Polymeric adsorbent and preparation method thereof

A technology for adsorbing resins and reaction products, applied in chemical instruments and methods, and other chemical processes, can solve problems such as complex processes and carcinogenicity, and achieve the effects of simple preparation methods, increased adsorption capacity, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention discloses a preparation method of an adsorption resin, comprising;

[0025] reacting chloromethylstyrene, divinylbenzene and benzoyl peroxide in an aqueous solution of polyvinyl alcohol to obtain a first reaction product;

[0026] The first reaction product is swelled in an organic solvent at 70-90° C., and the second reaction product is obtained after adding a catalyst for reaction, and the catalyst is aluminum chloride, ferric chloride, zinc chloride or tin chloride;

[0027] The second reaction product is reacted with the hydroxyl group-containing monomer at a constant temperature of 70-90° C. to obtain an adsorption resin.

[0028] The divinylbenzene is a crosslinking agent, the chloromethylstyrene is a reactive monomer, and the molar ratio of the divinylbenzene to the chloromethylstyrene is preferably 1 to 5:100, more preferably It is 3~5:100. The benzoyl peroxide is an initiator, and the mass ratio of the chloromethylstyrene to the benzoyl peroxide...

Embodiment 1

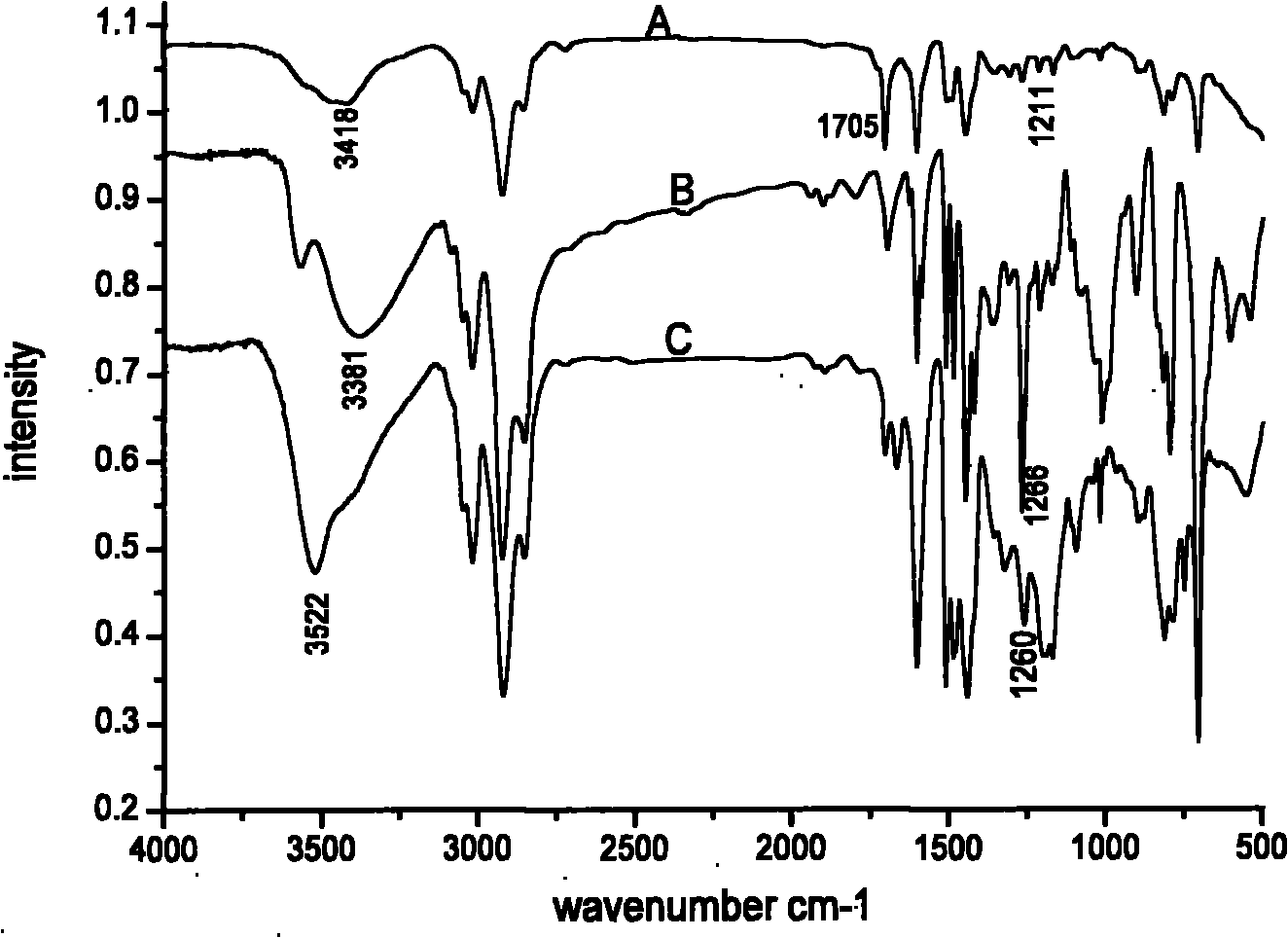

[0039] The crosslinking agent divinylbenzene and monomer chloromethylstyrene are added to the PVA solution with a mass concentration of 0.9 wt%, and the molar ratio of the divinylbenzene to the chloromethylstyrene is 3:100 , add the initiator benzoyl peroxide of 0.66wt% monomer quality again, 80 ℃ of reactions 6 hours after stirring, obtain beaded resin, the infrared spectrogram of described beaded resin is as follows figure 1 As shown in the middle B curve;

[0040]The obtained bead-shaped resin was washed several times with deionized water at 60° C., filtered and extracted with suction, and dried under vacuum. Swell 1 g of the obtained resin in 40 ml of 1,2-dichloroethane overnight, add catalyst aluminum chloride to resin mass ratio of 1:3, stir well and react at 80° C. for 6 h, then add 10 wt % of resin mass. Polarity-modified monomer phenol, reacted at 80°C for 6 hours, filtered, then washed with hydrochloric acid-acetone solution, then washed with acetone solution, extra...

Embodiment 2

[0043] The crosslinking agent divinylbenzene and monomer chloromethylstyrene are added to the PVA solution with a mass concentration of 1.1 wt%, and the molar ratio of the divinylbenzene to the chloromethylstyrene is 5:100 , then add 0.66wt% monomer mass initiator benzoyl peroxide, stir evenly and react at 80°C for 6 hours to obtain bead-like resin;

[0044] The obtained bead-shaped resin was washed several times with deionized water at 60° C., filtered and extracted with suction, and dried under vacuum. Swell 1 g of the obtained resin in 40 ml of 1,2-dichloroethane overnight, add catalyst ferric chloride to resin mass ratio of 1:5, stir evenly and react at 80° C. for 6 h, then add 0.5 wt % of resin mass. Polarity-modified monomer nitrophenol, reacted at 80°C for 7 hours, filtered, then washed with hydrochloric acid-acetone solution, then washed with acetone solution, extracted, and vacuum-dried to obtain a polar high specific surface area adsorption resin.

[0045] The obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com