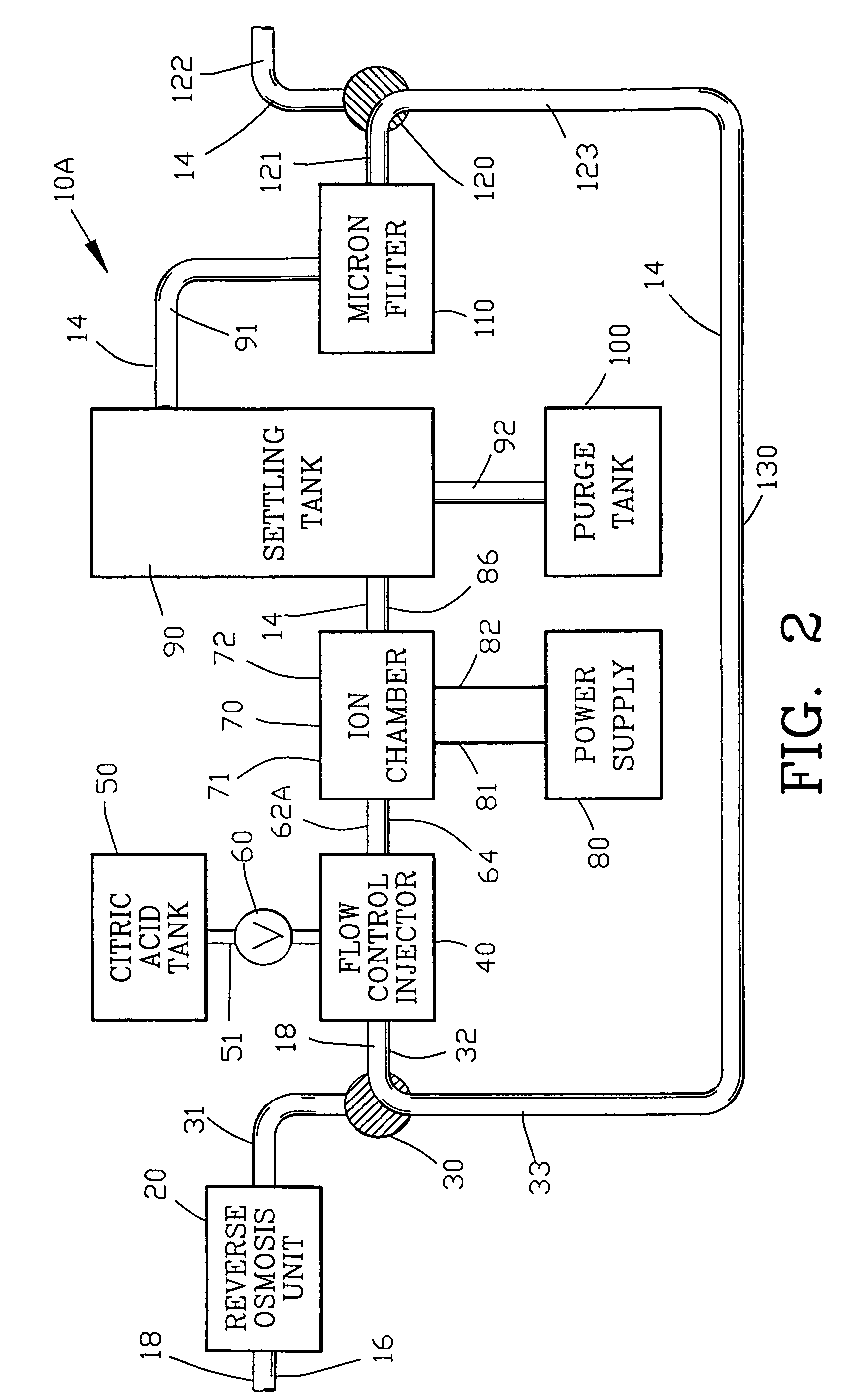

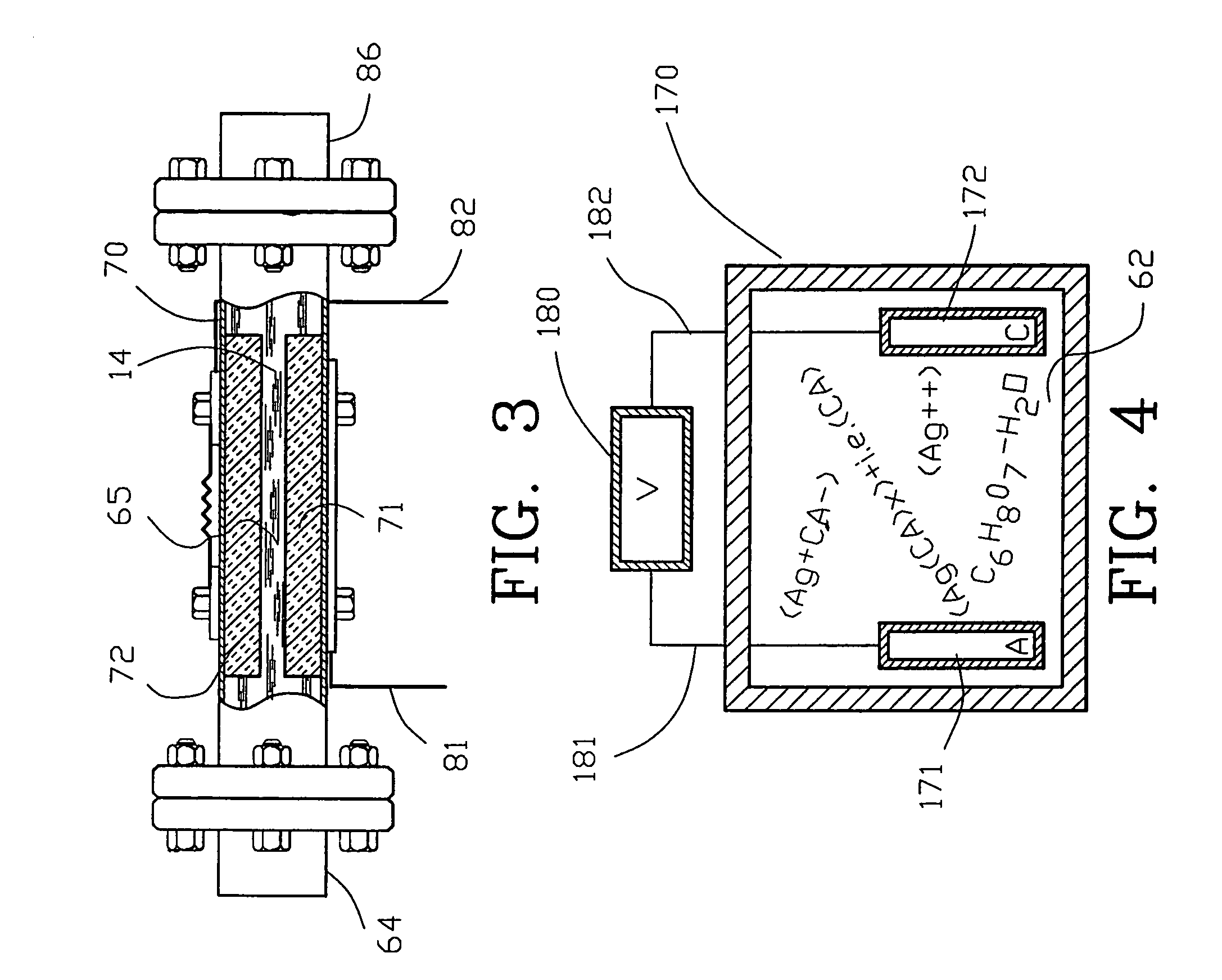

Process for treating water

A process is disclosed for treating impure water by introducing a solution of electrolyticially generated silver citrate into the impure water wherein the silver is electrolytically generated in a solution of citric acid and water.

Owner:PURE BIOSCI

Composition and process for treating acne

A composition and process is disclosed for treating an acne infection with a composition of electrolytically generated silver citrate. The composition of electrolytically generated silver citrate may be applied topically to the acne infection in an aqueous solution or may be incorporated within a cosmetic product., The acne composition may be combined with a composition component such as a cosmetic, a lotion, an emulsion, a gel or a soap.

Owner:INNOVATIVE MEDICAL SERVICES

Methods and compositions for the treatment of water

InactiveUS20060254988A1Inhibit biofilm growthAvoid maintenanceBiocideNature of treatment waterBiofilm growthSilver citrate

The present disclosure provides methods of treating water sources, including, but not limited to, dental unit water sources, in order to reduce the titer of bacteria and other pathogens in those water sources and also to inhibit biofilm growth and maintenance in surfaces, such as dental unit water lines, that come into contact with those water sources. The disclosure also provides solid compositions comprising silver citrate which are suitable for use in the disclosed treatment methods, and further provides methods for preparing such solid compositions.

Owner:CONFIRM MONITORING SYST

Process for treating water

A process is disclosed for treating impure water by introducing a solution of electrolyticially generated silver citrate into the impure water wherein the silver is electrolytically generated in a solution of citric acid and water.

Owner:PURE BIOSCI

Composition and process for treating acne

A composition and process is disclosed for treating an acne infection with a composition of electrolytically generated silver citrate. The composition of electrolytically generated silver citrate may be applied topically to the acne infection in an aqueous solution or may be incorporated within a cosmetic product. The acne composition may be combined with a composition component such as a cosmetic, a lotion, an emulsion, a gel or a soap.

Owner:PURE BIOSCI

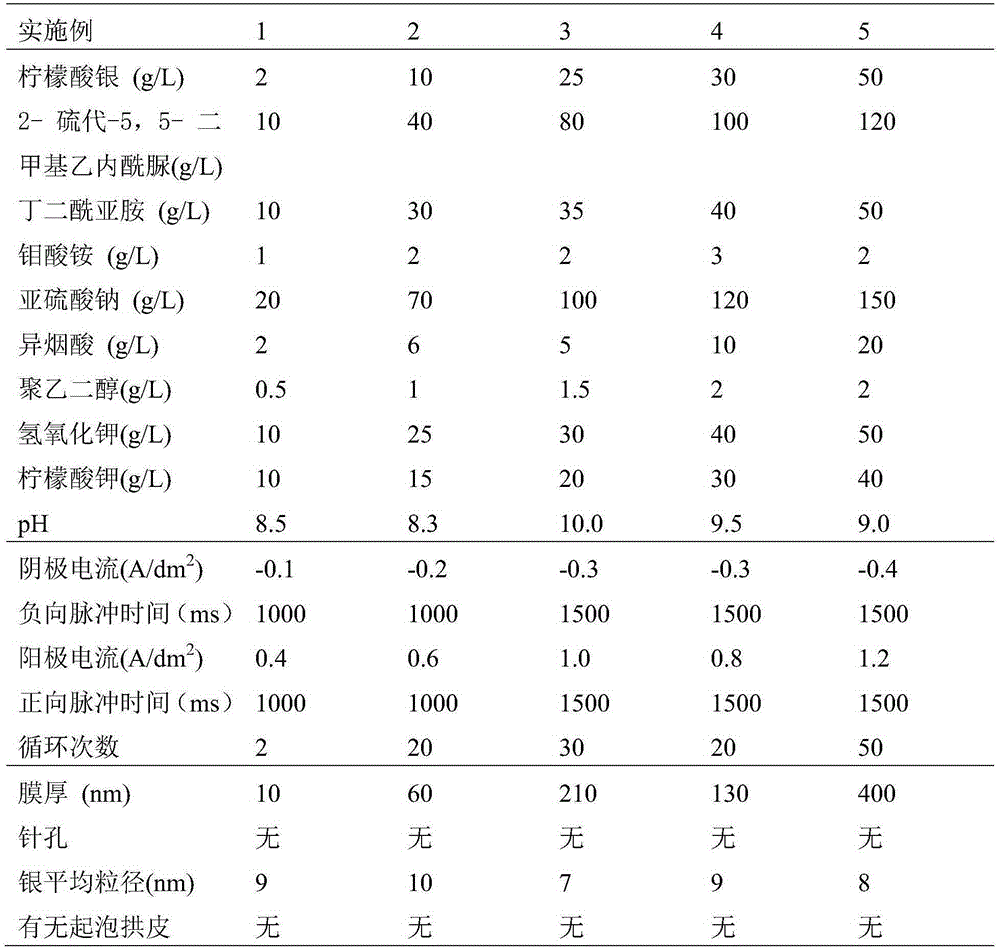

Electroplating liquid for pulse electroplating for compact silver film on ceramic surface and electroplating method thereof

InactiveCN105316716AUniform brightnessUniform film thicknessHydantoin derivativesPolyethylene glycol

The invention discloses an electroplating liquid for pulse electroplating for a compact silver film on a ceramic surface and an electroplating method thereof. The electroplating liquid comprises 2-50g / L of silver citrate, 10-120g / L of 2-sulpho-5,5-dimethyl hydantoin, 10-50g / L of succinimide, 10-50g / L of potassium hydroxide, 10-40g / L of potassium citrate, 1-3g / L of ammonium molybdate, 0.5-2g / L of polyethylene glycol, 20-150g / L of sodium sulphite, and 5-20g / L of isonicotinic acid, wherein the pH value of the electroplating liquid is adjusted to 8-10 by virtue of potassium hydroxide, and the temperature of the electroplating liquid is kept at 25-45 DEG C; and the ceramic pre-plated metal layer surface is electroplated by a square-wave pulse current method, and a layer of compact silver film can be electrodeposited. The electroplating liquid is high in stability; and the plating layers obtained by the pulse electroplating method are smooth and compact, uniform in brightness, and high in performance of binding with a ceramic matrix.

Owner:苏州市金星工艺镀饰有限公司

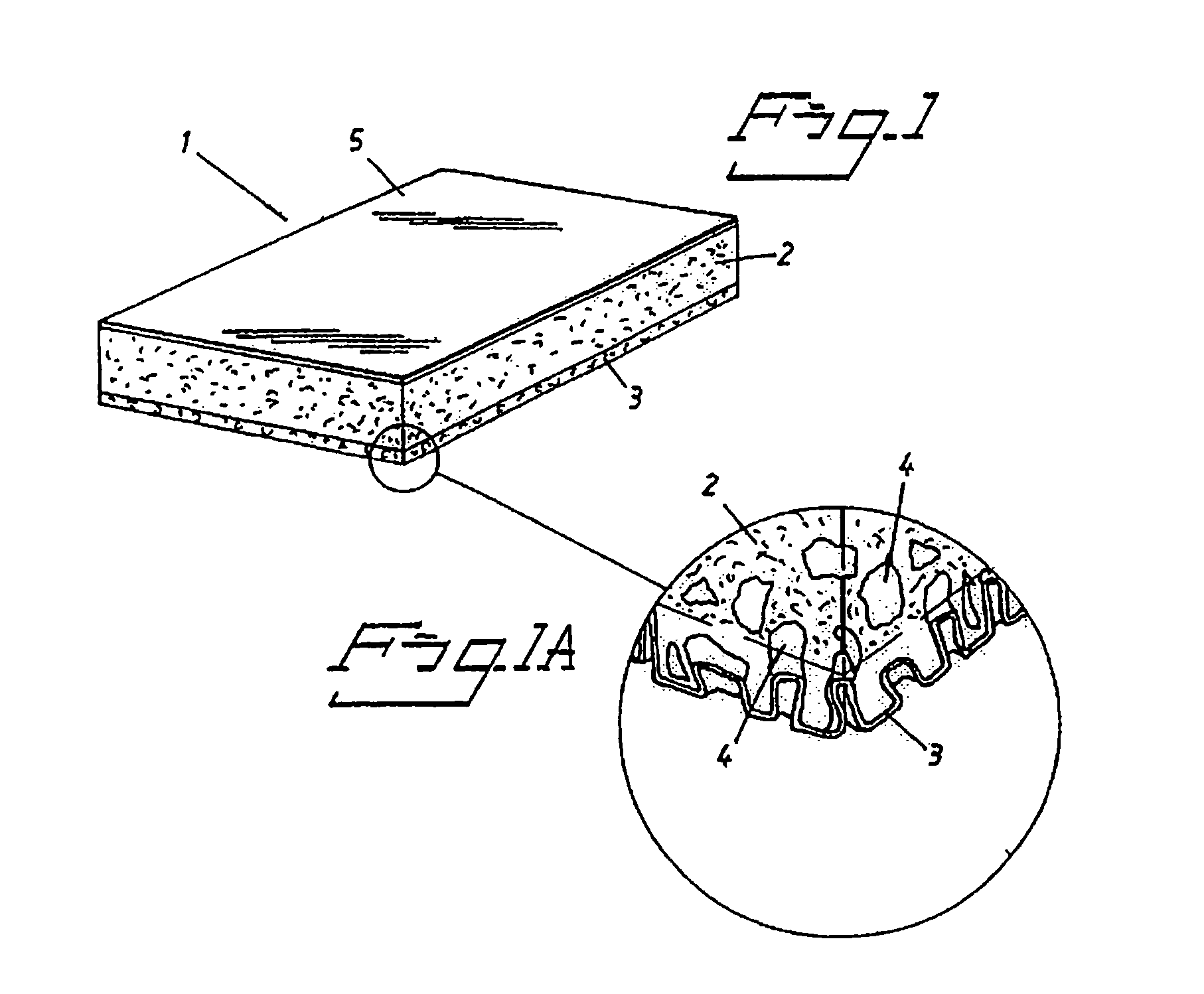

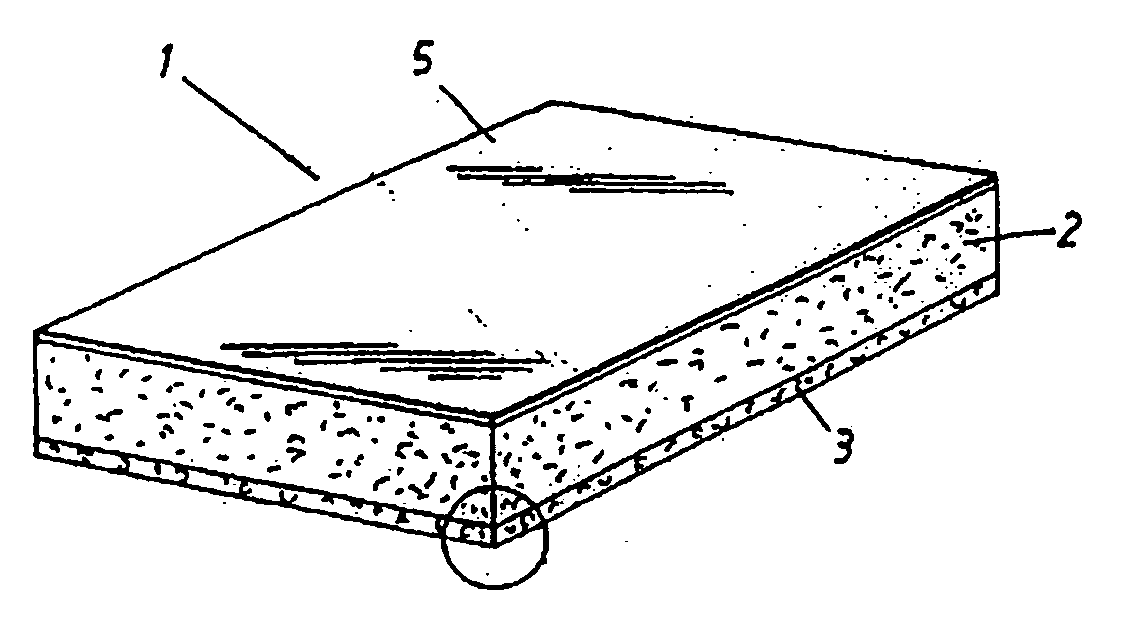

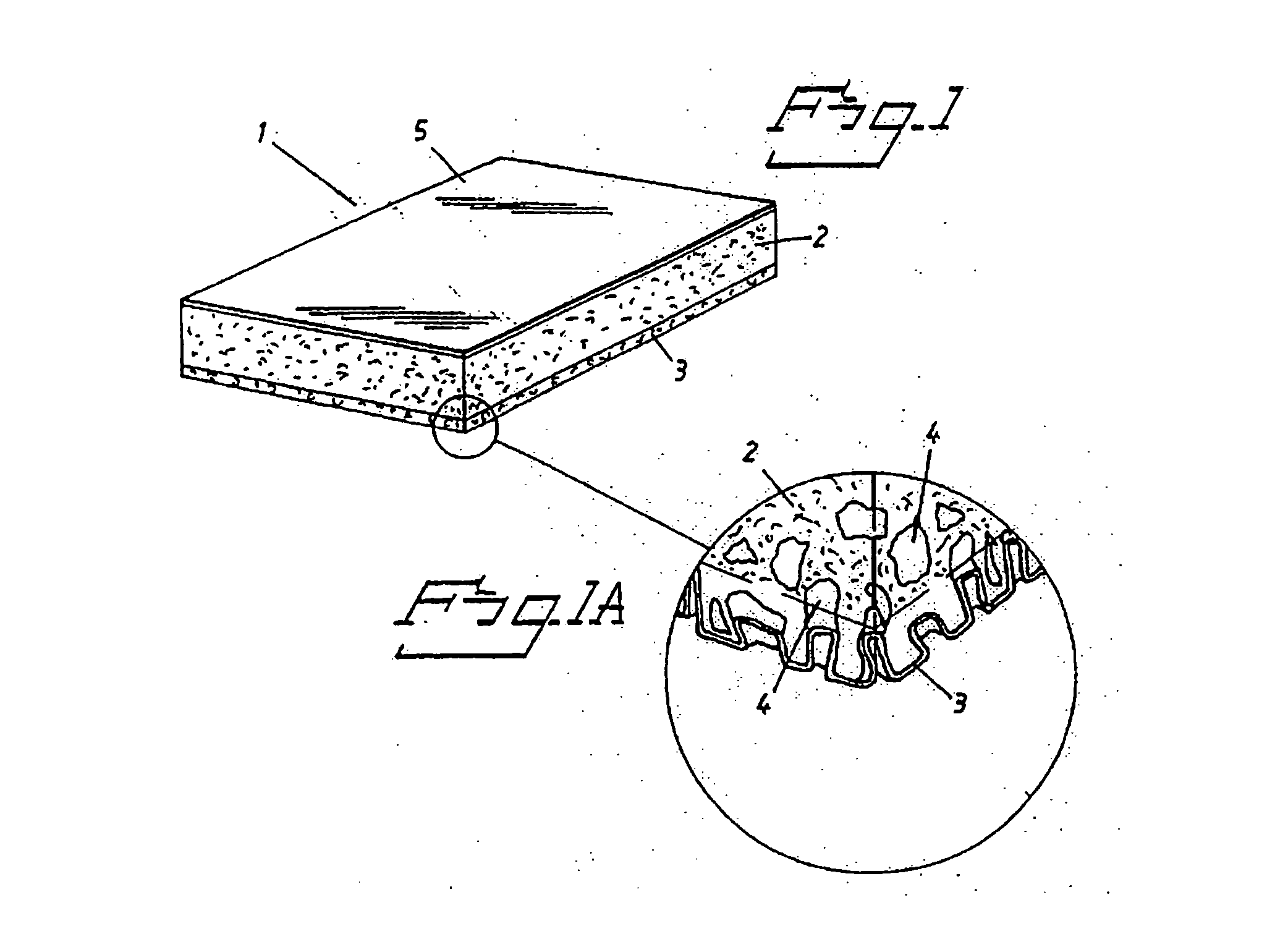

Silver-containing foam structure

ActiveUS8263100B2Reduce the amount requiredFacilitated releaseAntibacterial agentsPowder deliveryWound dressingSilver carbonate

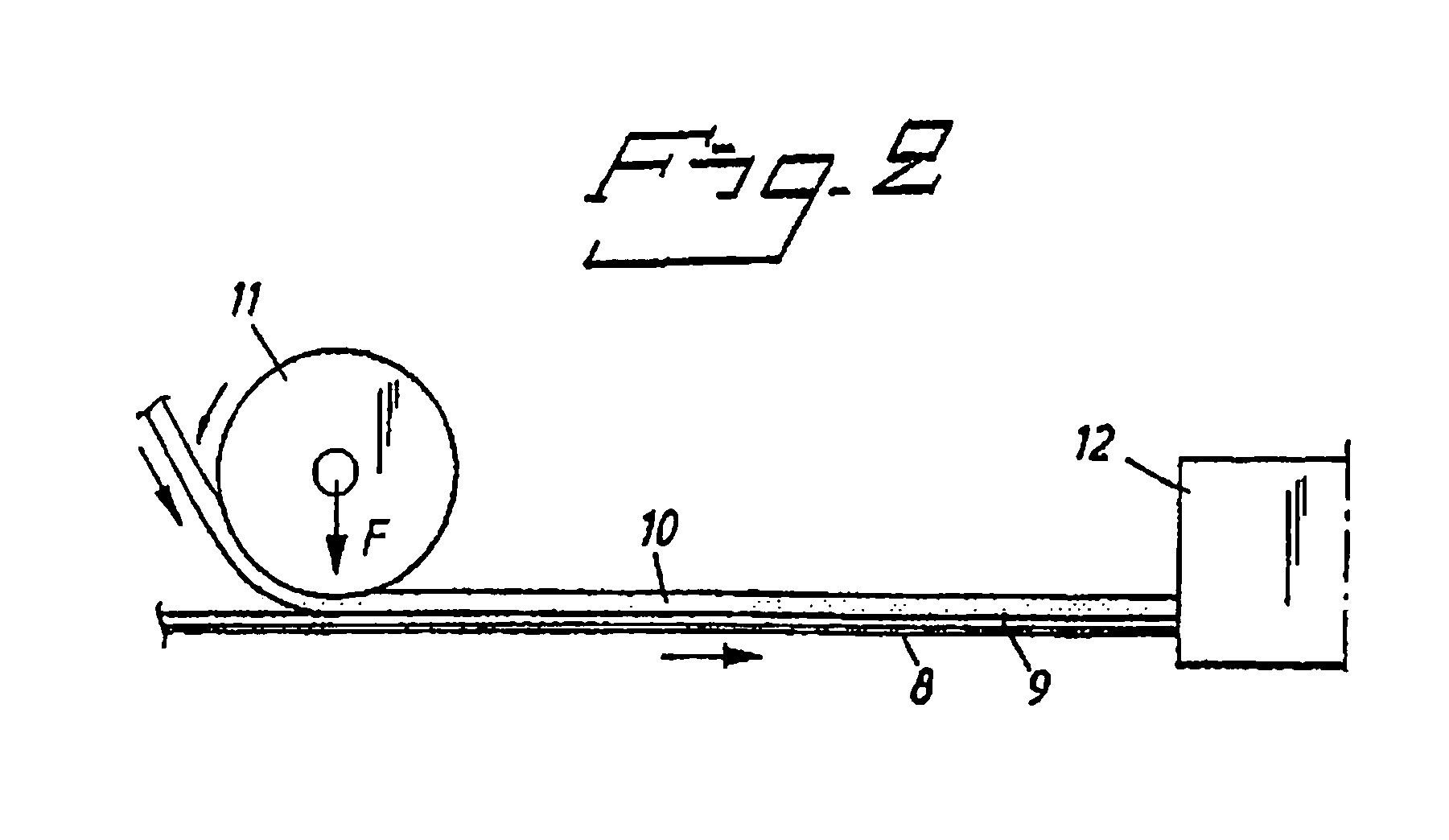

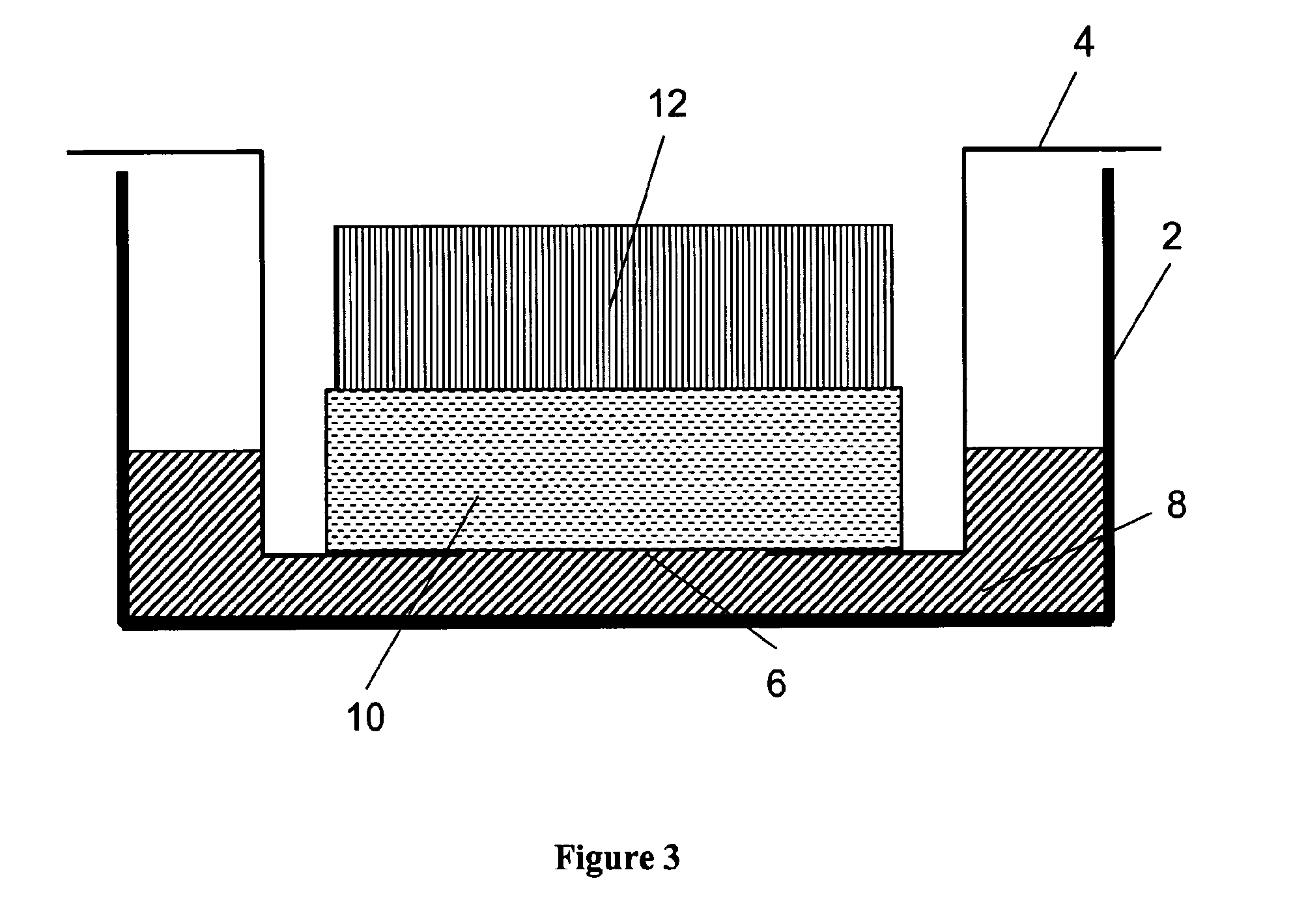

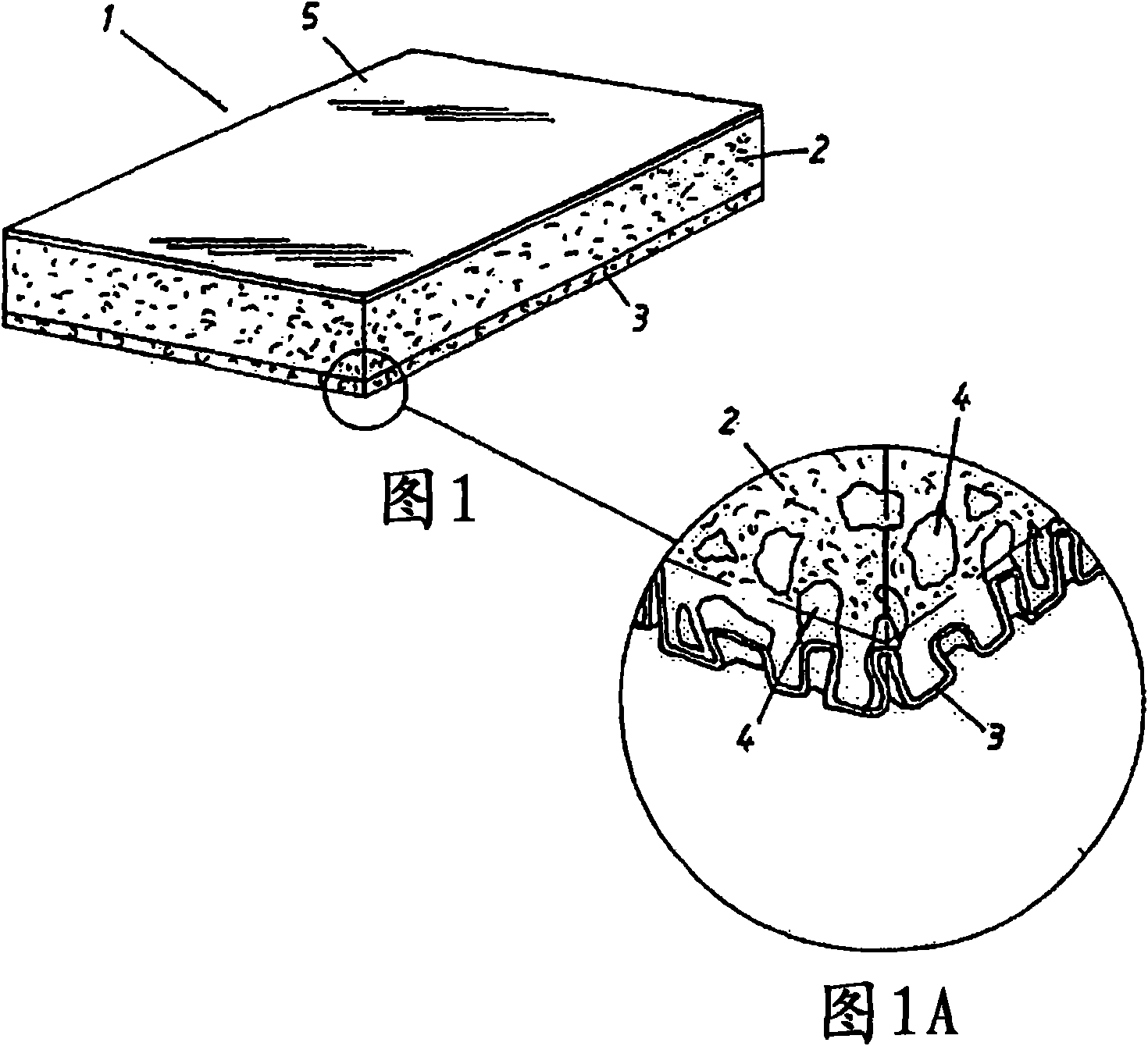

A method of producing a hydrophilic polyurethane foam structure containing a silver salt, chosen from the group of silver sulphate, silver citrate, silver acetate, silver carbonate, silver lactate and silver phosphate, or a mixture of these salts includes the steps of (a) providing a water phase containing a surfactant, and at least one silver salt, wherein the at least one silver salt is dispersed in the water phase; (b) providing a isocyanate-terminated polyether having functionality of more than (2); (c) mixing the water phase and the isocyanate-terminated polyether, immediately transferring the resulting mixture to a mould whereby a foam structure is obtained; and (d) drying the foam structure until it has a moisture content of at most 10% (wt). The hydrophilic polyurethane foam structure produced by the method and a wound dressing containing the foam structure are also described.

Owner:MOLNLYCKE HEALTH CARE AB

Composite visible-light-induced catalyst and preparation method and application thereof

InactiveCN107029777AHigh utilization rate of visible lightImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationSilver citrateWastewater

The invention discloses a composite visible-light-induced catalyst and a preparation method and application thereof. The composite visible-light-induced catalyst is prepared from CNT-silver citrate and g-C3N4-PO43- through a precipitation method, wherein the CNT-silver citrate is prepared from CNT, sodium citrate and AgNO3 through surface complexing action, and the g-C3N4-PO43- is prepared from g-C3N4 and NaH2PO4 through surface phosphorylation. The preparation method includes the steps of preparation of the CNT-silver citrate, preparation of the g-C3N4-PO43- and preparation of CNT / Ag3PO4 / g-C3N4. The composite visible-light-induced catalyst can be applied to treatment of antibiotic wastewater and has the advantages of high visible light utilization rate, stable presence in water and stable photocatalytic performance.

Owner:CHANGSHA UNIVERSITY

Silver-containing foam structure

Owner:MOLNLYCKE HEALTH CARE AB

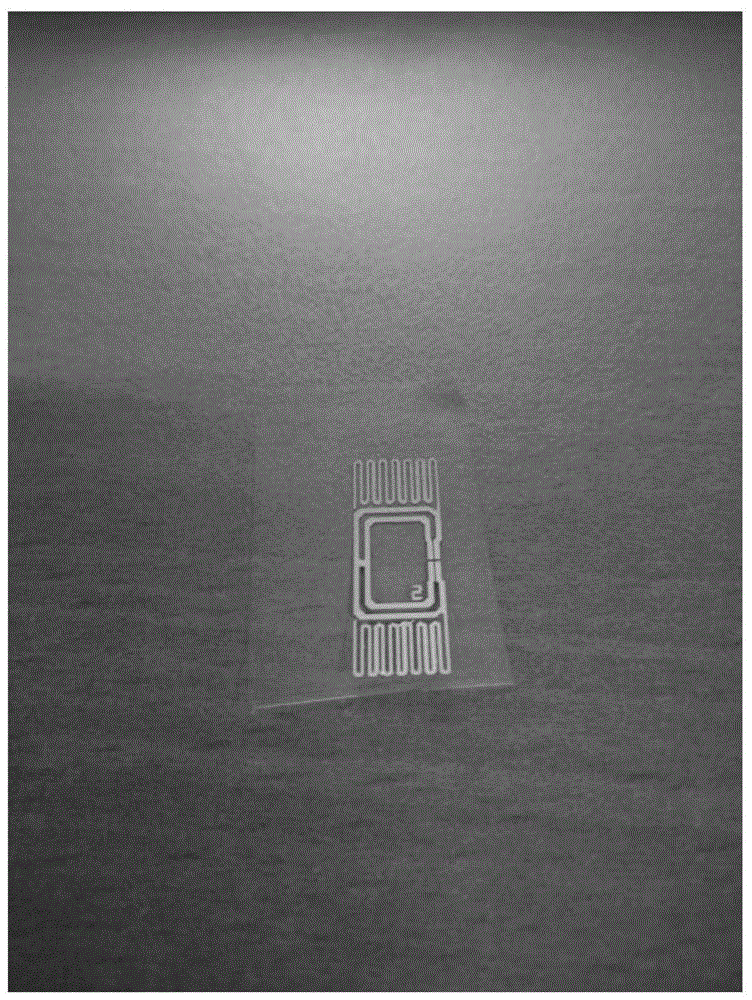

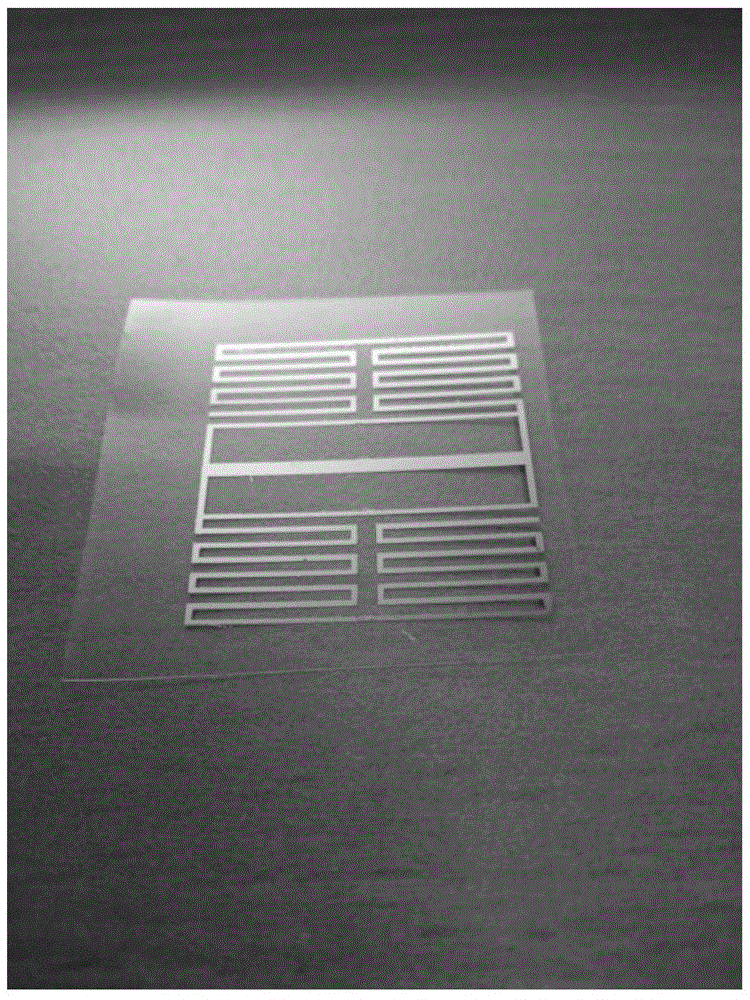

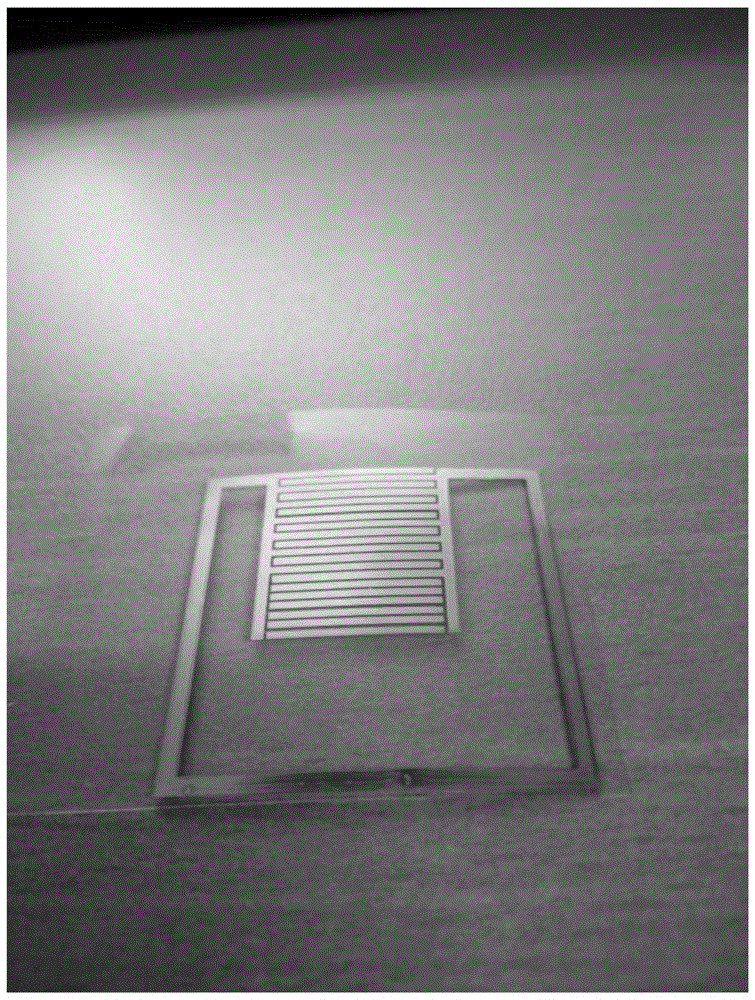

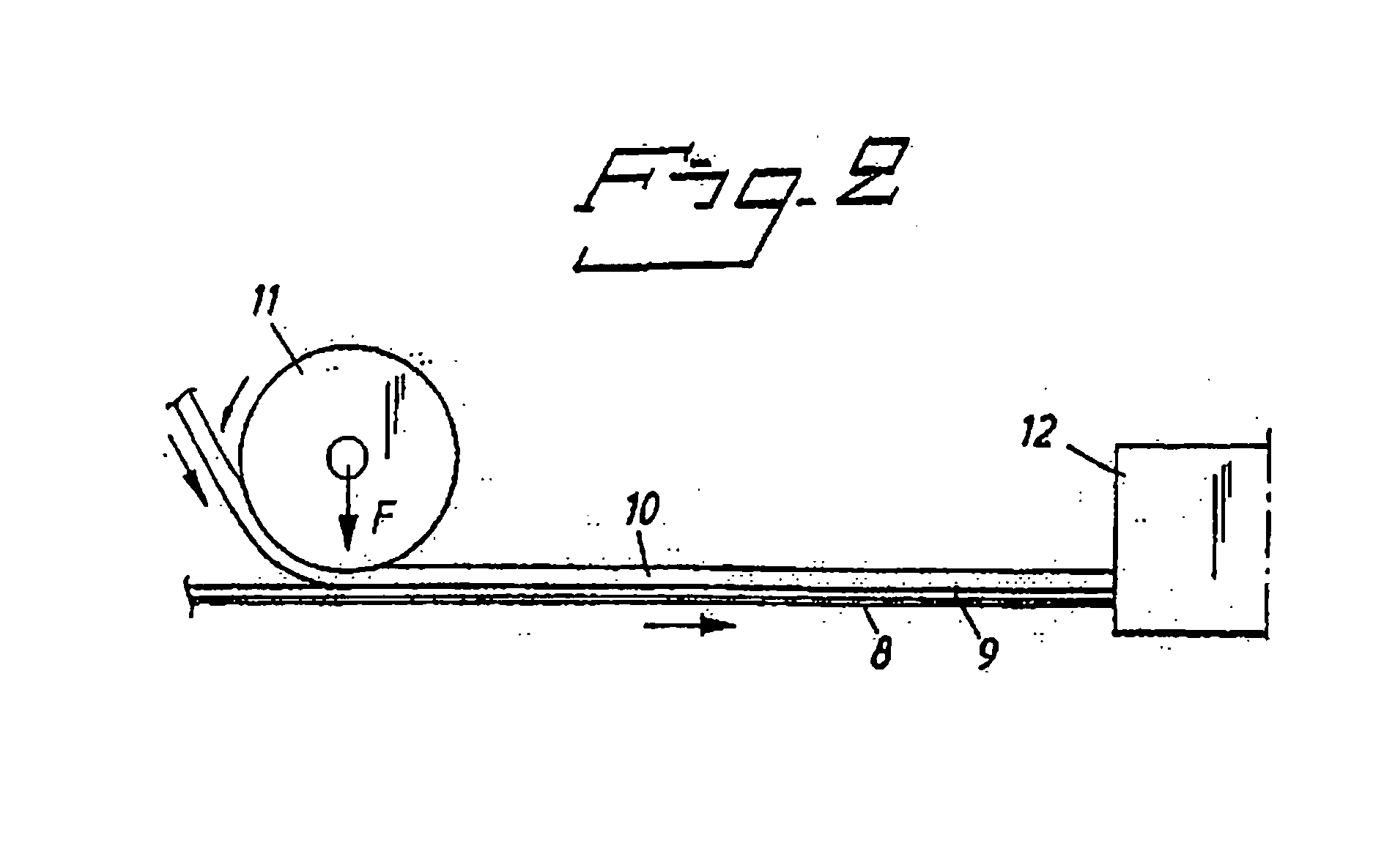

Agranular type silver-based conductive ink and preparation method therefor and application thereof

The invention discloses agranular type silver-based conductive ink. The agranular type silver-based conductive ink is prepared from the following raw materials in percentage by weight: 20-55% of a metal silver salt, 30-50% of an alcohol amine solution, 10-30% of a reducing agent and 0.3-0.5% of an additive, wherein the metal silver salt is at least one of silver nitrate, silver citrate and silver acetate; the alcohol amine solution is prepared by mixing an alcohol solvent and an amine solvent in a volume ratio of 1: (0.5-3); the reducing agent is at least one of ascorbic acid and formic acid; and the additive is at least one of curdlan and carboxymethyl cellulose sodium. The invention further discloses a preparation method for the conductive ink and the application in preparing an RFID label antenna. The conductive ink disclosed by the invention is strong in stability, low in thermal treatment temperature, simple in preparation method and easy to realize industrial production.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Silver-containing foam structure

ActiveUS20100196501A1Reduce the amount requiredFacilitated releaseAntibacterial agentsPowder deliveryWound dressingSilver carbonate

A method of producing a hydrophilic polyurethane foam structure containing a silver salt, chosen from the group of silver sulphate, silver citrate, silver acetate, silver carbonate, silver lactate and silver phosphate, or a mixture of these salts includes the steps of (a) providing a water phase containing a surfactant, and at least one silver salt, wherein the at least one silver salt is dispersed in the water phase; (b) providing a isocyanate-terminated polyether having functionality of more than (2); (c) mixing the water phase and the isocyanate-terminated polyether, immediately transferring the resulting mixture to a mould whereby a foam structure is obtained; and (d) drying the foam structure until it has a moisture content of at most 10% (wt). The hydrophilic polyurethane foam structure produced by the method and a wound dressing containing the foam structure are also described.

Owner:MOLNLYCKE HEALTH CARE AB

Powerful hair treatment agent with anti-washout effect

Hair treatment agents are provided herein. The hair treatment agent contains at least one fatty alcohol; at least one cationic surfactant; at least one divalent or trivalent metal salt; at least one silver salt selected from silver acetate, silver adipate, silver citrate, silver galactarate, silver gluconate, silver lactate, silver malate, silver mandelate, silver salicylate, silver succinate, silver sulfate, and silver tartrate; and at least one organic acid selected from adipic acid, succinic acid, citric acid, acetic acid, galactaric acid, gluconic acid, hydroxysuccinic acid, mandelic acid, lactic acid, salicylic acid, sulfuric acid, and tartaric acid. The hair treatment agent reduces or prevents the fading of color from dyed hair.

Owner:HENKEL KGAA

Antibacterial biological film material and preparation method thereof

The invention provides an antibacterial biological film material and a preparation method thereof. The antibacterial biological film material is prepared from the following components: polylactic acid, ethyl orthosilicate, silver citrate, titanium dioxide, chitosan solution, polyisopropyl acrylamide colloid, acetone, N,N-dimethylformamide, didecyl dimethyl ammonium chloride, sodium dodecyl sulfate, an antioxidant, an antibacterial agent and water. The biological film material prepared with the method provided by the invention has the functions of killing bacteria and preventing mildew, has long-lasting antibacterial property, can be used for various purposes in the antibacterial field, such as food packaging, fresh-keeping bags, and drug packaging, and is low in preparation cost, simple inmethod, non-toxic and harmless.

Owner:合肥市晨雷思建筑材料科技有限公司

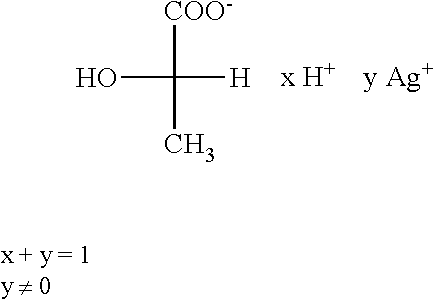

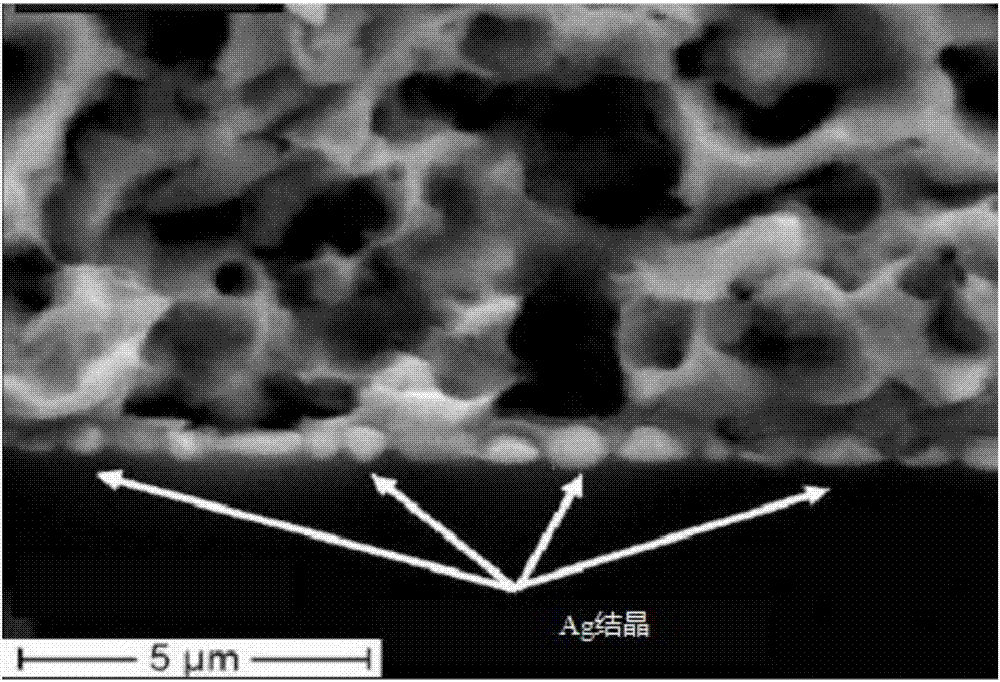

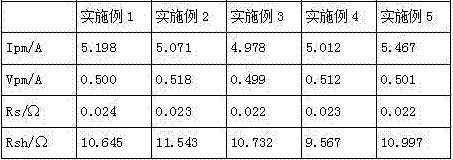

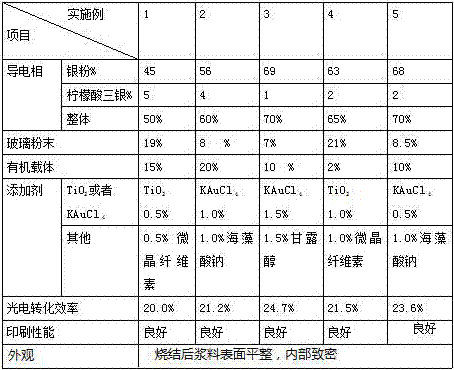

Photovoltaic cell applied silver paste and preparation method thereof

ActiveCN107240435AGood printabilityNarrow widthNon-conductive material with dispersed conductive materialPhotovoltaic energy generationMannitolMuffle furnace

The invention relates to photovoltaic cell applied silver paste and a preparation method thereof. The silver paste comprises the following components: 50-70% of conductive phase, 10-25% of glass frit, 10-25% of organic carrier and 1-3% of additive. The above proportions are in mass percent, wherein the conductive phase is a mixture of silver powder and tri-silver citrate. The additive is a mixture of TiO2 or KAuCl4 with any one the following elements: microcrystalline cellulose, sodium alginate and mannitol. The method comprises: (1) adding the mixture of the ethyl alcohol absolute and the ethylene glycol to the conductive phase and the glass frit; (2) taking the organic carrier to mix with the organic solvent and grinding it with a three-roll mill; (3) preparing a silver film through the screen printing technology; and (4) placing the printed silver film in a muffle furnace and calcining it at a temperature from 700-800 degrees for three to five seconds. The silver paste of invention has a good printing performance and a low contact resistance with the silicon wafer. After the sintering of the silver paste, the electrode has a narrow width and a high thickness and can achieve good compactness, reducing the use amount of silver paste greatly. The overall cost is also low.

Owner:JURONG GCL SYST INTEGRATION TECH CO LTD

Negative ion functional chip, preparation method and negative ion sanitary napkin

PendingCN112472863ADurable bacteriostasisSimple production processSanitary towelsBandagesCarboxylic acidAnti bacteria

The invention relates to a negative ion functional chip, a preparation method and a negative ion sanitary napkin. The preparation method of the negative ion functional chip comprises the following steps: uniformly adding 1-10 parts by weight of tourmaline powder, 1-10 parts by weight of medical stone powder, 0.5-1.5 parts by weight of carbomer or safflower seed gum, 5-15 parts by weight of carboxylated calcium lignosulphonate, 0.02-0.1 part by weight of copper citrate and 0.01-0.05 part by weight of silver citrate, 0.2-0.5 part of a nanometer titanium dioxide composite material into 50-120 parts of deionized water, performing stirring for 5-15 min at the rotating speed of 100-400 r / min, performing even mixing to obtain negative ion finishing liquid; putting a chip in the negative ion finishing liquid at the temperature of 40-50 DEG C to be soaked, the mass ratio of the chip to the negative ion finishing liquid being 1: (310), and the soaking time being 20-50 min; and then performing drying at a temperature of 40-60 DEG C for 1-5h to obtain the negative ion functional chip. The negative ion functional chip and the sanitary napkin prepared by the invention have the functions of instant absorption and softening, also have the effects of lasting bacteriostasis and anion release, and can dredge qi and blood, resist bacteria, diminish inflammation and relieve menstrual discomfort symptoms.

Owner:何志方

Process for treating water

A process is disclosed for treating impure water by introducing a solution of electrolyticially generated silver citrate into the impure water wherein the silver is electrolytically generated in a solution of citric acid and water.

Owner:PURE BIOSCI INC

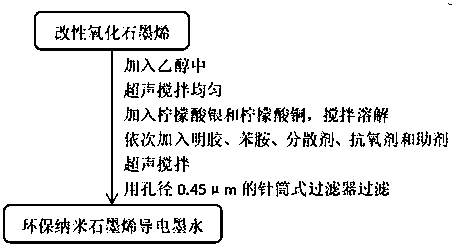

Environmentally friendly nano graphene conductive ink and preparation method and application thereof

The invention provides environmentally friendly nano graphene conductive ink. The environmentally friendly nano graphene conductive ink is prepared from the following raw materials in parts by weight:26 parts of modified graphene oxide, 20 parts of silver citrate, 17 parts of copper citrate, 6 parts of aniline, 4 parts of gelatin, 2.5 parts of a dispersing agent, 4 parts of an antioxidant, 3 parts of an auxiliary agent, 60 parts of ethanol and 30 parts of water. The preparation method of the modified graphene oxide comprises the following steps: S1, preparing graphene oxide by using a liquid-phase stripping method; S2, adding the prepared graphene oxide in deionized water, ultrasonically stirring uniformly, adding a silane coupling agent, carrying out stirring reaction at the temperatureof 60 DEG C, cooling to the room temperature, centrifuging, removing supernatant liquid, and drying solid to obtain silane coupling agent modified graphene oxide. The preparation method is simple, rawmaterial sources are wide, the electrical resistivity of the conductive ink is low, and the environmentally friendly nano graphene conductive ink adheres to a base material strongly, is unlikely to oxidize, is good in stability, can meet the requirement for printability, and is safe and environmentally friendly.

Owner:蓝宇涛

Preparation method of quick-dry fluorescent ink

The invention discloses a preparation method of quick-dry fluorescent ink, which comprises the following steps: taking a three-neck flask 1 with a mechanical stirring device and a condensing tube, adding phloroglucinol, acetyl ethyl acetate, 1, 4-dioxane and concentrated H2SO4 into the three-neck flask 1, and uniformly mixing; according to the preparation method of the quick-dry fluorescent ink, a fluorescent agent c and modified resin f are mixed, then a modified mixed base material is added, graphene subjected to oxidation treatment and a silver citrate complexing solution are mixed to prepare the modified mixed base material, and the prepared fluorescent ink is sintered to obtain the quick-dry fluorescent ink. The thermal treatment process is optimized, the conductivity of the fluorescent ink can be obviously improved, the ink prepared from the modified mixed base material has good stability, only a small amount of black precipitates appear at the bottom of a bottle after the ink is stored at room temperature for 60 days, the precipitates completely disappear after the ink is stirred again, and the prepared thin film is small in resistivity change and good in stability. The quality of the fluorescent ink is improved.

Owner:董凯辉

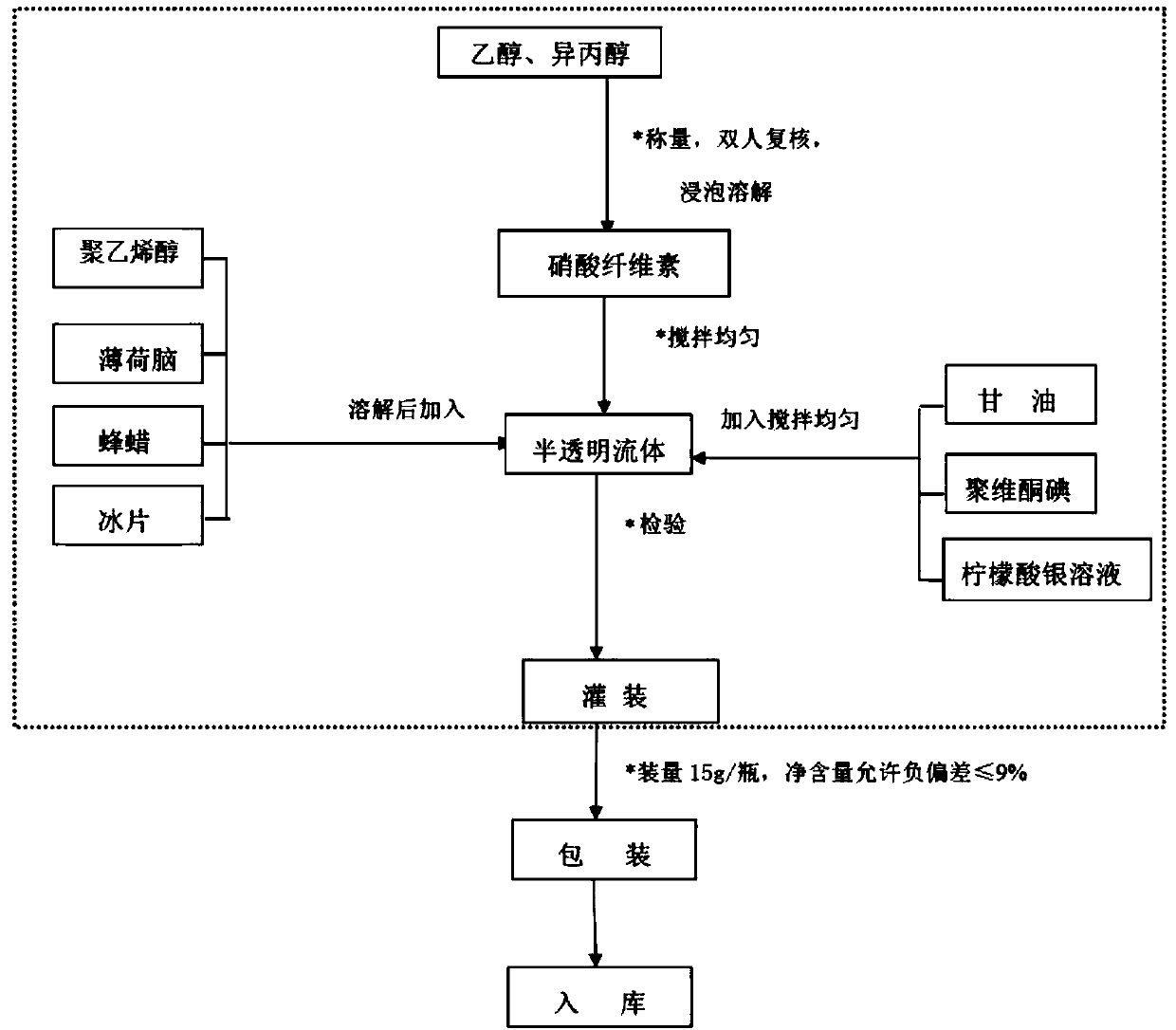

Liquid band-aid and preparation method thereof

The invention belongs to the technical field of medical treatment and in particular relates to a liquid band-aid and a preparation method thereof. The liquid band-aid is prepared from the following raw materials in percentage by mass: 20-30% of ethanol, 15-25% of nitrocellulose, 10-20% of isopropanol, 5-10% of glycerinum, 5-10% of povidone-iodine, 2-5% of beewax, 1-5% of borneol, 1-3.5% of menthol, 1-2% of polyvinyl alcohol and 0.1-0.2% of a silver citrate solution. The liquid band-aid compounded by the silver citrate solution, povidone-iodine, beewax, borneol and the like is relatively smallin skill irritation and quick to form a film, and has the functions of stopping bleeding, protecting wounds, preventing bacteria and eliminating inflammation and promoting wound healing. By adding thesilver citrate solution into the liquid band-aid, skin is far way from pollution as a result of antibacterial performance of silver. Growth of bacteria is controlled, and daily dirt is eliminated, sothat the liquid band-aid is suitable for all skin and crowds of all ages, and is a brand new natural skin care raw material.

Owner:西安中天生物医药有限公司

UV curable solventless antimicrobial compositions

ActiveUS9695323B2Reduce complicationsAntifouling/underwater paintsPaints with biocidesTriclosanChlorhexidine diacetate

Owner:BECTON DICKINSON & CO

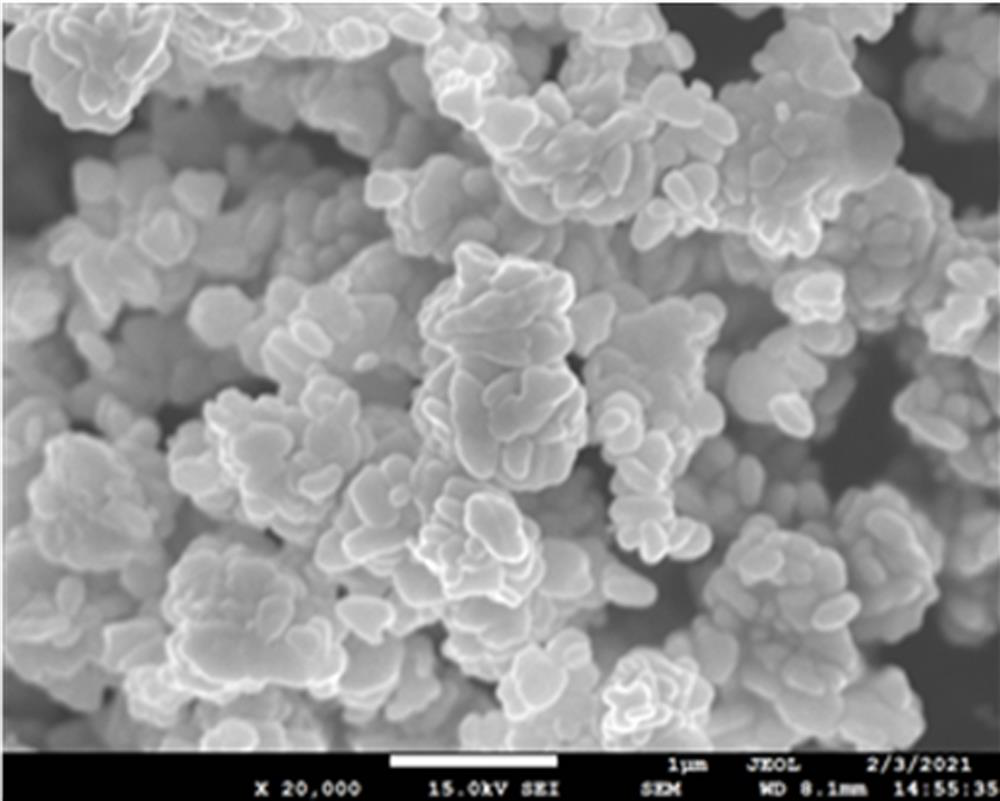

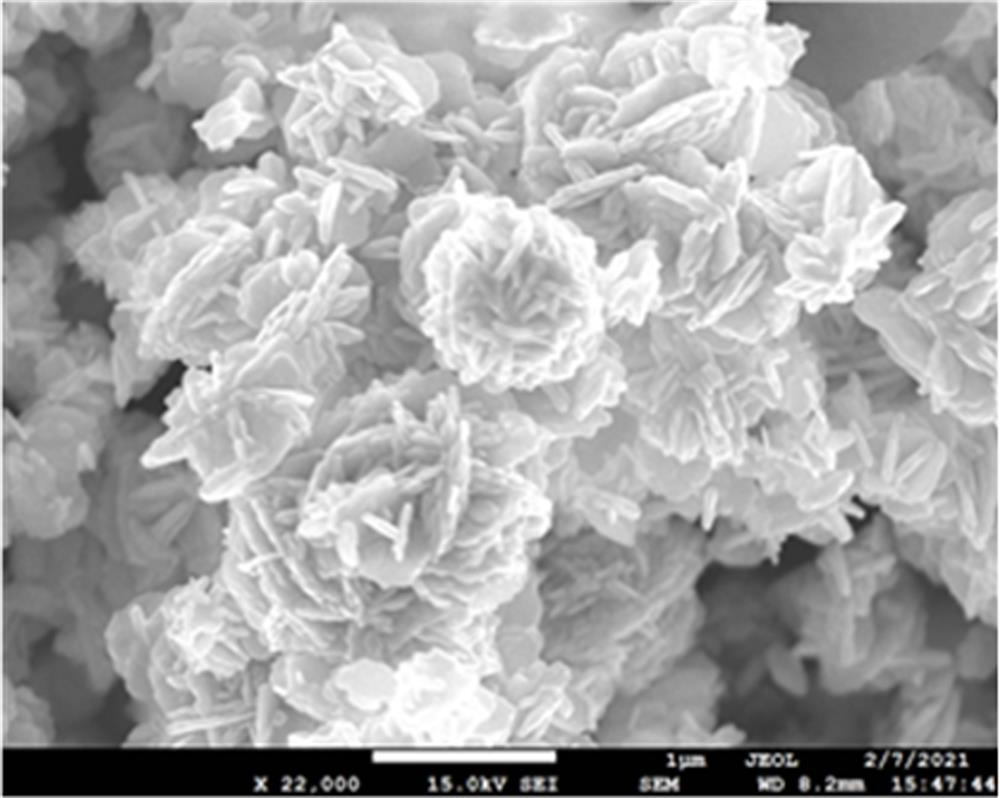

Method for preparing silver powder with environment-friendly metal silver salt

InactiveCN109014244AReduce pollutionSimple production processThermal decomposition methodSilver citrate

The invention discloses a method for preparing silver powder with environment-friendly metal silver salt, and belongs to the technical field of conductive metal powder preparation. The method comprises the following steps of preparing silver citrates and preparing the silver powder by a thermal decomposition method. The silver nitrates are used as raw materials to prepare the environment-friendlymetal silver salt, and the superfine silver powder with 9-12 microns is prepared through thermal decomposition. No wastewater containing ammonia nitrogen is produced in the preparation process of thesilver powder, the production process is simple, environment-friendly and low in cost, and industrial production can be achieved.

Owner:JINCHUAN GROUP LIMITED +1

Food safety detection reagent and preparation method thereof

InactiveCN107741421AThe detection process is fastHigh sensitivityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPlatinum saltsSilver carbonate

The invention discloses a food safety detection reagent. The detection reagent comprises sodium cholate, polyoxyethylene lauryl ether, alpha-ketoglutaric acid, calcium oxalate, sodium citrate and a reductive metal salt solution, wherein the metal salt is a compound of one or more out of gold salts, silver salts and platinum salts; the gold salts are potassium chloraurate, sodium gold sulfite and gold sodium chloride; the silver salts are silver acetate, silver nitrate, silver citrate, silver carbonate and silver oxide; and the platinum salts are platinum tetrachloride, platinum bichloride andpotassium chloroplatinate. The detection reagent disclosed by the invention is capable of rapidly and simply detecting foods and is high in detection speed, high in sensitivity and intuitive and accurate in detection results. Moreover, the detection agent disclosed by the invention is simple in preparation method, low in cost and convenient to carry, does not need any special instrument or equipment or professional and is easy to popularize and implement.

Owner:SHANDONG WUZHOU DETECTION

Silver nanowire and preparation method and application thereof

ActiveCN110722174ALarge aspect ratioImprove bending resistanceMaterial nanotechnologyTransportation and packagingSolventSeed crystal

The invention relates to a silver nanowire and a preparation method and application thereof. The preparation method of the silver nanowire comprises the following steps that silver salt is dissolved in a first solvent, a first mixture is obtained, the silver salt is selected from at least one of silver trifluoromethanesulfonate, silver diethyl dithiocarbamate and succinimide silver salt, and the first solvent is water; a seed crystal, a reducing agent and a dispersing agent are dissolved in a second solvent at the temperature of 48-72 DEG C, a second mixture is obtained, the seed crystal is selected from at least one of tri-silver citrate or silver tetrafluoroborate, and the second solvent is water; and the first mixture and the second mixture are mixed in a dropwise adding manner, the pHis adjusted to 8-8.5, solid-liquid separation is carried out, and the silver nanowire is obtained. By means of the preparation method, the silver nanowire with the good bending resistance and the longlength-diameter ratio can be obtained.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A kind of particle-free silver-based conductive ink and its preparation method and application

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

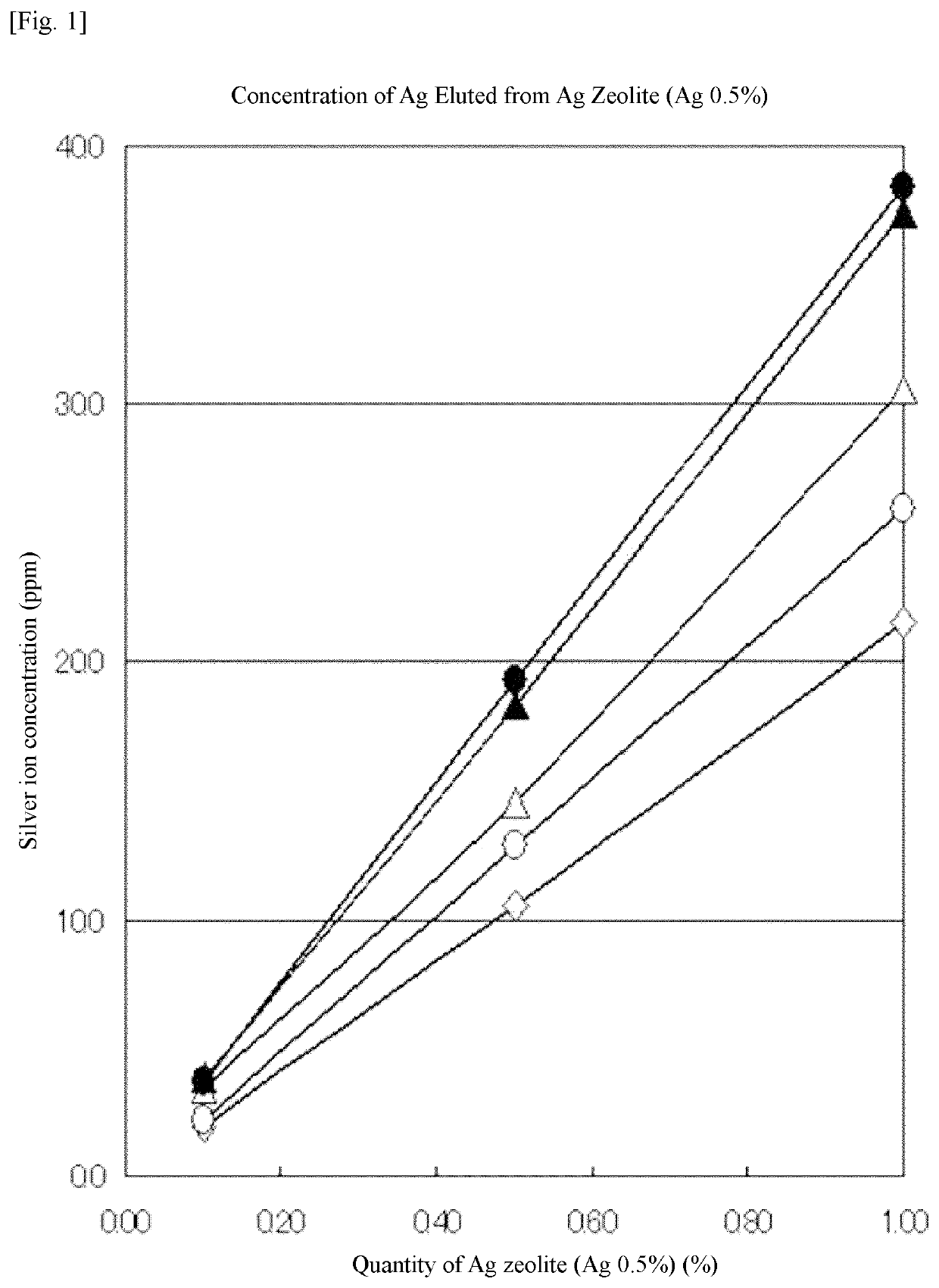

Method for producing silver-ion antibacterial liquid, silver-ion antibacterial liquid produced by said method, method for producing silver-ion antibacterial powder, and silver-ion antibacterial powder produced by said method

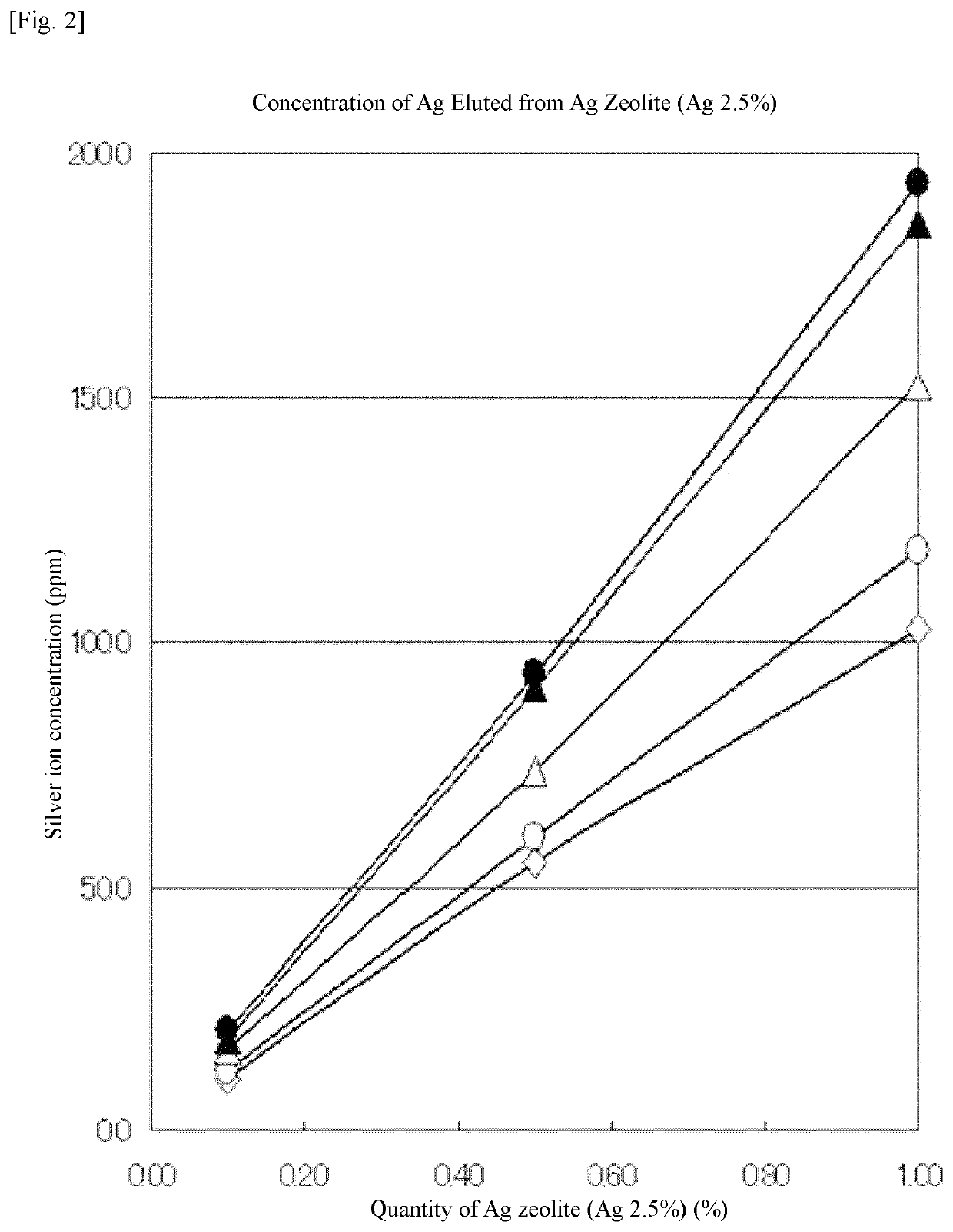

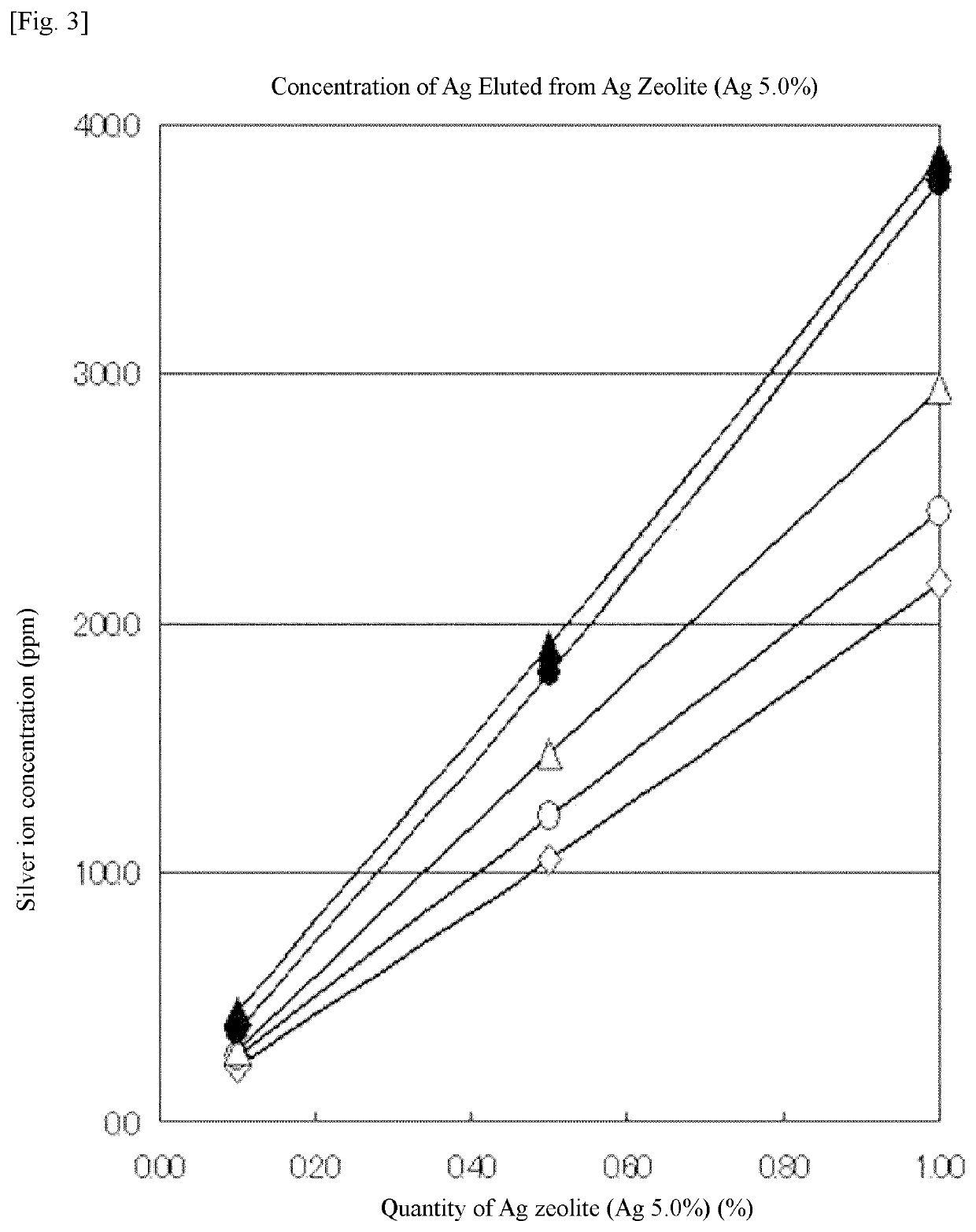

ActiveUS10806149B2Reduce manufacturing costEasy to operateBiocideCosmetic preparationsSilver citrateSilica Hydrate

A method for producing silver-ion antibacterial liquid using a type A or type X silver zeolite includes a process to weigh silver zeolite for obtain its blending quantity in a range of 0.1 to 20.0 percent by weight and to weigh citric acid for obtaining its blending quantity such that its blending ratio to the silver zeolite becomes 1.2 or greater, followed by blending of the two into purified water; a process to mix under agitation the silver zeolite and citric acid blended in the purified water to prepare a mixture liquid containing at least a citric acid-silver complex and silica hydrate; and a process to remove the silica hydrate produced in the mixture liquid. The production method can produce at low cost a silver-ion antibacterial liquid offering immediate bactericidal effect.

Owner:KK TAIKI

Anticorrosion antibacterial defoaming agent and preparation method thereof

InactiveCN109750556AImprove antibacterial propertiesImprove corrosion resistanceDefoamers additionPaper/cardboardCellulosePapermaking

The invention discloses an anticorrosion antibacterial defoaming agent, made from, by weight, 5060 parts of polyurethane elastomer, 37 parts of nano silver oxide, 26 parts of nano zinc oxide, 913 parts of 2-methylpropanol, 711 parts of p-toluenesulfonic acid, 25 parts of magnesium 3-picolinate, 14 parts of silver citrate, 610 parts of cellulose ecteola, 1013 parts of terpene resin, 914 parts of 2-methylacrolein, 58 parts of N-methylaminopropyltrimethoxysilane, 26 parts of 4-methylthiazole-5-carboxaldehyde, 713 parts of cyclic AMP, 1216 parts of phentolamine, and 48 parts of azodicarbonamide. The anticorrosion antibacterial defoaming agent, as a papermaking aid, has the good integrated properties of corrosion resistance, bacterial resistance and high temperature resistance, is more widely applicable and meets the diverse needs of the market.

Owner:青岛凯玉盈商贸有限公司

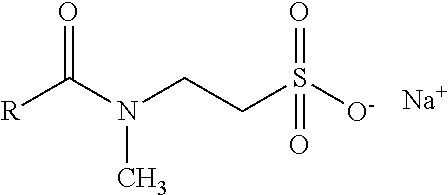

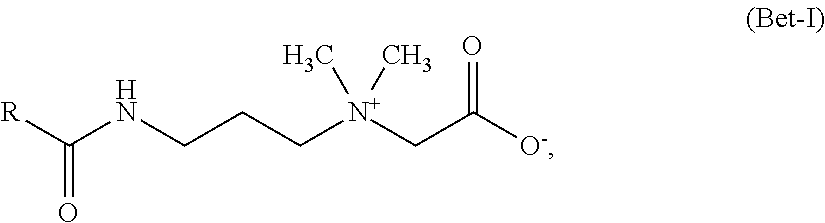

Powerful hair treatment agent having anti-washout effect

Hair treatment agents and methods for treating hair using the hair treatment agents are provided. In an embodiment, a hair treatment agent comprises: at least one anionic surfactant from the group of a-olefin sulfonates; at least one anionic surfactant from the group of taurides; at least one amphoteric surfactant; at least one silver salt selected from silver acetate, silver adipate, silver citrate, silver galactarate, silver gluconate, silver lactate, silver malate, silver mandelate, silver salicylate, silver succinate, silver sulfate, and silver tartrate; and at least one organic acid selected from adipic acid, succinic acid, citric acid, acetic acid, galactaric acid, gluconic acid, malic acid, mandelic acid, lactic acid, salicylic acid, sulfuric acid, silver acetate, and tartaric acid, to reduce or prevent washing out of color from dyed hair.

Owner:HENKEL KGAA

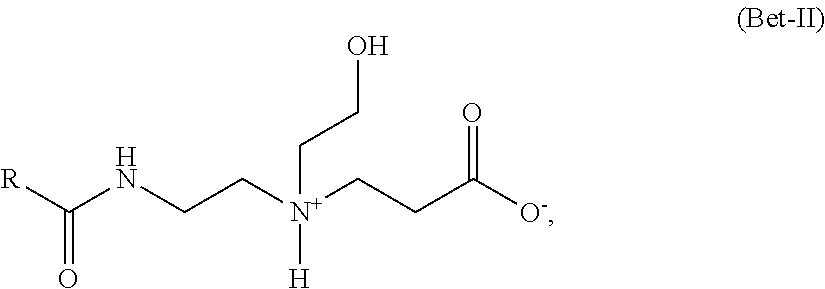

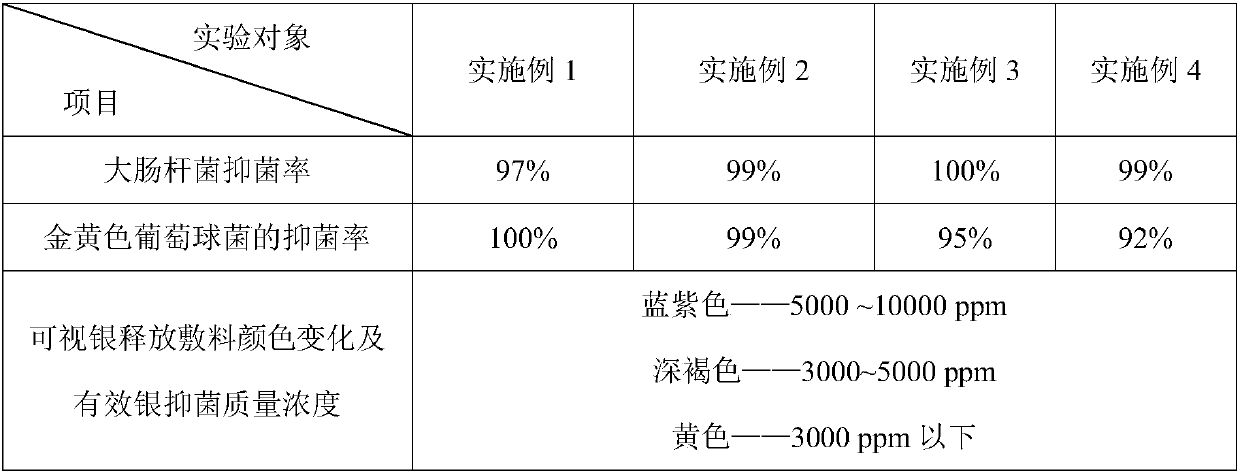

A kind of visible silver releasing dressing and preparation method thereof

InactiveCN105126148BReduced risk of excessive releaseNon-toxicAbsorbent padsLiquid/gas/vapor textile treatmentSilver citrateSodium borohydride

The invention belongs to the field of medical dressings, in particular to a visible silver-releasing dressing and a preparation method thereof. The dressing is composed of a nonwoven fabric and a mixed solution of nano-silver and tryptophan attached to the non-woven fabric. The antibacterial mass concentration of silver in the dressing is 5000-10000 ppm; Composed of sodium and silver compounds, the particle size range of the nano-silver is 1-100nm; the tryptophan mixed solution is composed of tryptophan solution and HCOOH-HCL solution. The visible silver-releasing dressing provided by the invention can judge the release amount of silver in the dressing by observing the color change, has strong bactericidal activity, and can effectively inhibit the growth of most bacteria.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Composite visible light catalyst and its preparation method and application

InactiveCN107029777BHigh utilization rate of visible lightImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationPhosphorylationSilver citrate

The invention discloses a composite visible light catalyst and its preparation method and application. The composite visible light catalyst is composed of CNT-silver citrate and g-C 3 N 4 ‑PO 4 3‑ Obtained by precipitation method, CNT-silver citrate is CNT, sodium citrate and AgNO 3 Obtained through surface complexation, g‑C 3 N 4 ‑PO 4 3‑ is g‑C 3 N 4 and NaH 2 PO 4 Obtained by surface phosphorylation. The preparation method includes: preparing CNT-silver citrate, preparing g-C 3 N 4 ‑PO 4 3‑ and preparation of CNT / Ag 3 PO 4 / g‑C 3 N 4 . The composite visible light catalyst of the present invention can be used to treat antibiotic wastewater, and has the advantages of high visible light utilization, stable existence in water, and stable photocatalytic performance.

Owner:CHANGSHA UNIVERSITY

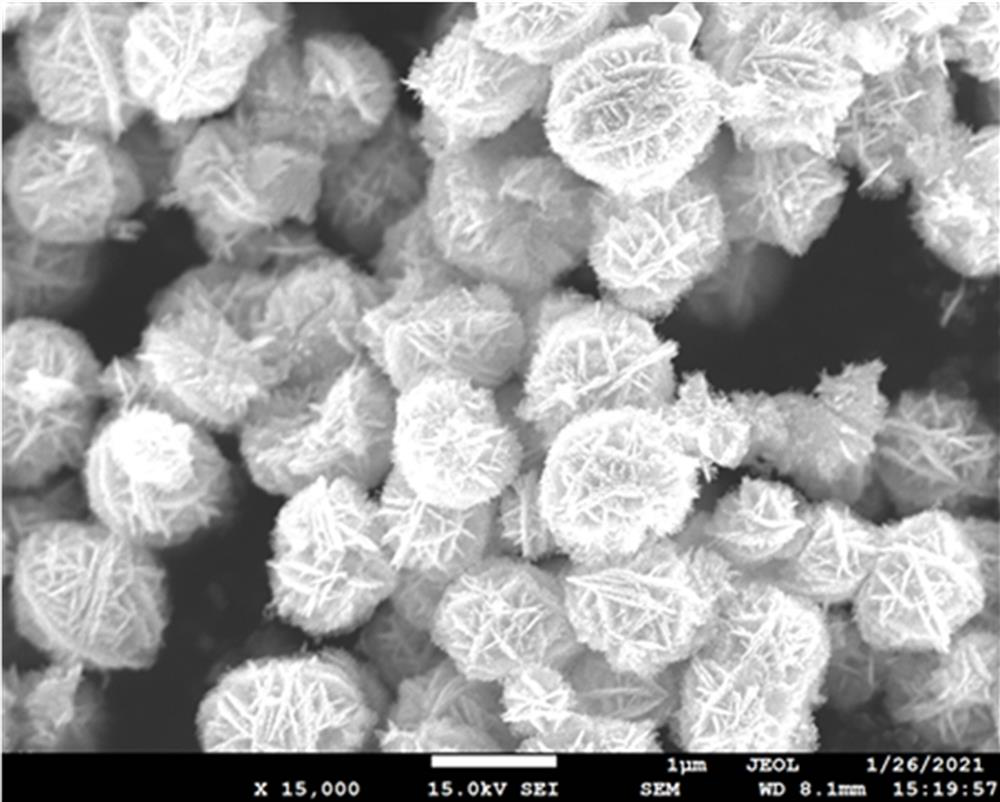

Multi-fold spherical silver powder and preparation method and application thereof

PendingCN114260461ALarge specific surface areaHas low temperature sintering propertiesTransportation and packagingMetal-working apparatusVitamin CSilver citrate

The invention discloses a preparation method of multi-fold spherical silver powder, which belongs to the technical field of conductive silver powder preparation, and comprises the following steps: 1) preparing a reducing agent solution A by taking vitamin C as a solute and water as a solvent; 2) dropwise adding the silver nitrate solution into the sodium citrate solution to obtain a silver-containing solution B; and (3) the silver-containing solution B is transferred into a water bath to be stirred and heated, the reducing agent solution A is added into the solution B at the dropwise adding speed of 20-60 mL / min, after dropwise adding is completed, after precipitation, the solution is centrifuged, cleaned and dried, and the silver-containing composite material is obtained. According to the method, the vitamin C solution is adopted as a reducing agent, the silver citrate solution is adopted as a silver-containing solution, the vitamin C solution is added into the citric acid solution in a quantitative and constant-speed mode, the multi-fold spherical silver powder is prepared, the specific surface area of the silver powder is increased through the multi-fold structure, the silver powder has the low-temperature sintering characteristic, a more compact silver layer is formed, and the silver layer is more compact. The conductive performance is excellent, no dispersing agent is needed, and the preparation cost is low.

Owner:成都市天甫金属粉体有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com