Patents

Literature

127 results about "Chloromethyl methyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

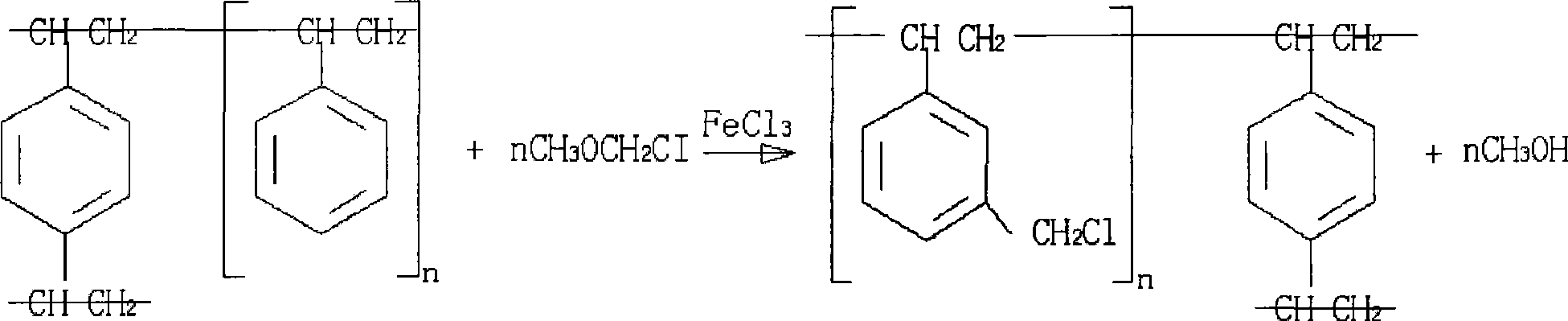

Chloromethyl methyl ether (CMME) is a compound with formula CH₃OCH₂Cl. It is a chloroalkyl ether. It is used as an alkylating agent and industrial solvent to manufacture the detergent dodecylbenzyl chloride, water repellents and ion-exchange resins. In organic synthesis, it is used for introducing the methoxymethyl (MOM) protecting group, and is thus often called MOM-Cl or MOM chloride. It also finds application as a chloromethylating agent in some variants of the Blanc chloromethylation.

Porous polymer material and preparation method thereof

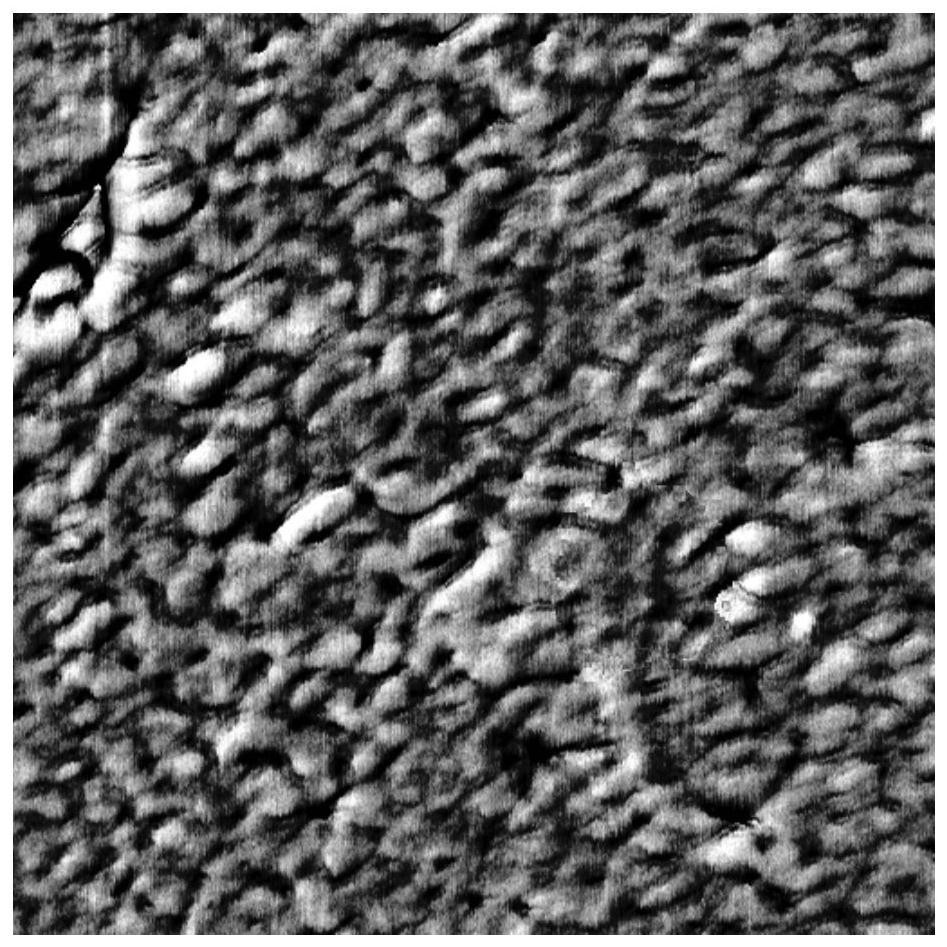

ActiveCN102093539AThe synthesis method is simpleMild reaction conditionsSemi-permeable membranesCatalyst carriersDimethoxymethaneStorage material

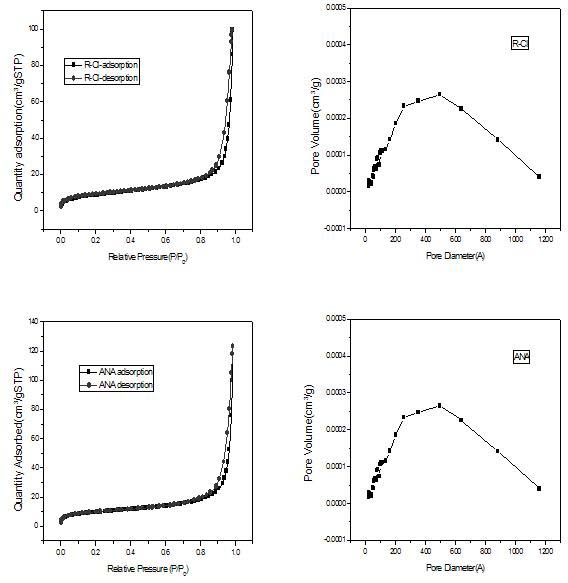

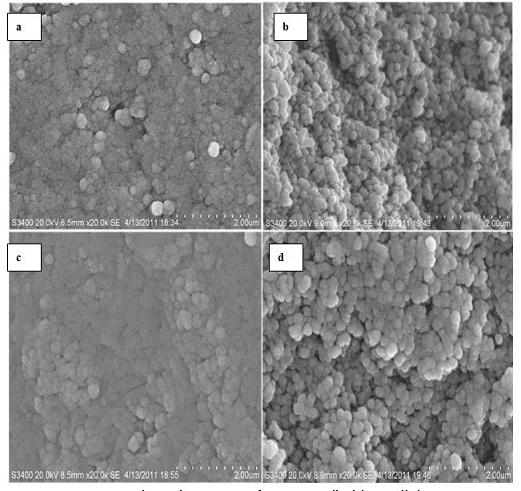

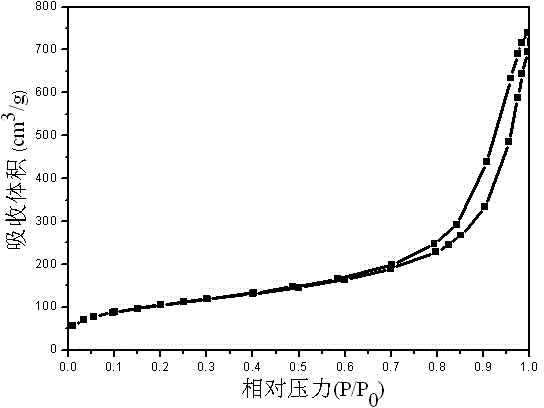

The invention provides a porous polymer material and a preparation method thereof. The porous polymer provided by the invention is prepared by crosslinking aromatic compounds with a crosslinking agent; the specific area of the porous polymer material is up to 2000 m<2>g<-1>, and the controllable range of the pore size is 0.3-100nm; and the porous polymer material can be used as a catalyst carrier, separation membrane, gas storage material and ion adsorbent. The preparation method comprises the following step: by using dimethoxymethane or chloromethyl methyl ether as the crosslinking agent andusing Lewis acid as the catalyst, crosslinking various aromatic compounds to obtain the porous polymer material by a one step method. The method has the characteristics of cheap and accessible raw materials and simple preparation technology, and the varieties of the aromatic compounds can be flexibly selected according to different application demands.

Owner:武汉华科中英纳米科技有限公司

Polymeric adsorbent and preparation method thereof

ActiveCN101912770ALarge specific surface areaSmall apertureOther chemical processesCross-linkChloromethyl Ether

The embodiment of the invention discloses a polymeric adsorbent and a preparation method thereof. The preparation method comprises the following steps of: preparing a bead-like resin from chloromethyl styrene serving as a polymerization monomer and divinyl benzene serving as a cross-linking agent by a suspension polymerization method; and adding a hydroxyl-containing monomer at the post-crosslinking stage to perform super cross-linking reaction so as to prepare the polymeric adsorbent. In the method, pores are formed in the polymeric adsorbent at the post-crosslinking stage of polychloromethyl styrene by using a chemical modification method, and polar groups are formed on the frame of the polymeric adsorbent by introducing the hydroxyl-containing monomer for modification, so the adsorption of an adsorbent substance by the polymeric adsorbent is increased. The preparation method provided by the invention is simple and the substances harmful to human body such as chloromethyl ether and the like and pore-forming agents are not used in the method. Experimental results show that the polymeric adsorbent prepared by the invention has the advantages of high specific surface area, small aperture, high adsorption selectivity and particularly high capacity of absorbing aromatic compounds.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Single-sheet type bipolar membrane and preparation method thereof

InactiveCN105833737AEliminate film forming processImprove thermal stabilityMembranesSemi-permeable membranesChloromethyl EtherHeat stability

A monolithic bipolar membrane and a preparation method thereof relate to functional polymer membrane materials. The monolithic bipolar membrane includes a cation exchange layer and an anion exchange layer. Preparation method 1: basement membrane pre-irradiation; simultaneous grafting on both sides; sulfonation; quaternization. Preparation method two: basement membrane pre-irradiation; double-sided step-by-step grafting; sulfonation; quaternization. The preparation of bipolar membranes by radiation grafting technology not only saves the film-forming process in the traditional bipolar membrane preparation process, but also does not need to add initiators and catalysts during the grafting process, and the prepared bipolar membranes are very uniform and pure. The steps are simple, and the thermal stability and chemical stability of the film are better. Even if it is used for a long time, there will be no problems such as bubbling and cracking in the middle interface layer that are easy to occur during the use of composite bipolar membranes. Good mechanical properties, thermal stability and chemical stability. Avoid the use of strong carcinogenic reagents such as chloromethyl ether, and reduce the harm to the human body and the environment.

Owner:XIAMEN UNIV

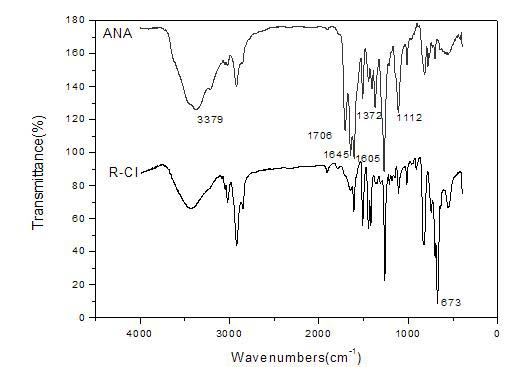

A kind of 6-aminopyridine-3-carboxylic acid chelating resin and preparation method thereof

ActiveCN102295723AHigh stability constantGood choiceOther chemical processesPolymer scienceChloromethyl Ether

The invention discloses a 6-aminopyridine-3-carboxylic acid chelating resin and its preparation method, which belongs to the field of chelating resin. The resin has a following structural unit: a functional group is 6-aminopyridine-3-carboxylic acid, wherein the color is yellowish, the particle size is 0.45-0.6 mm, the content of the functional group is 1.37-2.38 mmol / g. The preparation method comprises the following steps: using styrene as a monomer, employing a suspension polymerization method to prepare a low crosslinking degree macroporous styrene-divinylbenzens copolymer, air-flow dryingto obtain low crosslinking macroporous polystyrene-divinylbenzens resin (white ball for short); immersing the white ball in chloromethyl ether, adding zinc chloride as a catalyst, carrying out a chloromethylation reaction to obtain chloromethylated low crosslinking polystyrene-divinylbenzens resin (chlorine ball for short); taking N,N-dimethyl formamide as a swelling agent, taking DMF as a swelling agent to swell the chlorine ball, dissolving 6-aminopyridine-3-carboxylic acid and sodium carbonate in N, N-dimethyl formamide for reaction, then adding the above swelled chlorine ball, stirring for reacting to prepare 6-aminopyridine-3-carboxylic acid chelating resin. The resin prepared by the invention is suitable for selectively absorbing and separating heavy metal ions of copper and the like.

Owner:NANJING UNIV

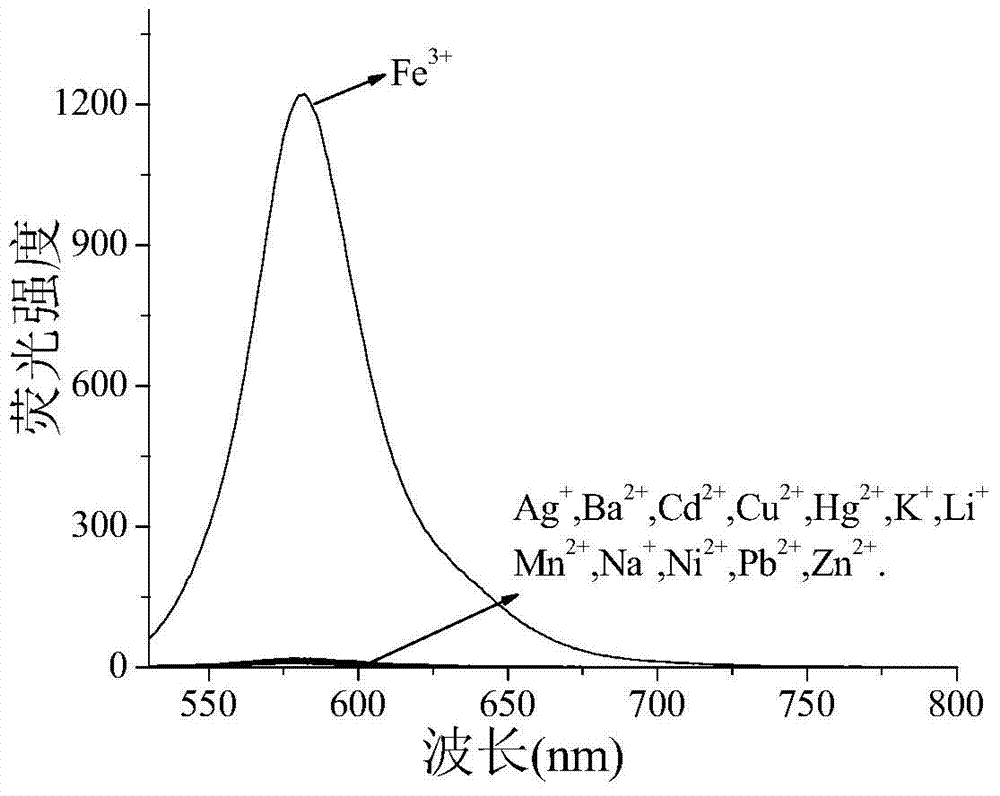

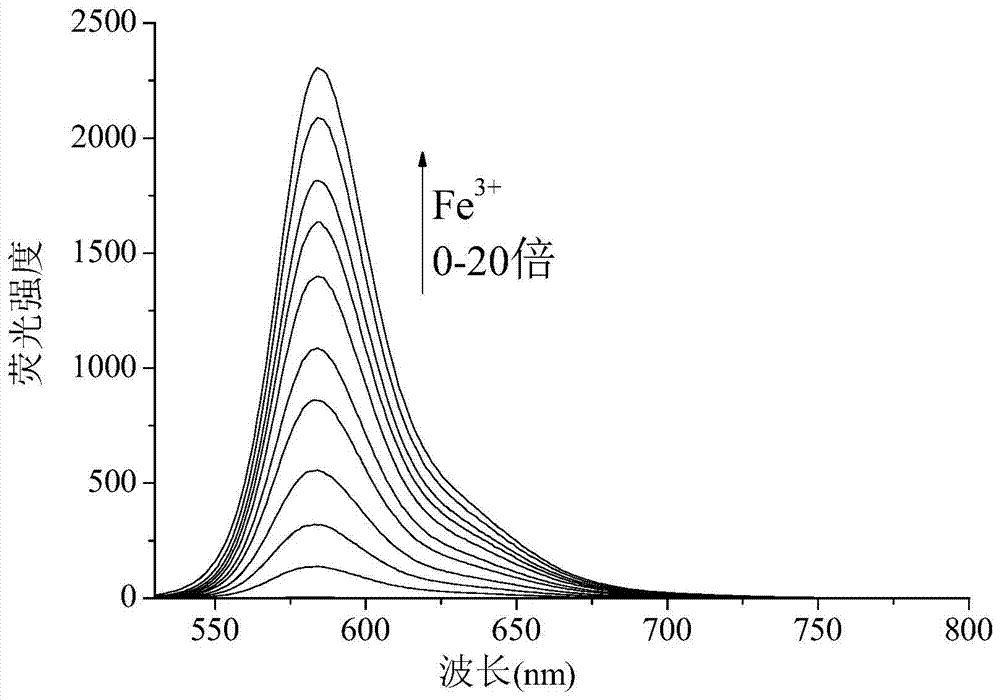

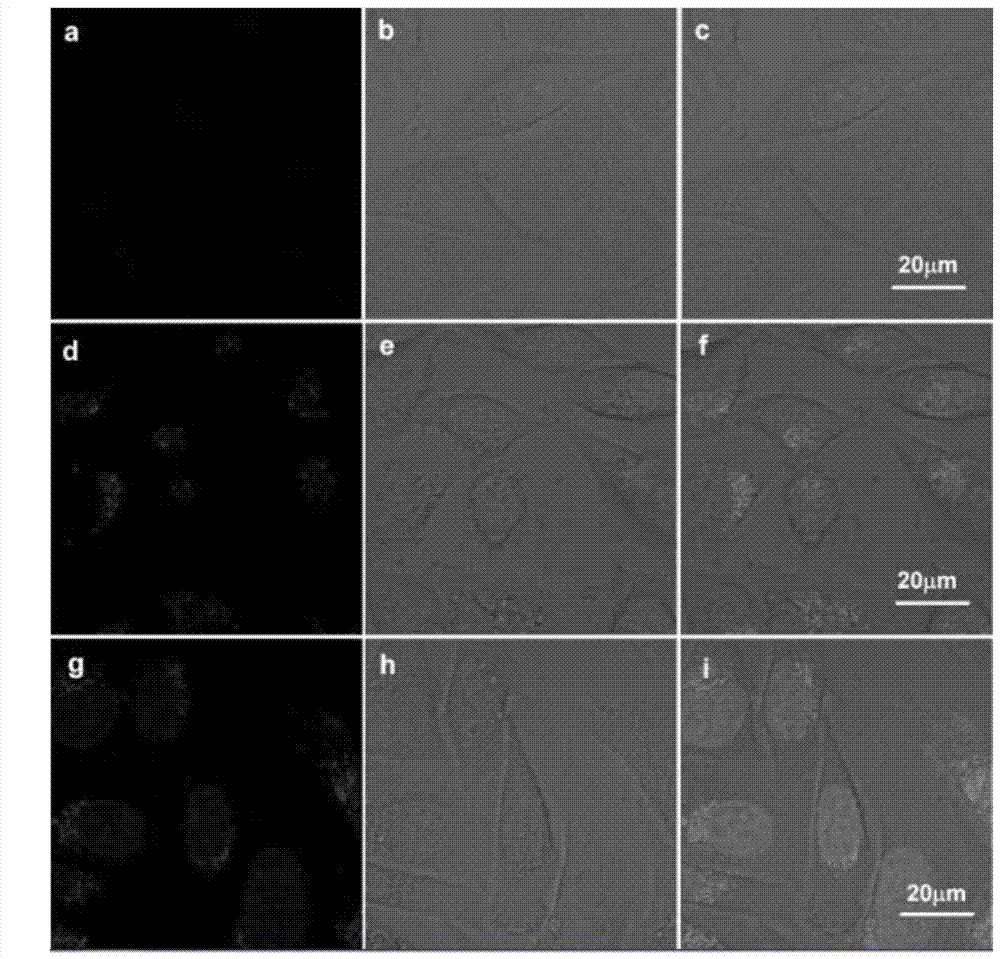

Ferric ion fluorescent probe compound as well as preparation method and application thereof

InactiveCN104496997AInnovative designGood choiceOrganic chemistryFluorescence/phosphorescenceN dimethylformamideButyl lithium

The invention relates to a ferric fluorescent probe compound as well as a preparation method and application thereof. The ferric fluorescent probe compound has the structure in formula I in the specification. The preparation method comprises the following steps: mixing rhodamine B with anhydrous ethanediamine and refluxing in ethyl alcohol to prepare amide of rhodamine; protecting hydroxyl of binaphthol by chloromethyl methyl ether, reacting with N,N-dimethylformamide under the action of butyl lithium, and removing methyl of methyl ether by hydrochloric acid to obtain binaphthol with aldehyde group; finally refluxing the amide of rhodamine and the binaphthol with aldehyde group in ethyl alcohol and washing to obtain the pure ferric fluorescent probe compound. The probe compound has favorable selectivity and sensitivity for the ferric ions, is simple to treat before sample detection and free of causing toxicity to cells, and is used for detecting the ferric ions in the water environment or the biological cells.

Owner:UNIV OF JINAN

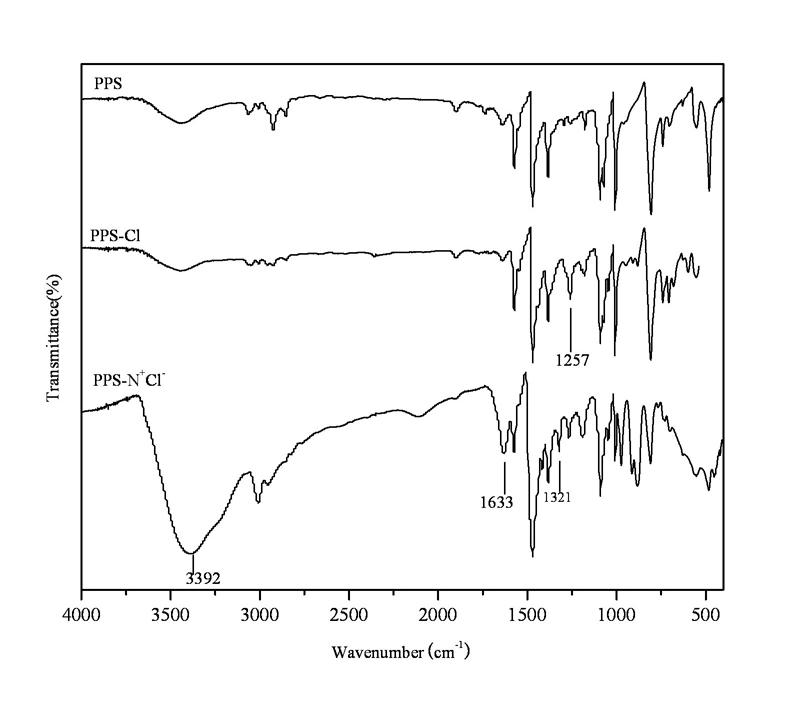

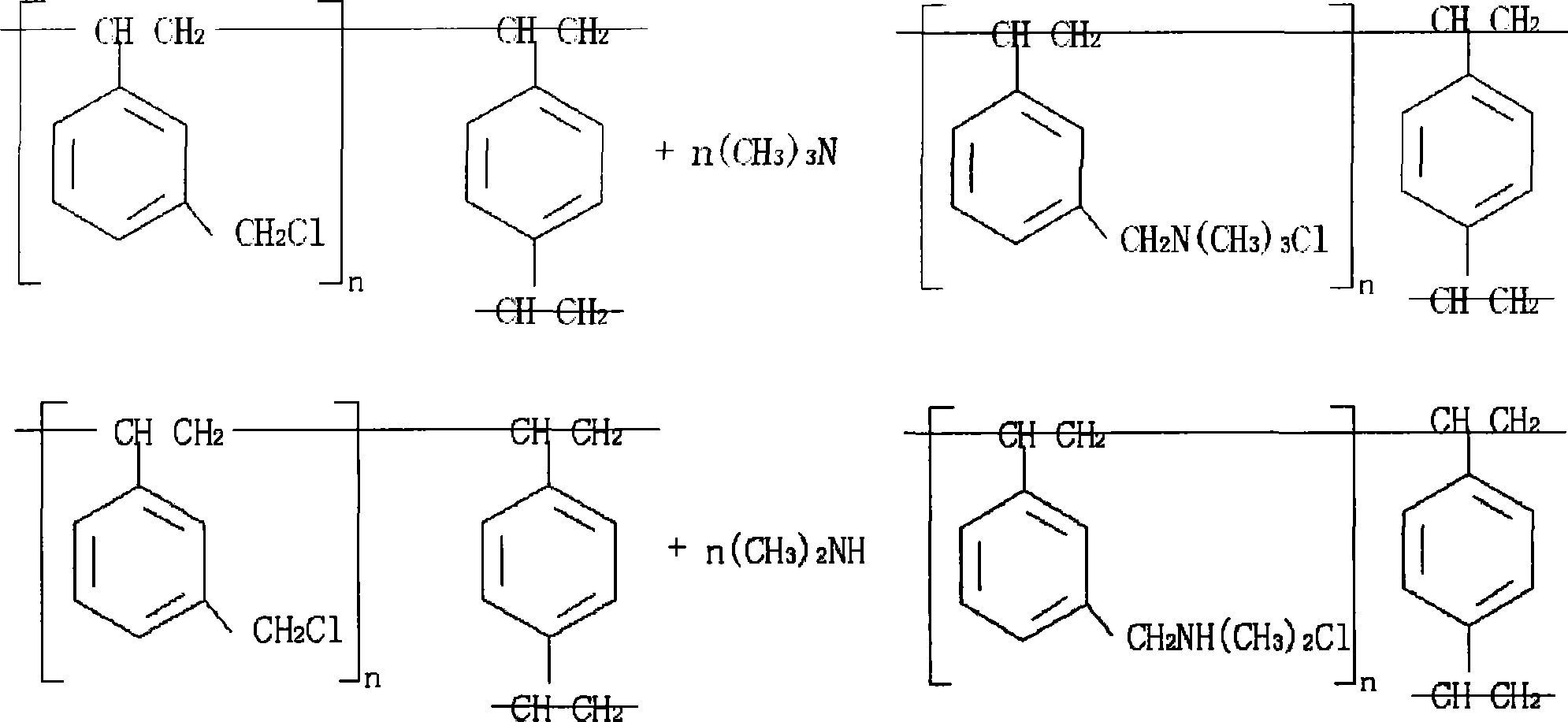

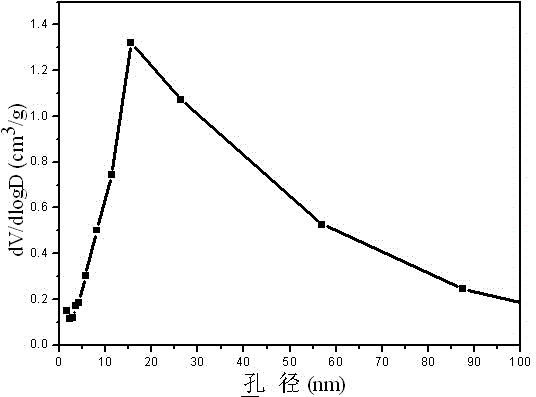

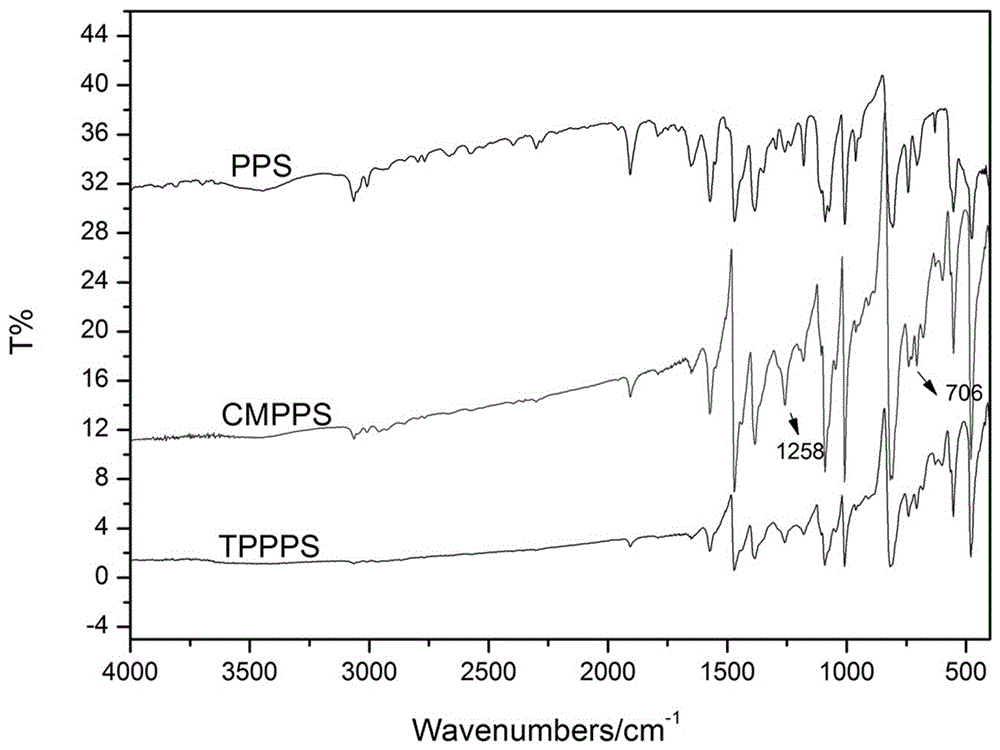

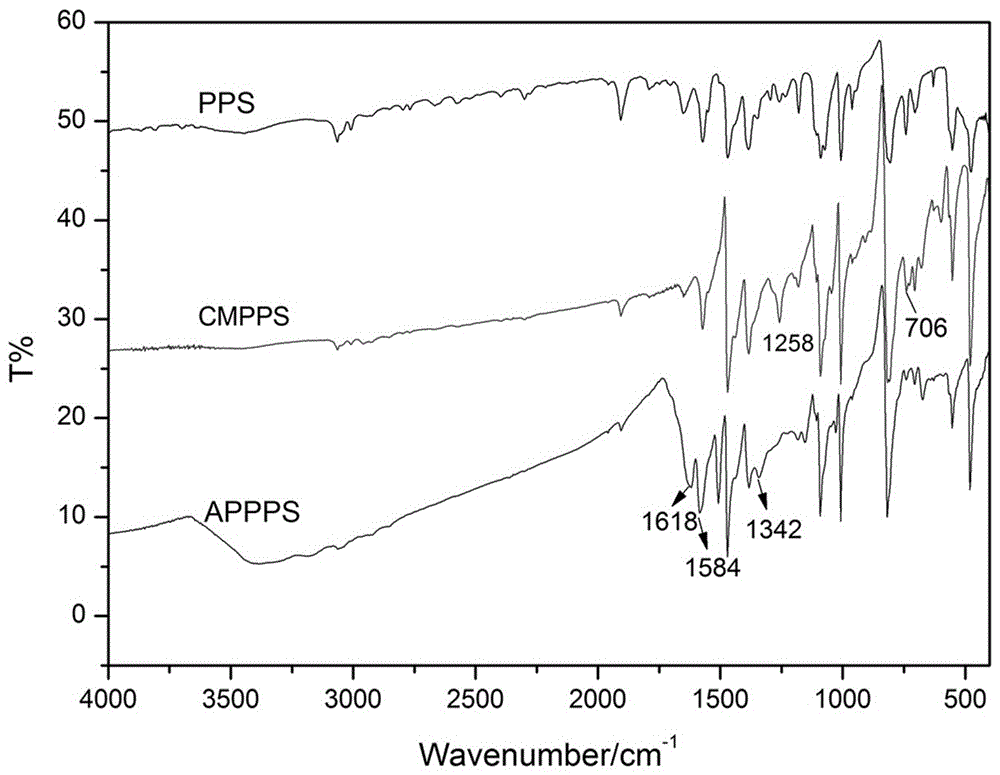

Method for preparing polyphenylene sulfide-based strong basic ion exchange fibers

InactiveCN102051811AEasy to operateEasy to prepareIon-exchange process apparatusOrganic anion exchangersFiberIndustrial effluent

The invention discloses a method for preparing polyphenylene sulfide-based strong basic ion exchange fibers, which comprises the following steps of: first swelling raw polyphenylene sulfide fibers in a solvent, adding a raw material polyphenylene sulfide and a catalyst after the raw polyphenylene sulfide fibers are swelled, heating the mixture for chloromethylation and crosslinking reaction, and obtaining chloromethylated crosslinked polyphenylene sulfide fibers after the reaction is finished; then swelling the obtained chloromethylated crosslinked polyphenylene sulfide fibers in the solvent, adding trimethylamine solution after the chloromethylated crosslinked polyphenylene sulfide fibers are swelled, heating the reaction solution for quaternization reaction, and obtaining the polyphenylene sulfide-based strong basic ion exchange fiber products after the quaternization reaction is finished; and finally washing the products, and performing extraction, brine-washing and drying. The method for preparing the polyphenylene sulfide-based strong basic ion exchange fibers is simple and easy to industrially popularize and apply, and ensures relatively lower production cost. The products prepared by the method can be applied in the fields of treatment of industrial wastewater, air purification, preparation of ultrapure water, separation and extraction of medicinal chemicals, and the like.

Owner:ZHENGZHOU UNIV +1

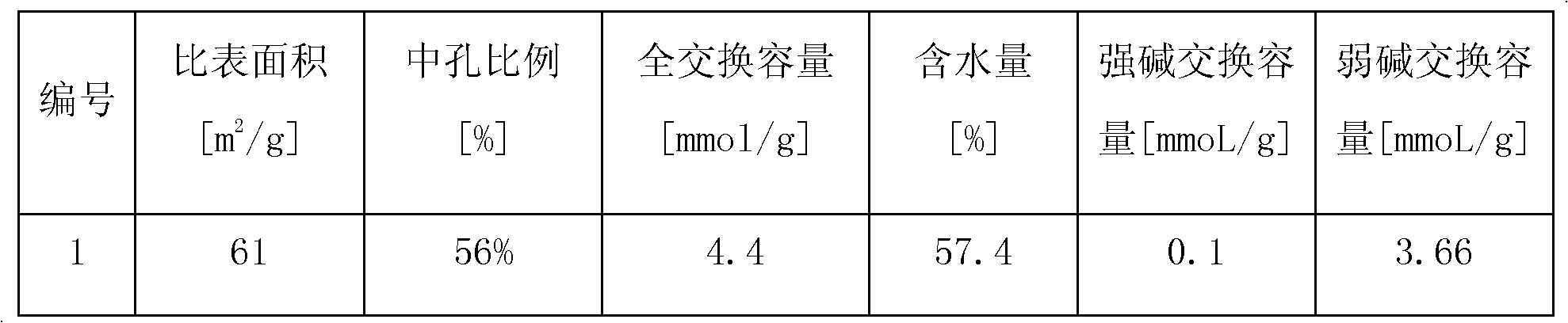

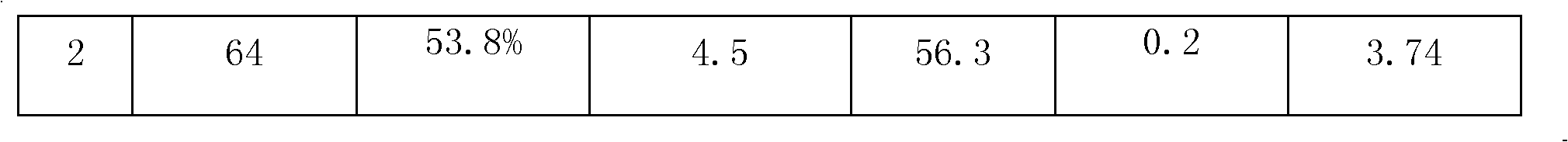

Method for preparing macroporous alkalescent anion exchange resin

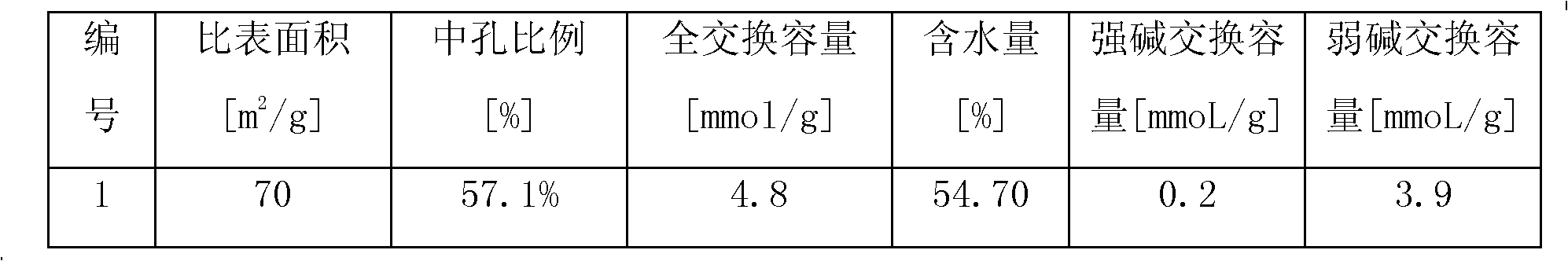

ActiveCN102463155AIncrease the ratio of mesoporesFast adsorptionAnion exchangersBenzoyl peroxideCatalytic effect

The invention relates to a method for preparing macroporous alkalescent anion exchange resin, which sequentially comprises the following steps that: 1, mixed alcohol of butanol and dodecanol according to the mol ratio of 1:0.3 is used as porogens, benzoyl peroxide is used as initiating agents, and gelatin and a small amount of ammonium salt are used as dispersing agents, so styrene and divinylbenzene are crosslinked and copolymerized to obtain the styrene-divinylbenzene copolymers; the volume of the porogens is 1 to 1.2 times the sum of the volume of the styrene and the divinylbenzene, the mol ratio of the divinylbenzene to the styrene is (4-8):100; 2, under the catalytic effect of zinc chloride, chloromethyl methyl ether is used for carrying out chloromethylation on white balls, and chloromethylation copolymers are obtained; and 3, dimethylamine solution is used for ammonifying chlorine balls, and the macroporous alkalescent anion exchange resin is obtained. The method has the advantages that the mesopore proportion of the white balls is improved, the absorption speed of the ion exchange resin is accelerated, the white balls are ensured to have a certain number of small-hole proportions, and the exchange volume of the ion exchange resin is ensured.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

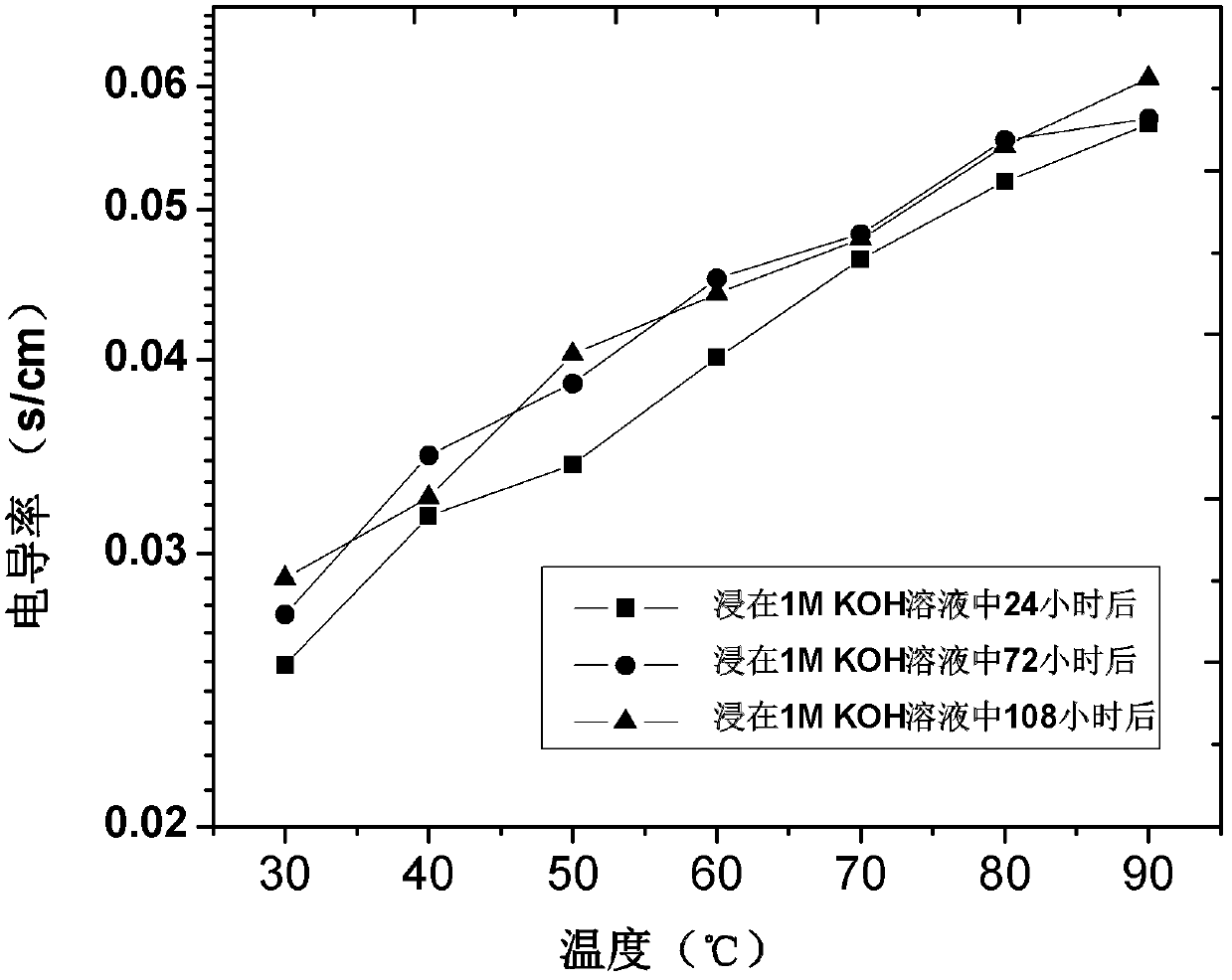

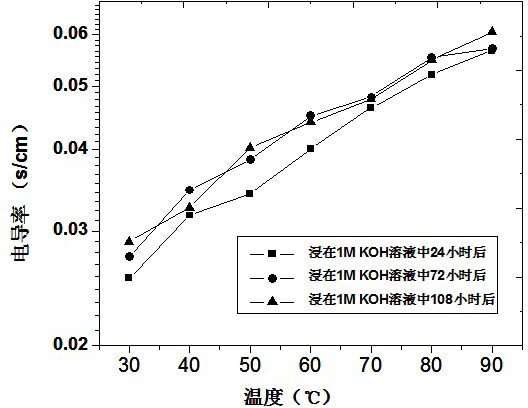

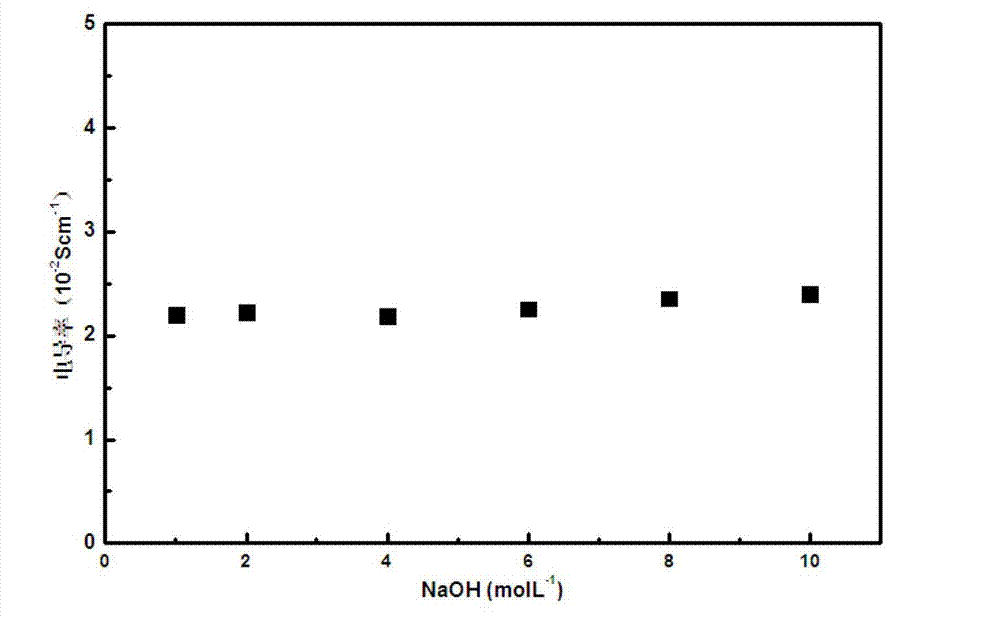

Polymer anion exchange membrane and preparation method thereof

InactiveCN102382293AImprove thermal stabilityGood alkali resistanceCell component detailsFuel cellsPolymer science

The invention belongs to the field of ion polymers, and relates to a anion exchange membrane for alkaline fuel cells. The invention discloses an anion polymer, the repeating unit of which is shown in the diagram. The imidazolium salt-based novel polymer anion exchange membrane with good properties, which is prepared with the anion polymer, the preparation method overcomes the chemical stability of the quaternary ammonium salt polymer anion exchange membrane is poor,and also avoids the usage of chloromethyl methyl ether in the conventional polymer anion exchange membrane preparation process,and therefore the harm on the human body and the environment is reduced.

Owner:SUZHOU UNIV

Synthetic method of strong-basic anion exchange resin used in compact bed

ActiveCN106243265ANovel granularityFine and uniform particle sizeAnion exchangersPolymer scienceChloromethyl Ether

The invention belongs to the technical field of synthetic methods of ion exchange resin and especially relates to a synthetic method of strong-basic anion exchange resin used in a compact bed. The synthetic method includes the steps of: 1) synthesizing a crosslinked polystyrene white sphere framework being 100-150 nm in particle size on the surface of inert crystal nucleus in a homogenous-phase wet chemical manner; adding chloromethyl ether as a chloromethylation reagent to carry out a Friedel-Crafts reaction to benzene rings in the styrene in the crosslinked polystyrene white spheres to obtain an intermediate product A; 2) performing an amination reaction to the intermediate product A with a tertiary amine containing a long carbon chain to generate the strong-basic anion exchange resin being 180-280 [mu]m in particle size. The framework synthetic method is novel and unique. The exchange resin is fine and uniform in particle size, has large specific surface area, is short in diffusion path and has high exchange speed during exchange, and is low in cost and has good application effects. The exchange resin can satisfy application demands in the compact bed.

Owner:ZHEJIANG XINGYU ENVIRONMENTAL TECH CO LTD

Chemical grating preparation method of partial fluorine-containing polymer based anion-exchange membrane

InactiveCN102489191AConvenient sourceReduce usageSemi-permeable membranesAnion exchangersPolymer scienceFluoropolymer

The invention relates to a chemical grating preparation method of partial fluorine-containing polymer based anion-exchange membrane. The preparation method comprises the following steps of: firstly, preparing a partial fluorine-containing polymer based membrane or adding a partial fluorine-containing polymer hybridization base membrane of nano-montmorillonite; secondly, performing alkali treatment to the surface of the base membrane, initiating the alkali to treat the membrane, and grafting a monomer with a specific functional group; at last, performing quaternized treatment to the grafting membrane so as to obtain the anion-exchange membrane. The method, provided by the invention, has the advantages of simple preparation process and high efficiency, can avoid carcinogenic substances, such as chloromethyl methyl ether and the like which are applied in the regular preparation of the anion-exchange membrane, and is easy to realize the large-scale industrial production.

Owner:SHENYANG POLYTECHNIC UNIV

Polymer anion exchange membrane based on imidazole onium salt and preparation method thereof

InactiveCN103035932AReduce usageAvoid damage phenomenonAnion exchangersCell component detailsChloromethyl EtherPolymer solution

The invention discloses a polymer anion exchange membrane based on imidazole onium salt and a preparation method thereof, and relates to an ion exchange membrane and a preparation method thereof. The preparation method comprises the following steps of: (1) synthesizing of an imidazole onium salt polymer through a radical copolymerizationic compound: adding a monomer A, a monomer B, a vehicle and an initiating agent in a reactor, carrying out sealing and a heating regurgitation reaction under the inert gas protection, and drying and washing a product to obtain the imidazole onium salt polymer; and (2) membrane formation: dissolving the obtained imidazole onium salt polymer in step (1) in an organic solvent to prepare a polymer solution, 5%-10% of mass percent concentration, casting to form a membrane through a phase inversion method, and drying to obtain the polymer anion exchange membrane based on the imidazole onium salt, wherein the imidazole onium salt polymer accounts for 5-10% of the organic solvent. The polymer anion exchange membrane provided by the invention has the advantages that the preparation method is simple, the cost is lower, the electric conductivity is higher, the anion exchange membrane has good heat stability and chemical stability, meanwhile, the use of chloromethyl ether in the traditional polymeric compound anion exchange membrane preparation process is avoided, and the polymer anion exchange membrane can reduce harms to human bodies and environment.

Owner:XIAMEN UNIV

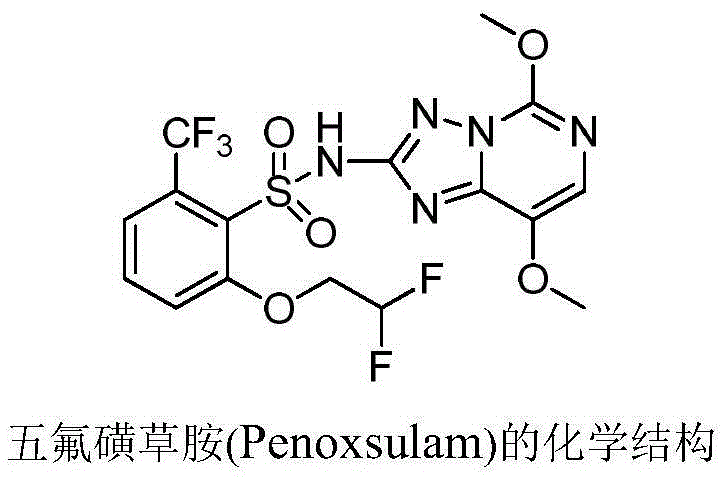

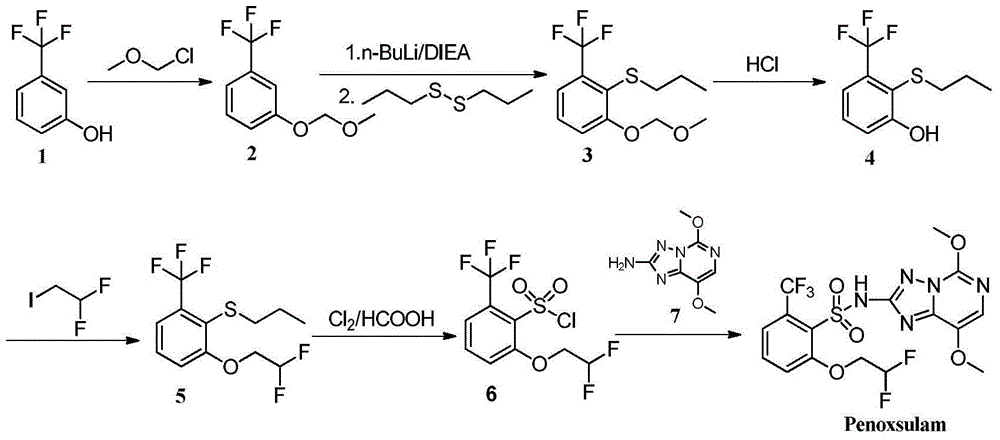

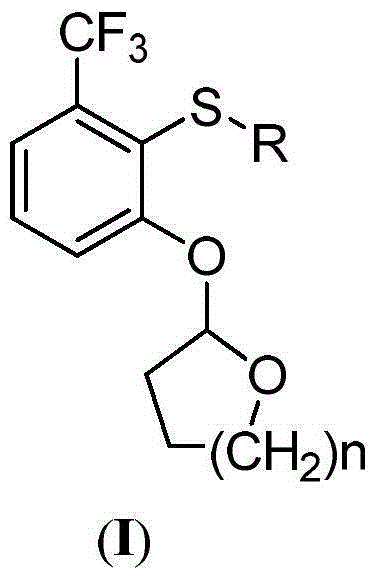

2-phenoxyl tetrahydrofuran (tetrahydropyrane) derivatives and application thereof in synthesis of penoxsulam

The invention discloses 2-phenoxyl tetrahydrofuran (tetrahydropyrane) derivatives and the application thereof in synthesis of penoxsulam, and belongs to the field of pesticide synthesis. A new intermediate of a penoxsulam pesticide is synthesized by the derivatives of the design of the invention. A high-toxicity raw material is not required to be used in the preparation of the intermediate; a product is convenient to purify and high in yield; a synthesizing process is environment-friendly; the synthesis cost is low. The penoxsulam pesticide can be prepared conveniently by utilizing the intermediate; the intermediate has a good application prospect. The series of derivatives are easy and convenient to synthesize; compared with the reported penoxsulam intermediate, a low-boiling-point raw material with high toxicity, namely, chloromethyl methyl ether, is not required to be used in the synthesizing process; the safety of the synthesizing process is improved; the derivatives are favorable to industrialized production and application.

Owner:CHANGZHOU UNIV

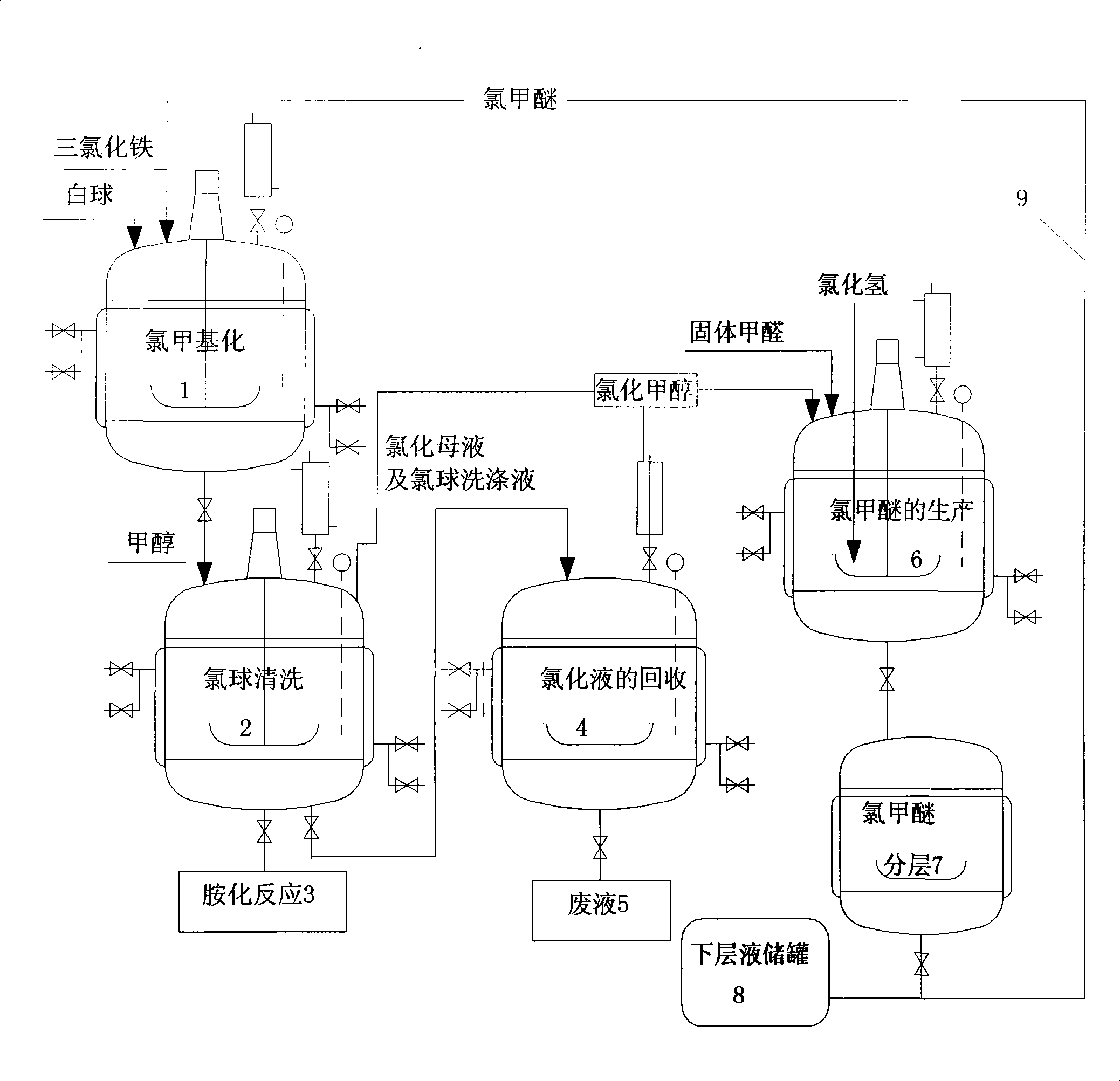

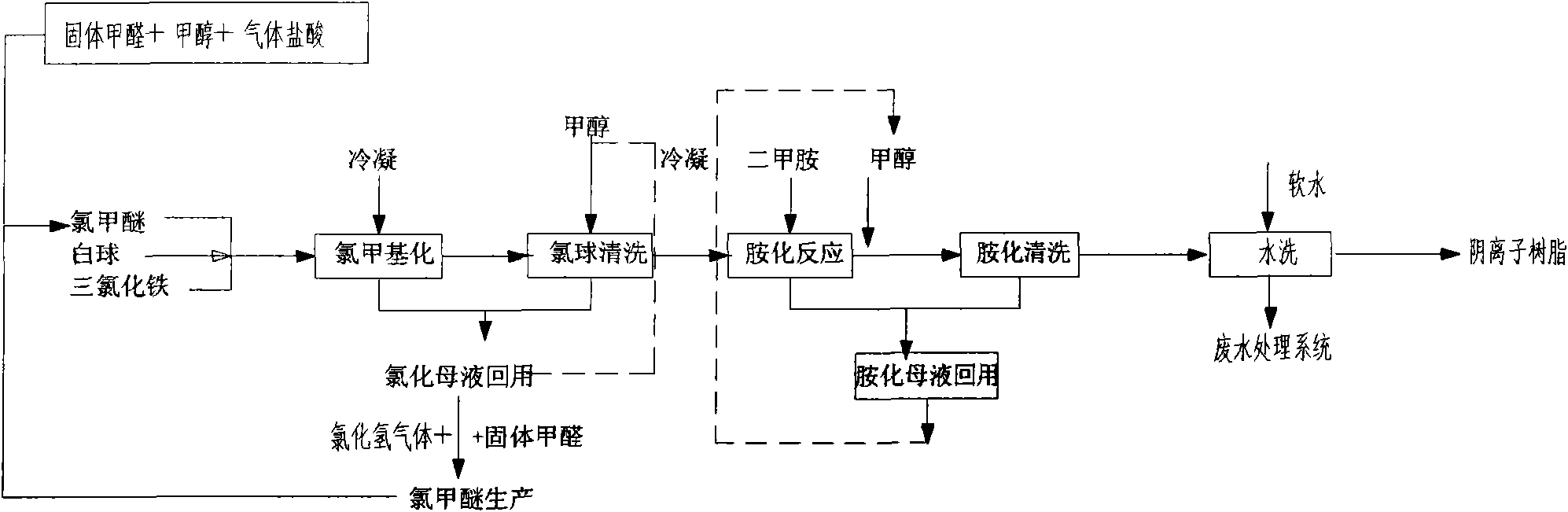

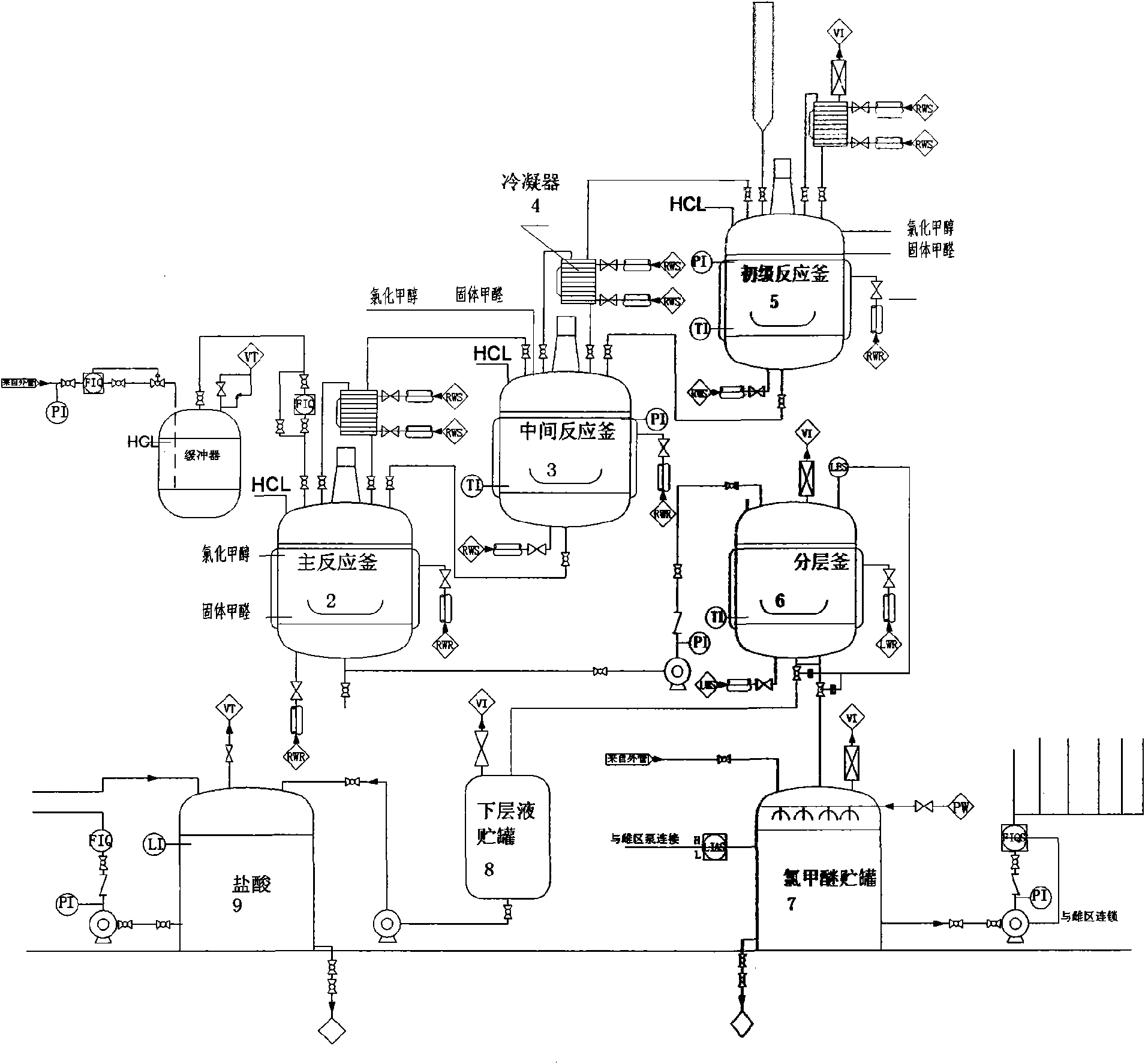

Recycling system of chlorination mother solution and recycling method thereof

InactiveCN101518747AEmission reductionReduce manufacturing costOrganic chemistryAnion exchangersChloromethyl EtherIon-exchange resin

The invention relates to a recycling system of chlorination mother solution and a recycling method thereof in an automatic anion exchange resin production system, white ball and chloromethyl ether are sent to a chloromethylation reaction kettle respectively by an airflow transmitting system and pump transmission, stirring is carried out at normal temperature; after inflating, ferric trichloride dissolvable in the chloromethyl ether is added for catalysis, and exothermic reaction is generated, the adding speed of the chloromethyl ether is regulated according to temperature, chlorine ball is prepared after the temperature is raised to 48 DEG C and temperature insulation is carried out for 10 hours, temperature reduction is carried out, the separated chlorine ball is washed sequentially by chloride methanol for two times, and by methanol for one time; then, solid-liquid separation is carried out, solid-phase chlorine ball enters amination reaction, liquid-phase chlorination mother solution and chlorine ball cleaning solution enter a chlorination liquid recycling reaction kettle, chloride methanol generated in the chlorination liquid recycling reaction kettle enters a chloromethyl ether reaction kettle; and then, solid methanol and chlorine hydride are added in the chloromethyl ether reaction kettle for reaction, chloromethyl ether volatilized in the reaction process enters a chloromethylation reaction kettle after condensation by a condenser, and noncondensable gas enters an alkali spray tower for absorption treatment.

Owner:ZHEJIANG ZHENGGUANG IND

Multi-sulfonic acid funtionalized mesoporous polymeric solid acid catalyst and preparation method and application thereof

ActiveCN104815690ALarge specific surface areaLarge hole volumeFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceBiodiesel

The invention discloses a multi-sulfonic acid funtionalized mesoporous polymeric solid acid catalyst and a preparation method thereof and an application of the catalyst in high-efficiency catalysis of an esterification reaction between free fatty acid and short-chain alcohols (ethanol and methanol) and catalysis of one-pot preparation of biodiesel from high acid-value grease and methanol. The preparation method of the catalyst comprises the following steps: mesoporous polydivinylbenzene is used as a carrier, and the carrier firstly reacts with chloromethyl methyl ether to introduce the carrier into chloromethylene; then, a product reacts with ethene diamine to make the carrier to be linked in the form of a covalent bond with ethene diamine; and finally, chlorosulfonic acid is used to carry out sulfonation so as to obtain the multi-sulfonic acid funtionalized mesoporous polymeric solid acid catalyst. The mesoporous polymeric solid acid catalyst obtained by the preparation method has a lot of mesoporous pore structures, large specific surface area and pore volume and high acid density. The catalyst is applied in catalysis of an esterification reaction between free fatty acid and short-chain alcohols (ethanol and methanol) and catalysis of one-pot preparation of biodiesel from high acid-value grease and methanol, and has a high catalytic activity. Thus, the catalyst has good industrial application value.

Owner:GUIZHOU UNIV

Diethylamine anion exchange resin and preparation method thereof

InactiveCN105153344ATroubleshoot Ion Exchange Performance IssuesAvoid secondary crosslinkingAnion exchangersPolymer scienceChloromethyl Ether

The invention relates to a diethylamine anion exchange resin and a preparation method thereof, belonging to the technical field of anion exchange resins. The resin is prepared from the following raw materials in parts by weight: 10-20 parts of macroporous styrene-divinylbenzene copolymer microsphere, 100-120 parts of dichloromethane, 15-25 parts of anhydrous aluminum trichloride, 10-20 parts of chloracetyl chloride, 5-9 parts of chloracetylated resin, 50-60 parts of diethylamine, 50-60 parts of tetrahydrofuran and 3-12 parts of NaHCO3. Chloracetylation reaction is performed on crosslinked polystyrene microspheres by Friedel-Crafts reaction to introduce chloracetyl group, and amination is performed to obtain the weakly alkaline tertiary-amine anion exchange resin. The method avoids using chloromethyl ether and other carcinogenic substances, and avoids secondary crosslinking, polysubstitution and other side reactions.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Production method of polyphenylene sulfide-based adsorption separation resin

ActiveCN105860077AImprove thermal stabilityImprove heat resistanceOther chemical processesWater contaminantsPtru catalystChloromethyl Ether

The invention discloses a production method of polyphenylene sulfide-based adsorption separation resin. The production method comprises the following steps: adding a solvent to polyphenylene sulfide resin to swell the polyphenylene sulfide resin adding anhydrous tin tetrachloride and chloromethyl ether, heating and reacting above materials, and post-processing the obtained reaction product to obtain CH2Cl-containing CMPPS resin; and adding a solvent to the obtained CMPPS resin to swell the CMPPS resin, adding a catalyst and a functionalized monomer, heating and reacting above materials, and post-processing the obtained reaction product to obtain the final product polyphenylene sulfide-based adsorption separation resin. Functional groups comprising a thienyl group, a 3-aminopyridyl group and a mercapto group, introduced to the invention, have good coordination adsorption ability to heavy metal ions, and the functional groups contain N and S hetero atoms, have small relative molecular mass, and can easily coordinate with the heavy metal ions, so an excellent adsorption purpose can be reached.

Owner:佛山市安芯纤维科技有限公司 +1

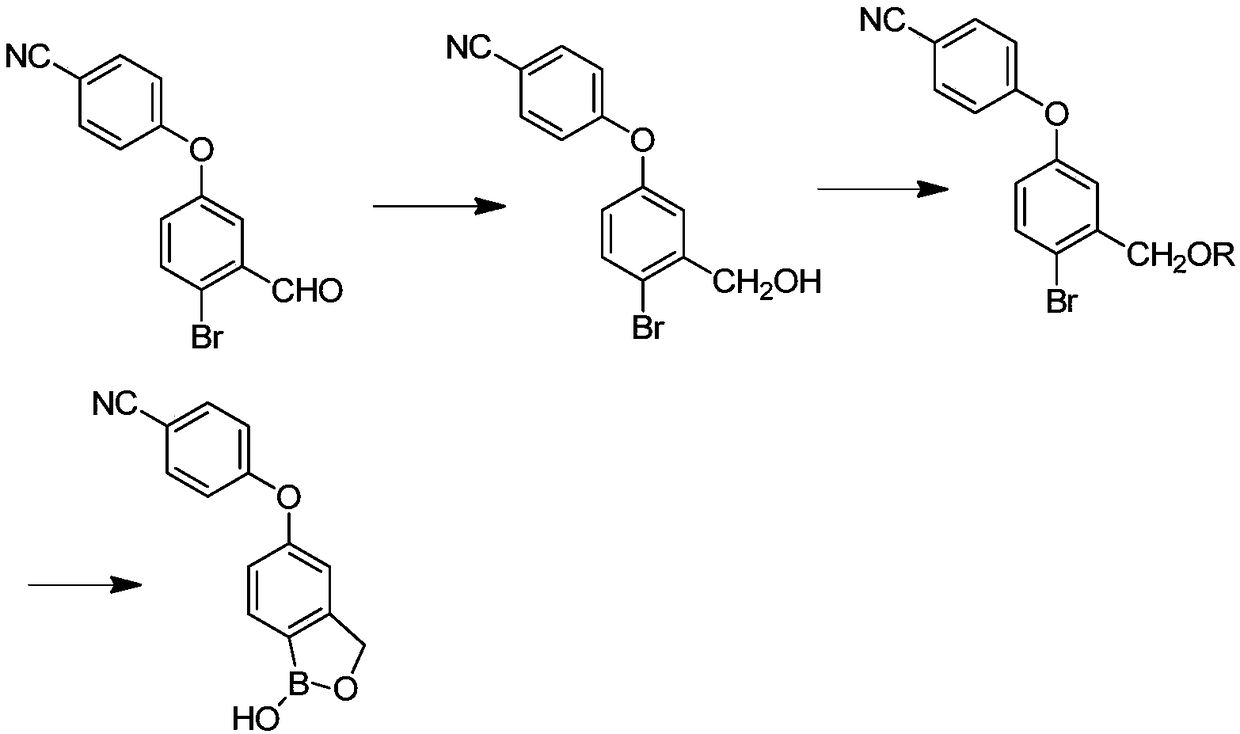

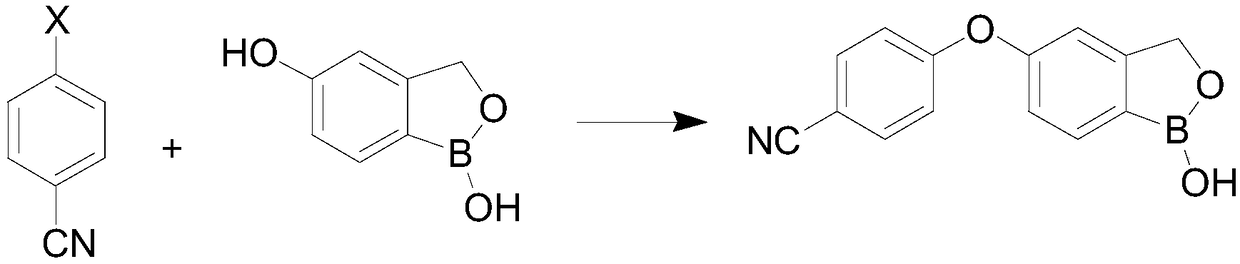

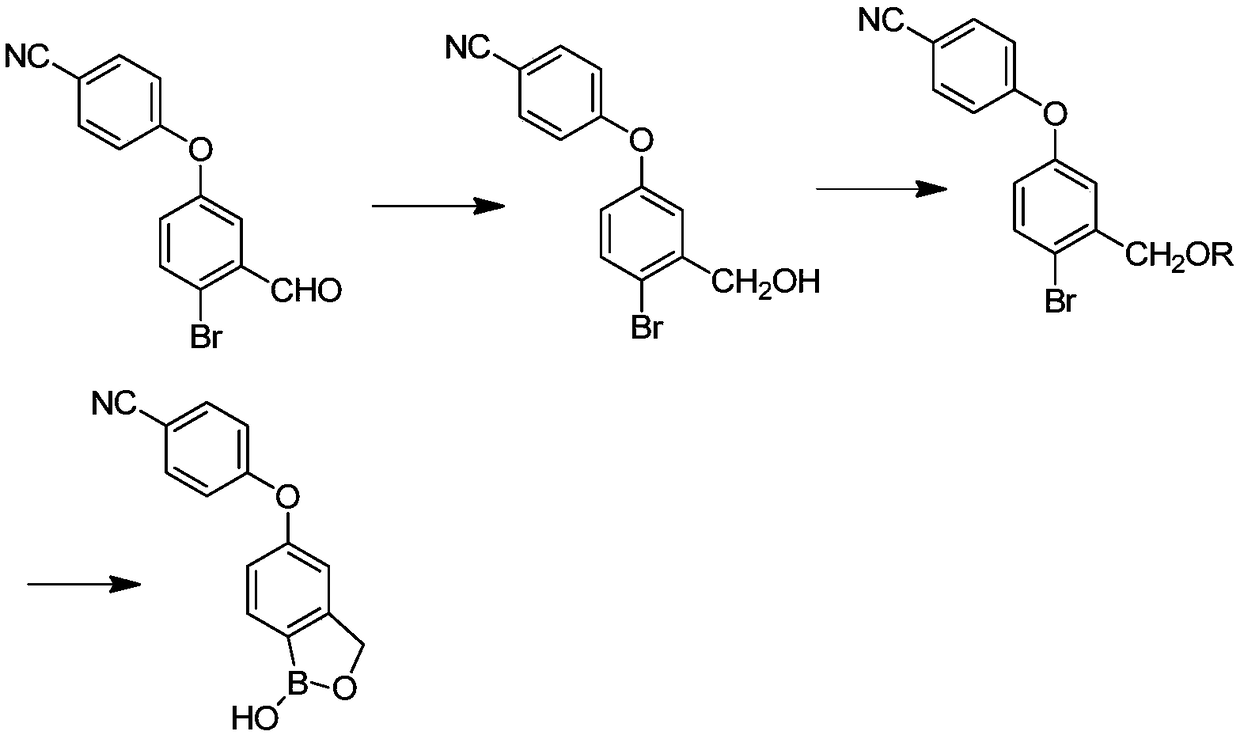

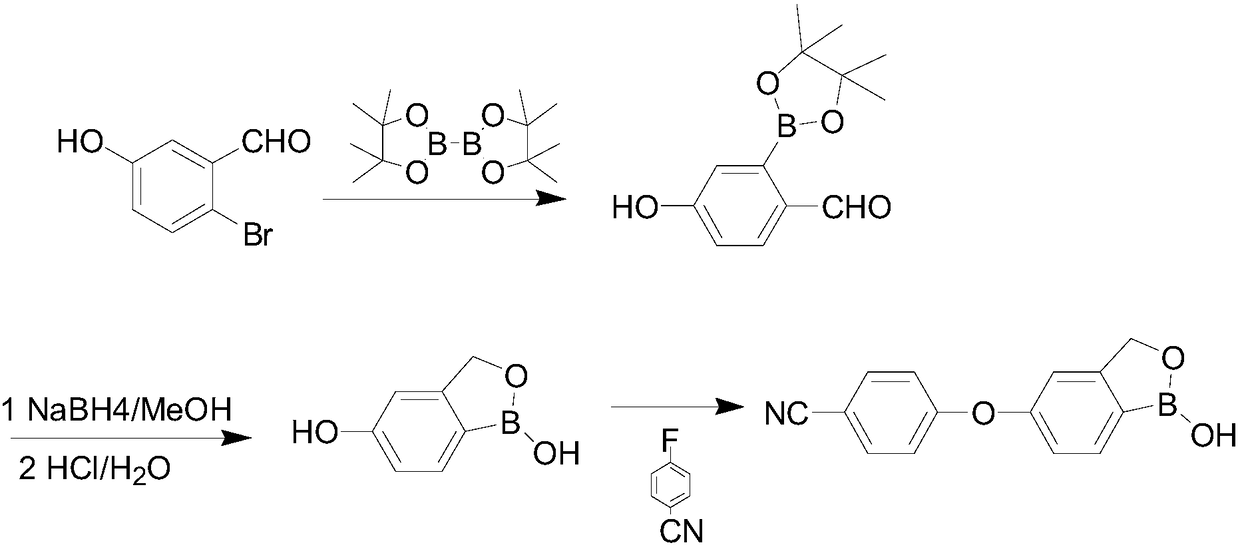

Preparation method of crisaborole

InactiveCN108659024ALow priceMild reaction conditionsGroup 3/13 element organic compoundsTert-butyldimethylsilyl chlorideTrimethyl borate

The invention discloses a preparation method of crisaborole. The method comprises the steps as follows: a compound shown in a formula I and alkali metal borohydride are subjected to a contact reaction, and a compound shown in a formula II is obtained; the compound shown in the formula II and a compound a are subjected to a contact reaction, and a compound III is obtained; or the compound shown inthe formula II and dihydropyran are subjected to a contact reaction, and a compound III is obtained, wherein the compound a is trimethylchlorosilane, tert-butyldimethylsilyl chloride or chloromethyl methyl ether; the compound shown in the formula III and an isopropylmagnesium chloride solution are subjected to a contact reaction, and a standby solution is obtained; then, the standby solution is added to a mixed solution of a compound b and a third organic solvent for a contact reaction, hydrochloric acid is added for a contact reaction, and crisaborole, namely, a compound shown in a formula IV, is obtained, wherein the compound b is 2-alkoxy-4,4,5,5-tetramethyl-1,3,2-dioxaborolane, triisopropyl borate or trimethyl borate.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Method for preparing solid-phase synthesized carrier

InactiveCN101230085AClear structureMaterial safetyPeptide preparation methodsDimethyl formamideSolid phases

The invention relates to a preparation method of solid phase synthesis carrier, which belongs to the functional high molecular material technology field. The invention adopts halogen acetylized crosslinked polystyrene resin and hydroxybenzyl alcohol as the raw material, and the solid phase synthesis carrier with hydroxymethyl as the active group is synthesized through the joint catalysis of N, N-dimethyl formamide used as the reaction solvent, inorganic base and phase-transfer catalyst. The invention is characterized in that the carrier is produced through the reaction between halogen acetylized crosslinked polystyrene resin and hydroxybenzyl alcohol. Halogen acetylized crosslinked polystyrene resin is used for replacing commonly used methyl chloride polystyrene resin. The method can avoid the use of toxic substances of chloromethyl ether, etc. during the preparation process of methyl chloride polystyrene resin, and also improves the polysubstitution in chloromethylation reaction. Simultaneously, halogen acetyl can react with phenolic hydroxyl singly, thus the competing side reaction between hydroxymethyl and phenolic hydroxyl can be avoided, the phase transition method can avoid the methoxylation side reaction caused by the introduction of organic base; therefore the structure of the product is clear.

Owner:NANJING UNIV OF TECH

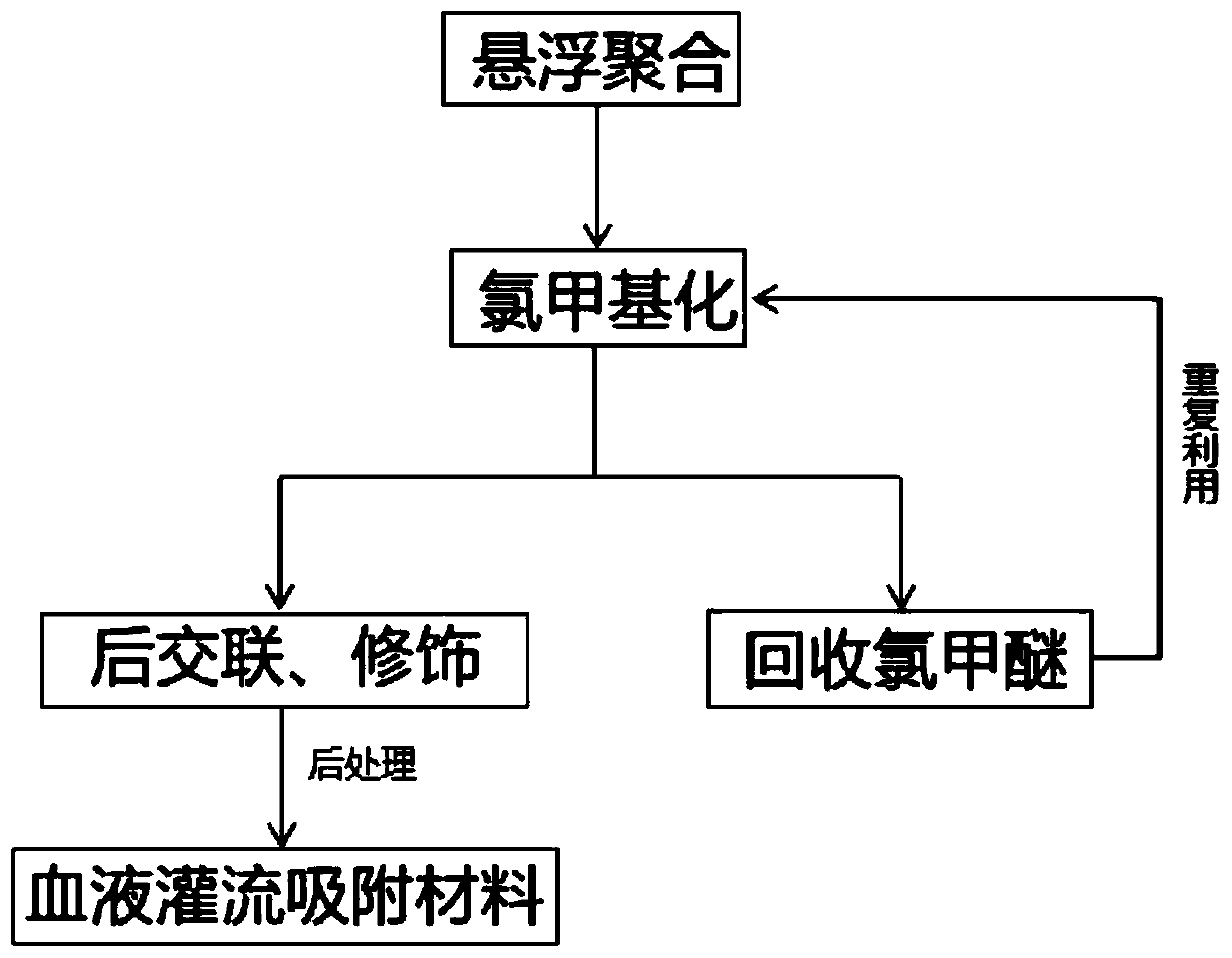

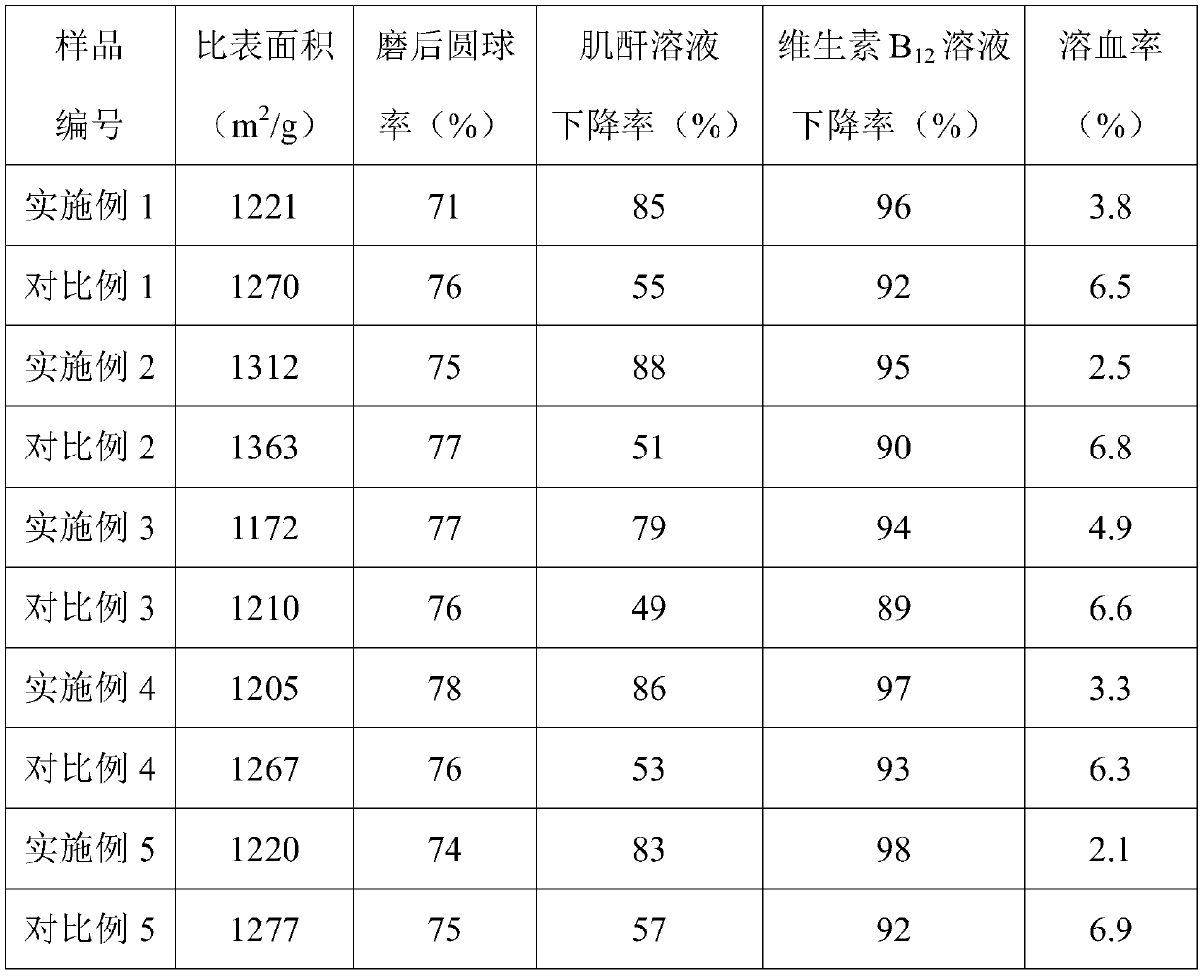

Preparation method of adsorbing material for blood perfusion

ActiveCN111530432AImprove adsorption capacityThe synthetic route is simpleOther blood circulation devicesOther chemical processesChloromethyl EtherOil phase

The invention discloses a preparation method of an adsorption material for blood perfusion. The preparation method comprises the following steps: preparing an oil phase and a water phase, by a suspension polymerization process, preparing a macroporous adsorption resin precursor with the particle size distribution being 0.315-0.8 mm from the the prepared oil phase and water phase, carrying out chloromethylation on the prepared macroporous adsorption resin precursor to prepare a chloromethylated macroporous adsorption resin precursor, carrying out post-crosslinking on the prepared chloromethylated macroporous adsorption resin precursor to prepare macroporous adsorption resin of which the residual chlorine content is less than or equal to 2%, and carrying out post-treatment on the prepared macroporous adsorption resin to prepare the surface functionalized macroporous adsorption resin with adsorption capacity for blood perfusion. According to the invention, recycling of residual chloromethyl ether after the chloromethylation reaction in the synthesis process of the macroporous adsorption resin for blood perfusion is realized, and remarkable economic benefits and environmental protection benefits are brought.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD +1

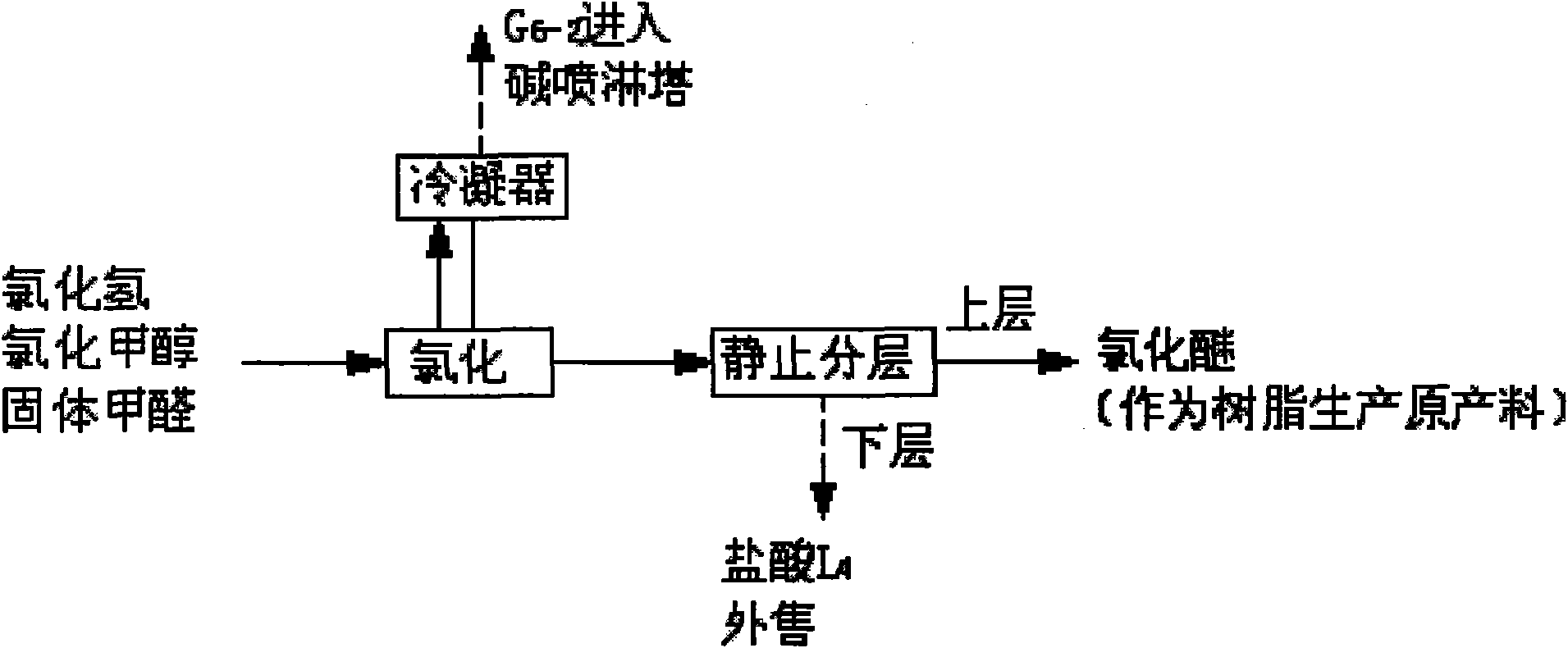

Anion exchange resin production system and production technology

ActiveCN101524653AReduce outputEmission reductionAnion exchangersChemical reactionIon-exchange resin

The invention relates to a production system used for anion exchange resin and production technology. The production technology comprises chloromethylether production technology, chloromethylation production technology, chlorine ball cleaning technology, an amination reaction, and washing technology and obtains the finished product anion resin finally. Chloromethylether needed by producing the anion resin first time is prepared by a chemical reaction generated by solid formaldehyde, methanol and gas hydrochloric acid. The system and the technology are characterized in that a chloridization mother liquor generated by the chloromethylation production technology and a cleaning solution generated by the chlorine ball cleaning technology are sent to chloridization solution recovering technology. Chloridization methanol in the chloridization mother liquor reacts with the additive solid formaldehyde and chloride hydrogen gas to obtain the chloromethylether directly taken as a raw material for circulating the anion resin production and circulate in the way to obtain the chloromethylether.

Owner:NINGBO ZHENGGUANG RESIN CO LTD

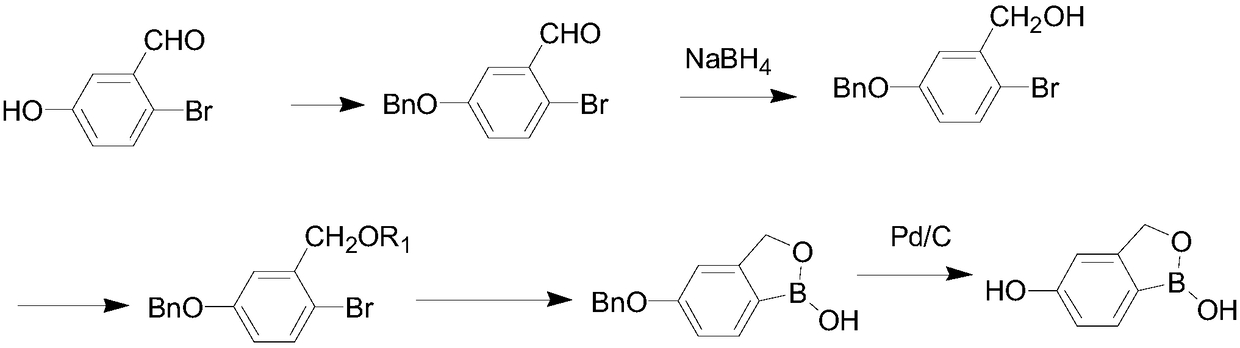

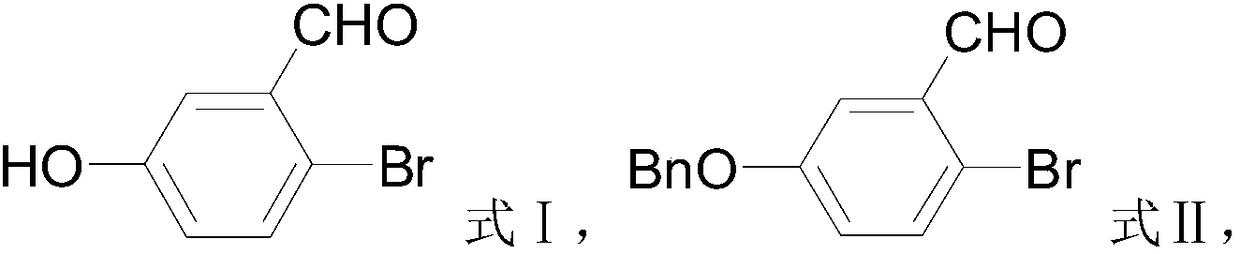

Preparation method of Crisaborole intermediate

InactiveCN108997399ALow priceMild reaction conditionsGroup 3/13 element organic compoundsTert-butyldimethylsilyl chlorideTrimethyl borate

The invention discloses a preparation method of a Crisaborole intermediate. The Crisaborole intermediate has a structure shown as the formula VI. The preparation method comprises the following steps:performing a contact reaction on a compound shown as the formula I and benzyl halide, so as to form a compound shown as the formula II; performing a contact reaction on the compound shown as the formula II and alkali metal borohydride, so as to obtain a compound shown as the formula III; performing a contact reaction on the compound shown as the formula III and a compound a, or performing a contact reaction on the compound shown as the formula III and dihydropyran, so as to obtain a compound shown as the formula IV, wherein the compound a is trimethylchlorosilane, tert-butyldimethylsilyl chloride and chloromethyl methyl ether; performing a contact reaction on the compound shown as the formula IV and an isopropylmagnesium chloride solution; adding an obtained solution into a compound b, performing a contact reaction on the mixture and fourth organic solvent mixed liquor and adding hydrochloric acid into the mixture for contact reaction, so as to obtain a compound shown as the formula V,wherein the compound b is 2-alkoxy-4, 4, 5, 5-tetramethyl-1, 3, 2-dioxaborolane, triisopropyl borate or trimethyl borate; performing a hydrogenation reaction on the compound shown as the formula V toobtain a compound shown as the formula VI.

Owner:WUHAN POLYTECHNIC UNIVERSITY

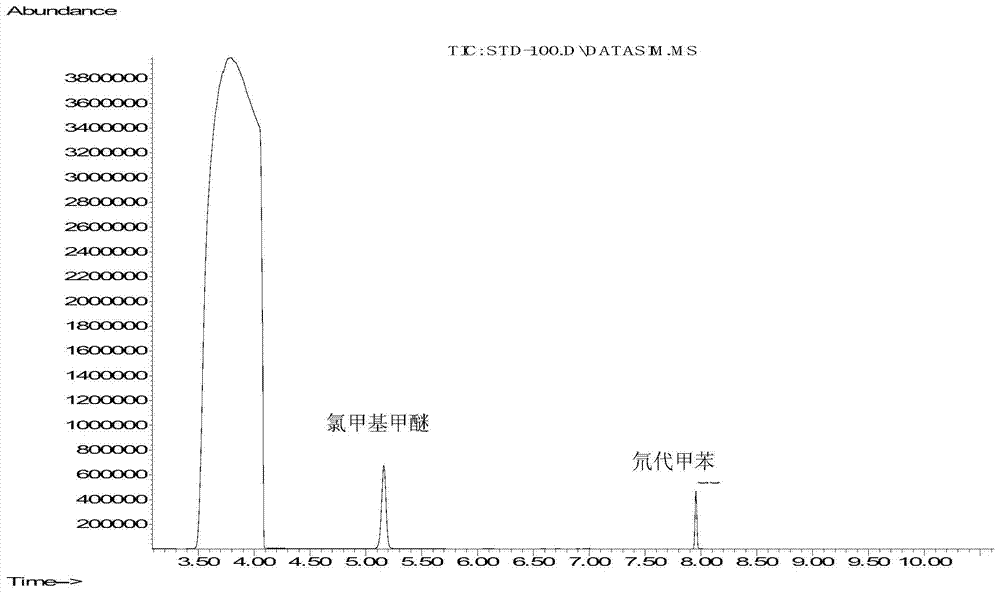

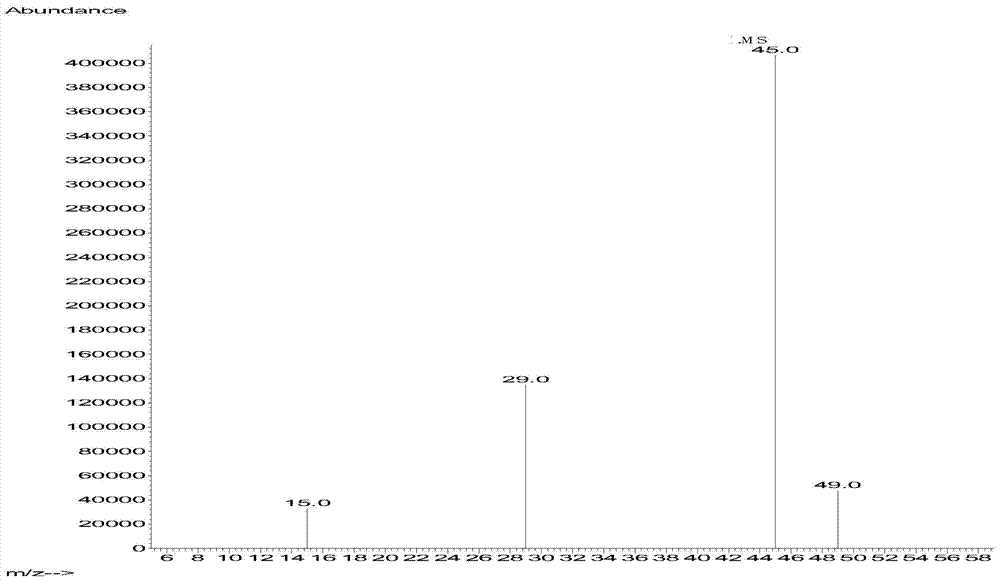

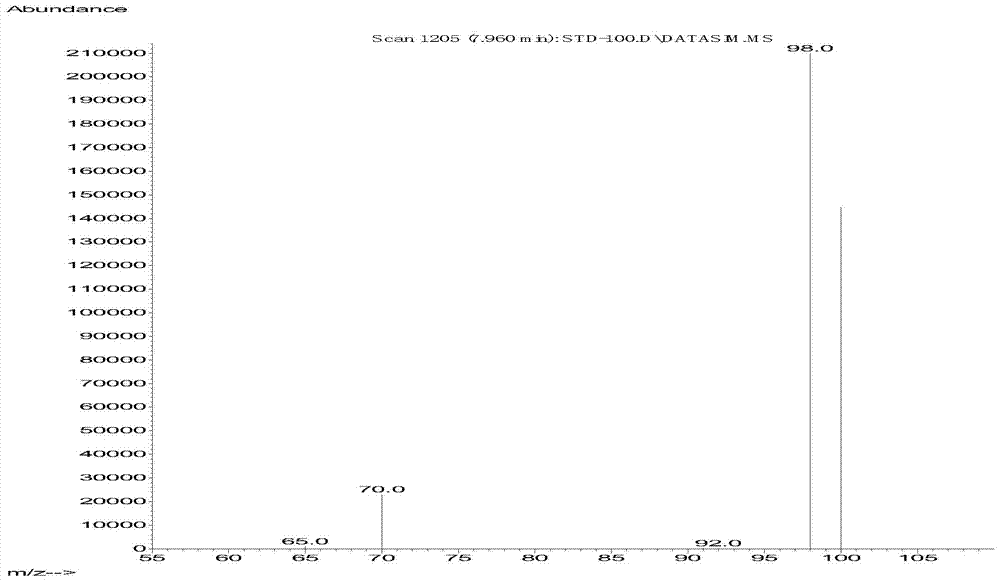

Method for determining chloromethyl methyl ether in automotive materials

ActiveCN104502487AAccurate measurementAvoid pollutionComponent separationGas liquid chromatographicInternal standard

The invention belongs to the technical field of analytic chemistry, and particularly relates to a method for determining the content of chloromethyl methyl ether in automotive materials. The method comprises the following determining steps: (1) cutting a to-be-determined sample into small cubes with sizes of about 2mm*2mm*2mm, and sealing for later use; (2) weighing a certain amount of sample and placing the sample in a headspace bottle, adding acetone, adding toluene-d8 as an internal standard, after fastening the bottle cover down, placing in a headspace sampler; and (3) determining the content of chloromethyl methyl ether in a sample by adopting a gas chromatography-mass spectroscopy meter. According to the method, the content of chloromethyl methyl ether in the automotive materials is determined by adopting the gas chromatography-mass spectroscopy meter, and is quantified by adopting an internal standard method; the method is little in sampling amount, simple in pretreatment operation, and rapid in testing; accurate determination of the content of chloromethyl methyl ether in the automotive materials can be realized, and the detection limit of the method is 100mg / kg.

Owner:SGS STANDARD TECHNICAL SERVICES SHANGHAI CO LTD

Method for synthesizing plasticizer 3-nitro furazan-4-methyl ether

InactiveCN102702131AOrganic chemistryPressure gas generationHydroxylamine HydrochlorideEthyl fumarate

The invention discloses a method for synthesizing plasticizer 3-nitro furazan-4-methyl ether. The method comprises the following steps: adding hydroxylamine under the alkaline condition by taking ethyl cyanoacetate as a starting material to form a ring, so as to obtain 3-amino furazan-4-carboxylic acid; then, reducing carboxyl group on the furazan ring to an alcoholic extract hydroxyl group by using a sodium borohydride / zinc chloride system, so as to obtain 3-amino furazan-4-methanol; then, oxidizing an amino group on the furazan ring to a nitro group by using a hydrogen peroxide / concentrated sulphuric acid system, so as to obtain 3-nitro furazan-4-methanol; in the presence of pyridine, carrying out chloride substituent on the alcoholic extract hydroxyl group by using thionyl chloride, so as to obtain 3-nitro-4-chloromethyl methyl ether furazan; and finally, reacting 3-nitro-4-chloromethyl methyl ether furazan with sodium methoxide in acetonitrile to remove NaCl so as to obtain the target compound. Compared with the traditional nitrate plasticizer, the plasticizer synthesized by using the method has higher positive enthalpies of formation and thermal stability, lower sensitivity and melting point, and has potential application prospect in the field of solid propellants.

Owner:太仓市新星轻工助剂厂

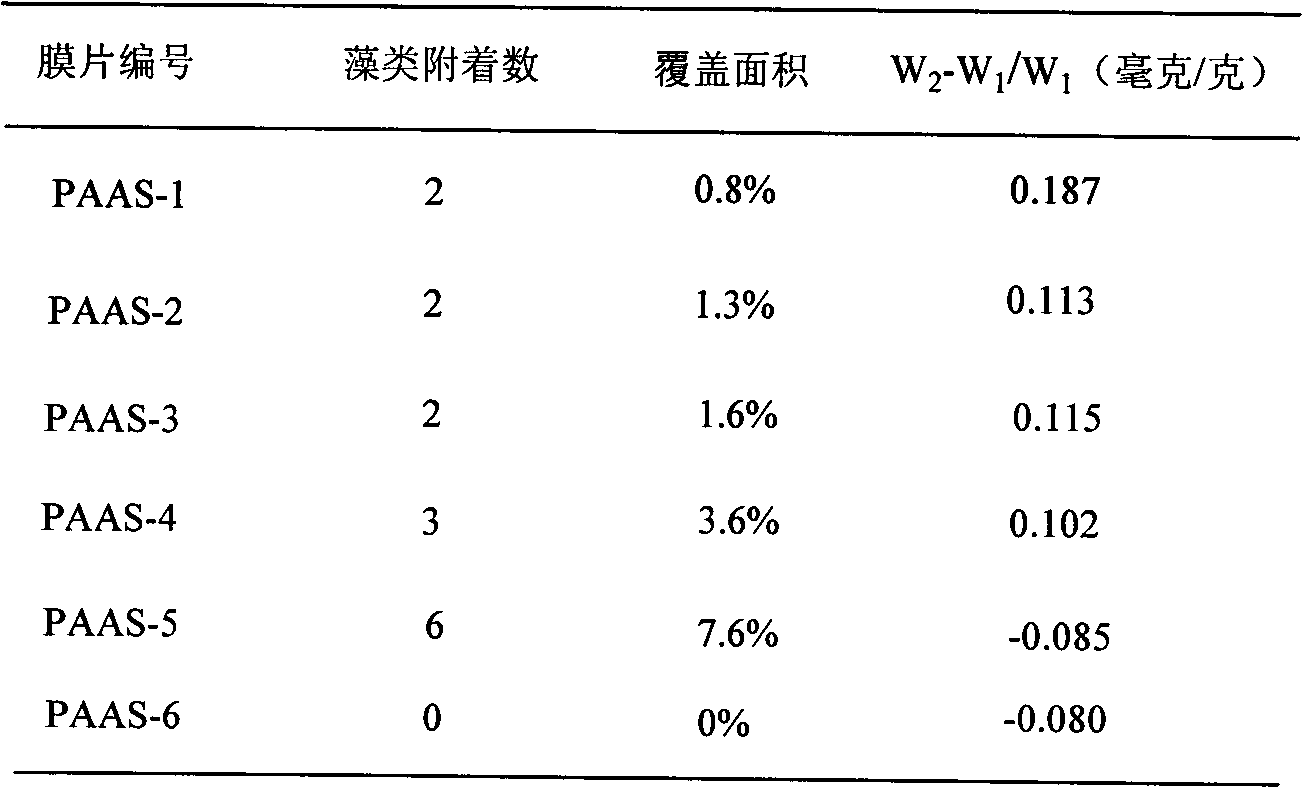

Silicone acrylic resin based ocean anti-fouling paint and preparation method thereof

InactiveCN102585646ASimple manufacturing methodRich sourcesAntifouling/underwater paintsPaints with biocidesMicroorganismAcrylic resin

The invention provides a silicone acrylic resin based ocean anti-fouling paint. The paint is characterized in that salicylic aldehyde and quaternary ammonium salt modified silicone acrylic resin serves as a coating of a film-forming substance; the salicylic aldehyde and quaternary ammonium salt modified silicone acrylic resin is obtained by reacting silicone acrylic resin of which the macromolecular side chain contains a tertiary amine group with 5-chloromethyl methyl ether salicylic aldehyde. The silicone acrylic resin based seawater anti-fouling paint has the antiseptic antibacterial synergy and can effectively lower the drug resistance of bacteria microorganism; and the salicylic aldehyde and quaternary ammonium salt modified silicone acrylic resin serves as the film forming substance in seawater and can chelate and adsorb copper ions or nickel ions in seawater and generates new antiseptic antibacterial efficiency.

Owner:HUAIHAI INST OF TECH

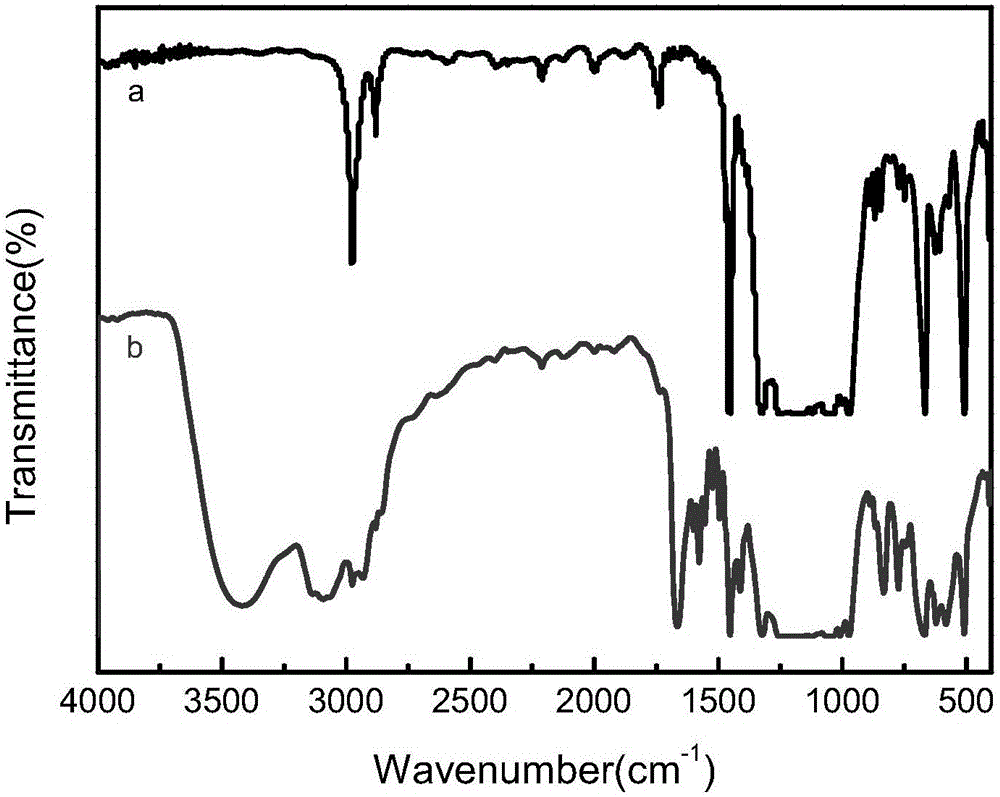

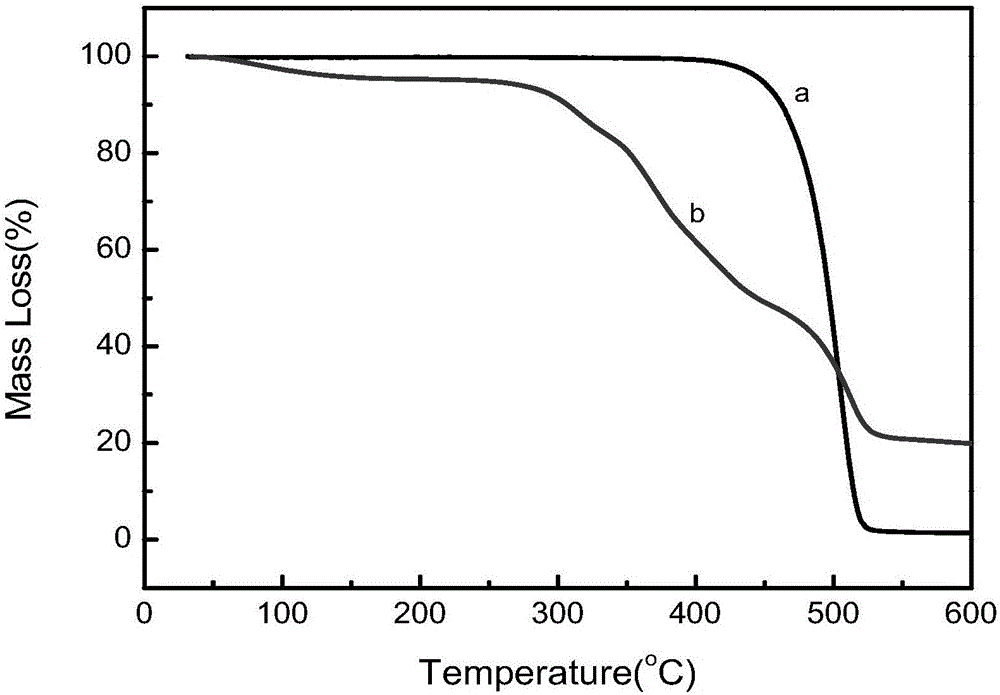

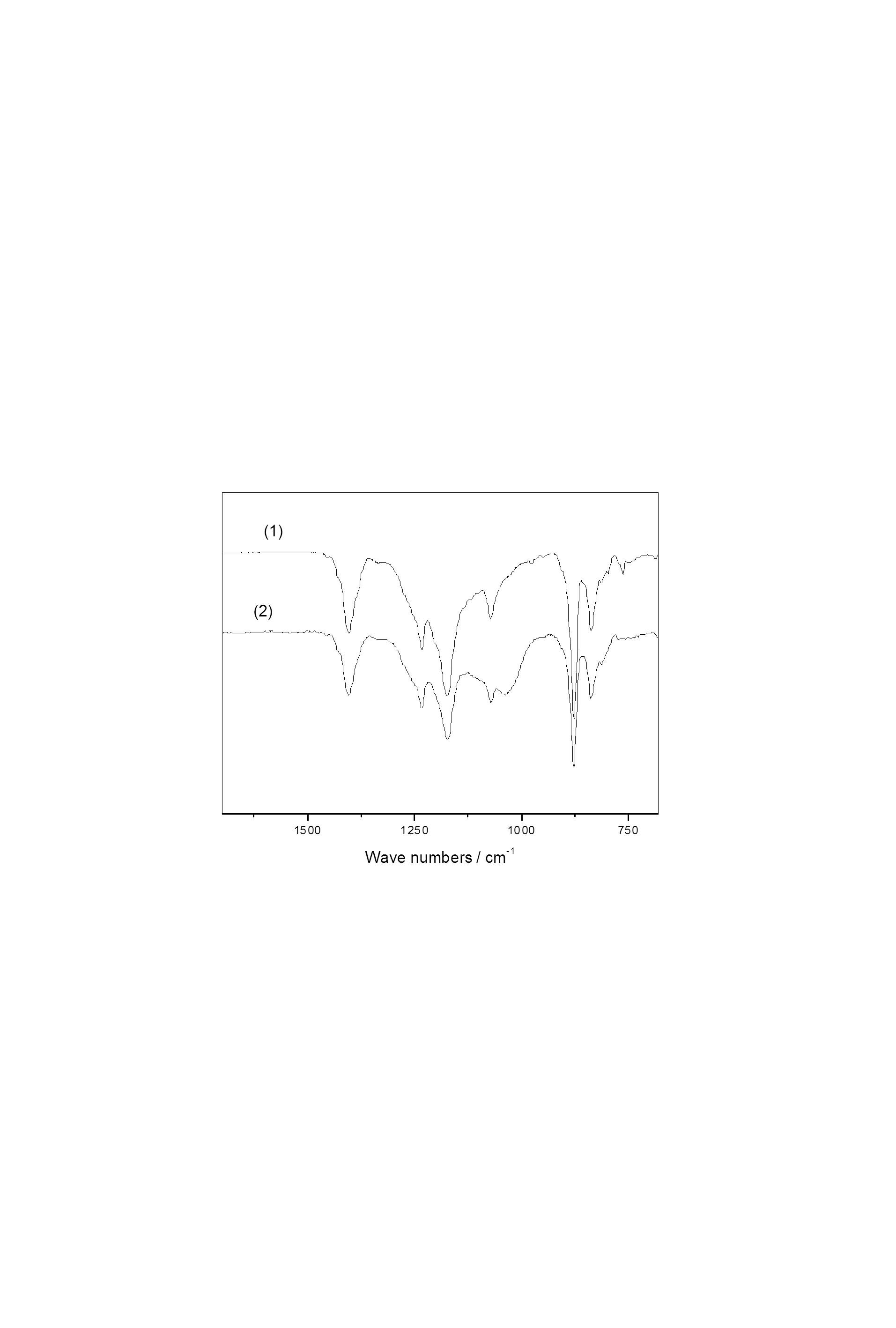

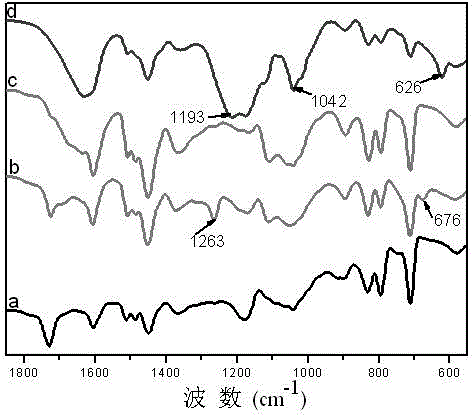

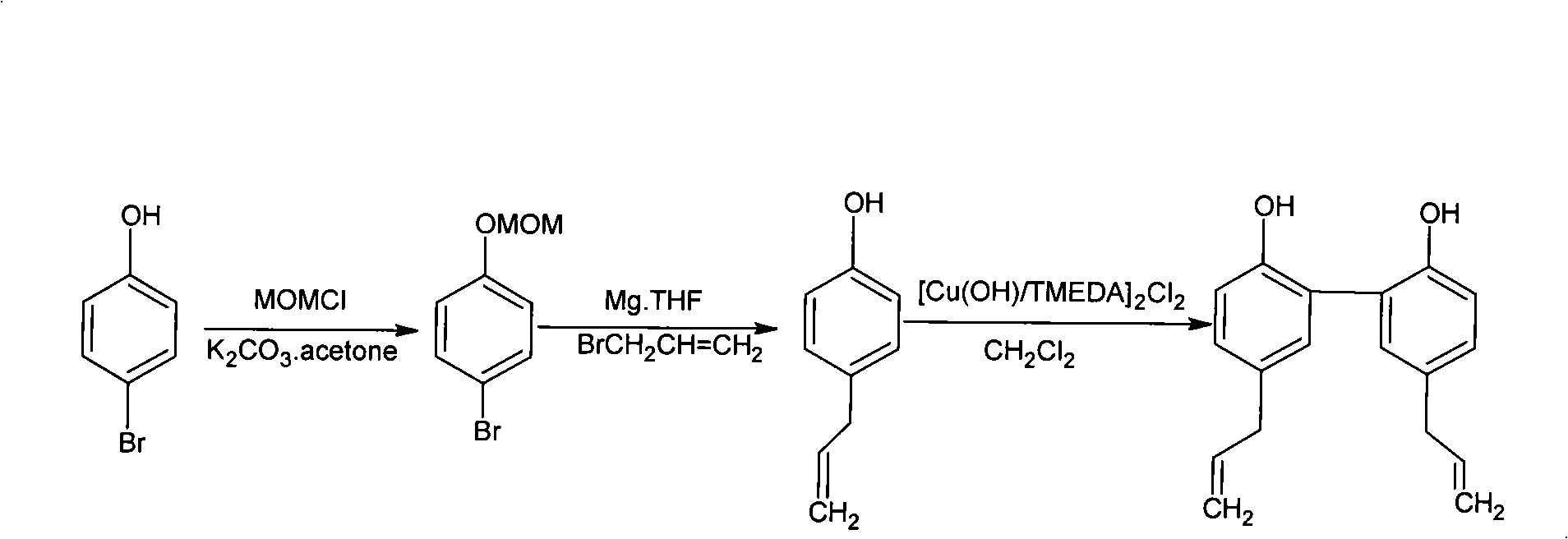

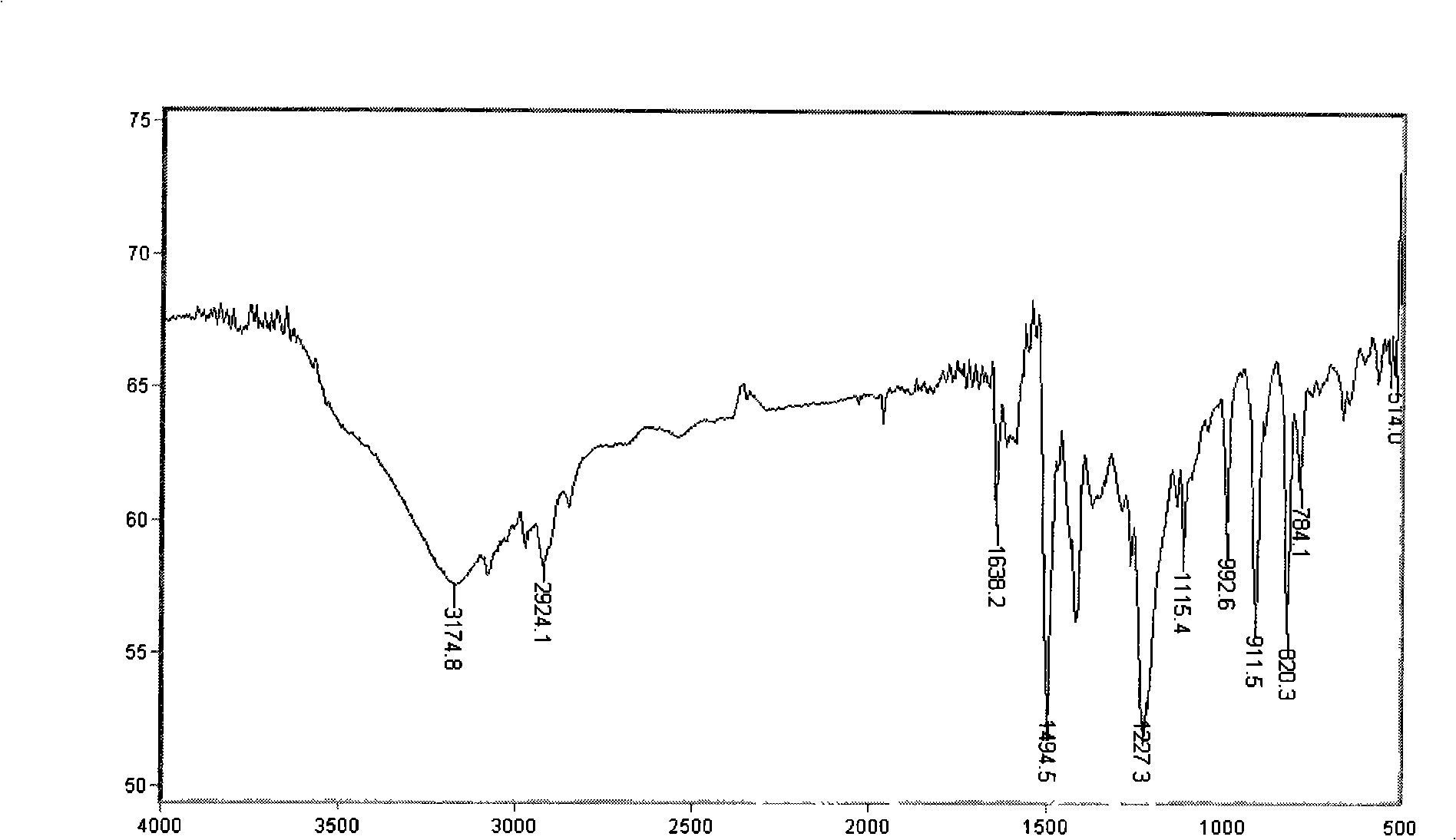

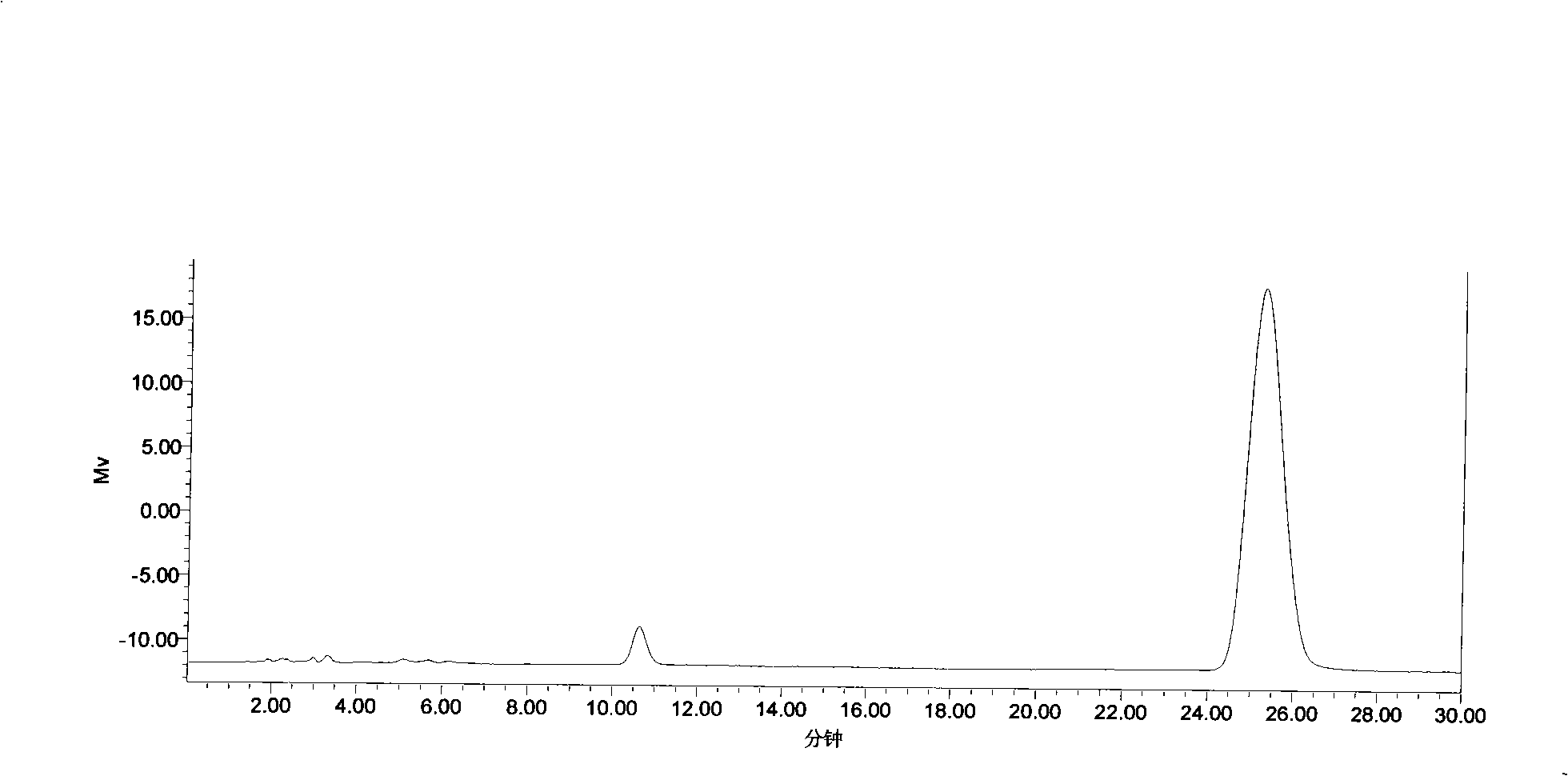

Magnolol synthesizing method

InactiveCN101293816AOxidative coupling reaction is not easy to occurOptimization of reaction process conditionsOrganic chemistryOrganic compound preparationChemical synthesisMagnolol

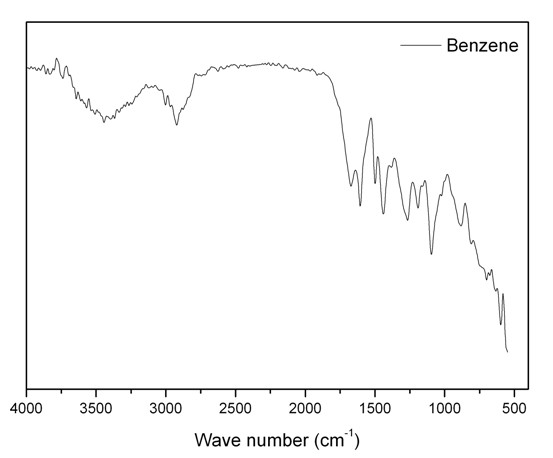

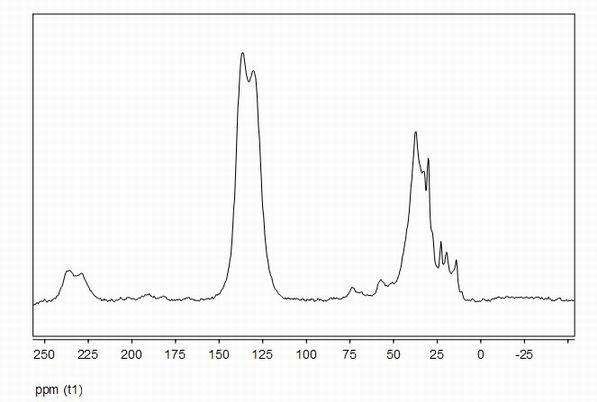

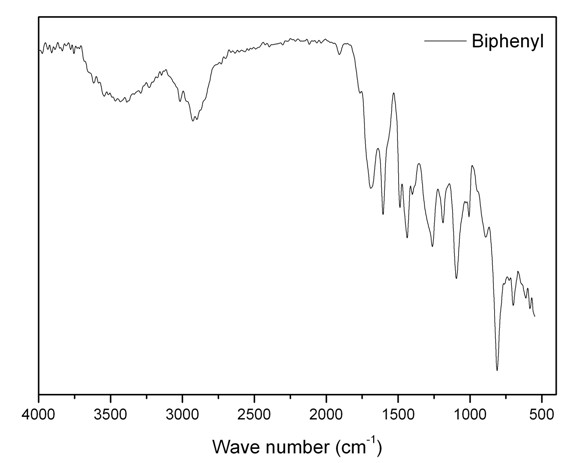

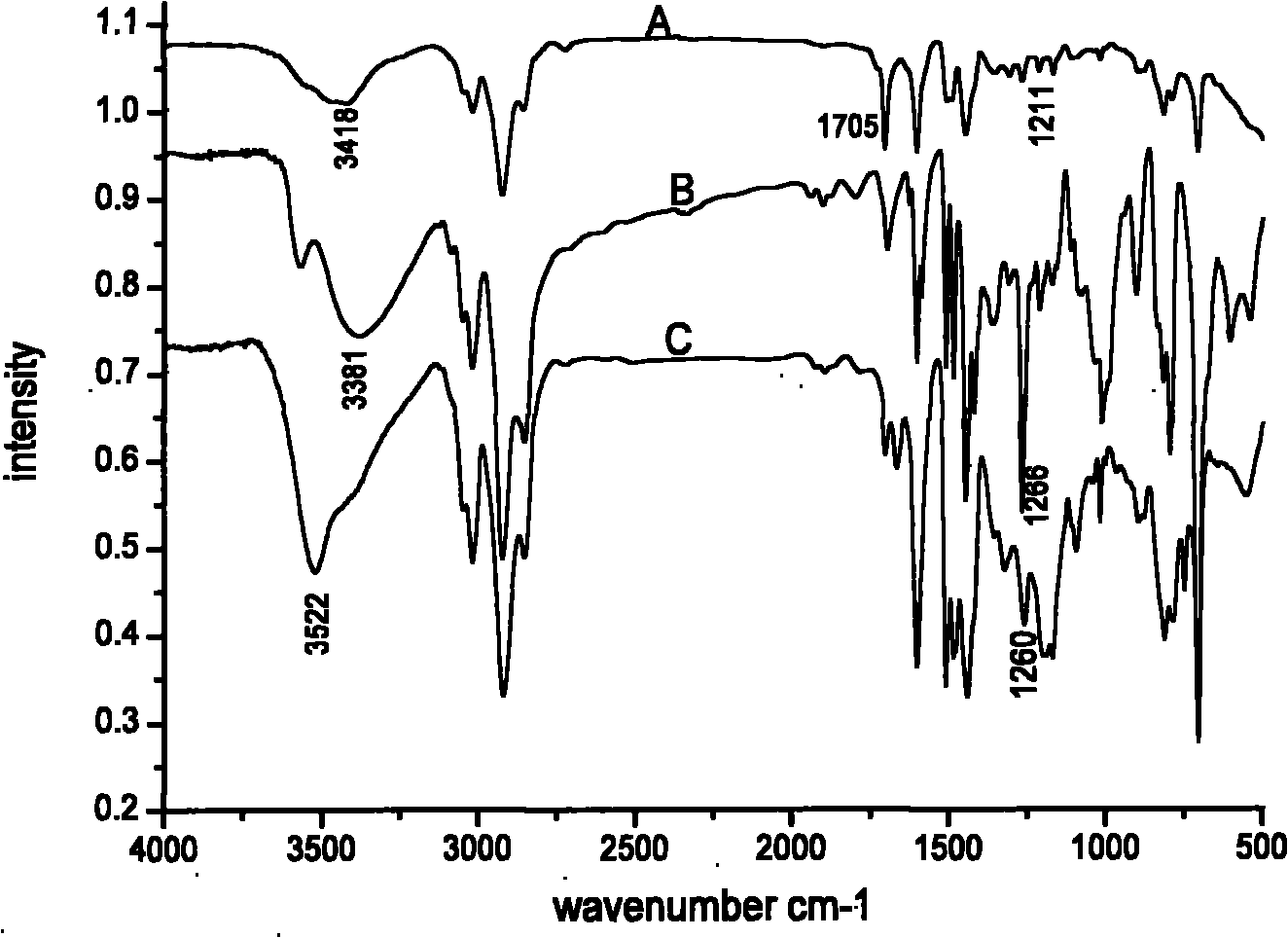

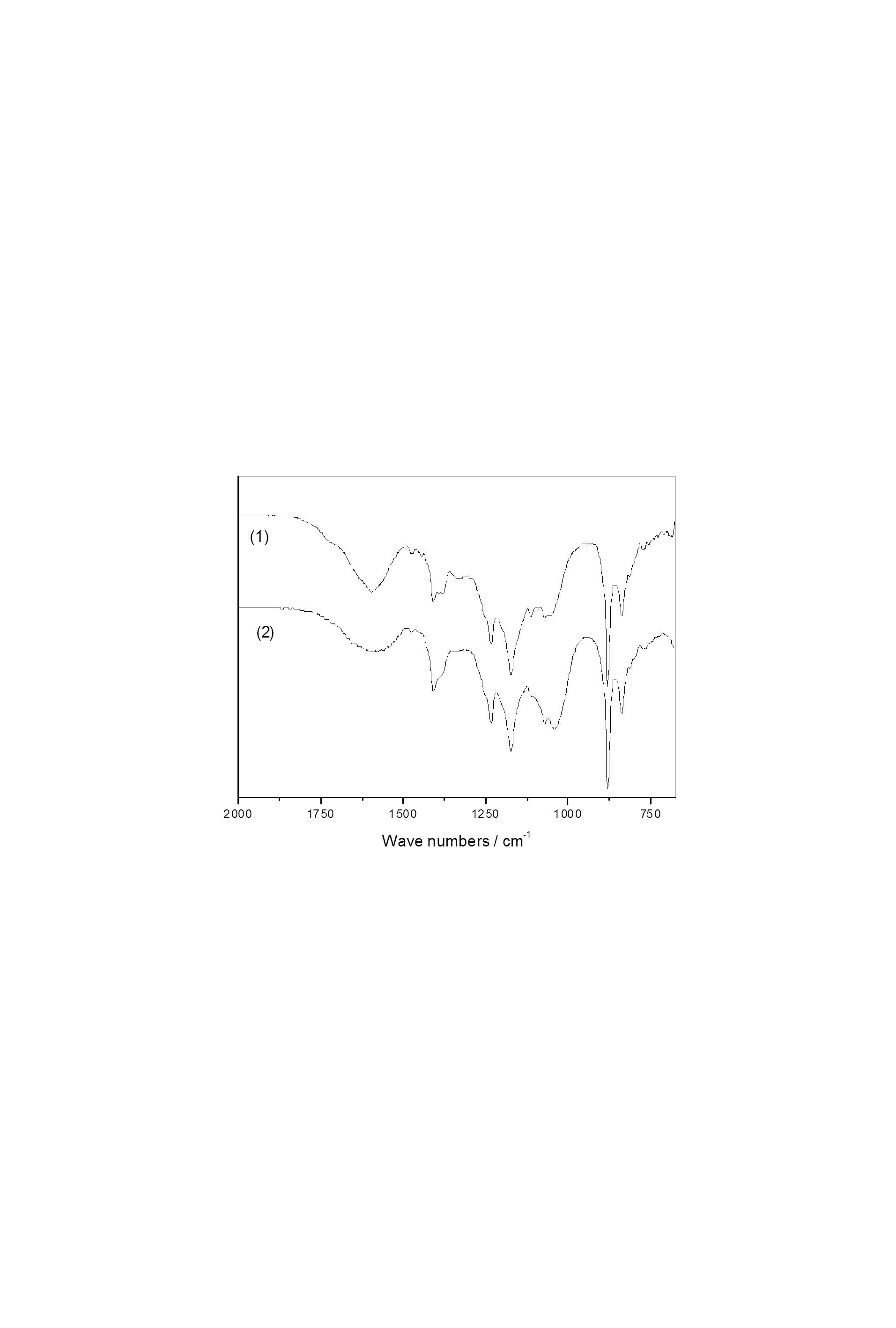

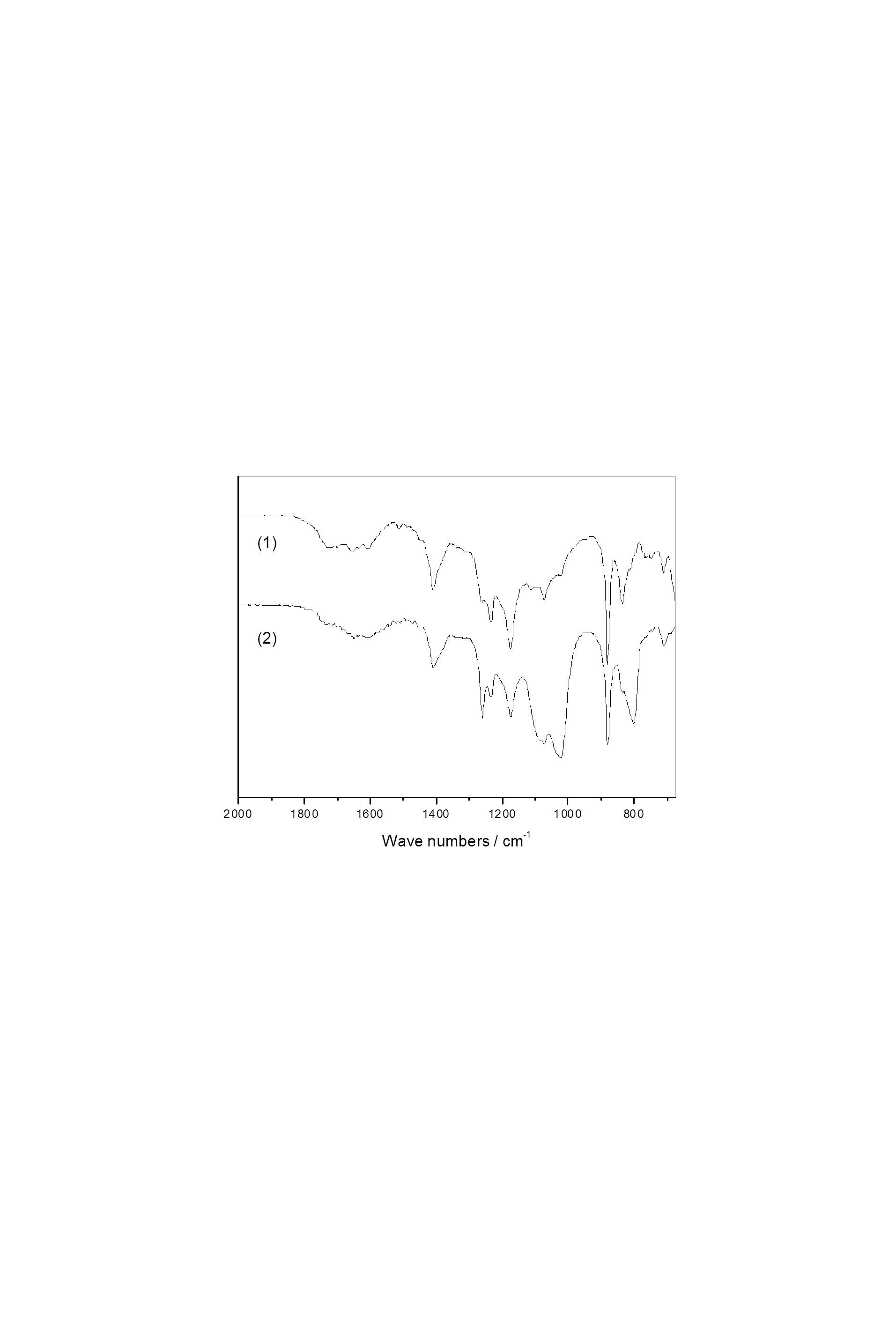

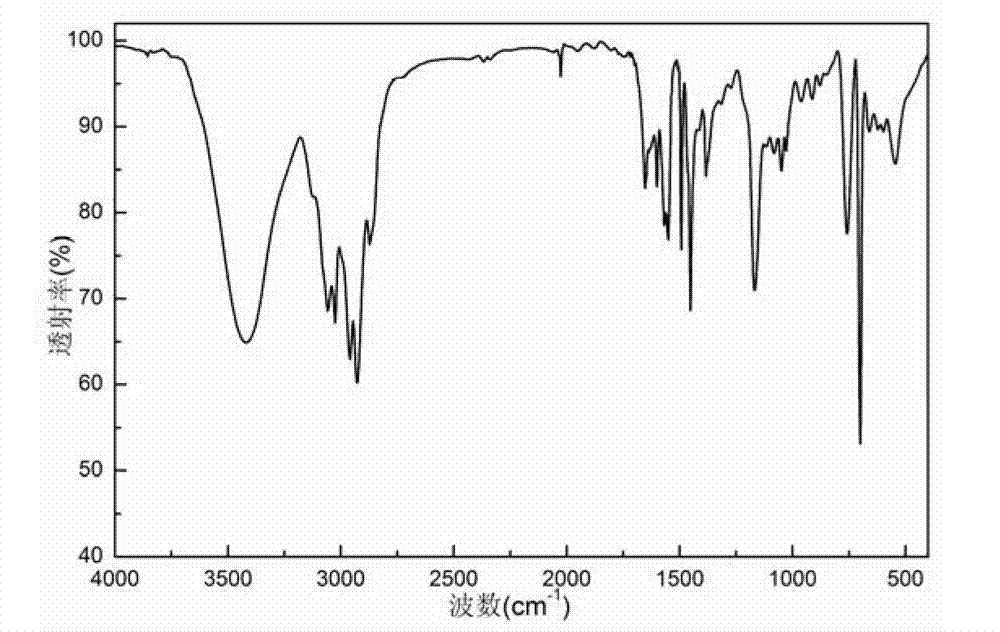

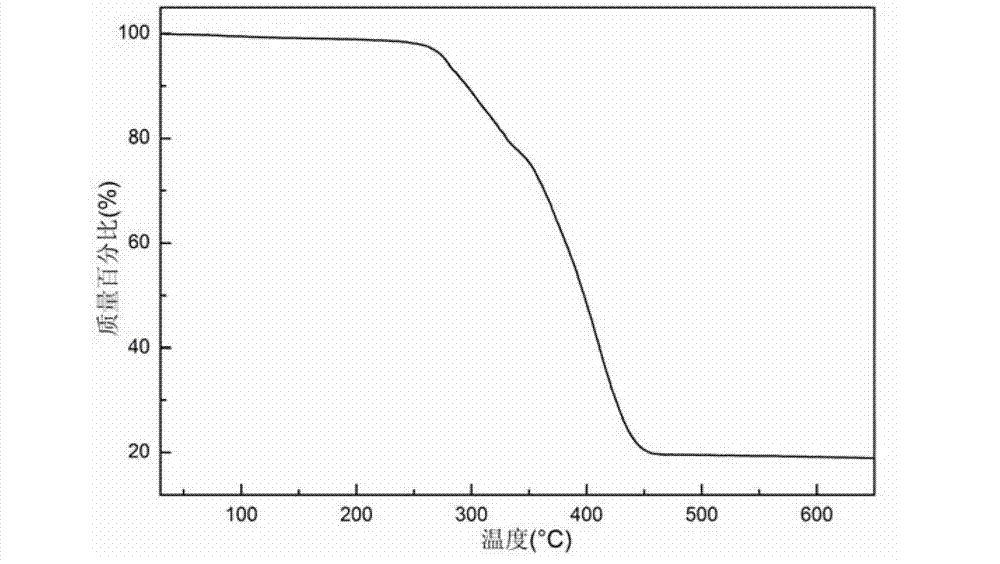

The invention provides a method for synthesizing magnolol. The magnolol is prepared from relatively cheap p-bromophenol, chloromethyl methyl ether and allyl bromide by being subjected to hydroxy protection and Grignard reaction to obtain allylphenol intermediate product; dissolving allylphenol into solvent; and carrying out oxidation coupling reaction in the presence of oxidation catalyst and introducing air or oxygen. The method is characterized in that the adopted catalyst is hydroxy*tetramethyl ethylene diamine copper (I) dichloride and has a molecular formula of [Cu(OH) / TMEDA]2Cl2, which allows p-allylphenol to carry out oxidation coupling reaction effectively and solves the problem of difficulty in industrial production of magnolol chemical synthesis; and the total yield of the synthesized magnolol product can reach 50%. The method has the advantages of simple synthetic process, high yield and low cost, and can be applied in industrial production. Comparing test results of infrared detection and high performance liquid phase analysis and detection with those of the magnolol product extracted from plants, the synthesized magnolol product has the similar or the same structure.

Owner:JIANGNAN UNIV

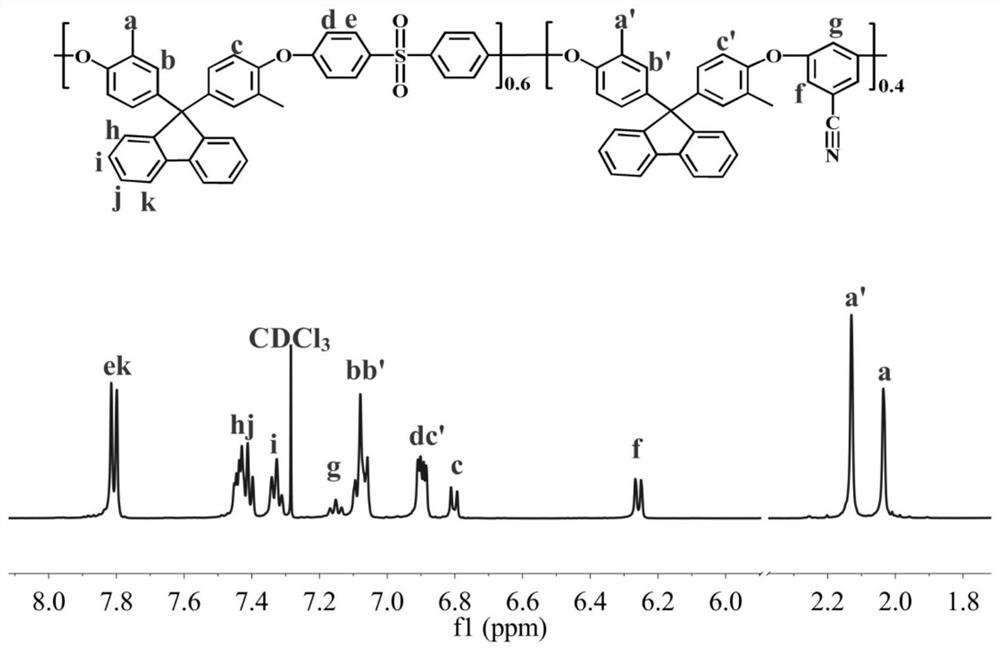

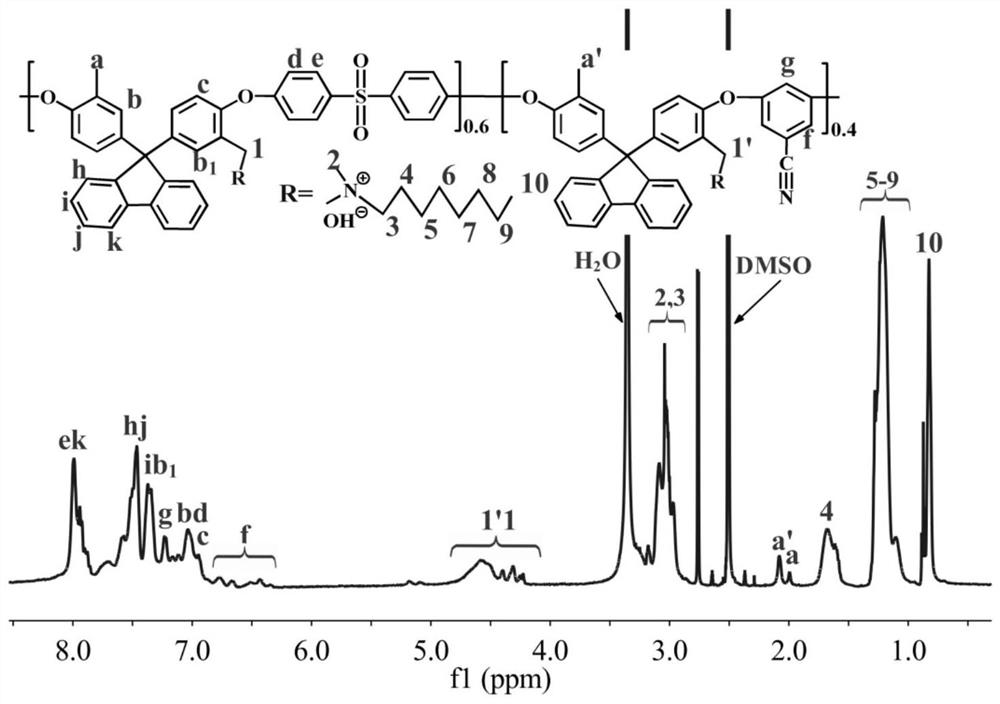

Fluorenyl anion-exchange membrane containing comb-shaped side chains and preparation method of fluorenyl anion-exchange membrane

InactiveCN111933982ASignificant microphase separation structureMicrostructure is easy to controlAnion exchangersFuel cellsFuel cellsSide chain

The invention discloses a fluorenyl anion-exchange membrane containing comb-shaped side chains and a preparation method of the fluorenyl anion-exchange membrane, which can be used for alkaline fuel cells. The anion-exchange membrane is made of a fluorenyl polyarylether polymer containing comb-shaped side chains, and is characterized in that quaternary ammonium ion groups containing flexible long carbon chains are grafted on units of the fluorenyl structure. The preparation method mainly comprises the steps of (1) synthesizing a fluorenyl-containing polyarylether polymer; (2) carrying out bromination modification of the polymer; and (3) preparing the fluorenyl anion-exchange membrane containing the comb-shaped side chains. The anion-exchange membrane prepared by the method has a developed ion transmission channel, has the characteristics of high water content and low swelling rate, overcomes the defect that the existing anion-exchange membrane cannot have high water content, high conductivity and low swelling rate at the same time, and has good stability in alkaline stability. In addition, a highly toxic carcinogenic chloromethyl ether reagent is not used in the preparation process,so that the anion-exchange membrane has a wide application prospect in the field of alkaline fuel cells.

Owner:HUAQIAO UNIVERSITY

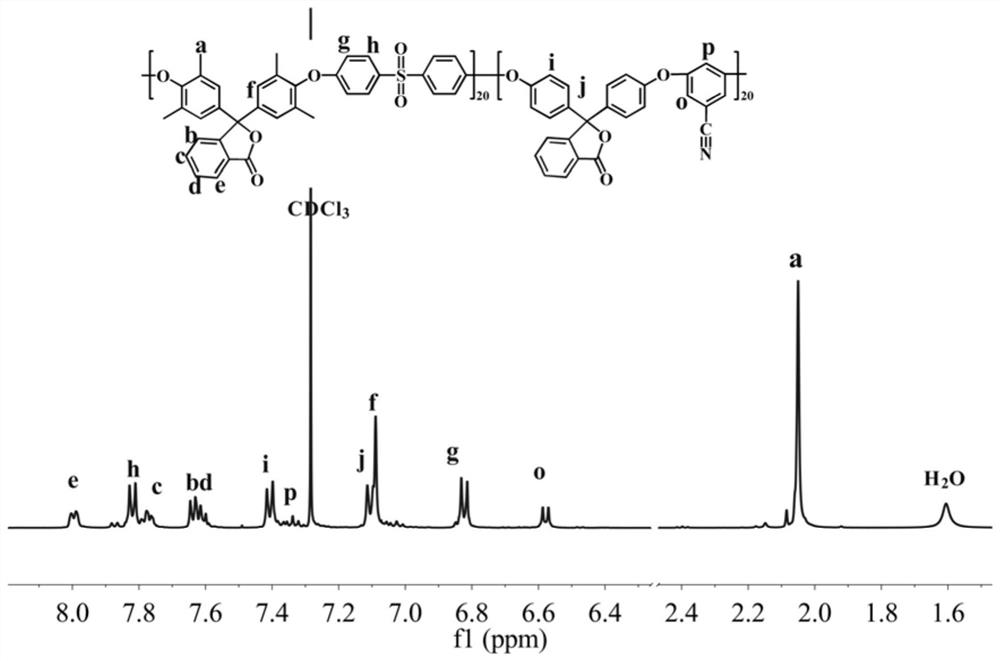

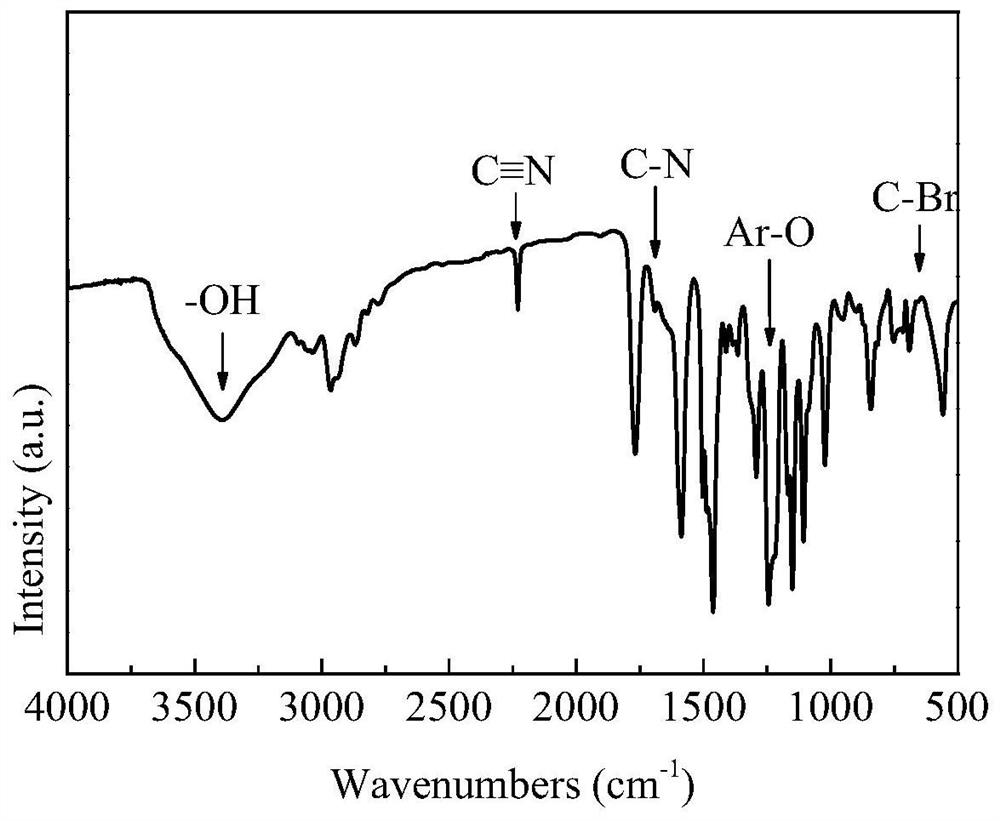

Block type anion exchange membrane containing dense ion strings, and preparation method thereof

InactiveCN111793230AIncrease moisture contentObvious microphase separationFuel cellsFuel cellsChloromethyl Ether

The invention provides a block type anion exchange membrane containing dense ion strings, and a preparation method thereof, wherein the block type anion exchange membrane can be used for an alkaline fuel cell, and is structurally characterized in that a plurality of ion strings are densely grafted on a hydrophilic segment of a block copolymer to serve as functional groups. The preparation method mainly comprises the following steps: (1) preparing a hydrophilic segment containing tetraphenylmethyl and a hydrophobic segment containing a suspended nitrile group; (2) preparing a block copolymer, and carrying out bromination modification; and (3) preparing the block type anion exchange membrane containing the dense ion strings. According to the invention, the anion exchange membrane prepared bythe method has a developed ion transmission channel, has the characteristics of high water content and low swelling rate, and overcomes the defect that the existing anion exchange membrane cannot have high water content, high conductivity and low swelling rate at the same time; and a highly toxic carcinogenic chloromethyl ether reagent is not used in the preparation process, so that the membranehas a wide application prospect in the field of alkaline fuel cells.

Owner:HUAQIAO UNIVERSITY

Broad-spectrum blood perfusion macroporous adsorption resin and preparation method thereof

ActiveCN111282555AAvoid harmPromote safe productionOther blood circulation devicesOther chemical processesChloromethyl EtherDivinylbenzene

The invention provides a preparation method of broad-spectrum blood perfusion macroporous adsorption resin. The preparation method comprises the following steps: 1) a poly(styrene-divinylbenzene) polymerization step, 2) a step of preparing chloromethylated beads by a one-pot method, 3) a step of grafting the chloromethylated beads with functional groups, and 4) a post-treatment step. In the chloromethylation stage of poly(styrene-divinylbenzene), a one-pot method is adopted to prepare the chloromethylated beads, the poly(styrene-divinylbenzene) and a catalyst are directly added after methylal,paraformaldehyde and thionyl chloride are reacted for a certain time, and then chloromethylation is carried out to prepare the chloromethylated beads, and therefore the harm caused by directly usinghighly toxic chloromethyl ether in the traditional process is avoided; when the dry chloromethylated beads prepared by the method are used for carrying out Friedel-Crafts reaction secondary crosslinking, no residual chlorine exists in a generated resin product basically, dichloroethane is used as a swelling agent in the cross-linking process, explosive high-toxicity nitrobenzene does not need to be used as a swelling agent, production is safe, and the prepared macroporous adsorption resin is improved in solvent residue, biocompatibility and other properties.

Owner:西安正阳嘉禾化工科技有限公司

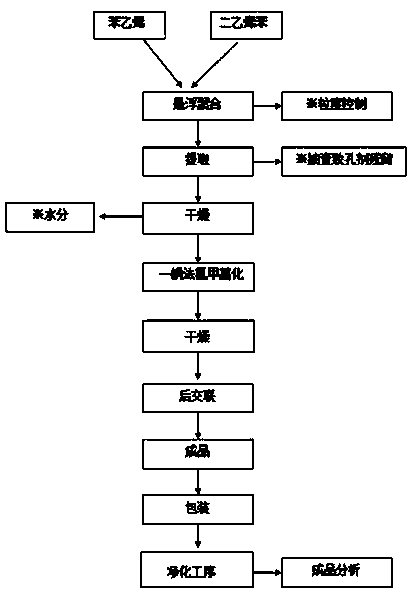

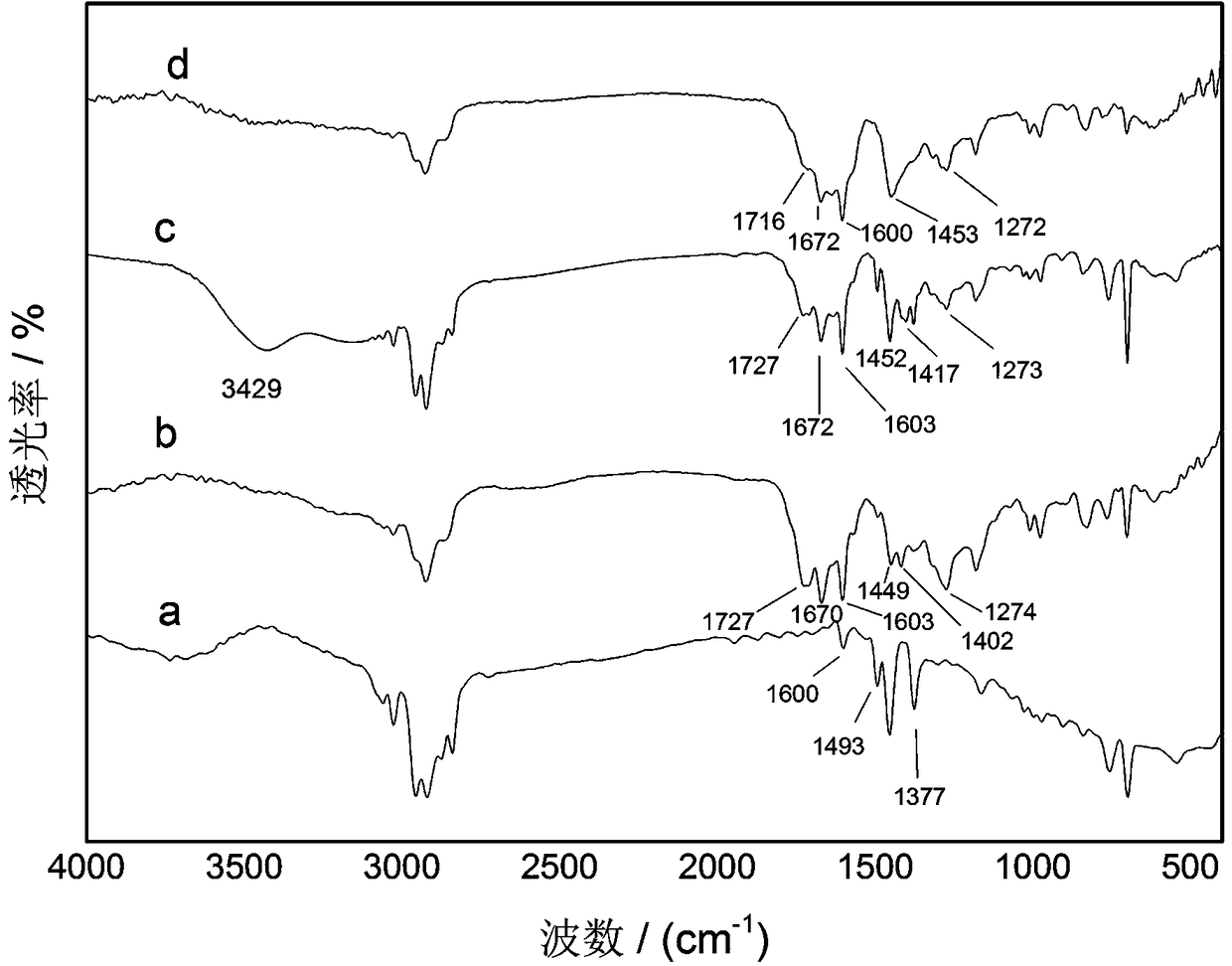

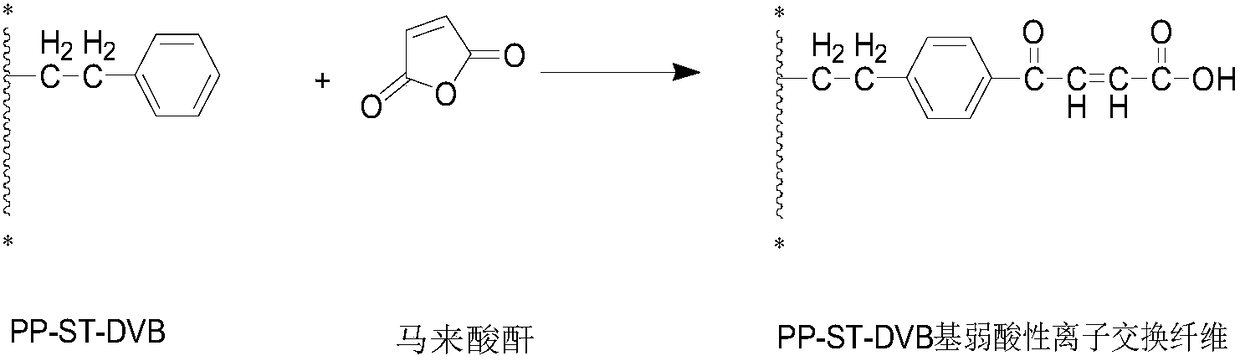

PP-ST-DVB-based cation exchange fiber and synthesis method thereof

ActiveCN108187765AIncrease profitReduce usageCation exchanger materialsOther chemical processesCarcinogenChloromethyl Ether

The invention discloses a PP-ST-DVB-based cation exchange fiber and a synthesis method thereof, and belongs to the technical field of polymer materials. A PP-ST-DVB fiber is taken as a raw material fiber, a benzene ring on the PP-ST-DVB fiber and an organic compound containing an intramolecular acid anhydride group are subjected to a reaction under the action of a catalyst, carboxyl is introduced,and the fiber material containing carboxyl is obtained. The fiber material has high carboxyl content, maintains good shape, elasticity and strength, and has application prospect in functional textiles, water and air purification, chemical substance separation and extraction, and the like. According to the synthesis method, carboxyl is introduced into the polypropylene fiber grafted with styrene with a one-step method, so that the use of carcinogens such as chloromethyl ether in the traditional synthesis method is avoided, and the synthesis method is simple in process, mild in condition and easy to control.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

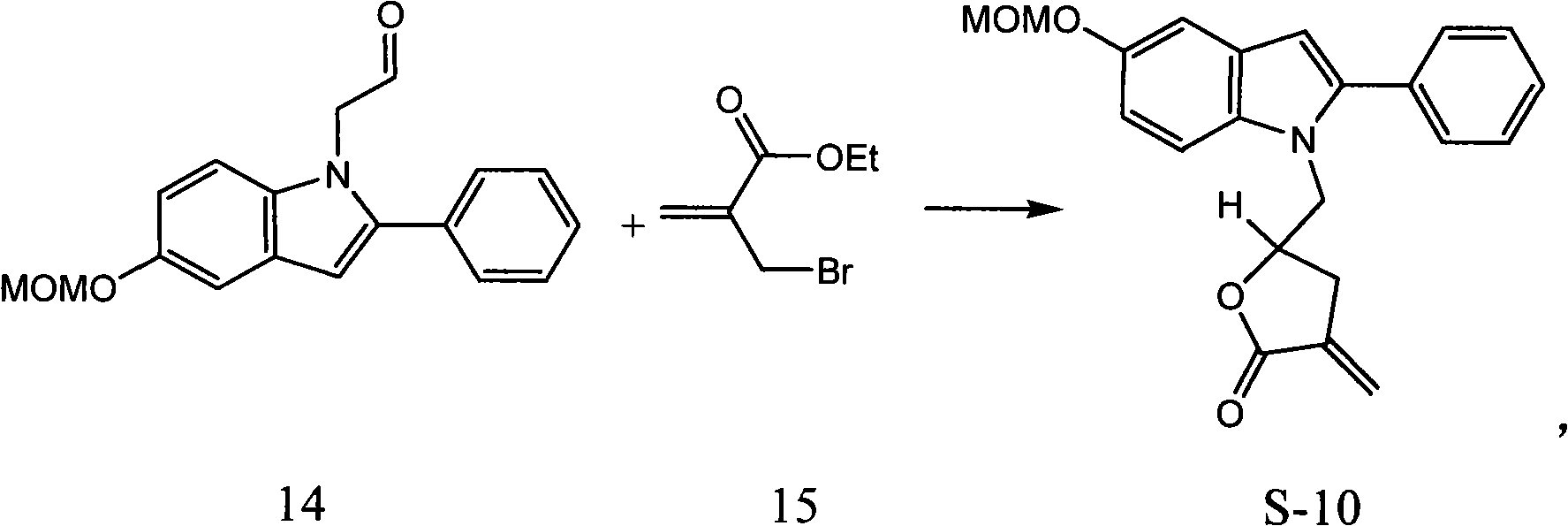

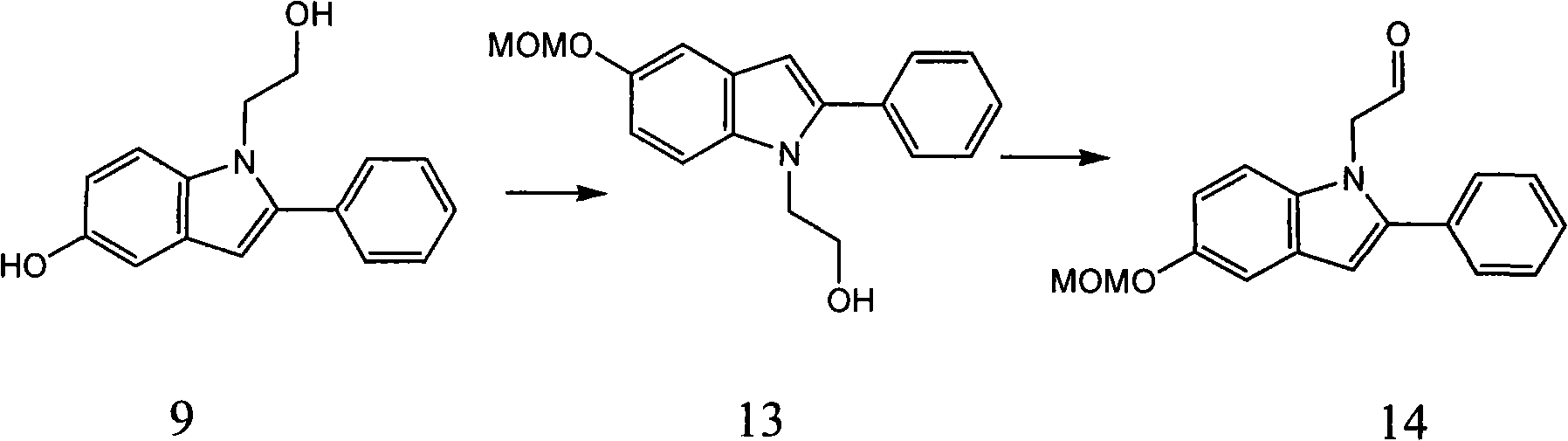

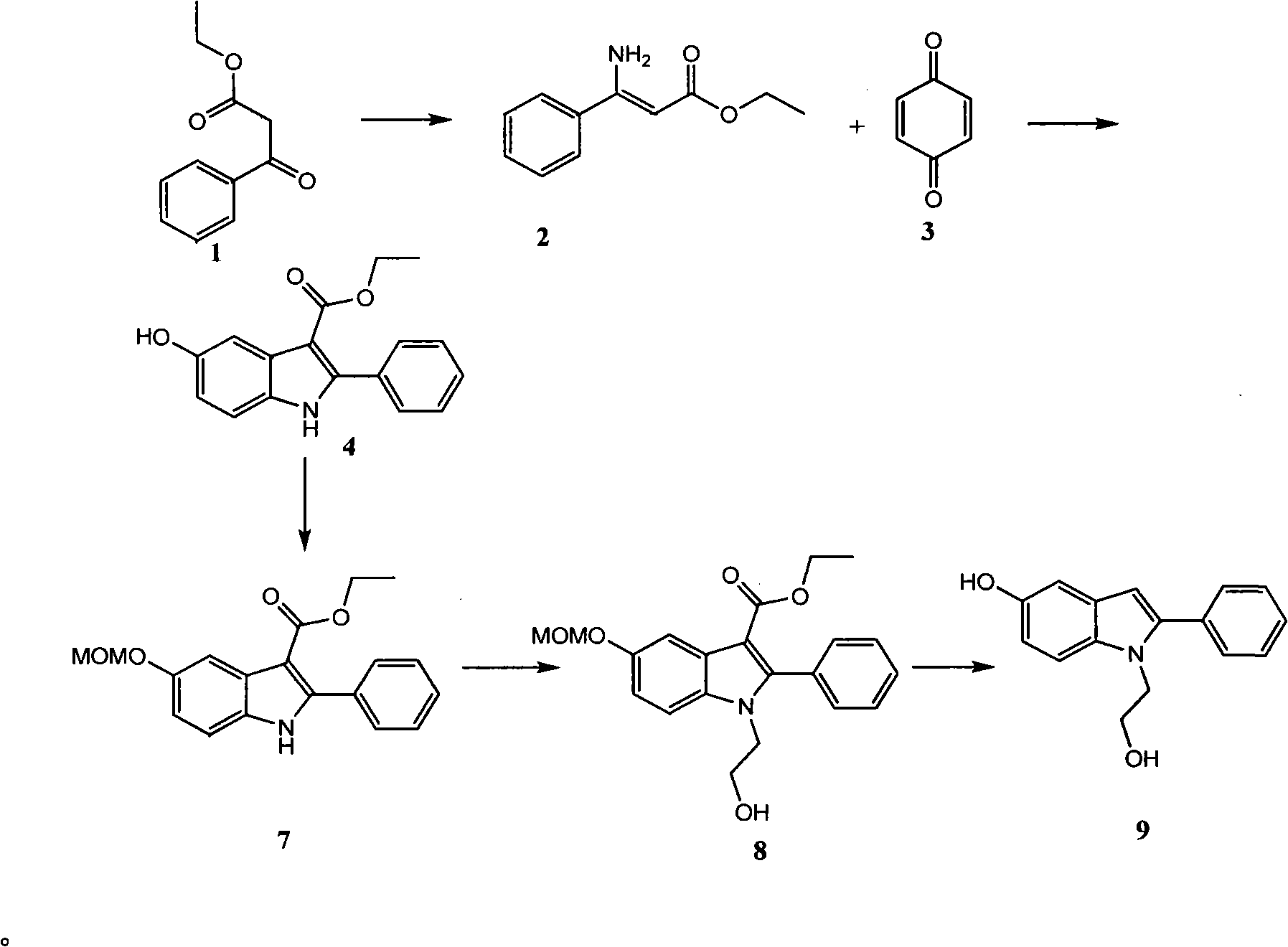

Preparation method of 5'-((5-methoxyl-2-phenyl indole-1-yl) methylene)-2'-oxo-3'-tetrahydrofurfuryl

InactiveCN101575331AAvoid expensiveEasy to routeOrganic chemistryAntineoplastic agentsBromineEthyl ester

The invention discloses a preparation method of 5'-((5-methoxyl-2-phenyl indole-1-yl) methylene)-2'-oxo-3'-tetrahydrofurfuryl which is an antineoplastic compound. The method comprises the following steps: performing reformatsky reaction on 2-(2-phenyl-5-methoxyl indole-1-yl) acetaldehyde and Alpha-bromine ethyl methacrylate to obtain the compound. Ethyl benzoylacetate and aminoethanol are used as raw materials and are condensed to obtain N-hydroxyethyl amino-3-ethyl phenylacrylate which makes a synthetic reaction with benzoquinone by Nenitzescu indole to remove an ester group at 3-position, and 2-(2-phenyl-5-hydroxyl indole-1-yl) ethanol is obtained; then 2-(2-phenyl-5-hydroxyl indole-1-yl) ethanol and chloromethyl methyl ether react to obtain a product, and the product is oxidized to obtain 2-(2-phenyl-5-methoxyl indole-1-yl) acetaldehyde. The invention has short route, mild reaction condition, convenient aftertreatment, cheap and easily-obtained reagent and avoids using dangerous hypertoxic reagents, thereby not only lowering the cost, but also being suitable for industrial production.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com