Blind hole uncapping method using laser

A blind hole and laser technology, which is applied in laser welding equipment, electrical components, printed circuit manufacturing, etc., can solve the problems of uneven removal of the insulating layer in the middle layer, low efficiency, and uneven thickness of the insulating layer, so as to save heating laser Increased power, processing efficiency, and reduced processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

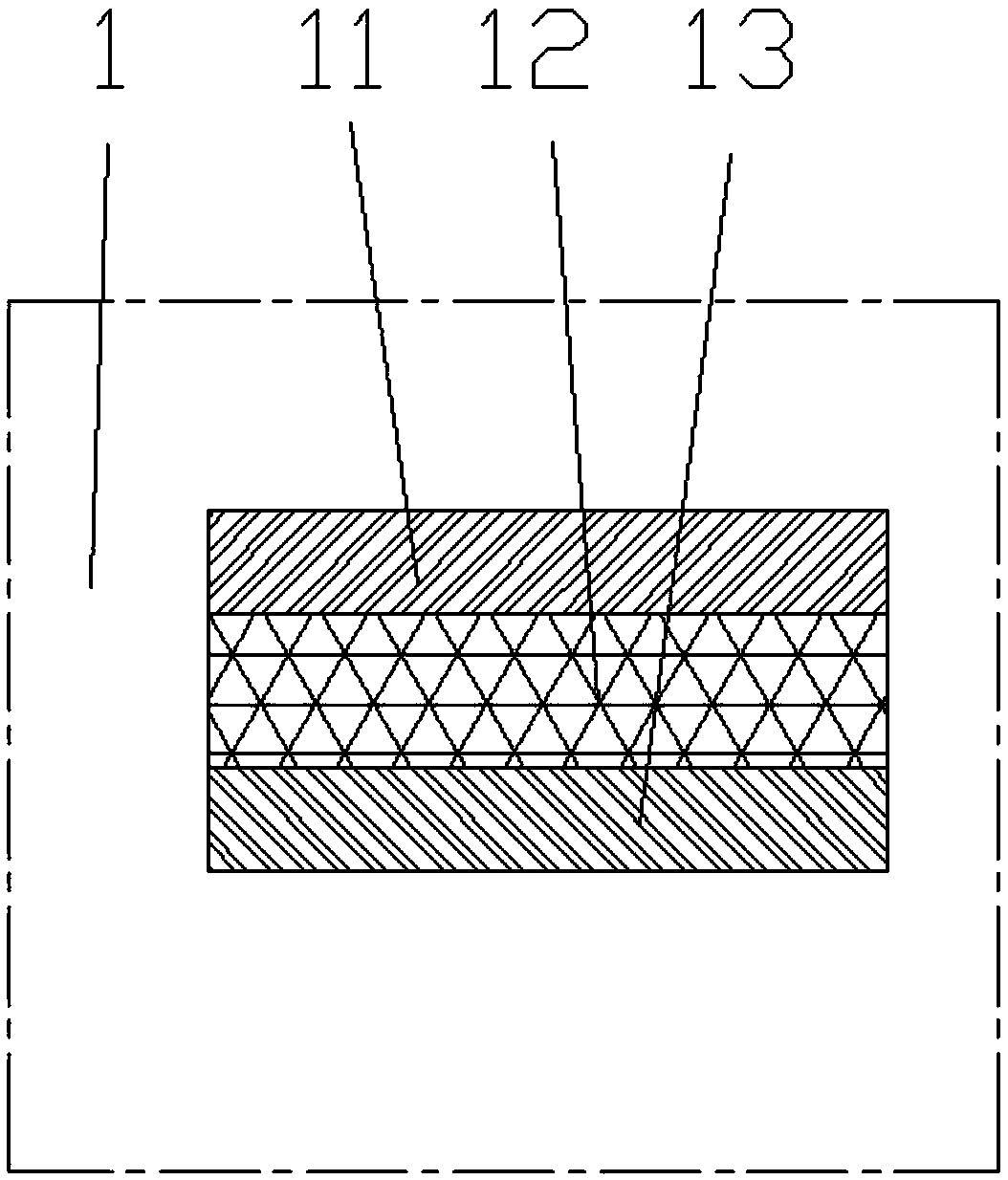

[0052] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

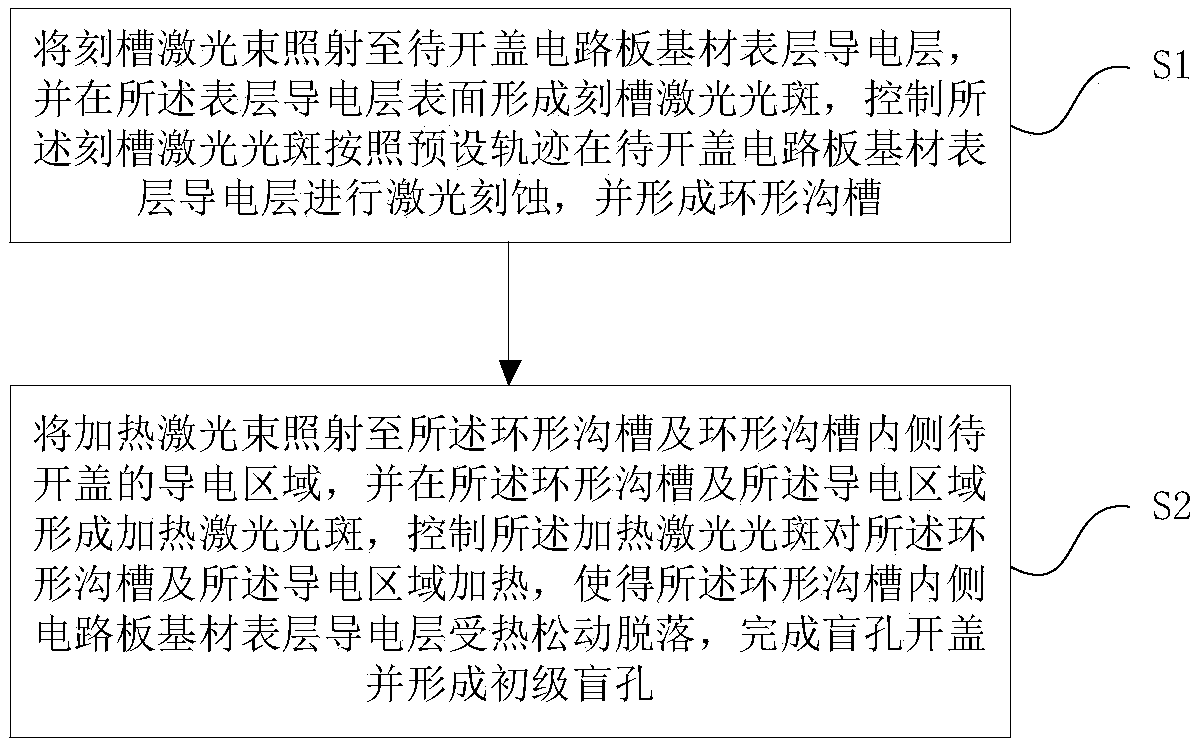

[0053] Such as figure 1 As shown, a laser blind hole uncapping method includes:

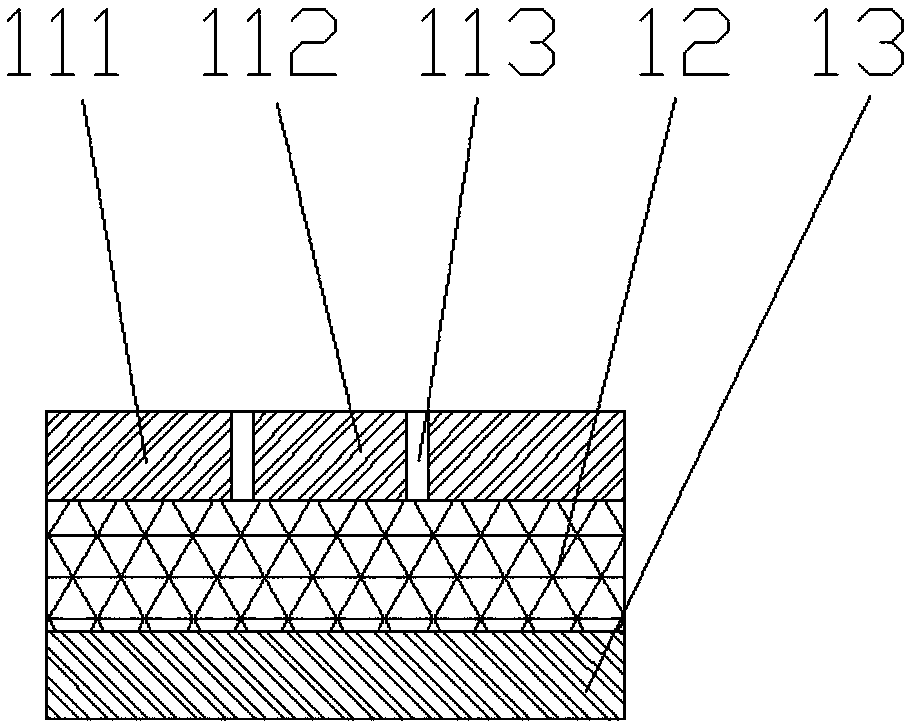

[0054] Step 1: Irradiate the groove laser beam to the surface conductive layer of the substrate of the circuit board to be opened, and form a groove laser spot on the surface of the surface conductive layer, and control the groove laser spot to follow the preset track on the cover to be opened The conductive layer on the surface of the circuit board substrate is laser etched to form an annular groove;

[0055] Step 2: irradiate the heating laser beam to the annular groove and the conductive area to be opened inside the annular groove, and form a heating laser spot on the annular groove and the conductive area, and control the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com