Preparation method of adsorbing material for blood perfusion

A technology of blood perfusion and adsorption materials, which is applied in the fields of blood circulation treatment, chemical instruments and methods, suction instruments, etc., can solve the problems of complicated synthesis routes, and achieve the effects of improving surface properties, simplifying synthesis routes, and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

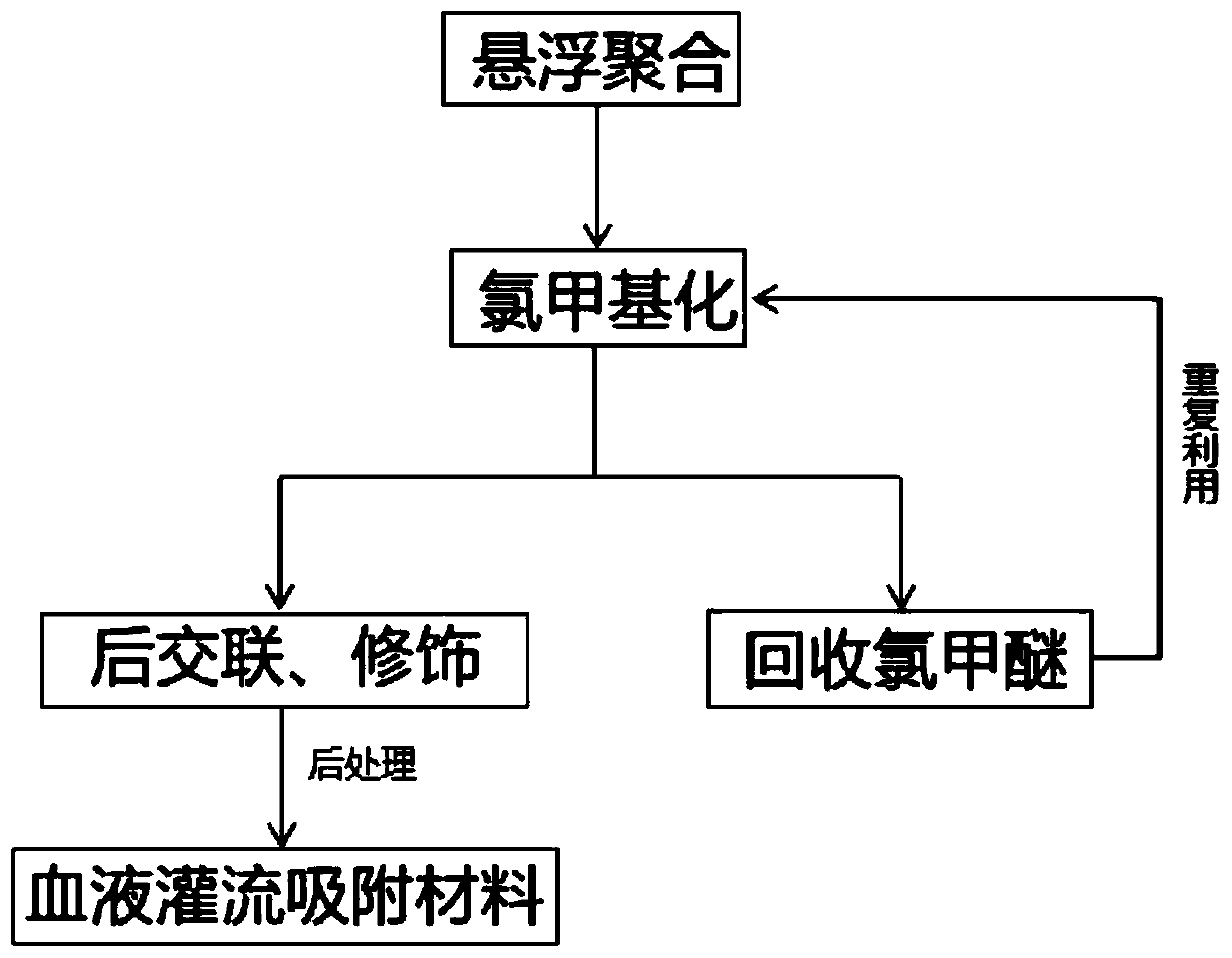

[0051] see figure 1 , a method for preparing an absorbent material for hemoperfusion of the present invention, comprising the following steps:

[0052] S1. Prepare oil phase and water phase for suspension polymerization reaction, the mass ratio of oil phase and water phase is 1:1.8-2.2, prepare 0.8%-1.2% dispersant aqueous solution as water phase; mix monomer and crosslinking agent Mixed monomers are configured at a mass ratio of 11 to 19:1, and the mixed monomers, porogens and initiators are formulated as an oil phase according to 1:(0.8~1.2):(0.006~0.012);

[0053] The monomer of the suspension polymerization reaction is one or more of styrene, methylstyrene, ethylstyrene and p-hydroxystyrene.

[0054] The crosslinking agent is one of divinylbenzene, dipropylenebenzene, divinylphenylmethane and trivinylbenzene.

[0055] The porogen is one or more of toluene, xylene, tetramethylbenzene, ethylbenzene, 200# gasoline, kerosene, liquid paraffin, and white oil.

[0056] The ini...

Embodiment 1

[0087] (1) Suspension polymerization

[0088] Mix 260.5g styrene, 39.5g 63.3%wt divinylbenzene, 240.0g white oil and 1.8g benzoyl peroxide evenly, and add 972.0g 1.2%wt gelatin aqueous solution into a 3000mL three-port container with mechanical stirring and a thermometer in the flask. Start the mechanical stirring, slowly raise the temperature to 75°C, keep warm for 4h; then slowly raise the temperature to 85°C, keep warm for 4h; finally slowly raise the temperature to 90°C, keep warm for 8h, then cool down.

[0089] The mother liquor was filtered and washed three times with water to remove residual dispersant. Filter the liquid, add methylal to submerge the resin layer, stir for 1 h, filter and dry, repeat 5 times. After filtering the methylal, add water to boil the balls, and finally raise the temperature to 100°C, distill and recover the remaining methylal in the chlorine balls, until the steamed gas has no methylal smell, filter the liquid, and dry at 85°C under reduced ...

Embodiment 2

[0102] (1) Suspension polymerization

[0103] Mix 225.3g styrene, 24.7g 63.3%wt divinylbenzene, 250.0g liquid paraffin and 2.5g benzoyl peroxide evenly, add 1000.0g 0.8%wt gelatin aqueous solution into a 3000mL three-port container with mechanical stirring and a thermometer in the flask. Start the mechanical stirring, slowly raise the temperature to 78°C, and keep it for 3 hours; then slowly raise the temperature to 88°C, and keep it for 3 hours; finally, slowly raise the temperature to 93°C, keep it for 7 hours, and then cool down.

[0104] The mother liquor was filtered and washed three times with water to remove residual dispersant. Filter the liquid, add methylal to cover the resin layer, stir for 45min, filter and dry, repeat 6 times. After filtering the methylal, add water to boil the balls, finally raise the temperature to 98°C, distill and recover the remaining methylal in the chlorine balls, until the evaporated gas has no methylal smell, filter the liquid, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com