Preparation method for hyperbranched polyurethane, modified polylactic resin, and preparation method for modified polylactic resin

A technology of hyperbranched polyurethane and polylactic acid resin, applied in the field of biomass materials, can solve the problems of low elongation at break, hindering the development and application of polylactic acid, and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a preparation method of modified polylactic acid resin, which comprises the following steps: under the protection of nitrogen, mix castor oil and diisocyanate in a molar ratio (1-5): 1, heat up to 60-90°C, and react Finally, hyperbranched polyurethane is obtained; polylactic acid and the hyperbranched polyurethane are mixed according to the mass ratio (80-98): (2-20), and the modified polylactic acid resin is obtained after melt blending.

[0029] In the above-mentioned process of preparing modified polylactic acid resin, the present invention first utilizes chemical method to prepare hyperbranched polyurethane, because hyperbranched polyurethane is polymerized by castor oil and diisocyanate, thus it melts and blends with polylactic acid, hyperbranched polyurethane Polyurethane introduces hyperbranched structure, cross-linked structure and a large number of hydrogen bonds into the polylactic acid system, which can effectively improve the comprehen...

Embodiment 1

[0052] (1) Preparation of hyperbranched polyurethane

[0053] Under the protection of nitrogen, mix castor oil and MDI at a molar ratio of 5:1, heat up to 80°C, stir mechanically, and react for 10 hours. After the reaction is complete, dry under reduced pressure for 2 hours to obtain a colorless and transparent viscous liquid that is overrun Polyurethane;

[0054] (2) Hyperbranched Polyurethane Modified Polylactic Acid Resin

[0055] Provide polylactic acid, said polylactic acid has a molecular weight of 90.6kg, a molecular weight distribution width of 1.24, and a melting point of 170.6°C, fully dried;

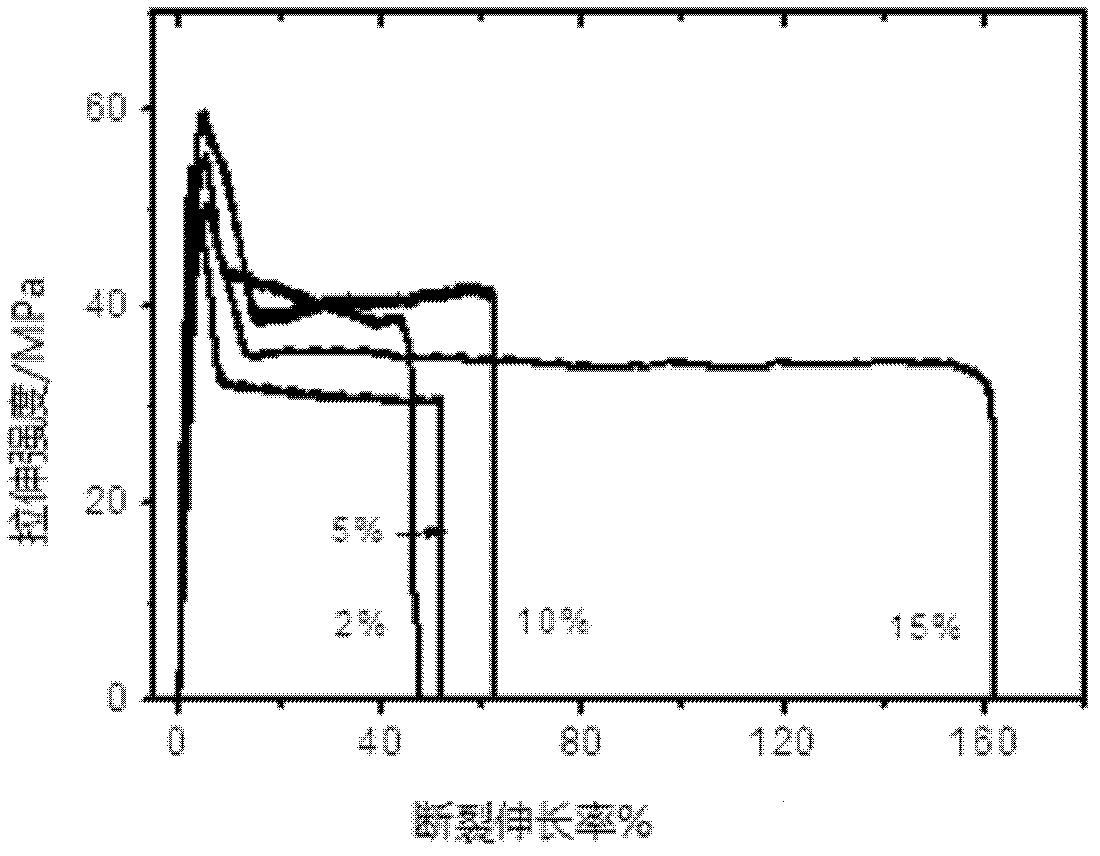

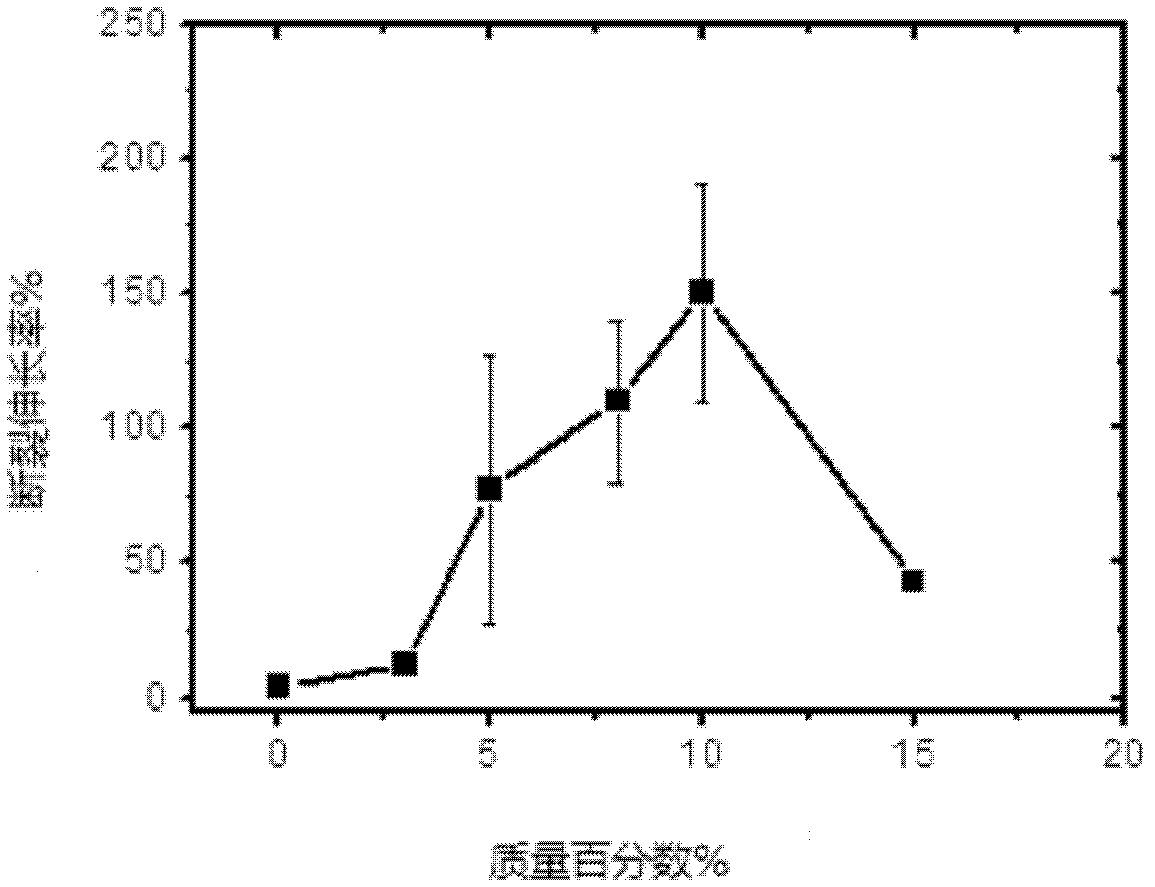

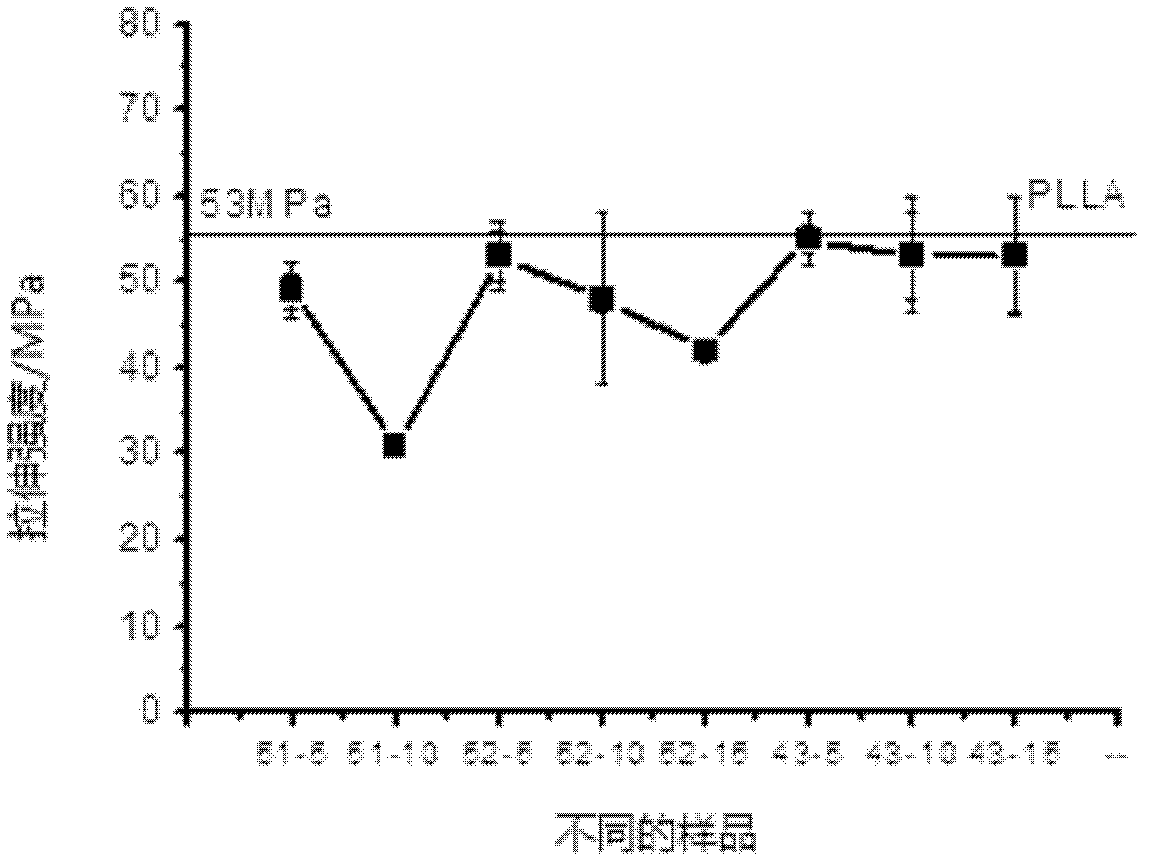

[0056] Polylactic acid is mixed with the hyperbranched polyurethane prepared above, and the addition ratio (mass ratio) of the hyperbranched polyurethane is controlled to be 2%, 5%, and 10% respectively, that is, polylactic acid 98%, hyperbranched polyurethane 2%; polylactic acid 95%, hyperbranched polyurethane 5%; polylactic acid 90%, hyperbranched polyurethane 10%; the mix...

Embodiment 2

[0061] (1) Preparation of hyperbranched polyurethane

[0062] Under nitrogen protection, mix castor oil and MDI at a molar ratio of 5:2, heat up to 85°C, stir mechanically, and react for 20 hours. After the reaction is complete, dry under reduced pressure for 2 hours to obtain a colorless and transparent viscous liquid that is overrun Polyurethane;

[0063] (2) Hyperbranched Polyurethane Modified Polylactic Acid Resin

[0064] Provide polylactic acid, said polylactic acid has a molecular weight of 90.6kg, a molecular weight distribution width of 1.24, and a melting point of 170.6°C, fully dried;

[0065] Polylactic acid is mixed with the hyperbranched polyurethane prepared above, and the addition ratio (mass ratio) of the hyperbranched polyurethane is controlled to be 5%, 10%, and 15% respectively, that is, polylactic acid 95%, hyperbranched polyurethane 5%; polylactic acid 90%, hyperbranched polyurethane 10%; polylactic acid 85%, hyperbranched polyurethane 15%;

[0066] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com