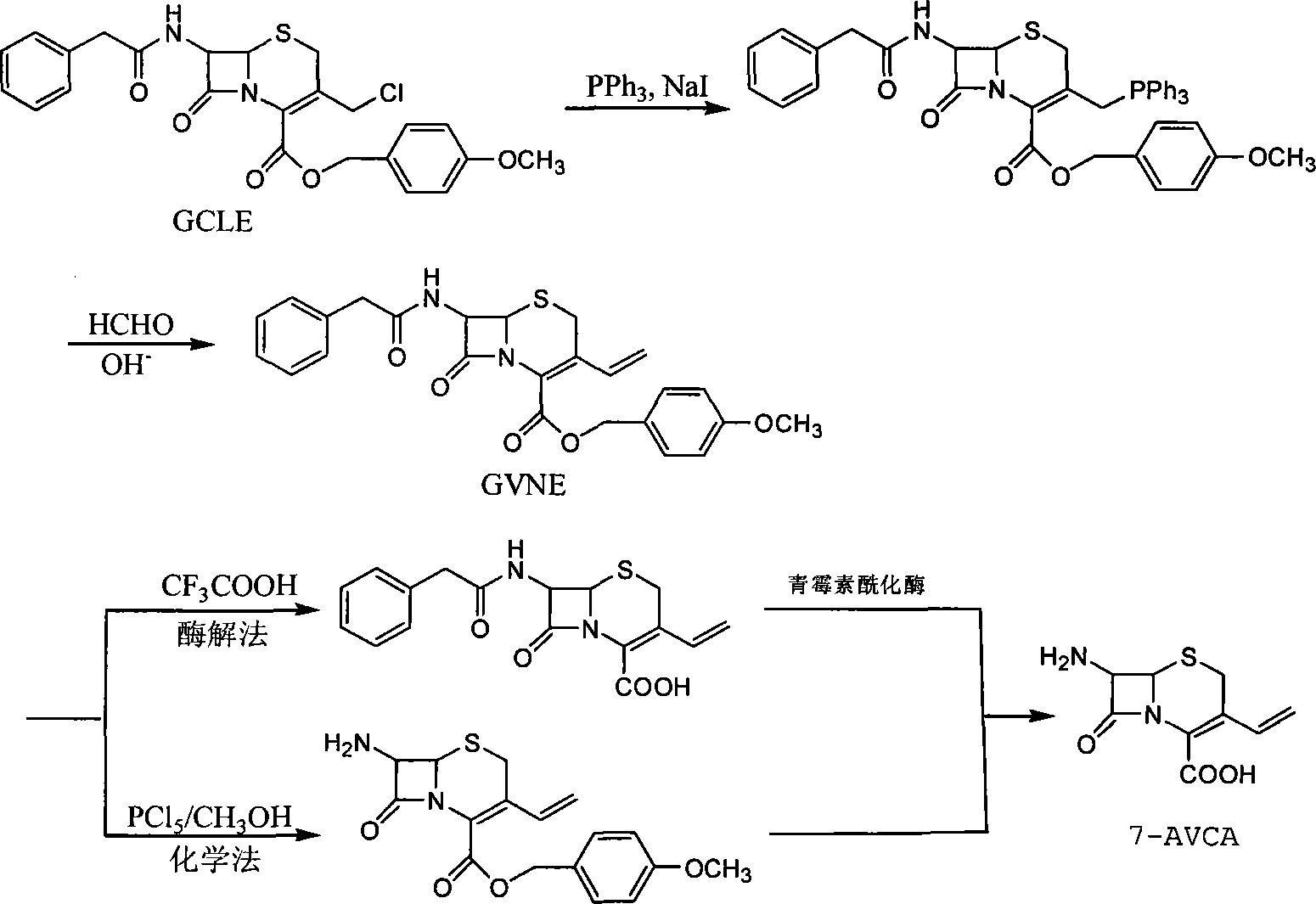

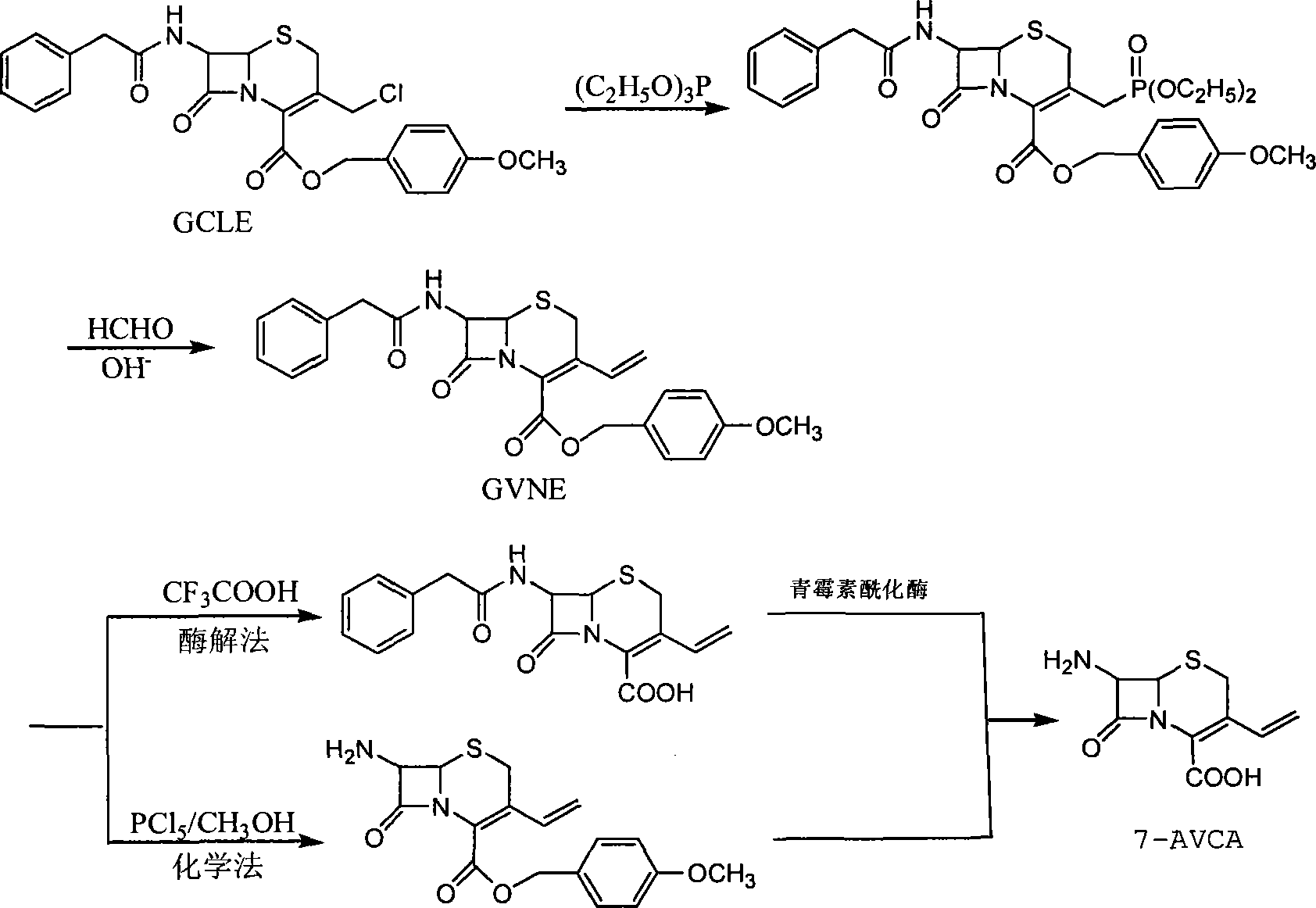

Method for preparing 7-amido-3-vinyl cethalosporanic acid

A technology of base cephalosporanic acid and chloromethyl cephalosporanic acid is applied in the synthesis field of low-cost production of 7-amino-3-vinyl cephalosporanic acid, and can solve the problems of large amount of triphenylphosphonium, high production cost, and raw materials. The problem of high cost, to achieve the effect of high comprehensive income efficiency, simple production method and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 250L tetrahydrofuran into a 2000L reactor, stir, blow in nitrogen, cool down to 10°C, then add 48.5Kg GCLE, 16.6Kg triethyl phosphite, and 15kg sodium iodide in sequence, and react at 10-20°C for 4 hours. Add 10Kg of 37% formaldehyde aqueous solution pre-cooled to 10-15°C and 40L of water, add dropwise sodium bicarbonate solution, and precipitate crystals. Keep the pH at 8.7-8.9, and react at 15-20°C for 3 hours under strong stirring. Add 800L of water, continue to react for 1h, filter with suction, wash the filter cake with water, drain it and transfer it to 180L of methanol, stir and wash at 0-10°C for 1h. Suction filtration, not exceeding 50°C, and vacuum drying to obtain 38.2Kg of white solid product GVNE, content 96.8% (high performance liquid chromatography area normalization method), melting point 180.2-182.4°C.

[0019] Add 540L of dichloromethane and 22.5Kg of phosphorus pentachloride into a 2000L reactor, stir and heat to 30°C to dissolve them completely....

Embodiment 2

[0021] Add 250L of dichloromethane into a 2000L reactor, stir, blow in nitrogen, cool down to 10°C, then add 48.5Kg of GCLE, 17.6Kg of triethyl phosphite, and 18kg of potassium iodide in sequence, and react at 10-20°C for 3 hours. Add 12Kg of 37% formaldehyde aqueous solution pre-cooled to 10-15°C and 60L of water, add dropwise sodium bicarbonate solution, and precipitate crystals. Keep the pH at 8.7-8.9, and react at 15-20°C for 3 hours under strong stirring. Add 800L of water, continue to react for 1h, filter with suction, wash the filter cake with water, drain it and transfer it to 180L of methanol, stir and wash at 0-10°C for 1h. Suction filtration, not exceeding 50°C, and vacuum drying to obtain 40.4Kg of white solid product GVNE, content 96.8% (HPLC area normalization method), melting point 180.2-182.4°C.

[0022] Below with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com