Patents

Literature

78results about How to "Reduce the risk of delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

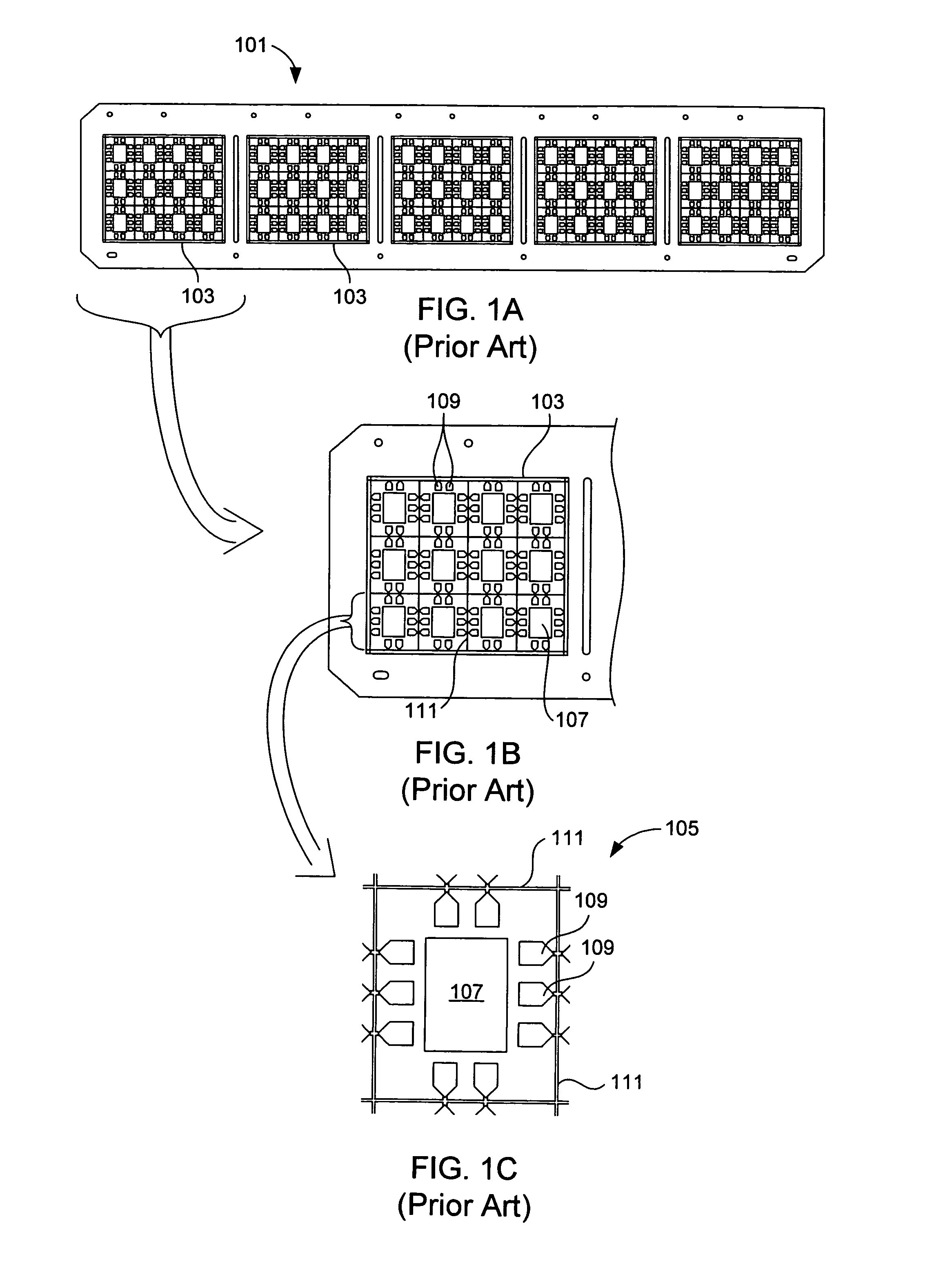

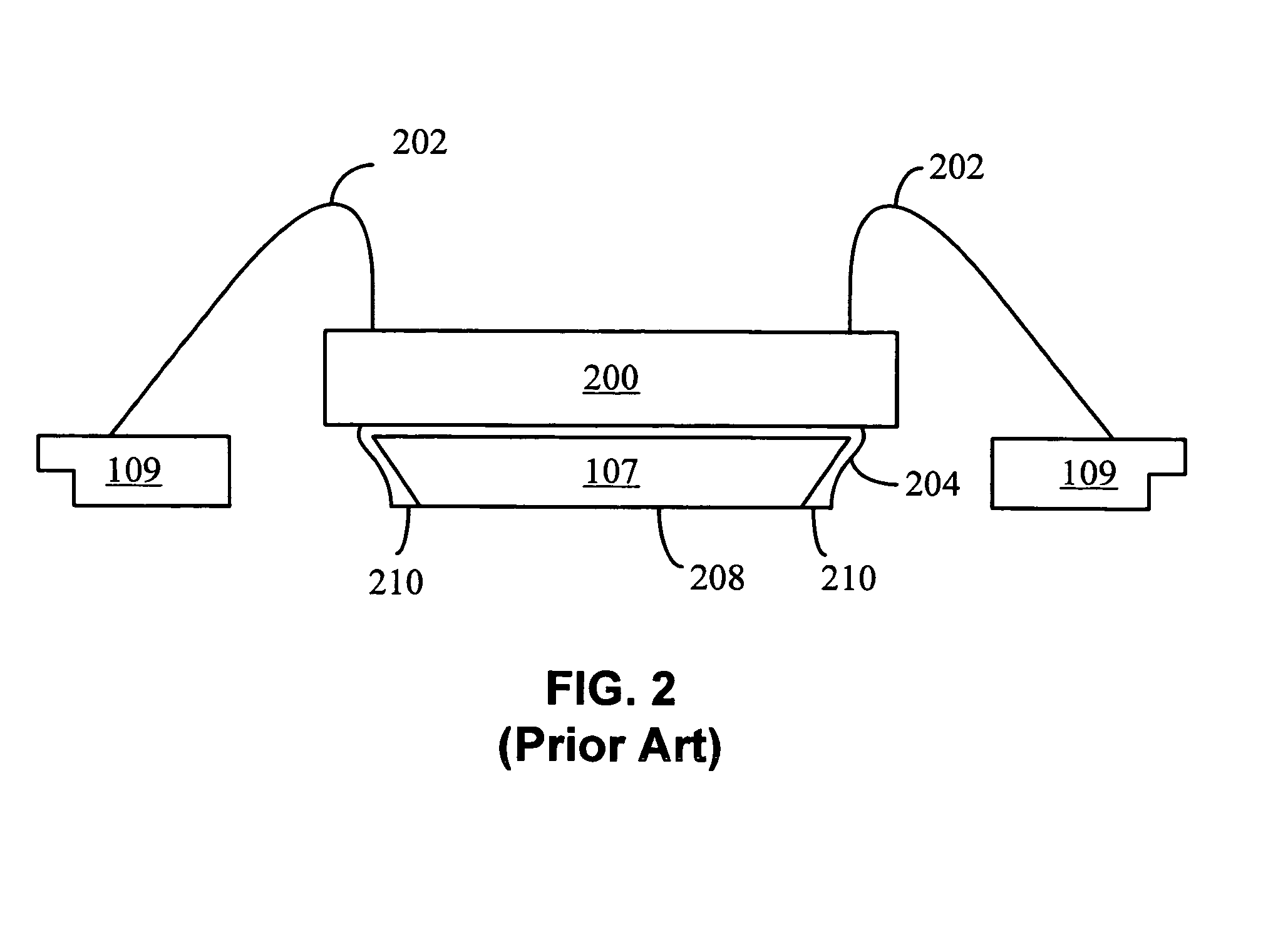

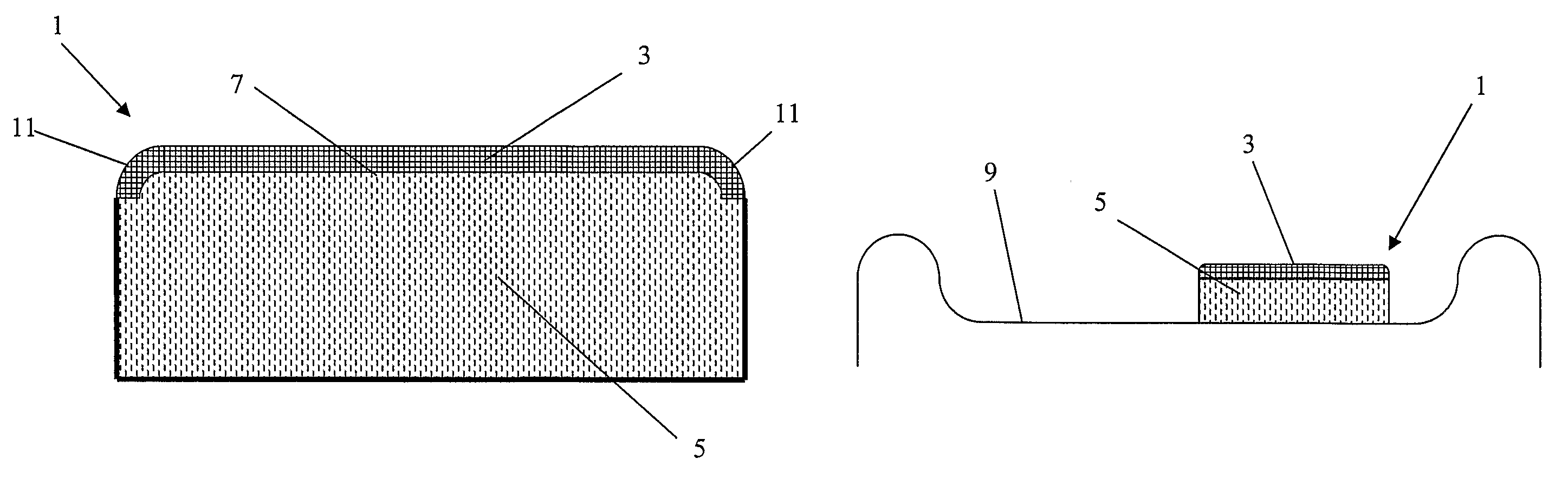

Die attach pad for use in semiconductor manufacturing and method of making same

ActiveUS7227245B1Reduce riskReduce die areaSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

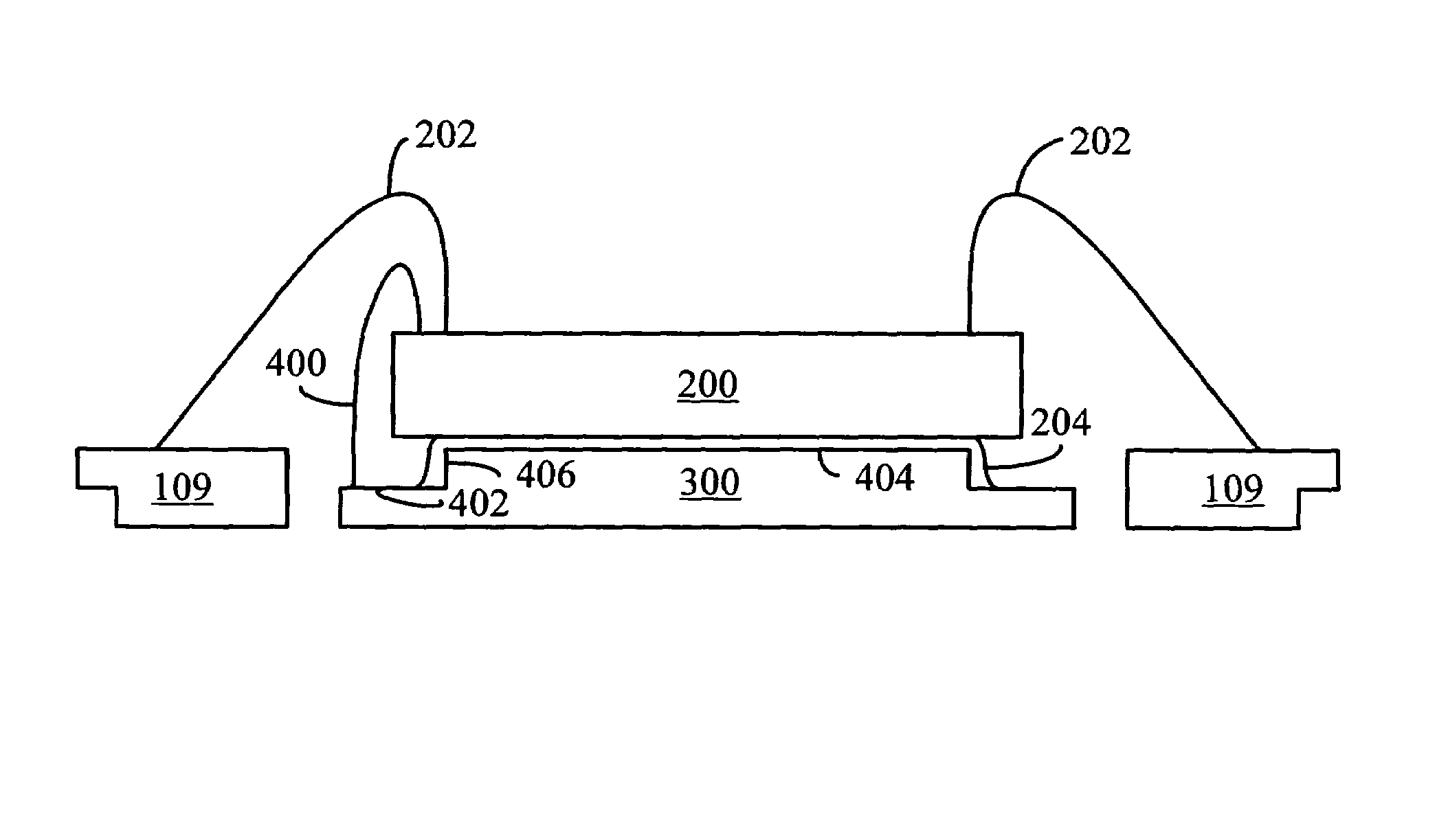

Broadly speaking, the invention pertains to substrates for use in semiconductor manufacturing. A peripheral ledge or similar structure can be provided in a die attach pad, so as to retain adhesive that may flow from the die support surface when the die is attached to the die attach pad. In this manner, adhesive is prevented from flowing off the die attach pad, where it can create unwanted conductive areas on the outer surface of an IC package. The accompanying reduction in area of the die support surface, and retention of adhesive from any downbond areas, also prevents delamination of the adhesive.

Owner:NAT SEMICON CORP

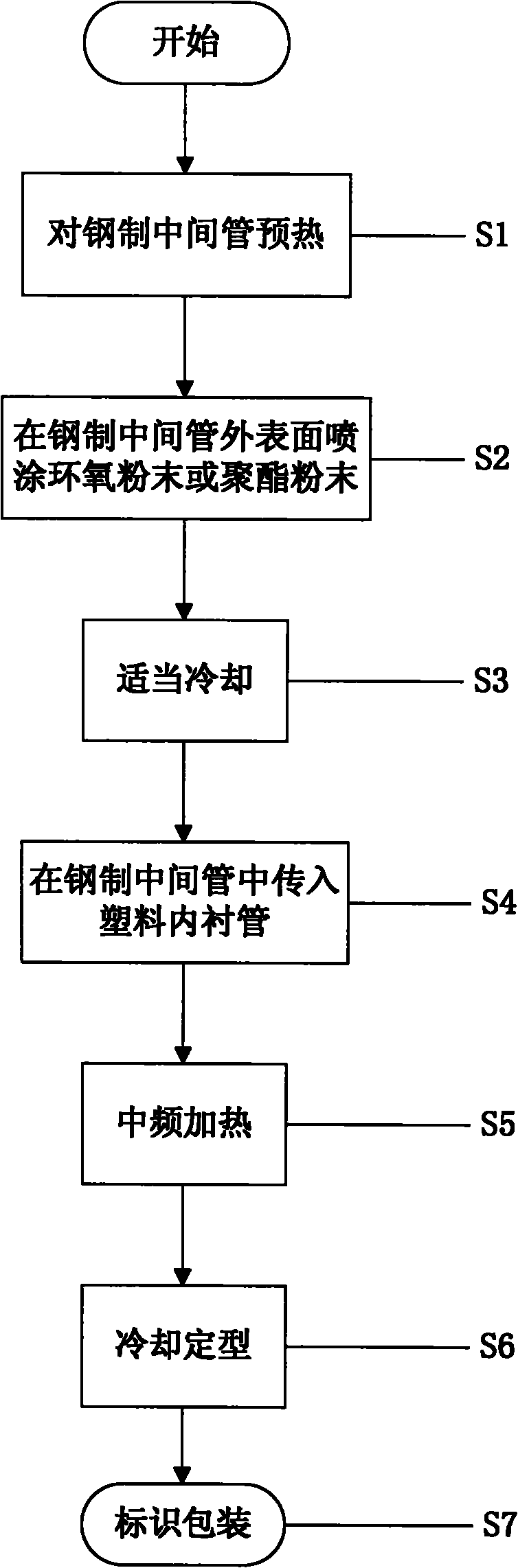

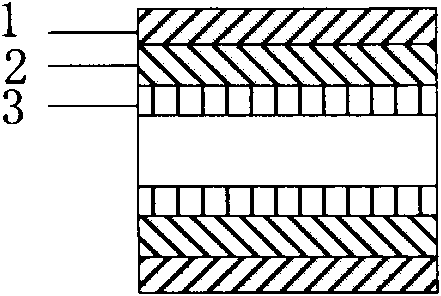

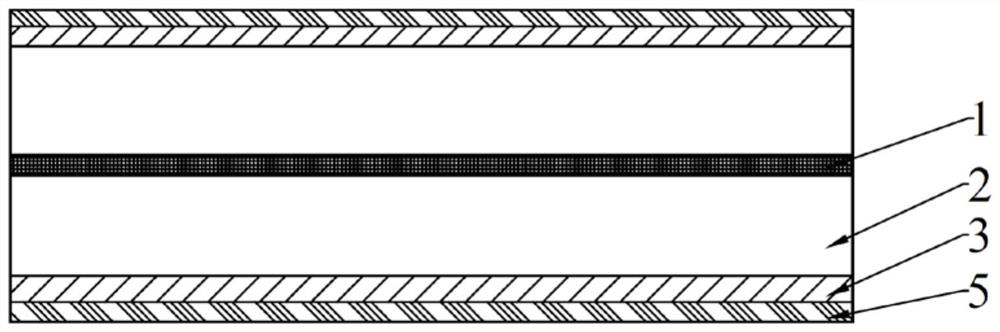

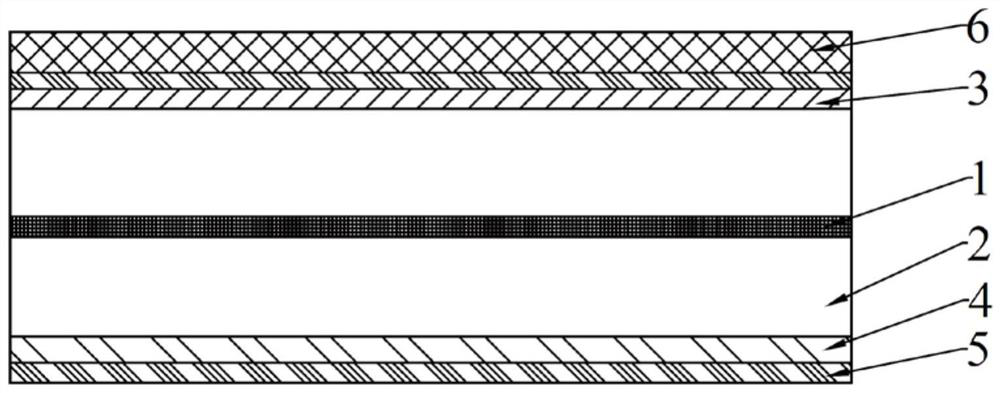

Plastic-lined steel plastic composite tube and manufacturing method thereof

The invention relates to the field of a steel plastic tube, in particular to a plastic-lined steel plastic composite tube and a manufacturing method thereof. The plastic-lined steel plastic composite tube comprises a plastic lining tube and a steel intermediate tube, wherein the outer of the steel intermediate tube is coated with outer paint of epoxy or polyester materials. Because of internal plastic lining and external plastic coating, the steel plastic tube makes full use of inlayer corrosion protection and rust protection of the plastic lining and favorable aging, functionalization (e.g. flame retardance and the like) and other properties of the external plastic coating, thereby improving the respective defects caused by single plastic lining and single plastic coating.

Owner:GUANGDONG LIANSU TECH INDAL

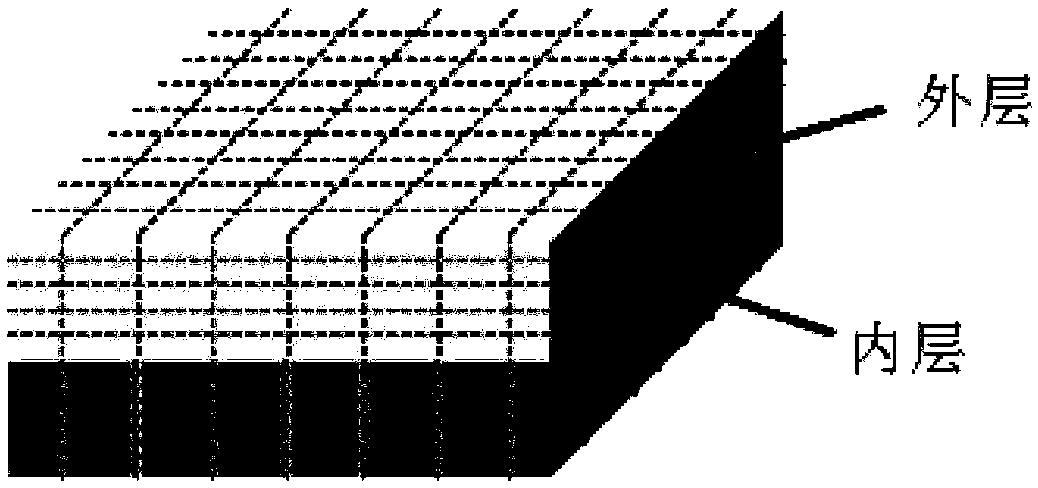

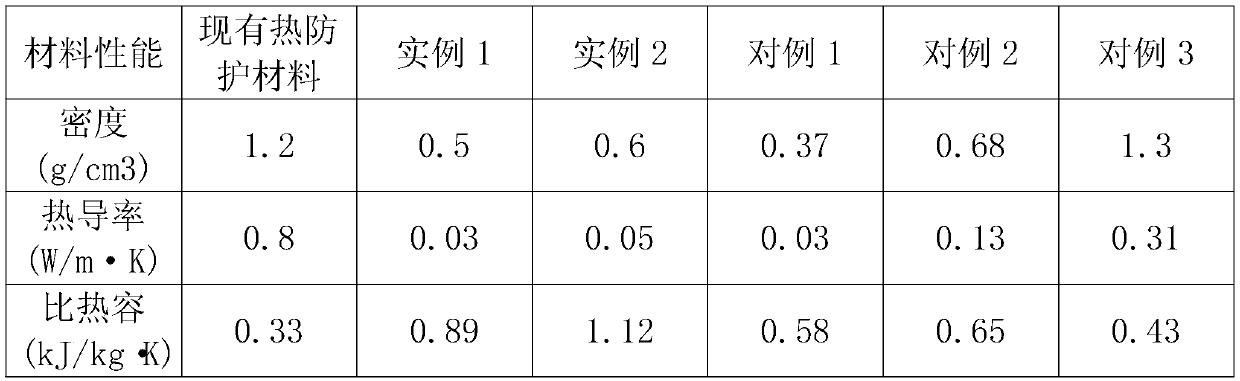

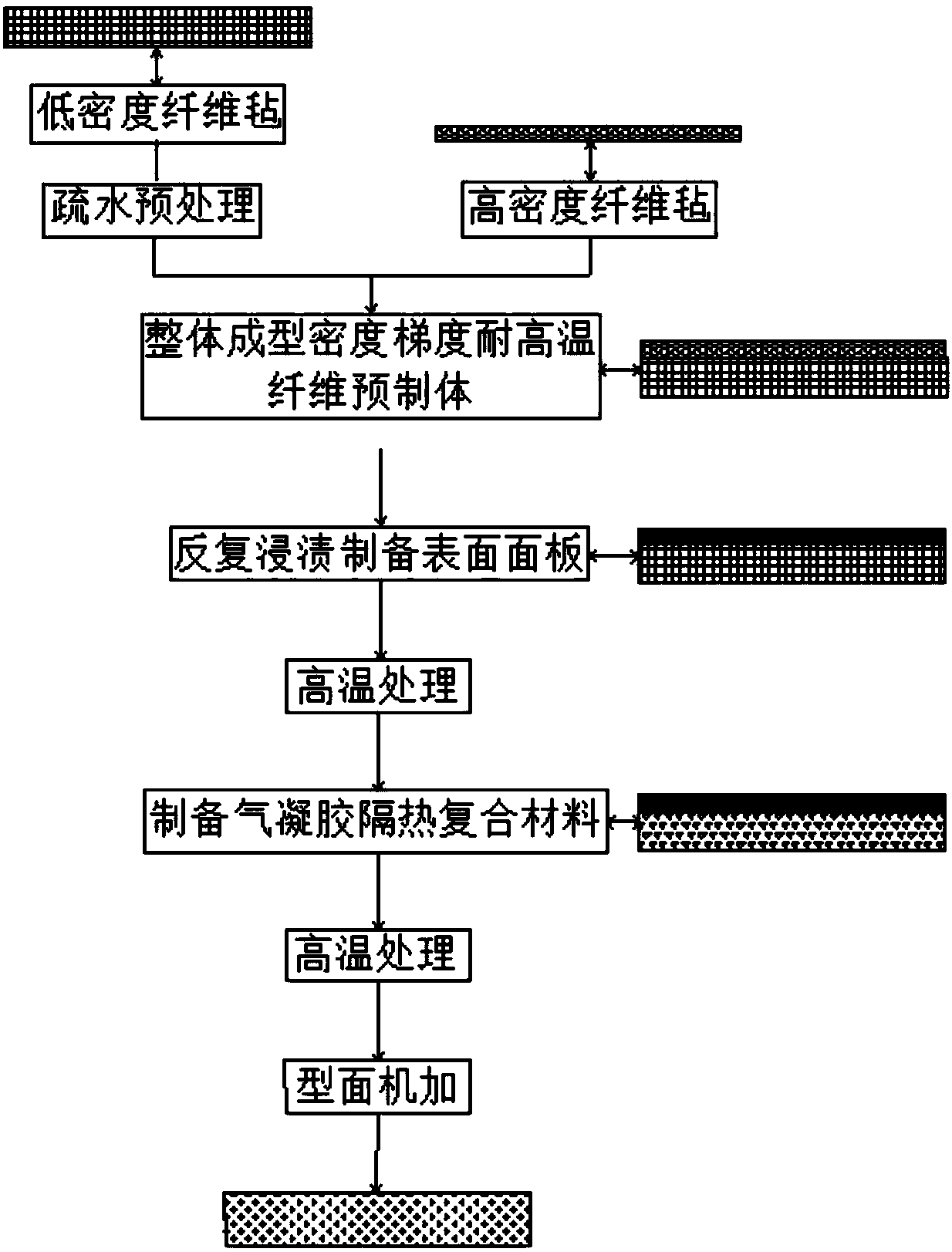

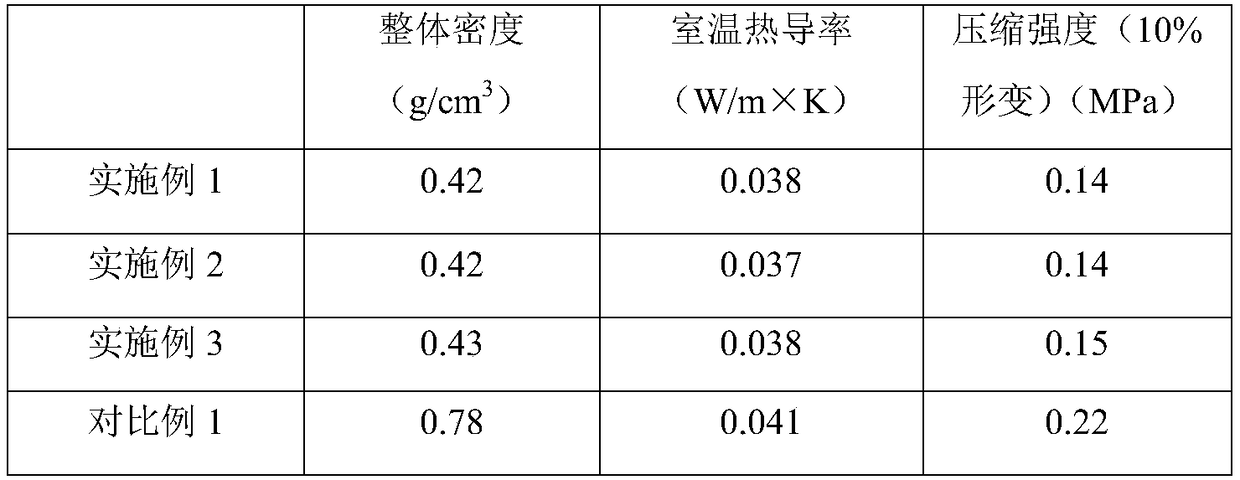

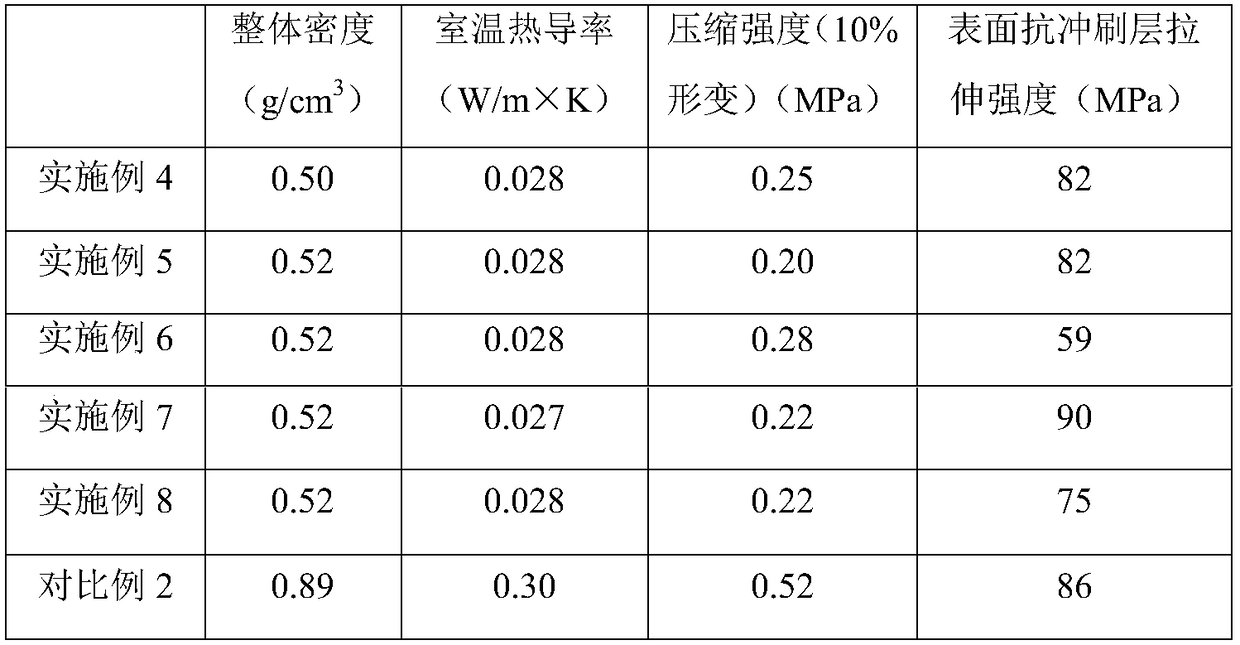

Integrated density gradient thermal protection material and preparation method thereof

ActiveCN111331941AGuaranteed insulation effectLow costSynthetic resin layered productsThermal protectionFiber reinforcement

The invention provides an integrated density gradient thermal protection material and a preparation method thereof. The thermal protection material comprises a matrix and a reinforcement body, whereinthe matrix is of a network-shaped porous resin structure; the reinforcement body comprises a fiber reinforcement body inner layer with a second volume density and a fiber reinforcement body outer layer with a first volume density arranged on the inner layer; a network-shaped porous structure is further dispersed and cured in the fiber reinforcement body outer layer and the fiber reinforcement body inner layer, and the first volume density is 0.5-2.0 g / cm<3>; and the second volume density is 0.05-0.4 g / cm<3>. The method comprises the following steps: preparing the reinforcement body; preparinga solution of a matrix raw material; injecting the solution into the reinforcement body to enable the reinforcement body to fully infiltrate the solution; and curing at a resin curing temperature. The technical problems that an outer heat-proof layer of an existing heat-proof material is prone to oxidation and cannot be used for a long time, an inner heat-insulating layer is long in forming process period and high in cost, and the overall heat-proof effect is poor due to a preparation method can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

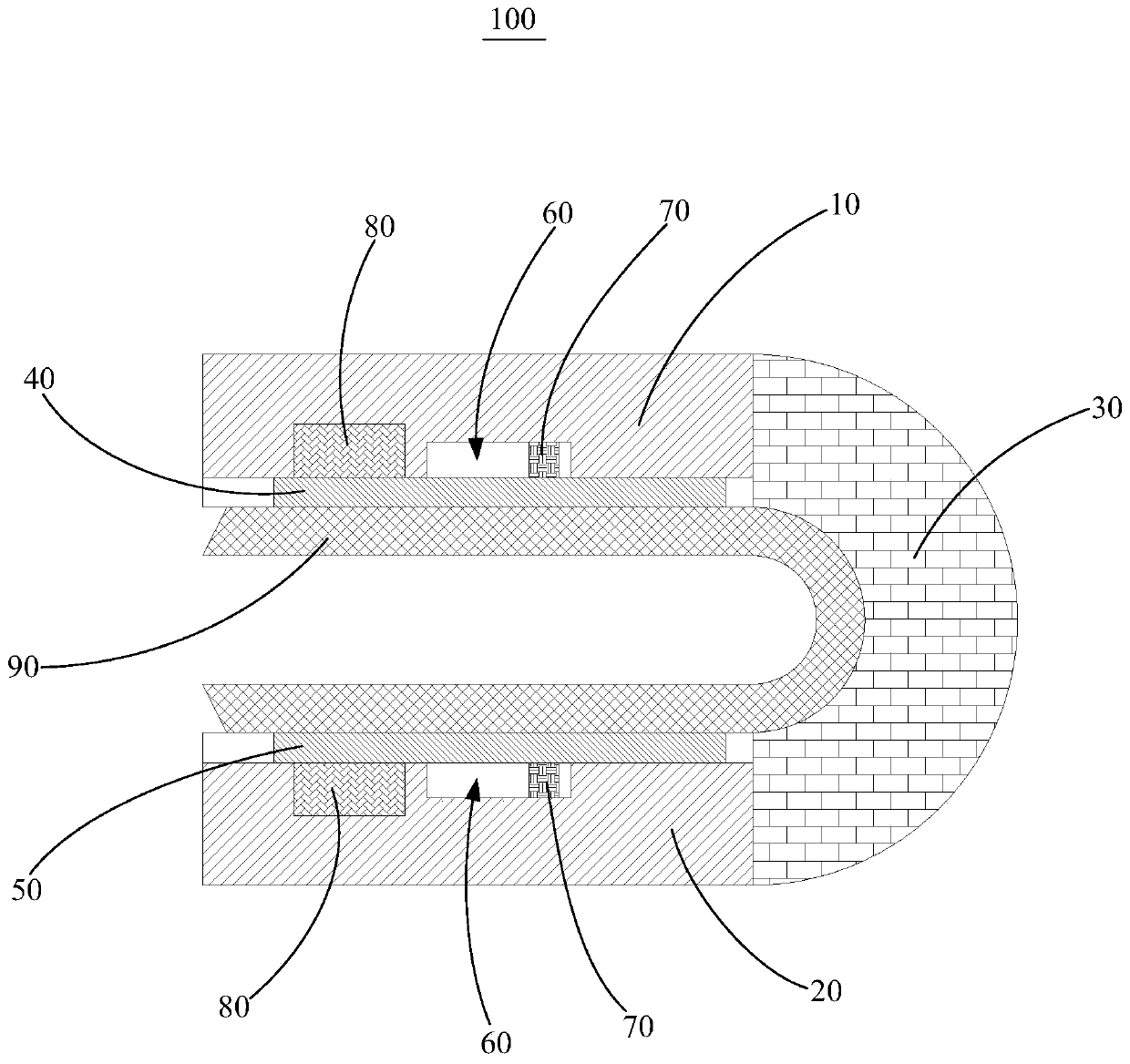

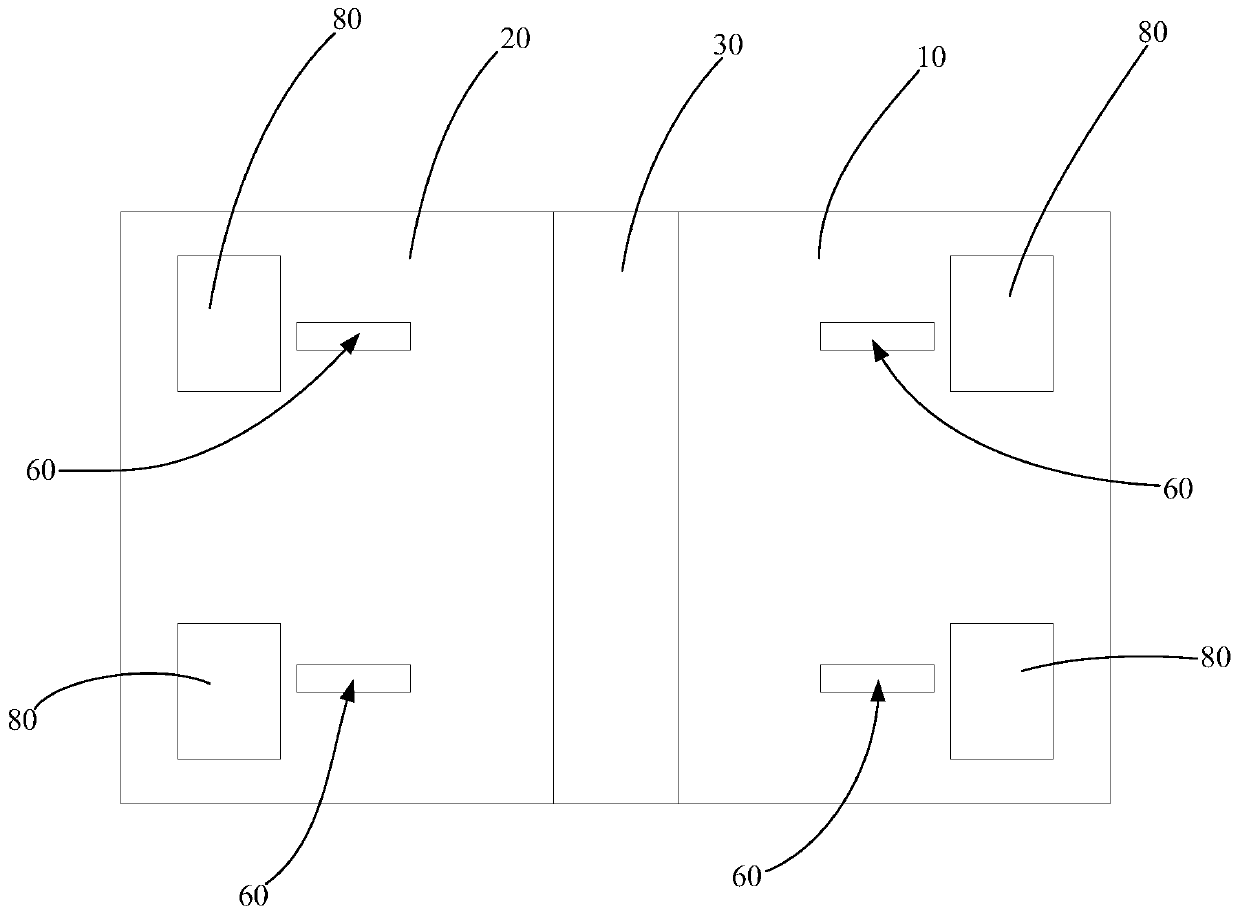

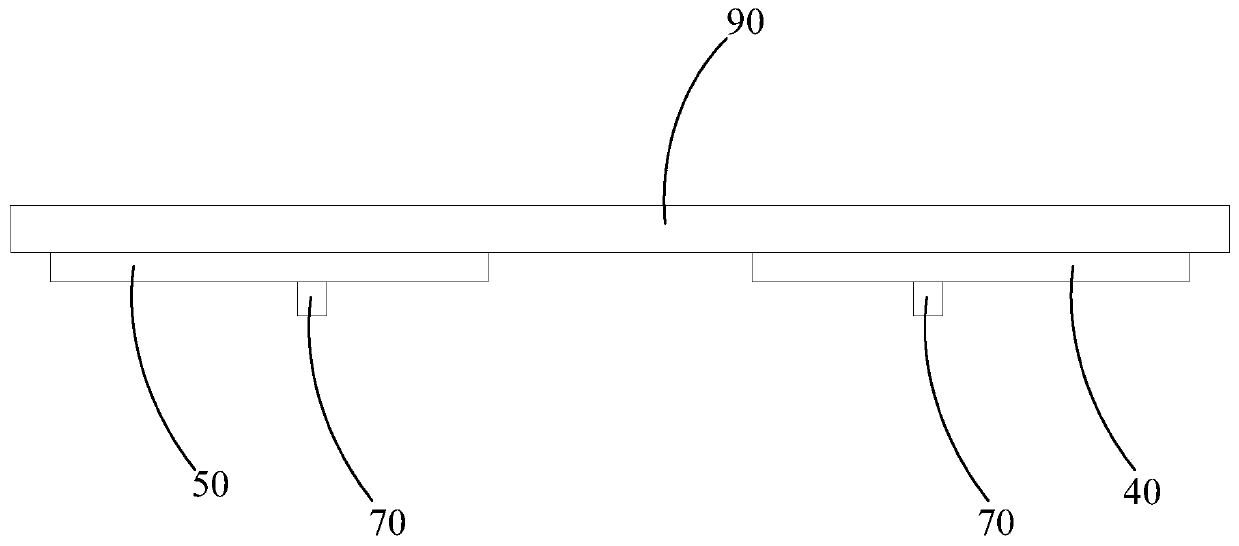

Shell assembly and foldable electronic device

ActiveCN110913628AAvoid stretching outwardsAvoid deformationCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringMechanical engineering

The invention discloses a shell assembly and a foldable electronic device. The shell assembly includes: a first shell; a second shell, arranged side by side at an interval with the first shell; a bending part, arranged between the first shell and the second shell and being provided with a first side edge and a second side edge which are arranged back to back, the first side edge facing the first shell and being connected with the first shell, and the second side edge facing the second shell and being connected with the second shell; a first supporting sheet, the first shell being provided witha first mounting surface, and the first supporting sheet being opposite to the first mounting surface and being connected to the first shell in a sliding manner; a second shell, provided with a second mounting surface which is opposite to or opposite to the first mounting surface when the second shell is folded in the first shell, and the second supporting sheet being opposite to the second mounting surface and is connected to the second shell in a sliding manner. The first supporting piece and the second supporting piece slide towards the bent part at the same time or deviate from the bent part at the same time. The layering risk of the flexible screen can be reduced, and the service life of the flexible screen is prolonged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

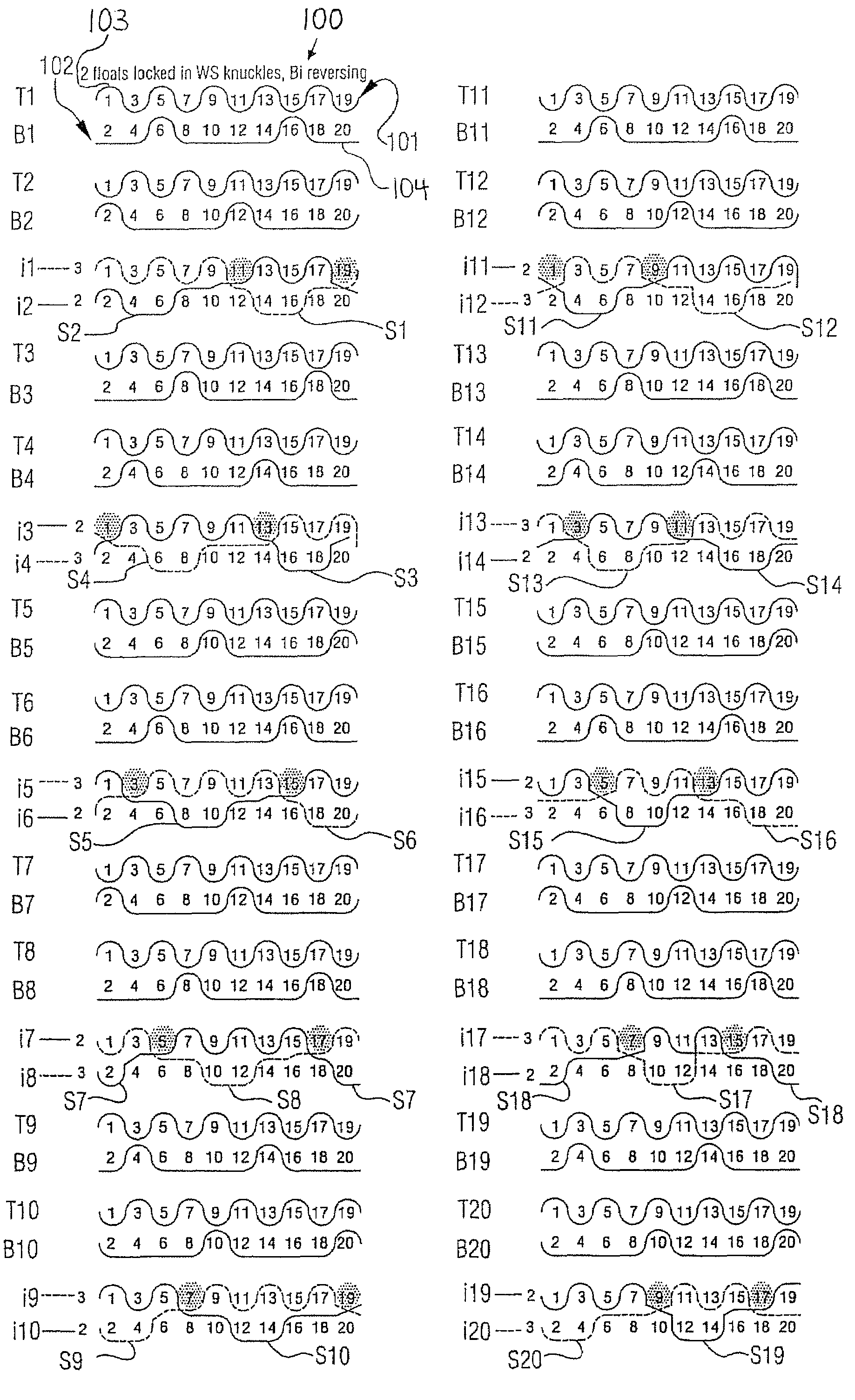

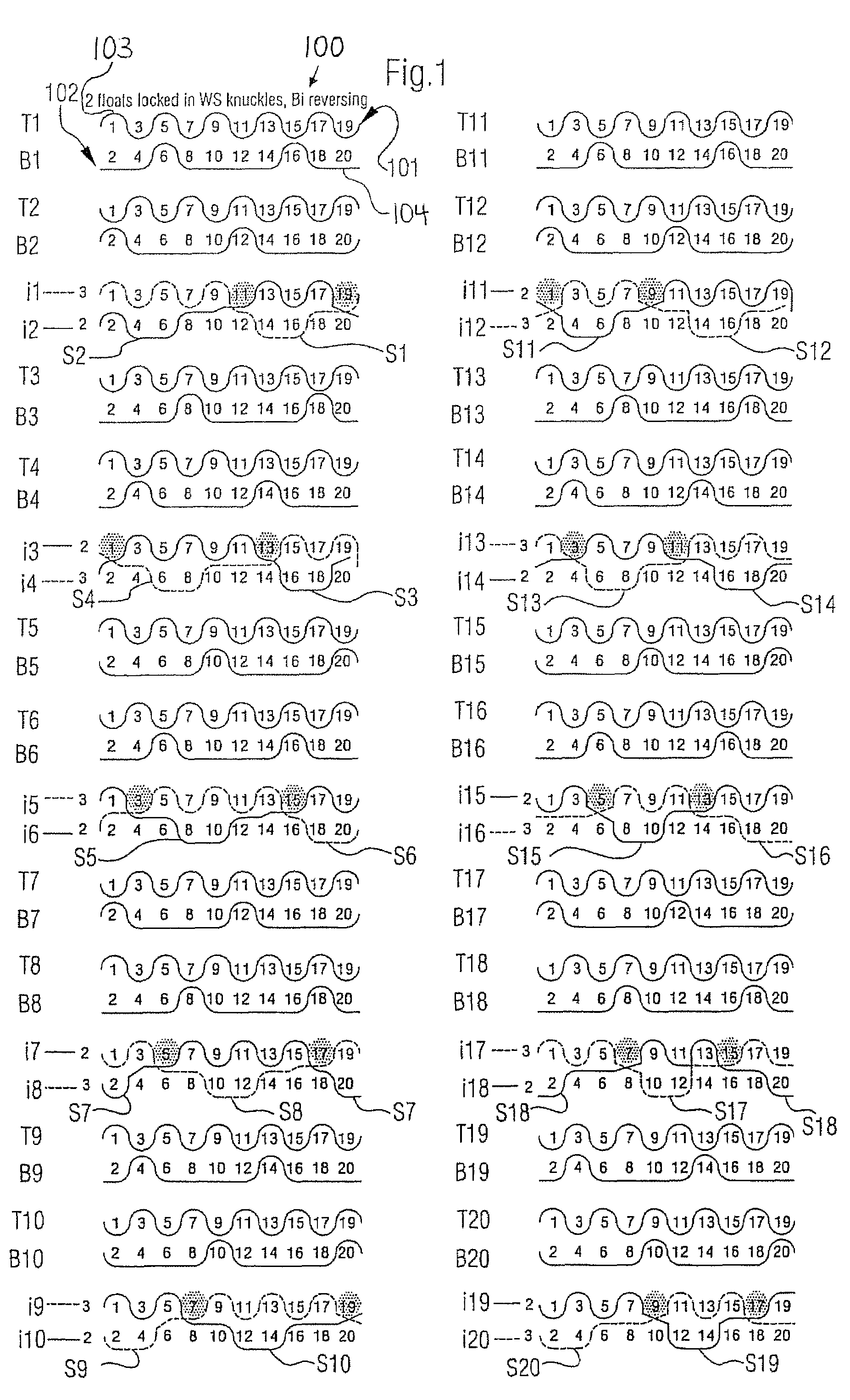

Forming mesh

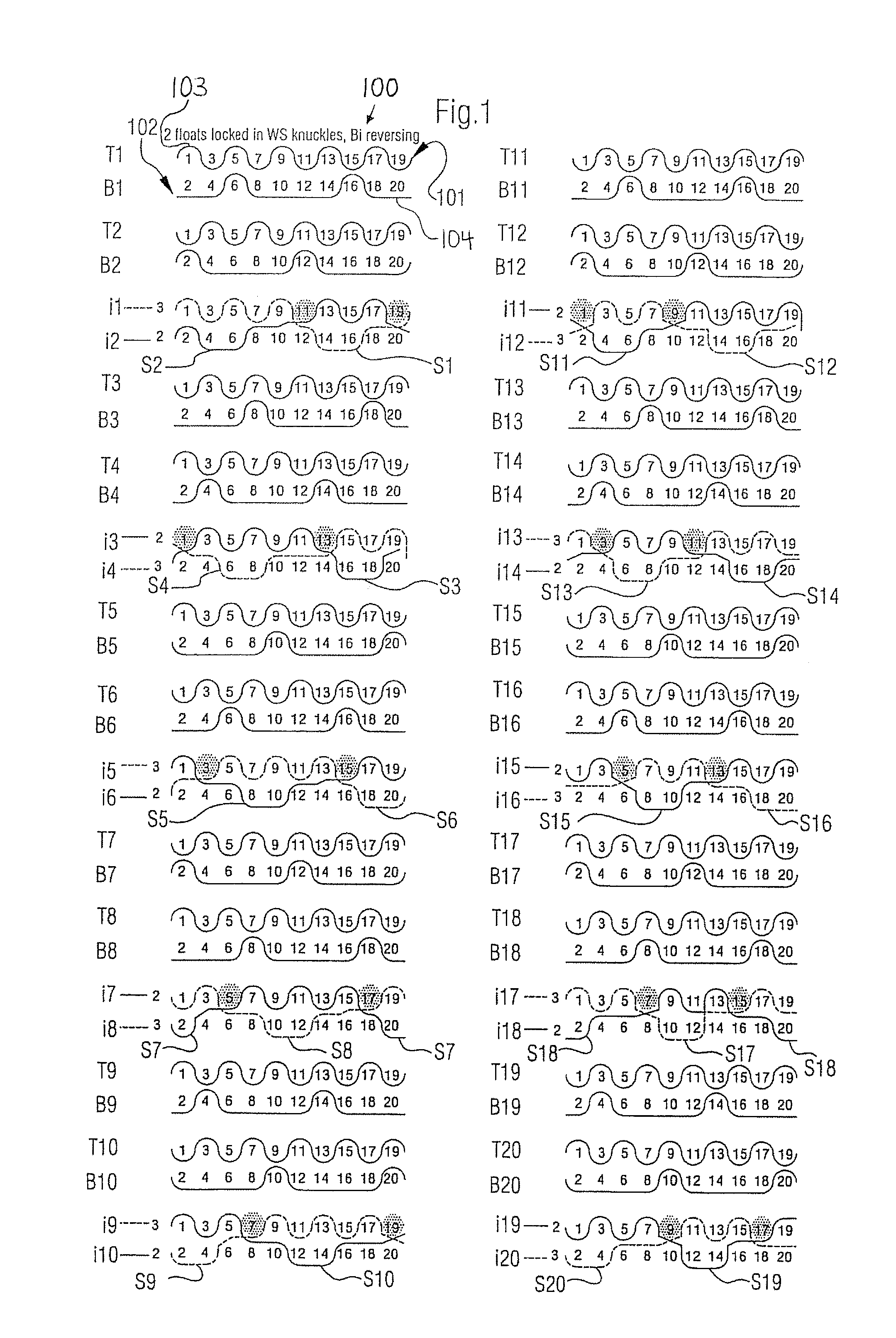

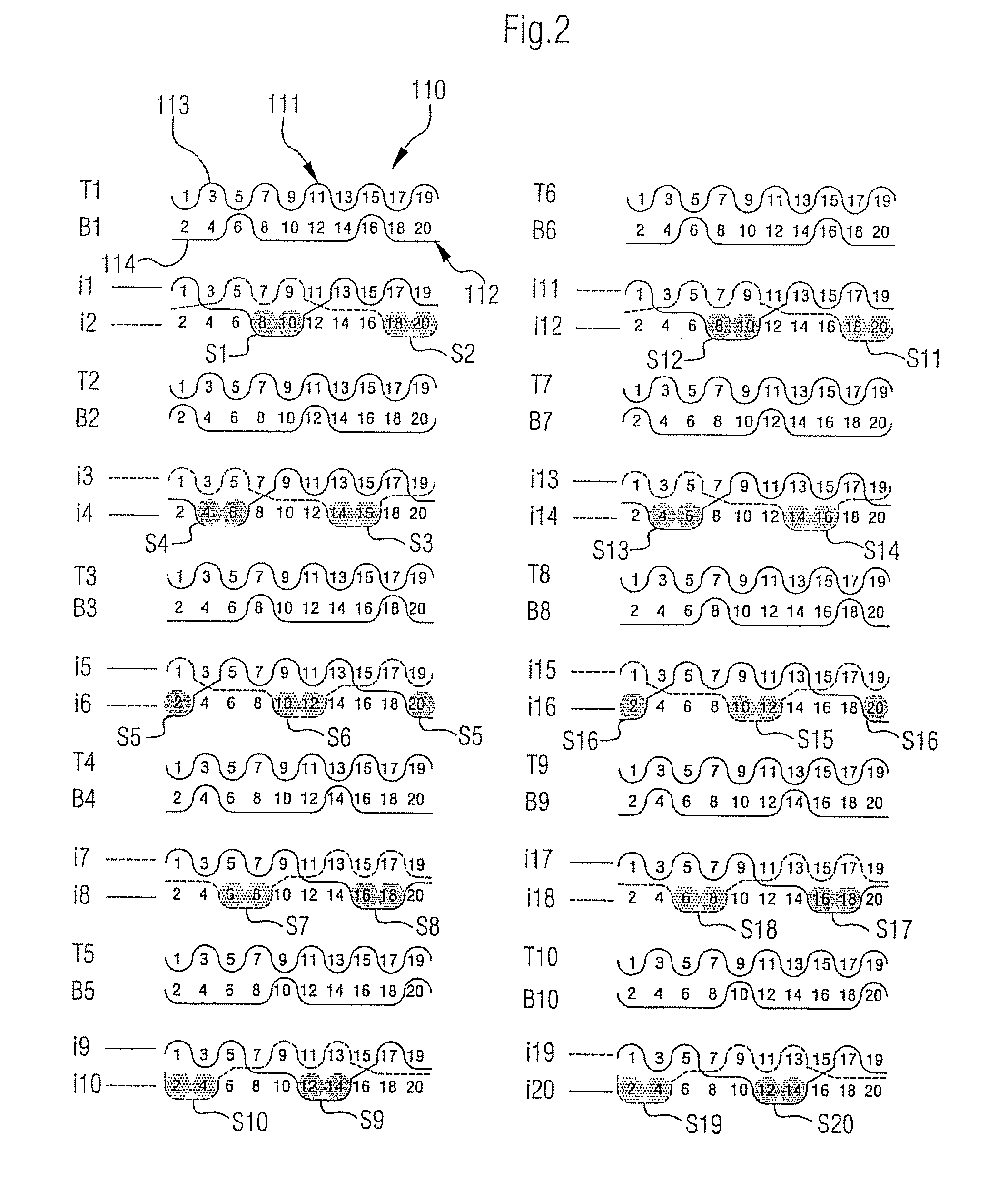

InactiveUS20080264511A1Reduce disadvantagesReduce thicknessMachine wet endPress sectionScrew threadMesh grid

A paper machine mesh, in particular forming mesh, includes an upper and a lower fabric layer and with binder threads to join the two fabric layers, whereby the lower fabric layer is formed by the binder threads, lower transverse threads and, woven therewith and extending transverse thereto, lower longitudinal threads, whereby the lower fabric layer has a weaving pattern which is repeated in lower repeats, whereby the binder threads are arranged in pairs and the binder threads of each pair are interchangingly woven with upper and with lower longitudinal threads, whereby each binder thread pair is flanked on both sides respectively by one lower transverse thread and each of the two flanking lower transverse threads is woven in periodic sequence with lower longitudinal threads as follows: i) the flanking lower transverse thread continually crosses several directly consecutive lower longitudinal threads on the outer side of the lower fabric layer; and ii) the flanking lower transverse thread continually crosses a lower longitudinal thread between the upper and the lower fabric layer and forms a thread knuckle. Within the lower repeat:i) each binder thread of each pair with lower longitudinal threads forms at least one tie segment and each tie segment is formed in that the respective binder thread of the pair continually crosses two or more directly consecutive lower longitudinal threads on the outer side of the lower fabric layer; andii) the tie segments of each binder thread pair are arranged relative to the lower transverse threads flanking said segments such that:a) the two flanking lower transverse threads continually cross on the outer side of the lower fabric layer at least the same lower longitudinal threads which together with the binder threads of the pair form the tie segments;b) the one of the two flanking lower transverse threads forms respectively one knuckle with the lower longitudinal thread which directly precedes the corresponding tie segment; andc) the other of the two flanking lower transverse threads forms respectively one knuckle with the lower longitudinal thread which directly follows the corresponding tie segment.

Owner:VOITH PATENT GMBH

External thermal insulation composite material and preparation method thereof

The invention relates to a preparation method of an external thermal insulation composite material, comprising the following steps: (1) performing a hydrophobic treatment on a hydrophilic first reinforcement to obtain a hydrophobic first reinforcement; (2) connecting the hydrophobic first reinforcement and a hydrophilic second reinforcement to obtain a preform; and (3) impregnating the part of thepreform including at least the second reinforcement with a hydrophilic impregnant used for impregnation, and then drying to obtain the external thermal insulation composite material. The invention also relates to an external thermal insulation composite material prepared by the above preparation method. The an anti-scouring aerogel composite material prepared from the external thermal insulationcomposite material can be used for profile machining to obtain a component of a desired profile, or the overall external profile machining is carried out after assembling of an aircraft, so as to accurately ensure aerodynamic shape of the aircraft.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

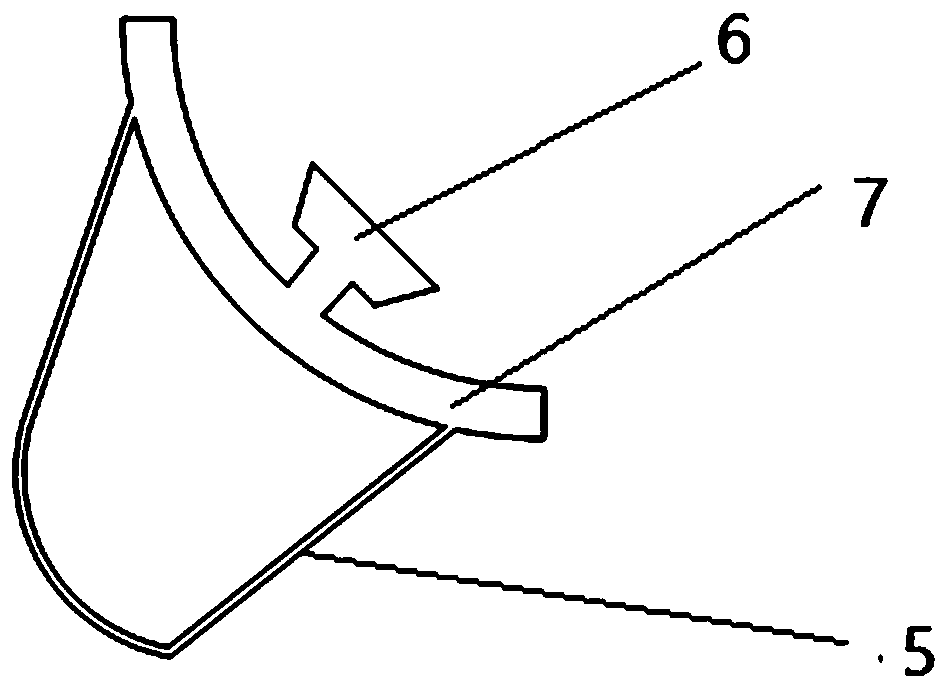

In Tyre Sound Absorber

ActiveUS20100000640A1Increase airflow resistanceHigh tensile strengthRimsLayered productsEngineeringSound Absorber

An in tire sound absorber for a pneumatic wheel assembly including a wheel rim and a tire fitted to the wheel rim. The sound absorber comprises a first fibrous layer and a second fibrous layer with a higher air flow resistance than the first layer. The sound absorber is configured to fit around the wheel rim with the first layer in contact with a surface of the wheel rim and extending substantially between the second layer and the wheel rim.

Owner:ZEPHYROS INC

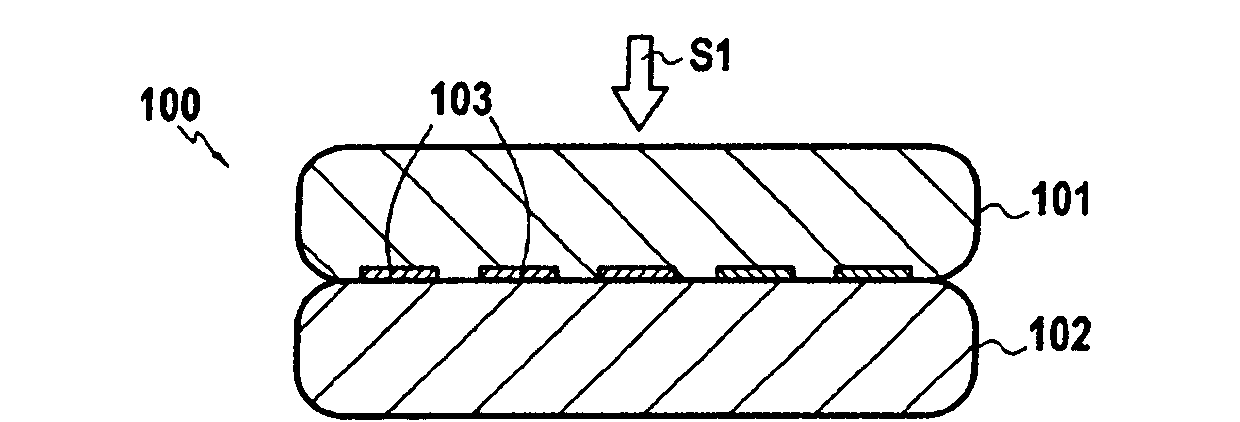

Co-extrusion adhesive film, solar cell module and double-layer glass

ActiveCN111454668AReduce the risk of delaminationReduce liquidityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersPolymer sciencePtru catalyst

The invention provides a co-extrusion adhesive film, a solar cell module and double-layer glass. The co-extrusion adhesive film comprises at least two adhesive film layers; raw materials for forming each adhesive film layer comprise a first component and a second component, wherein each first component is 1-100 parts of first matrix resin grafted with an electron withdrawing group, and second components respectively and independently contain 0.01-25 parts of a water producing agent and / or 0.01-2.5 parts of a catalyst, and the second components are not water producing agents or catalysts at thesame time; and the first matrix resin and the water producing agents can undergo cross-linking reactions, and the catalysts can catalyze the cross-linking reactions. When the co-extrusion adhesive film is used as a raw material for preparing the solar cell module, the photoelectric conversion efficiency of the solar cell module can be greatly improved; and cost is low, process is simple, and industrial popularization is convenient.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

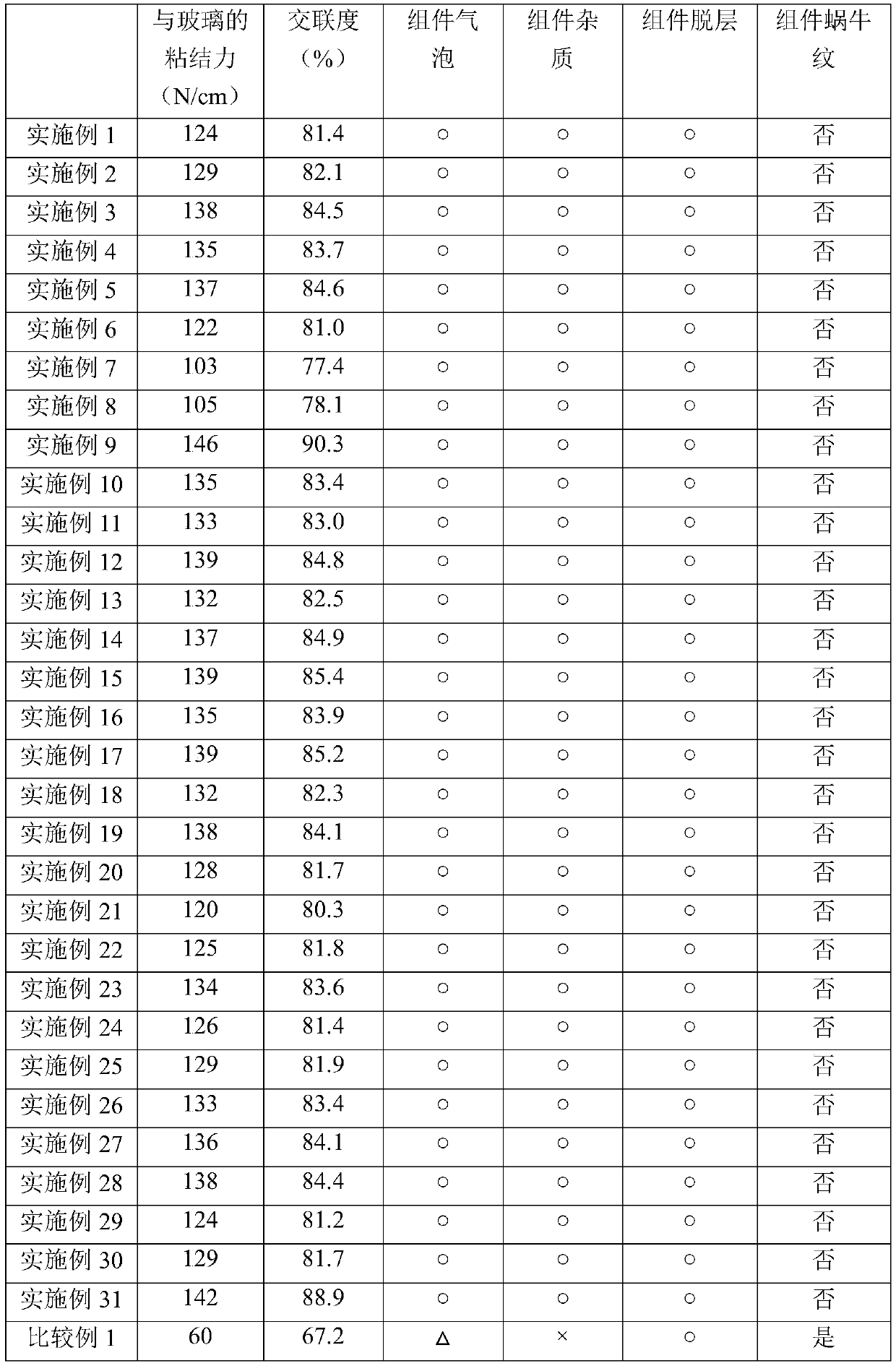

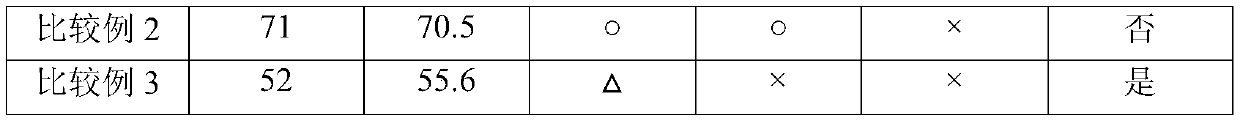

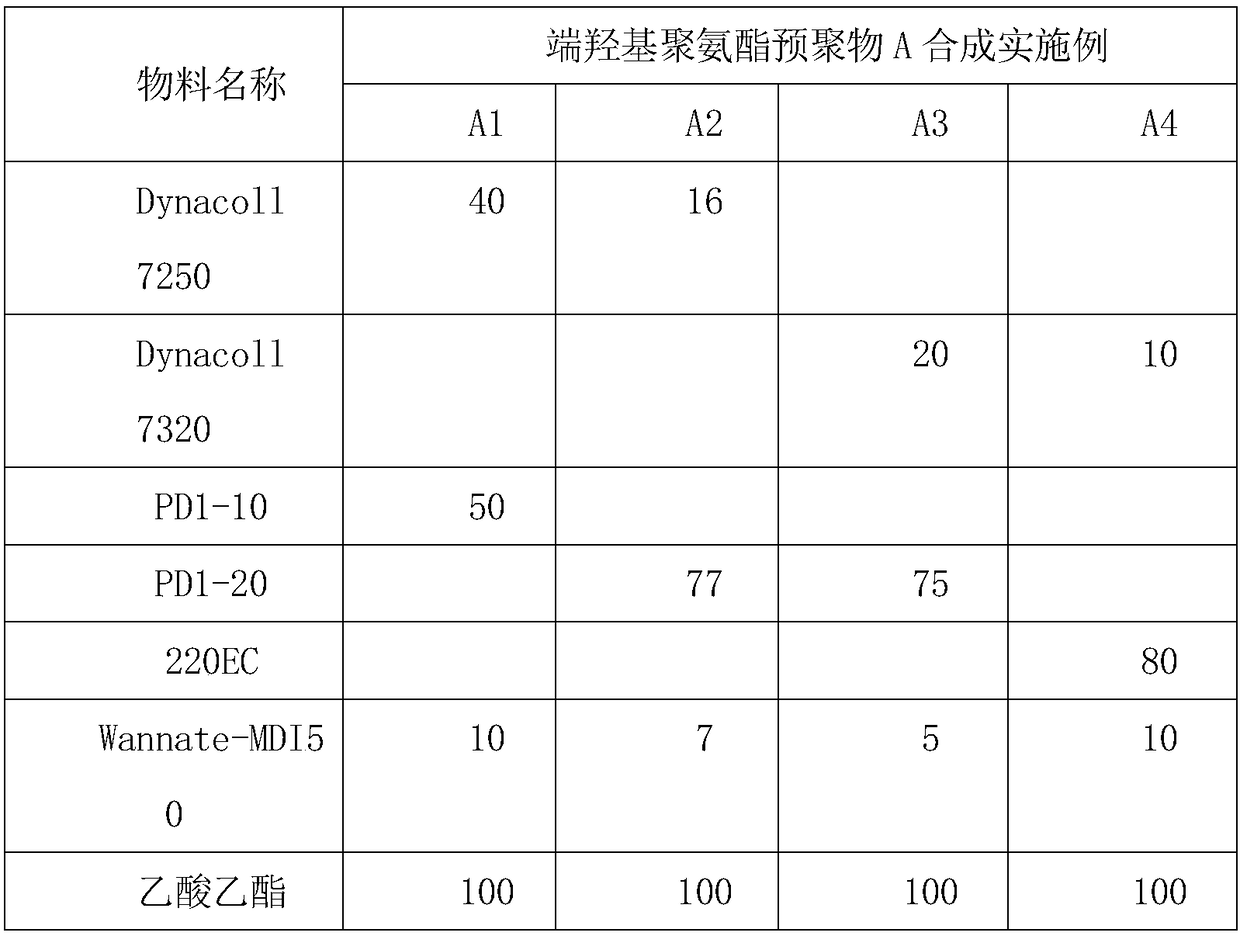

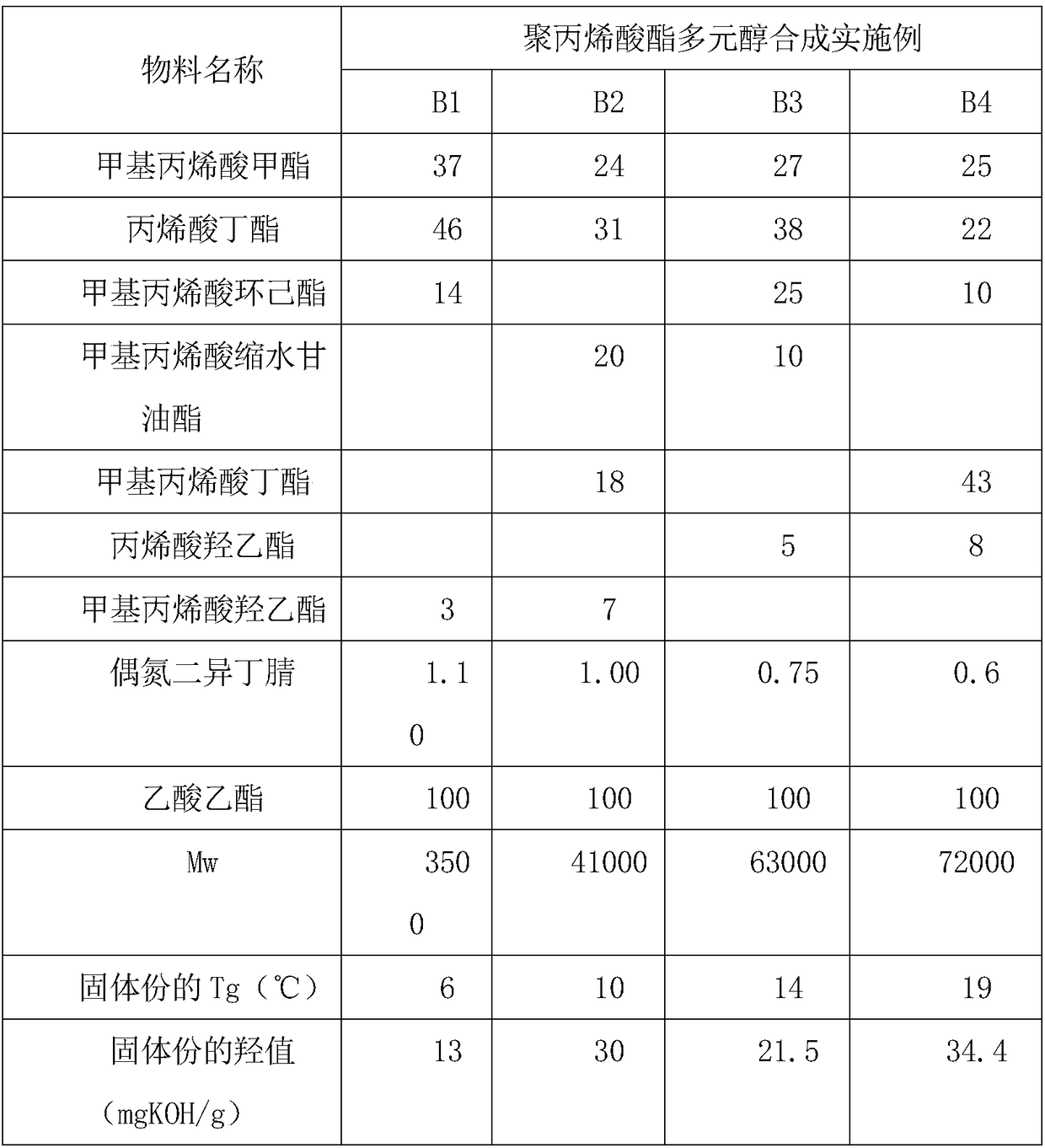

Weather-resistant two-component polyurethane adhesive and solar battery back plate

ActiveCN108546539AExcellent cured peel strengthReduce the risk of delaminationPolyureas/polyurethane adhesivesPhotovoltaic energy generationPolyesterPolyurethane adhesive

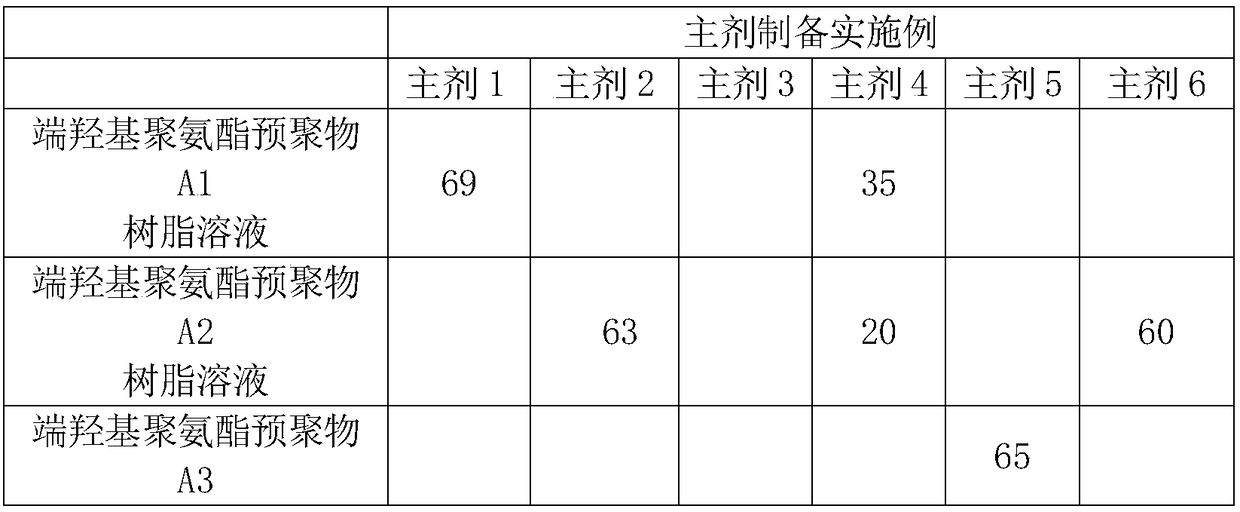

The invention discloses a weather-resistant two-component polyurethane adhesive. A main agent of the adhesive is composed of hydroxyl-terminated polyurethane prepolymer A and polyacrylate polyol B. The hydroxyl-terminated polyurethane prepolymer A is obtained by polymerization of polyester polyol with difunctional isocyanate, and the curing agent is a polyfunctional isocyanate compound. The hydroxyl-terminated polyurethane prepolymer A in the main agent accounts for 50-70 parts by weight, the polyacrylate polyol B accounts for 30-50 parts by weight, and the equivalence ratio NCO / OH of hydroxylin the main agent and an isocyanate group in the curing agent is 0.5-2.0. The adhesive can realize high cohesiveness between base film layers and maintain good bonding strength after high-temperatureand high-humidity aging testing.

Owner:CHINA LUCKY FILM CORP

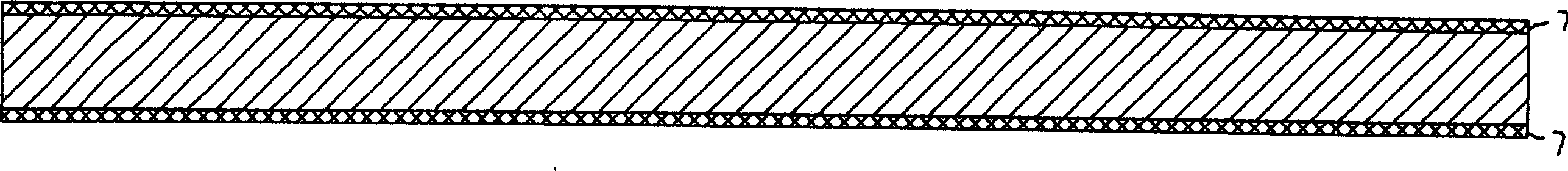

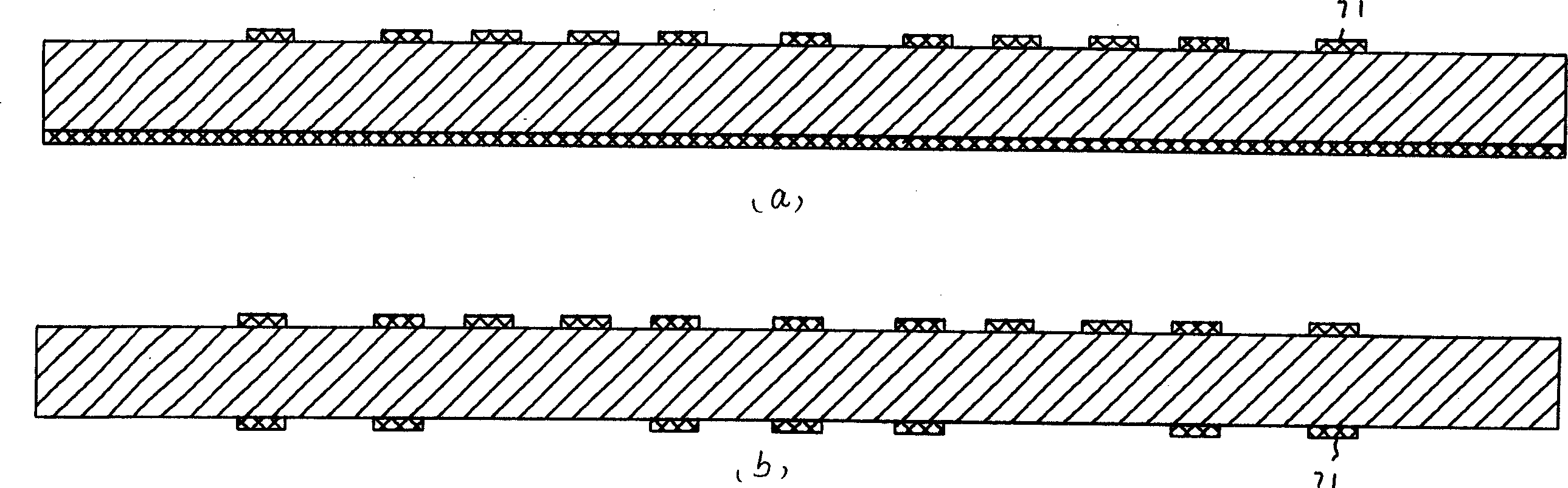

Reinforced material

InactiveCN101977762AReduce stiffnessImprove flexibilityShutters/ movable grillesConstructions elementsPolymer scienceNonwoven fabric

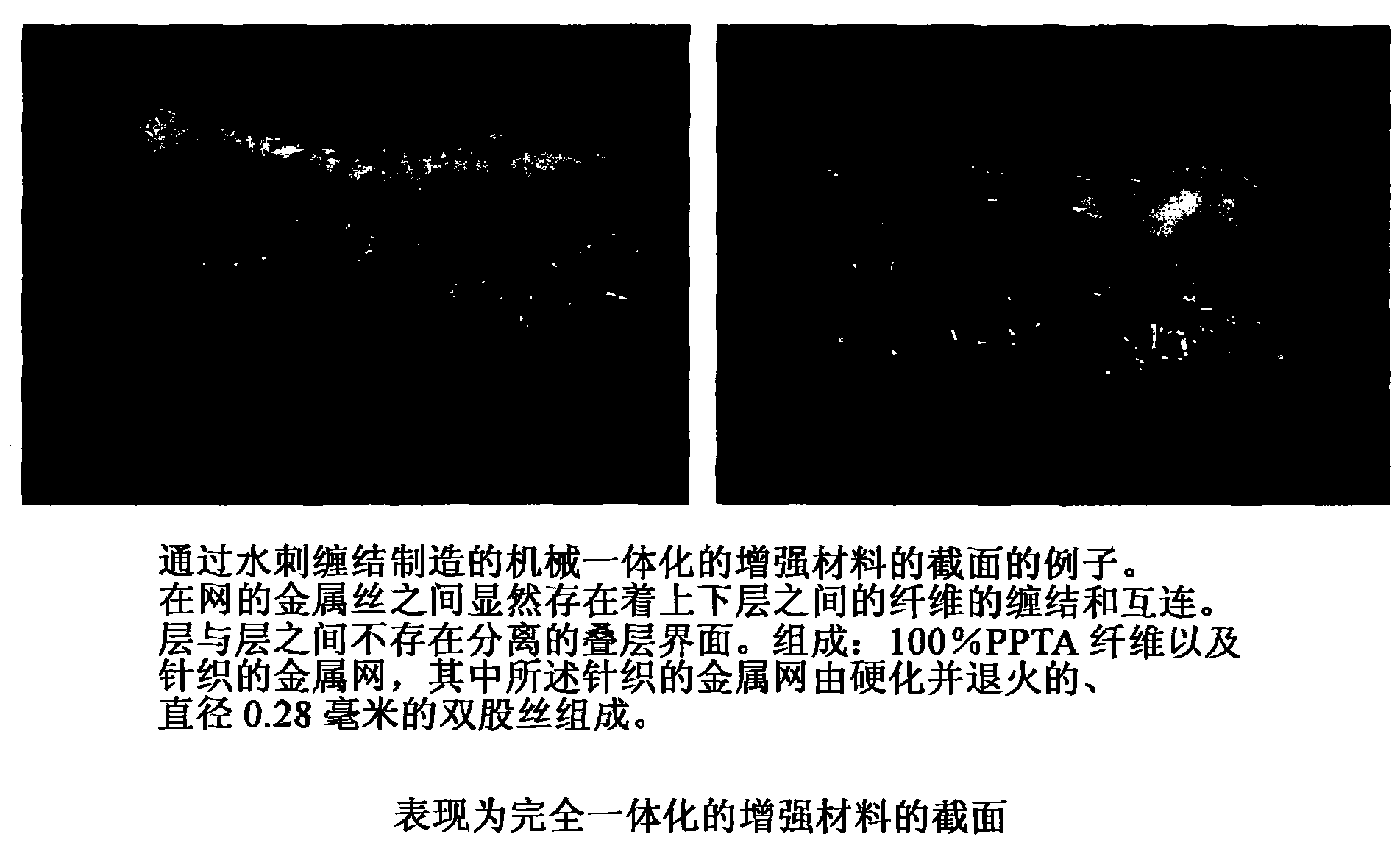

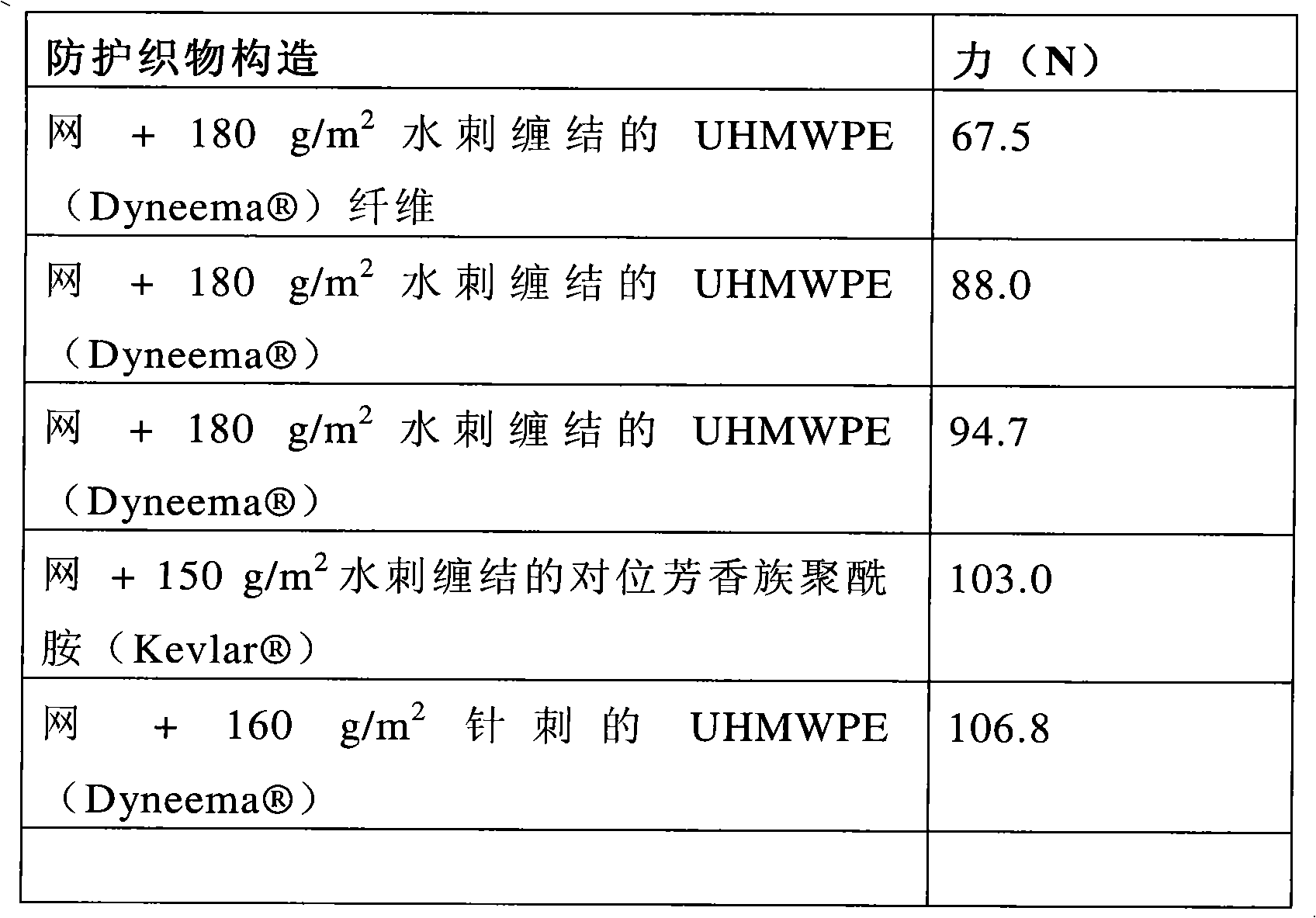

A reinforced fibrous material and production method and use thereof are described. The reinforced fibrous material comprises one or more nonwoven fabric layers entangled with a metallic mesh layer, methods for its preparation and uses thereof.

Owner:罗拉斯托普有限公司

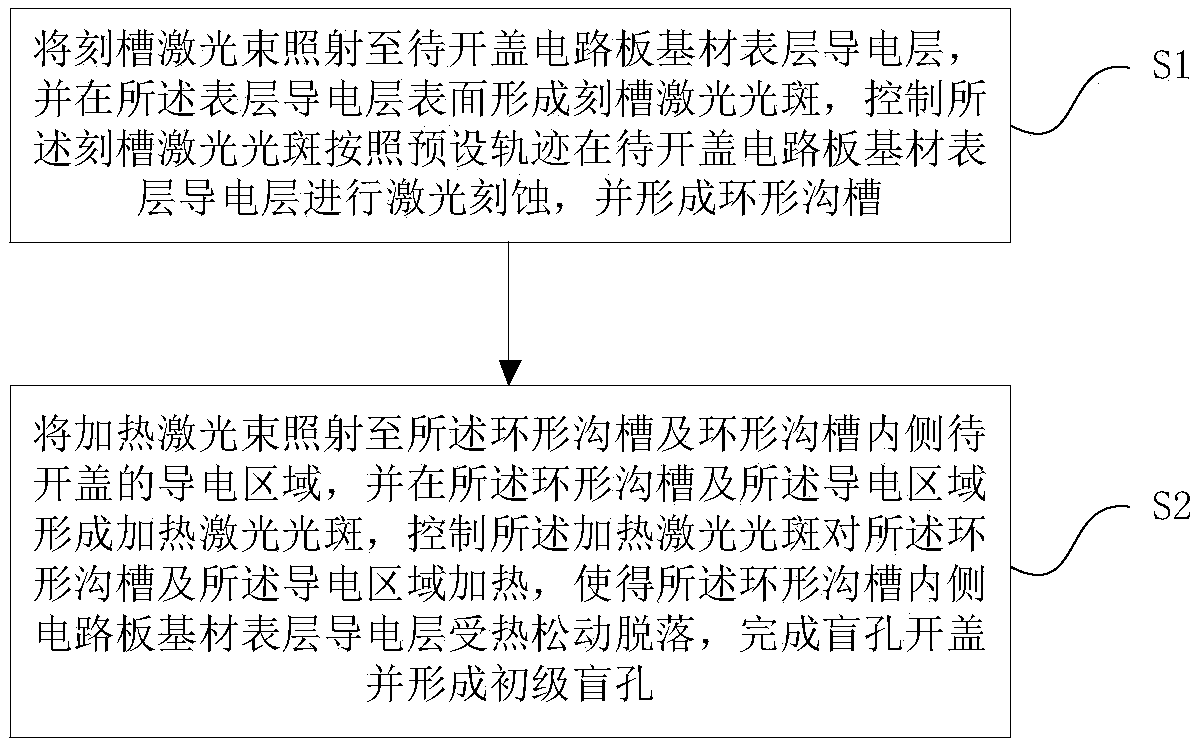

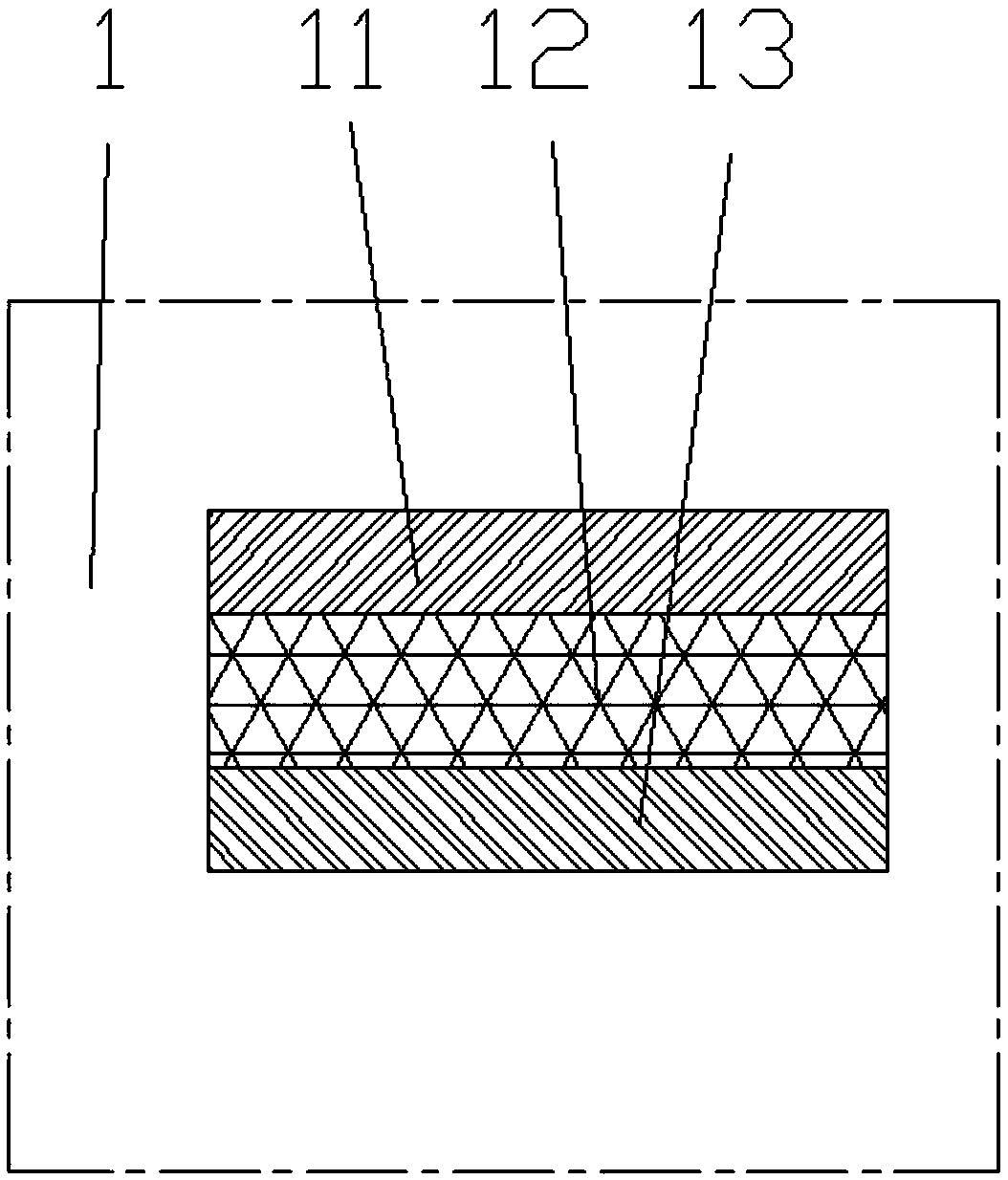

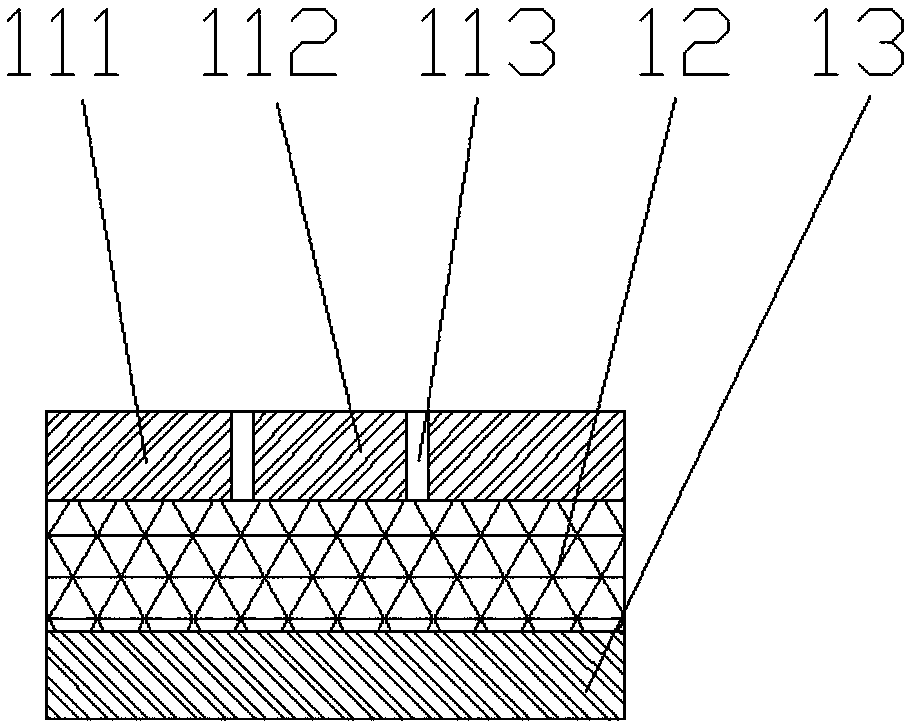

Blind hole uncapping method using laser

ActiveCN109640524AEasy to switchReduce processing timePrinted circuit manufactureLaser beam welding apparatusShock waveLaser etching

The invention relates to a blind hole uncapping method using laser. The blind hole uncapping method comprises the steps that grooving laser beams are irradiated to a surface layer conducting layer ofa to-be-uncapped circuit board substrate, laser etching is carried out on the surface layer conducting layer of the to-be-uncapped circuit board substrate according to a preset track, and an annular groove is formed; and heating laser beams are irradiated to the annular groove and a to-be-uncapped surface layer conducting layer area on the inner side of the annular groove, heating is carried out,the surface layer conducting layer of the circuit board substrate on the inner side of the annular groove becomes loose and drops off by heating, the blind hole uncapping is finished, and a primary blind hole is formed. According to the blind hole uncapping method using the laser, the surface layer conducting layer of a circuit board is subjected to closed-loop grooving using the grooving laser beams, the annular groove is obtained, the annular groove and a conducting area in the annular groove are heated using the heating laser beams, under the action of plasma shock waves generated by actionof heating laser light spots and substance in the groove, the surface layer conducting layer of a blind hole to-be-uncapped protecting area becomes loose and drops off, the blind hole uncapping is finished, the primary blind hole is formed, and the blind hole uncapping problem is ingeniously solved.

Owner:武汉铱科赛科技有限公司

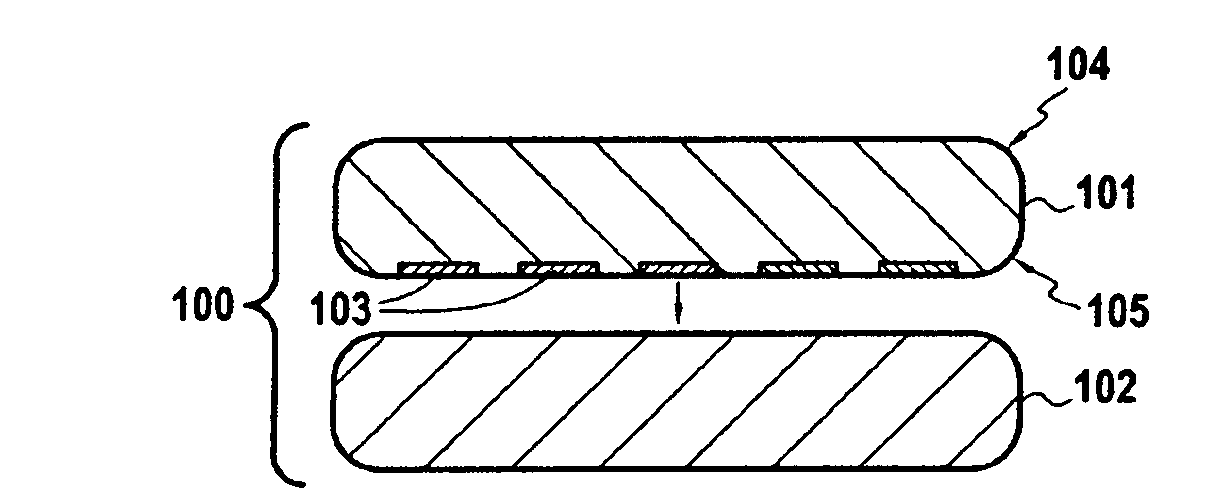

In tire sound absorber

ActiveUS9278586B2Increase airflow resistanceHigh tensile strengthRimsLayered productsEngineeringSound Absorber

An in-tire sound absorber for a pneumatic wheel assembly including a wheel rim and a tire fitted to the wheel rim. The sound absorber comprises a first fibrous layer and a second fibrous layer with a higher air flow resistance than the first layer. The sound absorber is configured to fit around the wheel rim with the first layer in contact with a surface of the wheel rim and extending substantially between the second layer and the wheel rim.

Owner:ZEPHYROS INC

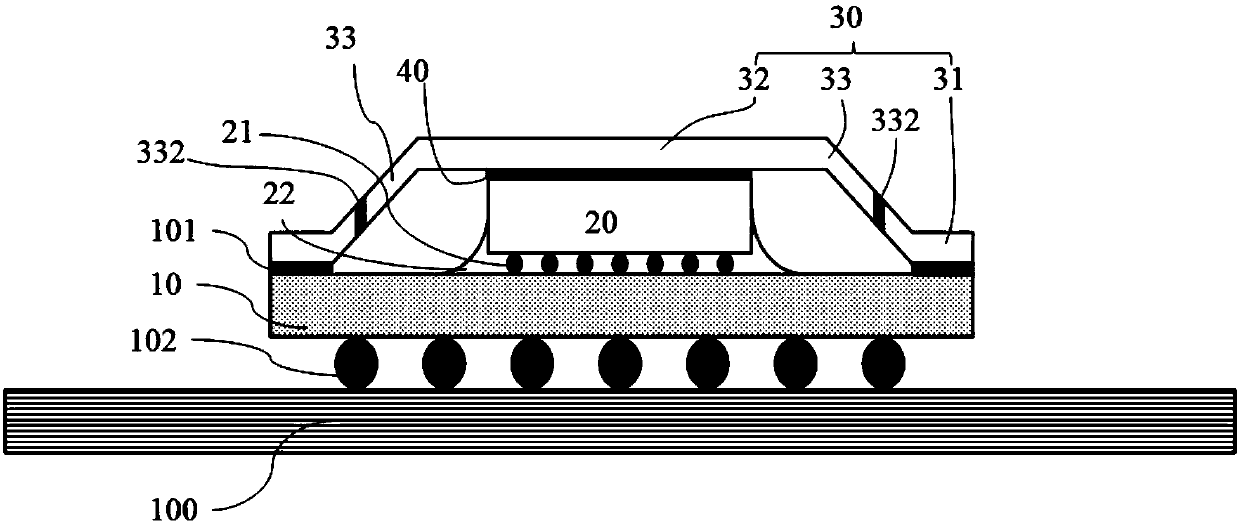

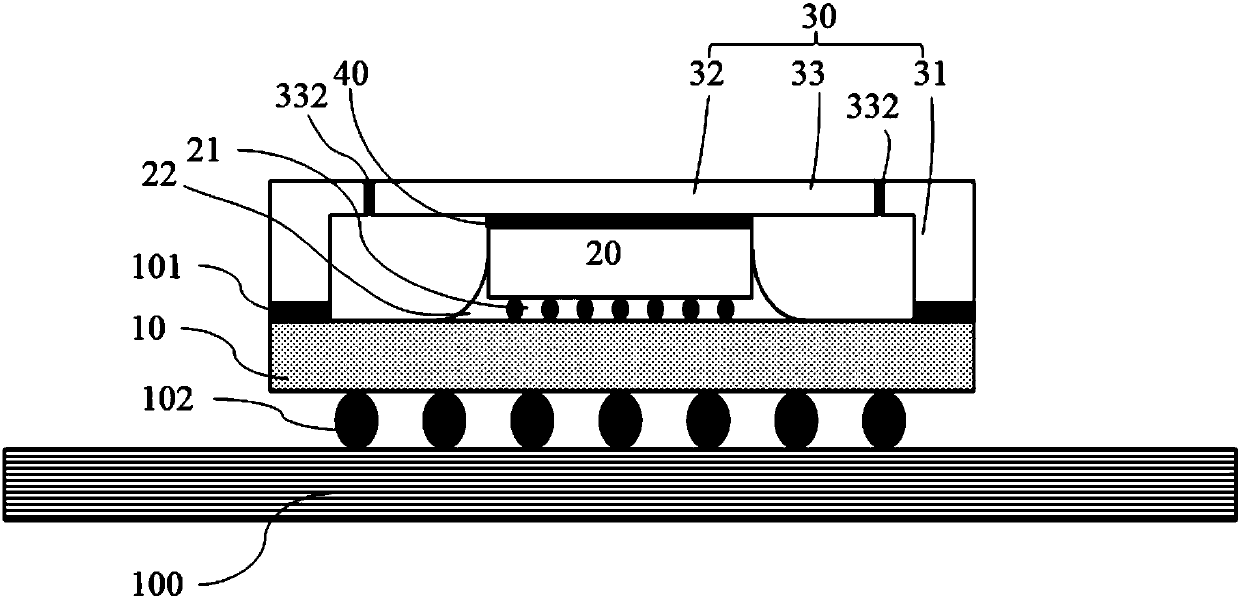

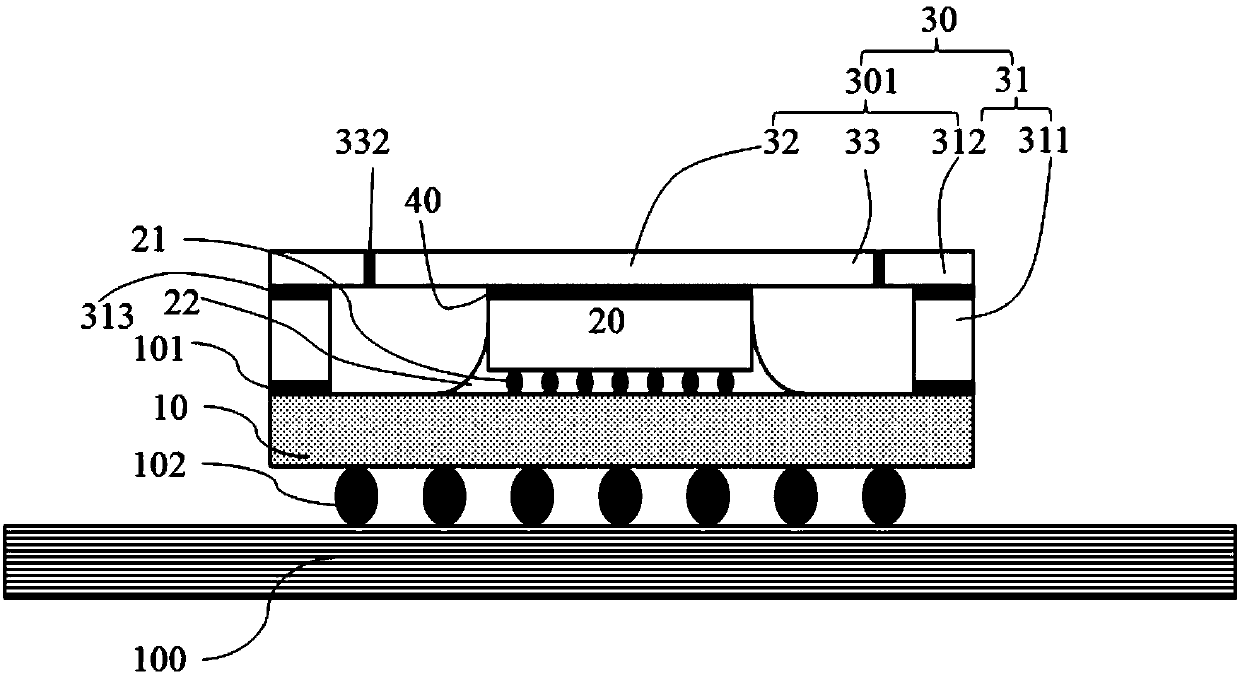

Encapsulation structure and electronic device

InactiveCN109786336AReduce the risk of delaminationReduce rigiditySemiconductor/solid-state device detailsSolid-state devicesAdhesiveSoftware engineering

An embodiment of the invention discloses an encapsulation structure comprising a substrate, a bare chip and a heat dissipation cover, wherein the bare chip is mounted on the surface of the substrate,the heat dissipation cover is connected to the substrate and covers the periphery of the bare chip, the heat dissipation cover comprises a fixing portion and a heat conduction portion, the fixing portion is fixedly connected to the substrate, the heat conduction portion directly faces the surface, facing away from the substrate, of the bare chip, a heat conduction adhesive is provided between thebare chip and the heat conduction portion, and a slot is provided between the heat conduction portion and the fixing portion to reduce the rigidity of the heat dissipation cover. The embodiment of theinvention further discloses an electronic device. The encapsulation structure and electronic device can reduce the risk of the heat conduction adhesive being delaminated and increase the reliabilityof the encapsulation structure.

Owner:HUAWEI TECH CO LTD

Forming mesh

InactiveUS7637291B2Reduce disadvantagesReduce thicknessMachine wet endPress sectionEngineeringScrew thread

A paper machine mesh, in particular a forming mesh, includes an upper and a lower fabric layer and binder threads to join the two fabric layers, the lower fabric layer having a weaving pattern which is repeated in lower repeats. Within the lower repeat, each binder thread of each pair with lower longitudinal threads forms at least one tie segment and each tie segment is formed in that the respective binder thread of the pair continually crosses two or more directly consecutive lower longitudinal threads on the outer side of the lower fabric layer, and the tie segments of each binder thread pair are arranged relative to the lower transverse threads flanking said segments.

Owner:VOITH PATENT GMBH

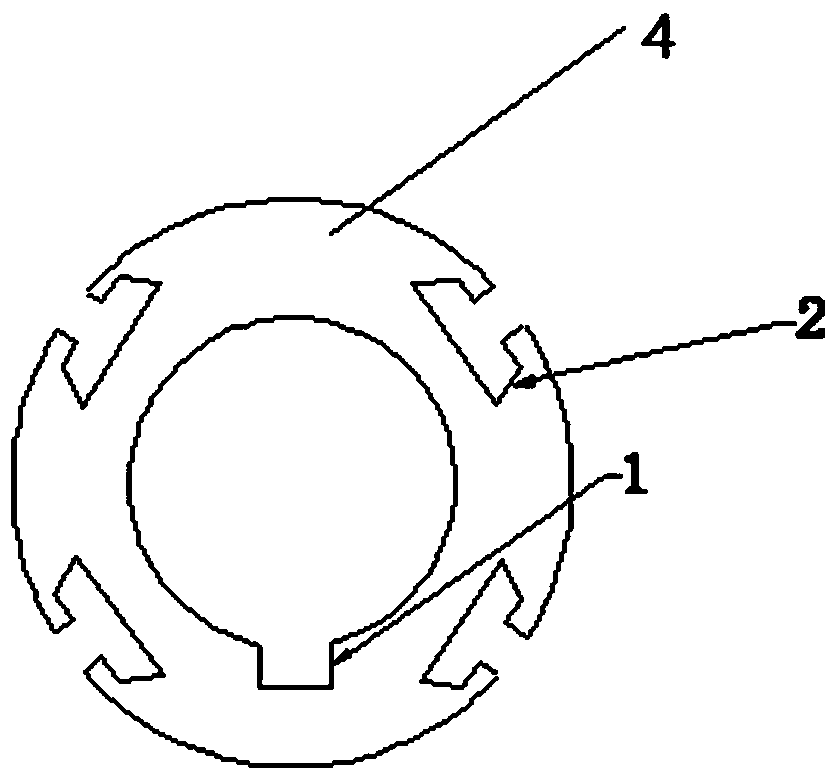

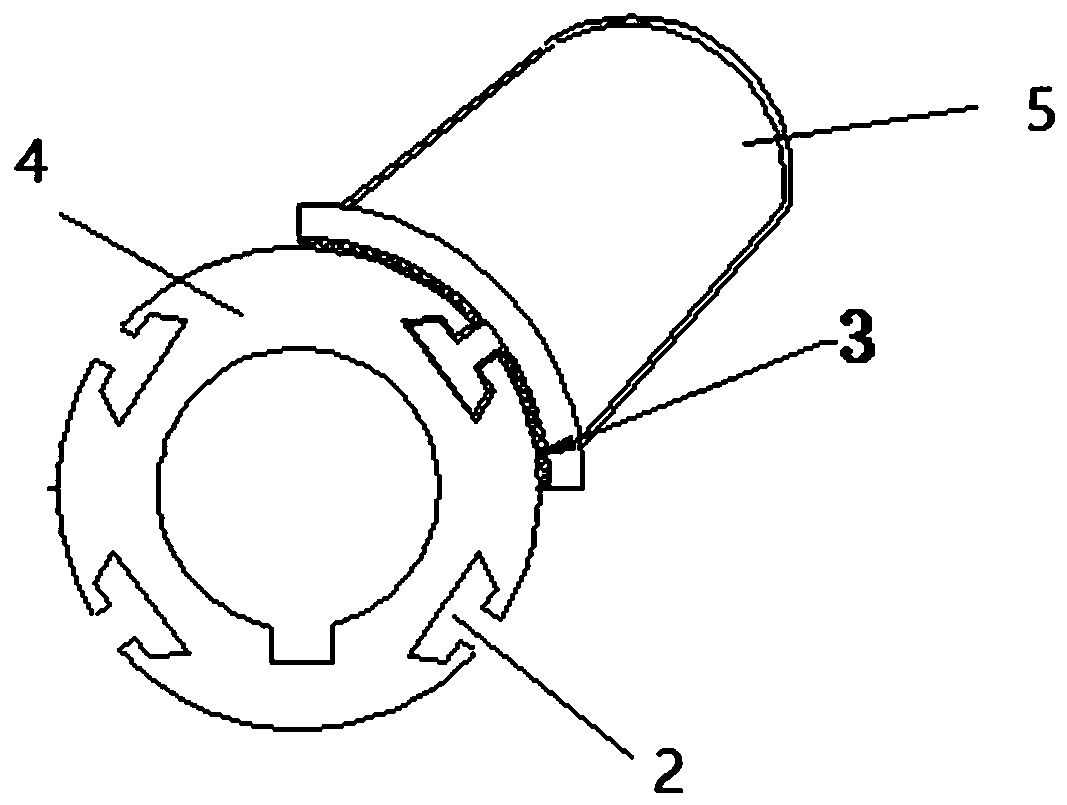

Flat-face saliant-point type packing base-board for integrated circuit or discrete device

InactiveCN1851915AStrong adaptabilityEasy to produceSemiconductor/solid-state device detailsSolid-state devicesThin layerIntegrated circuit

This invention relates to a plane button package base plate of an IC or a discrete device and its processing method characterizing that base islands and pins are distributed on the front of the base plate in buttons connected by metal thin layers, the base island is the one composed of multiple buttons, the pin is single, the fronts of the islands and the pins have metal layers, the number of the islands is one or many in the package unit of a single IC or discrete device formed in the post package, namely, single unit island or multiple unit base islands composed of multiple buttons, the pins are arrayed at one side, both sides or three sides or surrounding the base islands.

Owner:JCET GROUP CO LTD

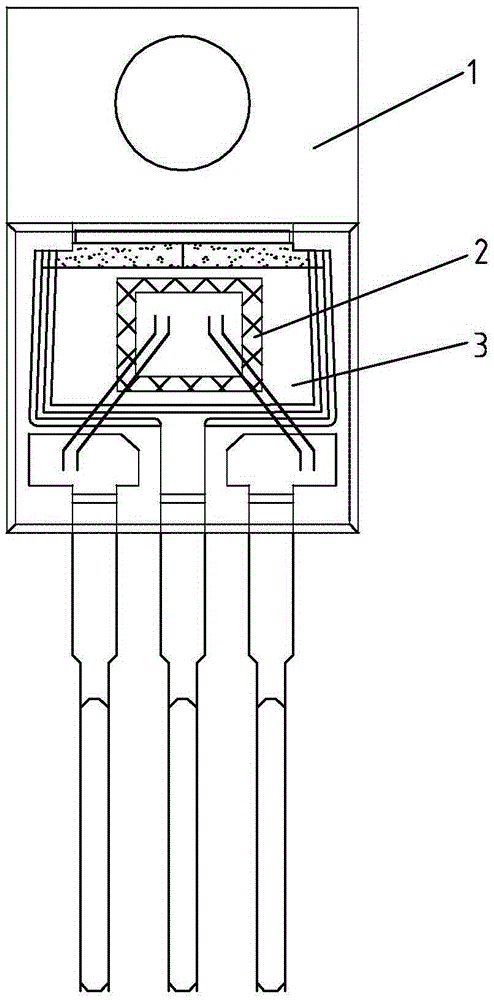

A mixed trimming method

InactiveCN102017090AReduce the risk of delaminationSemiconductor/solid-state device manufacturingEngineeringMachining

The invention relates to a method of trimming a structure (500) comprising a first wafer (200) bonded to a second wafer (300), the first wafer (200) having a chamfered edge. The method comprises a first step (S4) for trimming the edge of the first wafer (200) carried out by mechanical machining over a predetermined depth (Pd1) in the first wafer. This first trimming step is followed by a second step (S5) for non-mechanical trimming over at least the remaining thickness of the first wafer.

Owner:SOITEC SA

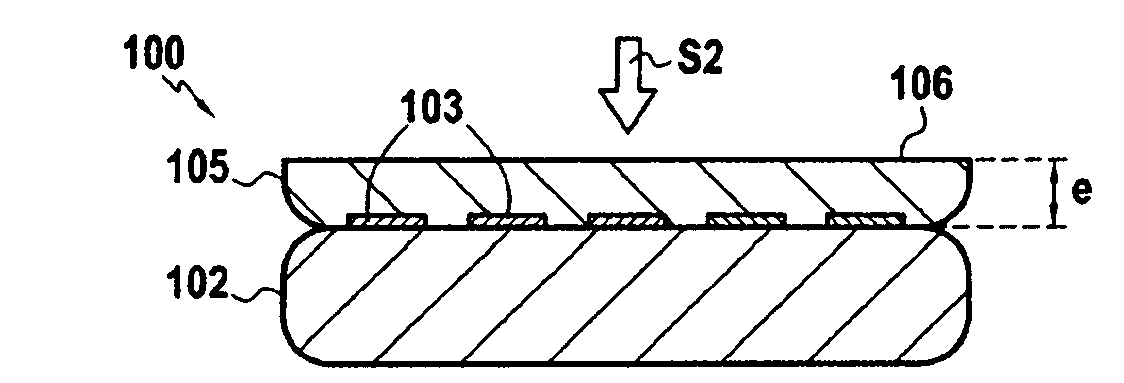

Power type high-current device mounting process

InactiveCN105428252AAvoid ups and downsImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingPower flowWork in process

The invention discloses a power type high-current device mounting process. The process adopts a temperature track provided with a temperature rising region, a temperature stabilizing region and a temperature reducing region; the process comprises the following steps: (a) moving a device framework to the temperature rising region, and heating the device framework in the temperature rising region; (b) then moving the device framework to the temperature stabilizing region, and welding solder on a PAD region of the device framework through a spot welding manner; (c) finishing the solder on the PAD region of the device framework into square-structured solder that is matched with a chip size and has a certain height by using a pressing die in the temperature stabilizing region; (d) placing the chip in the PAD region of the device framework in the temperature stabilizing region to enable the metal and the solder on the back surface of the chip to be co-melted in a temperature environment to form alloy so as to obtain a semifinished product; and (e) moving the semifinished product to the temperature reducing region, and enabling the alloy between the chip and the device framework to be cured in the temperature reducing region. According to the power type high-current device mounting process, the processing quality and the reliability level of the product can be improved, the invalidation rate of clients can be reduced, and the service life of the power type high-current device can be improved.

Owner:CHANGZHOU GALAXY CENTURY MICROELECTRONICS CO LTD

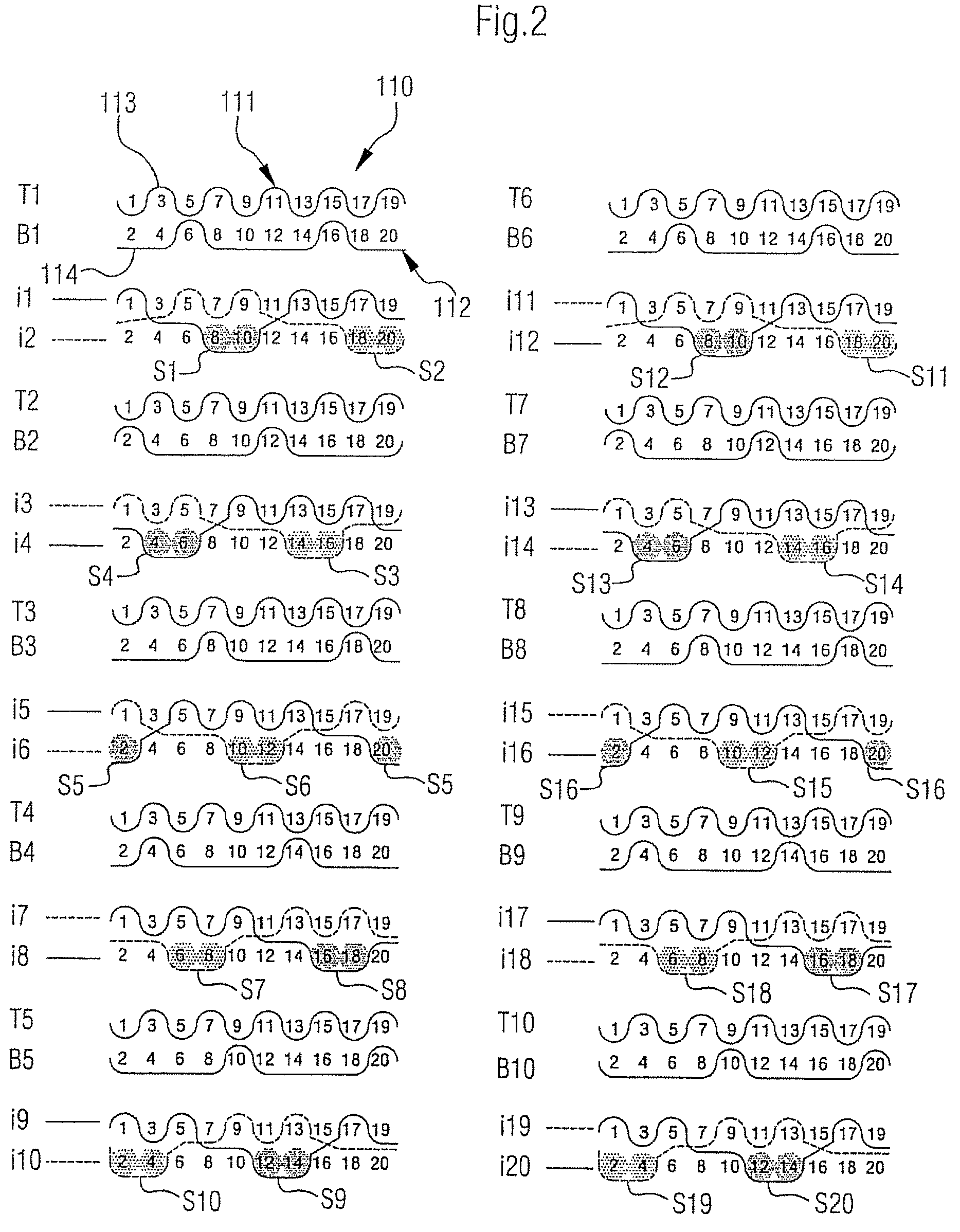

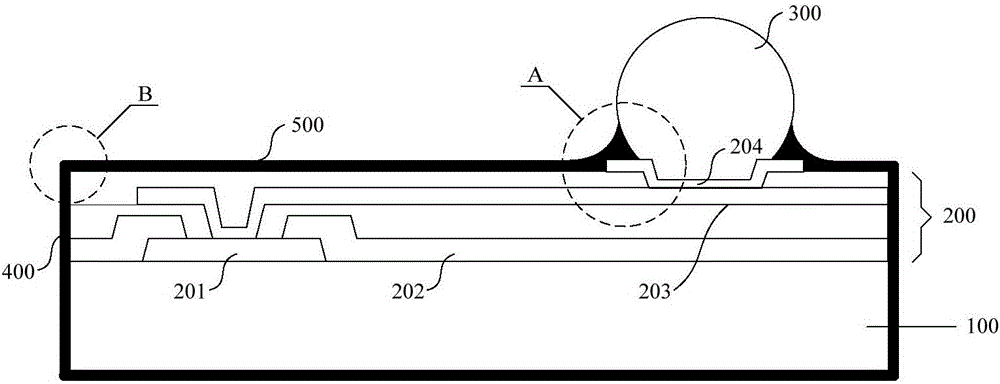

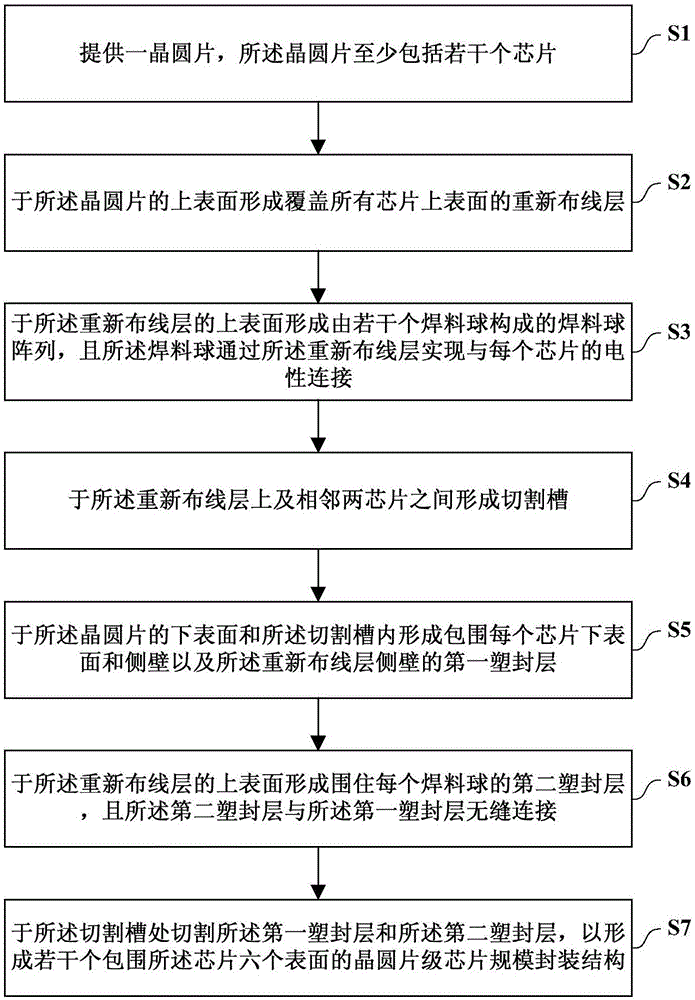

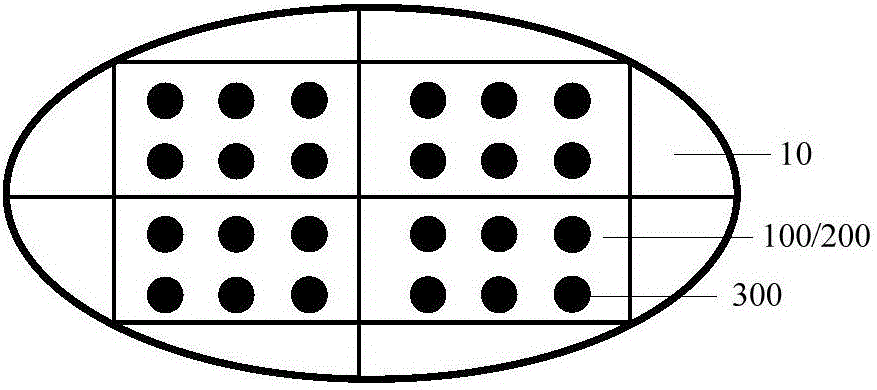

Silicon wafer stage chip scale packaging structure and manufacturing method thereof

InactiveCN106684053AEffectively fixedReduce the risk of delaminationSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSolder ball

The invention provides a silicon wafer stage chip scale packaging structure and a manufacturing method thereof. The silicon wafer stage chip scale packaging structure comprises a chip, a rewiring layer, a plurality of solder balls, a first plastic packaging layer and a second plastic packaging layer, wherein the rewiring layer covers the upper surface of the chip; the plurality of solder balls are formed on the upper surface of the rewiring layer and are electrically connected to the chip by the rewiring layer; the first plastic packaging layer surrounds the lower surface and side wall of the chip and the side wall of the rewiring layer; and the second plastic packaging layer is formed on the upper surface of the rewiring layer, surrounds each solder ball and is in seamless connection with the first plastic packaging layer, thereby forming the silicon wafer stage chip scale packaging structure surrounding the six surfaces of the chip. The silicon wafer stage chip scale packaging structure has the beneficial effects that the packaging protection surrounding the six surfaces of the chip is formed through seamless connection of the two plastic packaging layers, the buckling deformation of the packaging structure resulting from stress is effectively compensated, the packaging structure with the relatively big size can be prepared, and the packaging requirement of the large-sized chip is met.

Owner:SJ SEMICON JIANGYIN CORP

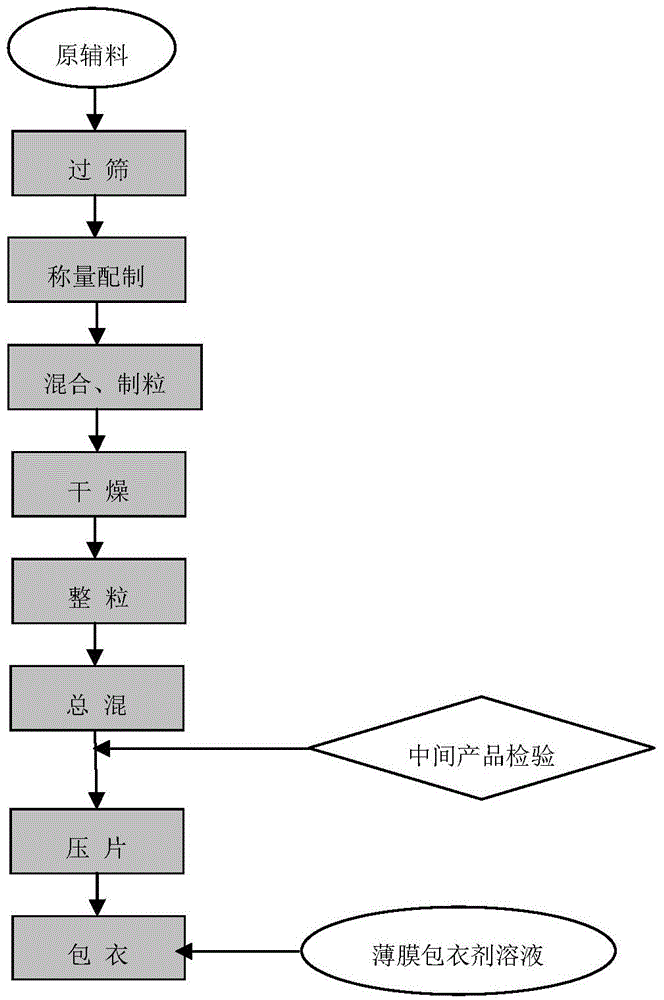

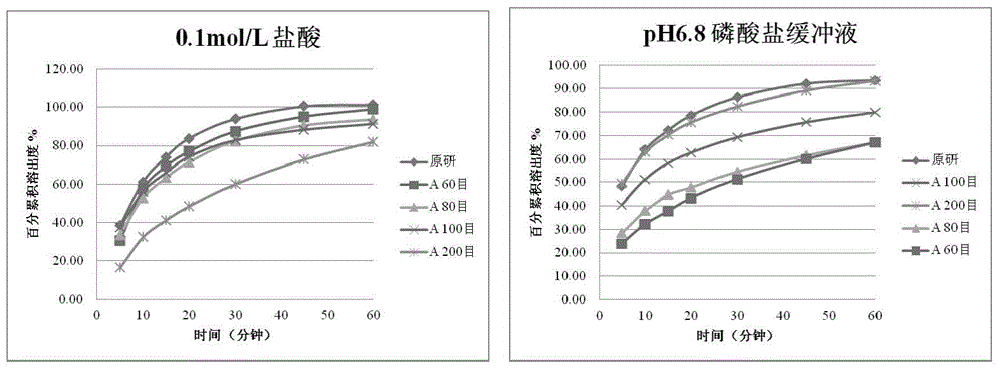

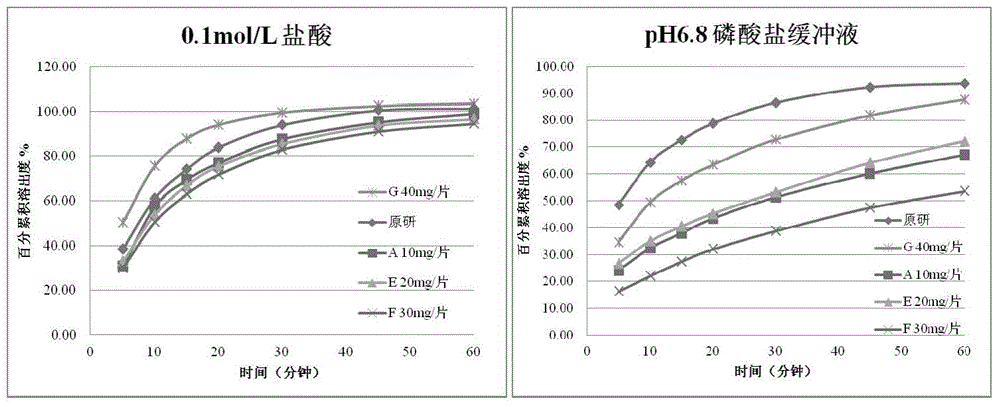

Erlotinib hydrochloride tablet and preparation method thereof

InactiveCN105616374AReduce the risk of delaminationDoes not affect in vivo permeabilityOrganic active ingredientsPharmaceutical non-active ingredientsDissolutionSilicon dioxide

The invention provides an erlotinib hydrochloride tablet. The erlotinib hydrochloride tablet is prepared from 109-164 parts by weight of erlotinib hydrochloride, 69-104 parts by weight of lactose, 120-180 parts by weight of microcrystalline cellulose, 5-50 parts by weight of sodium carboxymethyl starch, 0.1-1 part by weight of sodium dodecyl sulfate, 10-30 parts by weight of silica, 0.5-10 parts by weight of magnesium stearate and 0-25 parts by weight of a coating agent. The invention also provides a preparation method of the erlotinib hydrochloride tablet. The preparation method solves the problem that the fine raw materials can easily form airborne dust and has high adhesion and a slow dissolution rate. The preparation method utilizes a wet granulation process, improves raw material granularity and utilizes a wetting agent so that material airborne dust is greatly reduced and sticking possibility is reduced. Through wet granulation, the raw materials and accessory materials are uniformly dispersed and bonded with each other and layering possibility is reduced. Through prescription adjustment of silica addition, a raw material dissolution rate is improved. The erlotinib hydrochloride tablet provides a novel choice for clinical application.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

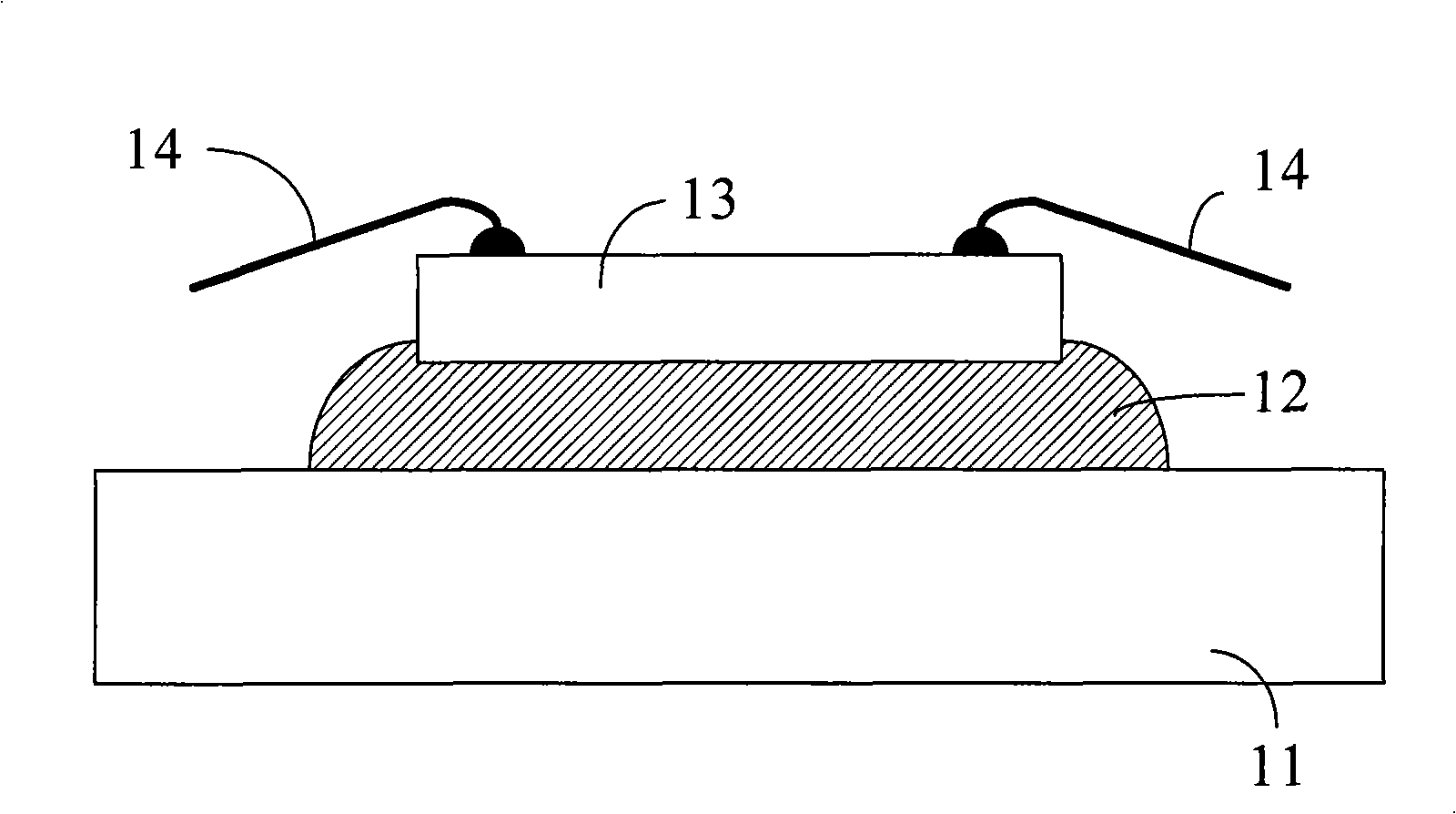

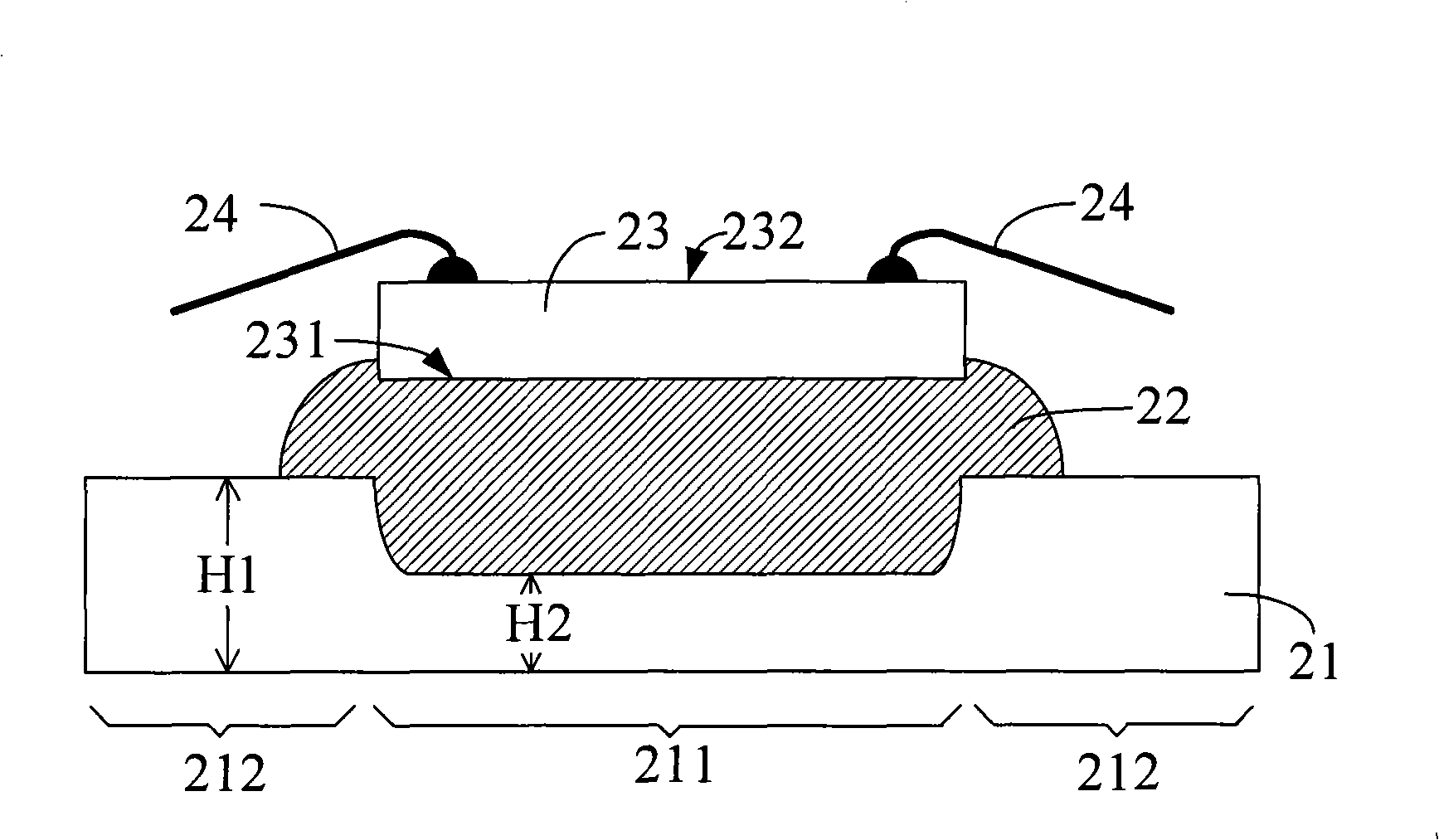

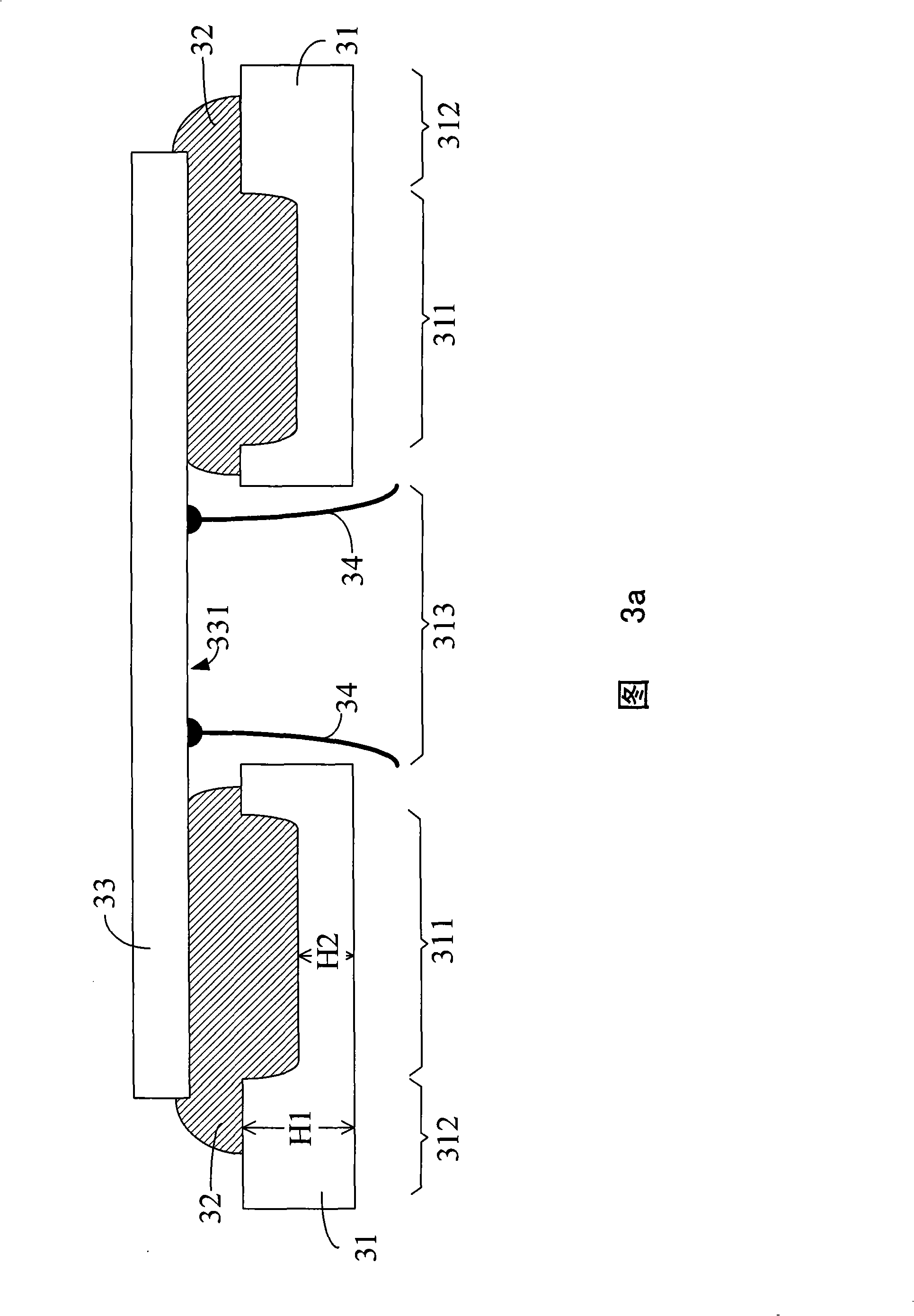

Substrate for semiconductor package structure, semiconductor package structure and manufacturing method thereof

InactiveCN101409265AImprove joint reliabilityReduce the risk of delaminationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

The invention relates to a semiconductor packaging structure and a manufacturing method thereof. The semiconductor packaging structure comprises a baseplate, a junction layer and a chip. A concave part is formed on the baseplate to ensure that the concave part has thicker longitudinal dimension when the junction layer is coated on the baseplate. Therefore, the baseplate has the thicker junction layer when the junction layer is joined with the chip, and the invention provides more stable junction.

Owner:CHIPMOS TECH INC

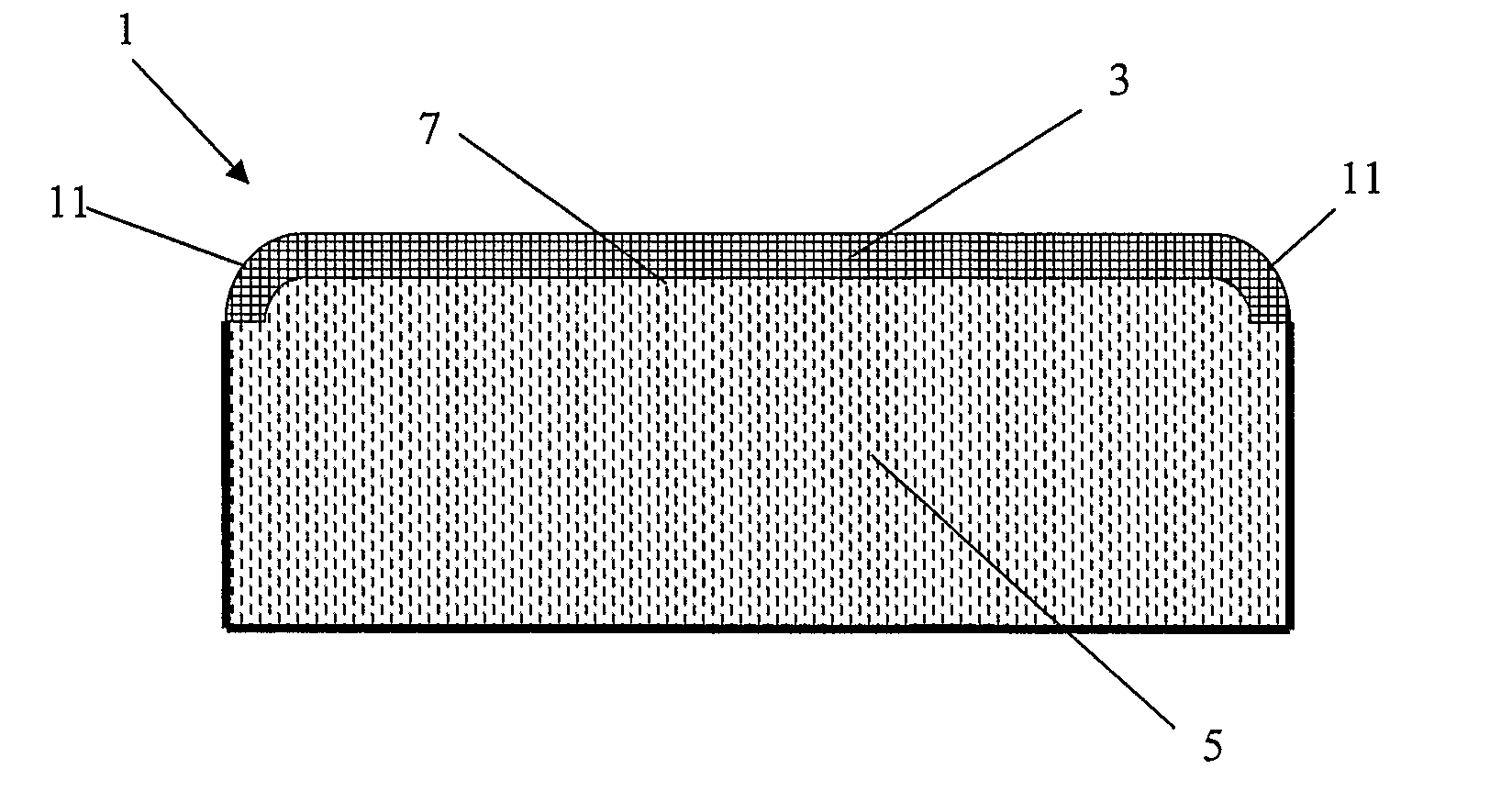

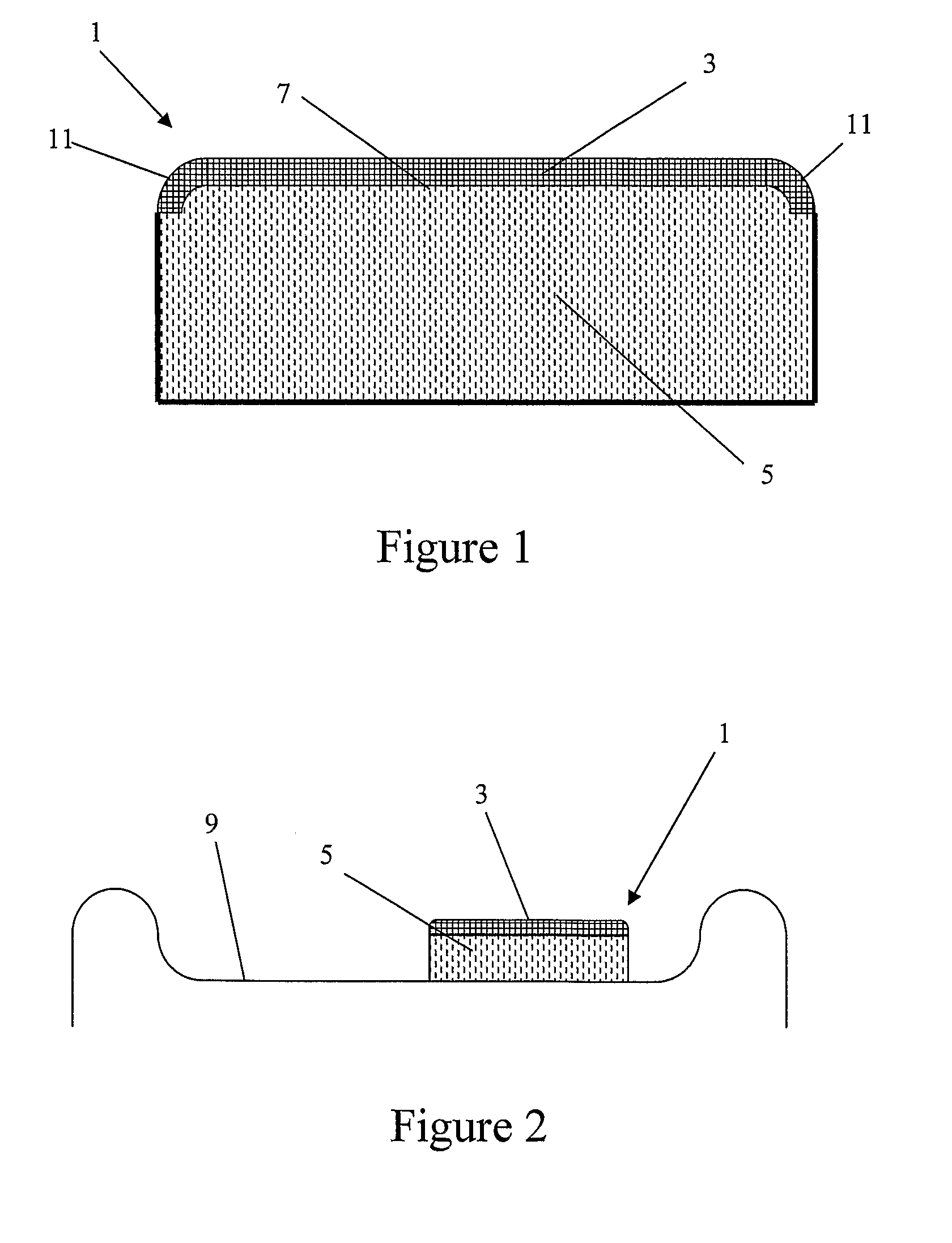

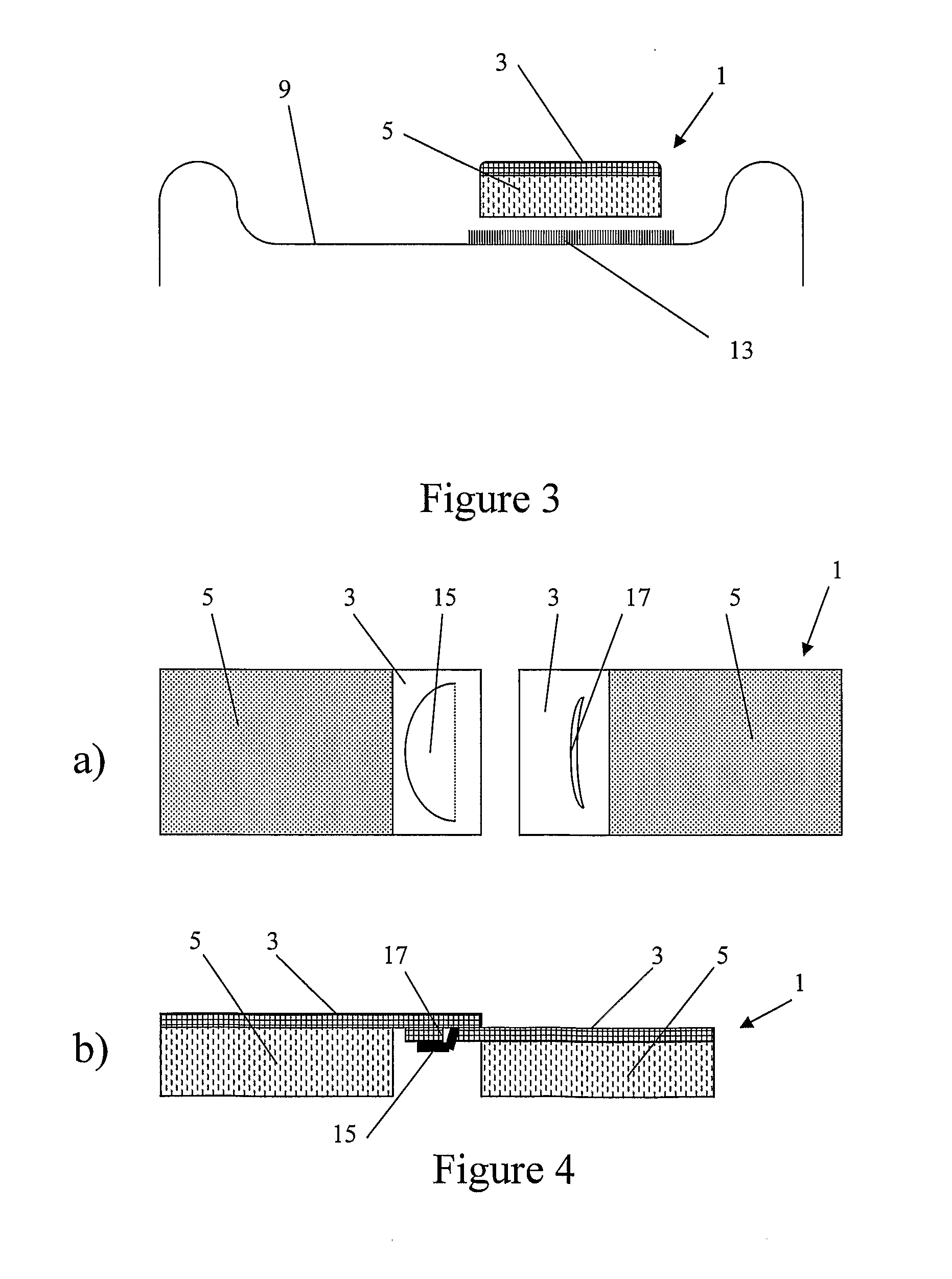

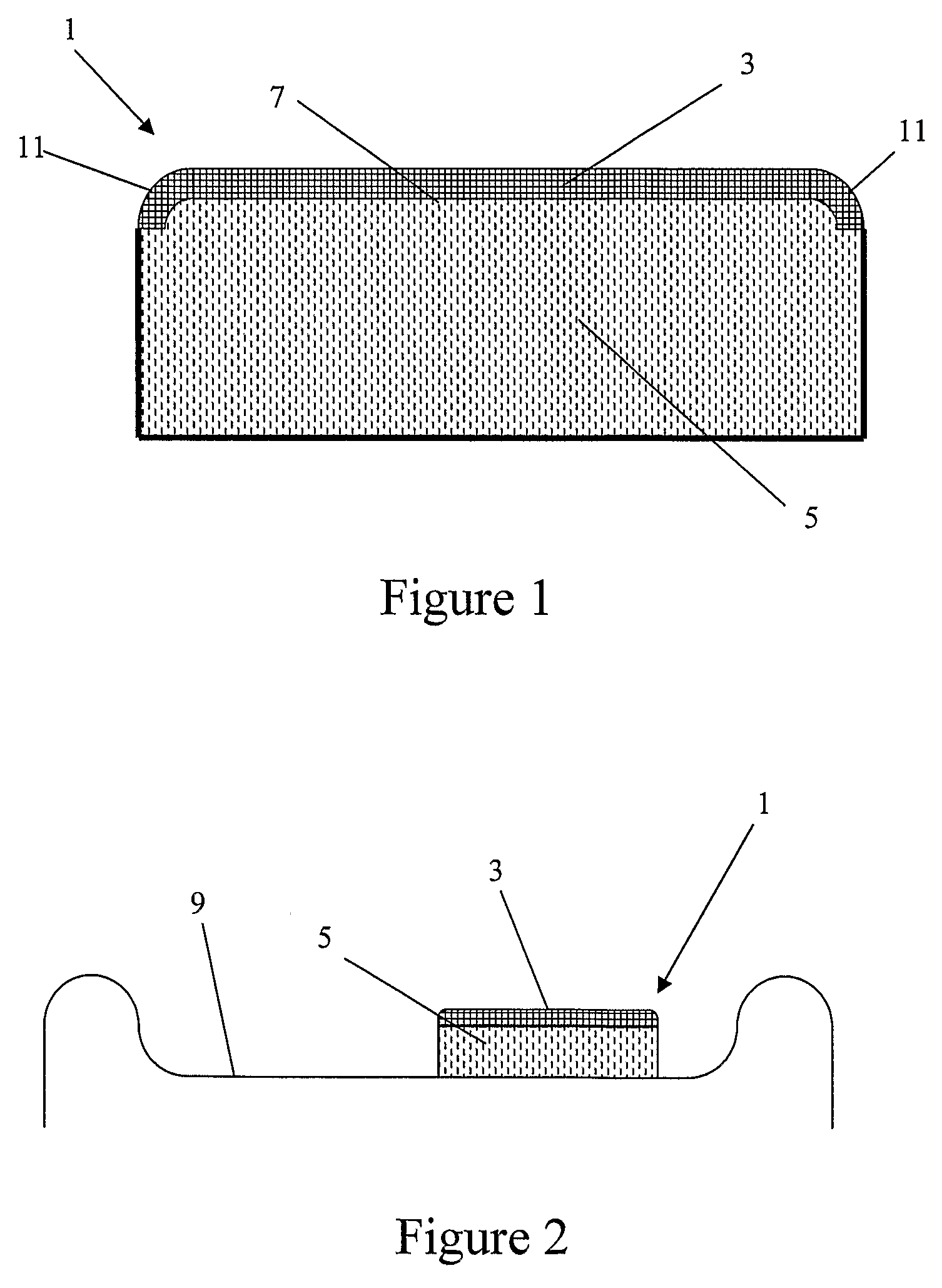

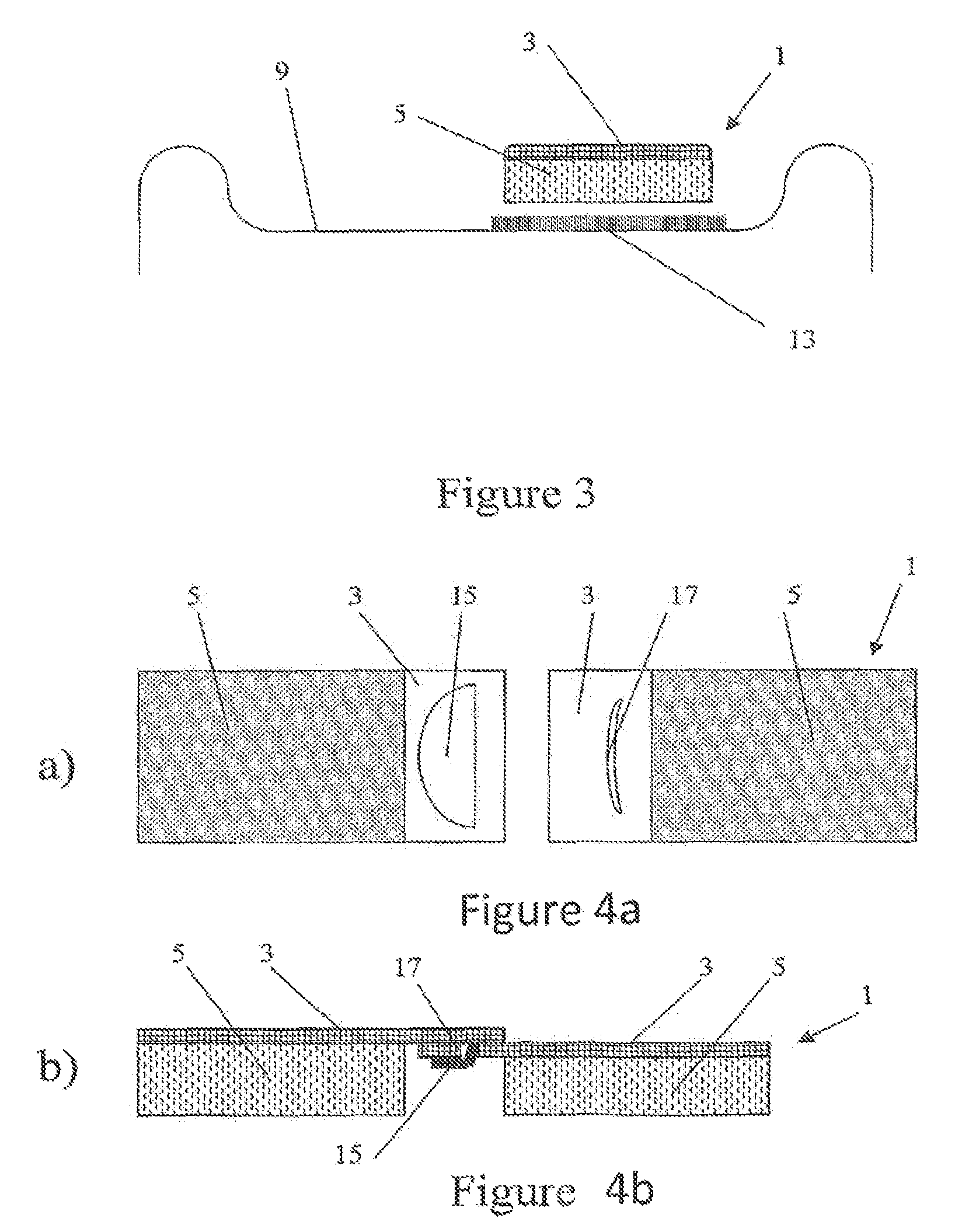

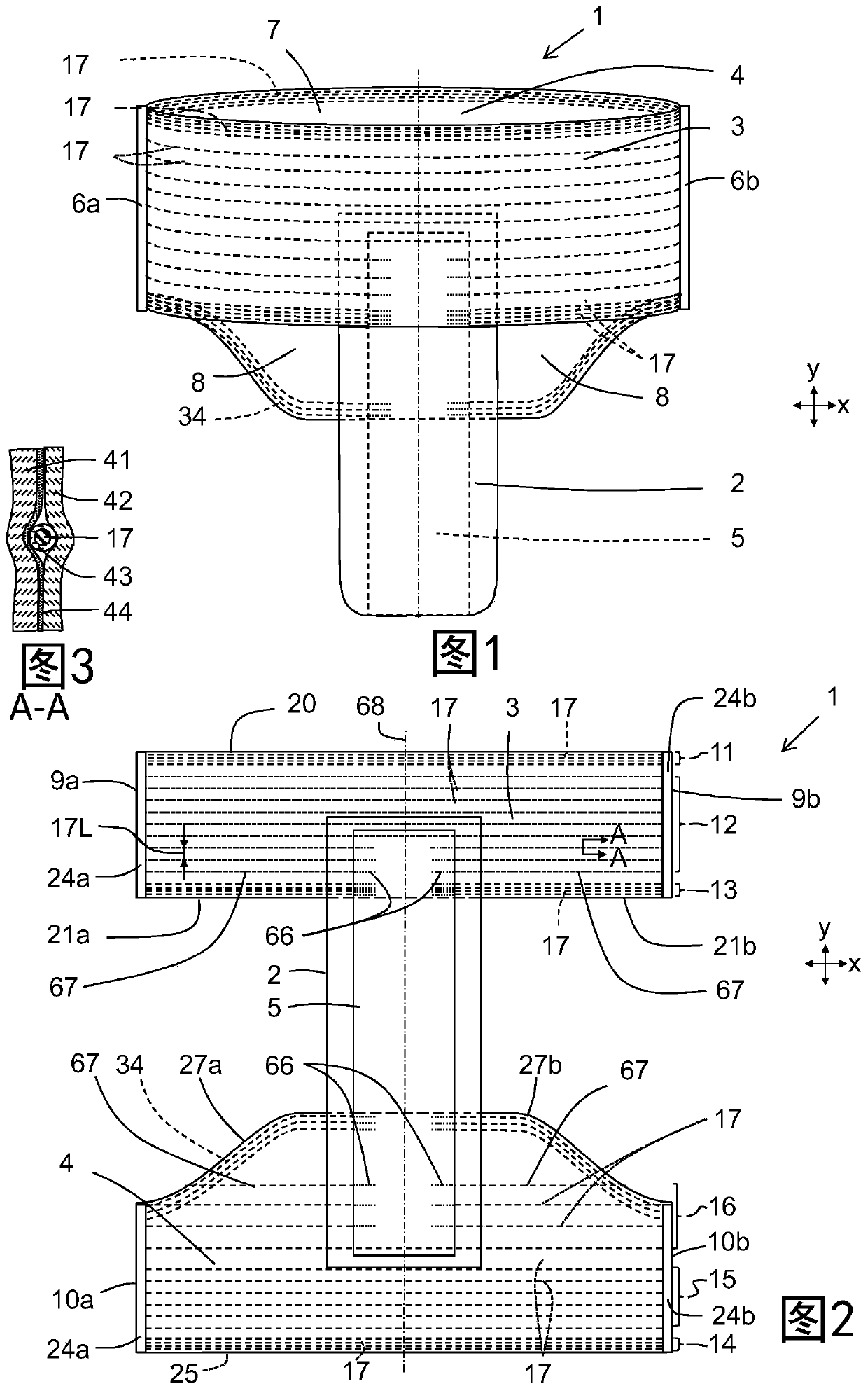

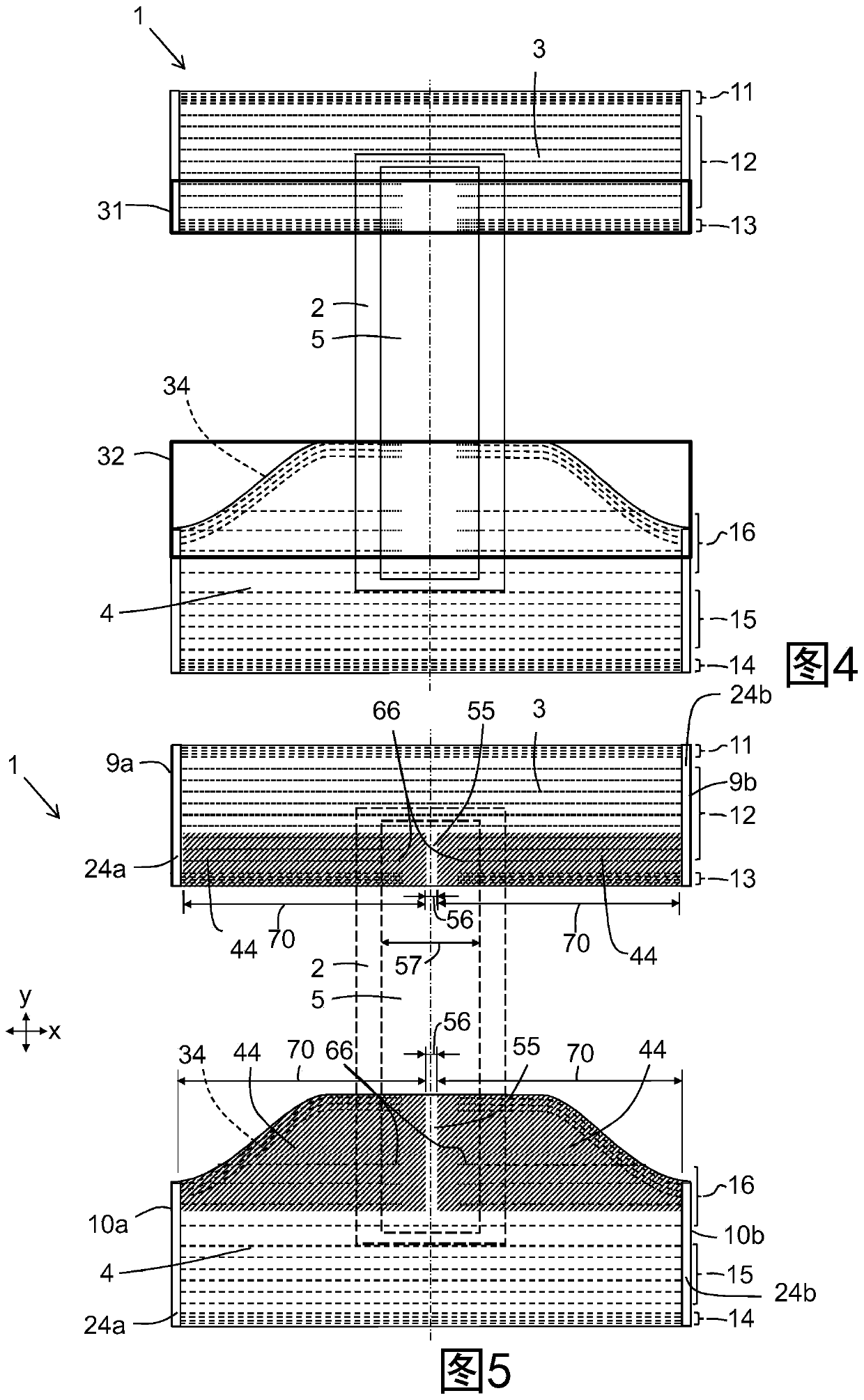

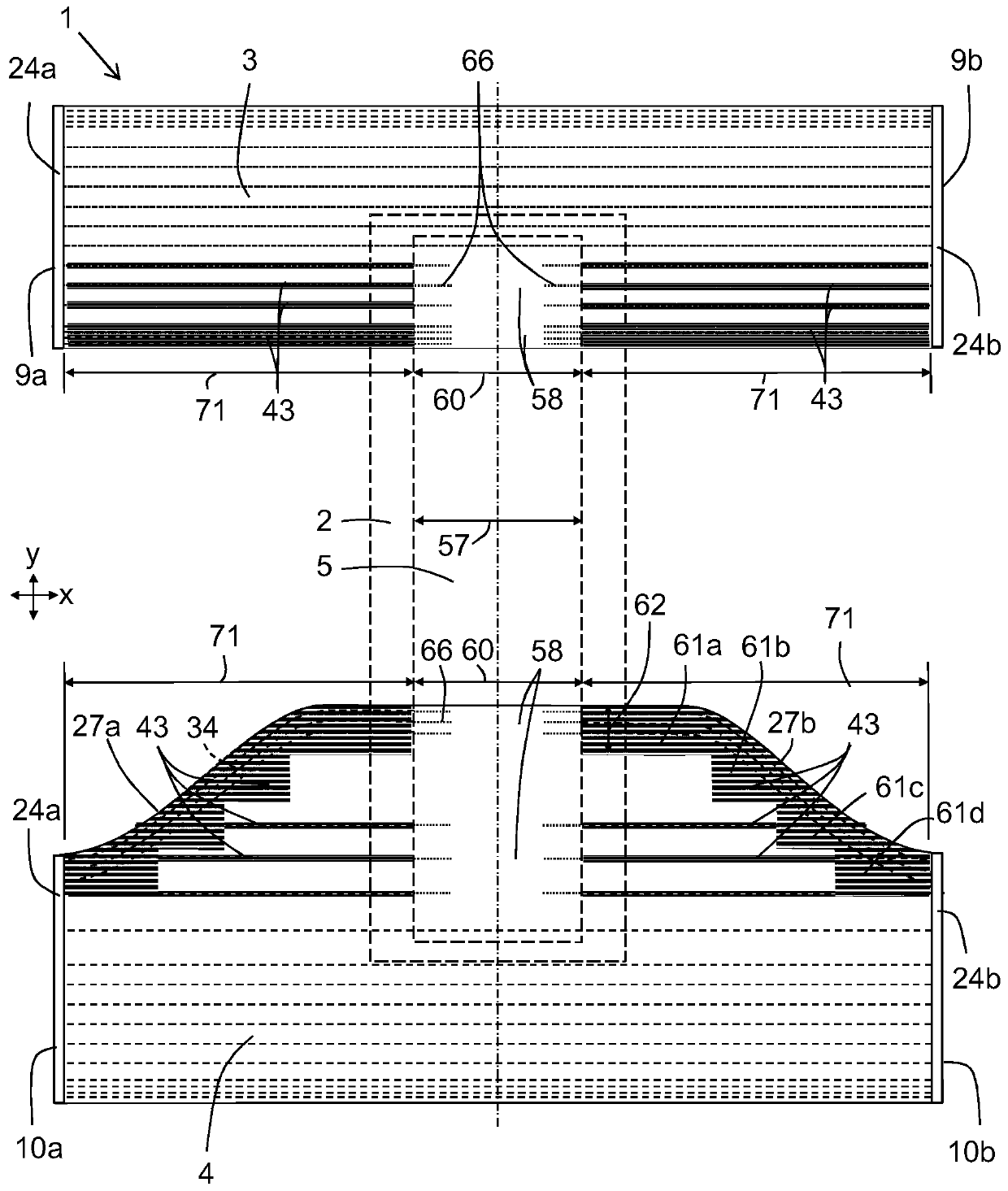

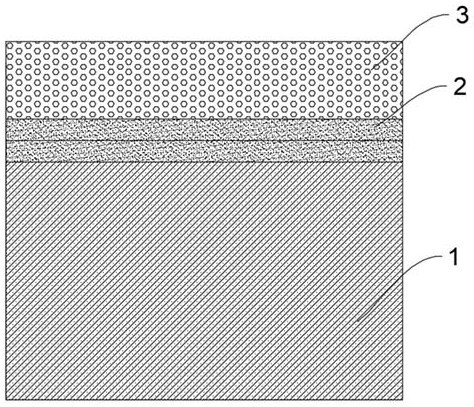

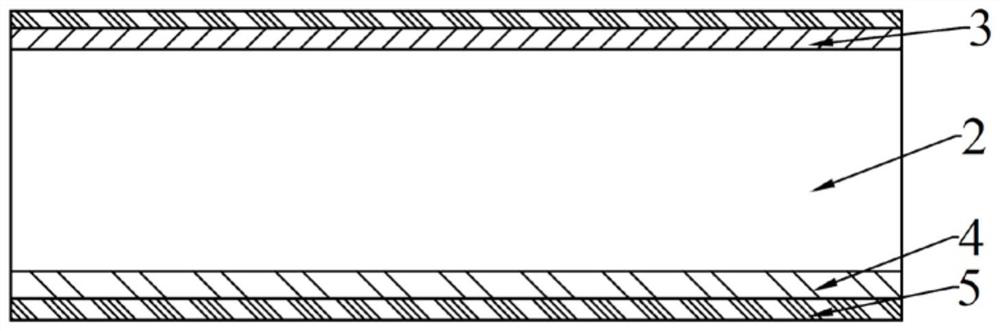

A disposable pant-type absorbent article

ActiveCN110022815AImprove comfortImprove fitAdhesive articlesLaminationEngineeringAdhesive materials

The invention relates to a disposable pant-type absorbent article (1) such as a pant diaper, a sanitary pant or incontinence pant, having a longitudinal direction (Y) and a transverse direction (X). Said disposable pant-type absorbent article comprises: a chassis made of laminated web material and having a front section (3) and a back section (4), an absorbent insert (2) located mainly in a crotchportion of the absorbent article (1) and connected to the front and back sections (3, 4) and having an absorbent core (5), wherein a region (31, 23) of the front and / or back section (3, 4) is made ofa laminated elastic web material comprising a plurality of elastic threads extending from a location adjacent a first lateral side of the front and / or back section (3, 4) to a location adjacent an opposite lateral side of the front and / or back section (3, 4). The elastic threads are interrupted in a central area of the absorbent article (1). A first adhesive material (44) primarily for securing sheets of web material of the laminated web material to each other is applied in the region from a location adjacent a first lateral side of the front and / or back section (3, 4) to a location adjacentan opposite lateral side of the front and / or back section (3, 4), while leaving a first gap (55) in the central area of the absorbent article free from the first adhesive (44). A second adhesive material (43) primarily for securing the elastic threads to the sheets of laminated web material is applied in the region from a location adjacent a first lateral side of the front and / or back section (3,4) to a location adjacent an opposite lateral side of the front and / or back section (3, 4), while leaving a second gap (58) in the central area of the absorbent article (1) free from the second adhesive material. A width (56) of the first gap (55) in the direction (X) is smaller than a width (60) of the second gap (58) in the transverse direction (X), such that an adhesive gradient is provided inthe region (31, 32) as seen from a centre of the absorbent article (1) towards the lateral edges of the absorbent article (1).

Owner:ESSITY HYGIENE & HEALTH AB

Manufacturing method of low-residual-stress polycrystalline diamond compact

PendingCN113976892AImprove heat resistanceReduce mining costsTurbinesOther manufacturing equipments/toolsPolycrystalline diamondAlloy substrate

The invention discloses a manufacturing method of a low-residual-stress polycrystalline diamond compact. The polycrystalline diamond compact is formed by sintering a diamond layer and a transition layer with a hard alloy matrix by using a traditional cubic press under the conditions that the pressure is 5-10 GPa and the temperature is 1200-1800 DEG C. The diamond layer is formed by mixing diamonds with the average particle size of 0.5-100 microns, the transition layer is formed by mixing tungsten carbide micro powder or tungsten carbide micro powder with at least one of metal cobalt, metal tungsten and diamond micro powder, and the micro powder of the transition layer is sequentially laid according to the particle size from small to large or according to the diamond duty ratio from large to small, and at least two layers are laid. The polycrystalline diamond compact with low residual stress and high impact toughness in the field of drilling is prepared, and the comprehensive performance of the PDC compact is improved. The impact toughness is further improved, the residual stress between the diamond layer and the alloy substrate is reduced, and the delamination risk of the PDC composite sheet is reduced so as to cope with geological drilling under more and more complex geological conditions.

Owner:HENAN JINGRUI SUPERHARD MATERIAL

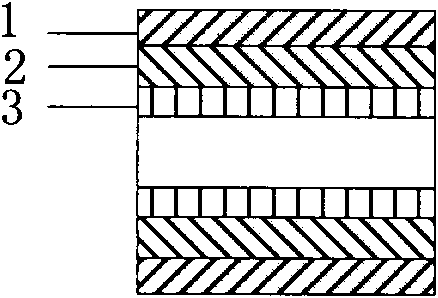

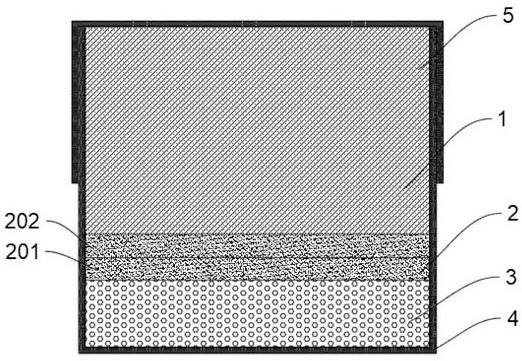

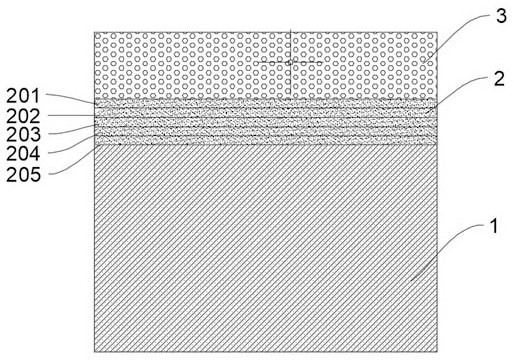

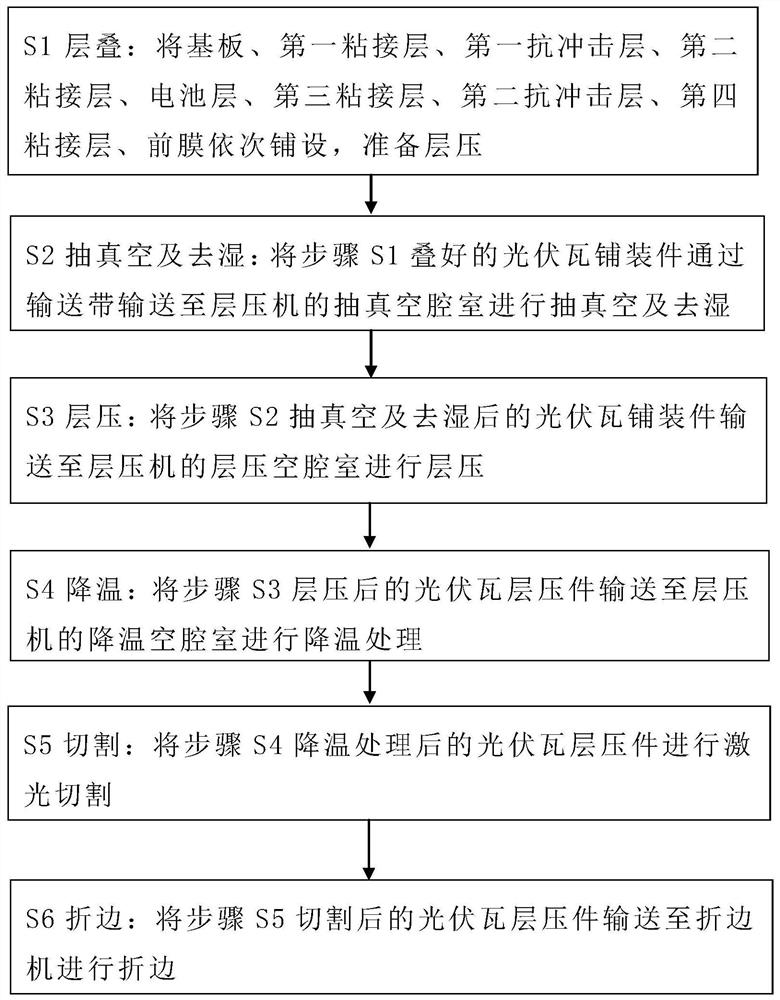

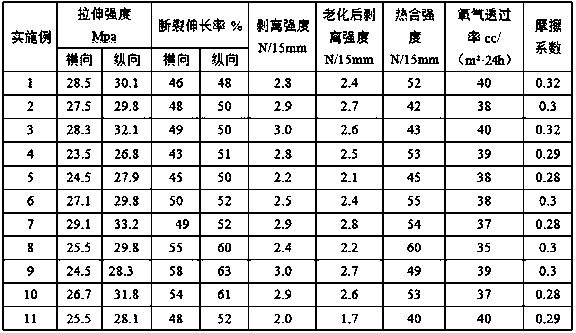

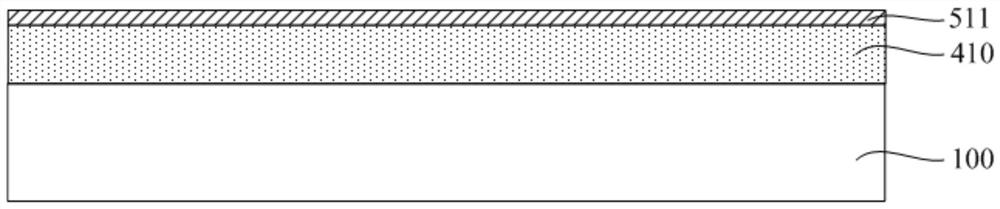

Photovoltaic tile preparation method and photovoltaic tile

InactiveCN113027042AReduce thickness requirementsWith insulating layer functionPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringBattery cell

The invention discloses a photovoltaic tile preparation method and a photovoltaic tile. The photovoltaic tile preparation method comprises the following steps of: laminating: sequentially laying a substrate, a first bonding layer, a first impact-resistant layer, a second bonding layer, a battery layer, a third bonding layer, a second impact-resistant layer, a fourth bonding layer and a front film, and preparing lamination; vacuumizing and dehumidifying; laminating; cooling; cutting; and folding edges. The photovoltaic tile is prepared by the method.

Owner:武汉美格科技股份有限公司

Anticorrosive gas penetration composite packaging material and preparation method thereof

PendingCN110497660AImprove barrier propertiesImprove toleranceFlexible coversWrappersLow-density polyethylenePolymer science

The invention discloses an anticorrosive gas penetration composite packaging material and a preparation method thereof. The composite packaging material is formed by compounding a polyamide polyethylene coextruded film and a biaxially-oriented polyethylene glycol terephthalate film, and the polyamide polyethylene coextruded film is formed by coextruding a heat sealing layer and a corona layer; theheat sealing layer is composed of metallocene polyethylene and low-density polyethylene, and the corona layer is made of a polyamide resin; and an adhesive is applied between the polyamide polyethylene coextruded film and the biaxially-oriented polyethylene glycol terephthalate film in a coating manner. The preparation method comprises the following steps: (1) preparing the polyamide polyethylenecoextruded film; and (2) carrying out intaglio printing on the biaxially-oriented polyethylene glycol terephthalate film, and carrying out dry compounding on the printed biaxially-oriented polyethylene glycol terephthalate film and the polyamide polyethylene coextruded film by using the adhesive. The composite strength, the heat sealing strength and other indexes of the composite packaging material all meet the requirements of product design, and the composite packaging material has good tolerance to corrosive gas, and is suitable for packaging products containing essence and the like.

Owner:河北永新包装有限公司

PTFE composite glue blocking film for LCP high-temperature lamination and production process thereof

ActiveCN111040649ASimple production processEasy to implementFilm/foil adhesive release linersPolymer chemistryPtfe composite

The invention discloses a PTFE composite glue blocking film for LCP high-temperature lamination, which is characterized in that the PTFE composite glue blocking film sequentially comprises a first release film layer, a first adhesive layer, a high-temperature glue blocking layer, a second adhesive layer and a second release film layer from top to bottom, the first adhesive layer and the second adhesive layer are independently formed by a high-temperature adhesive; and the high-temperature glue blocking layer is a PTFE / PE / hydroxyl-terminated methyl vinyl fluorosilicone oil blended film layer. The invention also provides a production process of the PTFE composite glue blocking film for LCP high-temperature lamination. The PTFE composite glue blocking film for LCP high-temperature laminationdisclosed by the invention is remarkable in release and glue blocking effects, excellent in mechanical property, long in service lifetime and good in high-temperature resistance.

Owner:苏州市新广益电子股份有限公司

Semiconductor structure and forming method thereof

PendingCN112349581AImprove adhesion strengthReduce the risk of delaminationSemiconductor/solid-state device manufacturingSemiconductor structureDielectric layer

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the steps: providing a substrate; forming a first electrode layer on the substrate; forminga dielectric layer on the first electrode layer; forming a second electrode layer on the dielectric layer; forming an oxide layer on the second electrode layer; forming a first etching stop layer onthe surface of the oxide layer; forming an insulating layer on the first etching stop layer; and etching the insulating layer, the first etching stop layer and the oxide layer to form a first contacthole, wherein the bottom of the first contact hole expose the top surface of the second electrode layer, and the first contact hole penetrates through the insulating layer, the first etching stop layer and the oxide layer. According to the invention, the adhesion strength of the second electrode plate and the first etching stop layer is improved, and the risk of layering between the second electrode plate and the first etching stop layer is reduced, so that the packaging quality is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Rework double-sided foam tape, reworking method and preparation method

ActiveCN113444466AReduce workloadEasy to reworkAdhesive processesFilm/foil adhesivesElastomerPolymer science

The invention discloses a rework double-sided foam tape comprising: an elastomer stretching layer having a first surface and a second surface opposite to each other in thickness direction; two foam layers which are fixedly arranged on the first surface and the second surface of the elastomer stretching layer respectively; two reinforcing film layers which are fixedly arranged on the surface, opposite to the elastomer stretching layer, of the foam layers respectively; and two pressure-sensitive adhesive layers which are respectively and fixedly arranged on the surface, opposite to the foam layers, of the reinforced film layers. The elongation at break and the tensile strength of the elastomer stretching layer are superior to those of the foam layers, and the elastomer stretching layer deforms to damage the foam layers and then is separated from the foam layers. The invention also discloses a reworking method and a preparation method based on the rework double-sided foam tape.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

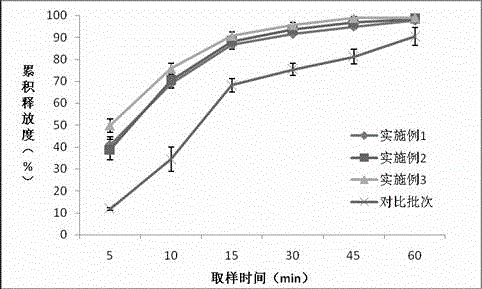

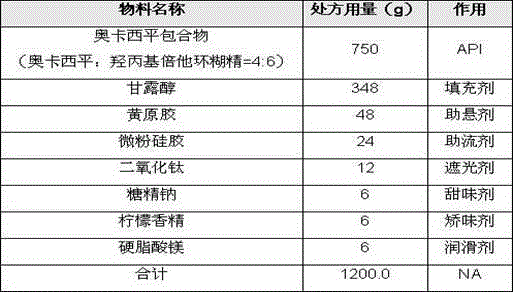

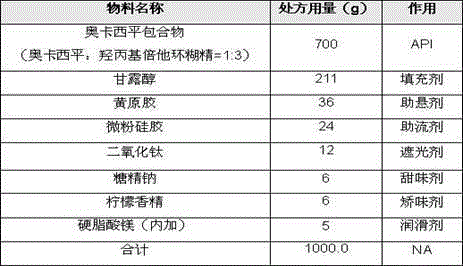

Oxcarbazepine dry suspension, and preparation method thereof

InactiveCN106606483AImprove solubilityImprove bioavailabilityNervous disorderPharmaceutical non-active ingredientsAdditive ingredientSuspending Agents

The invention relates to an oxcarbazepine dry suspension, and a preparation method thereof. The oxcarbazepine dry suspension comprises following ingredients, by weight, 30 to 70% of an oxcarbazepine hydroxypropyl-beta-cyclodextrin inclusion compound, 20 to 60% of a filling agent, 1 to 5% of a suspending agent, 0.5 to 5% of a flow aid, 0.3 to 3% of an opacifying agent, and 0.1 to 5% of a flavoring agent; wherein the oxcarbazepine hydroxypropyl-beta-cyclodextrin inclusion compound is prepared via inclusion of oxcarbazepine with hydroxypropyl-beta-cyclodextrin at a weight ratio of 1:1-3. Inclusion of main drug oxcarbazepine with hydroxypropyl-beta-cyclodextrin is capable of increasing the solubility of oxcarbazepine greatly, and increasing bioavailability; and in addition, inclusion of cyclodextrin is capable of covering the bitter taste of oxcarbazepine, and improving compliance of child patients. In preparation process, dry granulation is adopted, and compared with wet granulation, dry granulation possesses following advantages: technical process of dry granulation is stable, and layering risk is reduced.

Owner:ZHEJIANG POLY PHARMA +1

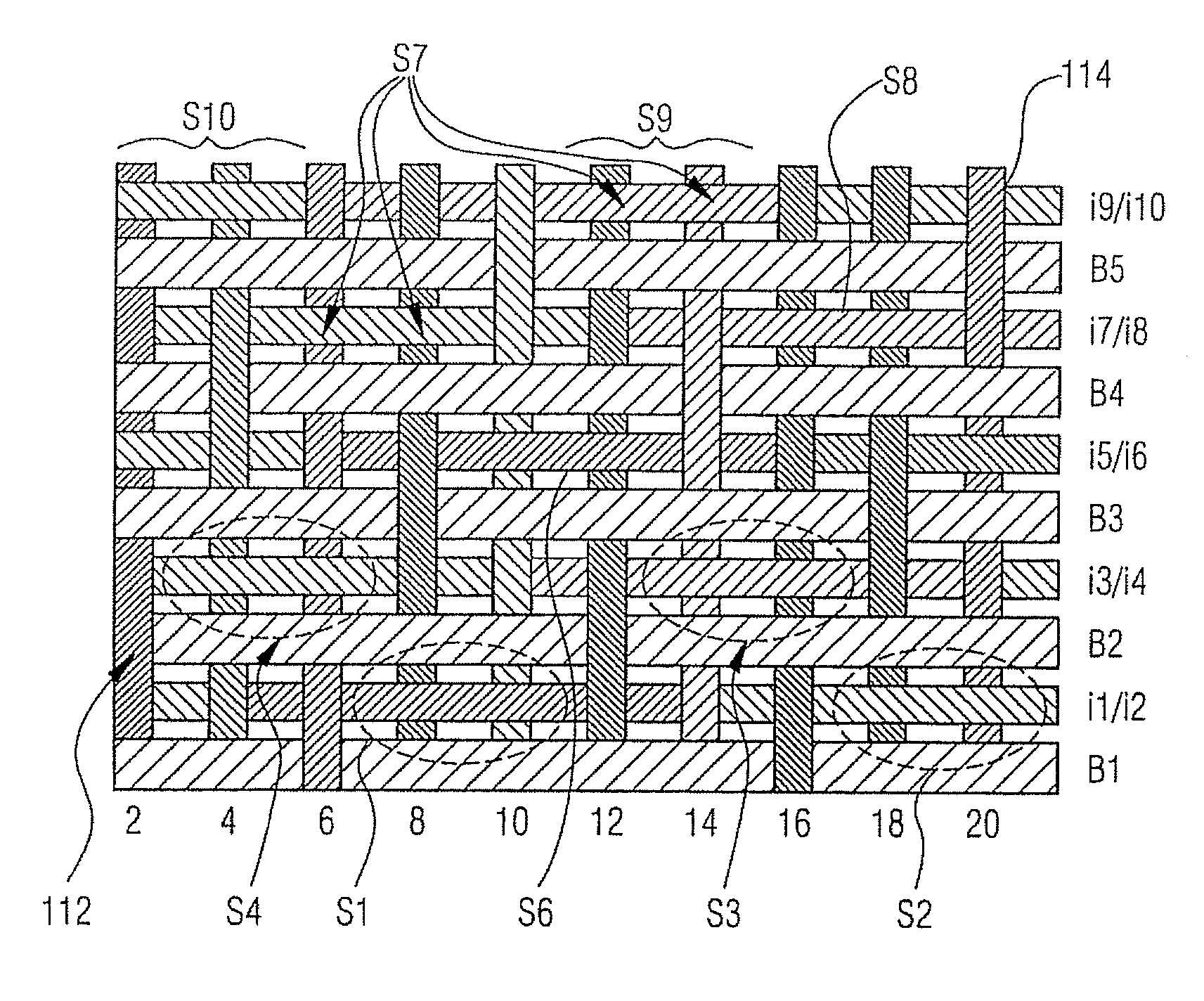

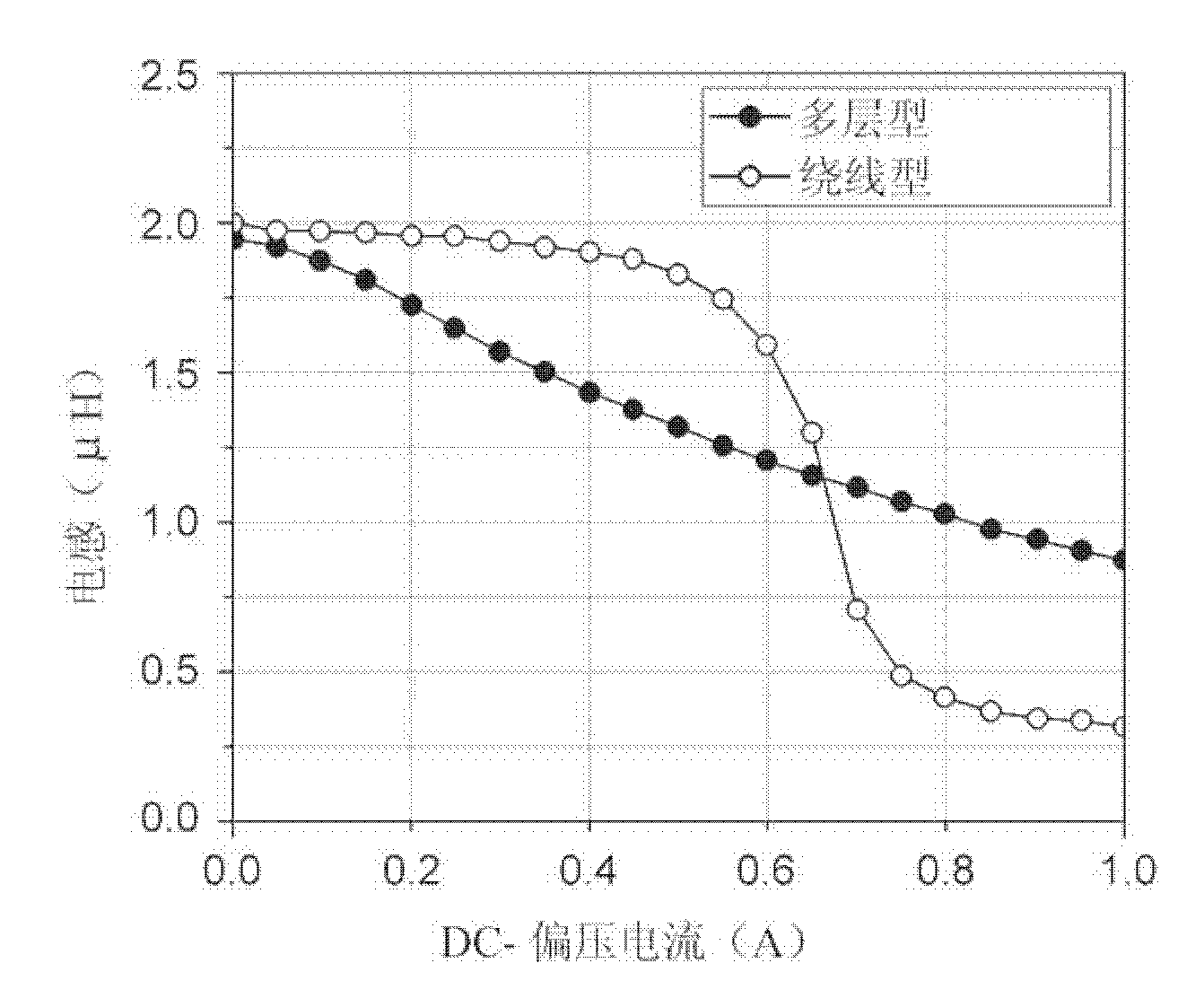

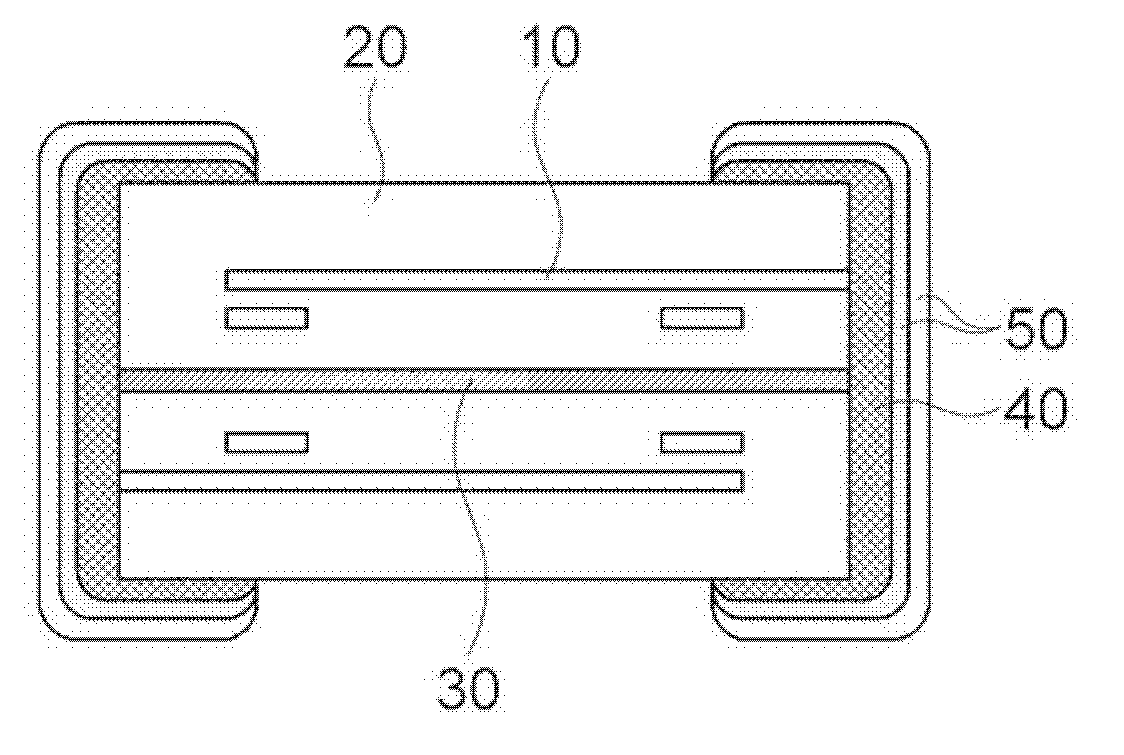

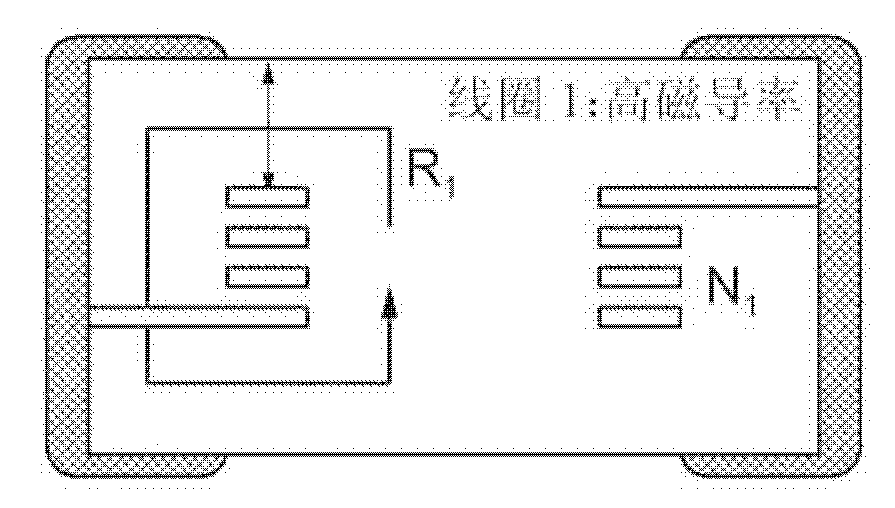

Multilayer type power inductor

InactiveCN102760566AReduce the risk of delaminationImproved bias-TCL characteristicsTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureMagnetizationInductor

Disclosed herein is a multilayer type power inductor including: a plurality of body layers including internal electrodes and having magnetic material layers stacked therein,and a plurality of gap layers, wherein the gap layer has an asymmetrical structure. In the multilayer type power inductor, portions that are in contact with the body layers have, a non-porous structure, which is a dense structure, and portions that are not in contact with the body layers have a porous structure, such that the gap layer has the asymmetrical structure. Therefore, a magnetic flux propagation path in a coil is dispersed to suppress magnetization at a high current, thereby making it possible to improve a change in inductance (L) value according to the application of current.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Carbon fiber composite propeller for ship and preparation method thereof

ActiveCN109515667AReduce noiseEasy maintenanceRotary propellersDomestic articlesResin matrixPropeller

A carbon fiber composite propeller for a ship comprises a metal hub and four carbon fiber composite blades installed on the metal hub. The metal hub and the carbon fiber composite blades are assembledthrough installation clamping grooves and installation protrusions, and adhesive layers are additionally arranged so that the metal hub and the carbon fiber composite blades are fixedly connected; each carbon fiber composite blade is formed by compositing a prefabricated body and a resin matrix, wherein the prefabricated body is formed by stacking and pasting joint-laying fabrics layer by layer on a mold of the prefabricated body. The prepared carbon fiber composite propeller has the advantages of being high in size precision, high in strength, good in rigidity, light in dead weight, low in noise, resistant to corrosion, resistant to microbial adhesion and the like, and meanwhile has good fatigue performance and impact resistance.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com