A kind of polyethylene resin composition for pipe material

A technology of polyethylene resin and resin composition, applied in the field of resin composition for pipes, can solve the problems of inability to price and grade, limit the scope of use, complicated technology, etc., and achieve improved compatibility, improved dispersion effect, and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

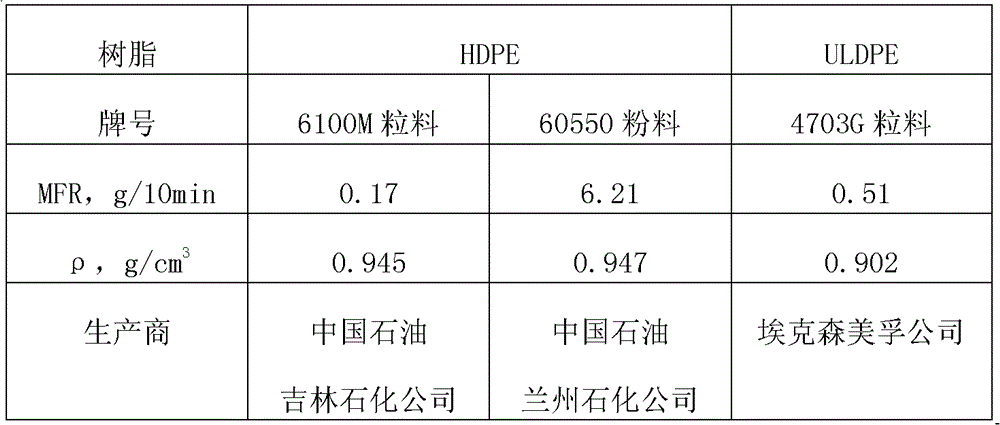

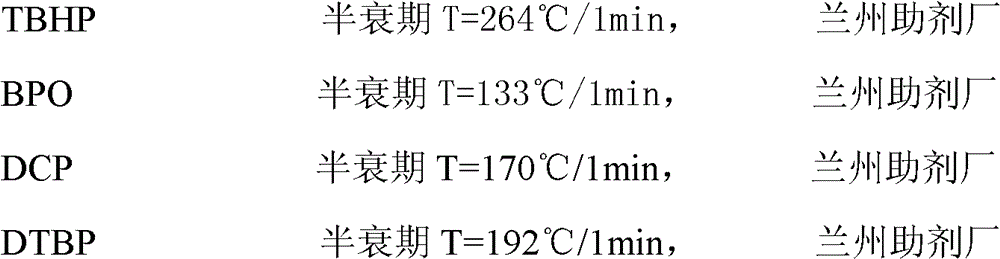

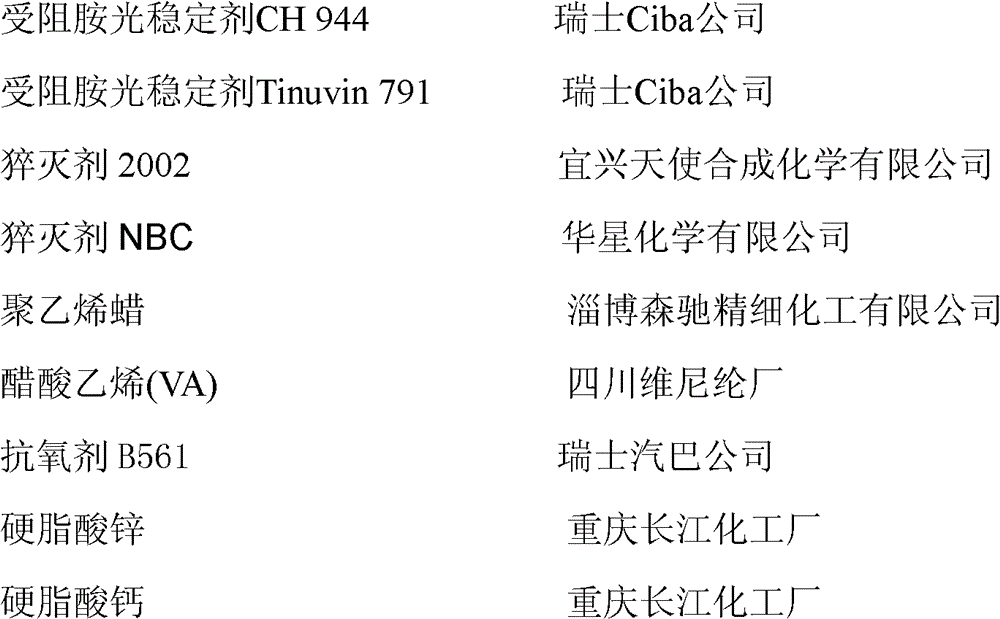

[0044] (1) Preparation of ULDPE-g-VA graft: According to the weight percentage of ULDPE, 7 parts of vinyl acetate (VA) and 100 parts of ULDPE (4703G) were mixed at high speed for 7 minutes, and the mixed materials were placed in an airtight container Place in the middle for 10hr; then take 0.03 parts of DCP and 0.3 parts of acetone and mix them in a beaker, then put the mixed solution and the placed mixed material, 0.15 parts of antioxidant 1010, and 0.15 parts of calcium stearate into 10L In the high-speed mixer, mix at high speed for 5 minutes; finally, add the mixed material into the Φ67 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 160, 170, 180, 190, 200, 190, 180, 175, 170; carry out melt grafting reaction, after reacting for 7 minutes, extrude, cool, and granulate to obtain ULDPE-g-VA graft (grafting rate: 3.1%).

[0045] (2) Preparation of ULDPE weather-resistant masterbatch: according to the weight percentage of ULDPE, 100 par...

Embodiment 2

[0048] (1) The preparation of the ULDPE-g-VA graft is completely the same as in Example 1.

[0049] (2) The preparation of ULDPE weather-resistant masterbatch is completely identical with embodiment 1.

[0050] (3) Preparation of polyethylene pipe resin composition: after mixing 0.003 part of BPO and 0.06 part of TBHP with 0.2 part of acetone solvent, then add 5 parts of HDPE (6100M) granular resin, mix in 10 liters of high-speed mixer for 3 minutes, Make a premixed masterbatch; take out 16 parts of ULDPE weather-resistant masterbatch a and premixed masterbatch, 95 parts of HDPE (6100M) resin, 0.15 parts of antioxidant B561, 0.2 parts of zinc stearate and add them to Φ67 double In the screw extruder, the reaction temperature (℃) of each section of the screw is: 160, 170, 180, 190, 200, 210, 220, 200, 190; Vinyl pipe resin composition. The composition is made into a standard sample by injection method, and the tested properties are shown in Table 1.

Embodiment 3

[0052] (1) The preparation of the ULDPE-g-VA graft is completely the same as in Example 1.

[0053] (2) The preparation of ULDPE weather-resistant masterbatch is completely identical with embodiment 1.

[0054] (3) Preparation of polyethylene pipe resin composition: after mixing 0.004 part of BPO and 0.07 part of TBHP with 0.2 part of acetone solvent, then add 5 parts of HDPE (6100M) granular resin, mix in 10 liters of high-speed mixer for 3 minutes, Make a premixed masterbatch; take out 20 parts of ULDPE weather-resistant masterbatch a and premixed masterbatch, 95 parts of HDPE (6100M) resin, 0.15 parts of antioxidant B561, 0.2 parts of zinc stearate and add them to Φ67 double In the screw extruder, the reaction temperature (℃) of each section of the screw is: 160, 170, 180, 190, 200, 210, 220, 200, 190; Vinyl pipe resin composition. The composition is made into a standard sample by injection method, and the tested properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com