Method for preparing endotoxin adsorbing agent

An adsorbent and endotoxin technology, applied in chemical instruments and methods, suction devices, and other chemical processes, can solve problems such as risk of use, easy generation of particles, and large damage to the strength of agarose gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

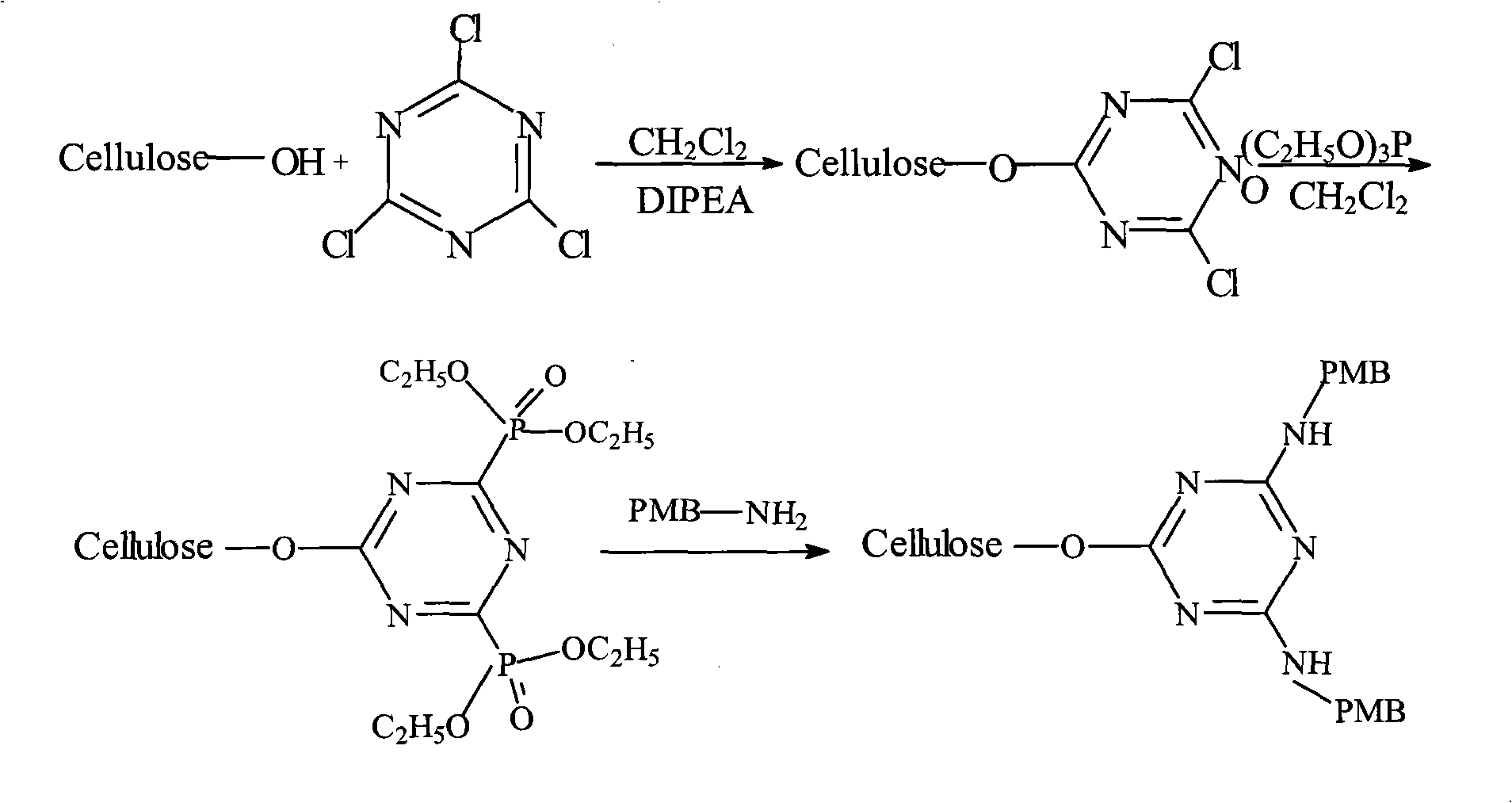

[0043] A. Trichlorotriazine activation of spherical porous cellulose

[0044] First vacuum filter the spherical porous cellulose ball to remove the surface moisture.

[0045] Add 50 grams of spherical porous cellulose balls to the three-necked flask, add 100 milliliters of dichloroethane, adjust the temperature of the system to 4 ± 1 ° C, stir well, slowly add 18.2 grams of trichlorotriazine and 15.8 milliliters of N, N- The mixed solution of diisopropylformamide and 100 milliliters of dichloroethane, after the dropwise addition was completed, continued to stir and react for 4 hours.

[0046] After the reaction is completed, the reaction residual liquid is filtered out, and the activated spherical porous cellulose spheres are washed several times with cold anhydrous ether, and then washed with a large amount of purified water, and filtered to obtain the activated spherical porous cellulose, which is ready for use.

[0047] B. Coupling of activated spherical porous cellulose w...

Embodiment 2

[0055] A. Trichlorotriazine activation of spherical porous cellulose

[0056] First vacuum filter the spherical porous cellulose ball to remove the surface moisture.

[0057] Add 50 grams of spherical porous cellulose balls to the three-necked flask, add 100 milliliters of dichloroethane, adjust the temperature of the system to 1 ± 1 ° C, stir well, slowly add 22.8 grams of trichlorotriazine and 14 milliliters of N, N- The mixed solution of diisopropylformamide and 100 milliliters of dichloroethane, after the dropwise addition was completed, continued to stir and react for 6 hours. After the reaction is completed, the reaction residue is filtered out, the activated spherical porous cellulose is washed several times with cold anhydrous ether, and then washed with a large amount of purified water, and filtered to obtain the activated spherical porous cellulose, which is set aside.

[0058] B. Coupling of activated spherical porous cellulose with triethyl phosphite

[0059] Add...

Embodiment 3

[0066] A. Trichlorotriazine activation of spherical porous cellulose

[0067] First vacuum filter the spherical porous cellulose ball to remove the surface moisture.

[0068] Add 50 grams of spherical porous cellulose balls to the three-necked flask, add 100 milliliters of dichloroethane, adjust the temperature of the system to 3±1°C, and after stirring evenly, slowly add 11.4 grams of trichlorotriazine and 12 milliliters of N,N- The mixed solution of diisopropylformamide and 100 milliliters of dichloroethane, after the dropwise addition was completed, continued to stir and react for 2 hours. After the reaction is completed, the reaction residue is filtered out, the activated spherical porous cellulose is washed several times with cold anhydrous ether, and then washed with a large amount of purified water, and filtered to obtain the activated spherical porous cellulose, which is set aside.

[0069] B. Coupling of activated spherical porous cellulose with triethyl phosphite

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com