Manufacturing method of low-residual-stress polycrystalline diamond compact

A polycrystalline diamond and manufacturing method technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve problems such as interface delamination, and achieve the effects of improving heat resistance, improving service life, and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

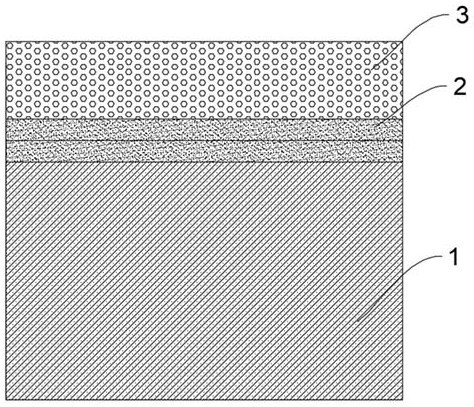

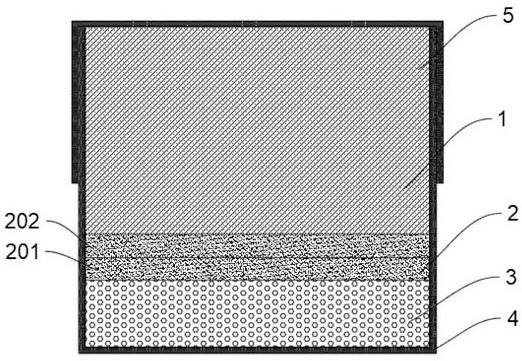

[0036] Such as figure 1 and figure 2 shows a low residual stress polycrystalline diamond composite sheet, when assembling, first assemble the polycrystalline diamond layer 3 in the metal bottom cup 4, put tungsten carbide and at least one of metal cobalt, metal tungsten, and diamond powder to mix and form The formed micropowder is the transition layer 2, then put into the hard alloy layer 1, and finally place the metal cap cup 5 on the upper end of the hard alloy substrate.

[0037]The specific assembly process is: the first step is to put the mixed diamond powder with a particle size of 0.5~100 μm. The average characteristic particle size used in this invention is 16 μm. Or into a stepped structure or planar structure, the thickness of the micropowder is 3.5mm; the second step is to mix tungsten carbide and at least one of metal cobalt, metal tungsten, and diamond micropowder after high-temperature vacuum reduction treatment. , the characteristic particle size of the micr...

Embodiment approach 2

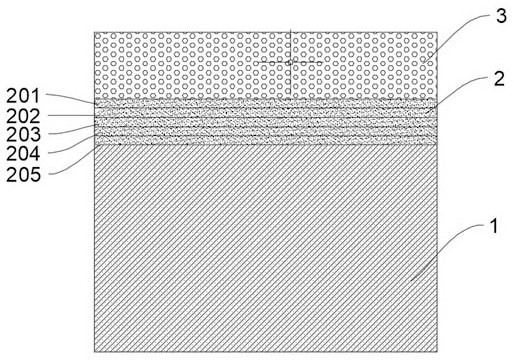

[0039] Such as image 3 and 4 As shown, this embodiment specifically discloses a method for manufacturing a low residual stress polycrystalline diamond composite with 5 layers of transition layers. When assembling, the polycrystalline diamond layer 3 is first assembled in the metal bottom cup 4, and a layer of tungsten carbide and diamond is put in. Mix the micropowder to form the transition layer 2, then put it into the cemented carbide layer 1, and finally place the metal cap cup 5 on the upper end of the cemented carbide substrate.

[0040] The specific assembly process is that the first step is to put the mixed diamond powder with a particle size of 0.5~100 μm. The average characteristic particle size used in this invention is 16 μm. Or turn it into a stepped structure or a flat structure, and the thickness of the micropowder in the cup is 3.5mm;

[0041] The second step is to mix the tungsten carbide micropowder that has undergone high-temperature vacuum reduction treat...

Embodiment approach 3

[0047] Such as image 3 and 4 As shown, this embodiment specifically discloses a method for manufacturing a low residual stress polycrystalline diamond composite with five transition layers. When assembling, the polycrystalline diamond layer 3 is first assembled in the metal bottom cup 5, and tungsten carbide and diamond are mixed. The micropowder is the transition layer 2, then put into the hard alloy layer 1, and finally place the metal cap cup 6 on the upper end of the hard alloy substrate.

[0048] The specific assembly process is that the first step is to put the mixed diamond powder with a particle size of 0.5~100 μm. The average characteristic particle size used in this invention is 16 μm. Or turn it into a stepped structure or a flat structure, and the thickness of the micropowder in the cup is 3.5mm;

[0049] The second step is to mix the tungsten carbide micropowder that has undergone high-temperature vacuum reduction treatment with at least one of metal cobalt, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com