Polyethylene tubing resin composition

A resin composition, polyethylene pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of destroying the ESCR performance of the resin, difficult to control the processing process, and adding a large amount of cross-linking agent. Avoid migration and precipitation problems, good environmental stress crack resistance, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

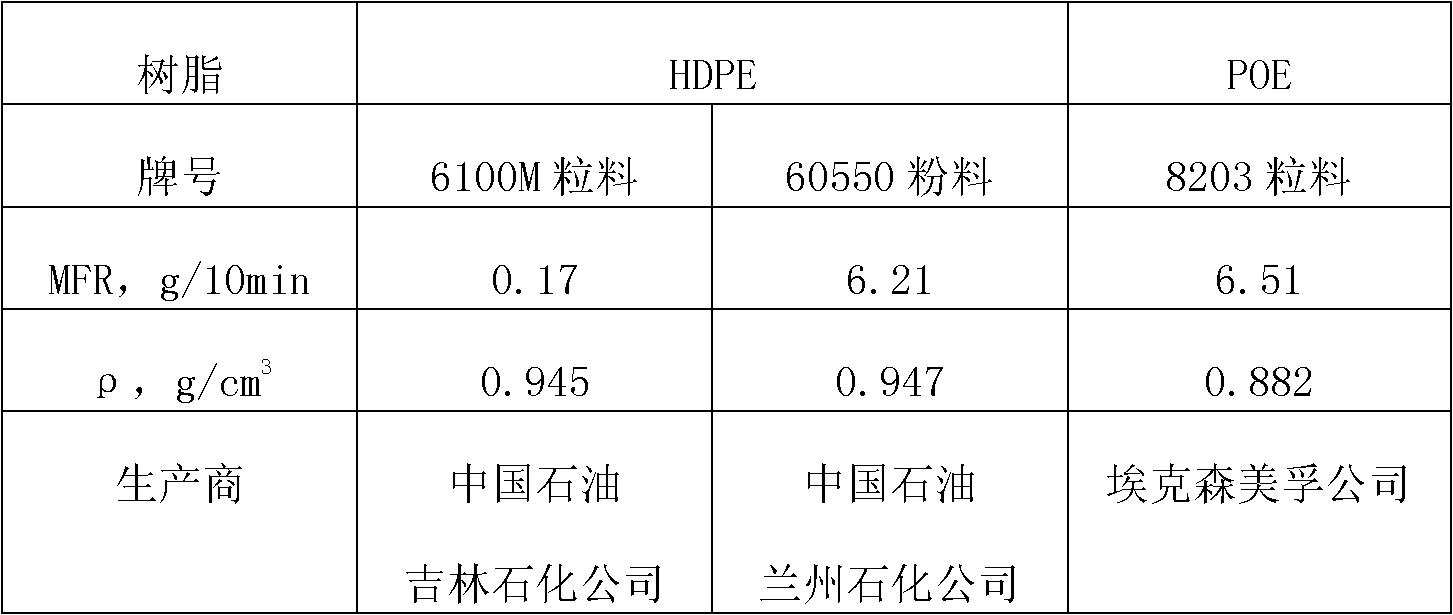

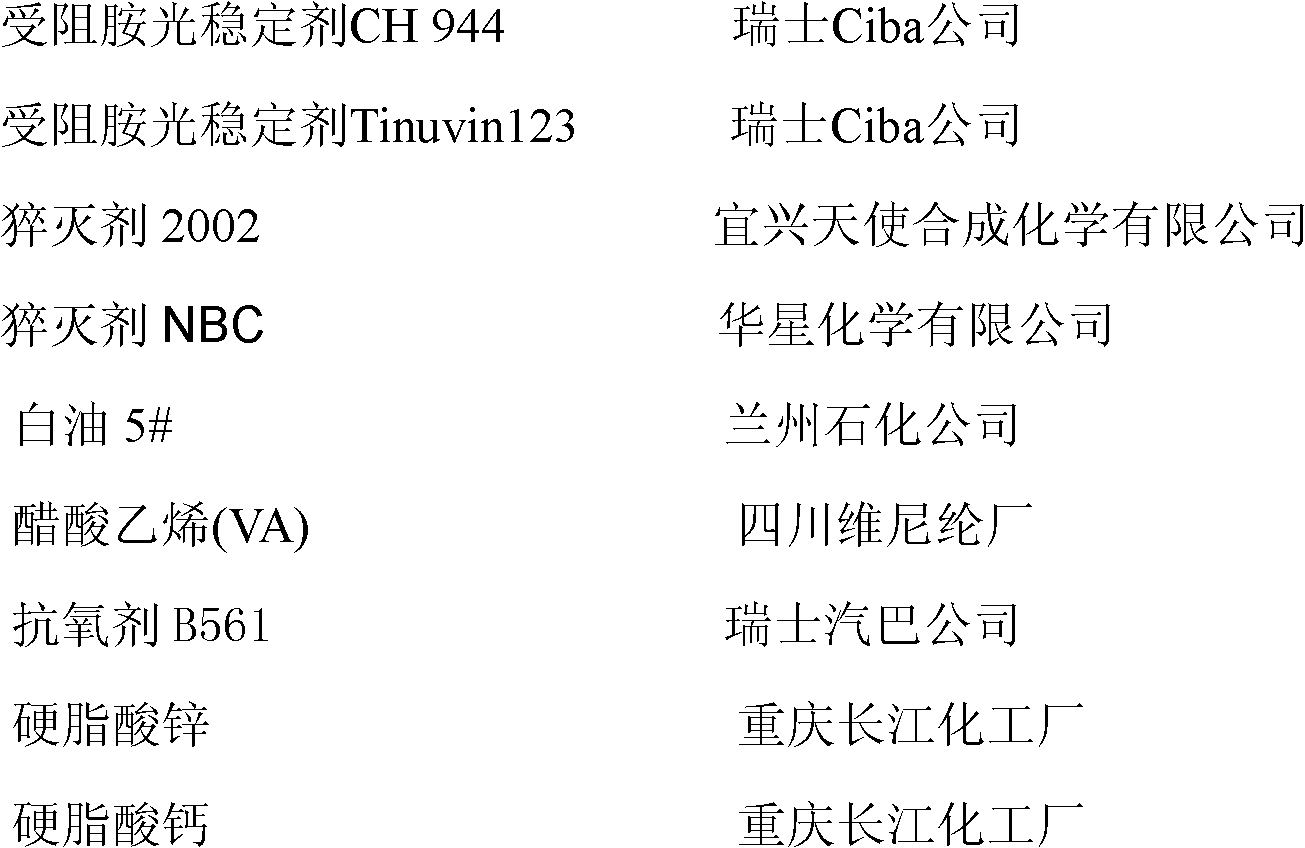

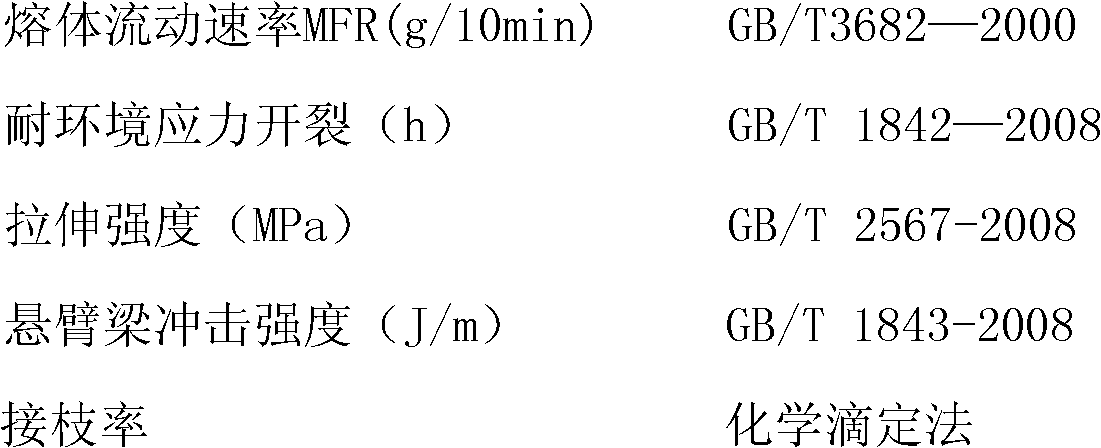

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of POE-g-VA graft: According to the weight percentage of POE, mix 3.5 parts of vinyl acetate (VA) with 100 parts of POE at high speed for 6 minutes, and place the mixed material in a closed container for 10 hours ; Then get 0.03 part of BPDH and 0.3 part of acetone and put it into a beaker and mix it, then put the mixed solution and placed mixed material, 0.15 part of antioxidant 1010, and 0.15 part of calcium stearate together into a 10L high-speed mixer Medium and high speed mixing for 5 minutes; finally, add the mixed material into the Φ67 twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 160, 170, 180, 190, 200, 190, 180, 175, 170 Carry out melt grafting reaction, after reacting for 7 minutes, extrude, cool and granulate to obtain POE-g-VA graft (grafting rate: 1.8%).

[0047] (2) Preparation of POE weather-resistant masterbatch: According to the weight percentage of POE, 100 parts of POE and 6 parts of POE-g-VA graf...

Embodiment 2

[0050] (1) The preparation of the POE-g-VA graft is completely the same as in Example 1.

[0051] (2) The preparation of POE weather-resistant masterbatch is completely the same as that of Example 1.

[0052] (3) Preparation of polyethylene pipe resin composition: after mixing 0.003 part of BPO and 0.06 part of TBHP with 0.2 part of acetone solvent, then add 5 parts of HDPE (6100M) granular resin, mix in 10 liters of high-speed mixer for 3 minutes, Make a premixed masterbatch; take out 12 parts of POE weather-resistant masterbatch a and premixed masterbatch, 95 parts of HDPE (6100M) resin, 0.15 parts of antioxidant B561, 0.2 parts of zinc stearate and add them to Φ67 double In the screw extruder, the reaction temperature (°C) of each section of the screw is: 170, 180, 190, 195, 200, 210, 210, 200, 190; after 3 minutes of reaction, extrusion, cooling, granulation, and preparation of polymer Vinyl pipe resin composition. The composition is made into a standard sample by inject...

Embodiment 3

[0054] (1) The preparation of the POE-g-VA graft is completely the same as in Example 1.

[0055] (2) The preparation of POE weather-resistant masterbatch is completely the same as that of Example 1.

[0056] (3) Preparation of polyethylene pipe resin composition: after mixing 0.004 part of BPO and 0.07 part of TBHP with 0.2 part of acetone solvent, then add 5 parts of HDPE (6100M) granular resin, mix in 10 liters of high-speed mixer for 3 minutes, Make a premixed masterbatch; take out 14 parts of POE weather-resistant masterbatch a, premixed masterbatch, 95 parts of HDPE (6100M) resin, 0.15 parts of antioxidant B561, and 0.2 parts of zinc stearate and add them to Φ67 double In the screw extruder, the reaction temperature (°C) of each section of the screw is: 170, 180, 190, 195, 200, 210, 210, 200, 190; after 3 minutes of reaction, extrusion, cooling, granulation, and preparation of polymer Vinyl pipe resin composition. The composition is made into a standard sample by injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com