Side-chain sulfonated polysulfone/ polyvinyl alcohol proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and sulfonated polysulfone, which is applied in the field of exchange membrane, can solve the problems such as the decrease of proton conductivity, and achieve the effects of improving chemical stability, low preparation cost and improving proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of polyvinyl alcohol solution

[0031] Take 100 parts of PVA and dissolve it in dimethyl sulfoxide at 90°C to prepare a solution with a mass fraction of 10%.

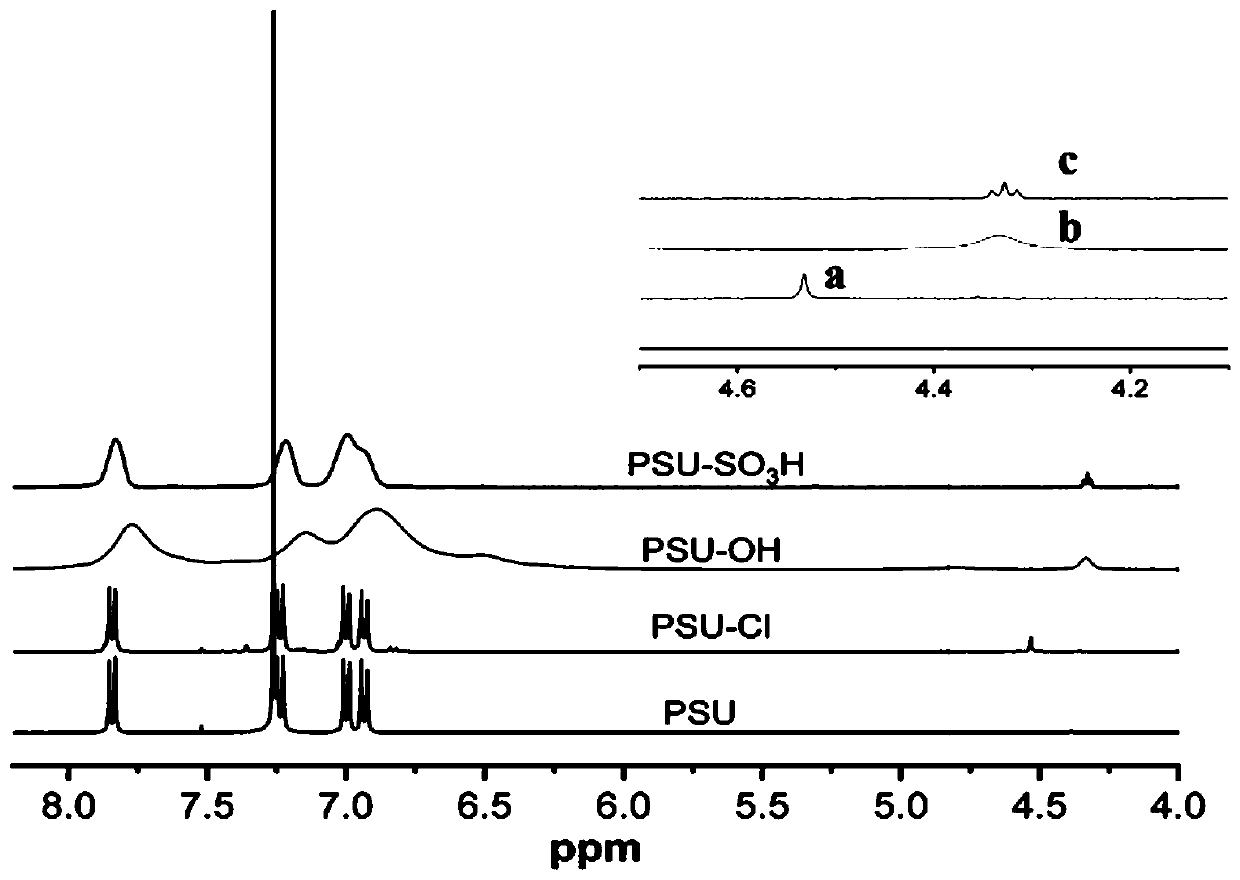

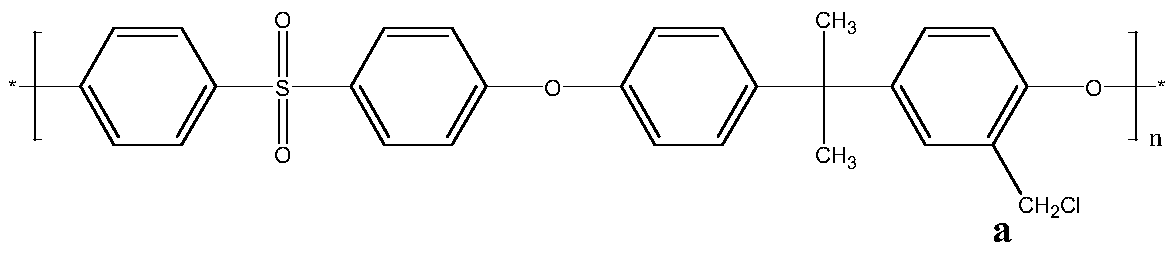

[0032] 2) Preparation of chloromethylated polysulfone

[0033] Dissolve 10 parts of purchased Solvay Adv Polymers Udel P-1700 polysulfone in 190 parts of 1,2-dichloroethane at 60°C, add 1 part of zinc powder, 6 parts of trifluoroacetic acid and 4 parts of chloromethyl methyl ether , react at 30°C for 6h, continue to add solvent to dilute to 2% solid content after the reaction is completed, pour the diluted solution into 400 parts of methanol for precipitation, and the obtained precipitate is vacuum-dried at 60-80°C after repeated washing to obtain Chloromethylated polysulfone solid.

[0034] Its structural formula is as follows:

[0035]

[0036] 3) Preparation of polysulfone grafted bisphenol

[0037] Take 100 parts of chloromethylated polysulfone and dissolve it in dimethyl sulfoxide at 90°C...

Embodiment 2

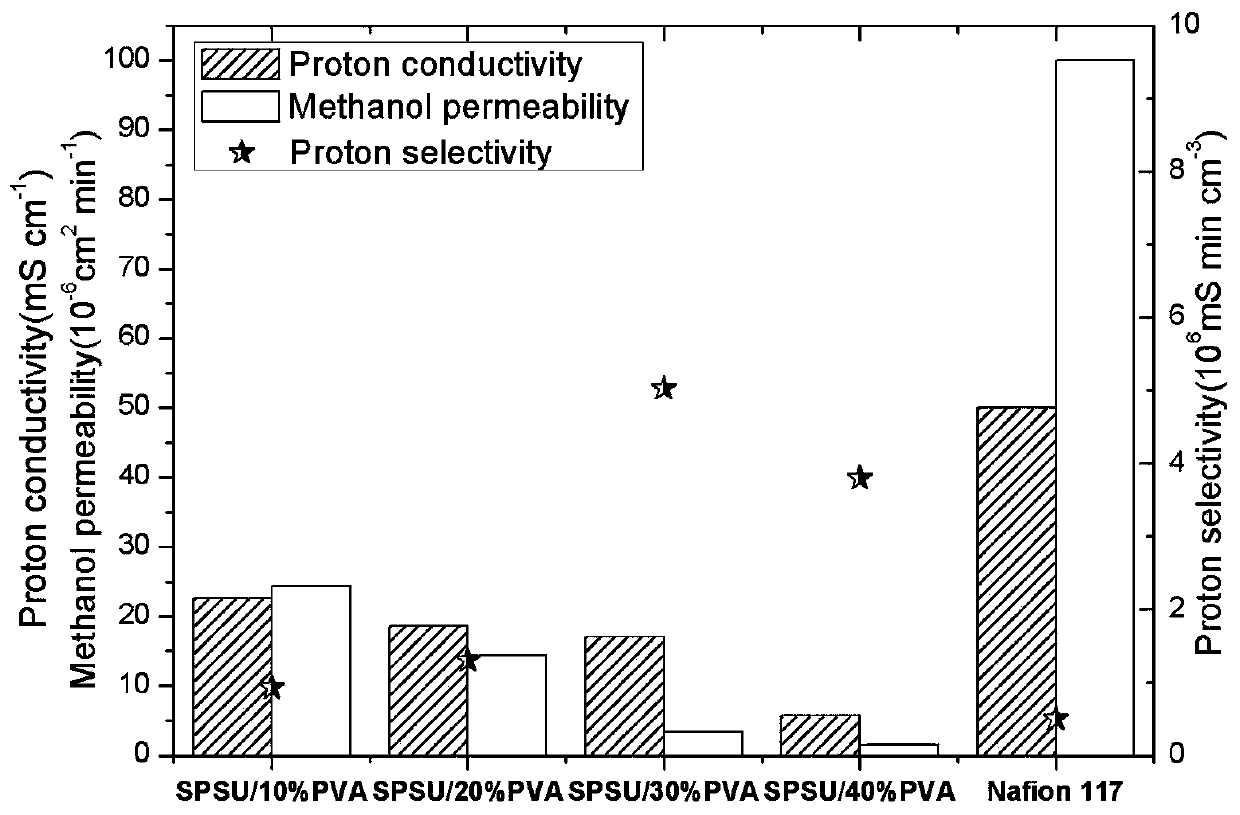

[0050] In step (5), the mass ratio of side-chain sulfonated polysulfone / polyvinyl alcohol is 8:2, and the rest are the same as in Example 1. The proton conductivity of the proton exchange membrane is 19mS / cm, and the methanol permeability is 15×10 -6 cm 2 / min.

Embodiment 3

[0052] In step (5), the mass ratio of side-chain sulfonated polysulfone / polyvinyl alcohol is 7:3, and the rest are the same as in Example 1. The proton conductivity of the proton exchange membrane is 18mS / cm, and the methanol permeability is 3×10 -6 cm 2 / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Methanol permeability | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com