Proton exchange membrane for medium-temperature fuel cell and preparation thereof

A proton exchange membrane, fuel cell technology, applied in fuel cells, fuel cell components, solid electrolyte fuel cells, etc., can solve the problem of reducing proton conductivity, improve operating temperature, increase mechanical properties and high temperature resistance Excellent performance and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

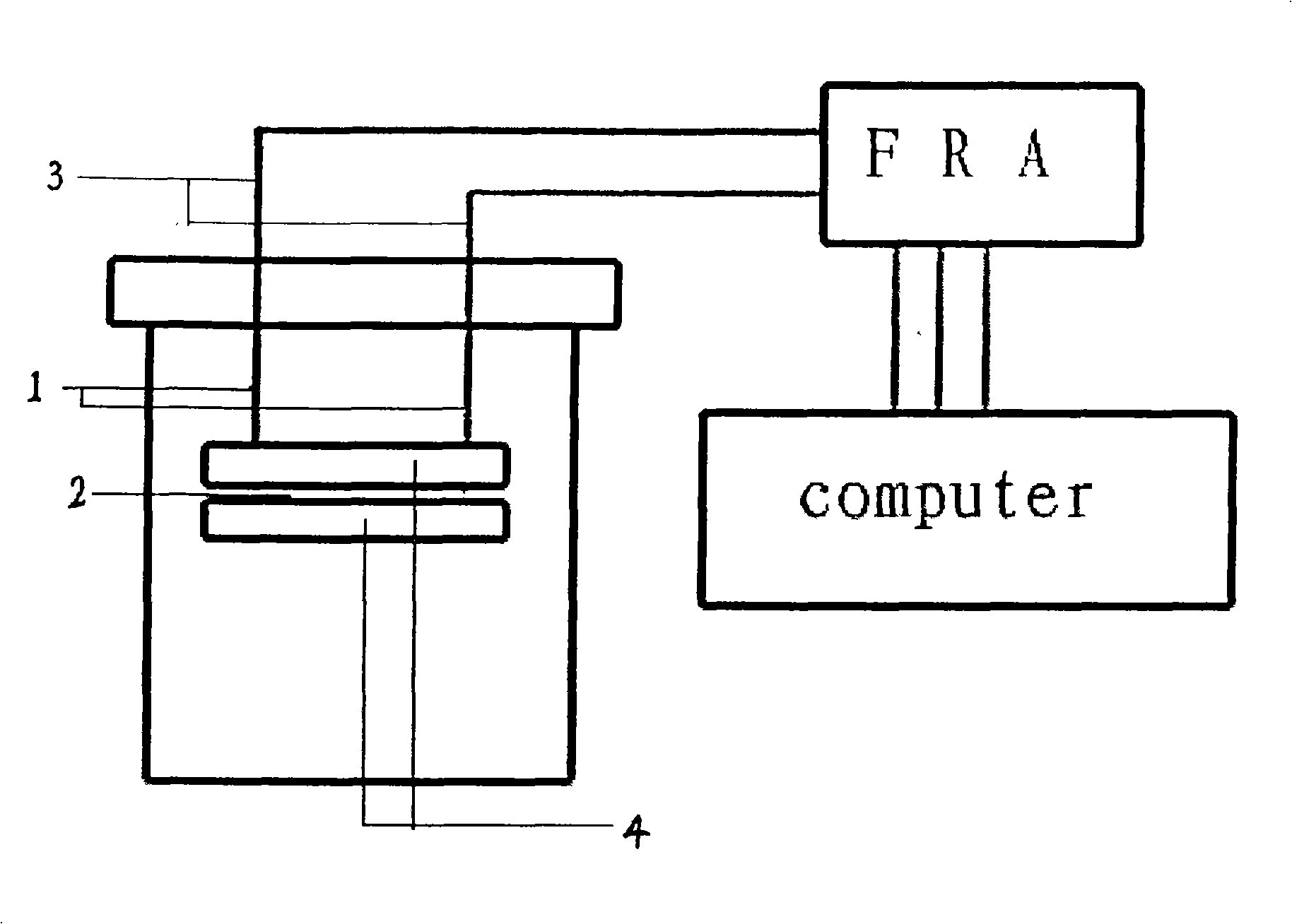

Image

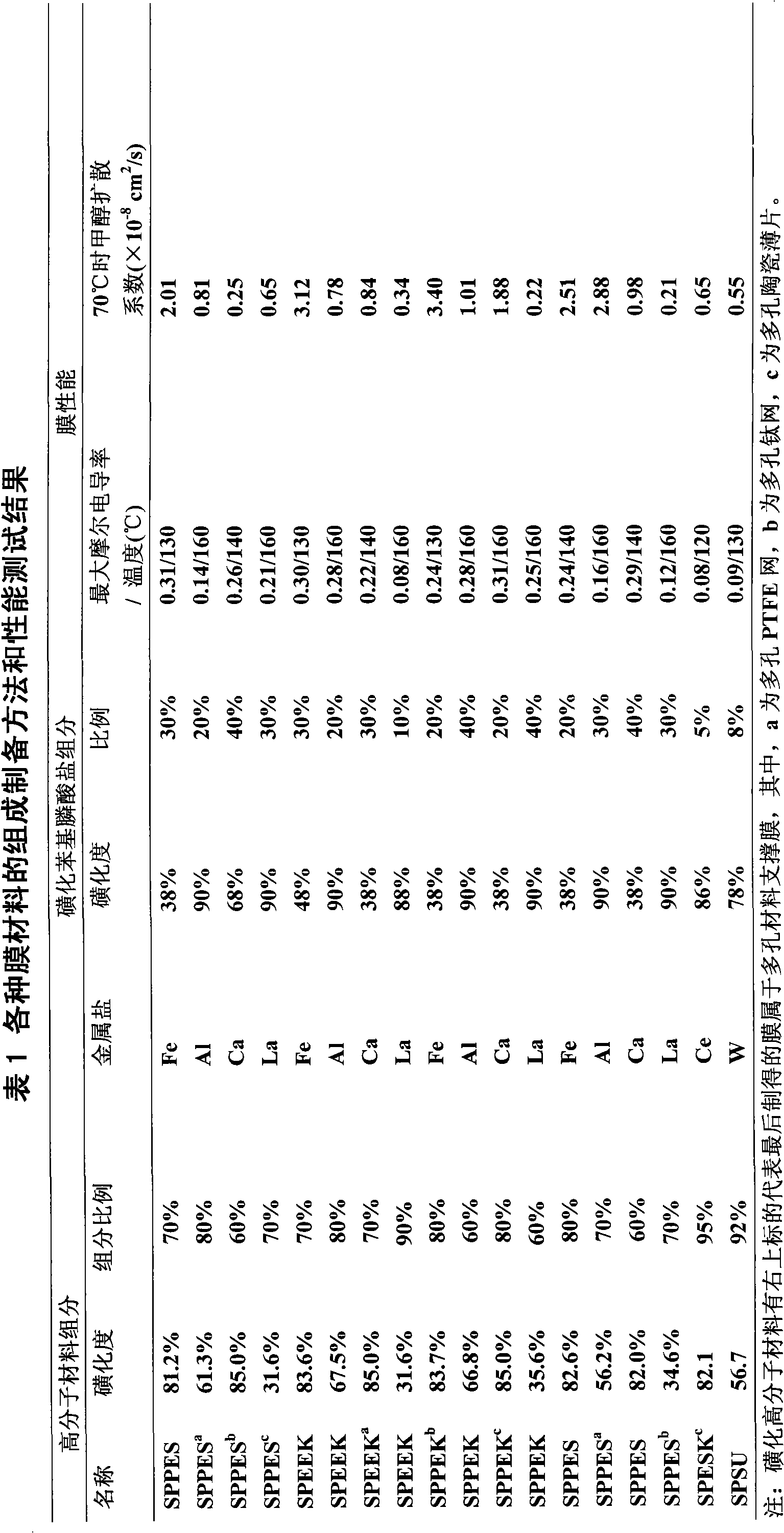

Examples

Embodiment 1

[0041] [Example 1]: Preparation of sulfonated poly(ether sulfone ketone) (SPPESK)

[0042] Add 3g PPESK to the three-necked flask equipped with an electric stirrer, a reflux condenser, and a dropping funnel. Under heating in a water bath, stir and add dropwise a mixed solution of concentrated sulfuric acid and oleum (volume ratio of 1:1~ 1:2), dropwise within 10~30min, reflux and stir for 3~5h at 60℃~80℃, the reaction is complete, pour out the supernatant in the three-necked flask, and pour the brown viscous liquid at the bottom into Spinning in a mixture of ice and water to obtain white filaments, washed with water until neutral (pH about 7), and dried in a vacuum oven for 24 hours. Take out and pulverize, wash with water until the pH is about 7, filter with suction, put the filter cake in a vacuum drying oven to dry for 24 hours, and pulverize to obtain a white powder. Determine the degree of sulfonation.

Embodiment 2

[0043] [Example 2]: Sulfonated polynaphthalene polyether ketone (SPPEK), the preparation of sulfonated polynaphthalene polyether sulfone (SPPES) is the same as in Example 1, except that the raw material polynaphthyl polyether sulfone (PPESK) ) can be replaced by polynaphthalene polyether ketone (PPEK) and polynaphthalene polyether sulfone (PPES) respectively.

Embodiment 3

[0044] [Example 3]: The preparation of sulfonated polyetheretherketone (SPEEK) and sulfonated polyethersulfone (SPES) is the same as in Example 1, except that the raw material polyethersulfone (PPESK) is replaced by polyether ether For ketone (PEEK) and polyethersulfone (PES), just replace the sulfonating reagent with concentrated sulfuric acid.

[0045] The sulfonation of other materials is the same as embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com