Patents

Literature

59results about How to "Control the degree of crosslinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

ActiveCN104189963AReduce the degradation rateReduce sheddingSurgeryCoatingsMg alloysBiocompatibility

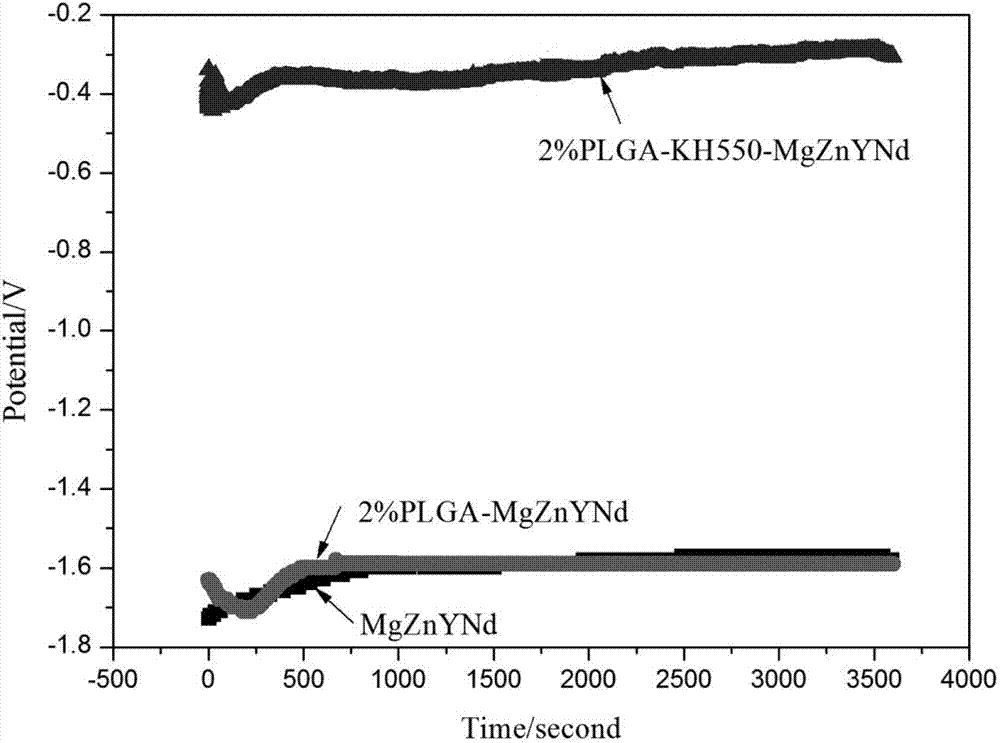

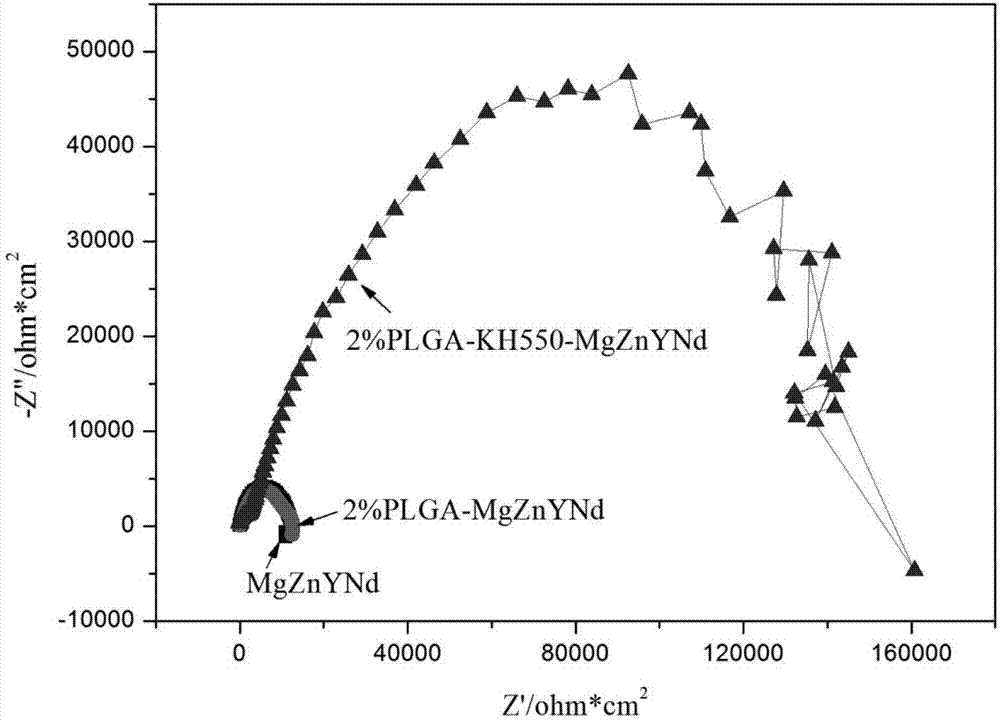

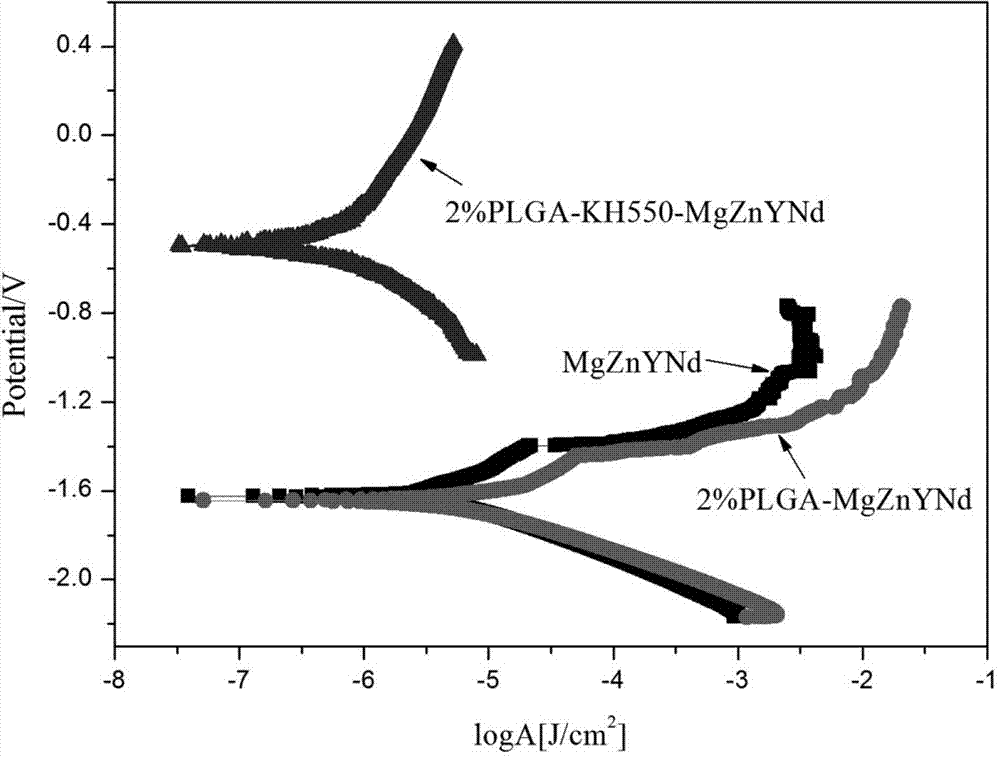

The invention relates to a preparation method of a surface coating capable of lowering the degradation rate of a fully-degradable magnesium alloy vascular stent. The method comprises the following steps: preparing a silane coupling agent on a magnesium alloy surface in a way that a silane coupling agent and an organic solvent are mixed, the silane coupling agent is grafted to the magnesium alloy surface of a biodegradable vascular stent by adopting a dip coating method and heating and curing are performed to form a coating; and preparing a polymer coating on the surface pre-treated by the silane coupling agent in a way that a spin-coating method is adopted to coat a polymer on a sample surface treated by the silane coupling agent, vacuum drying is realized and the polymer coating is formed after solvent volatilization. Through the technical scheme, a strong binding force exists between the polymer coating on the magnesium alloy surface pre-treated by the silane coupling agent and the surface of the fully-degradable magnesium alloy vascular stent, so that the magnesium alloy base body is prevented from excessively quick degradation, and the biocompatibility is improved; and as the coating is completely degraded with the base body at last, no toxic or side effects are brought to a human body.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

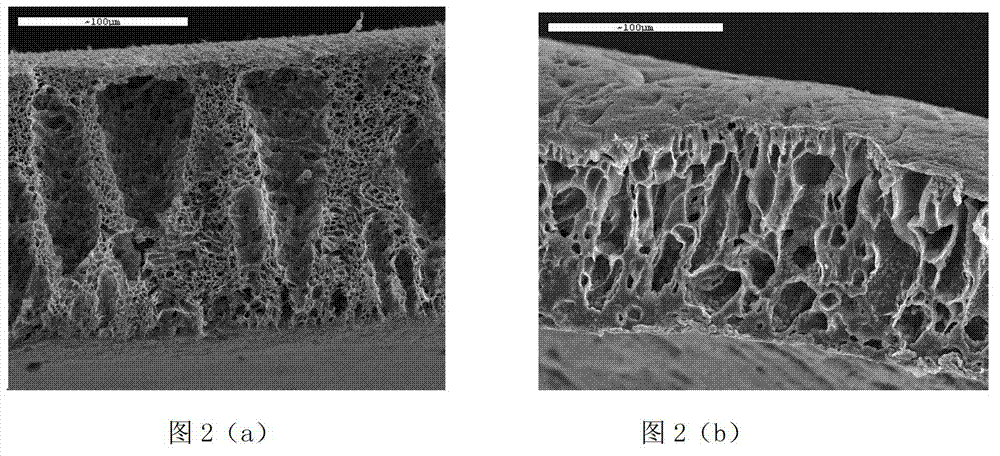

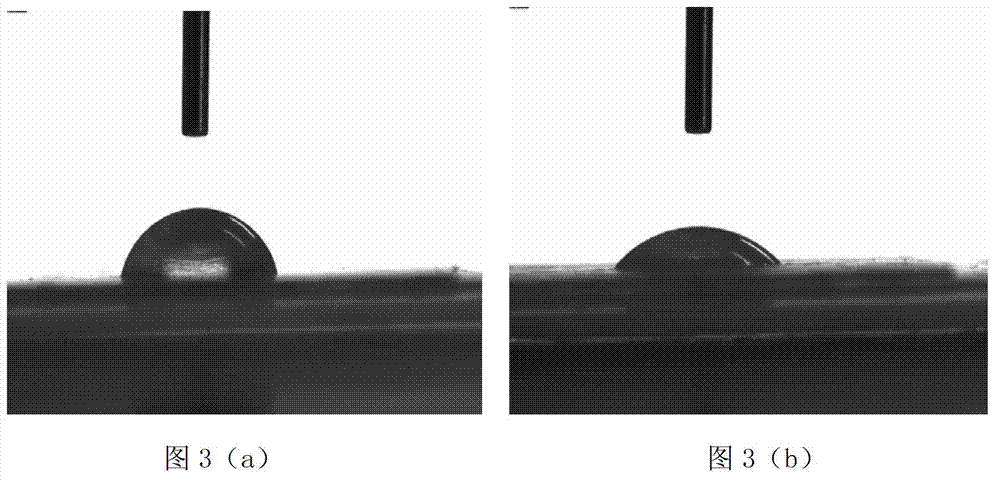

Preparation method of hydrophilic ultra-filtration membrane

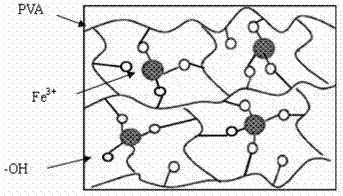

The invention provides a preparation method of a hydrophilic ultra-filtration membrane, wherein the method comprises the following steps: introducing high-valence metal salt containing Fe3+, Al3+ and the like into film casting solution to perform cross-linking reaction with hydrophilic additives in the film casting solution so as to limit dissolution and loss behaviors of the water-soluble hydrophilic additives in film forming and running processes. The method is convenient to operate and easy to control, applicable to preparing the hydrophilic macromolecular ultra-filtration membrane by a dry or wet process, fixing the hydrophilic additives containing oxygen and nitrogen functional groups, such as polyvinyl alcohol (PVA), polyethylene glycol (PEG), polyethylene oxide (PEO) and polyvinyl pyrrolidone (PVP). The method is capable of effectively improving and stabilizing the hydrophilic property of the ultra-filtration membrane and resolving easy loss and uneven distribution problems of the hydrophilic additives in the prior art.

Owner:西安金藏膜环保科技有限公司

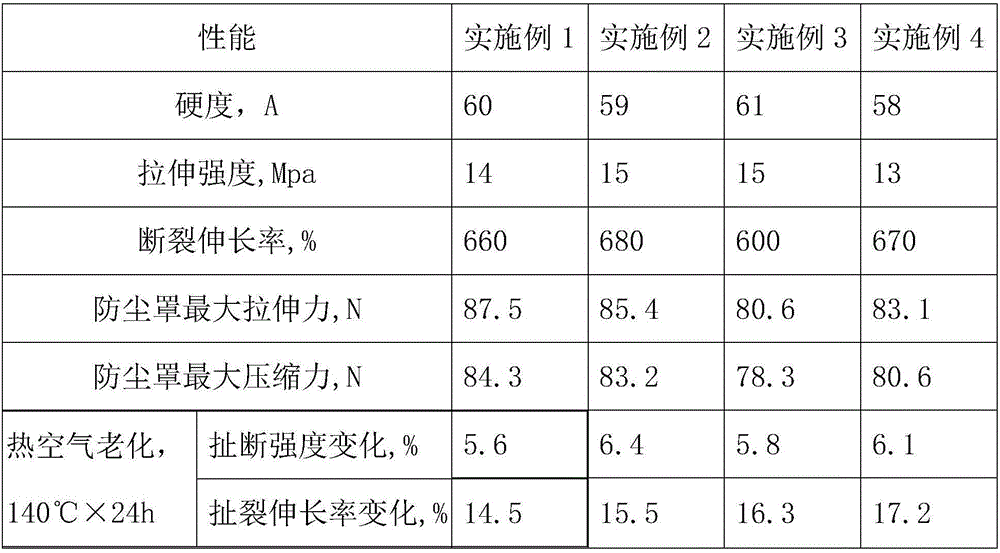

Thermoplastic vulcanized rubber material for automobile turning dust cover and preparation method of thermoplastic vulcanized rubber material

ActiveCN105860284AImprove blow molding processabilityMeet performance requirementsRubber materialThermoplastic

The invention discloses a thermoplastic vulcanized rubber material for an automobile turning dust cover and a preparation method of the thermoplastic vulcanized rubber material. The thermoplastic vulcanized rubber material is prepared from, by weight, 100-300 parts of EPDM, 20-80 parts of polypropylene, 10-50 parts of linear low density polyethylene, 40-100 parts of thermoplastic polyurethane elastomers, 5-15 parts of ethylene-octylene copolymers, 5-15 parts of compatilizer, 10-80 parts of inorganic filler, 3-5 parts of silane coupling agent, 0.2-10 parts of cross-linking agent, 1-5 parts of activated zinc oxide, 1-3 parts of primary antioxidant, 0.5-1 part of auxiliary antioxidant, 1-3 parts of ultraviolet light absorber, 20-100 parts of processing oil and 2-6 parts of lubricating oil. The thermoplastic vulcanized rubber material has excellent strength, high temperature resistance, flexibility and blow molding performance.

Owner:ANHUI ZHONGDING RUBBER PLASTIC PROD CO LTD

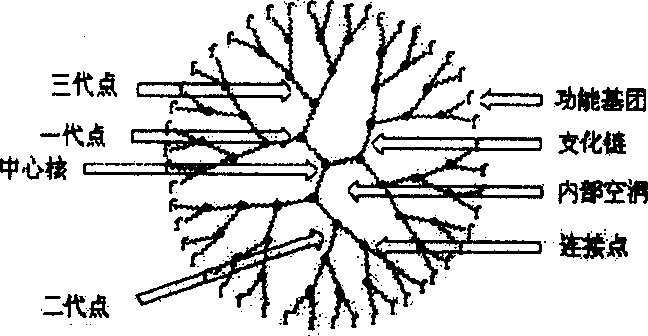

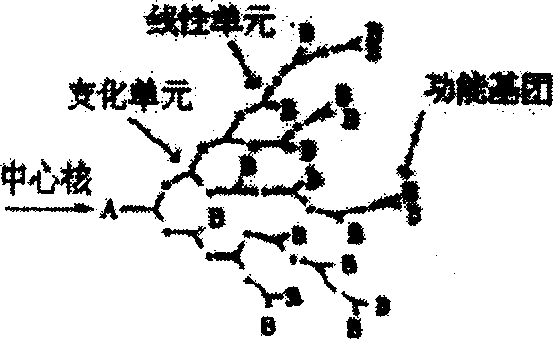

Method for preparing cross-linked polymer film by branching molecule

A process for preparing the cross-linked polymer membrane from the tree-shaped branched molecular terminated by hydroxy, amino and carboxy includes such steps as dissolving the branched moleculae in solvent, adding cross-linking agent, stirring, heating while stirring for pre-cross-linking, coating it on carrier, scraping to a certain thickness, baking in vacuum oven for volatiizing solvent, baking for solidifying, and separating the membrane from its carrier.

Owner:ZHEJIANG UNIV

Preparation method of cross-linked hydroxypropyl composite modified starch by one-step process

InactiveCN103113478AImprove the efficiency of crosslinking and etherification reactionsReduce manufacturing costIonEmulsion

The invention discloses a preparation method of cross-linked hydroxypropyl composite modified starch by a one-step process. The method, considering that both cross-linking and etherification reactions is performed under high temperature and alkaline conditions, synchronously implements the cross-linking and etherification reactions, and comprises the following steps of: adding a swelling inhibitor, a cross-linker and sodium hydroxide into de-ionized water by certain mass percent, stirring and dissolving, adding starch to obtain a starch emulsion, and alkalizing for a certain duration; and increasing temperature, adding a starch etherifying agent of a certain mass percent, neutralizing, washing, centrifuging, hydrating, drying and sieving after the etherification reaction to obtain the cross-linked hydroxypropyl composite modified starch. The preparation method, by synchronously implementing the cross-linking and etherification reactions, shortens independent cross-linking reaction time, prolongs cross-linking reaction time, reduces dosage of a cross-linker, and lowers production cost and energy consumption of products.

Owner:甘肃圣大方舟马铃薯变性淀粉有限公司

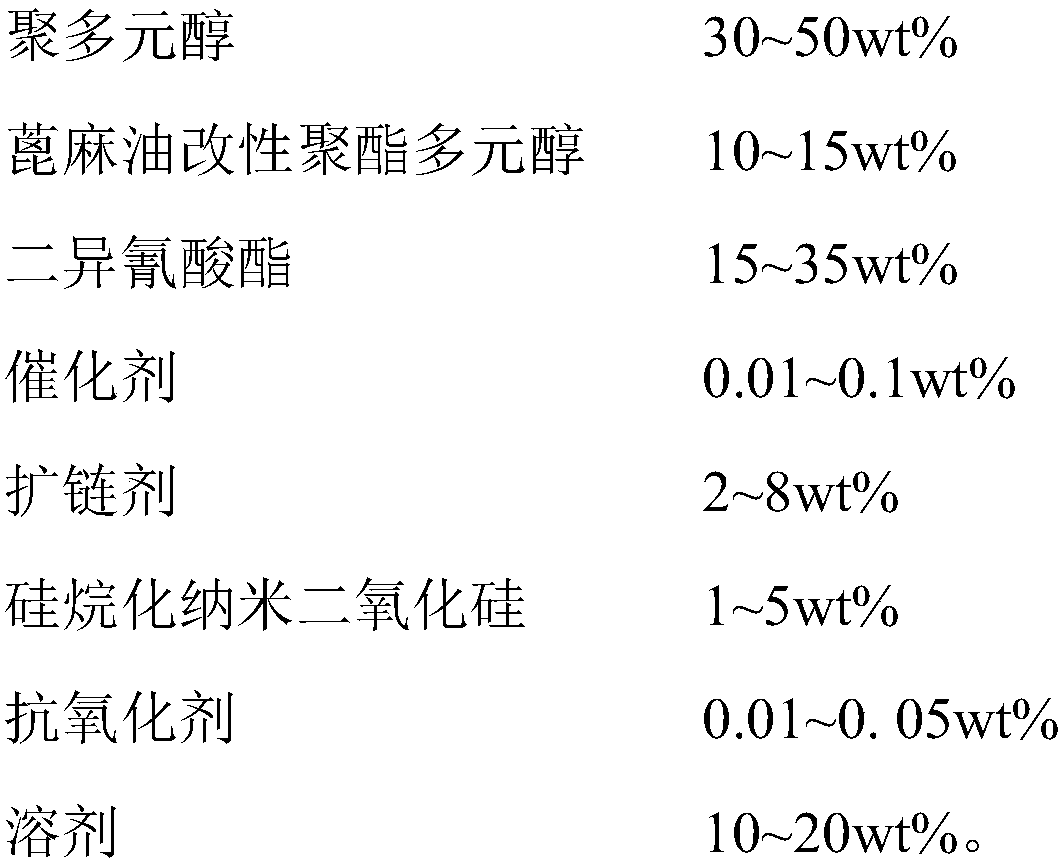

Heat-resistant single-component moisture-curing polyurethane adhesive and preparation method and application thereof

InactiveCN109749692AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a heat-resistant single-component moisture-curing polyurethane adhesive and a preparation method and application thereof. The preparation method comprises the following step: carrying out esterification reaction on castor oil, phthalic anhydride and dihydric alcohol at first to prepare a castor oil modified polyester polyol with the functionality of 2.0-2.5 and containing abenzene ring aromatic structure and a long fatty acid molecular segment. When partially substituted polyols are used for modification of polyurethane, rigid benzene rings can be introduced into a soft segment. Distribution of microcrystals in the soft segment structure is controlled, so that the flexibility of an adhesive layer is enhanced; the cohesive strength is increased, and the heat resistance is improved; meanwhile, the modified castor oil polyester polyol can effectively control the crosslinking degree of the polymer and prevent the drastic reduction of performance of an adhesive or coagulation caused by excessive crosslinking degree. The castor oil modified polyester polyol is used for modifying polyurethane, so that the adhesive property and the heat resistance of the adhesive can be obviously improved. The adhesion problem of cracking at an adhesion position of wood during high-temperature baking processes such as wood drying and bent plate making in a wood processing process is solved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +1

Foaming composite material with high thermal conductivity

ActiveCN103818075AOvercoming thermal conductivityOvercome functionNon-macromolecular adhesive additivesSynthetic resin layered productsAntioxidantPlasticizer

The invention relates to a resin foaming composite material, especially to a foaming composite material with high thermal conductivity. The foaming composite material is prepared by the following steps: primary mixing: 8-12 parts by weight of a heat conduction material is added into 40-100 parts by weight of matrix resin to obtain a primary mixed object; plasticization and granulation: 2-8 parts by weight of a fire retardant, 6-10 parts by weight of a softening plasticizer, 3-7 parts by weight of a flexibilizer, 1-4 parts by weight of a coupling agent and 0.6-1.2 parts by weight of an antioxidant are added into the primary mixed object for blending modification and plasticization, and extrusion and granulation are carried out to obtain a first granule; remixing and foaming: 15-25 parts by weight of one or more selected from fatty alcohol polyoxyethylene lauryl ether sulfate sodium or an azo-compound are mixed with one or more selected from the first granule and 30-70 parts by weight of the matrix resin, extrusion and foaming are conducted to prepare a foaming material, and a full-open foaming material layer is compounded on the foaming material through glue to form the foaming composite material with high thermal conductivity. The material provided by the invention has high thermal conductivity and is waterproof and shock-absorbing.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Gelatin composition, and preparation method and application thereof

ActiveCN103263688AGood hemostatic abilityControl flexibilityAbsorbent padsMacromolecular non-active ingredientsGlutaminaseGelatin

The invention provides a gelatin composition. The gelatin composition comprises hydroxylated gelatin, microbial glutamine transaminase and protein glutaminase, wherein the hydroxylated gelatin is 20-60%proline-hydroxylated gelatin. The gelatin composition has an extremely-good bleeding stopping effect at a temperature in a range of 4-10DEG C. The invention also discloses a preparation method of the gelatin composition and an application of the gelatin composition.

Owner:李肯

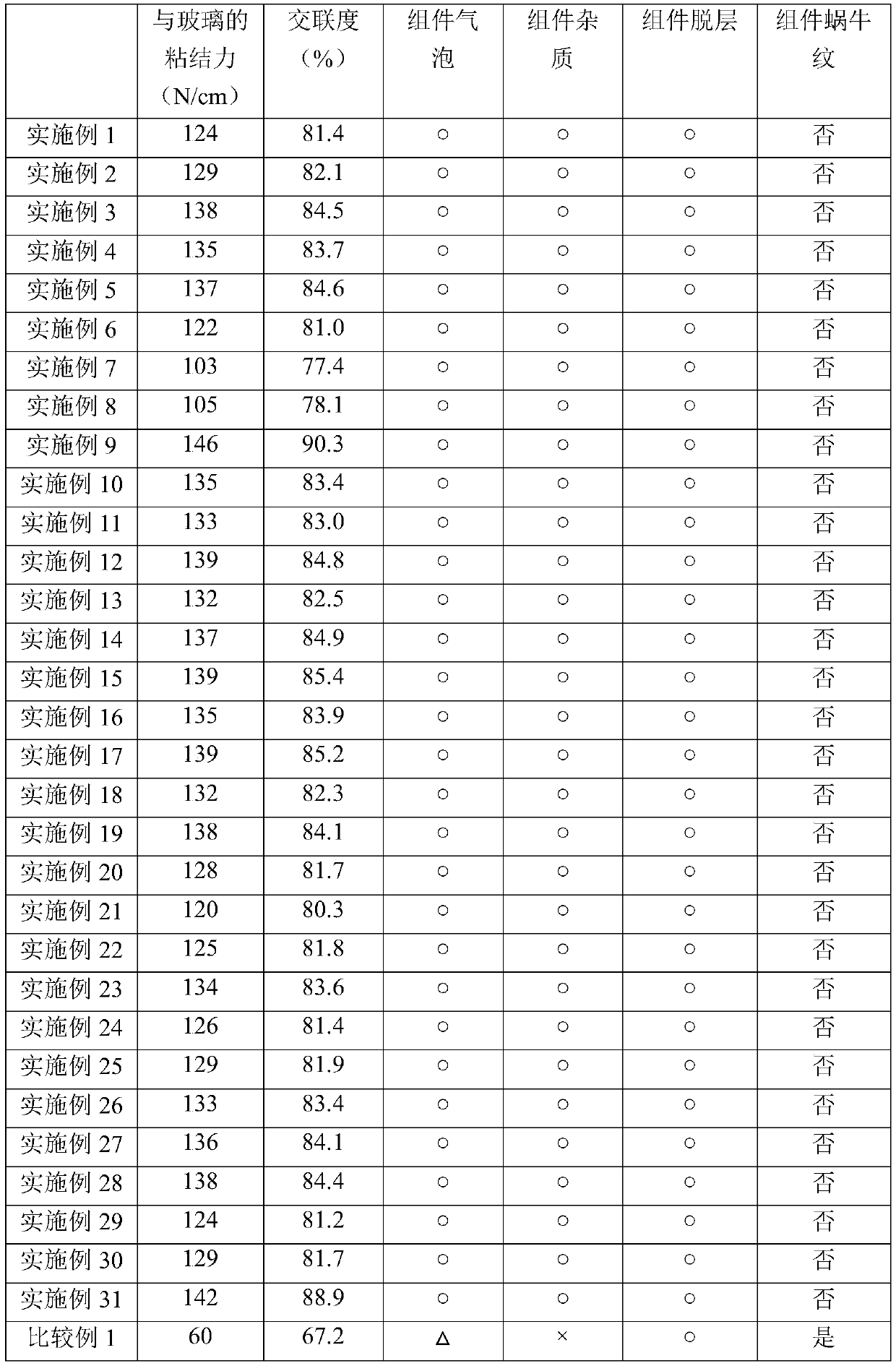

Co-extrusion adhesive film, solar cell module and double-layer glass

ActiveCN111454668AReduce the risk of delaminationReduce liquidityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer sciencePtru catalyst

The invention provides a co-extrusion adhesive film, a solar cell module and double-layer glass. The co-extrusion adhesive film comprises at least two adhesive film layers; raw materials for forming each adhesive film layer comprise a first component and a second component, wherein each first component is 1-100 parts of first matrix resin grafted with an electron withdrawing group, and second components respectively and independently contain 0.01-25 parts of a water producing agent and / or 0.01-2.5 parts of a catalyst, and the second components are not water producing agents or catalysts at thesame time; and the first matrix resin and the water producing agents can undergo cross-linking reactions, and the catalysts can catalyze the cross-linking reactions. When the co-extrusion adhesive film is used as a raw material for preparing the solar cell module, the photoelectric conversion efficiency of the solar cell module can be greatly improved; and cost is low, process is simple, and industrial popularization is convenient.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

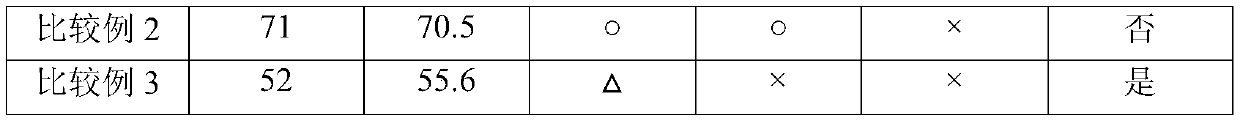

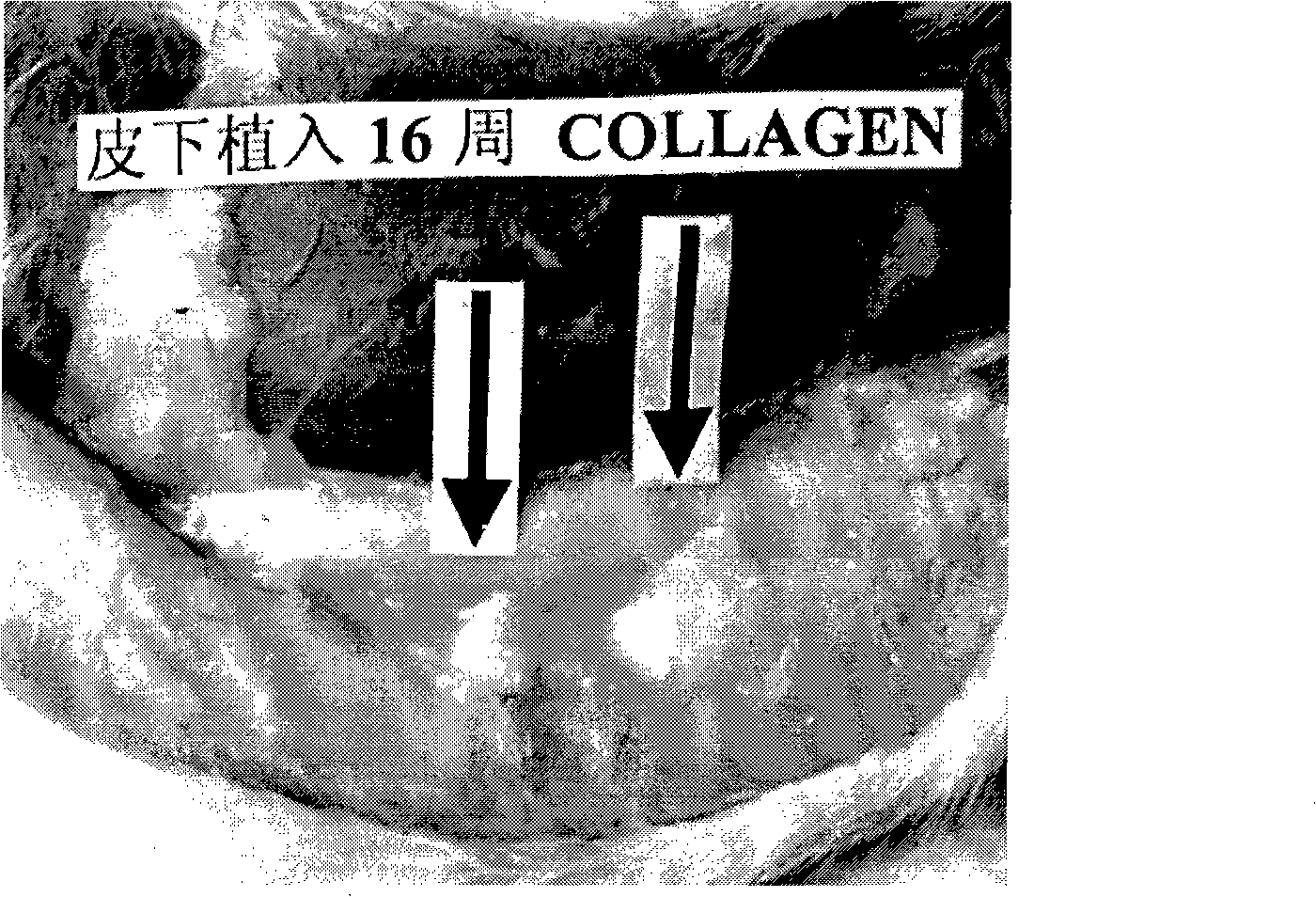

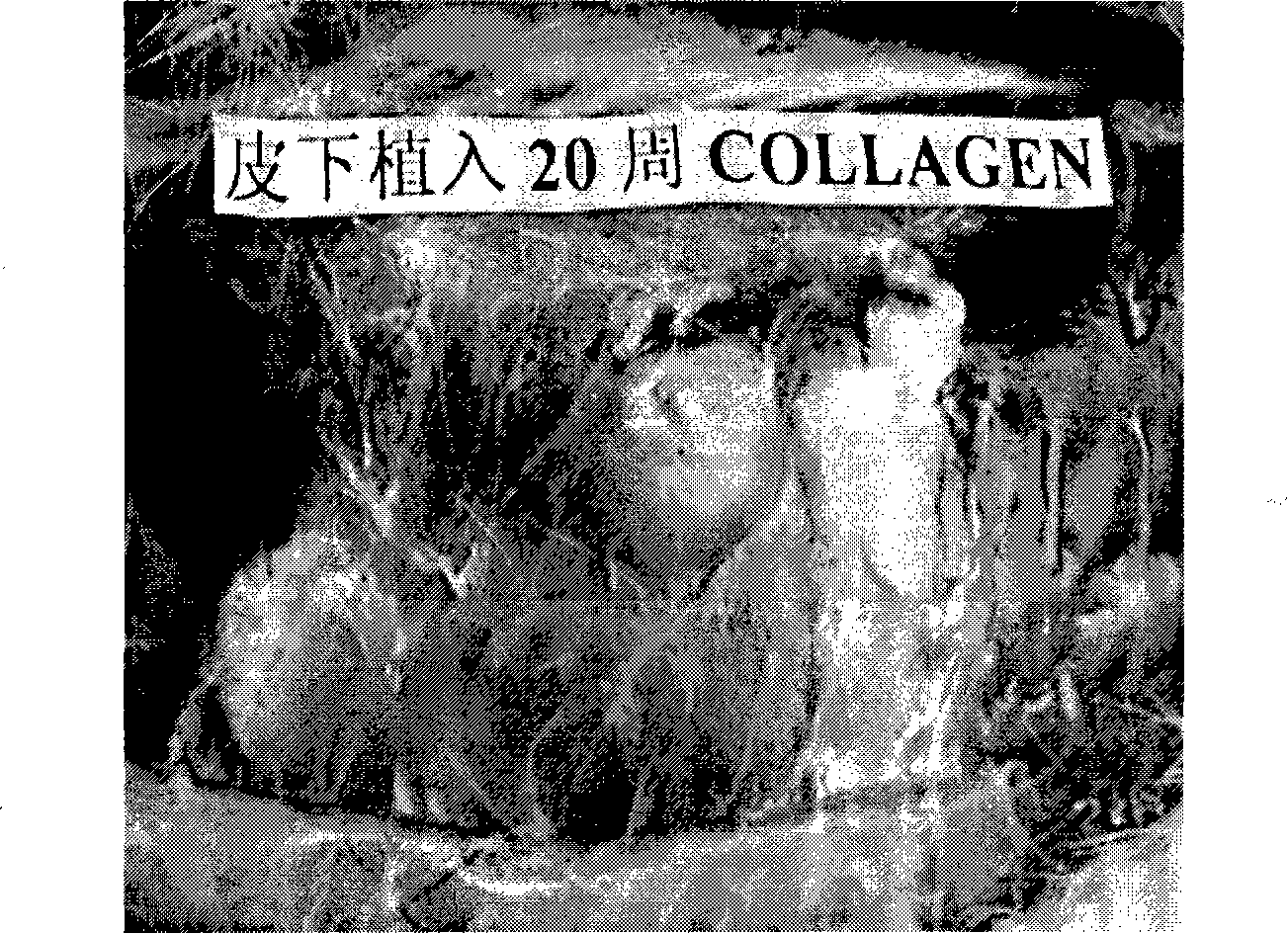

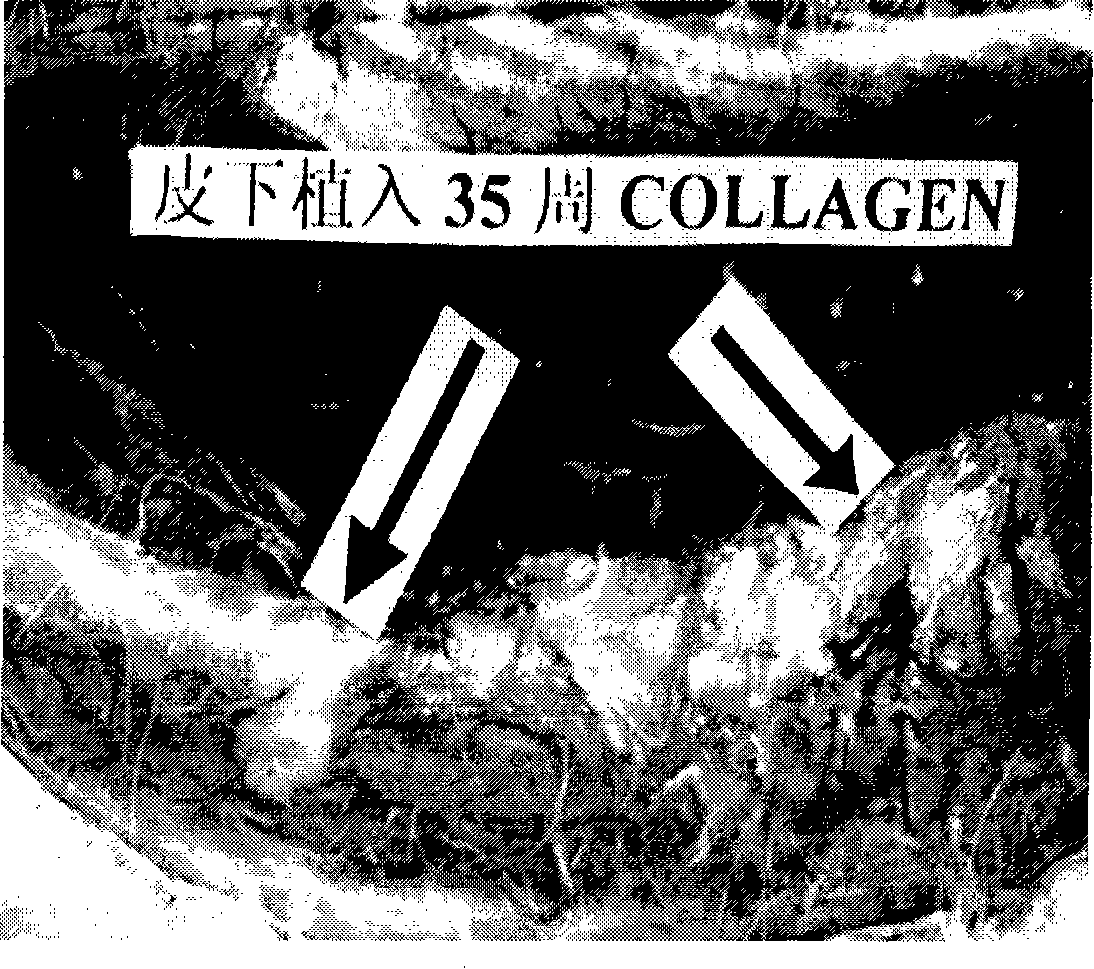

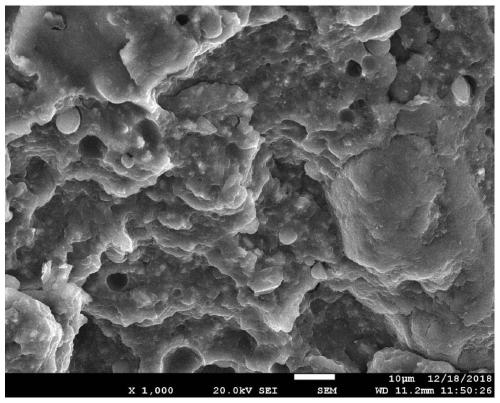

Medical grade reconstructed collagen cross-linking modified method

InactiveCN101323670AEase of cross-linkingControl the degree of crosslinkingProsthesisIonModified method

The invention discloses a method for cross-linking and modifying medical-grade reconstructed collagen, which is characterized in that 1 to 5 weight parts of phosphate solution with the concentration of 0.1 mol / L to 0.5mol / L is added into 5 to 25 weight parts of uniform regular collagen solution with the concentration of 5 mg / ml to 10mg / ml at the temperature of 15 DEG C to 20 DEG C while slowly stirring. Acid solution or aqueous alkali is used for adjusting the pH value of the mixed solution to 7.0 to 8.5. The mixed solution stands for 6 hours to 12 hours at the temperature of 25 DEG C to 40 DEG C and humidity of 50 percent to 70 percent so as to form uniform colloid. The colloid is sequentially arranged in the environment of minus 20 DEG C to minus 40 DEG C and minus 60 DEG C to minus 80 DEG C to be frozen for 24 hours to 48 hours, and then dehydrated in a lyophilizer to obtain the reconstructed collagen with cross-linked and modified ions.

Owner:SICHUAN UNIV

Heat-conducting water-proof gasket

ActiveCN103804761AOvercoming thermal conductivityOvercome functionNon-macromolecular adhesive additivesSynthetic resin layered productsDamping functionHeat conducting

The invention relates to a resin formed composite material, and in particular relates to a heat-conducting water-proof gasket. The heat-conducting water-proof gasket is prepared by the following steps: initially mixing, namely adding 8-12 parts by weight of heat-conducting material into 40-100 parts by weight of matrix resin to obtain an initial mixture; plasticizing and granulating, namely adding 2-8 parts by weight of flame retardant, 6-10 parts by weight of softening and plasticizing agent, 3-7 parts by weight of toughening agent, 1-4 parts by weight of coupling agent and 0.6-1.2 parts by weight of antioxidant into the initial mixture, coblending, modifying, plasticizing, extruding and granulating to obtain first particles; remixing and foaming, namely mixing 15-25 parts by weight of either or both of fatty alcohol-polyoxyethylene ether sodium sulfate or an azoic compound with either or both of the first particles and 30-70 parts by weight of matrix resin, extruding and foaming to obtain a foamed material, compounding a fully-perforated foamed material layer and a moisture-proof film layer on the foamed material in sequence by using glue to form the heat-conducting water-proof gasket. The heat-conducting water-proof gasket is high in heat-conducting efficiency and resistant to water, and has a damping function.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

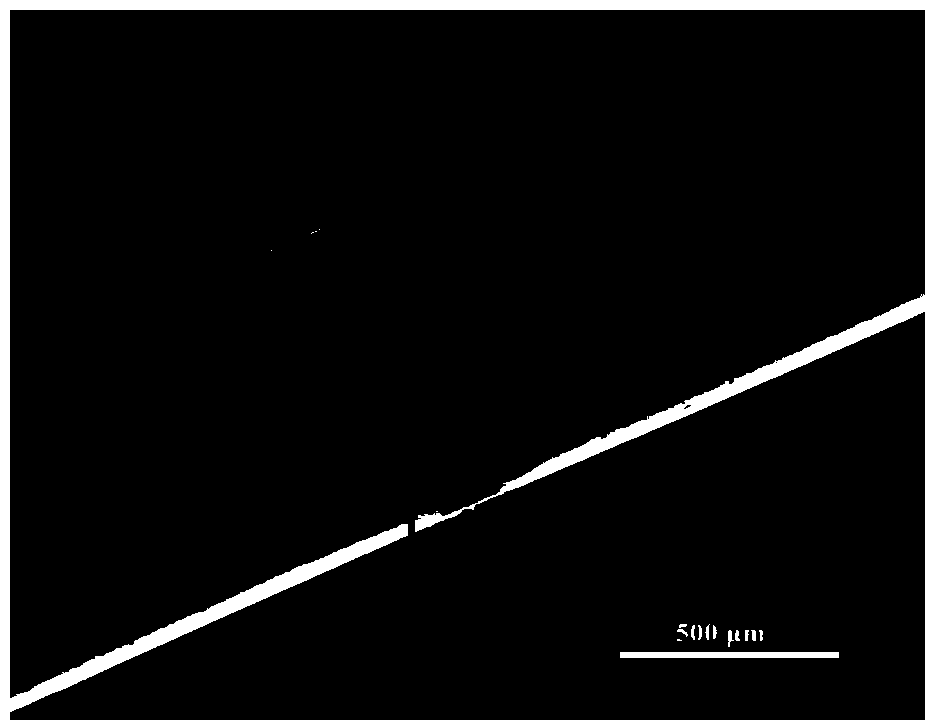

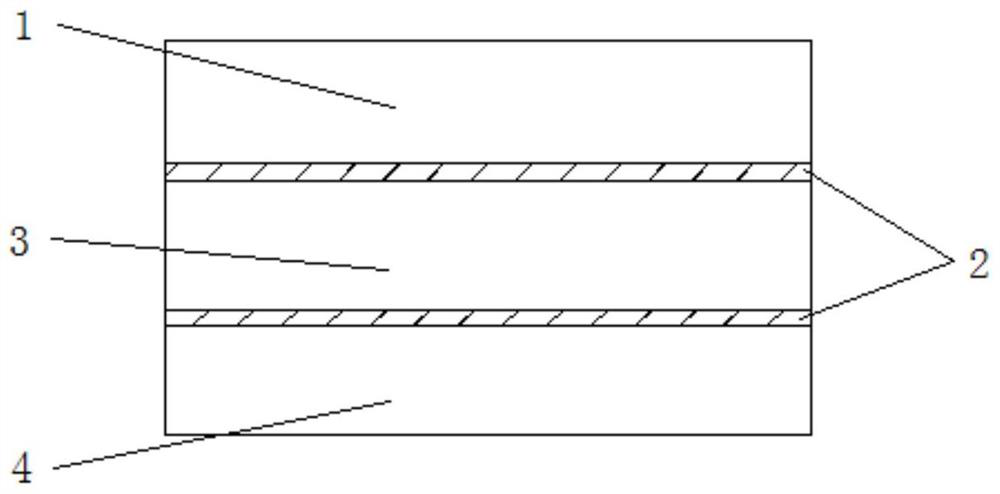

Hemostasis needle and preparing method and application thereof

ActiveCN109330654AEffectively blockedEffective synchronous hemostasisSurgical needlesOcculdersCross-linkDrug administration

The invention belongs to the field of biomedical polymer materials, and particularly relates to a hemostasis needle and a preparing method and application thereof. The hemostasis needle comprises a syringe needle and a hemostasis coating for coating the surface of the periphery of the syringe needle, wherein the hemostasis coating is a non-toxic cross-linked polymer which can swell and shed off from the surface of the periphery of the syringe needle when meeting a solvent. The hemostasis needle prepared by means of the method is utilized for puncturing the blood vessels and the visceral organs, after the hemostasis needle is pulled out, the coating is left at the puncturing position to block a puncturing hole, and thus synchronous hemostasis is achieved. The preparing method of the hemostasis needle is easy to operate and low in cost, takes effect quickly, and can be widely applied to the fields such as drug administration, blood sampling, sampling and interventional therapy on patients with normal or abnormal clinical blood coagulation functions. The hemostasis needle is adjustable in size, easy to produce on a large scale, capable of effectively solving the problem that unnecessary hemorrhage is caused when the patients with normal or abnormal clinical blood coagulation functions are subjected to blood vessel and visceral organ puncturing, and free of obvious untoward effects.

Owner:HUAZHONG UNIV OF SCI & TECH

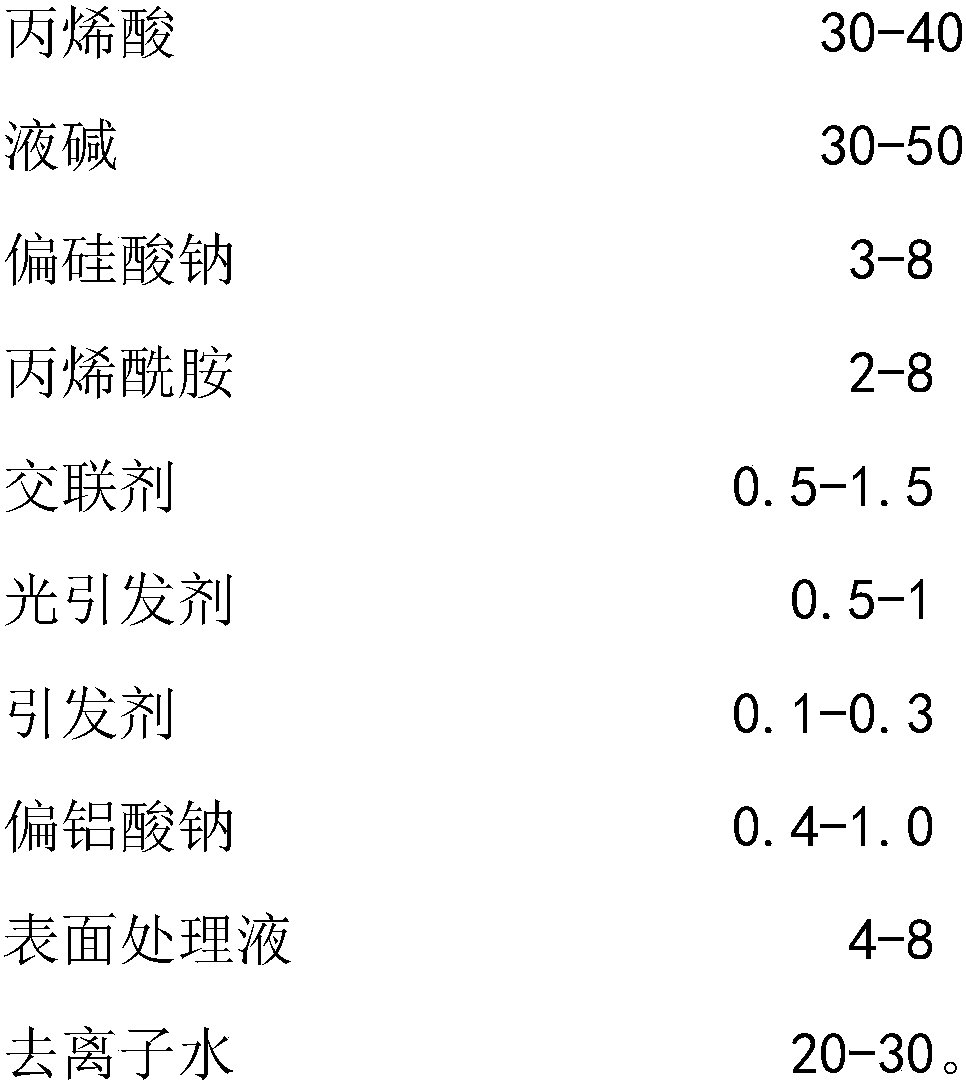

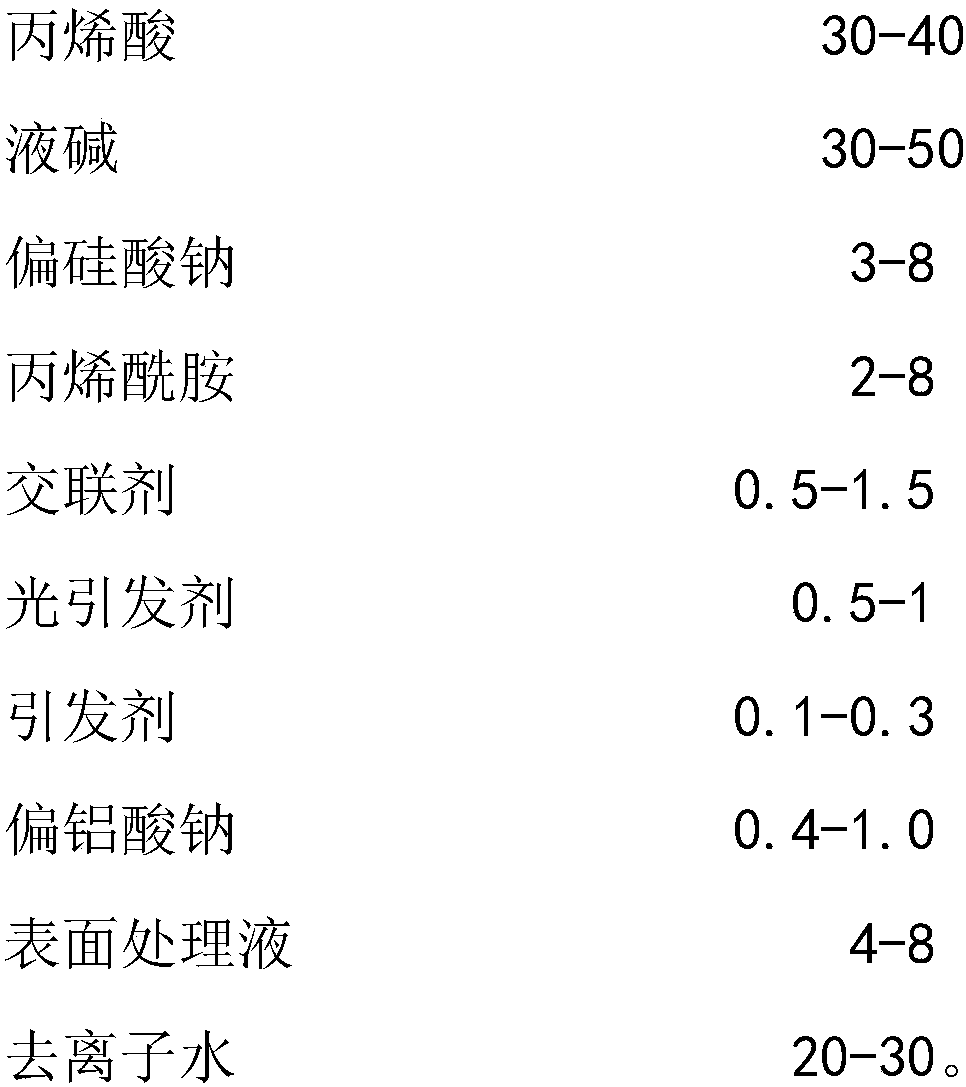

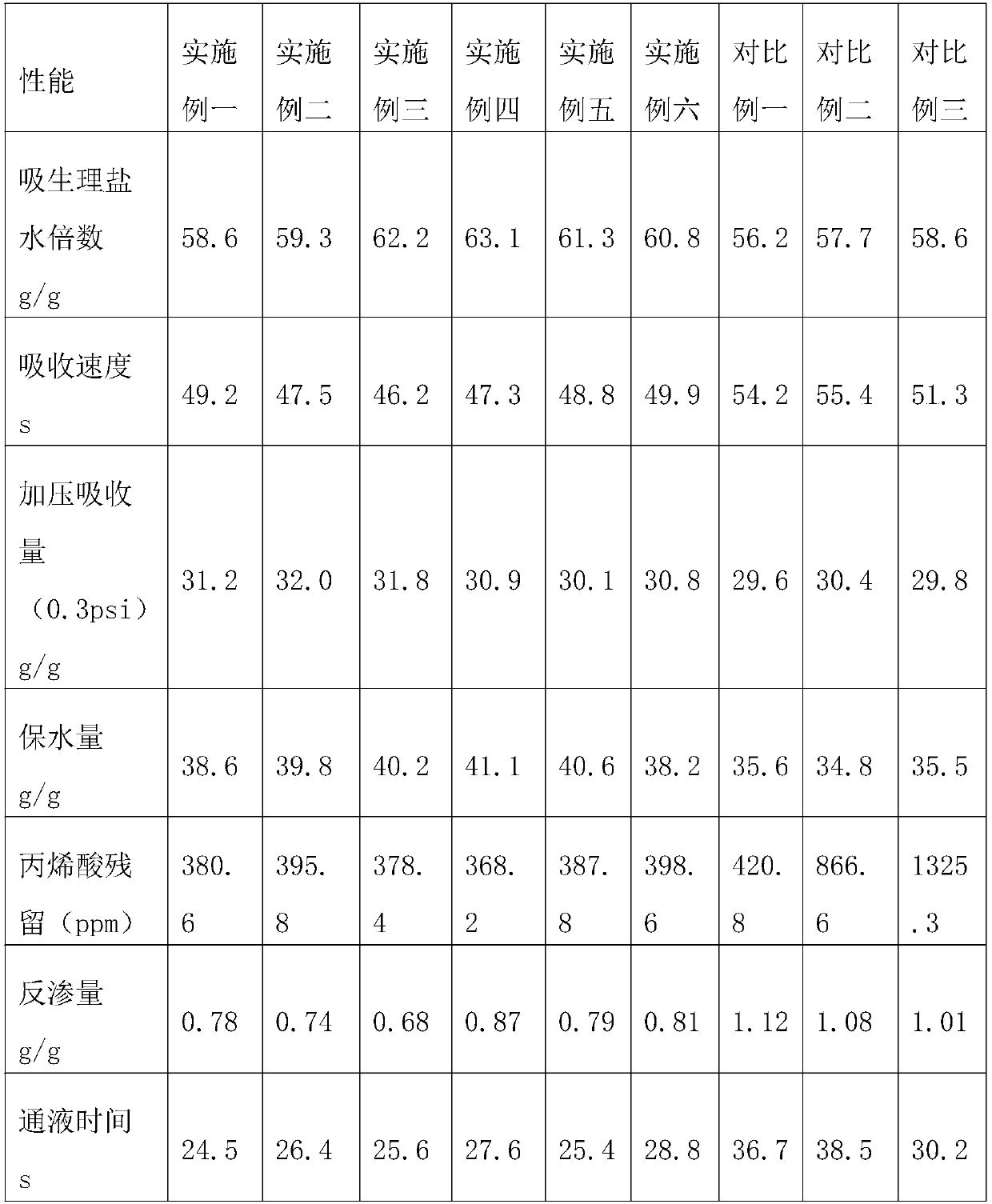

Water absorbent resin suitable for wood-pulp-core paper diaper and preparing method thereof

ActiveCN107854223AModerate water absorption speedResidue reductionAbsorbent padsBaby linensCross-linkSodium metasilicate

The invention discloses a water absorbent resin suitable for a wood-pulp core and a preparing method thereof. The preparing method includes the following steps that after acrylic acid and deionized water are mixed, then a neutral reaction is carried out with a sodium hydroxide solution, the reaction is completed, then a sodium metasilicate water solution, acrylamide, a cross-linking agent and an initiating agent are sequentially added, and a milk-white mixed solution is obtained; nitrogen is introduced, mixed liquid is subjected to a polymerization reaction under ultraviolet rays, and transparent colloid is obtained; the colloid is granulated, dried and smashed, and resin powder is obtained; the resin powder is taken and evenly stirred with sodium metaaluminate, surface treatment liquid isadded for treatment, and the product is obtained. According to the water absorbent resin suitable for the wood-pulp core and the preparing method thereof, nanoscale silicon dioxide is generated in the neutral process and evenly dispersed in a reaction system and is capable of improving the liquid passing performance and the diffusivity of the water absorbent resin; the water absorbent resin prepared with the method is low in residual monomer, small in reverse osmosis amount, large in water retaining capacity, high in particle strength after water absorption, loose and particularly suitable for a wood-pulp-core paper diaper.

Owner:LUNALER HEALTH TECH GUANGZHOU CO LTD

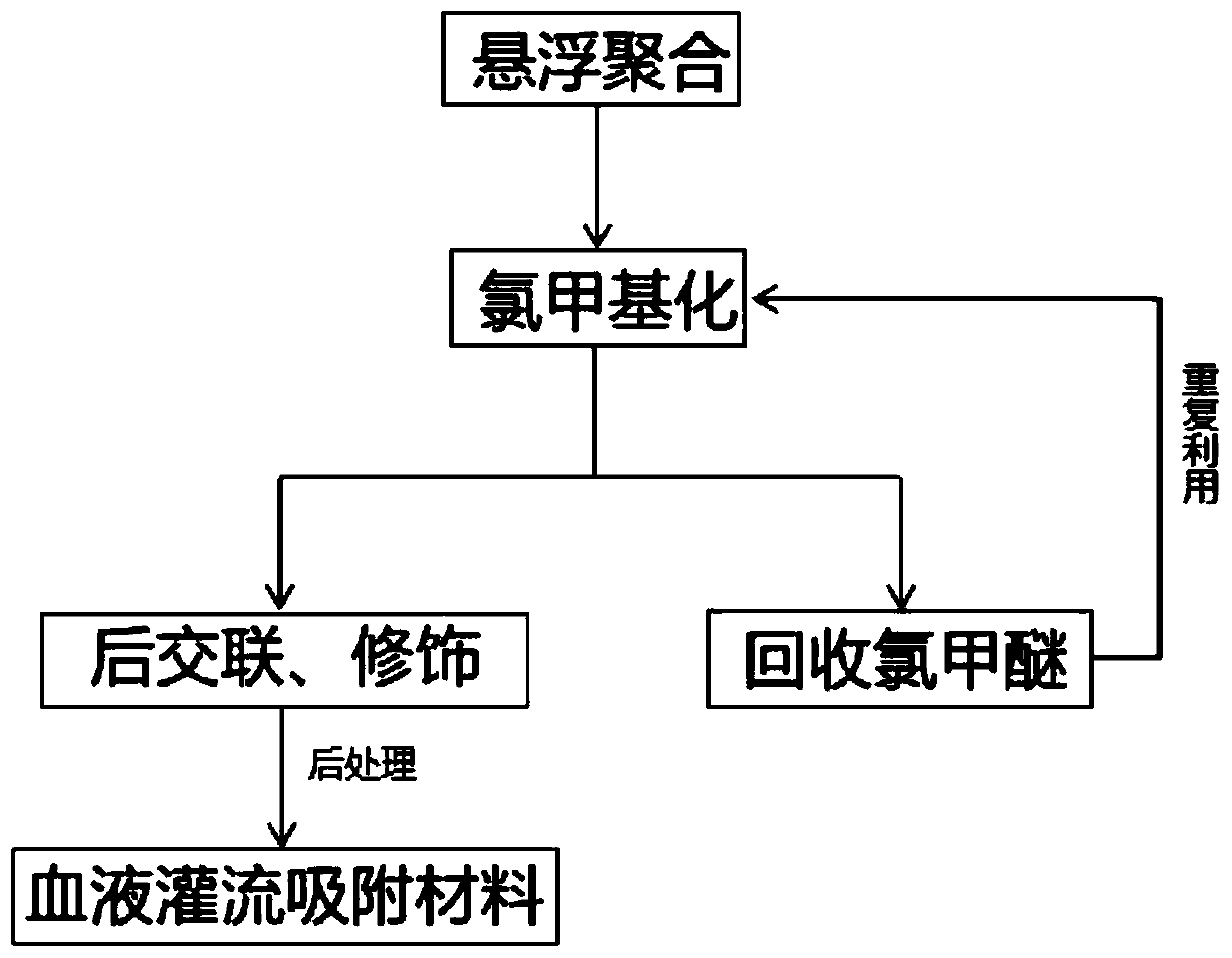

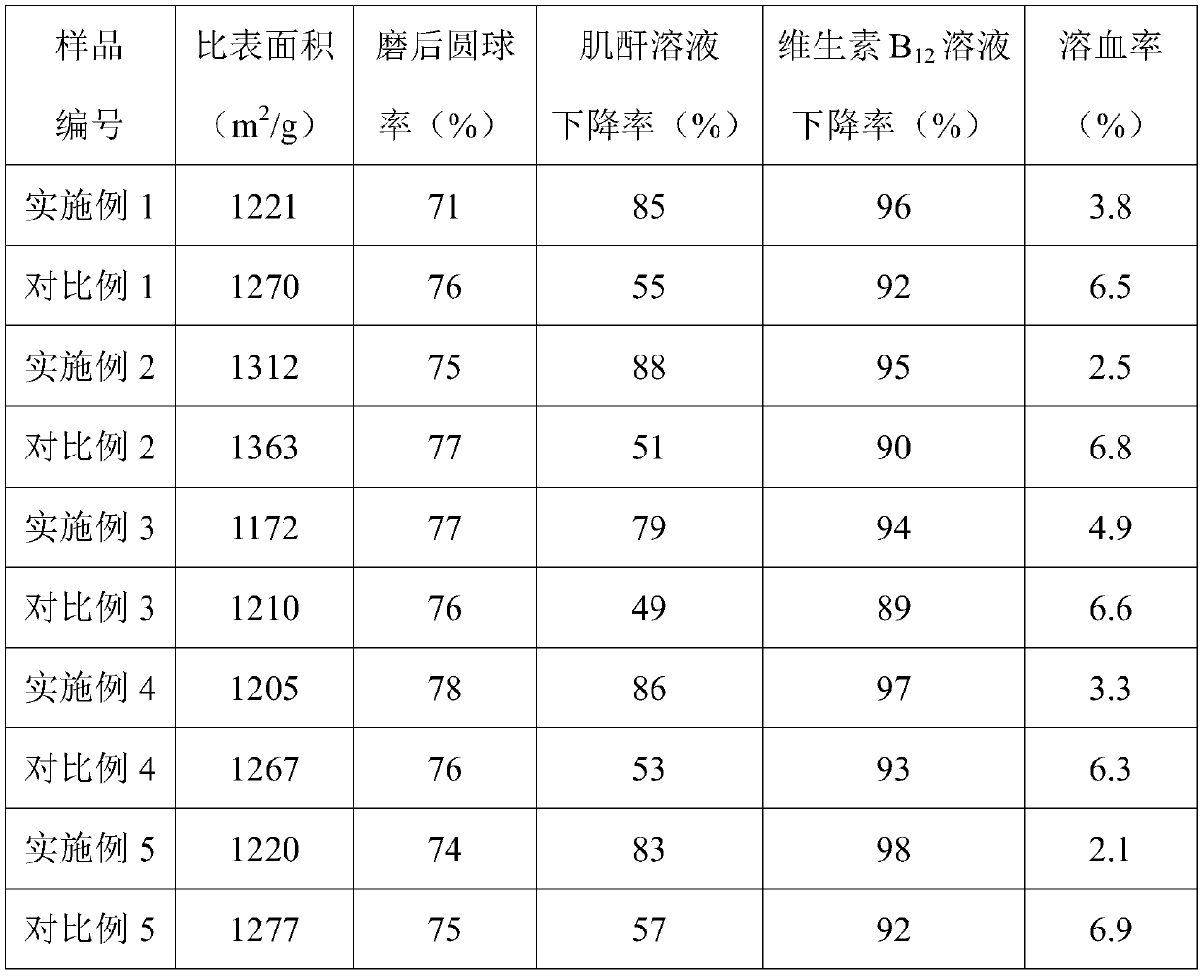

Preparation method of adsorbing material for blood perfusion

ActiveCN111530432AImprove adsorption capacityThe synthetic route is simpleOther blood circulation devicesOther chemical processesChloromethyl EtherOil phase

The invention discloses a preparation method of an adsorption material for blood perfusion. The preparation method comprises the following steps: preparing an oil phase and a water phase, by a suspension polymerization process, preparing a macroporous adsorption resin precursor with the particle size distribution being 0.315-0.8 mm from the the prepared oil phase and water phase, carrying out chloromethylation on the prepared macroporous adsorption resin precursor to prepare a chloromethylated macroporous adsorption resin precursor, carrying out post-crosslinking on the prepared chloromethylated macroporous adsorption resin precursor to prepare macroporous adsorption resin of which the residual chlorine content is less than or equal to 2%, and carrying out post-treatment on the prepared macroporous adsorption resin to prepare the surface functionalized macroporous adsorption resin with adsorption capacity for blood perfusion. According to the invention, recycling of residual chloromethyl ether after the chloromethylation reaction in the synthesis process of the macroporous adsorption resin for blood perfusion is realized, and remarkable economic benefits and environmental protection benefits are brought.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD +1

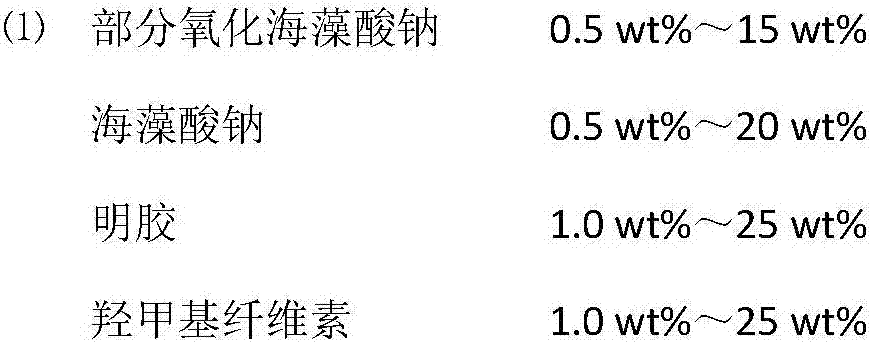

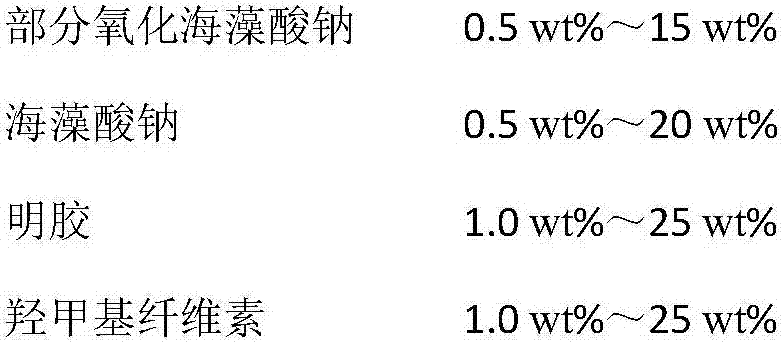

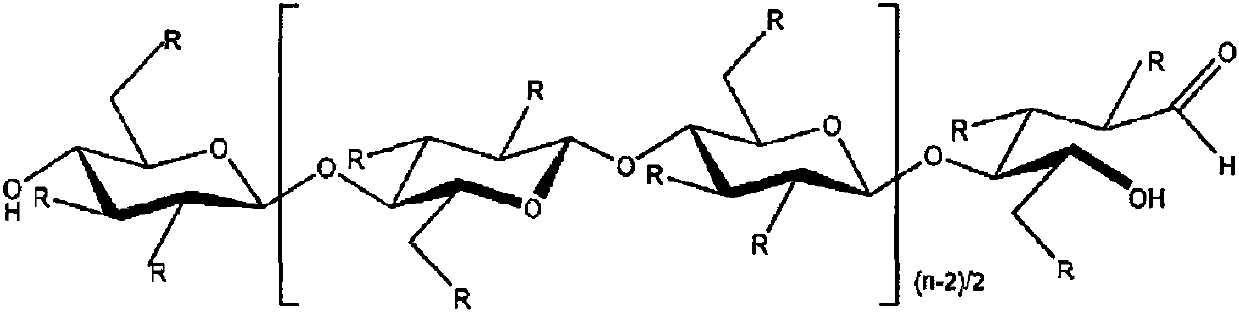

Totally biodegradable short fibre enhanced medical hydrogel body dressing and preparation method thereof

InactiveCN107456602AControl the degree of crosslinkingImprove mechanical propertiesCoatingsBandagesColloidToughness

The invention relates to a totally biodegradable short fibre enhanced medical hydrogel body dressing and a preparation method thereof. A hydrogel system is enhanced by adopting short fibres; a substrate is formed by blending partially oxidized sodium alginate / sodium alginate / gelatine / hydroxymethyl cellulose solution; and the short fibres are prepared from the sodium alginate and hydroxymethyl cellulose by wet spinning. The hydrogel obtained by the preparation has outstanding mechanical performance, excellent toughness and high water resistance, and is biodegradable; raw materials are easily obtained; a process flow is simple; and conditions are mild. The mechanical performance can be controlled by regulating the concentration of calcium ions and the content of the enhancing short fibres.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

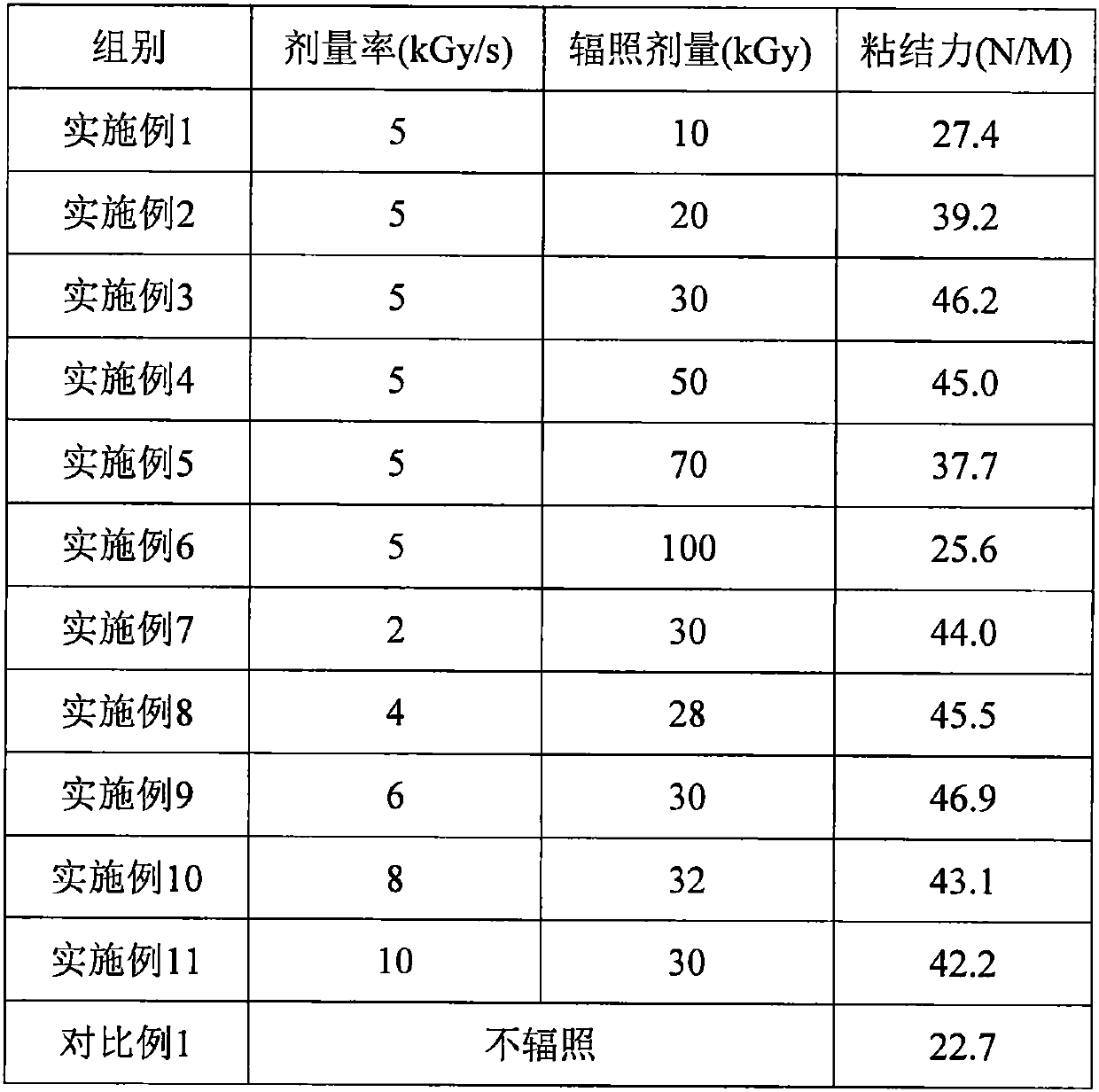

Method for improving electrolytic solution resistance of binder in lithium battery negative electrode sheet by irradiation

InactiveCN111600075AStable thicknessThe circulatory system is beneficialCell electrodesFinal product manufactureElectrolytic agentElectrical battery

The invention discloses a method for improving electrolytic solution resistance of a lithium battery negative electrode binder through irradiation, and belongs to the technical field of lithium batteries. The method comprises the following steps: preparing a lithium battery containing a negative electrode taking sodium carboxymethyl cellulose (CMC-Na) and styrene-butadiene rubber emulsion (SBR) asbinders; and placing the whole battery on an under-beam device of an electron beam irradiation accelerator, and irradiating the whole lithium ion battery, wherein the irradiation dose is 10 to 100 kGy, the irradiation dose rate is 2-10 kGy / s, and in the negative electrode, CMC-Na and SBR can generate intramolecular and intermolecular chemical cross-linking so as to improve the electrolytic solution resistance of the binders CMC-Na and SBR in the negative electrode sheet, reduce the swelling of the binders CMC-Na and SBR in the electrolytic solution, reduce the thickness expansion rate of thenegative electrode sheet in the battery circulation process, improve the capacity retention rate of the battery and prolong the service life of the battery. The process is simple and easy to implement, low in cost and suitable for consumer electronic lithium batteries and power type lithium batteries.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

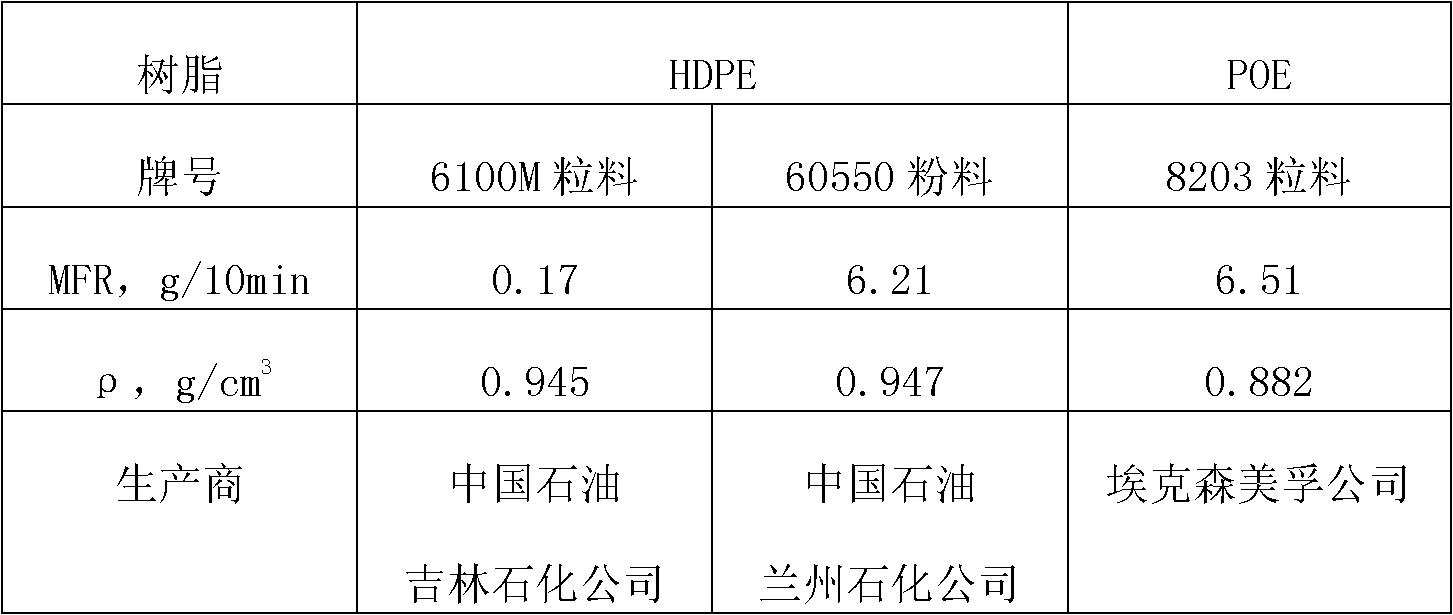

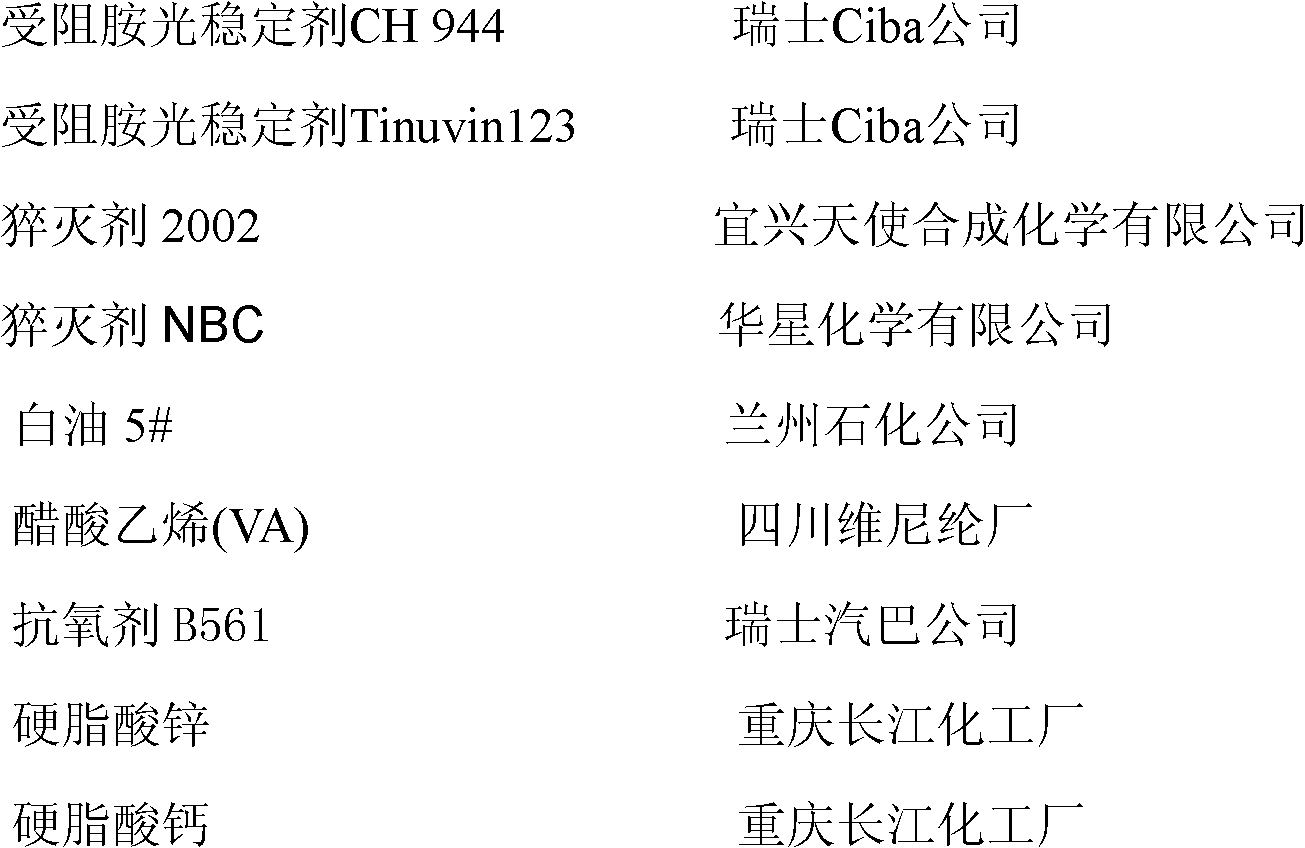

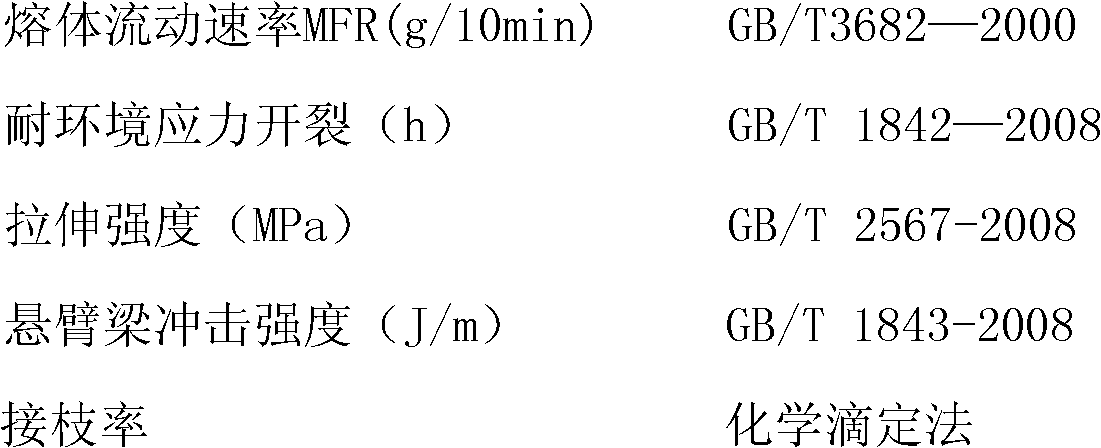

Polyethylene tubing resin composition

ActiveCN102924775AImprove ESCR performanceImprove efficiencyRigid pipesEnvironmental stress crackingPolyresin

The invention aims to provide a polyethylene tubing resin composition. HDPE (high-density polyethylene) is treated as a base material and is modified through the micro-crosslinking of weather-resistant POE master batches and an organic peroxide, so the tubing resin composition has an excellent ESCR (environmental stress cracking resistance) (for above 3000h). The invention further provides a preparation method of the composition. The resin composition comprises 100wt% of the HDPE, 0.05-0.2wt% of a complex crosslinking assistant and 10-30wt% of the weather-resistant POE master batches, wherein the weather-resistant POE master batches are a mixture composed of a polymer POE, a composite light stabilizing agent, a POE-g-VA graft (POE and vinyl acetate graft) and a dispersant.

Owner:PETROCHINA CO LTD

Medical grade reconstructed collagen cross-linking modified method

InactiveCN101323670BNon-cytotoxicThe degree of cross-linking is controllableProsthesisCross-linkPhosphate

Owner:SICHUAN UNIV

High thermal conductivity foam material

ActiveCN103804762AOvercoming thermal conductivityOvercome functionLow-density polyethyleneLinear low-density polyethylene

The invention relates to a resin foam material, and particularly relates to a high thermal conductivity foam material. The high thermal conductivity foam material is prepared by adopting the following steps: uniformly mixing 8-12 parts of heat conduction material and 40-100 parts of one or more of low density polyethylene, high density polyethylene, linear low density polyethylene or ethylene-vinyl acetate copolymer by weight so as to obtain a primary mixture; plasticizing and pelleting, to be specific, adding 2-8 parts of flame retardant, 6-10 parts of softening plasticizer, 3-7 parts of toughening agent, 1-4 parts of coupling agent and 0.6-1.2 parts of antioxidant by weight to the primary mixture, carrying out blending modification, plasticizing, and extruding and pelleting so as to obtain first particles; blending again and foaming, to be specific, mixing 15-25 parts of one or more of fatty alcohol polyoxyethylene ether sodium sulphate or azo-compounds, the first particles and 30-70 parts of one or more of low density polyethylene, high density polyethylene, linear low density polyethylene or the ethylene-vinyl acetate copolymer by weight, and extruding and foaming. The prepared high thermal conductivity foam material has high thermal conductivity and is waterproof and shock-proof.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Petroleum drilling fluid viscosity reducing agent as well as preparation method and application method thereof

InactiveCN103320099ALong period of rheological stabilityControl hydrationFlushingDrilling compositionWater basedPetroleum oil

The invention relates to a petroleum drilling fluid processing agent and provides a petroleum drilling fluid viscosity reducing agent as well as a preparation method and an application method thereof. The petroleum drilling fluid viscosity reducing agent is obtained by using the following method which comprises the following steps: firstly, respectively weighing 10-15 parts of humic acid, 10-15 parts of an alkali and 70-80 parts of lime in parts by weight; then mixing the humic acid, the alkali and the lime to obtain the petroleum drilling fluid viscosity reducing agent. The viscosity reducing agent applicable to water base drilling fluid can control the hydration and cross-linking degrees of clay and the processing agent in the drilling fluid, so that the viscosity of the drilling fluid is controlled within a suitable range and the rheological property stable period of the drilling fluid is long; the petroleum drilling fluid viscosity reducing agent is unique in composition, abundant in raw material sources, low in price, and easy and convenient to produce and apply.

Owner:CNPC XIBU DRILLING ENG

Preparation method of interface-modified rice husk powder/polylactic acid biodegradable composite material

The invention discloses a preparation method of an interface-modified rice husk powder / polylactic acid biodegradable composite material. The preparation method comprises the following steps: grindingrice husks to form a 80-200 mesh powder, performing alkali treatment by using a sodium hydroxide solution, and drying the alkali-treated rice husk powder for later use; and injecting the dried rice husk powder, polylactic acid and a silane coupling agent into a twin-screw extruder according to a weight part ratio of 60:40:(4-6), and performing screw extrusion to obtain the interface-modified ricehusk powder / polylactic acid biodegradable composite material. The method has the advantages of simplicity, easily available raw materials, and easiness in realization of large-scale production. The rice husk powder / polylactic acid biodegradable composite material obtained by the preparation method has the characteristics of hardness, high density, non-toxicity, environmental protection, and good toughness, good firmness and good aging resistance, and can be automatically degraded into an organic fertilizer after being used.

Owner:BEIJING FORESTRY UNIVERSITY

Anti-aging cable sheath material and preparation method thereof

InactiveCN107236283AStrong economic valueImprove aging resistancePlastic/resin/waxes insulatorsUltraviolet lightsEngineering

The invention belongs to the technical field of an electric material and provides an anti-aging cable sheath material and a preparation method thereof. The cable sheath material comprises the following raw materials in parts by weight: 52-64 parts of modified polyurethane resin, 13-22 parts of chlorinated polyethylene, 7-22 parts of dibutyl maleate, 12-19 parts of organic nanometer montmorillonite, 2-5 parts of bocour blue, 2-5 parts of chlorinated paraffin, 1-4 parts of an anti-aging agent, 0.6-2.8 parts of a coupling agent, 1.3-3.4 parts of an ultraviolet light absorber and 1.6-2.9 parts of a plasticizer. The cable sheath material provided by the invention has an anti-aging property. The modified polyurethane resin is used as a main raw material, and the organic nanometer montmorillonite, bocour blue, chlorinated paraffin, anti-aging agent and ultraviolet light absorber are used as auxiliaries, so that the prepared cable sheath material has an excellent anti-aging property.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

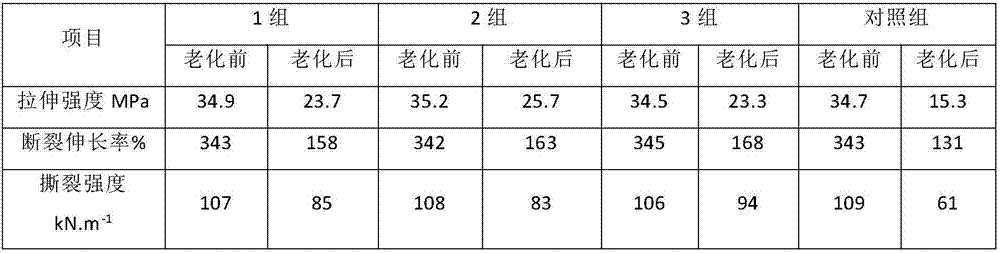

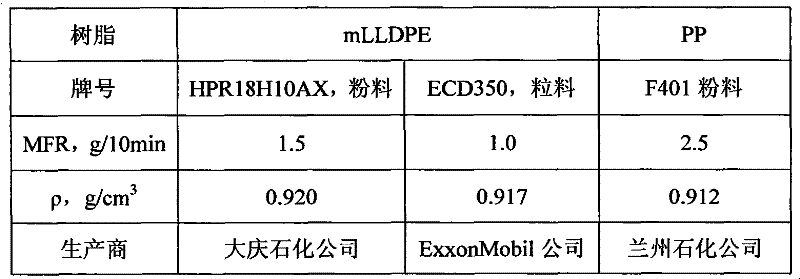

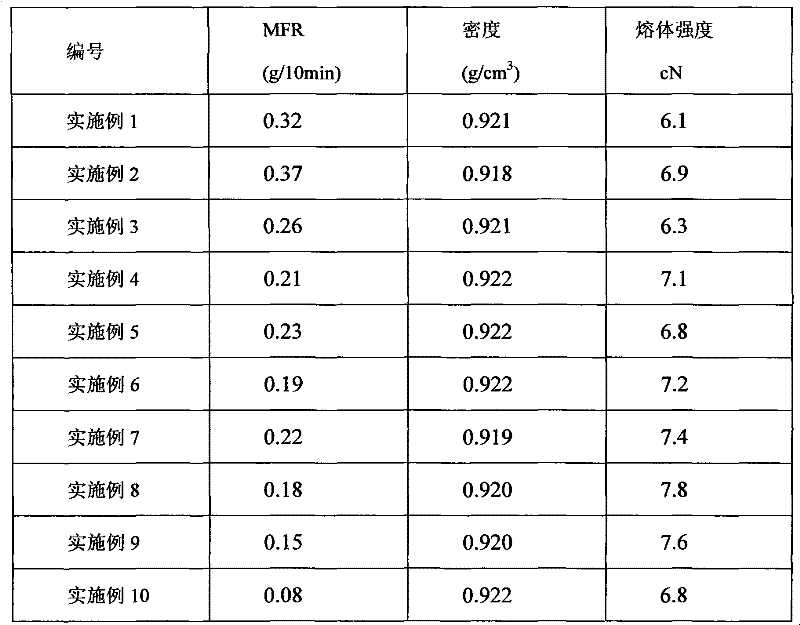

Metallocene polyethylene greenhouse film resin composition with high intensity and ultra-broad width, and its preparation method

The invention discloses a metallocene polyethylene greenhouse film resin composition with high intensity and ultra-broad width and its preparation method, by referring linear low density metallocene polyethylene in weight percent, the resin composition comprises: 1) 100% of mLLDPE; 2) 0.11%-0.37% of compound crosslinking auxiliary agent (1,1-hydroxyphenyl-hydrogen peroxide and tert-butyl acetate peroxide); 3) 0.011%-0.027% of dibenzoyl peroxide; 4) 11%-29% of PP / LLDPE blended grafted polymer. According to the invention, the composition is capable of steadily blowing the ultra-broad width greenhouse film (broad width is greater than or equal to 14m, the thickness is greater than or equal to 60 mum) on a general film blowing machine group, and the tear strength of film product is high, the product has no fish eye on the appearance, the polyethylene greenhouse film resin composition is capable of resisting 8-9 grade sand storm, and is especially suitable for laying in central and westernregions in which the sandstorm occurs frequently. The present invention also discloses a preparation method of the resin composition.

Owner:PETROCHINA CO LTD

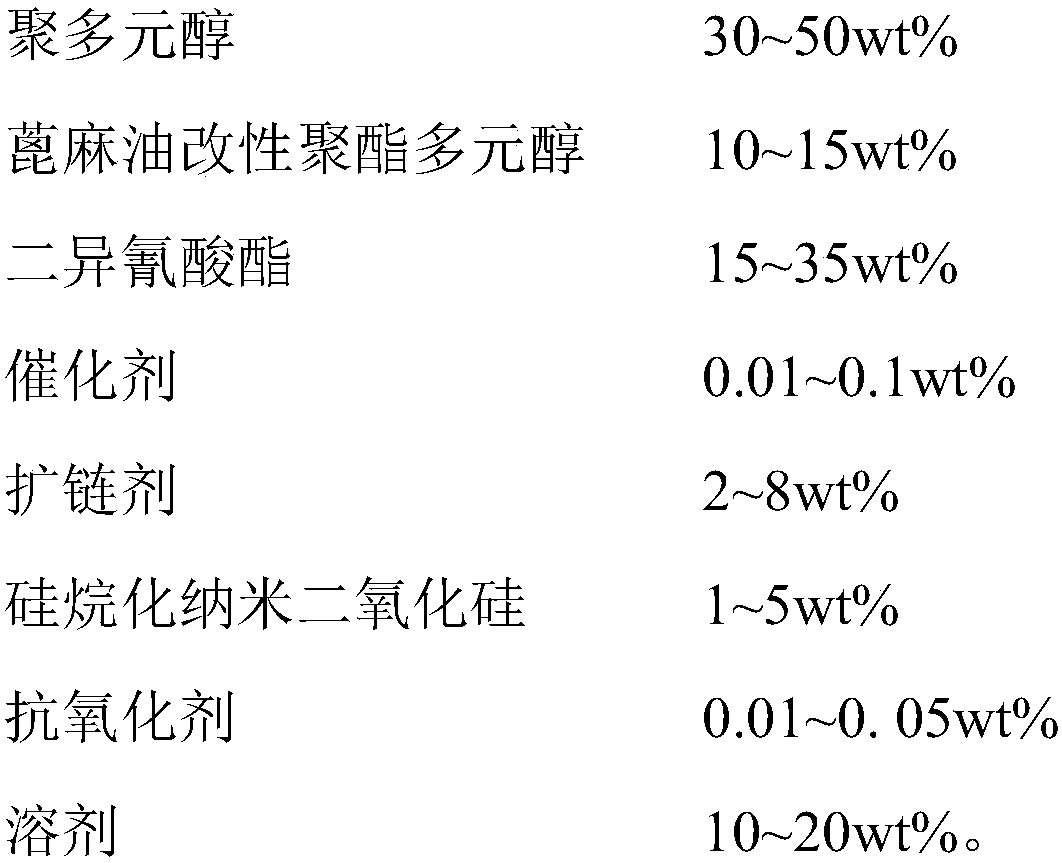

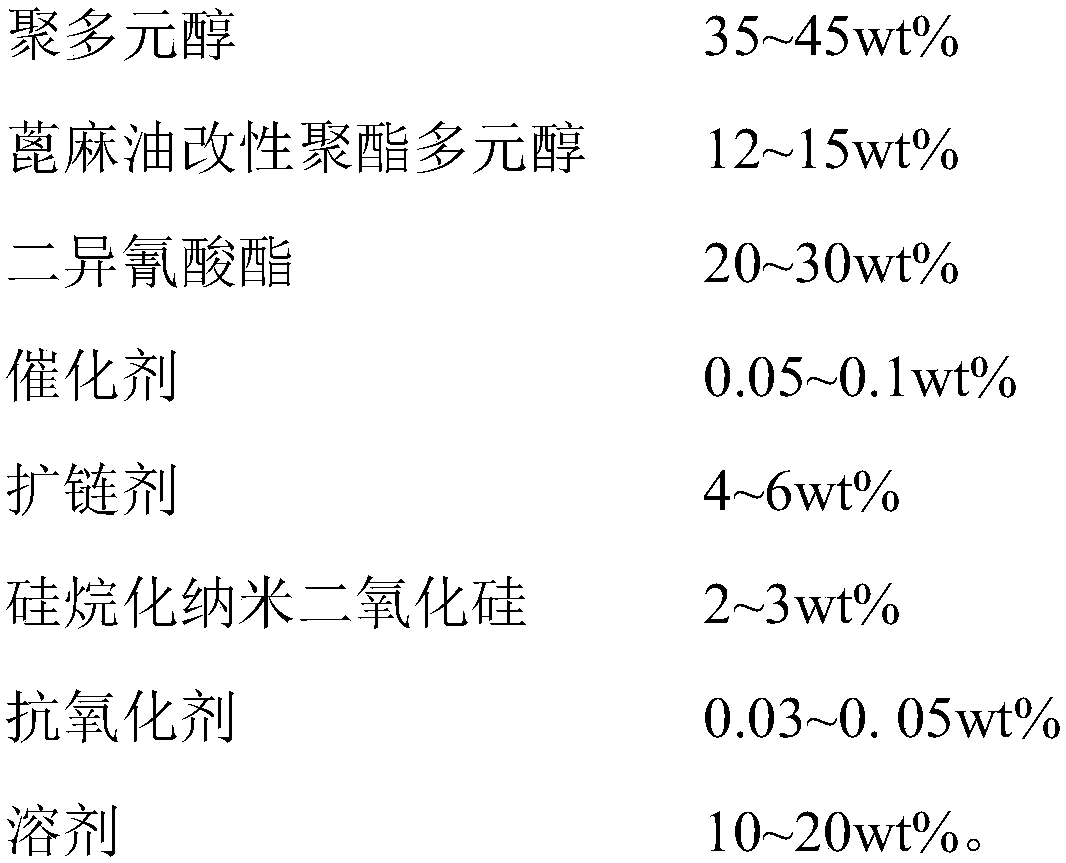

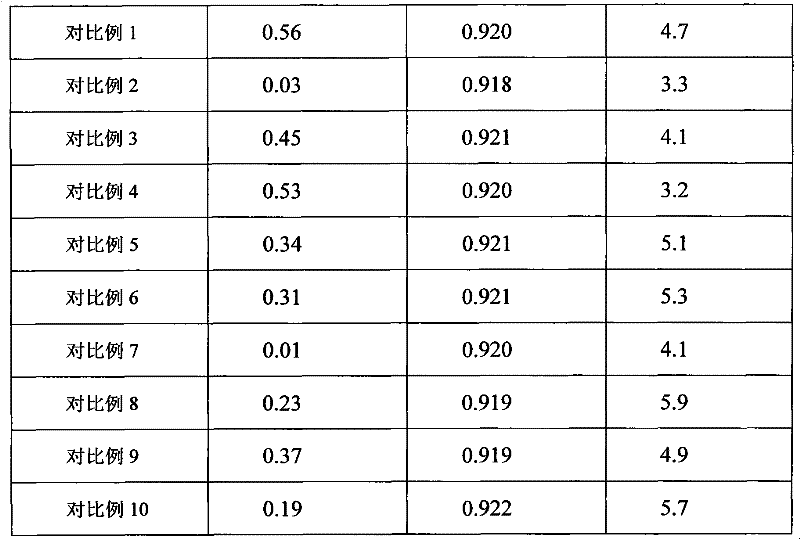

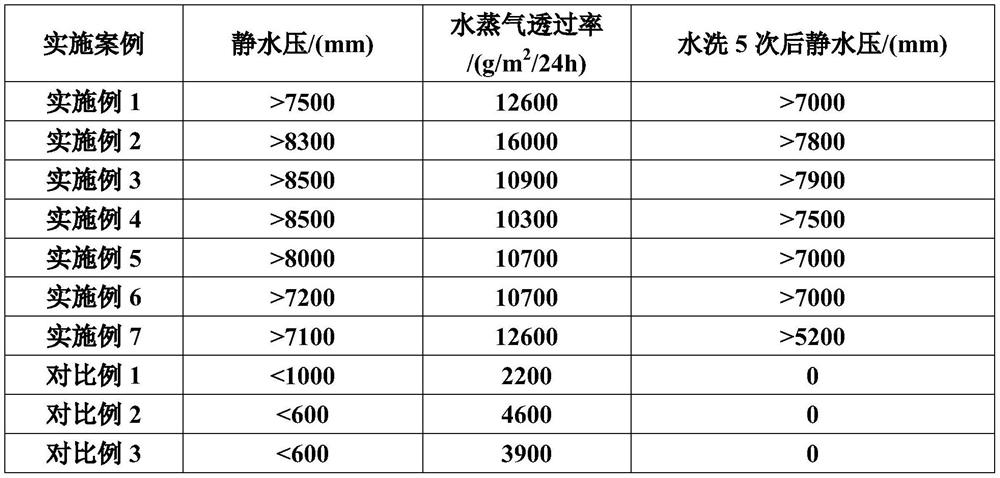

Waterproof and moisture-permeable waterborne polyurethane resin as well as preparation method and application thereof

ActiveCN113061227ALow viscosityControl the content of hydrophilic groupsTextiles and paperPhenylboronic acidPolymer science

The invention relates to waterproof and moisture-permeable waterborne polyurethane resin as well as a preparation method and application thereof. The waterborne polyurethane resin is prepared from the following components through reaction: A) polyisocyanate, B) polyether polyol, C) an amino compound, D) dihydroxy carboxylic acid and E) micromolecular dihydric alcohol. The waterborne polyurethane resin provided by the invention is a water-soluble polyurethane resin, and has the advantages of simple synthesis process, convenience in construction, better film formation and higher water vapor permeability; and the phenylboronic acid unit contained in the polyurethane polymer structure enables the waterproof moisture-permeable adhesive to have good adhesion, high hydrostatic pressure value and washing resistance on the surface of a cloth base material.

Owner:WANHUA CHEM GRP CO LTD +1

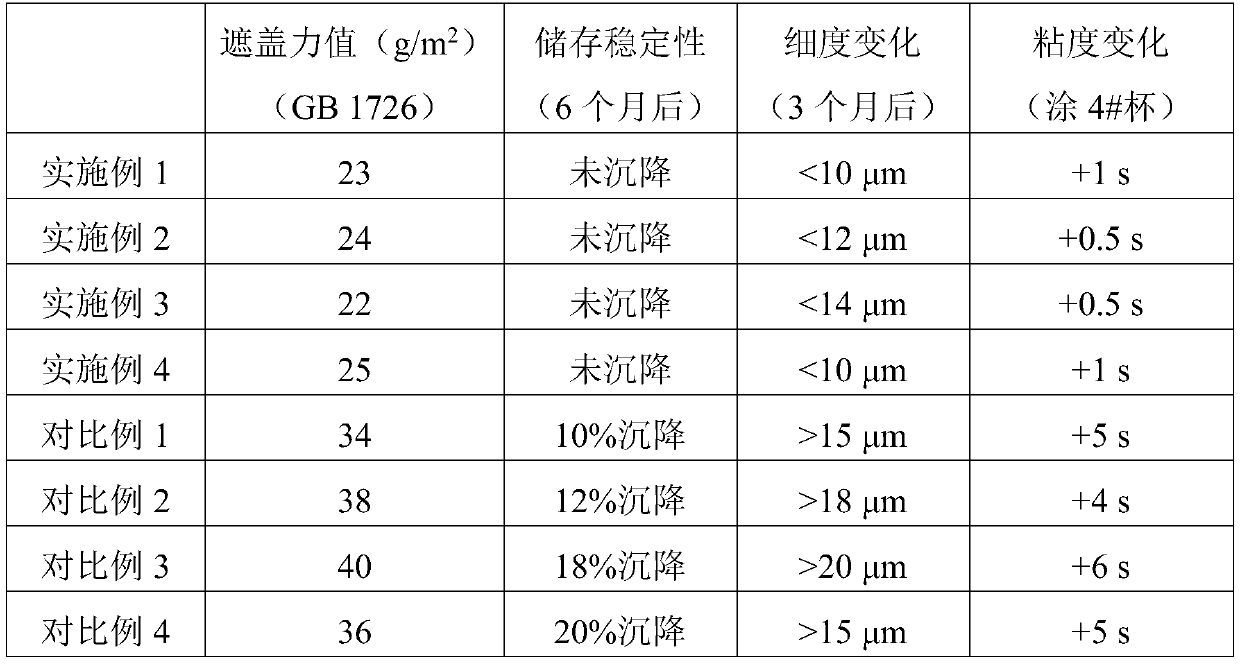

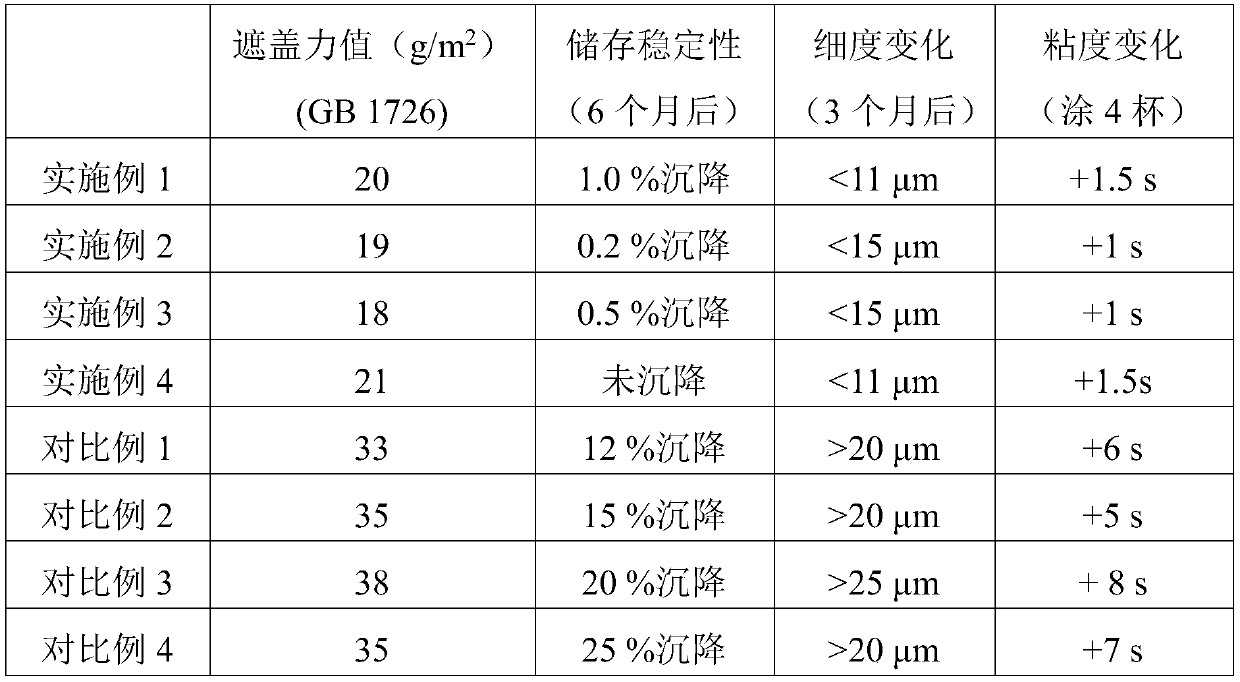

Reactive color paste and preparation method thereof

InactiveCN111117372APrevent subsidenceAvoid problems such as thickeningTransportation and packagingInksPolymer sciencePrinting ink

The invention relates to a reactive color paste and a preparation method thereof. The reactive color paste is prepared from, by weight, a styrene-maleic anhydride copolymer, an aminated pigment and adiluent, wherein the addition amounts of the styrene-maleic anhydride copolymer and the aminated pigment enable the molar weight ratio of maleic anhydride to amino groups to be 1:1 to 1:2, and the addition amount of the diluent adjusts the viscosity range to be 20-100 s. The preparation method comprises the following steps: uniformly stirring and mixing the styrene-maleic anhydride copolymer and the aminated pigment in the presence of the diluent; and heating to 90-150 DEG C, and reacting for 2.0-6.0 h to obtain the reactive color paste. Compared with like products in the prior art, the colorpaste of the invention has the advantages of good storage stability, and good dispersibility and color development for other pigments and fillers, can form a color paste system with good performance,and can be widely applied to the fields of coatings and printing inks.

Owner:DONGLAI COATING TECH SHANGHAI

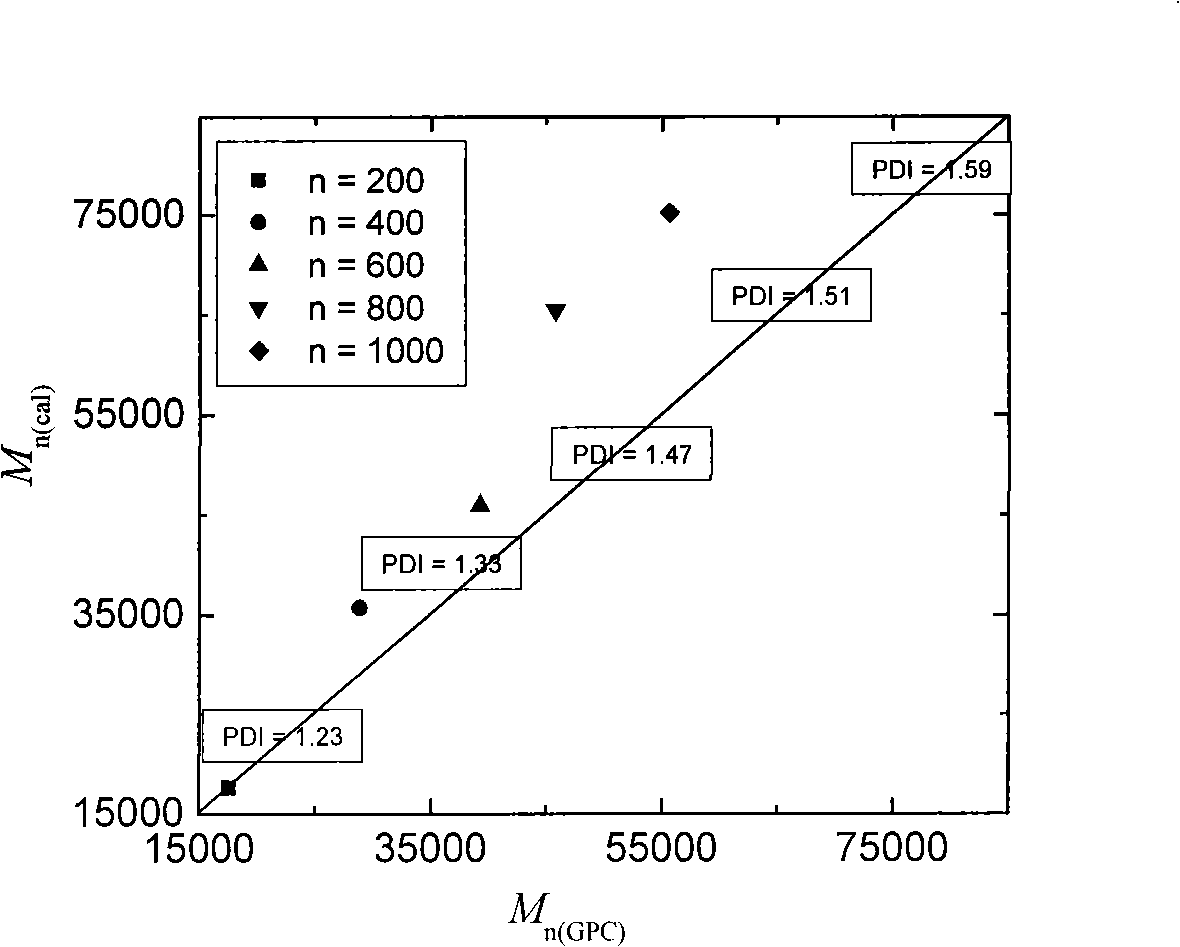

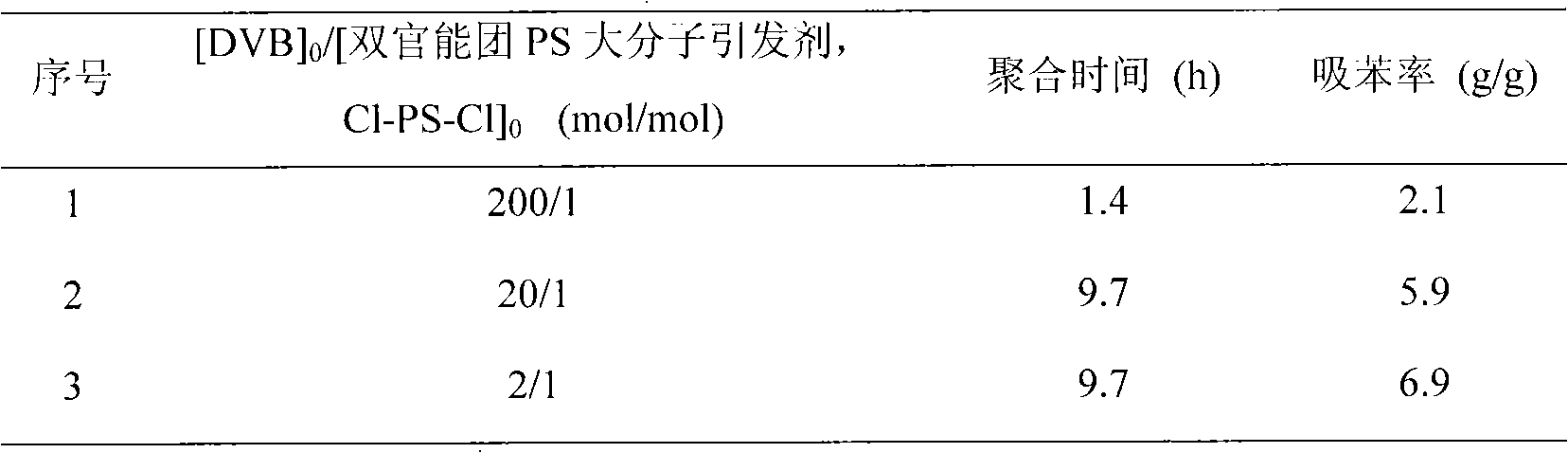

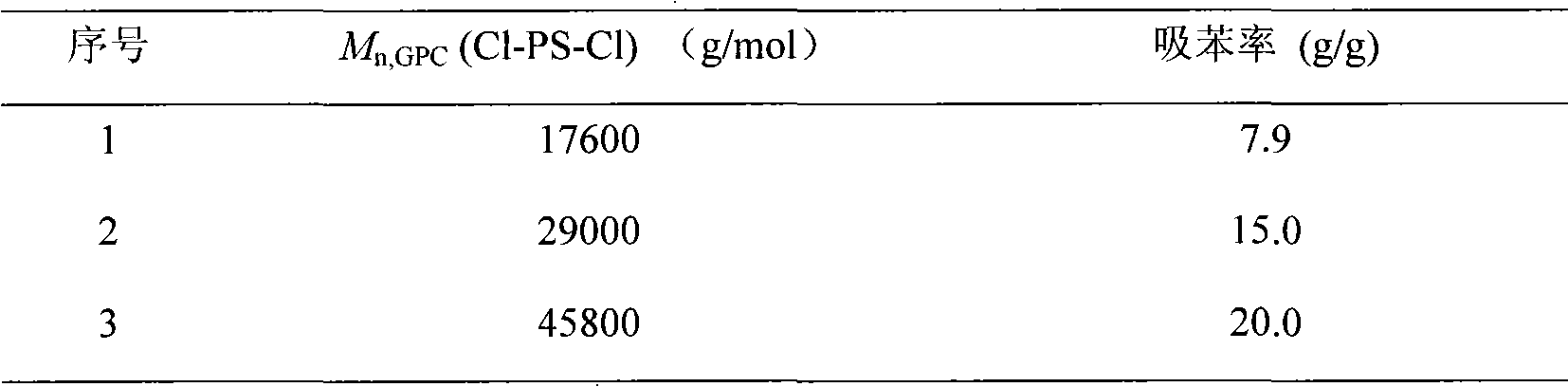

Process for synthesizing pipetting block copolymer gel

InactiveCN101284898AControllable crosslink densitySegment molecular weight distribution is uniformCross-linkPolymer science

The invention discloses a method for synthesizing an imbibing block polymer gel. The method comprises the following steps that: (1) the ATRP reaction is performed on a monomer A to synthesize a polyfunctional group macromolecule evocating agent; (2) the polymer polyfunctional group macromolecule is taken as the evocating agent, the ATRP reaction is performed on a monomer B to synthesize the block polymer evocating agent; (3) a cross-linking agent is added to perform the ATRP reaction in order to synthesize the block polymer gel; wherein, the monomer A and the monomer B are selected from different one of the cinnamene and (methyl) acrylic ester. The network size of the polymer obtained by the method can be conveniently controlled by the molecular weight of a linear polymer or the dosage of the cross-linking agent; in addition, the structure of the polymer can be conveniently controlled by the selection and the combination of the monomer kinds, thereby controlling the imbibing performance of the polymer gel.

Owner:SUZHOU UNIV

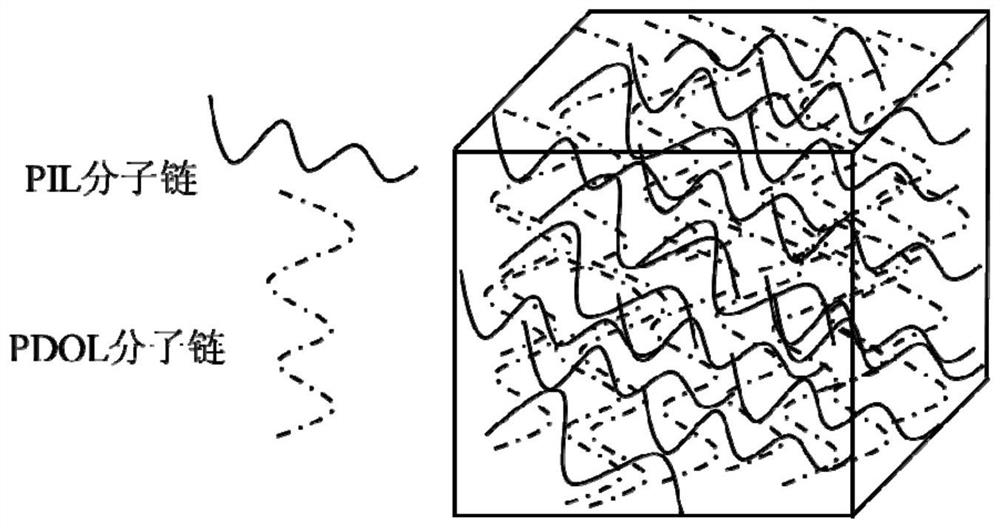

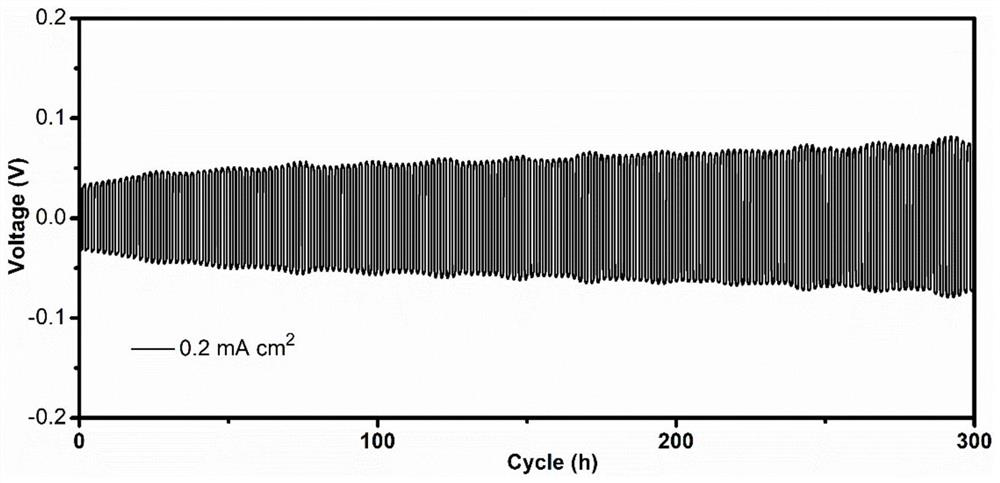

Interpenetrating network structure layer and in-situ preparation method and application thereof

ActiveCN114292484AImprove cycle performanceControl the degree of crosslinkingFinal product manufactureLi-accumulatorsSolid state electrolyteInterface impedance

The invention discloses an interpenetrating network structure layer and an in-situ preparation method and application thereof. The layer can be used as an interface buffer layer between an inorganic solid electrolyte and a lithium metal negative electrode, or a polymer electrolyte. The preparation method comprises the following steps: carrying out ultraviolet irradiation polymerization to obtain a polyion liquid (PIL) polymer molecular chain network, mixing an alkylene oxide monomer with the network, uniformly dispersing the alkylene oxide monomer in the network, carrying out ring-opening polymerization reaction to generate a polyether molecular chain network with high molecular weight, and obtaining the polymer electrolyte membrane with an interpenetrating network structure in situ. As an interface layer, side reaction caused by contact of inorganic solid electrolyte and lithium metal can be effectively avoided, and the cycle performance of the all-solid-state battery is improved. The in-situ formation of the electrolyte can also significantly improve the compatibility of the electrolyte and the electrode, reduce the interface impedance, and improve the conductivity and mechanical strength of the lithium ion battery.

Owner:XIAMEN UNIV

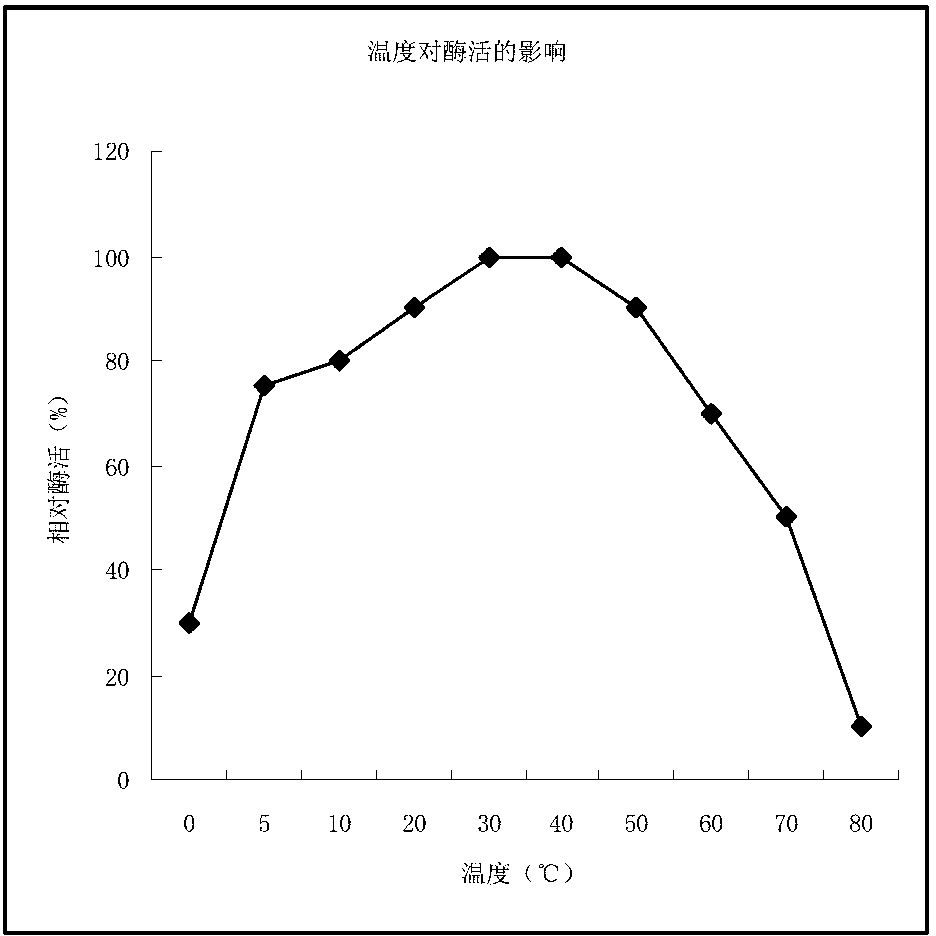

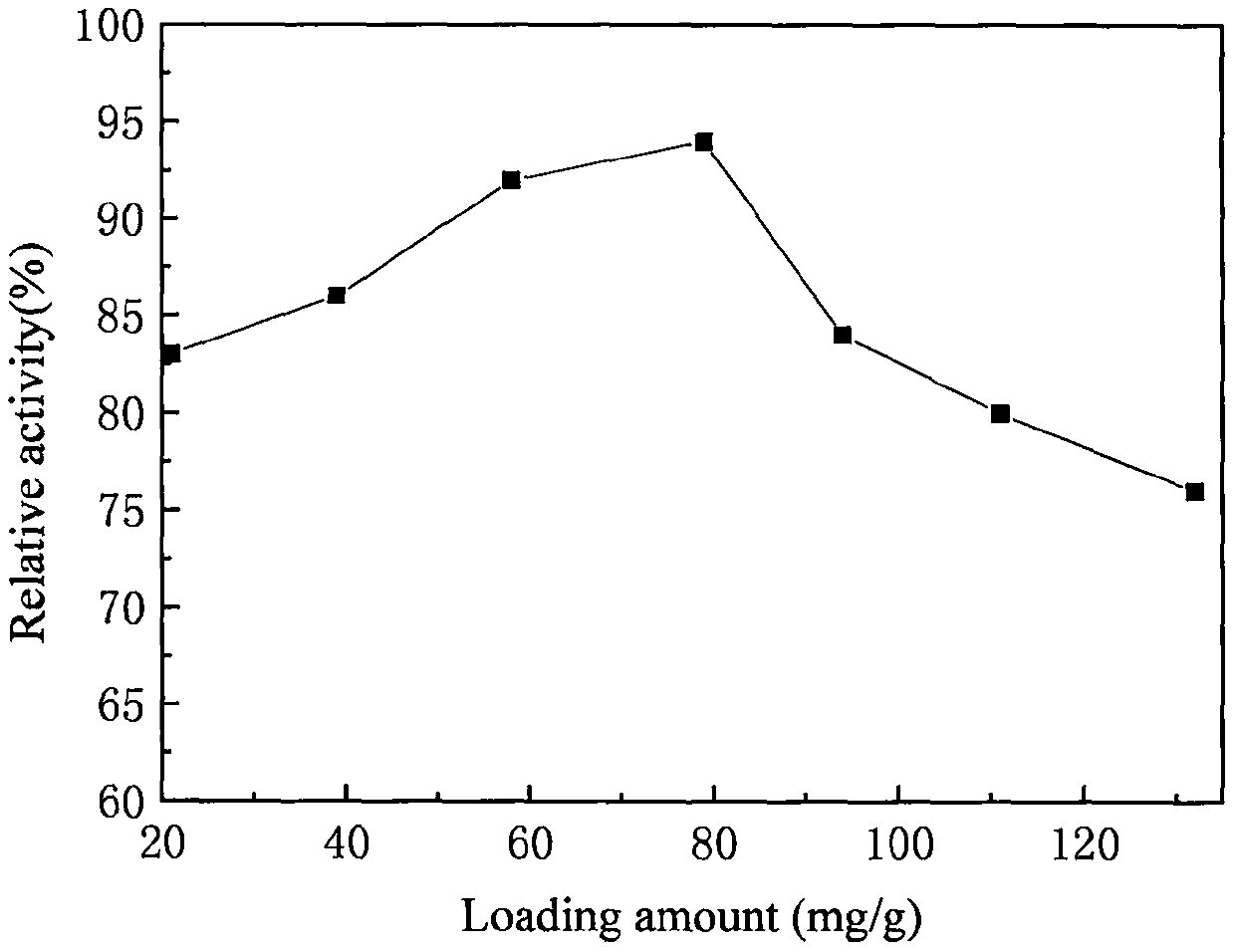

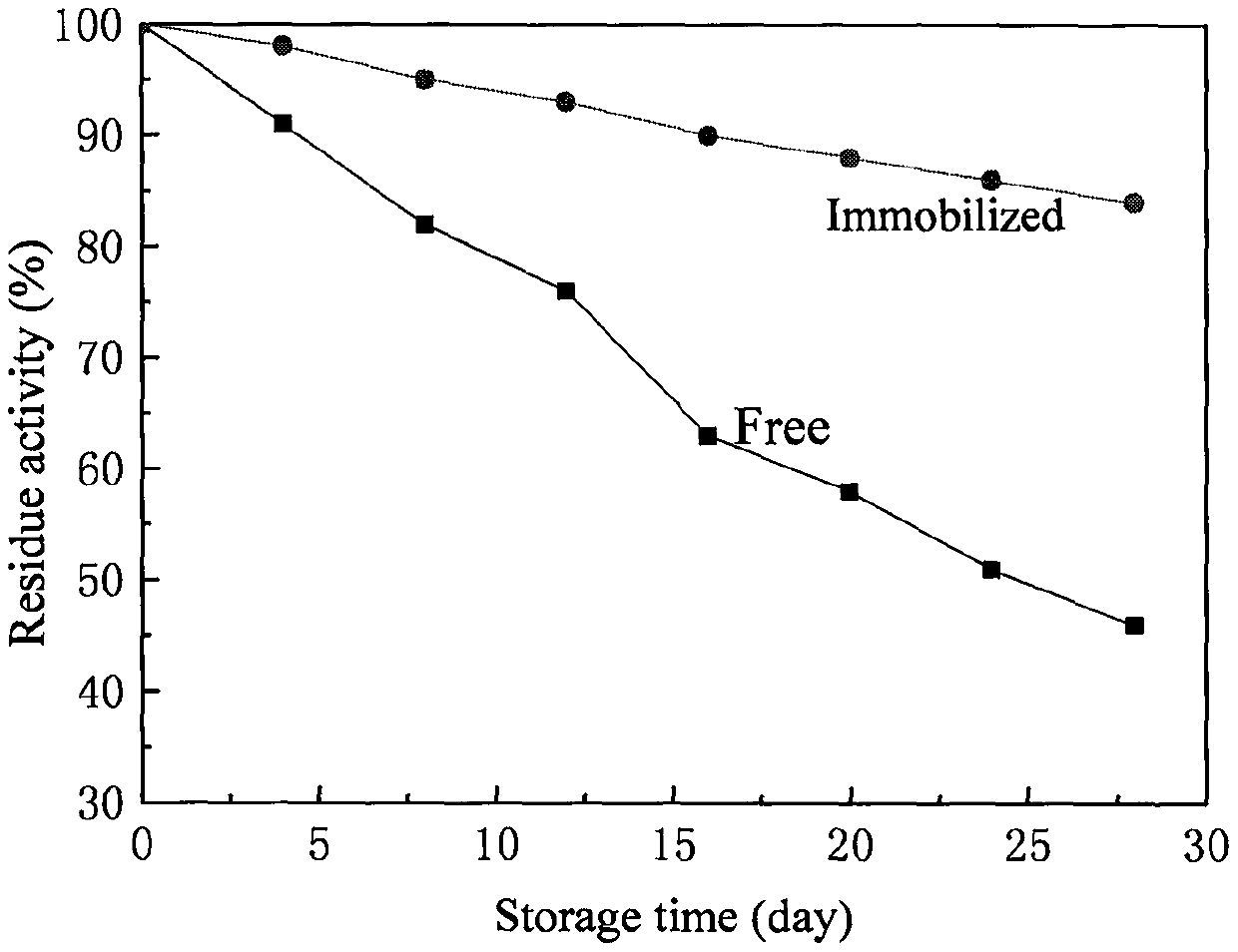

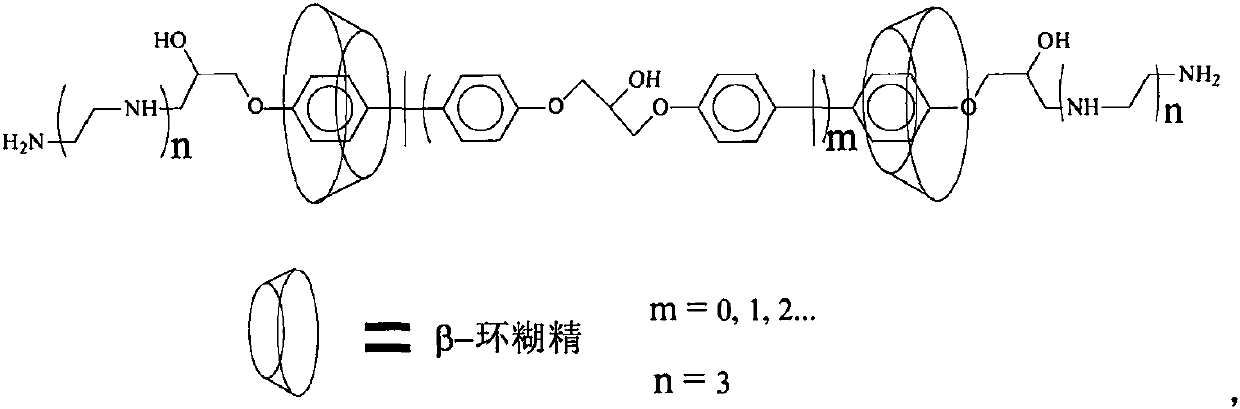

Alkali protease co-crosslinking immobilization method

ActiveCN110804605AReduce usageEasy to manufactureChemical industryOn/in organic carrierEpoxyPolymer science

The invention relates to an alkali protease co-crosslinking immobilization method. Oil-soluble diethylene glycol diacrylate is used as a cross-linking agent, a reactant in an aqueous phase is a supermolecule compound prepared from amino containing alkali protease, aminated epoxy resin and beta-cyclodextrin, through a Michael addition reaction of dual bonds and amino, the co-crosslinking is generated at low temperature, and the immobilization alkali protease of different loading quantities can be prepared. The cross-linking degree is controlled, so that the dispersibility is improved, and internal mass transfer microenvironment can be improved. An immobilized enzyme has high catalytic activity, and when the loading quantity is 58-79mg of enzymes / 1g of carriers, the relative activity achieves 90% or above of free enzymes.

Owner:NINGBO UNIV

Antibacterial collagen-based medical material and preparation method thereof

InactiveCN113274541AImprove mechanical propertiesImprove resistance to degradationSurgical adhesivesPharmaceutical delivery mechanismCyclodextrinBiocompatibility

The invention relates to an antibacterial collagen-based medical material and a preparation method thereof, and belongs to the field of biomedical materials. According to the antibacterial collagen-based medical material, beta-cyclodextrin is used as a raw material, and an aldehyde group derivative of beta-cyclodextrin and a plant essential oil antibacterial agent are simultaneously applied to crosslinking modification of a collagen-based material. The preparation method can improve the structural stability of materials; and on the other hand, the loaded plant essential oil antibacterial agent can endow the material with a good and lasting antibacterial function, and the preparation method is a novel preparation method of the antibacterial collagen-based medical material. The collagen-based medical material has good degradability, mechanical property and biocompatibility, further has a lasting antibacterial function, and has important clinical application value.

Owner:SICHUAN UNIV

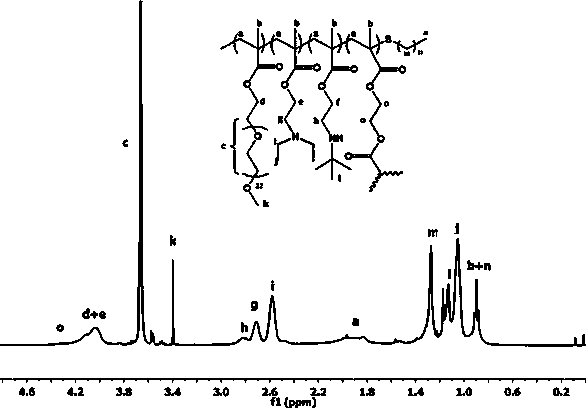

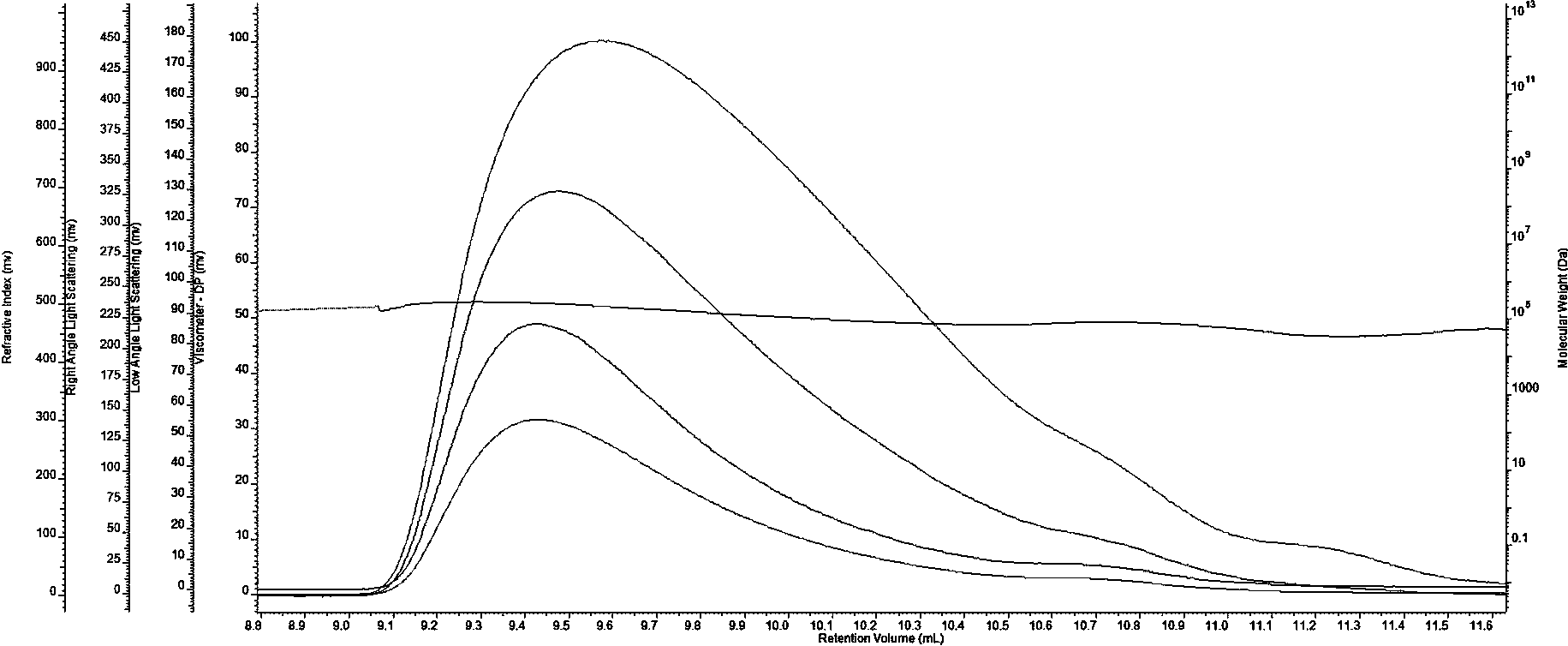

Ph response graft copolymer as well as preparation method and use thereof

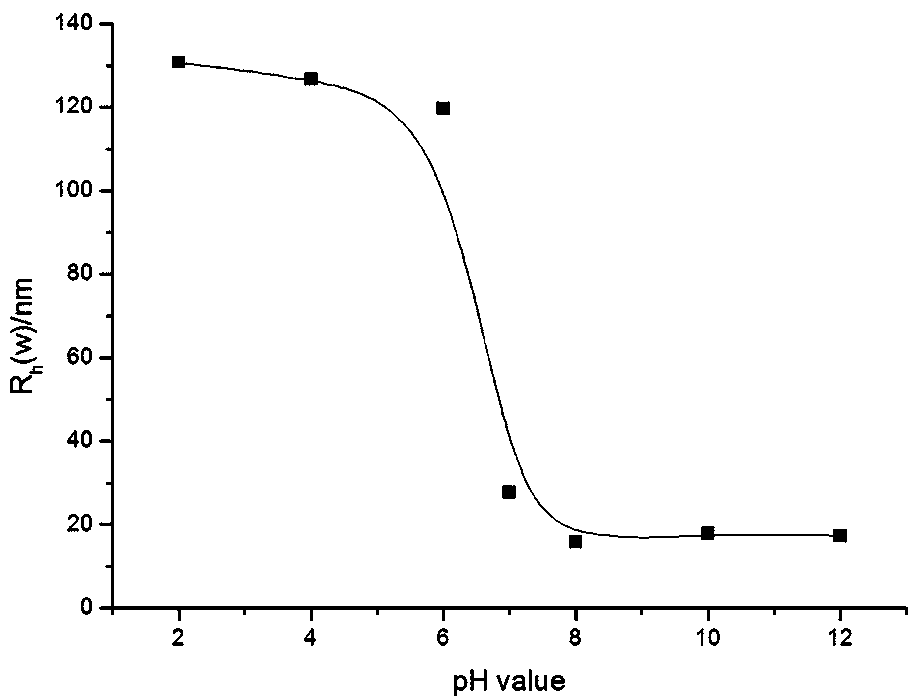

The invention provides a preparation method of a pH response graft copolymer based on methacrylic acid amino ester. The preparation method comprises the following steps: firstly dissolving methacrylic acid macrogol ester and methacrylic acid amino ester in a solvent; adding a divinyl cross-linking agent; taking a thiols compound as a chain transfer agent, and triggering a polymerization reaction with a radical initiator; controlling the molar ratio of the cross-linking agent to the chain transfer agent to control the reaction so as to obtain the graft copolymer. When the pH of the graft copolymer is smaller than 6, aggregates with the hydrodynamic radius of 130-140 nm are aggregated; when the pH of the graft copolymer is about 7, the shapes of the aggregates change suddenly; and when the pH of the graft copolymer is greater than 8, the hydrodynamic radius of the aggregates becomes about 20 nm, and good pH response performance is represented. Moreover, the reactivity site points of amino groups, and carboxyl groups and the like on the surface of the graft copolymer are easily subjected to macromolecular modification, functional groups are introduced, and the graft copolymer has a wide application prospect in the fields of materials science, medical science, biology and the like.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com