Thermoplastic vulcanized rubber material for automobile turning dust cover and preparation method of thermoplastic vulcanized rubber material

A technology of thermoplastic vulcanization and rubber materials, which is applied in the field of rubber materials, can solve the problems that cannot meet the performance requirements of automobile steering dust cover, strength, high temperature resistance, poor flexibility, and difficult blow molding processing, so as to improve blow molding processing Performance, sufficient blending process, and small particle size of the rubber phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

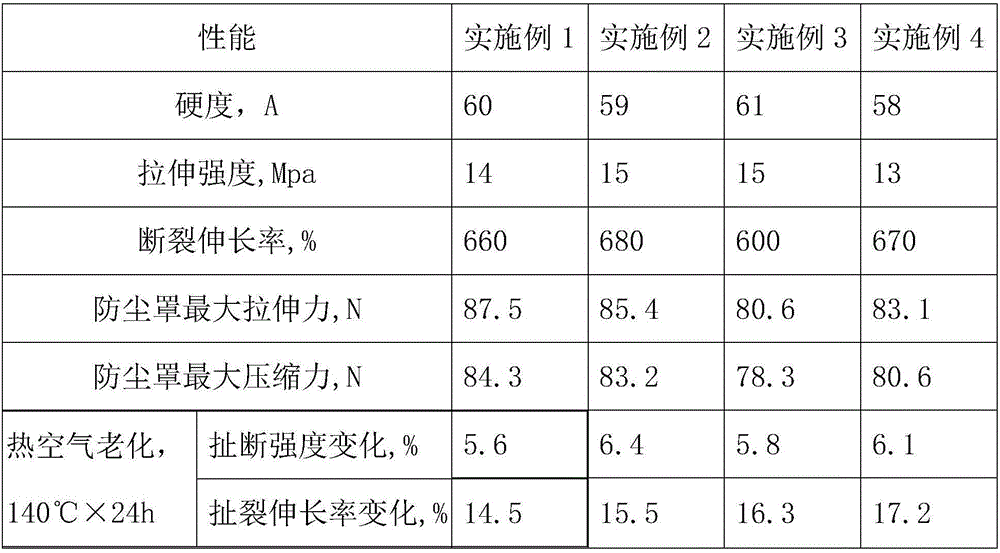

Examples

Embodiment 1

[0023] A thermoplastic vulcanized rubber material for automobile steering dust cover, its raw materials include by weight: 100 parts of EPDM, 80 parts of polypropylene, 10 parts of linear low density polyethylene, 100 parts of thermoplastic polyurethane elastomer, and 5 parts of ethylene-octene copolymer , maleic anhydride grafted ethylene-octene copolymer POE-g-MAH 15 parts, wollastonite 10 parts, silane coupling agent KH-570 5 parts, crosslinking agent 0.2 parts, active zinc oxide powder 5 parts, anti 1 part of oxygen agent 1010, 1 part of 2-mercaptobenzimidazole MB, 1 part of ultraviolet absorber UV-326, 100 parts of paraffin oil, 2 parts of ethylene bis stearic acid amide;

[0024] Wherein, the EPDM is composed of E-type EPDM rubber whose third monomer is vinylidene norbornene at 40 wt%, and D-type EPDM rubber whose third monomer is dicyclopentadiene at 30 wt%. and 30wt% of the third monomer is 1,4-hexadiene H-type EPDM composition;

[0025] The thermoplastic polyurethane...

Embodiment 2

[0028] A thermoplastic vulcanized rubber material for automobile steering dust cover, its raw materials include by weight: 300 parts of EPDM, 20 parts of polypropylene, 50 parts of linear low density polyethylene, 40 parts of thermoplastic polyurethane elastomer, 15 parts of ethylene-octene copolymer , maleic anhydride grafted styrene-ethylene-butadiene-styrene copolymer SEBS-g-MAH 5 parts, talc powder 80 parts, silane coupling agent A-137 3 parts, crosslinking agent 10 parts, active zinc 1 part of oxygen powder, 3 parts of antioxidant 3114, 0.5 part of triphenyl phosphite TPP, 93 parts of ultraviolet absorber UV-93 parts, 20 parts of naphthenic oil, 6 parts of oleic acid amide;

[0029] Wherein, the EPDM is composed of E-type EPDM rubber in which 60 wt% of the third monomer is vinylidene norbornene, and D-type EPDM rubber in which the third monomer is dicyclopentadiene in 10 wt%. and 30wt% of the third monomer is 1,4-hexadiene H-type EPDM composition;

[0030] The thermoplas...

Embodiment 3

[0033] A thermoplastic vulcanized rubber material for automobile steering dust cover, its raw materials include by weight: 200 parts of EPDM, 50 parts of polypropylene, 30 parts of linear low density polyethylene, 70 parts of thermoplastic polyurethane elastomer, 10 parts of ethylene-octene copolymer , maleic anhydride grafted EPDM-g-MAH 10 parts, glass microspheres 45 parts, silane coupling agent KH-570 4 parts, crosslinking agent 5 parts, active zinc oxide powder 3 parts, antioxidant 2 parts of agent DSTP, 0.7 parts of dilauryl thiodipropionate DLTP, 2 parts of ultraviolet absorber UV-326, 60 parts of aromatic hydrocarbon oil, 4 parts of zinc stearate;

[0034] Wherein, the EPDM is composed of E-type ethylene-propylene-diene rubber whose third monomer is vinylidene norbornene at 50 wt%, and D-type ethylene-propylene-diene rubber whose third monomer is dicyclopentadiene at 10 wt%. And 40wt% of the third monomer is 1,4-hexadiene H-type EPDM composition;

[0035] The thermopla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com