Plastic-lined steel plastic composite tube and manufacturing method thereof

A steel-plastic composite pipe, a technology for manufacturing method, applied in the direction of pipe, rigid pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of poor anti-aging ability of outer layer and poor anti-rust ability of inner layer, etc., and save heating cost , the effect of reducing the risk of stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

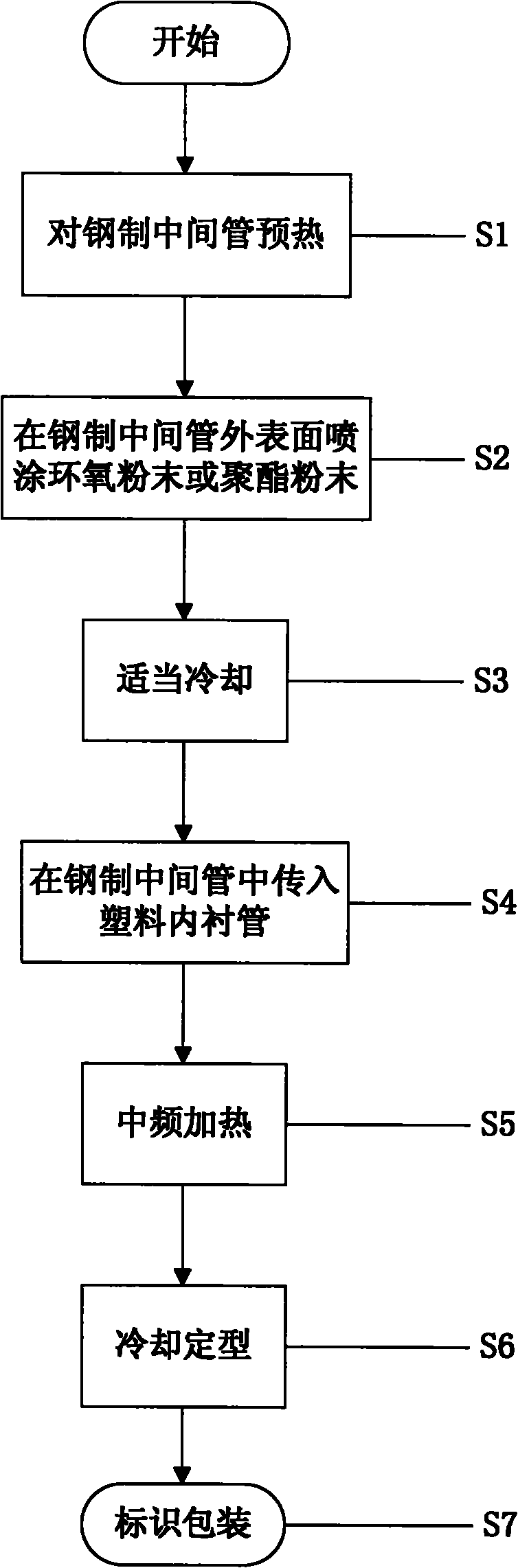

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

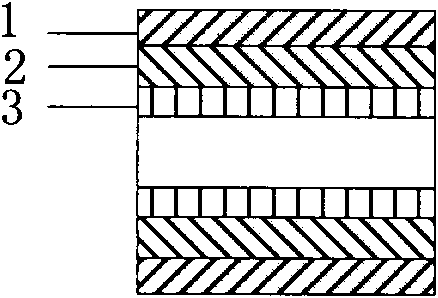

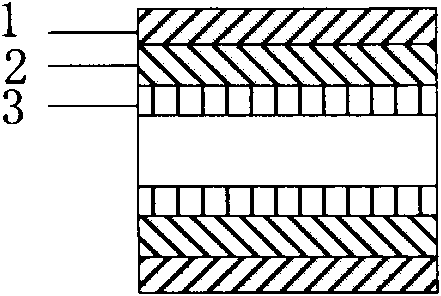

[0029] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0030] This embodiment is a plastic-lined steel-plastic composite pipe, which includes a plastic inner pipe 1 and a steel intermediate pipe 2, and the outer surface of the steel intermediate pipe is coated with an epoxy or polyester material with protection and aging resistance. Layer paint 3. Among them, epoxy has strong flame retardancy and can be used in the field of fire protection, while polyester has strong ultraviolet aging resistance and can be used for surface-mounted pipes.

[0031] Wherein the plastic lining pipe 1 is thermoplastic, preferably, said thermoplastic is PVC, PVC-C, PE, PERT, PPR, ABS.

[0032] Wherein the steel intermediate pipe 2 is a phosphated steel pipe, preferably, straight seam welding, spiral seam submerg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com