Polyethylene modified material used for honeycomb restraint system

A polyethylene modification and restraint system technology, applied in the field of polyethylene modified materials, can solve the problems of reduced elongation and increased brittleness, and achieve the effects of improving tensile strength, improving impact strength and reducing negative stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

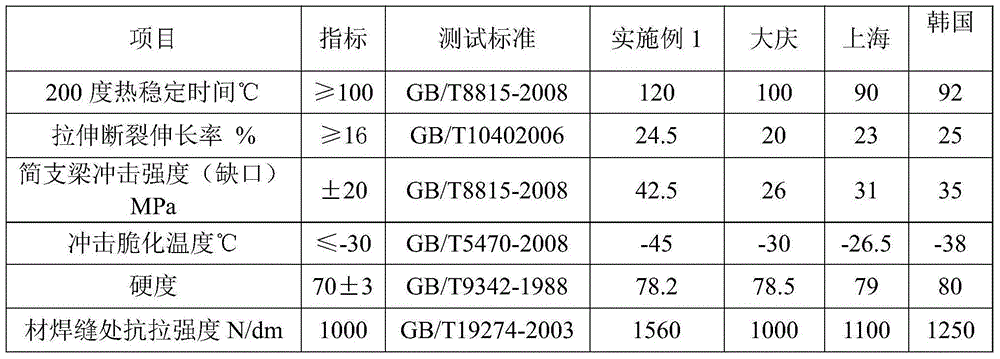

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: This embodiment is a polyethylene modified material used in a honeycomb restraint system prepared from A component, B component, lubricant B and surfactant; the A group described in step three The mass ratio of component B to component B is 75:25; the mass ratio of component A to lubricant B described in step 3 is 75:(1~3); the component A and surface active component described in step 3 The mass ratio of the agent is 75:(5~10);

[0015] The A component is prepared according to the following steps: 20-70 parts of HDPE resin, 6-10 parts of low-temperature toughening modifier, 0.2-0.4 part of antioxidant, 0.9-1.3 parts of cross-linking modifier and 1- Mix the 3 parts of lubricant evenly to obtain the mixture A, transfer the mixture A to the mixer for kneading, the kneading temperature is 140-180°C, the kneading time is 5min-20min, and the A component is obtained;

[0016] The B component is prepared according to the following steps: 8-15 parts of L...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the A component is prepared according to the following steps: 60-70 parts of HDPE resin, 9-10 parts of low-temperature toughening modifier, 0.2- Mix 0.3 parts of antioxidant, 0.9-1.3 parts of cross-linking modifier and 1-3 parts of lubricant A evenly to obtain mixture A, transfer mixture A to a mixer for kneading, and the kneading temperature is 140-180°C, The mixing time is 5min to 20min to obtain component A. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the HDPE resin has a fluid flow rate of 7.98g / 10min -1 of high-density polyethylene. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com