Patents

Literature

292results about How to "Precise heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

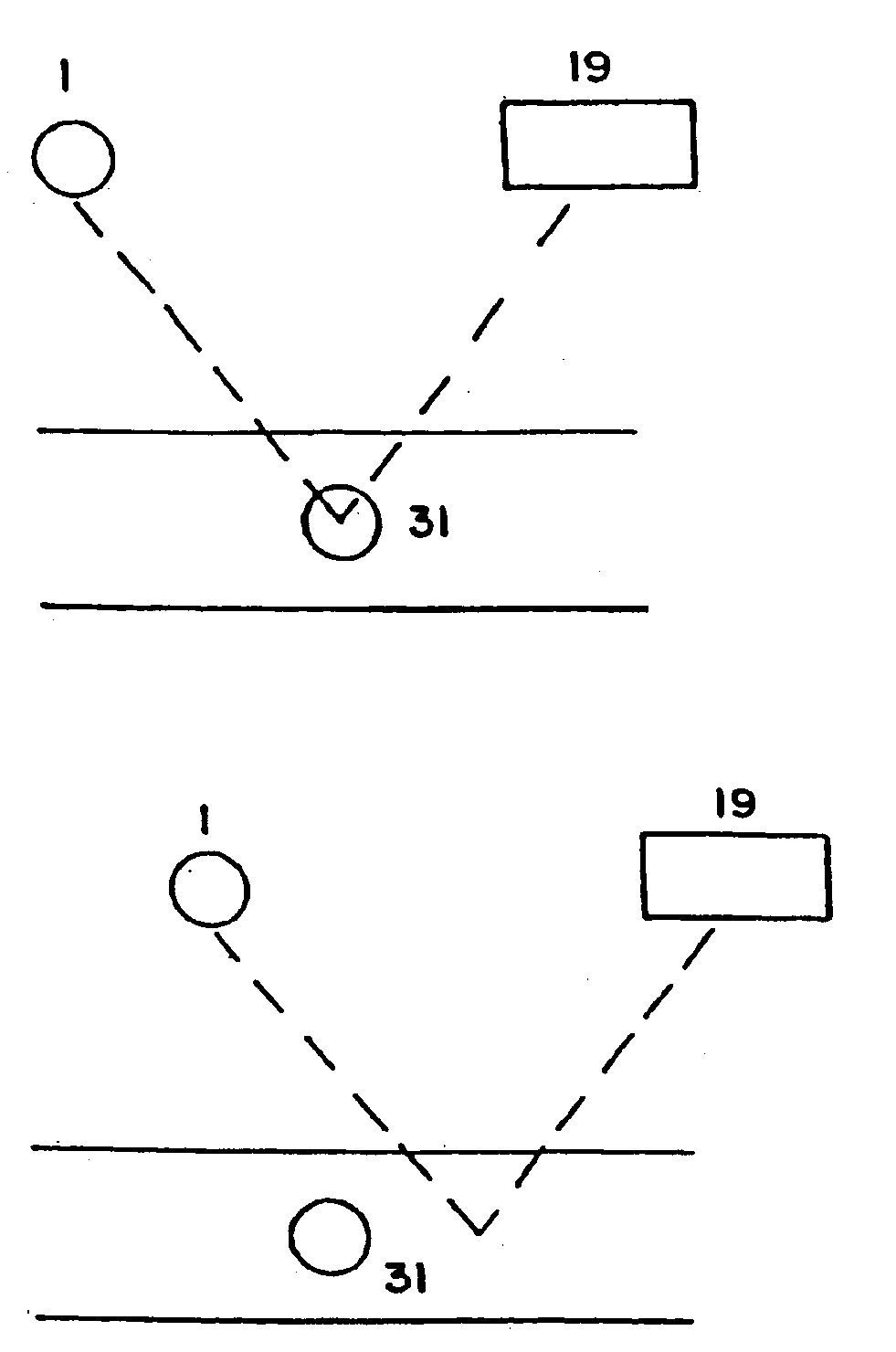

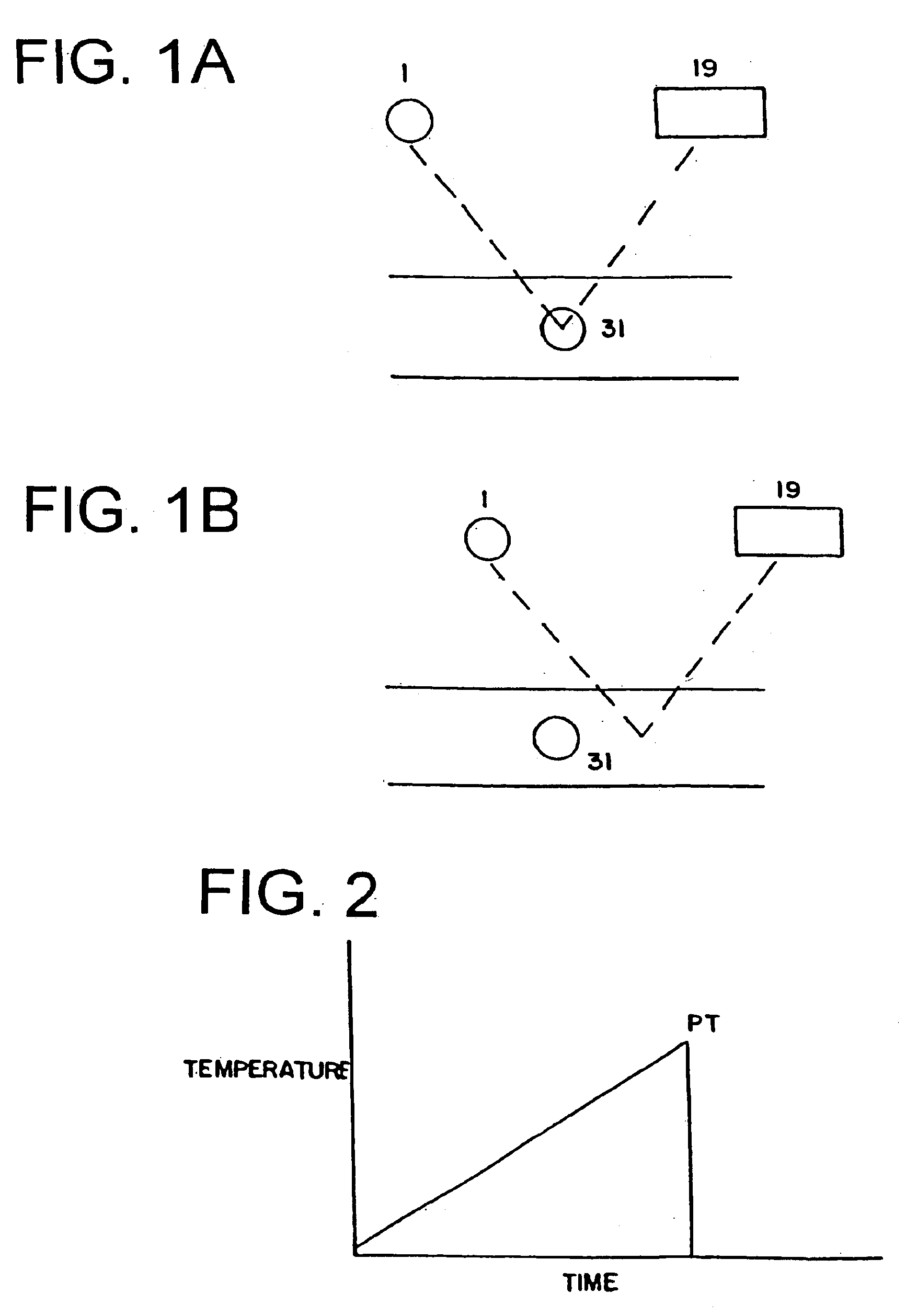

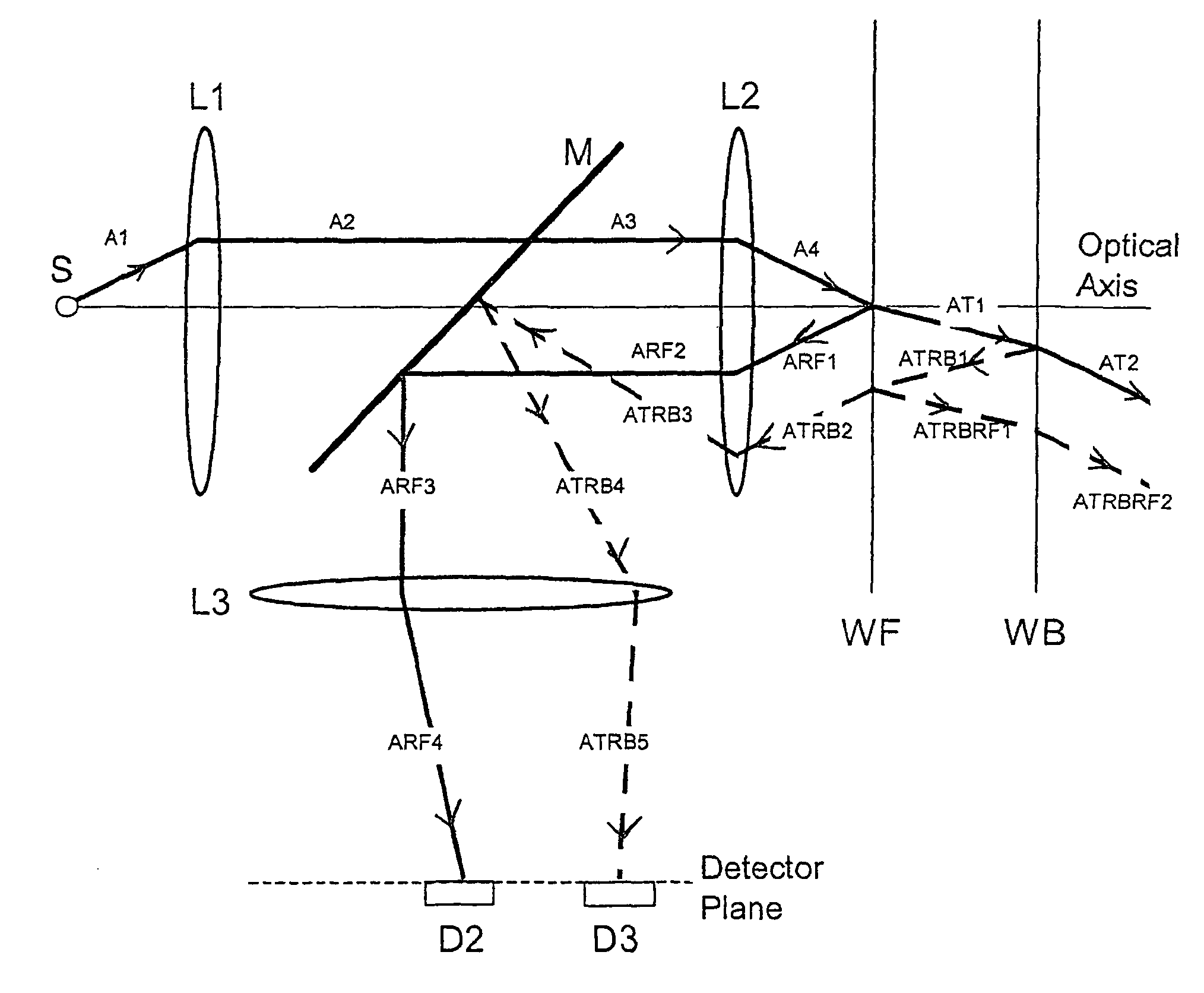

Method and apparatus for performing localized thermal analysis and sub-surface imaging by scanning thermal microscopy

InactiveUS6095679AReduce areaSuitable shapeNanotechMaterial thermal conductivityMaximum depthTemperature wave

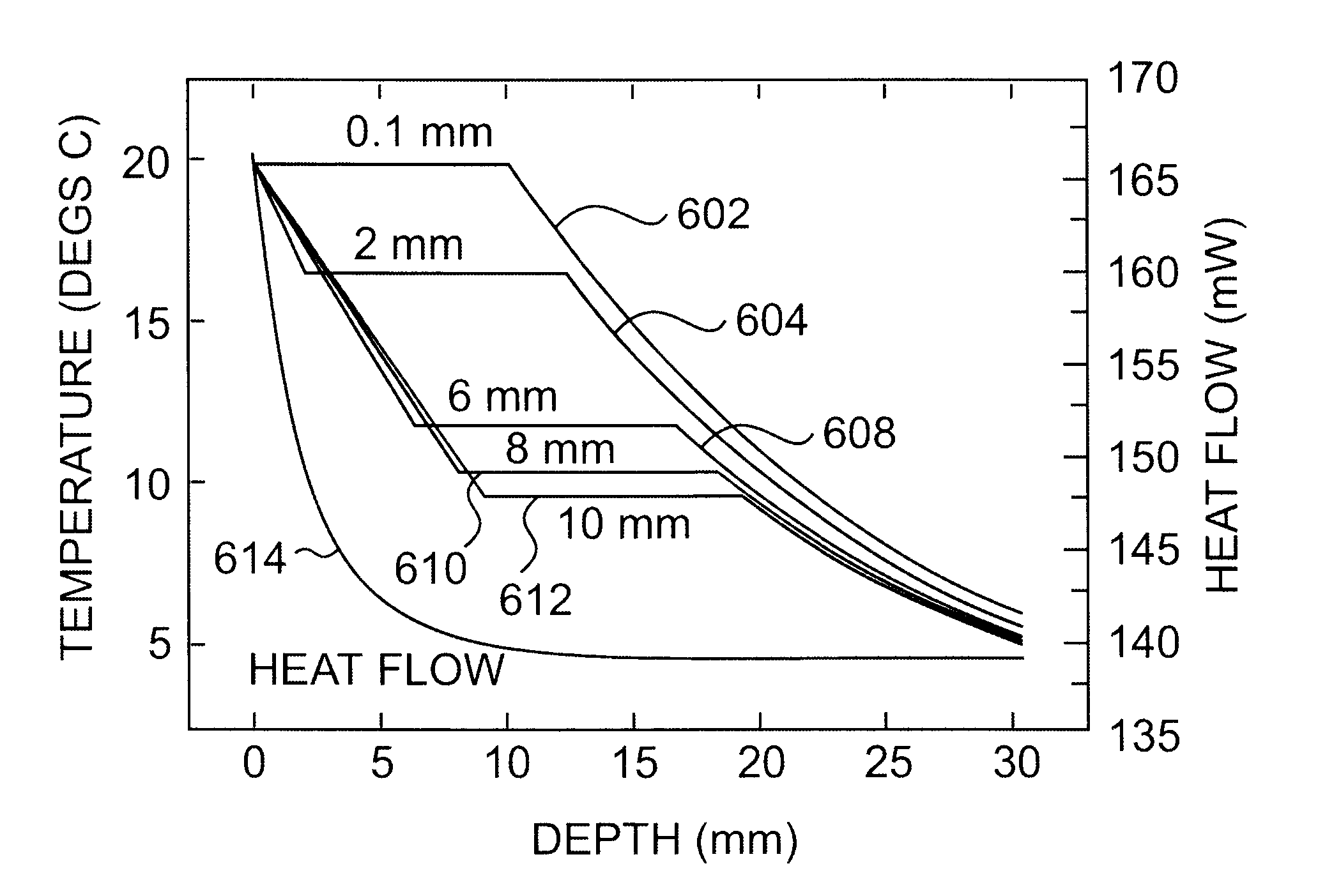

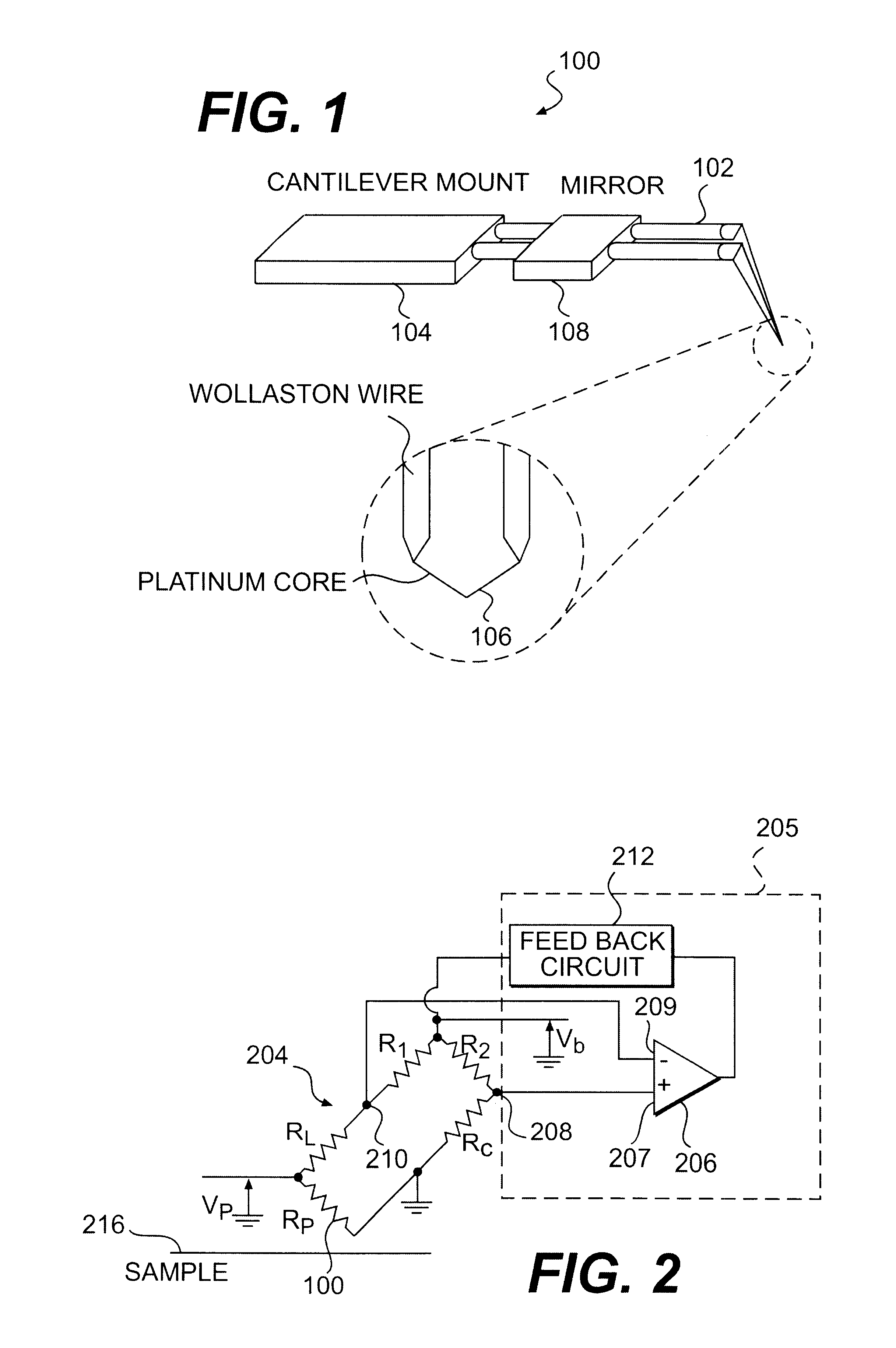

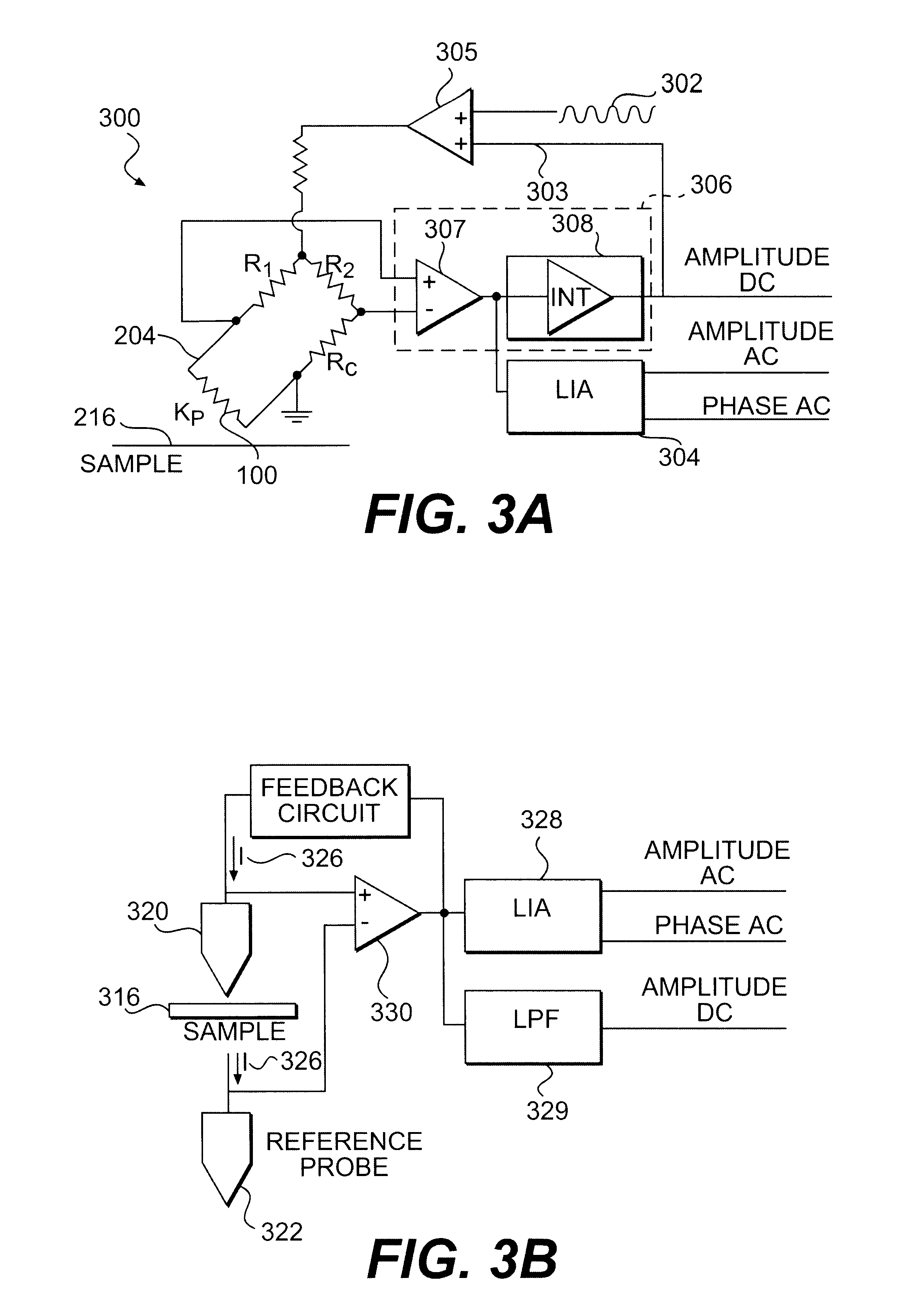

A platinum / Rhodium resistance thermal probe is used as an active device which acts both as a highly localized heat source and as a detector to perform localized differential calorimetry, by thermally inducing and detecting events such as glass transitions, meltings, recystallizations and thermal decomposition within volumes of material estimated at a few mu m3. Furthermore, the probe is used to image variations in thermal conductivity and diffusivity, to perform depth profiling and sub-surface imaging. The maximum depth of the sample that is imaged is controlled by generating and detecting evanescent temperature waves in the sample.

Owner:WATERS TECH CORP

Method and apparatus for performing localized thermal analysis and sub-surface imaging by scanning thermal microscopy

InactiveUS6491425B1Reduce areaSuitable shapeNanotechMaterial heat developmentMaximum depthTemperature wave

A platinum / Rhodium resistance thermal probe is used as an active device which acts both as a highly localized heat source and as a detector to perform localized differential calorimetry, by thermally inducing and detecting events such as glass transitions, meltings, recystallizations and thermal decomposition within volumes of material estimated at a few mum3. Furthermore, the probe is used to image variations in thermal conductivity and diffusivity, to perform depth profiling and sub-surface imaging. The maximum depth of the sample that is imaged is controlled by generating and detecting evanescent temperature waves in the sample.

Owner:WATERS TECH CORP

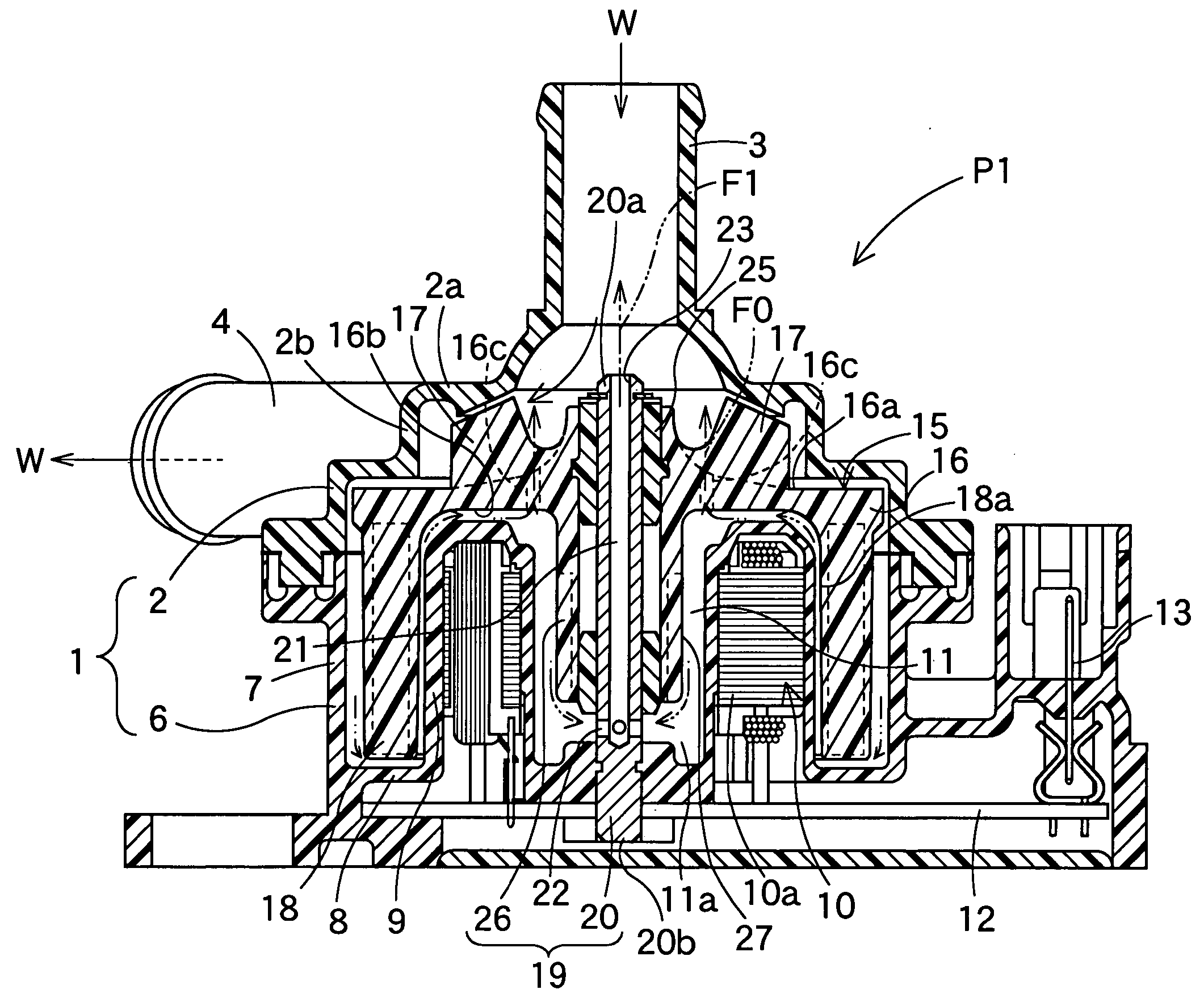

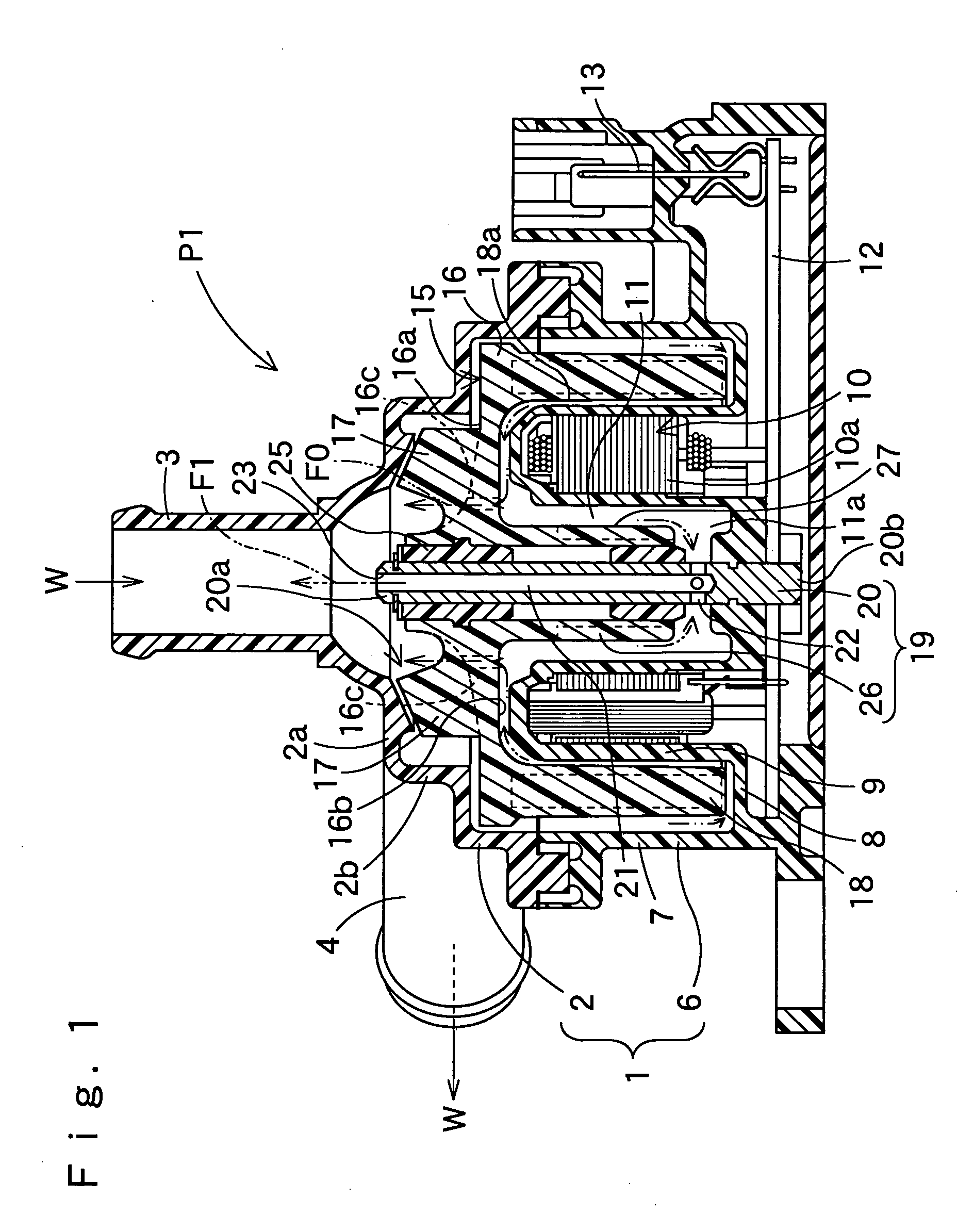

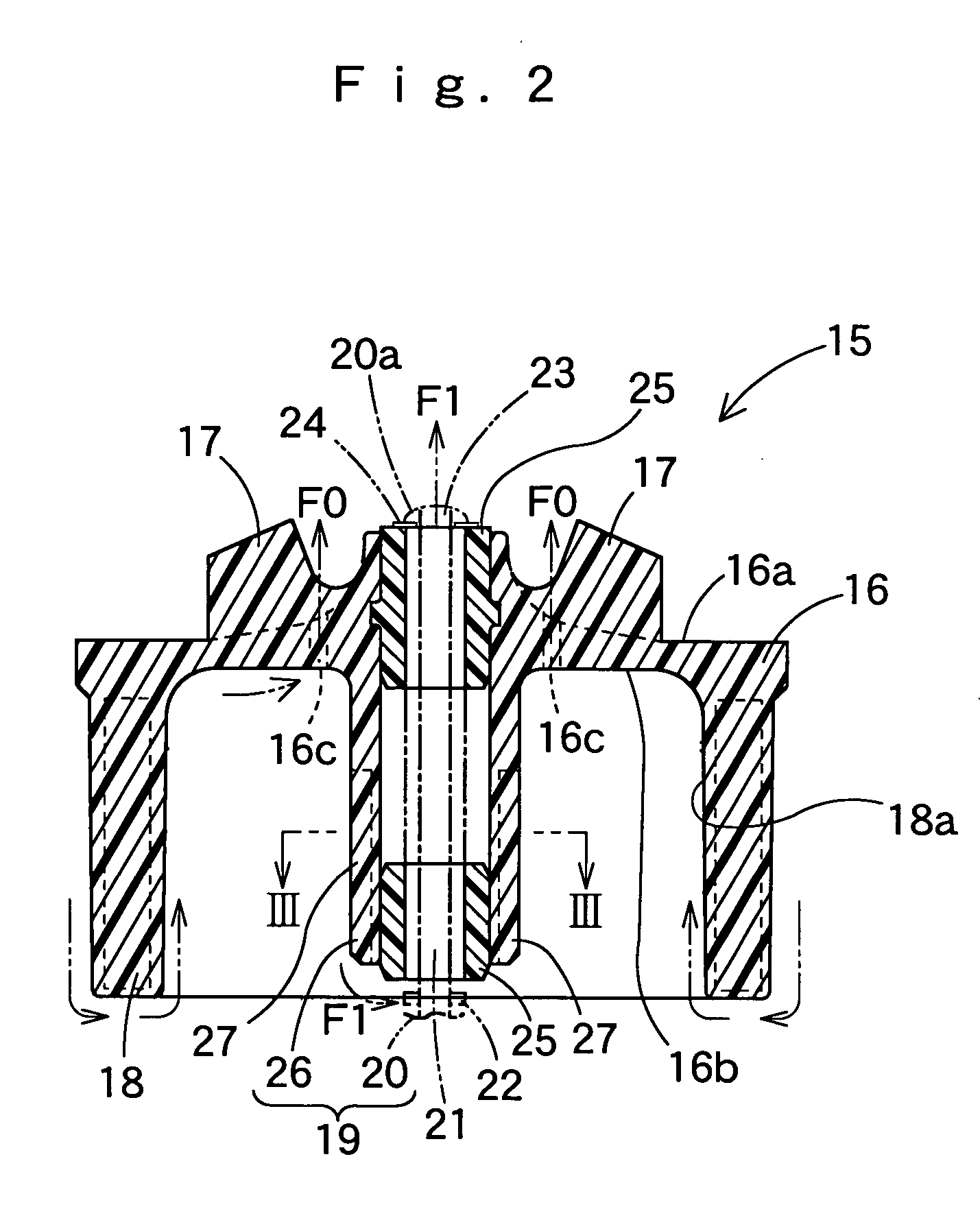

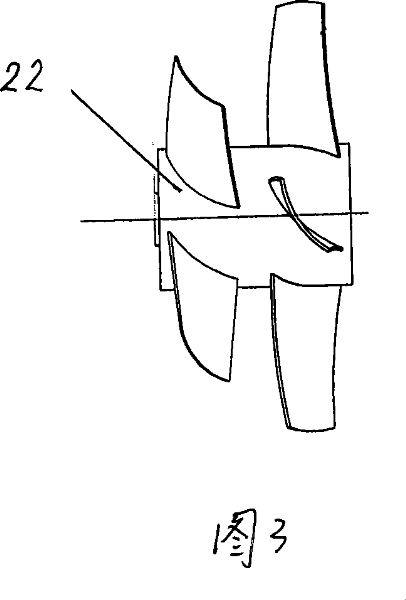

Magnetic coupling pump

InactiveUS20040234395A1Precise heatingAvoid heatingPump componentsPiston pumpsMagnetic tension forceImpeller

A magnetic coupling pump according to the present invention has a housing including a pump chamber a motor chamber. The rotor includes a plurality of impellers projected from top face of a substantially disc-shaped main body of the rotor to be located in the pump chamber, and a substantially cylindrical magnet section projected from back face of the main body to be located in the motor chamber. The rotor is located in engine coolant, and is driven by a stator located inward of the magnet section in the motor chamber for sucking coolant from an inlet port and exhausting it from an outlet port. The pump is provided along an inner circumference of the stator with a cavity communicating with passages of fluid along an inner circumference of the magnet section and the back face of the main body of the magnet section. The cavity admits the coolant. The pump according to the present invention is able to prevent heat-up in the inner circumferential part of the stator.

Owner:AISAN IND S

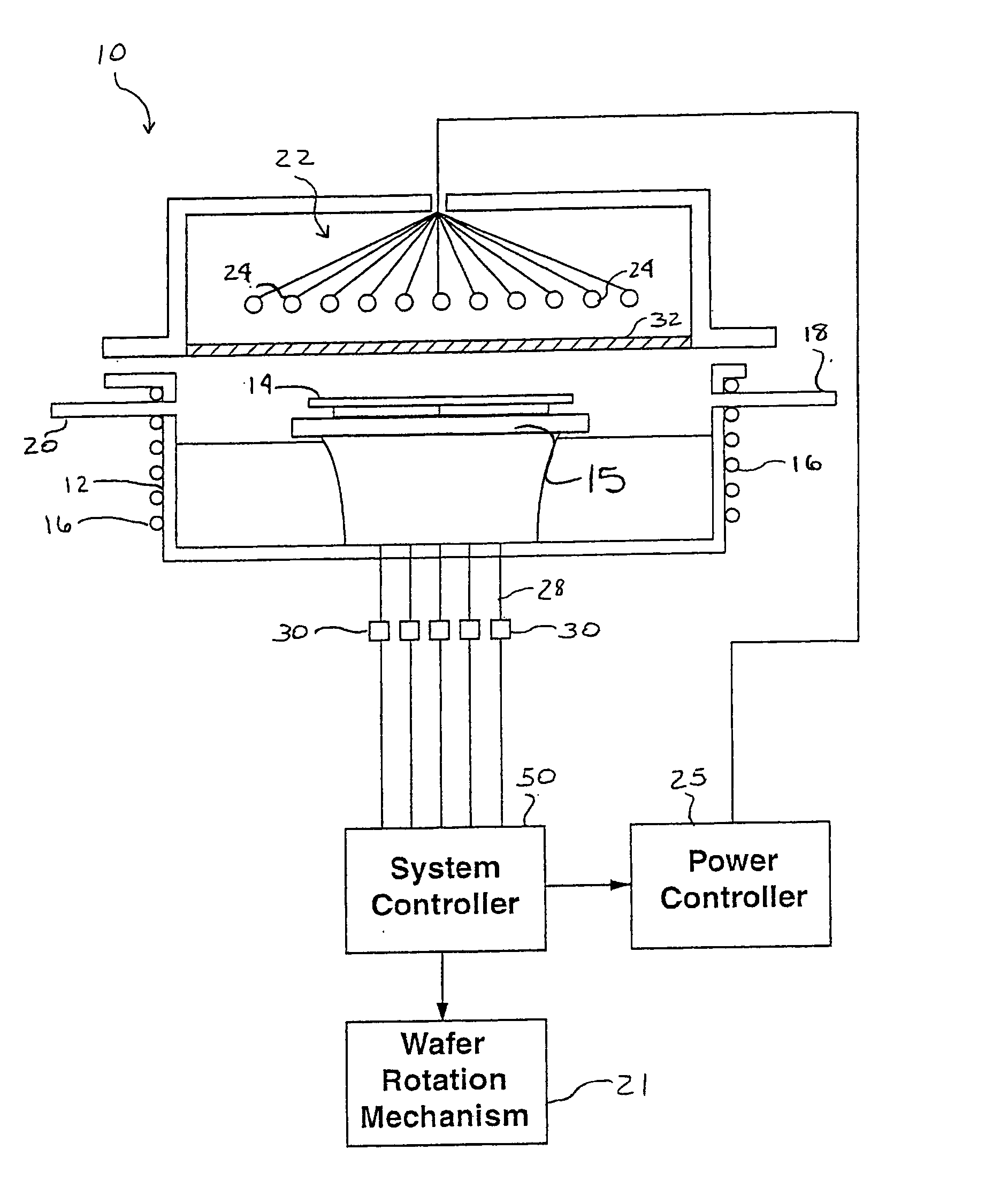

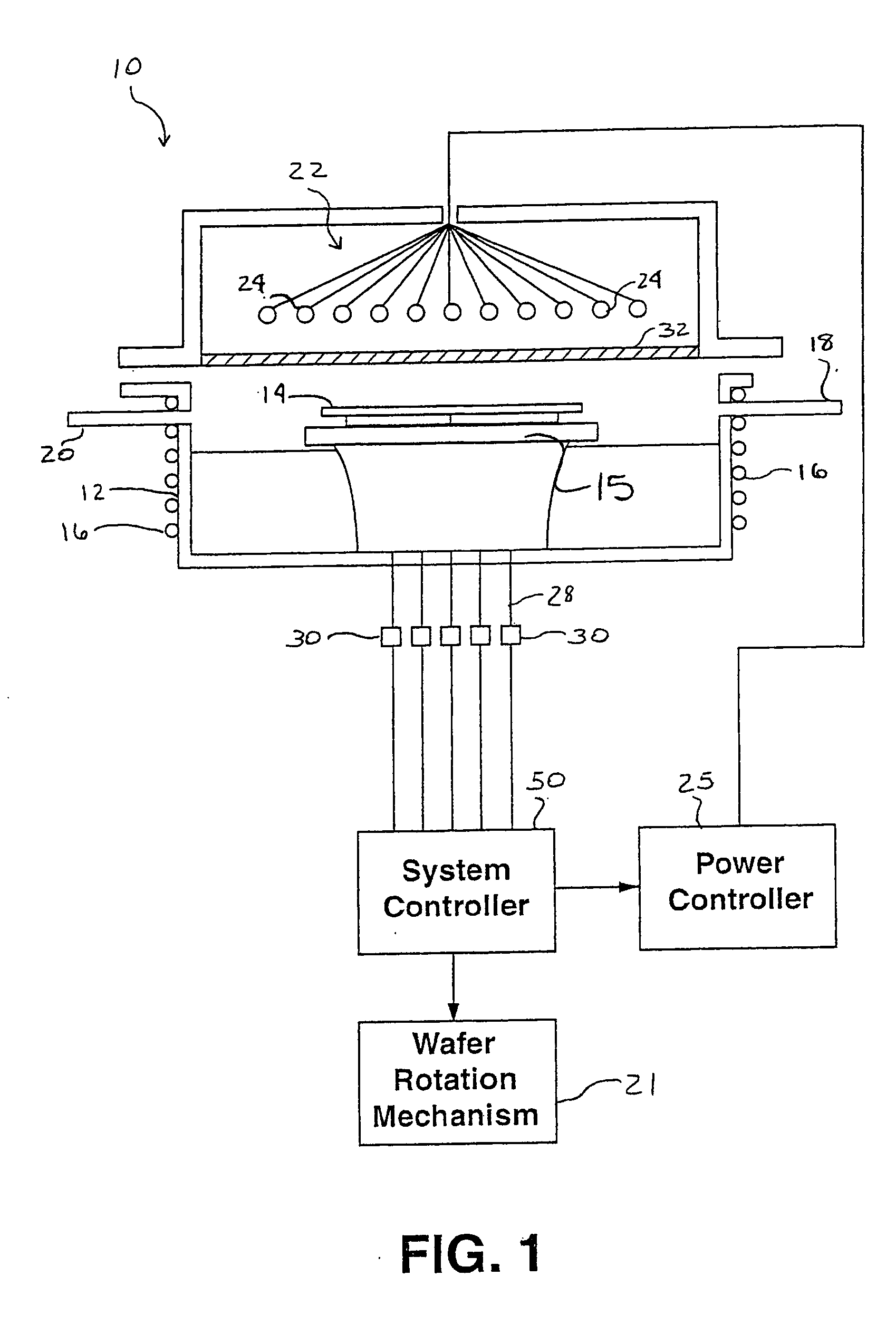

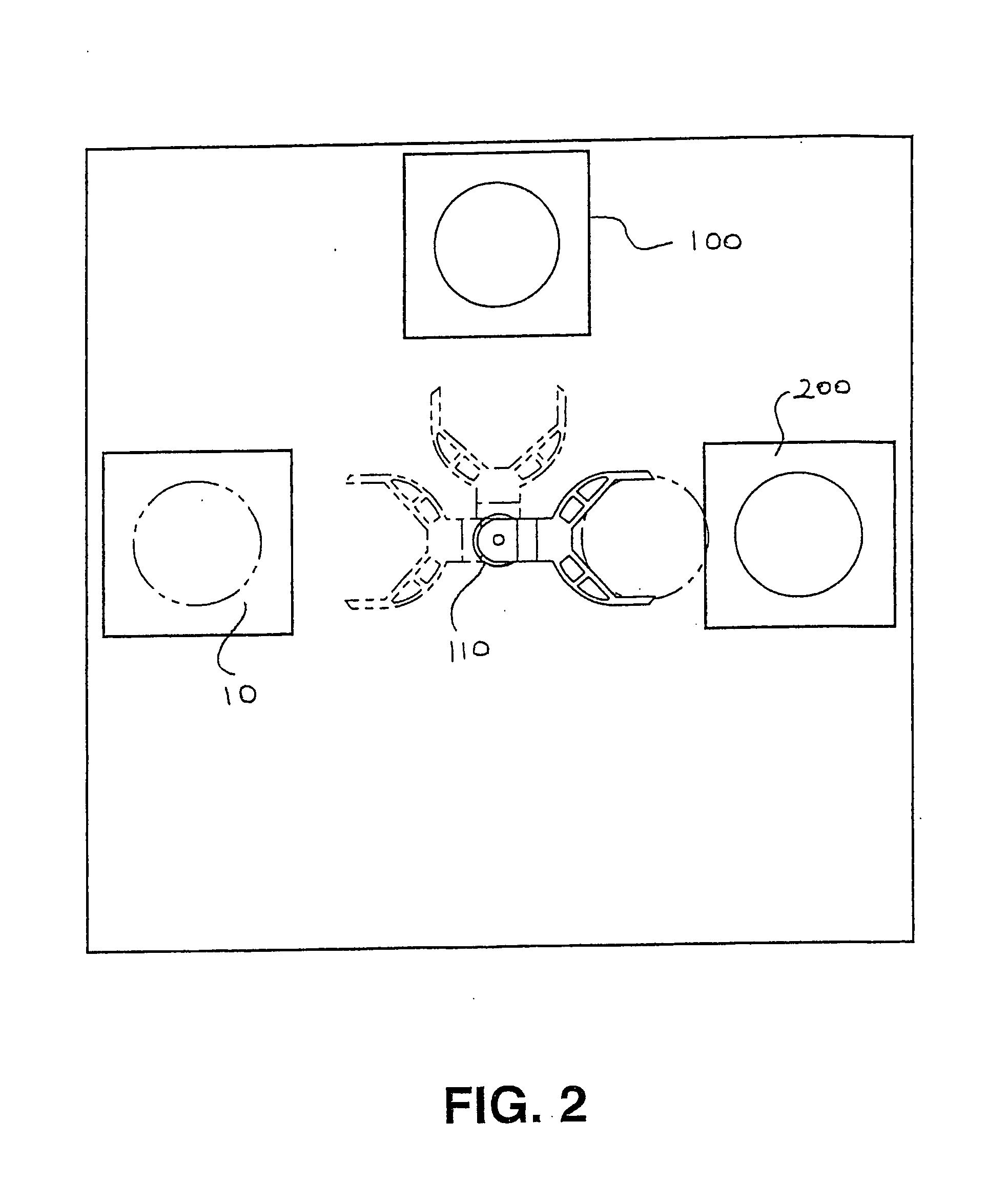

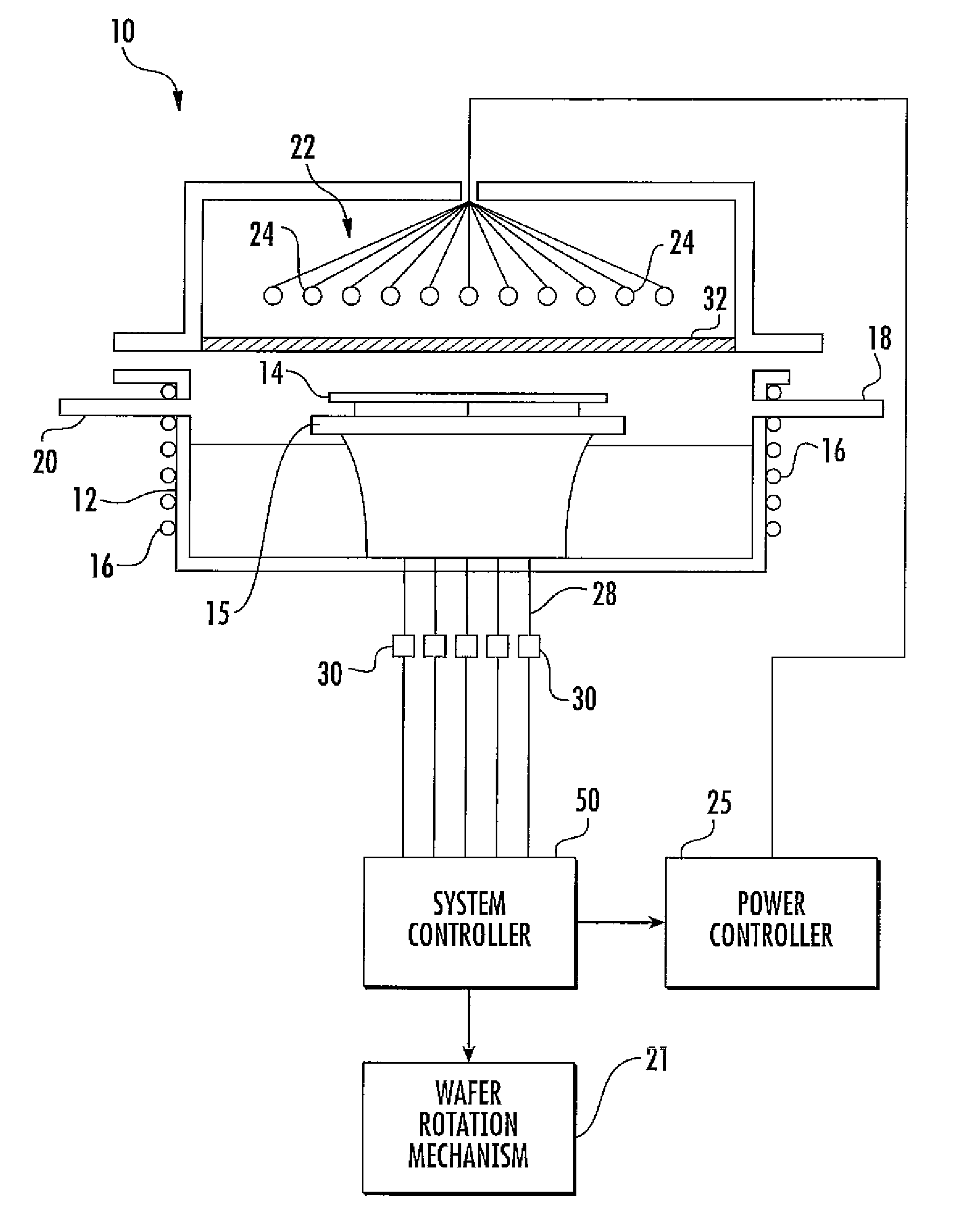

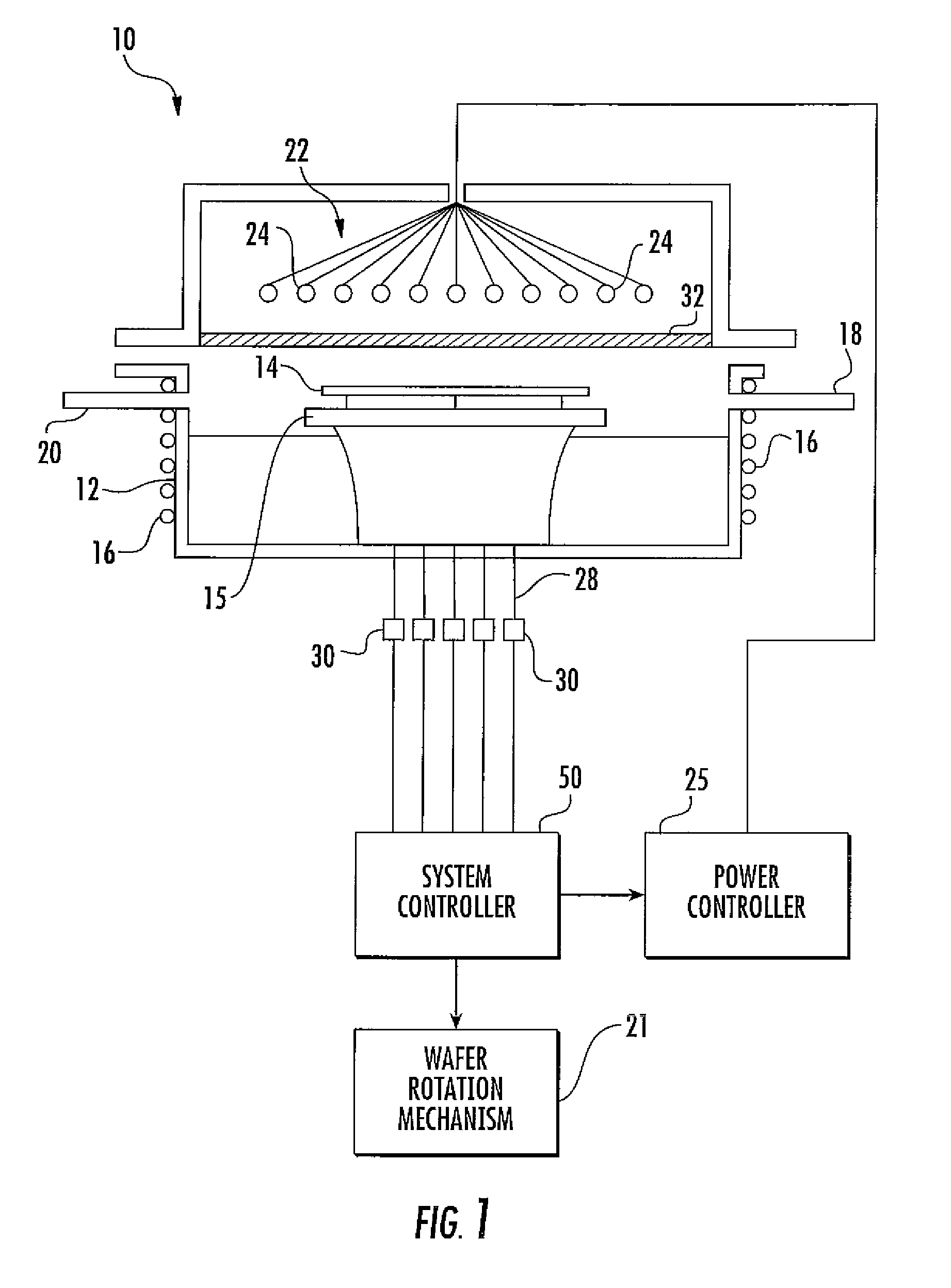

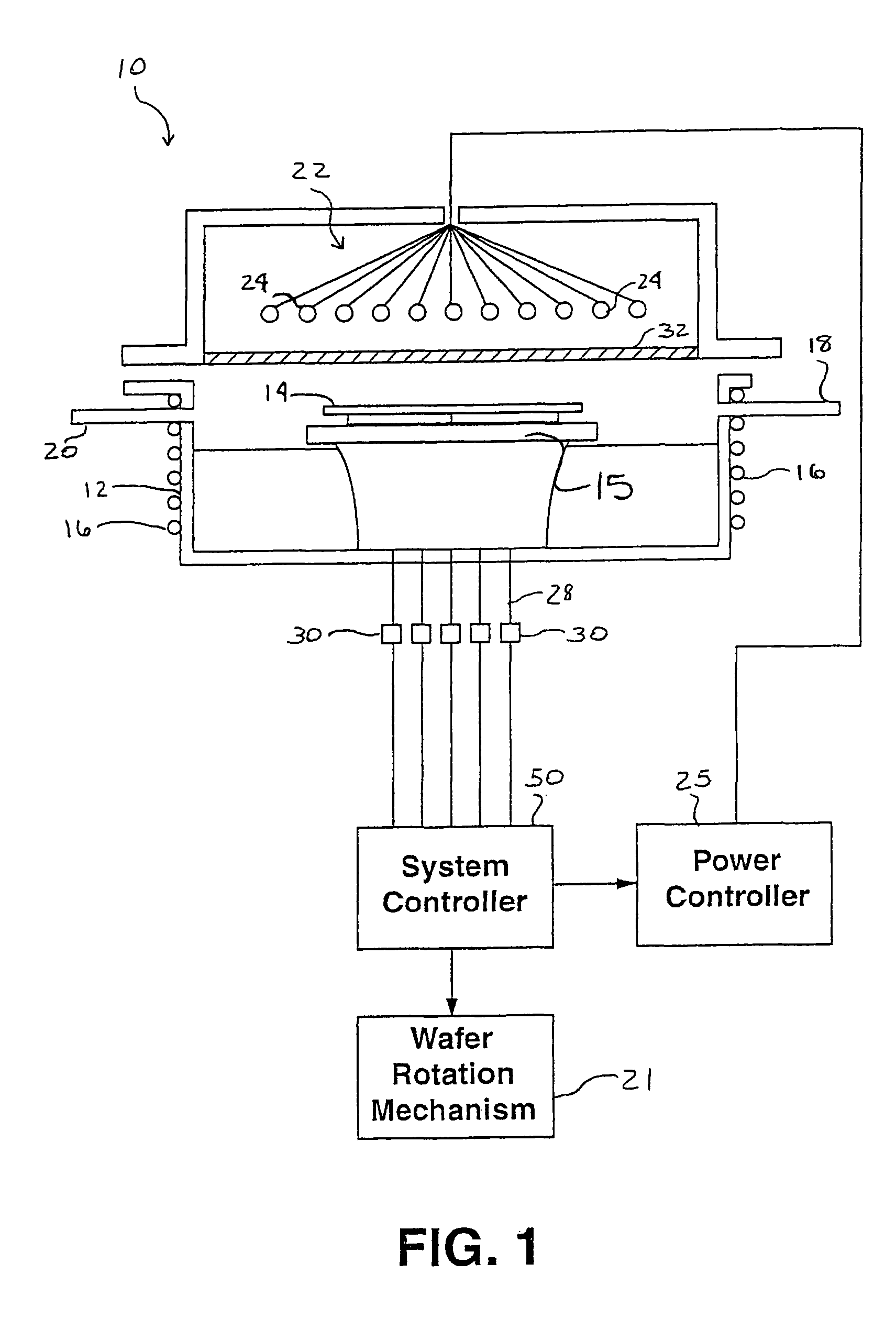

Method and system for determining optical properties of semiconductor wafers

ActiveUS20070020784A1Precise heatingImprove accuracyRadiation pyrometrySemiconductor/solid-state device testing/measurementOptical propertyEmissivity

A method and system are disclosed for determining at least one optical characteristic of a substrate, such as a semiconductor wafer. Once the optical characteristic is determined, at least one parameter in a processing chamber may be controlled for improving the process. For example, in one embodiment, the reflectivity of one surface of the substrate may first be determined at or near ambient temperature. From this information, the reflectance and / or emittance of the wafer during high temperature processing may be accurately estimated. The emittance can be used to correct temperature measurements using a pyrometer during wafer processing. In addition to making more accurate temperature measurements, the optical characteristics of the substrate can also be used to better optimize the heating cycle.

Owner:MATTSON TECHNOLOGY +1

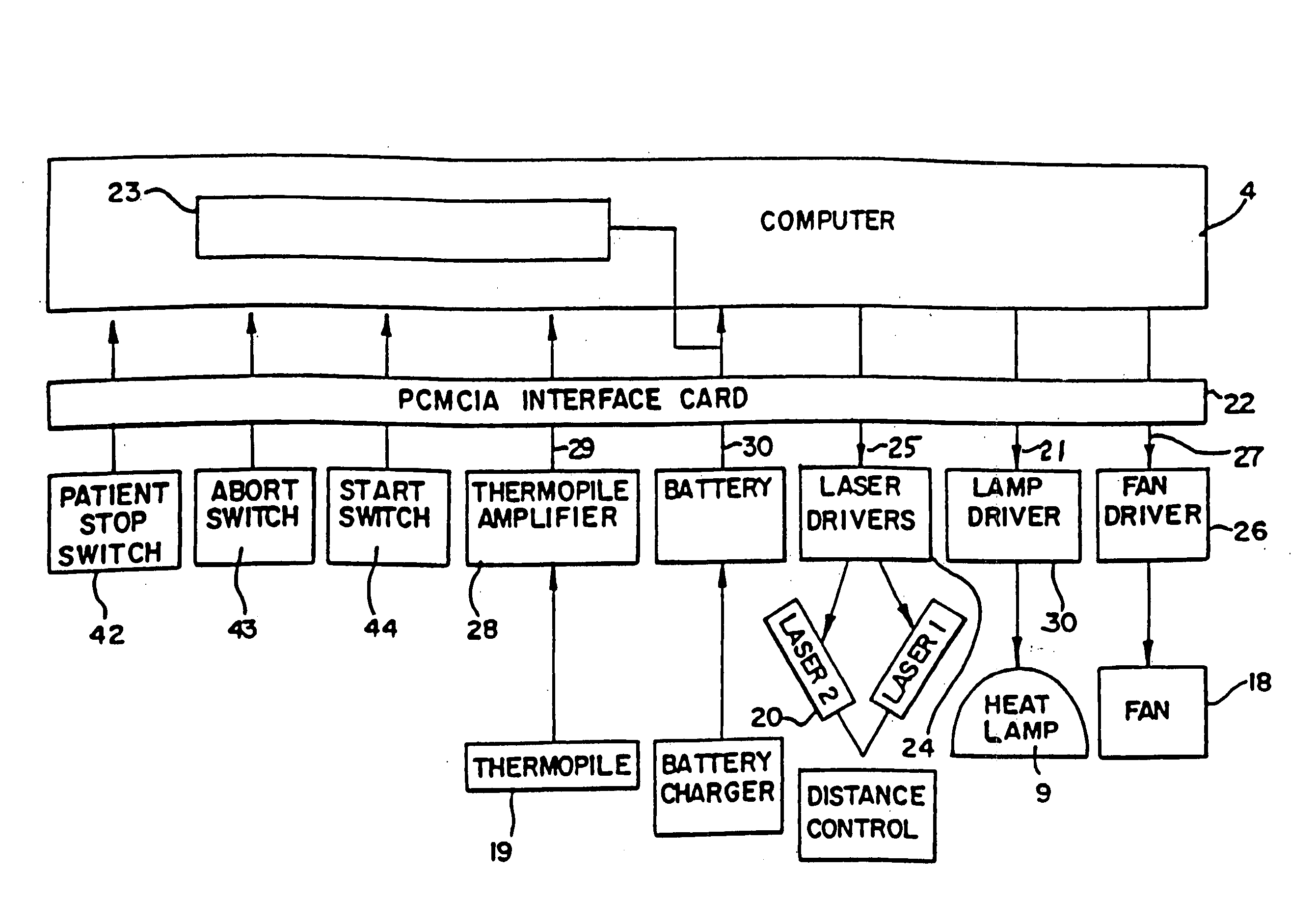

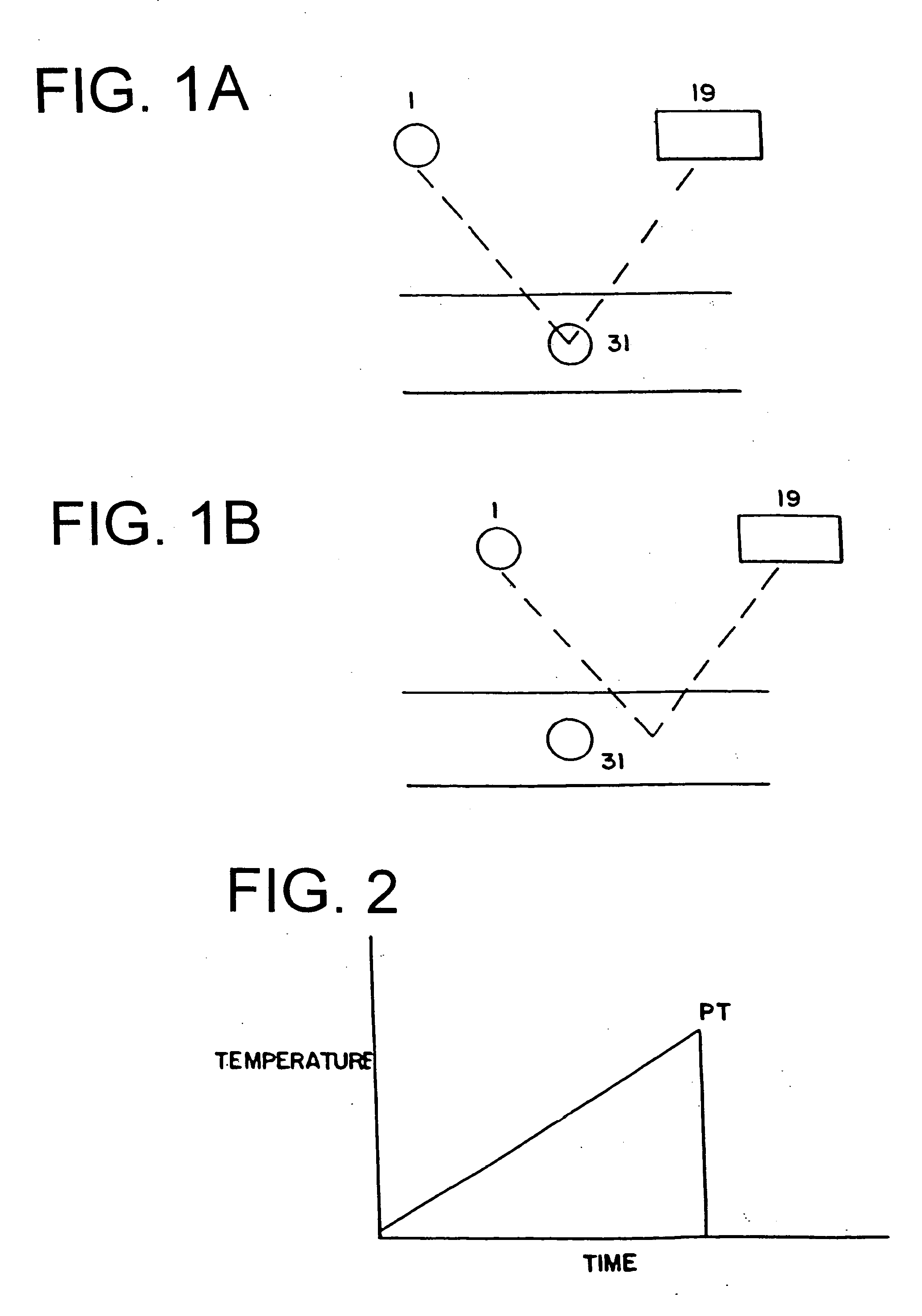

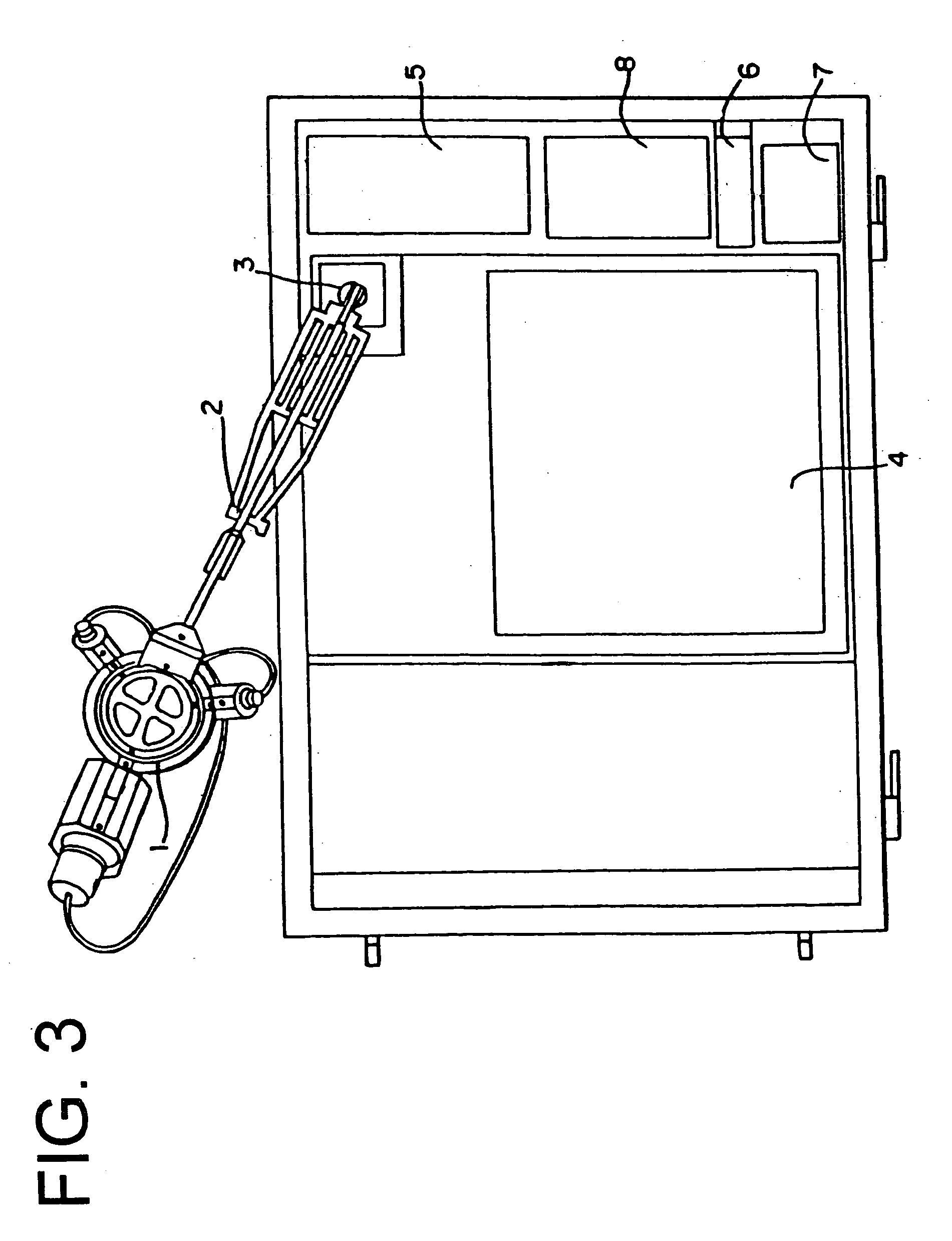

Comprehensive pain assessment systems and methods

Systems, devices, and methods are provided for simultaneous assessment of a subject's subjective and objective pain states. These include a dolorimeter arrangement for determining a subject's cutaneous pain tolerance level at any site on the body. In certain preferred embodiments, the dolorimeter is hand-held and utilizes a sonar distance-measuring device. In another aspect, the systems, devices, and methods of the current invention include platforms effective for implementing pain monitoring methods that include delivering pain questionnaires to patients over a period of time points. The platforms may harvest analgesic drug data from nurses attending the patients, and may provide simple statistical analysis of collected data useful both at the bedside and at central base-stations. The platforms may provide additional functions based on analysis of patient pain data. Preferred embodiments of the current invention combine the dolorimeter arrangement with the platforms for implementing pain monitoring methods.

Owner:NEUROSCI TOOLWORKS

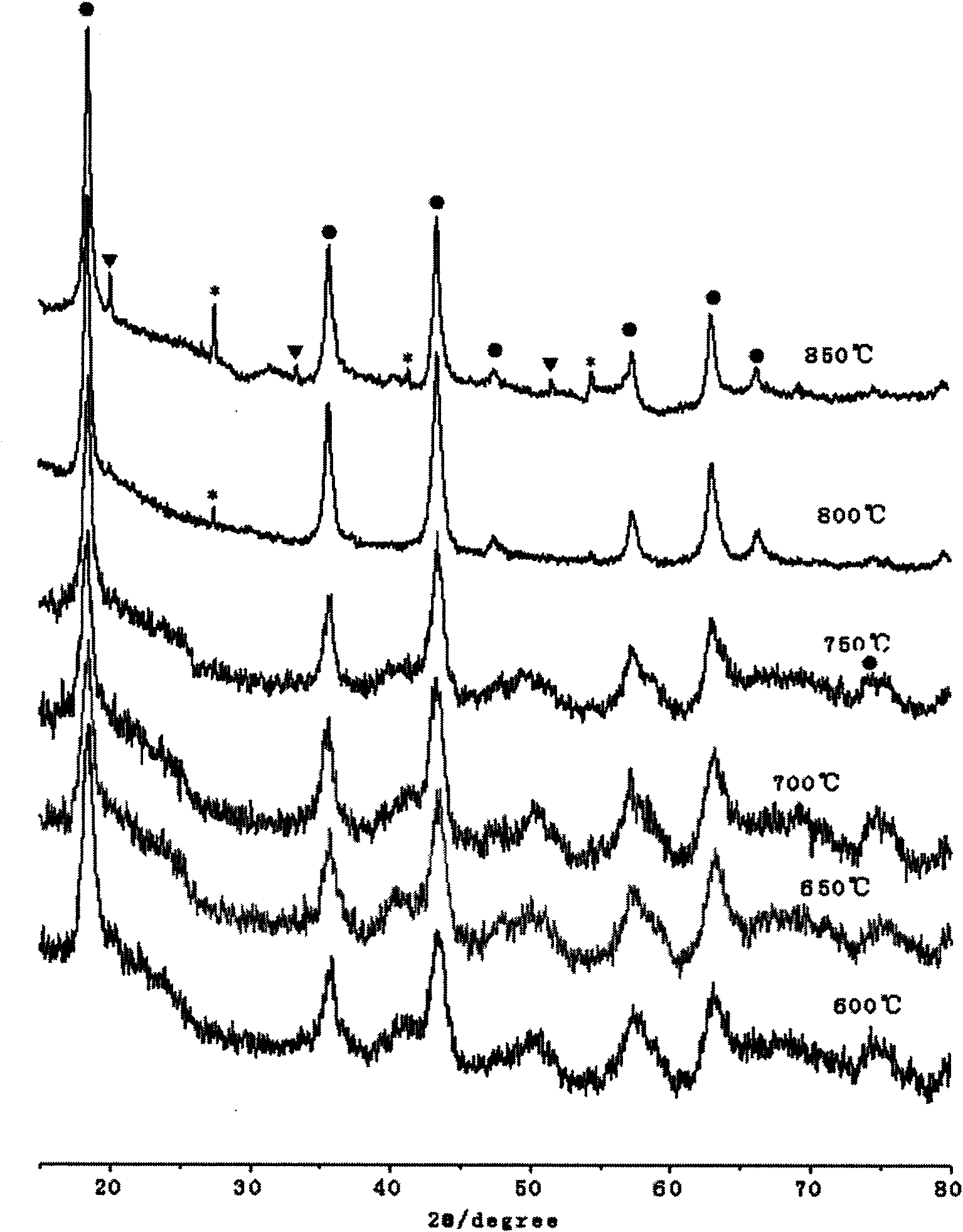

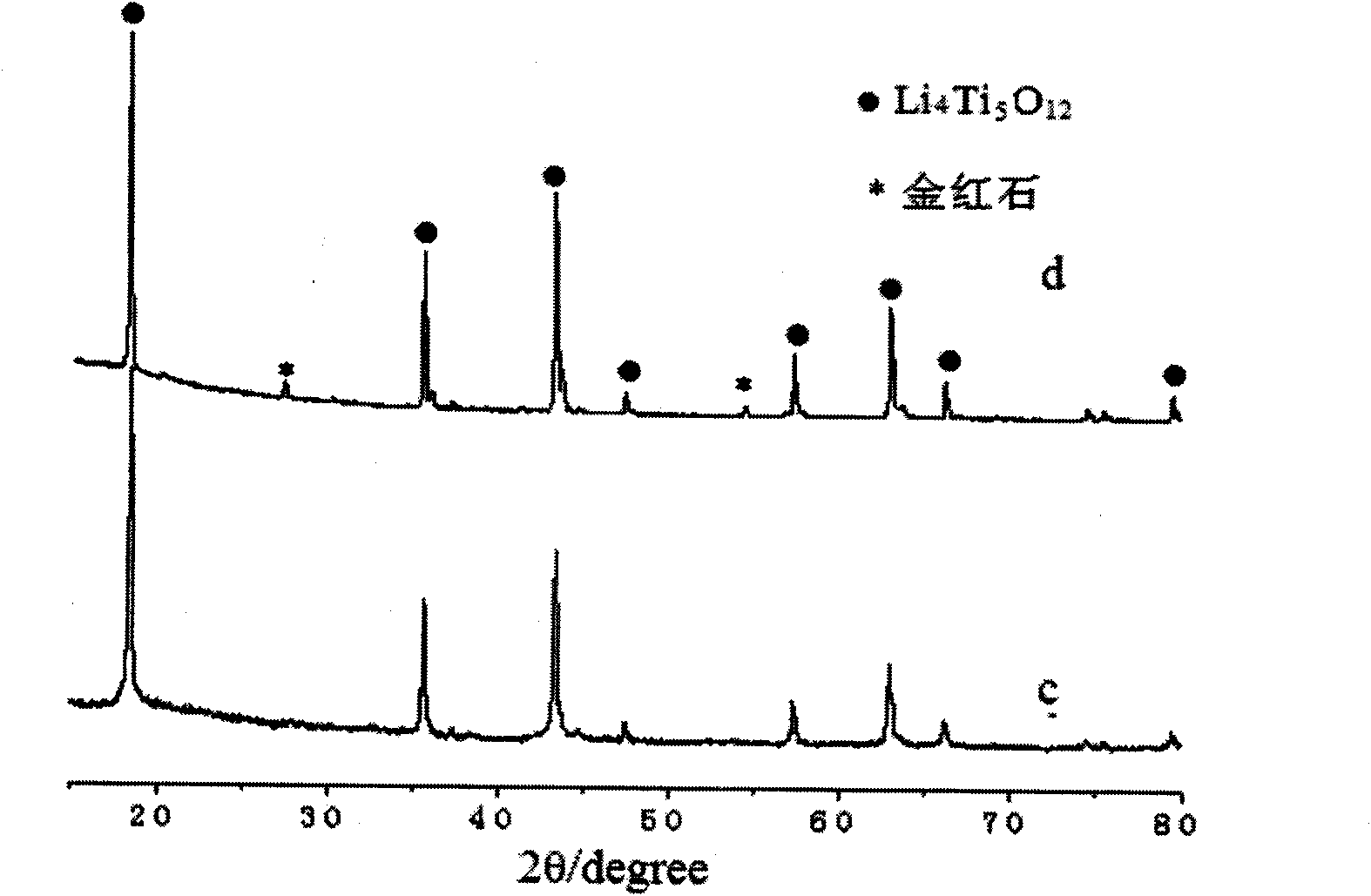

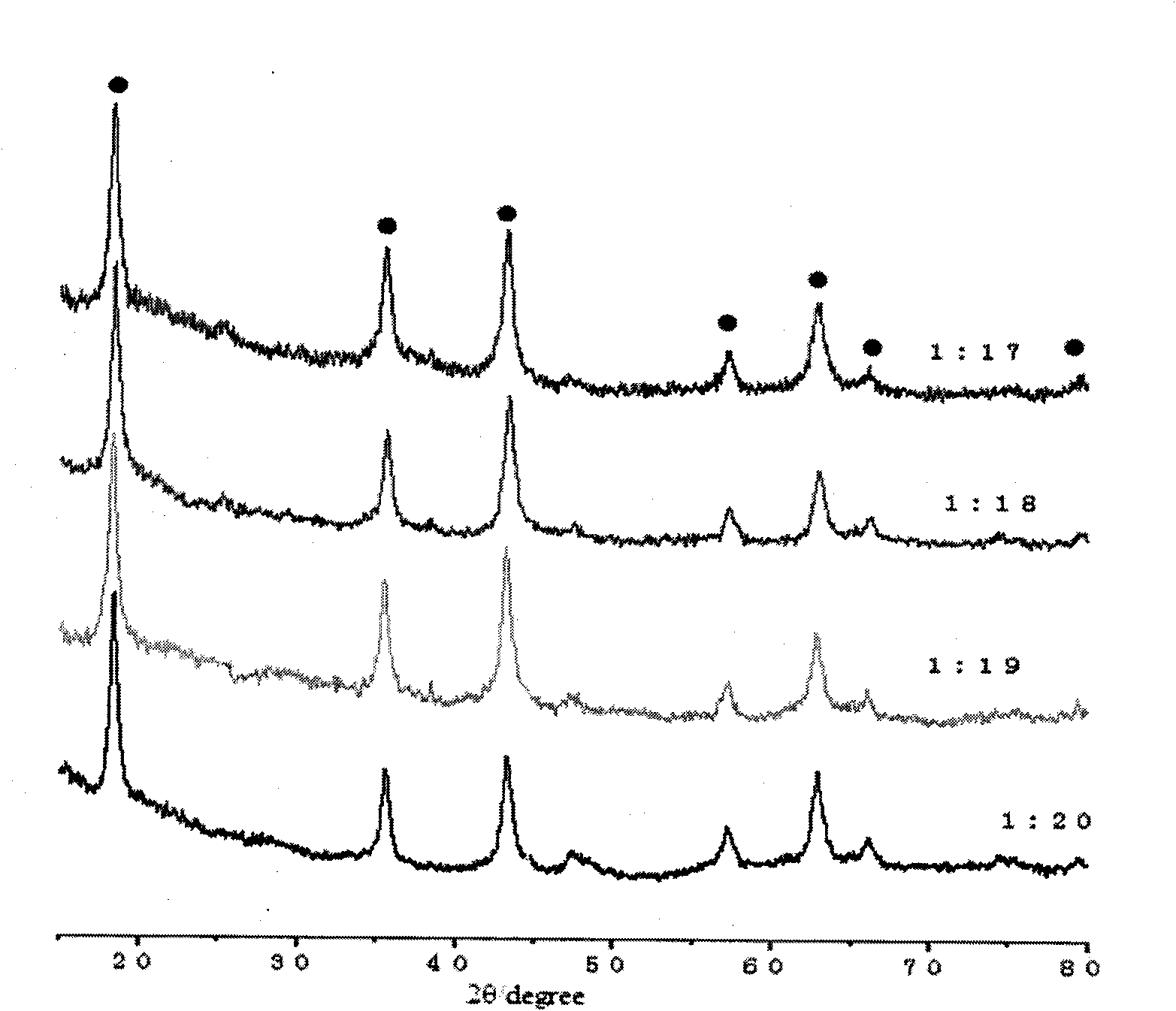

Method for preparing spinel lithium titanate of cathode material of lithium ion battery

InactiveCN101593830ALow costReduce energy consumptionElectrode manufacturing processesCombined methodMicroparticle

The invention relates to a method for preparing a cathode material Li4Ti5O12 of a high-performance lithium ion battery. The method comprises the following steps of: adopting the combined method of sol-gel and microwave treatment to prepare micro powder of nano-class Li4Ti5O12, and simultaneously modifying Li4Ti5O12 by carbon doping and metallic doping. The method utilizes the sol-gel method to effectively control chemical composition, phase composition and powder size of the Li4Ti5O12, thereby improving the uniformity and the electric conductivity of the Li4Ti5O12; simultaneously by utilizing the characteristics of the microwave technique of quick temperature rise, even heating and conglobation resistance, the high-power industrial microwave oven is used for treatment, so that the treatment time of the Li4Ti5O12 is greatly shortened, the yield is greatly improved, and the cost and the energy consumption of the material are reduced, the process is simplified, the efficiency on the industrialized production of the lithium ion battery is improved, and the industrialized application is easily achieved; and by doping carbon and metallic elements, the electric conductivity of lithium iron phosphate is greatly improved, and the charging and discharging capacities and the cycle index of the lithium iron phosphate are simultaneously and effectively increased.

Owner:ZHENGZHOU UNIV +1

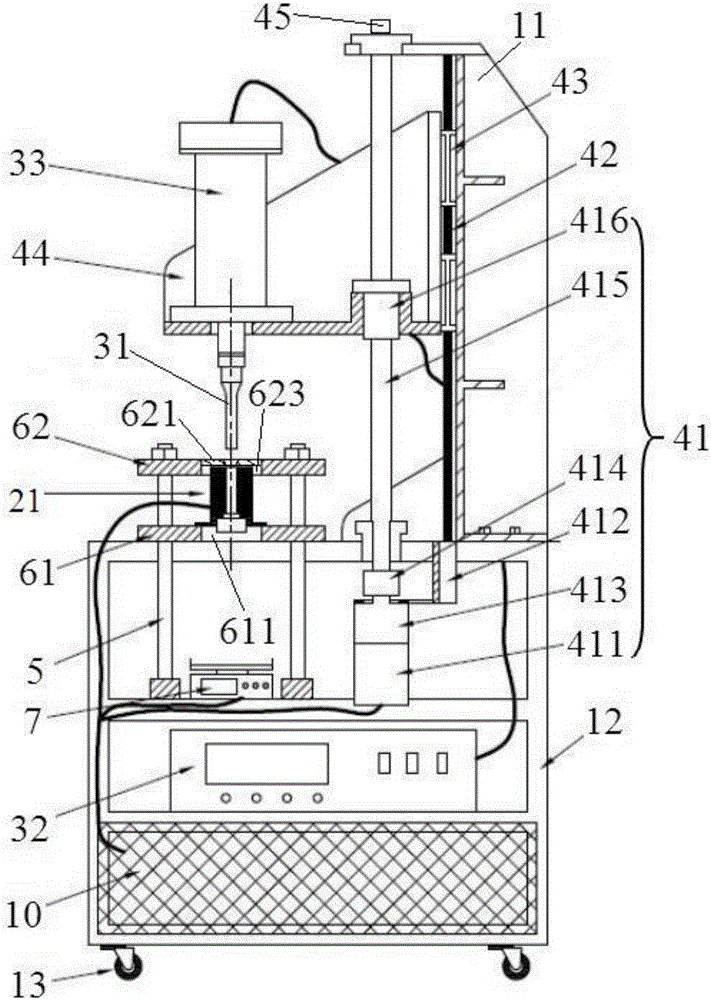

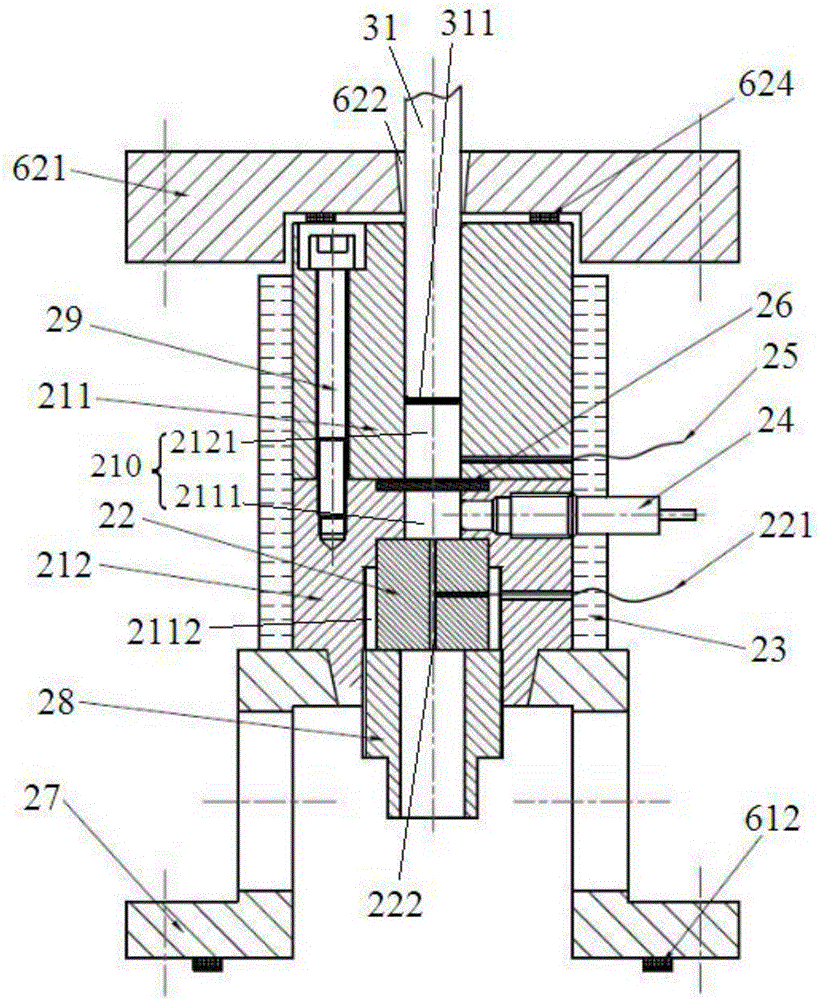

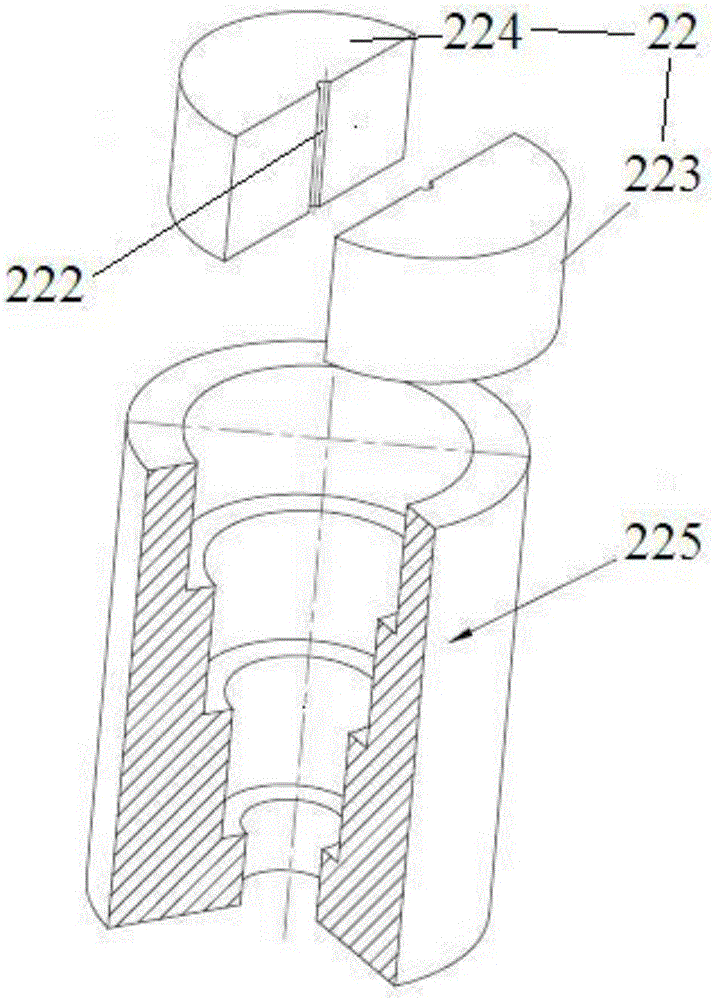

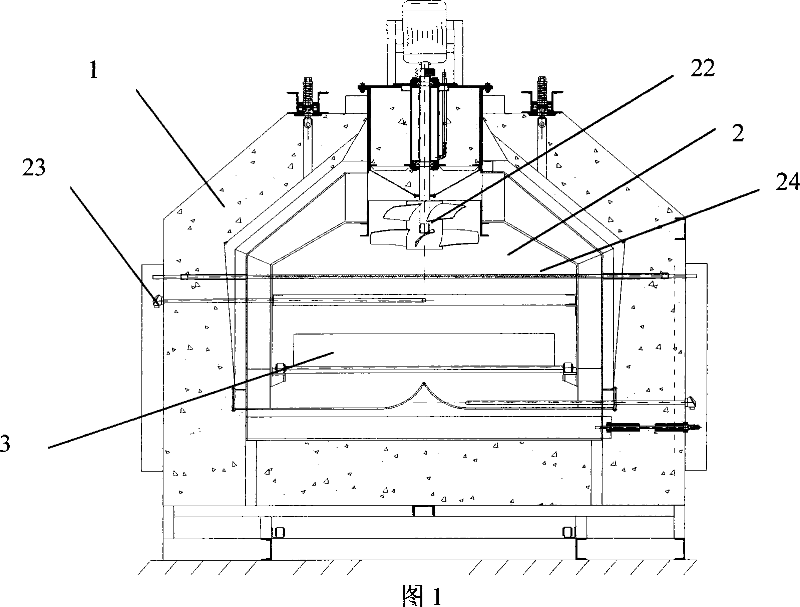

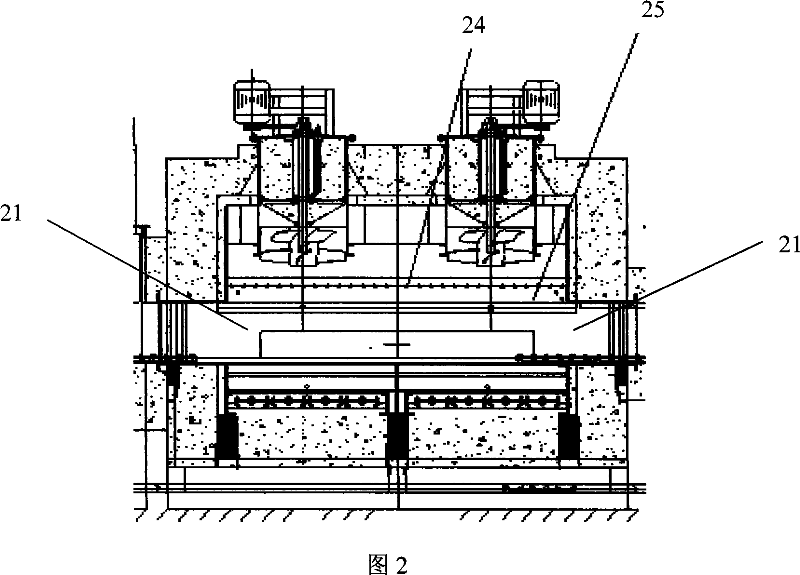

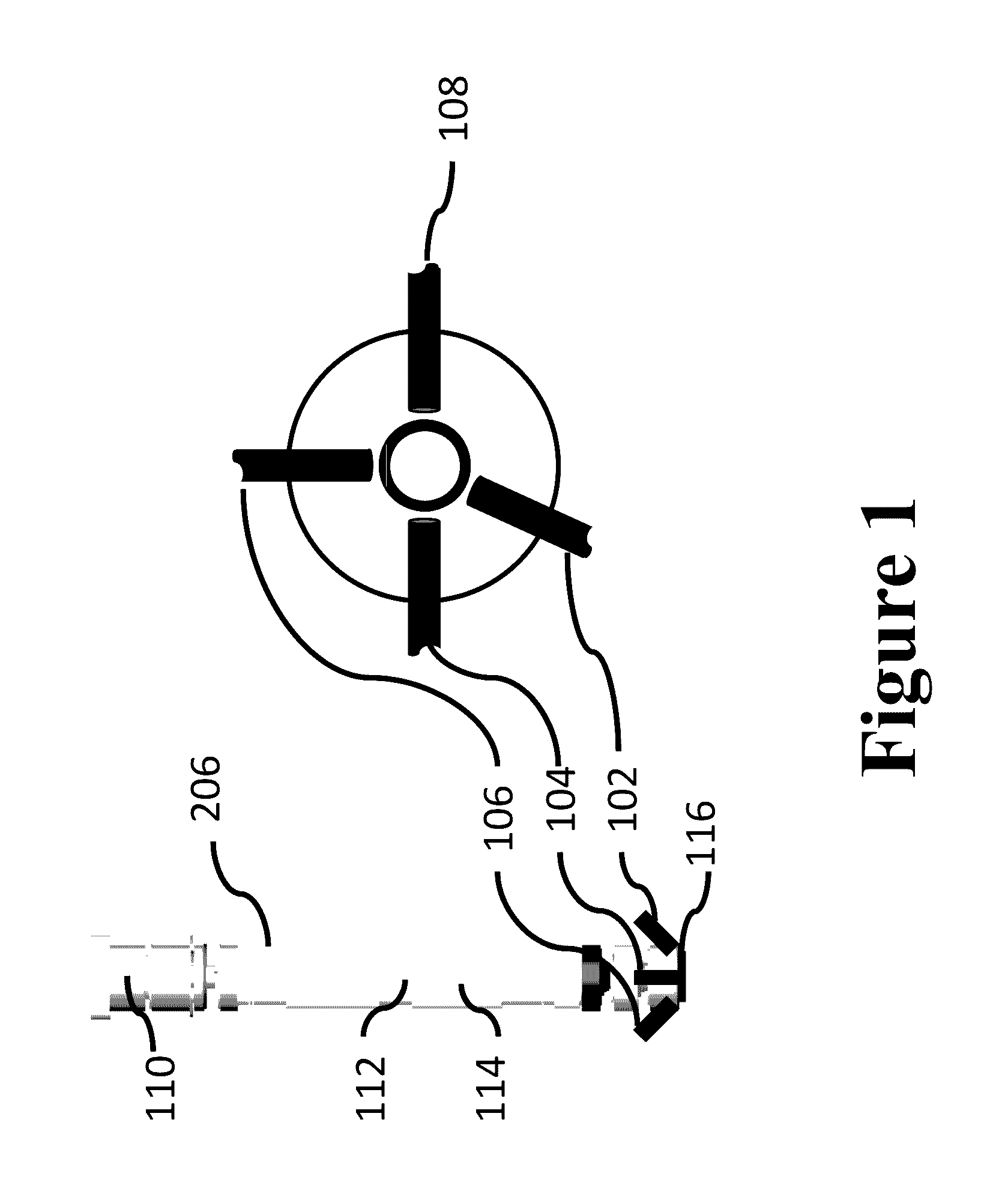

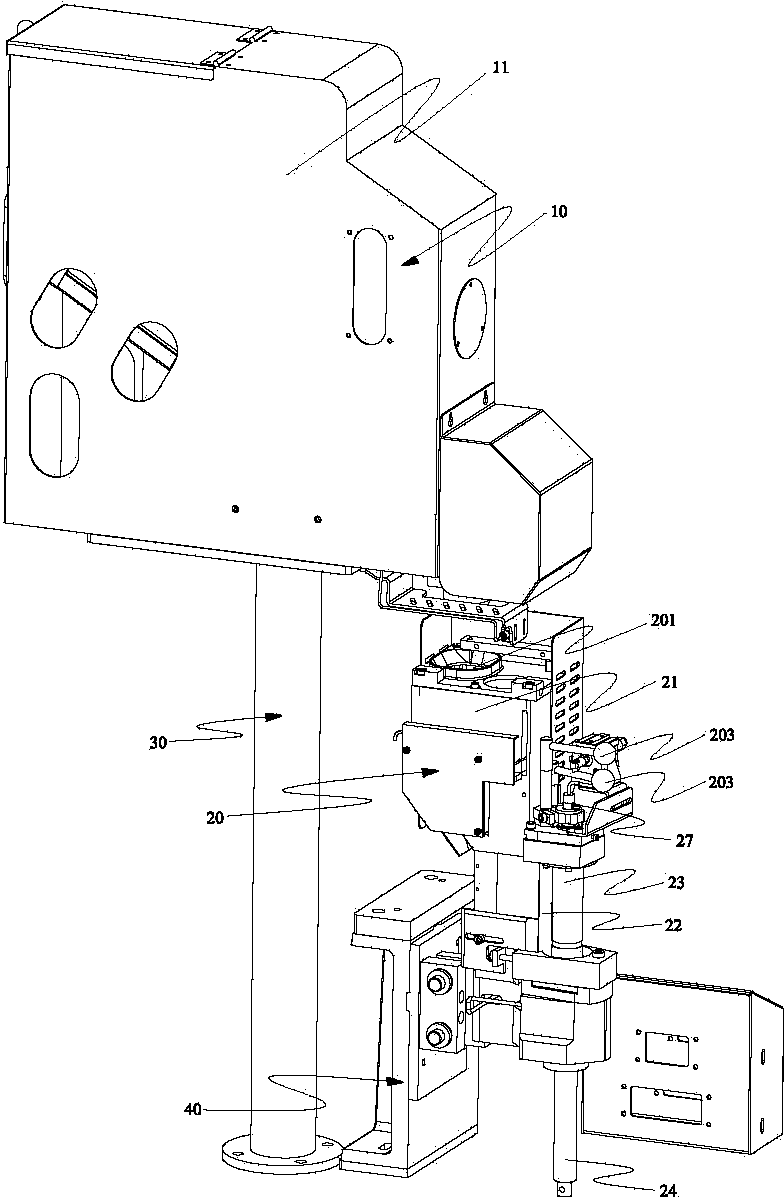

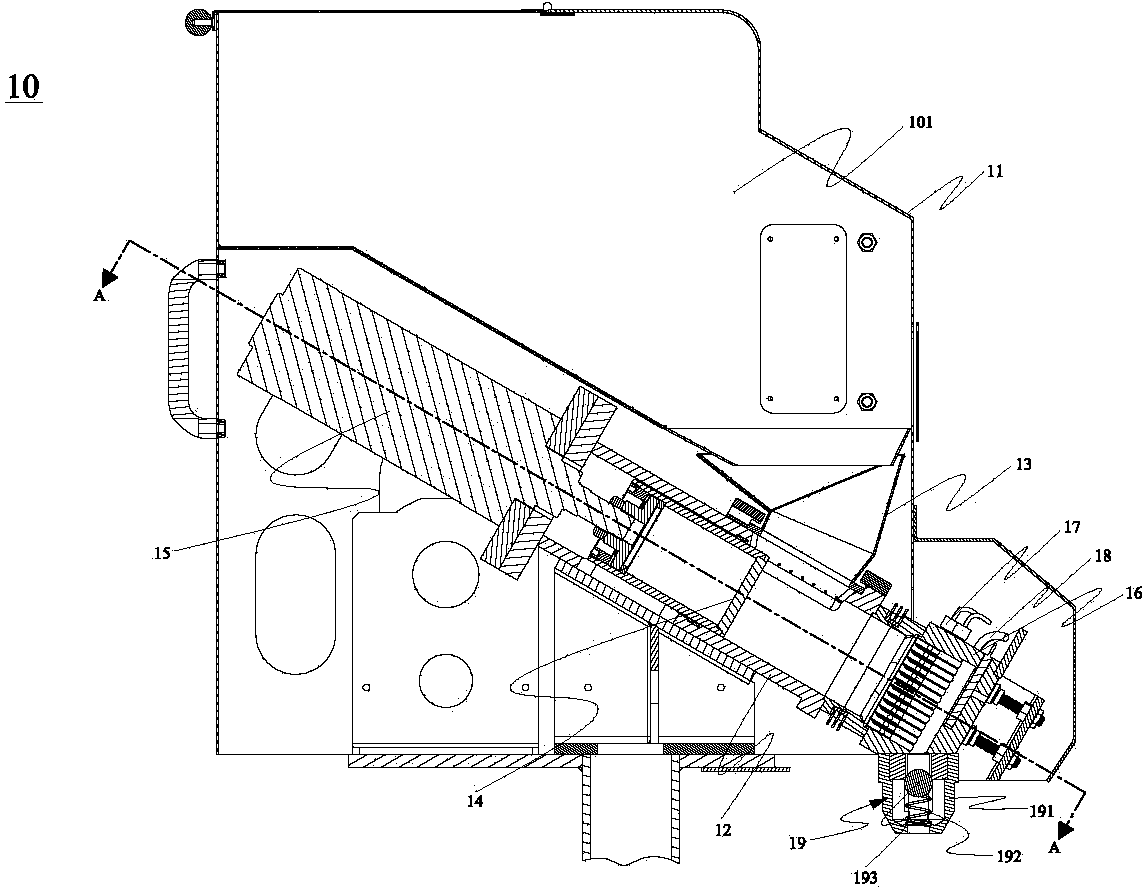

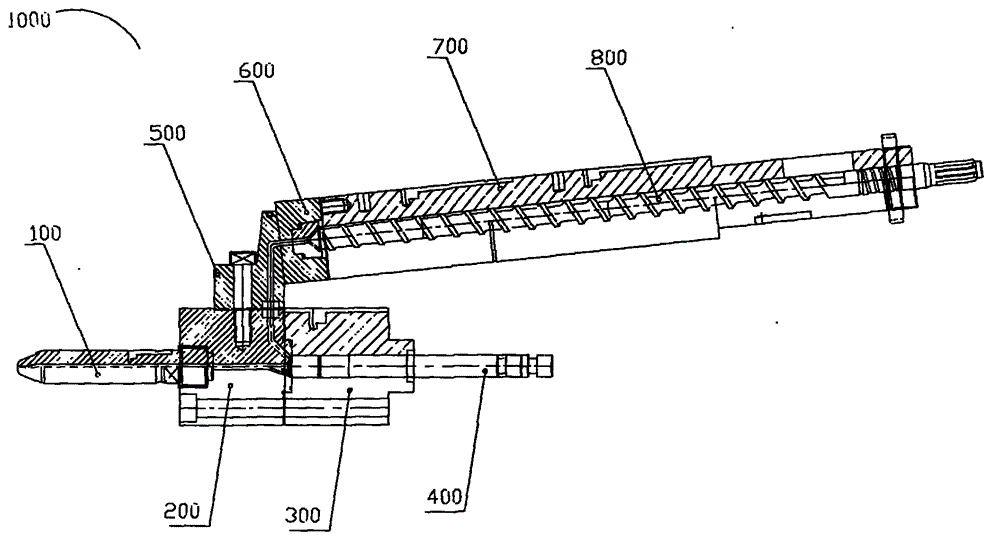

Ultrasonic plasticizing capillary rheometer and viscosity test method

ActiveCN106124362AImprove liquiditySimplify the delivery pathIndirect flow property measurementEngineeringPolymer

An ultrasonic plasticizing capillary rheometer comprises a frame, a rheological test unit, an ultrasonic vibration apparatus, and a tool head moving and loading unit. The ultrasonic vibration apparatus is provided with an ultrasonic tool head capable of extending into a plasticizing chamber along an axial direction, providing extrusion force for polymer in the plasticizing chamber, and providing ultrasonic wave energy required by the polymer for fusion from a solid state to a liquid state. In the ultrasonic plasticizing capillary rheometer, three steps including heating fusion, ultrasonic vibration for fluidity increase, and material extrusion are completed through the ultrasonic tool head and in the plasticizing chamber, thereby simplifying the conveying path. A heating ring providing the required initial temperature for the plasticizing process sleeves a material canister, provides a constant material canister temperature for the rheometer, and reduces the test error. A filter screen is arranged in the material canister, centralizes fused polymer, and improves the test accuracy. During a test process, a viscosity test method is accurate in heating, short in fusion time, and wide in application range, is slightly affected by the external environment, and can provide viscosity data high in accuracy.

Owner:CENT SOUTH UNIV

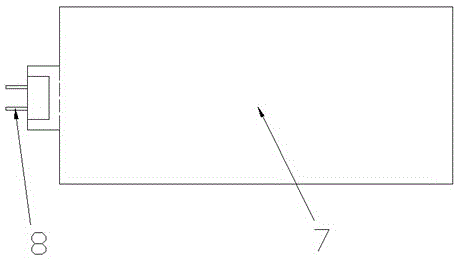

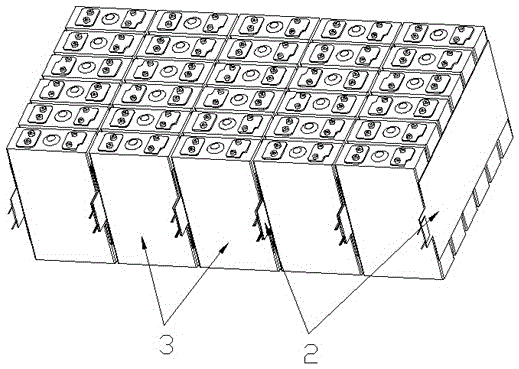

Power battery heating device and control method

The invention relates to a heating device which can uniformly heat a power battery used for an automobile, and a control method. The heating device comprises heating pieces, temperature sensors and a control unit. The heating pieces are attached to surfaces of batteries to heat the batteries. The temperature sensors are fixed to temperature evaluation points on the surfaces of the batteries and the heating pieces. The control unit is connected with the temperature sensors and the power batteries and controls the temperature of the batteries and the heating device. The power batteries form a battery set structure composed of the batteries. The intervals between the batteries are larger than the thickness of the heating pieces. The control unit is used for collecting and processing temperature data, monitoring current and voltage in circuits, diagnosing insulating faults of the heating device and turning on or turning off all or n specific heating piece circuits according to preset conditions, wherein n is larger than or equal to 1. The heating device can safely, rapidly, uniformly and accurately heat the power batteries.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

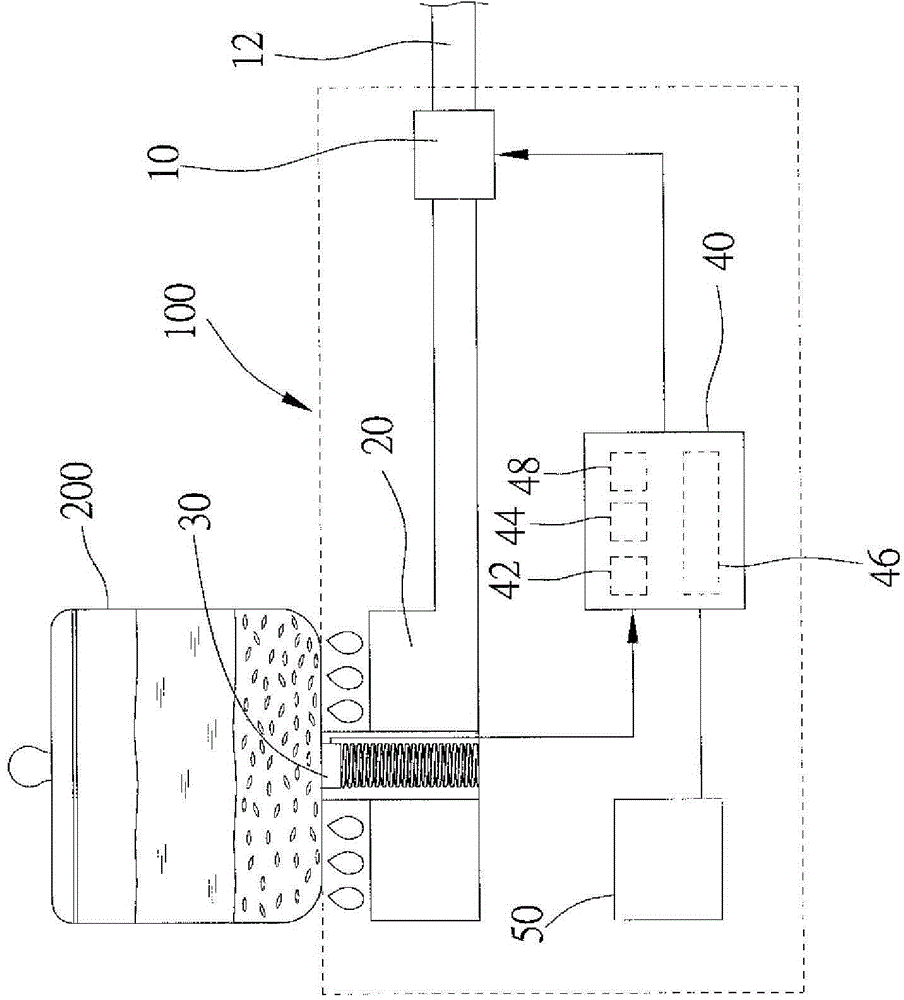

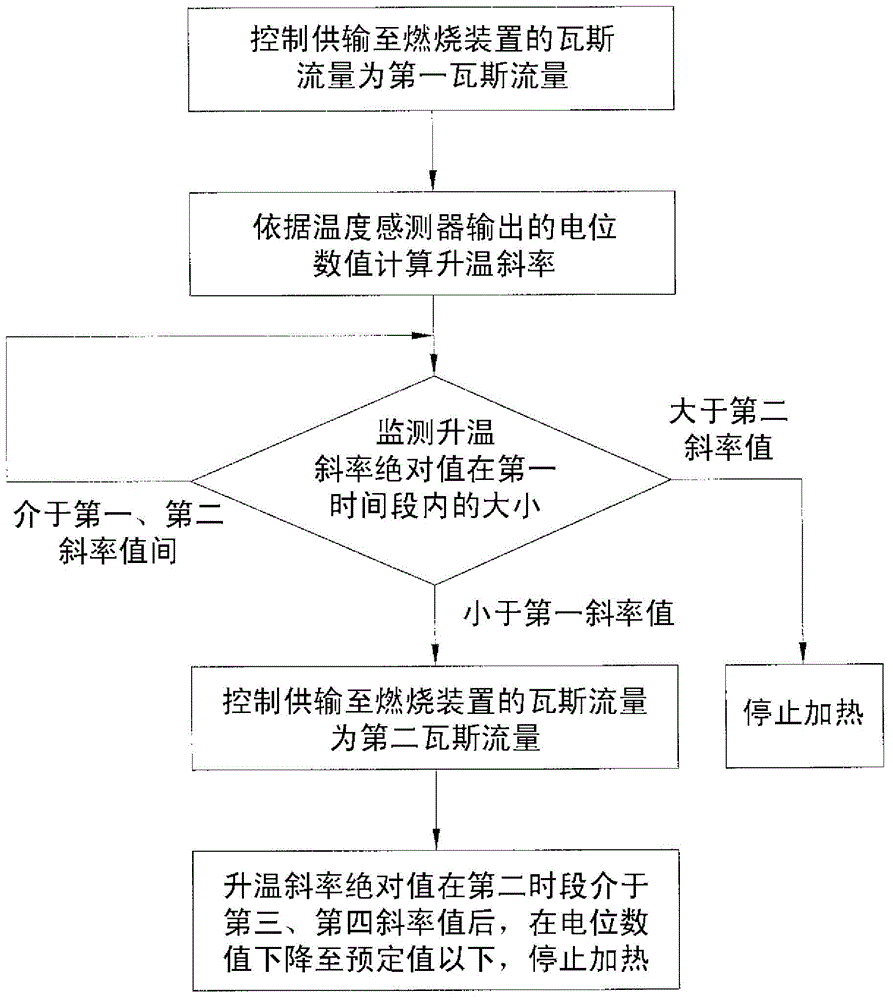

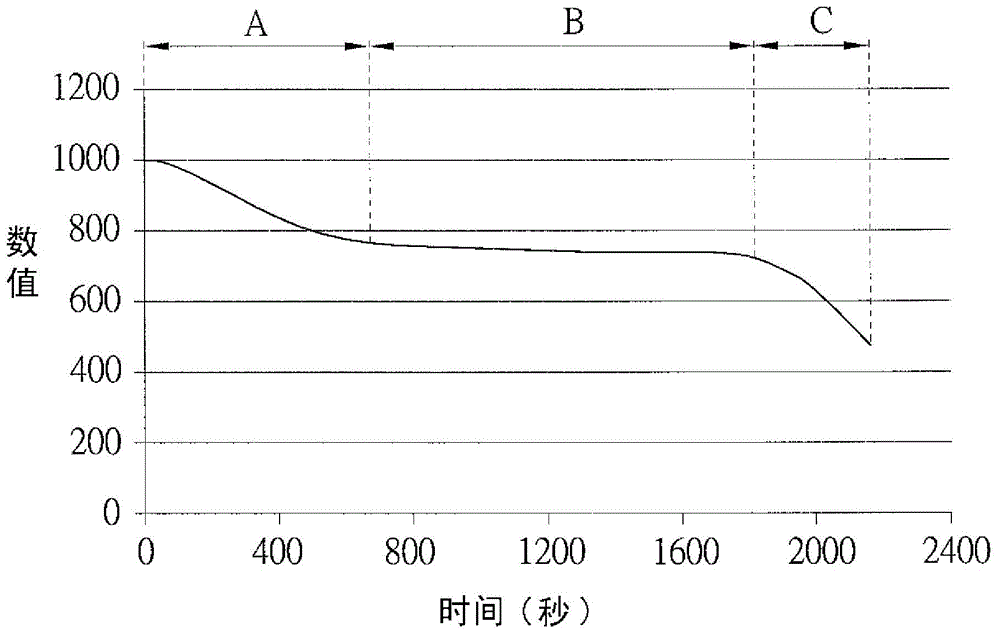

Cookware heating controlling method and heating-state examination method

ActiveCN105444213APrecise heatingJudging the heating stateDomestic stoves or rangesLighting and heating apparatusExamination methodStreamflow

The invention relates to a cookware heating controlling method and a heating-state examination method. The heating controlling method comprises the following steps: controlling the gas flow conveyed to a heating apparatus to be a first gas flow; monitoring the heating gradient when the cookware is heated, determining that the interior in the cookware is at a boiling state when the heating gradient absolute value is less than a first gradient value in a first time frame, controlling to reduce the supplied gas flow to a second gas flow, and continuing to heat; and determining the cookware is at an empty burning state when the heating gradient absolute value is larger than a second gradient value in the first time frame, and stopping conveying gas to the heating apparatus.

Owner:GRAND MATE

Method of adhesively bonding a first component to a second component

InactiveUS20080196831A1Resists meltingPrecise heatingWindowsWindscreensHot-melt adhesiveElectromagnetic induction

A method of adhesively bonding a first component to a second component, which comprises a peripheral zone with which the first component is adhesively bonded in overlapping manner is provided. In such method, a) at least one body of hot-melt adhesive is adhesively bonded to the first component in such a way that it comes into contact with the peripheral zone upon adhesive bonding of the first component to the second component, b) the peripheral zone is heated locally at at least one point, at which the applied body of hot-melt adhesive comes into contact with the peripheral zone upon adhesive bonding of the first component, indirectly or directly by electromagnetic induction to a temperature above the melting temperature of the hot-melt adhesive, c) the first component is brought into contact with the peripheral zone of the second component in such a way that the body of the hot-melt adhesive comes into contact with the point of the peripheral zone heated in step b), such that the hot-melt adhesive melts at the point of contact with the peripheral zone and bonds the first component to the peripheral zone of the second component after cooling. In addition, prior to step b) or after step c) a reactive adhesive is introduced in such a way between the first and the second component that it bonds the first component to the peripheral zone of the second component, the reactive adhesive being cured or allowed to cure.

Owner:HENKEL KGAA +1

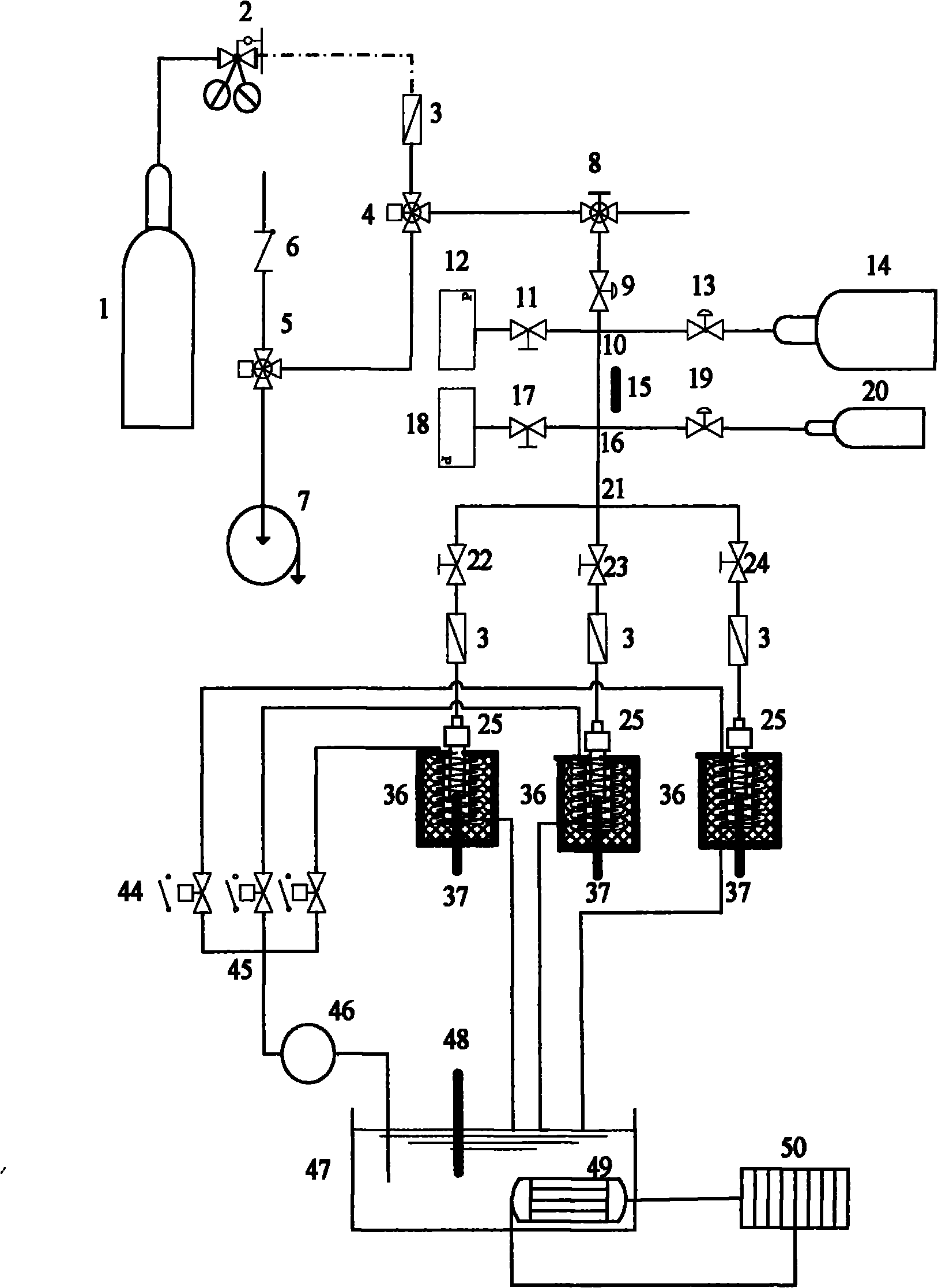

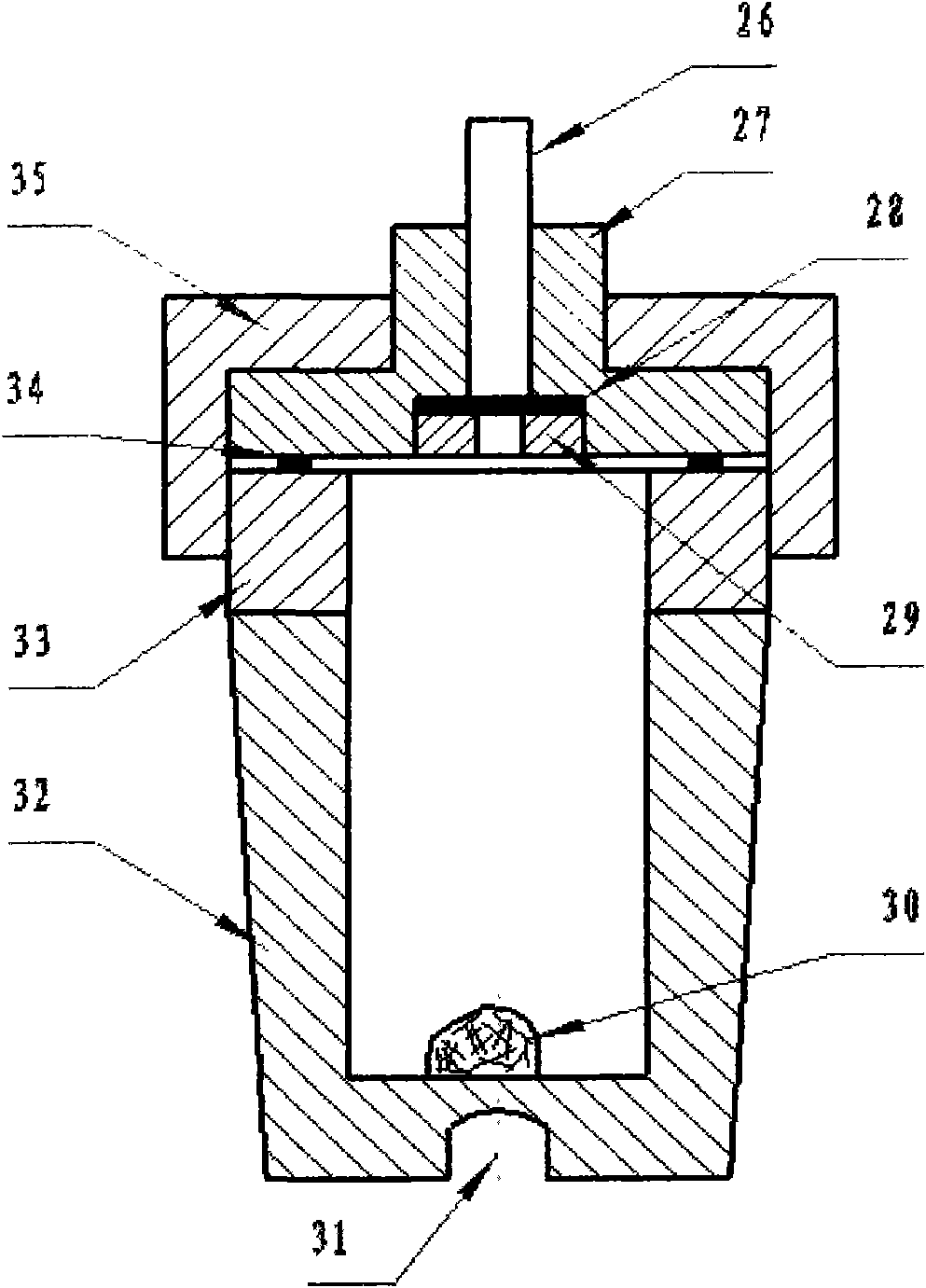

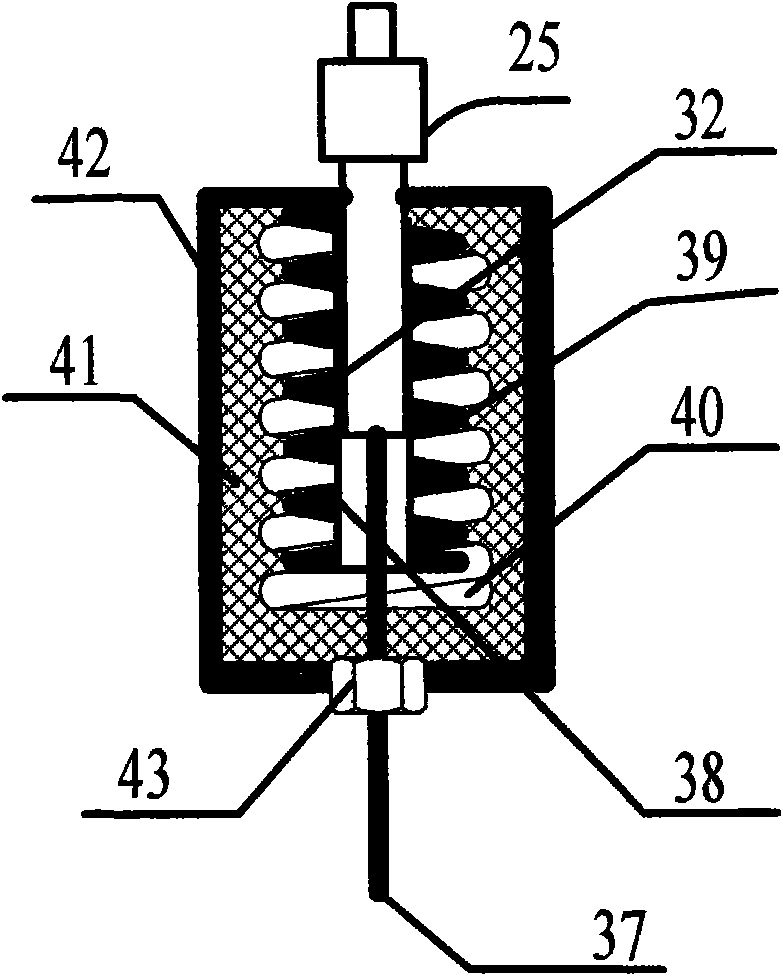

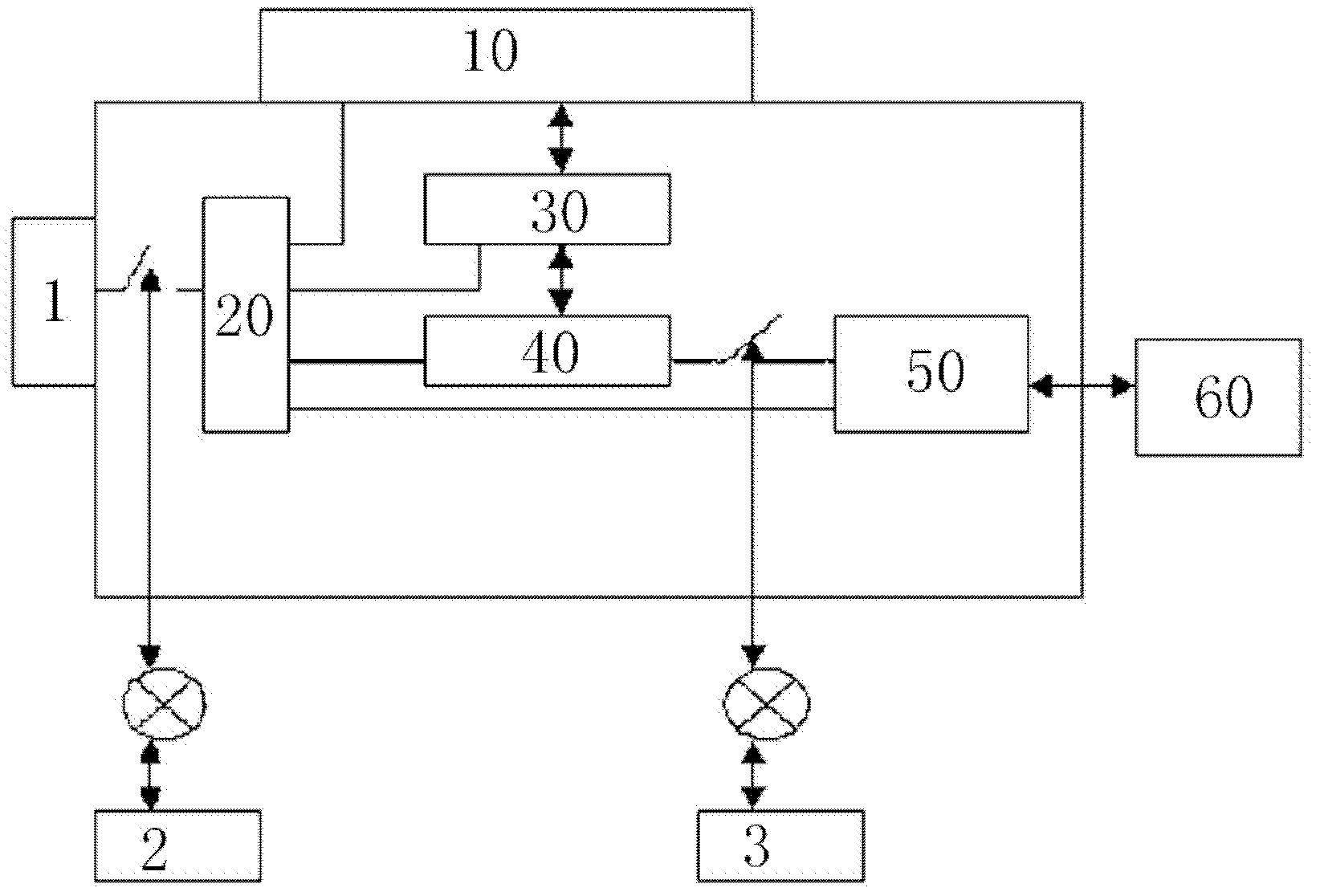

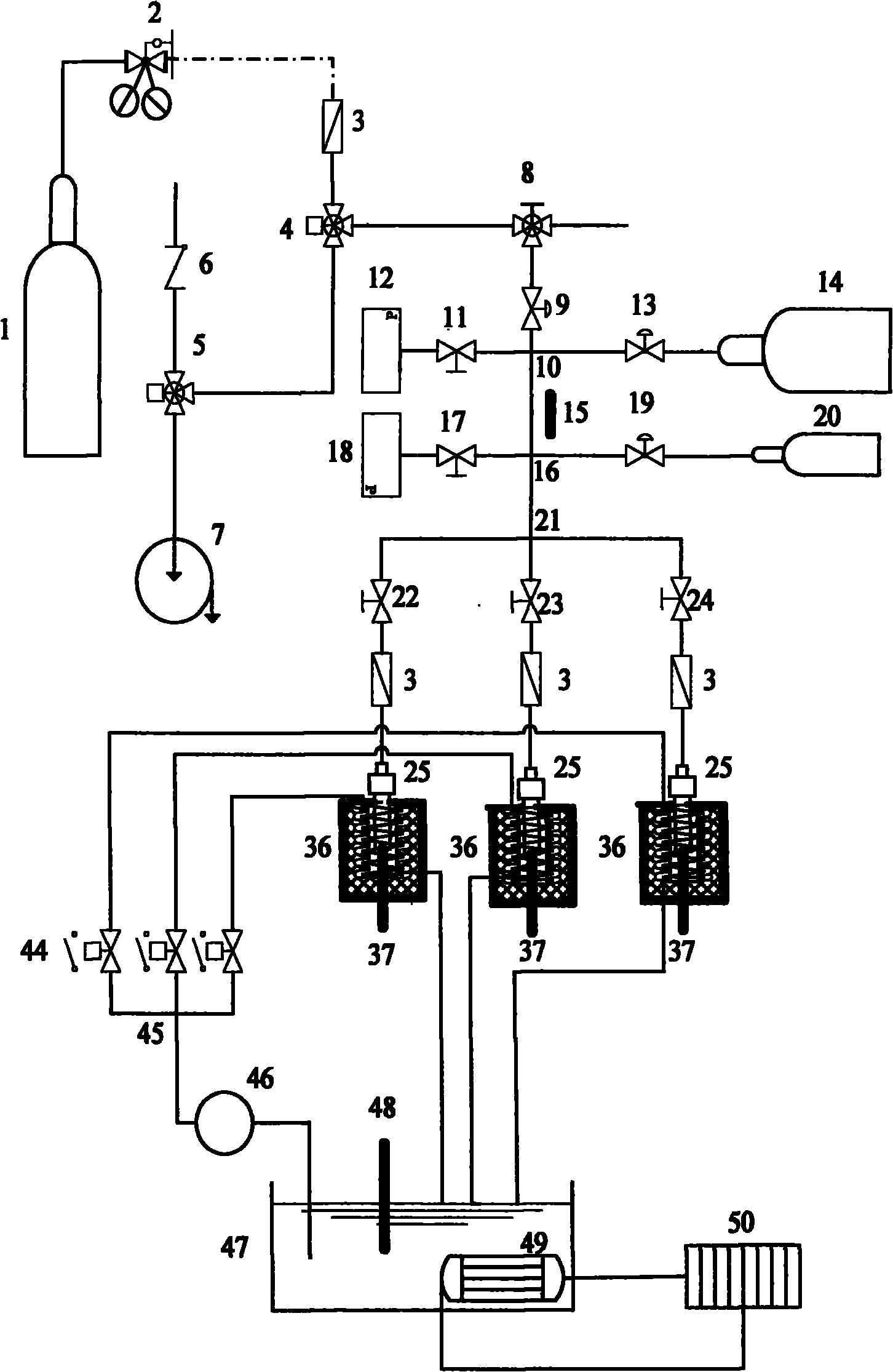

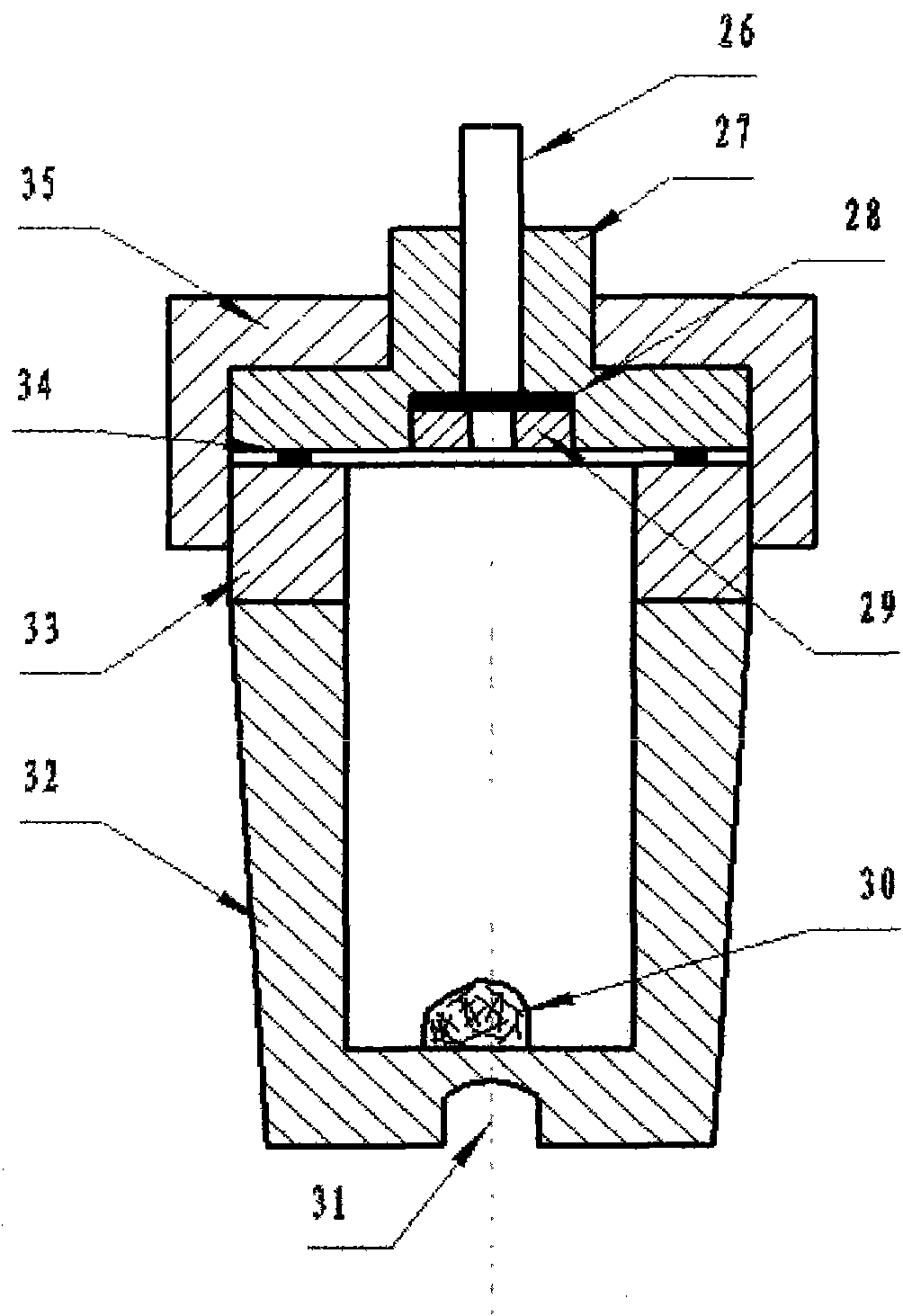

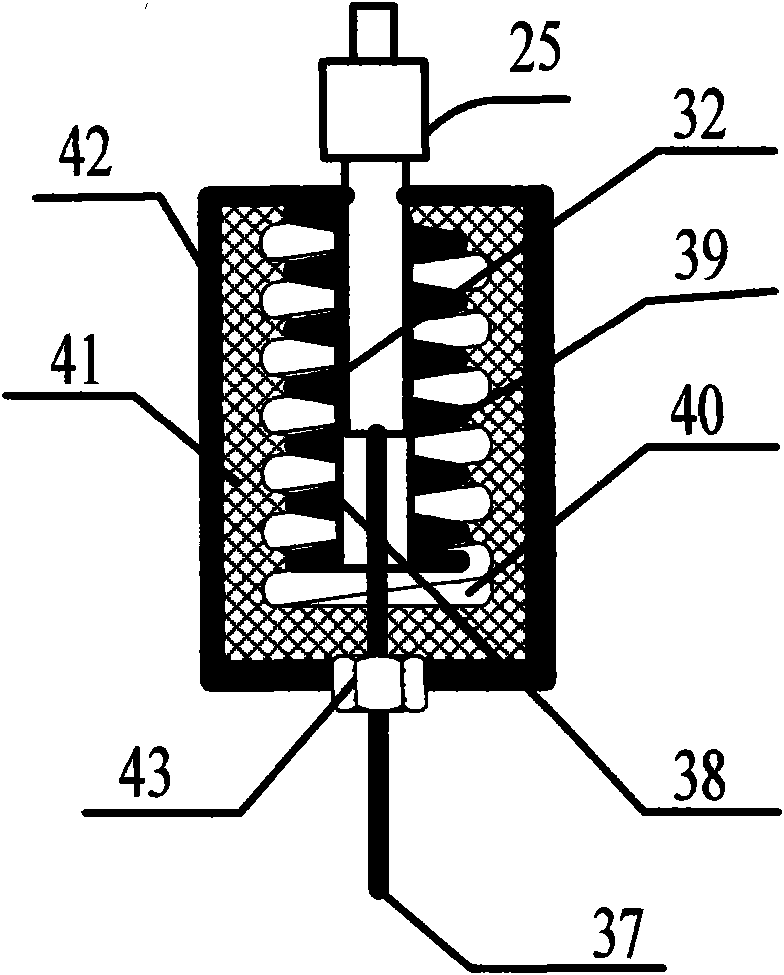

Test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and special device thereof

InactiveCN101858842AAutomatic control is reliableThe control process is stable and reliableMaterial analysisDesorptionData acquisition

The invention discloses a test method of metal hydride thermal adsorption and desorption of hydrogen cycle life and a special device thereof. The test device consists of a gas cycling system, a sample chamber heating and cooling system and a computer data collection and control system. The gas cycling system provides a vacuum environment and high-purity hydrogen source to the test system; the sample chamber heating and cooling system rapidly and circularly heats and cools the test sample; and the computer data collection and control system controls a heating and cooling program to run and controls the opening and closing of relevant electromagnetic valve and electric valve and instantly collect the pressure and temperature signal of the system. While completing the test of the cycle of the metal hydride thermal adsorption and desorption of hydrogen, the system also can test the alloy adsorption and desorption hydrogen performance such as PCT curve and dynamics curve and the constant-temperature adsorption and desorption hydrogen service life in situ.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

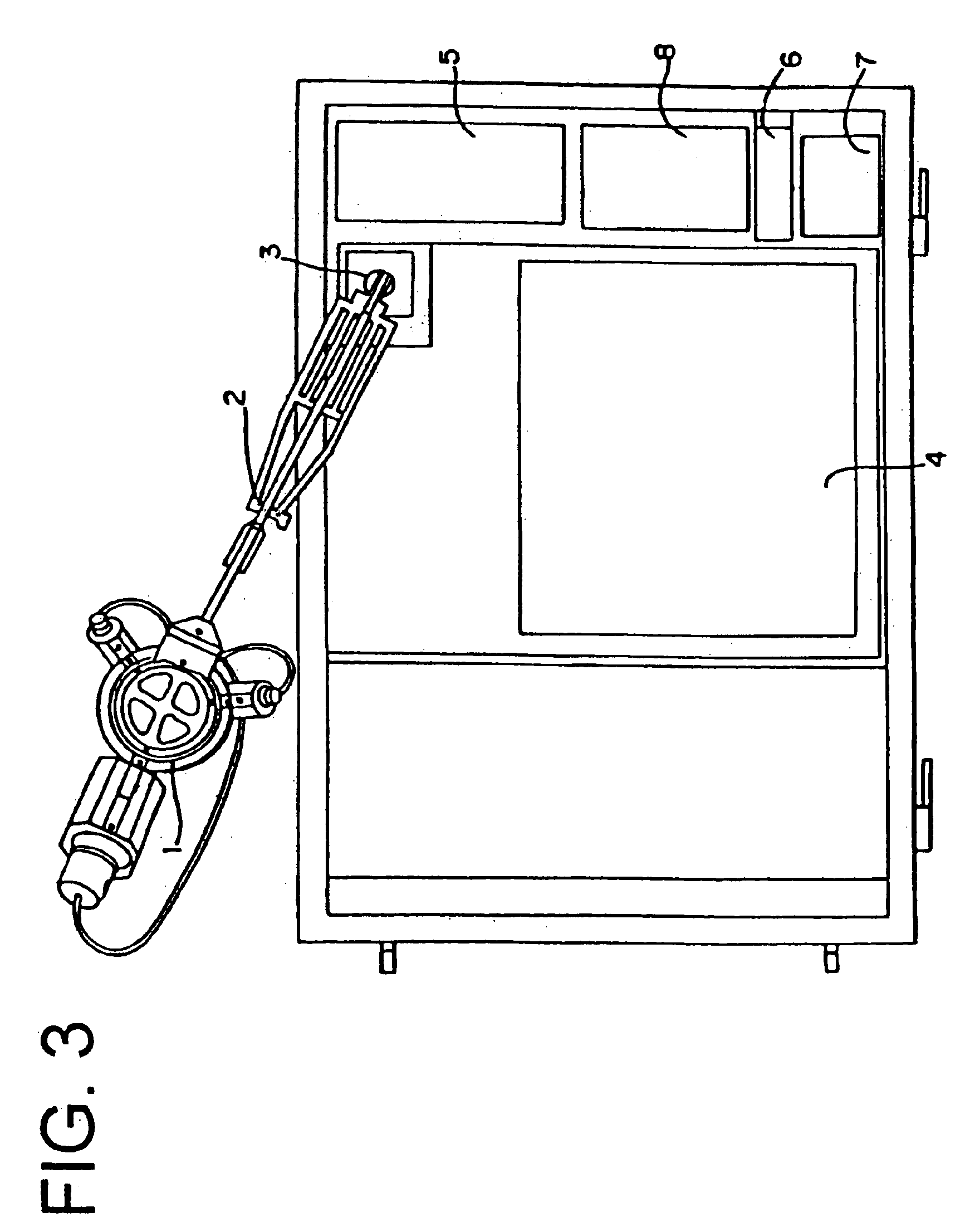

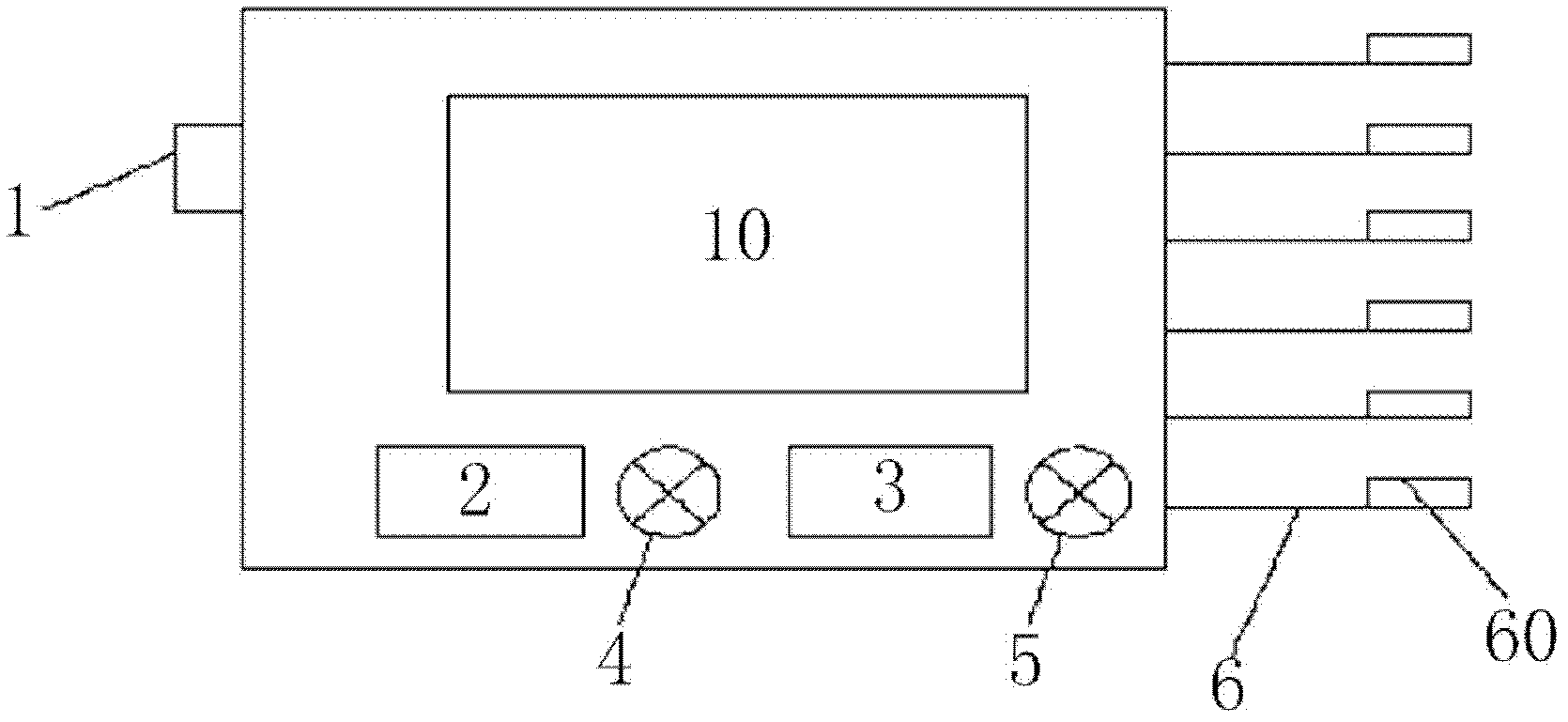

Intelligent temperature control acupuncture therapeutic apparatus

ActiveCN103126881AAccurate temperature controlHeating fastDevices for heating/cooling reflex pointsAcupunctureEngineeringElectrical and Electronics engineering

The invention discloses an intelligent temperature control acupuncture therapeutic apparatus. The intelligent temperature control acupuncture therapeutic apparatus comprises a power module, a liquid touch screen, a touch-screen controller, an electronic temperature control component used for simulating moxibustion temperature curve and a heating head used for being inserted into the handle portion of an acupuncture pin to conduct heating, wherein the electronic temperature control component is composed of a system control module and a heating driving module, the system control module is connected with the heating driving module in a communication mode, the system control module is connected with the power module and the touch-screen controller in a communication mode, the liquid touch screen is connected with the touch-screen controller in a communication mode and used for setting the heating time and the temperature cycle period of the heating head and displaying the temperature change and the heating time of the heating head in work, the heating head is connected with the heating driving module through a guide line, and the system control module and the heating driving module control the temperature change range of the heating head from 30 DEG C to 59 DEG C. According to the intelligent temperature control acupuncture therapeutic apparatus, moxibustion technique change and moxa-cone temperature change are effectively simulated, a continuous and variational thermal stimulus state is kept, fast - slow adaptation phenomenon caused when a human body experiences the apparatus is avoided, and clinical effect is improved.

Owner:上海中医药大学附属龙华医院浦东分院 +2

Metal hydride thermal adsorption and desorption hydrogen cycling comprehensive test device

InactiveCN101858841AAutomatic control is reliableThe control process is stable and reliableMaterial analysisDesorptionData acquisition

The invention discloses a metal hydride thermal adsorption and desorption hydrogen cycling comprehensive test device, which consists of a gas cycling system, a sample chamber heating and cooling system and a computer data collection and control system. The gas cycling system provides a vacuum environment and high-purity hydrogen source to the test system; the sample chamber heating and cooling system rapidly and circularly heats and cools the test sample; and the computer data collection and control system controls a heating and cooling program to run and controls the opening and closing of relevant electromagnetic valve and electric valve and instantly collect the pressure and temperature signal of the system. While completing the test of the cycle of the metal hydride thermal adsorption and desorption of hydrogen, the system also can test the alloy adsorption and desorption hydrogen performance such as PCT curve and dynamics curve and the constant-temperature adsorption and desorption hydrogen service life in situ.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Comprehensive pain assessment systems and methods

InactiveUS20050267338A1Cost-effectivePrecise heatingCatheterDiagnostic recording/measuringAnalgesics drugsPain assessment

Owner:NEUROSCI TOOLWORKS

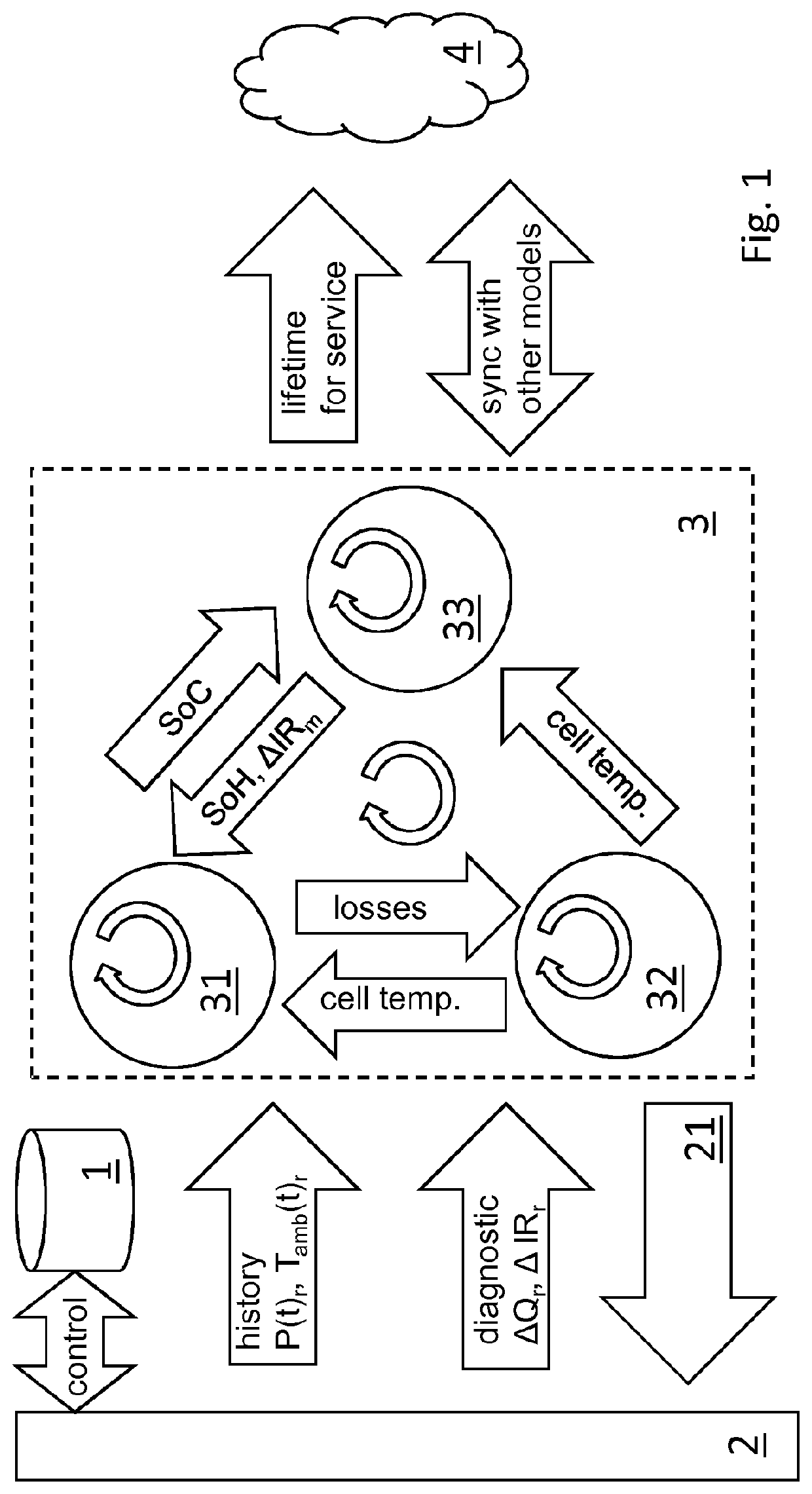

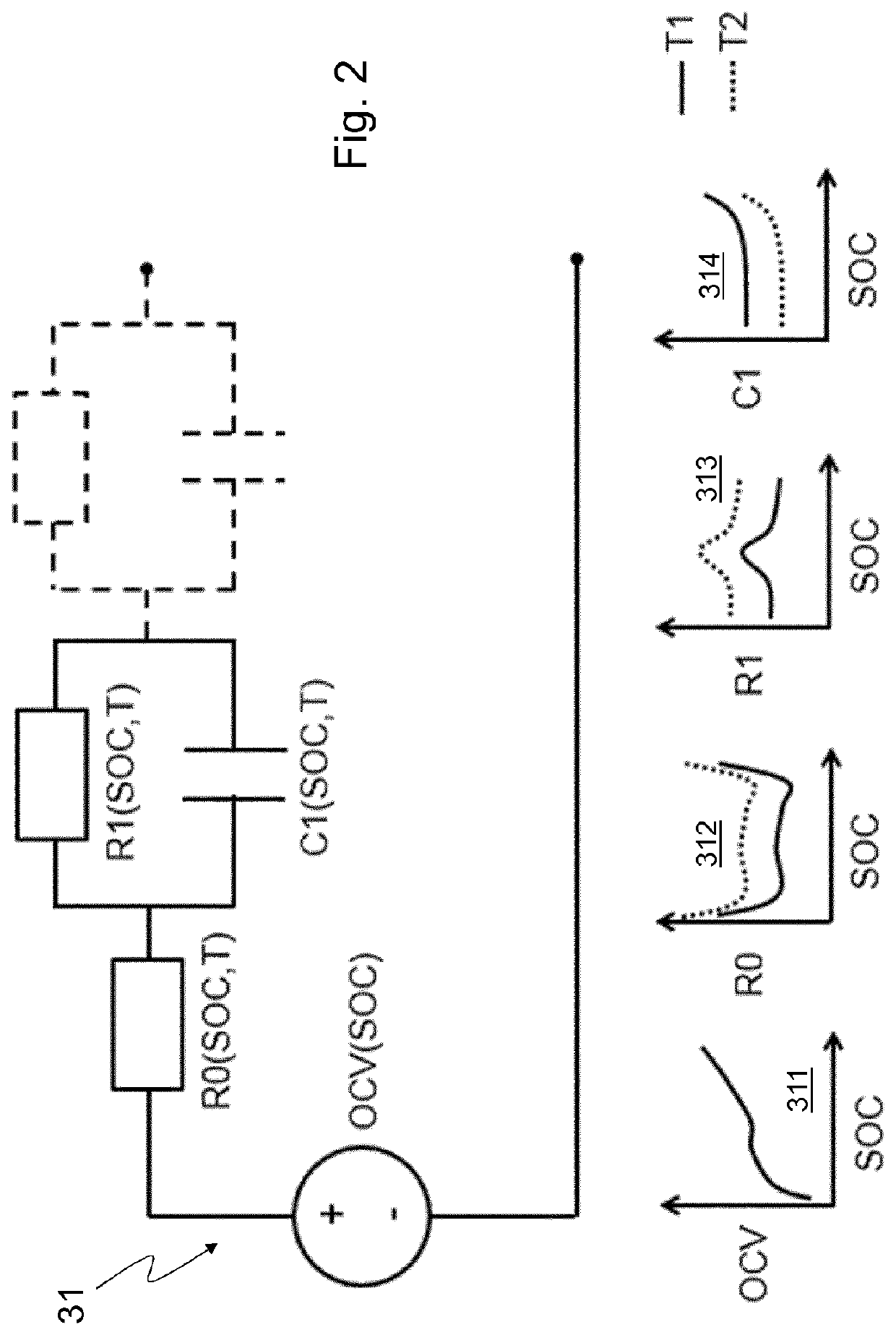

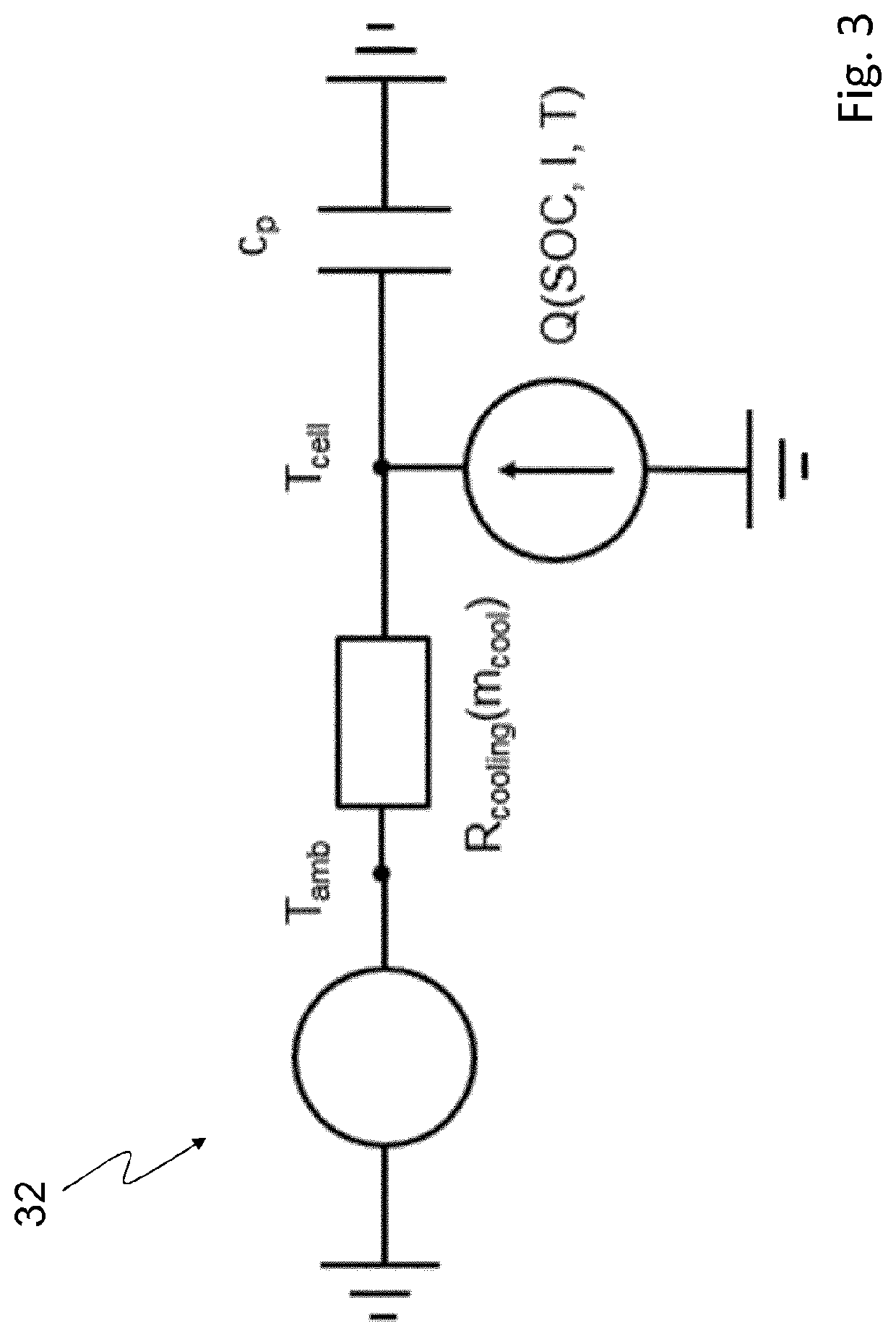

Method and System For Controlling a Rechargeable Battery

ActiveUS20200227791A1Extensive characterizationLower requirementCircuit monitoring/indicationElectrical testingThermodynamicsElectrical battery

A battery management system for a rechargeable battery is disclosed which includes a control system configured to control, a numerical battery model, including a parametrized electric model; a parametrized thermal model; an aging model configured to provide stress parameters indicative of an instantaneous consumption of an expected lifetime of the battery in dependence on an internal temperature of the battery, and one or more of momentary state of charge, current, voltage and power delivered; updated electric parameters and / or updated thermal parameters based on a chronological sequence of internal temperature as obtained from the parametrized thermal model; a control system settings update unit configured to adapt controller settings based on stress parameters.

Owner:ABB (SCHWEIZ) AG +1

Air protecting and heating type braze welding furnace

InactiveCN101041195APrecise heatingImprove welding qualityMetal working apparatusSoldering auxillary devicesTemperature controlElectricity

The invention discloses an air protection heating brazing furnace, comprising furnace body and welding room constituted by furnace. The welding room is divided into a group of control regions with different temperature. In each temperature control region internal thermal cycling fan, temperature sensor, electrical heater and temperature controller are set. Preheated protection air is connected with wind cavity of internal thermal cycling fan through pipes so that the internal thermal cycling fan with uniform temperature and protection air is set above the whole welding room and electrical heaters are set above and under workpeice properly. The data received by temperature controller from the temperature sensor is compared with setting parameters and the temperature controller controls electrical heaters in all temperature controlling regions. The invention can heat the brazing region in furnace accurately so that the temperature in the whole brazing region is uniform, the protection air is uniform and the workpeice welding quality is high.

Owner:JIANGSU KANGJIE MACHINERY

Heating method of heating furnace for glass tempering

ActiveCN102690048AShorten the radiation distanceHeating fastGlass tempering apparatusGlass productionEngineeringHeating furnace

The invention provides a heating method of a heating furnace for glass tempering; air in the heating furnace is driven by a high temperature blower fan to flow circularly so as to take away heat generated by an electric heating element; the air is pressurized and injected onto a surface of glass to be processed; and thus heating in a convection heating manner is realized; the heat generated by the electric heating element is also transmitted to the surface of the glass to be processed through radiation heating; during the heating process, the glass to be processed is heated in a main manner of convection heating; when the glass to be processed is heated to a temperature near a glass softening temperature, the glass to be processed is heated in a main manner of radiation heating till the glass to be processed reaches a temperature at which tempering can be completed. With the heating method, using the characteristic that convection heating is faster than radiation heating, the temperature of the glass to be processed is increased quickly; and with the characteristic that matrix radiation heating of a device allows regional temperature adjustment, each part of the glass to be processed can be heated to the temperature at which glass tempering can be completed.

Owner:LUOYANG NORTHGLASS TECH +2

Method and system for determining optical properties of semiconductor wafers

ActiveUS20120231558A1Precise heatingImprove accuracyRadiation pyrometrySemiconductor/solid-state device testing/measurementOptical propertyEmissivity

A method and system are disclosed for determining at least one optical characteristic of a substrate, such as a semiconductor wafer. Once the optical characteristic is determined, at least one parameter in a processing chamber may be controlled for improving the process. For example, in one embodiment, the reflectivity of one surface of the substrate may first be determined at or near ambient temperature. From this information, the reflectance and / or emittance of the wafer during high temperature processing may be accurately estimated. The emittance can be used to correct temperature measurements using a pyrometer during wafer processing. In addition to making more accurate temperature measurements, the optical characteristics of the substrate can also be used to better optimize the heating cycle.

Owner:MATTSON TECHNOLOGY +1

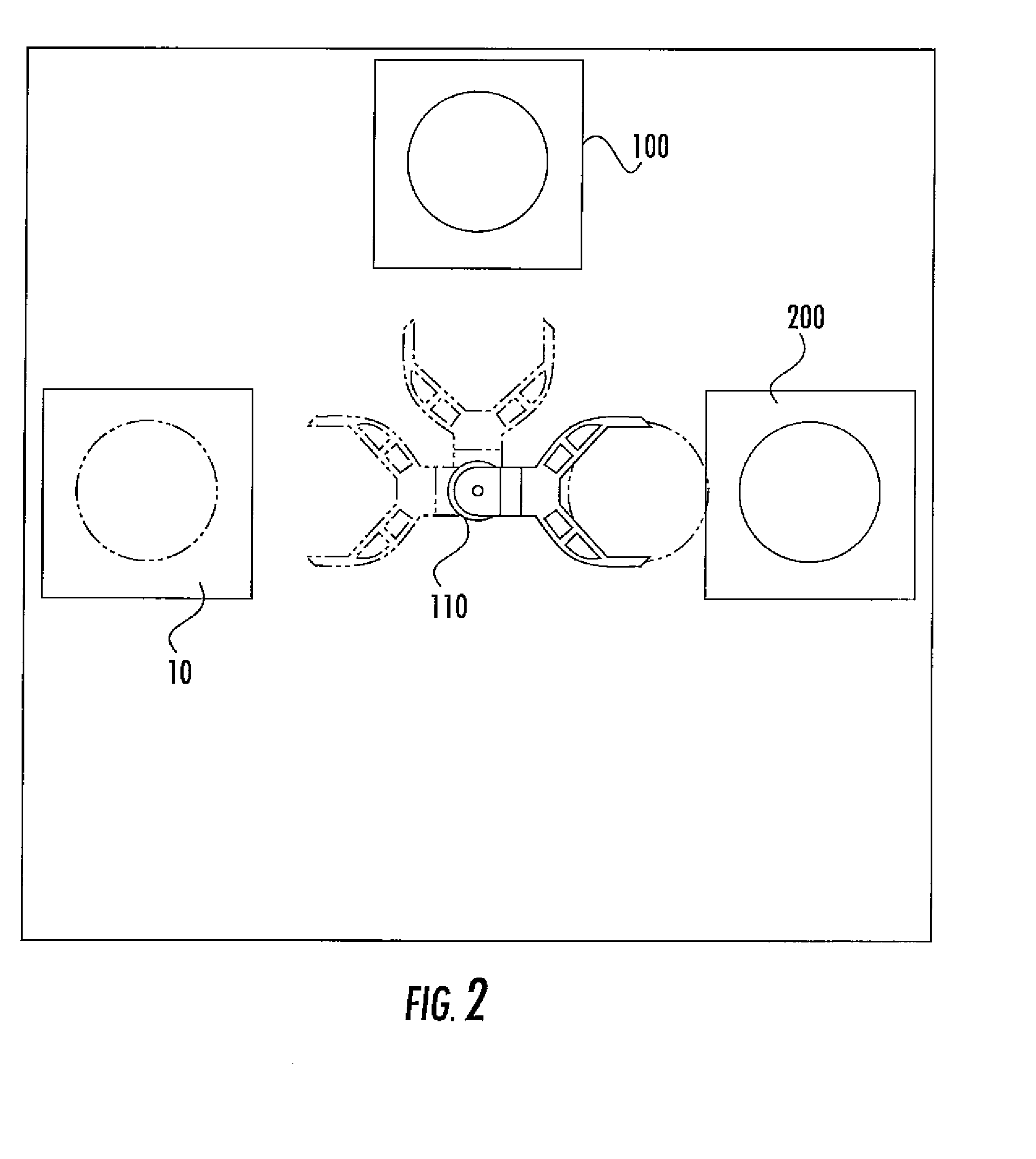

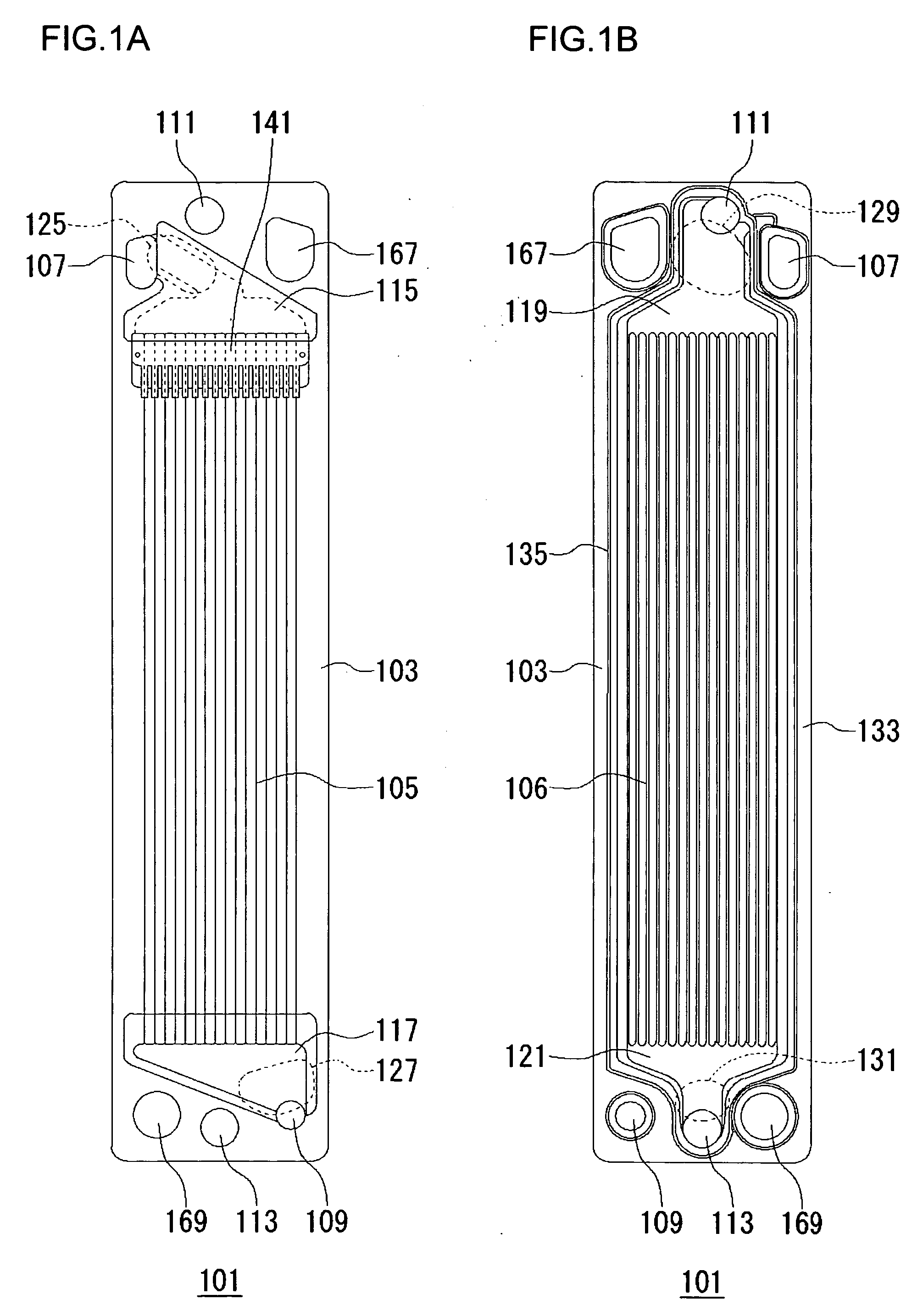

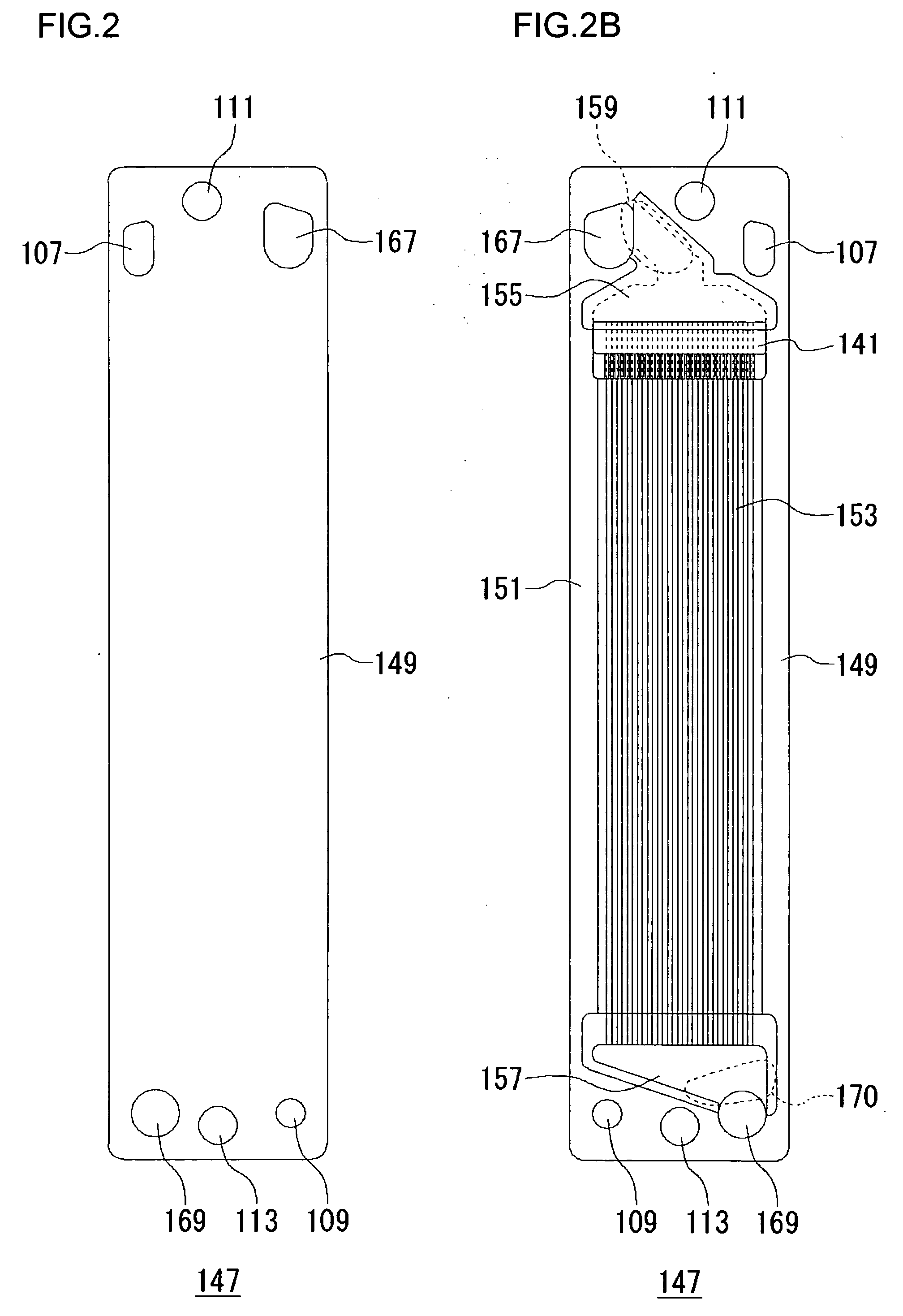

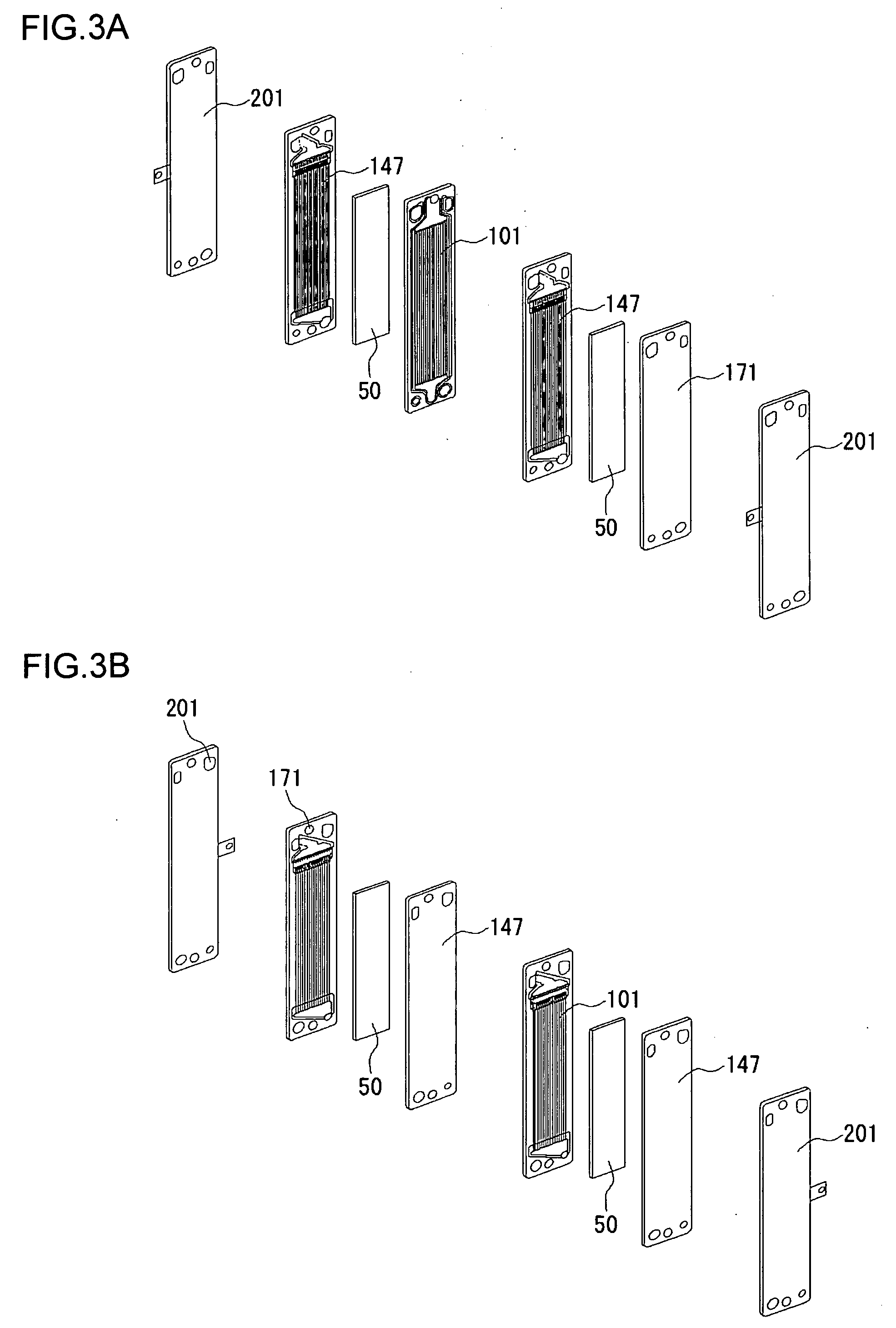

Fuel cell and fuel cell separator

InactiveUS20050112422A1Improve output stabilityIncrease temperatureFuel cells groupingRegenerative fuel cellsFuel cellsEngineering

A pair of separators sandwiches an electrode assembly of fuel cell including an electrolyte and a pair of electrodes provides on respective sides of the electrolyte. The separator facing a fuel electrode is provided with a coolant introduction passage on the back of a fuel introduction passage and a second manifold for fuel supply.

Owner:SANYO ELECTRIC CO LTD

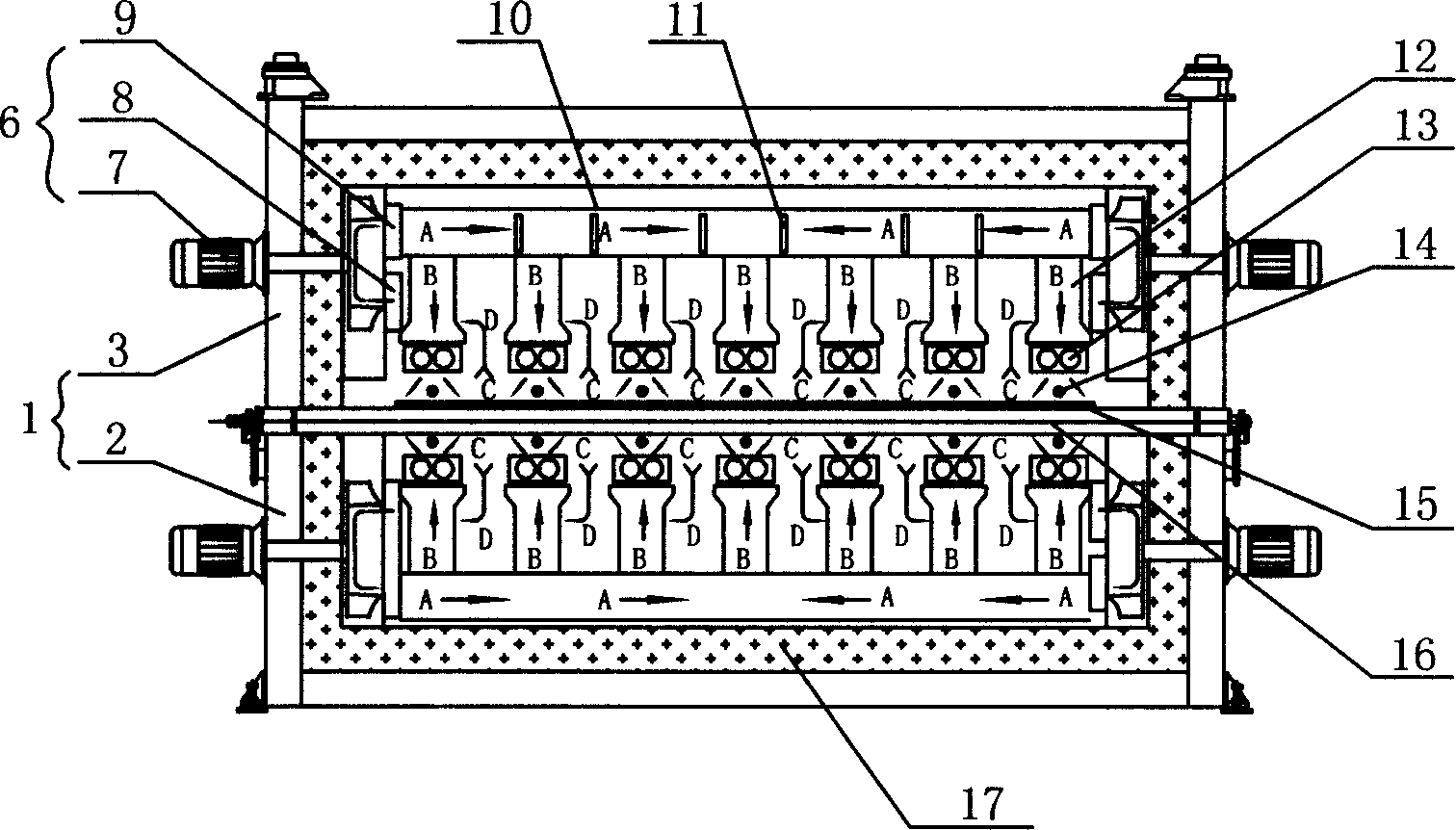

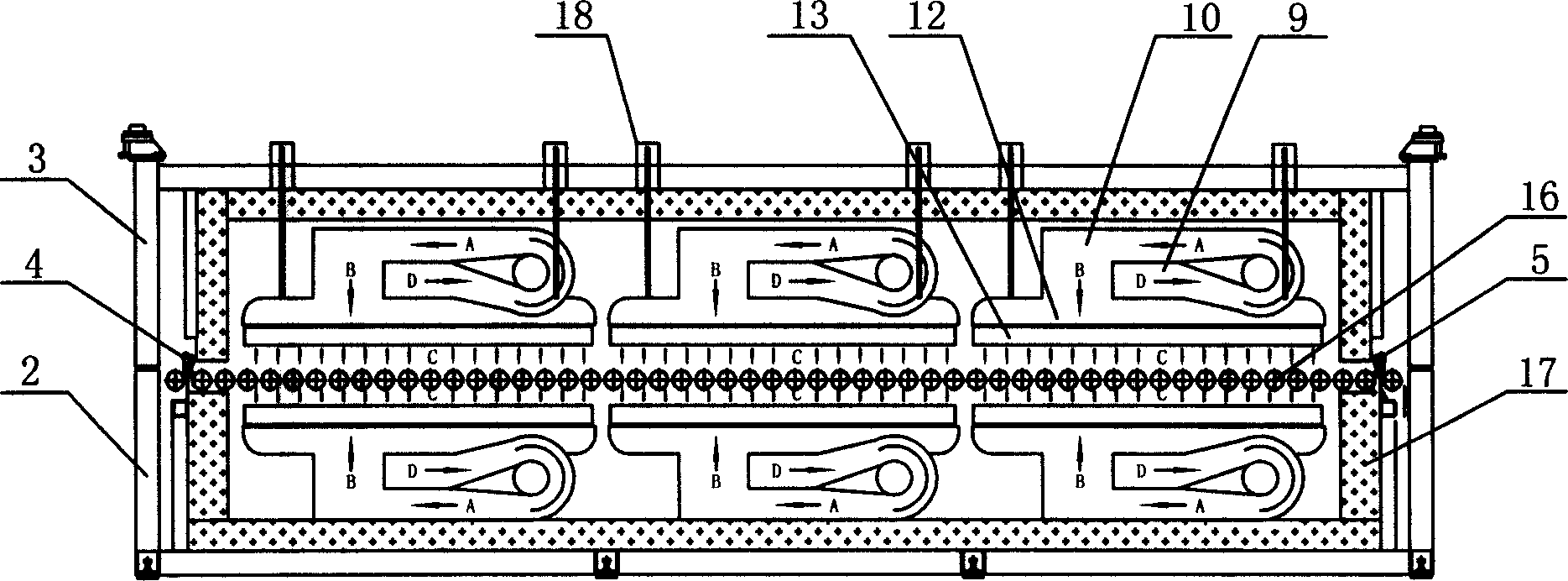

Energy saving strong convection sheet glass heating oven

InactiveCN1861535ANo pollution in the processEasy to control temperature balanceGlass tempering apparatusFlat glassEngineering

An energy-saving plate glass heating furnace with strong convection is composed of a furnace body consisting of the life upper half and the lower half fixed to ground and with glass plate inlet and outlet gates, several groups of upper and lower refractory blowers, the upper and lower pipelines with the inlets connected to the air outlets of blowers and outlets to generate strong convection, the primary heaters at the air inlets of said blowers, and the secondary heaters at the air outlets of said pipelines.

Owner:姚敏

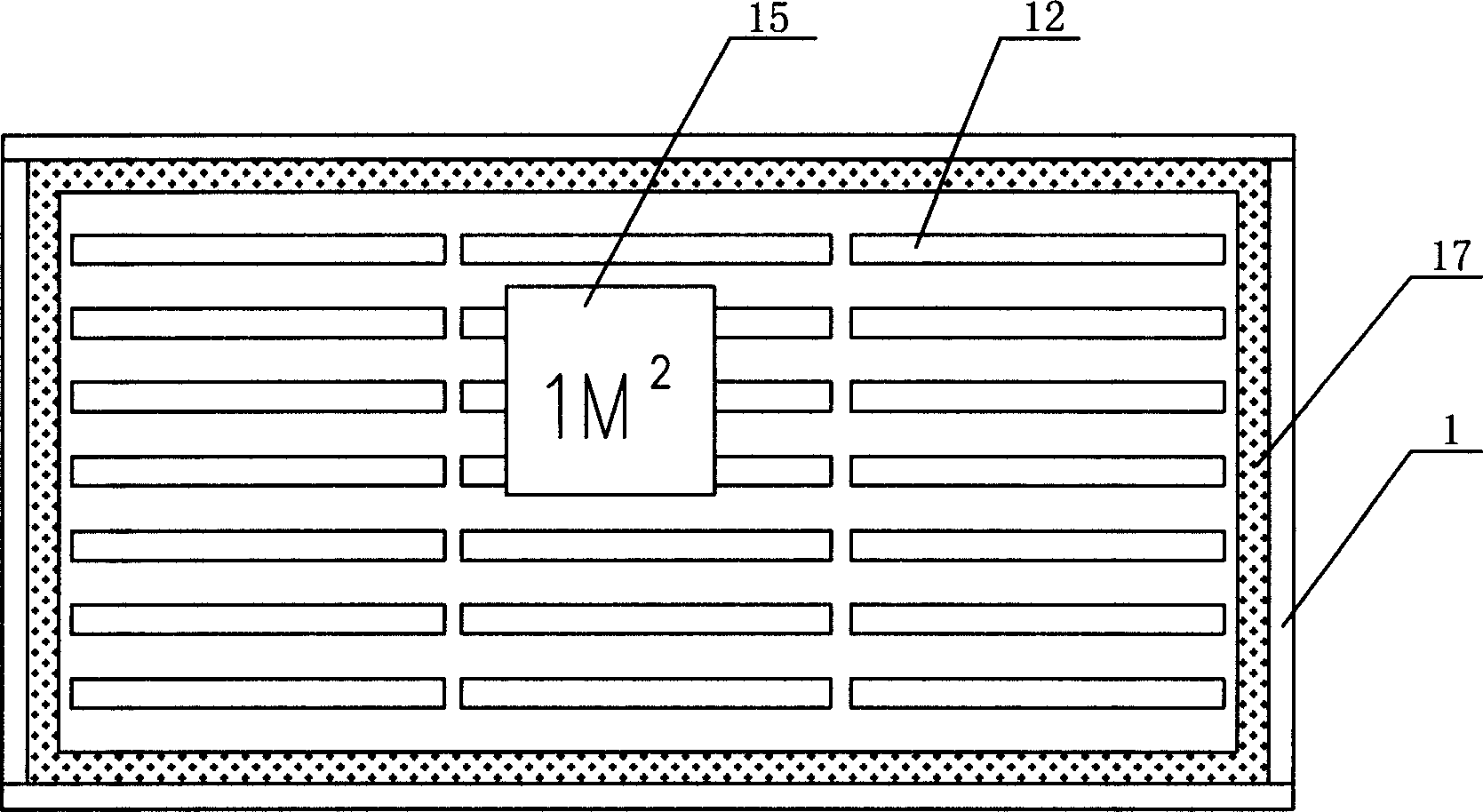

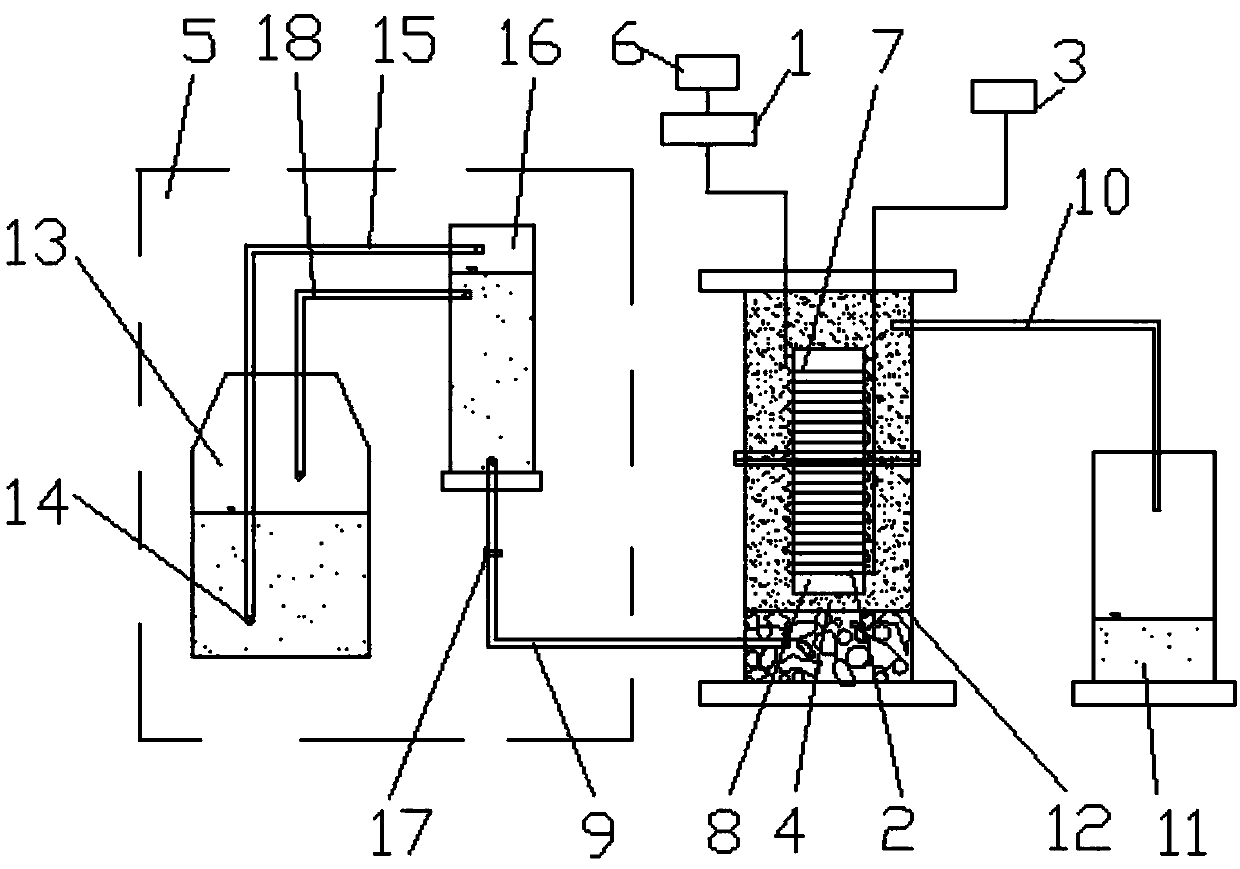

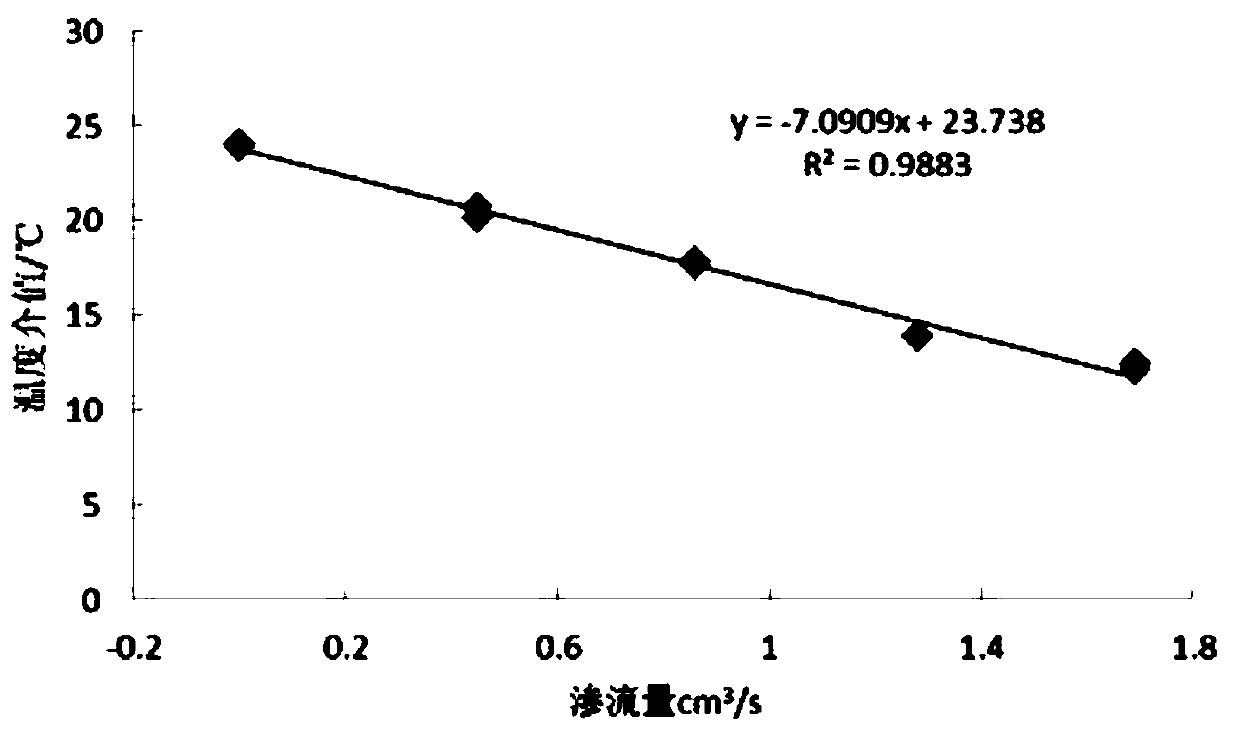

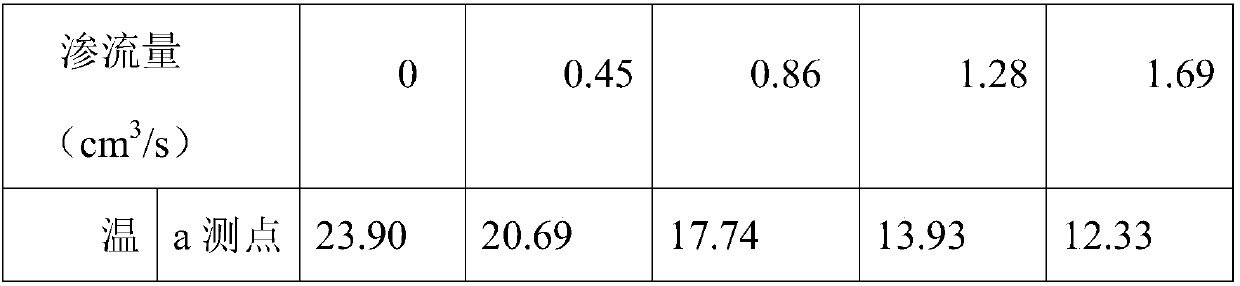

Si-DTS-based sandy soil seepage quantity monitoring platform

InactiveCN109596496AImprove monitoring accuracyIncreased sensitivityThermometers using physical/chemical changesPermeability/surface area analysisEngineeringStreamflow

The invention discloses a Si-DTS-based sandy soil seepage quantity monitoring platform. The platform comprises a heating system, a seepage system and a distributed optical fiber temperature measurement system, wherein the heating system comprises a silicone rubber heating band and an AC power supply; the seepage system comprises a model pipe and a water supply system for providing seepage for sandy soil in the model pipe; the distributed optical fiber temperature measurement system comprises a temperature measurement optical fiber and a DTS demodulator and a distributed optical fiber temperature measurement main control computer, which are connected with the temperature measurement optical fiber in sequence; the temperature measurement optical fiber is wound on the outer wall of a PVC pipe; the silicone rubber heating band is wound outside the temperature measurement optical fiber to form a measurement pipe; and the distributed optical fiber temperature measurement main control computer is used for acquiring and analyzing corresponding position and temperature information of the temperature sensing optical fibers. The platform is capable of testing a relative relationship between atemperature intermediate value of the measurement pipe in the sandy soil and a seepage quantity through the heating system, the seepage system and the distributed optical fiber temperature measurement system, so as to obtain a seepage quantity of a seepage field in the sandy soil, and is simple to operate and high in correctness.

Owner:XIAN UNIV OF TECH

Method and system for determining optical properties of semiconductor wafers

ActiveUS8152365B2Precise heatingImprove accuracyRadiation pyrometrySemiconductor/solid-state device testing/measurementEmissivityOptical property

A method and system are disclosed for determining at least one optical characteristic of a substrate, such as a semiconductor wafer. Once the optical characteristic is determined, at least one parameter in a processing chamber may be controlled for improving the process. For example, in one embodiment, the reflectivity of one surface of the substrate may first be determined at or near ambient temperature. From this information, the reflectance and / or emittance of the wafer during high temperature processing may be accurately estimated. The emittance can be used to correct temperature measurements using a pyrometer during wafer processing. In addition to making more accurate temperature measurements, the optical characteristics of the substrate can also be used to better optimize the heating cycle.

Owner:MATTSON TECHNOLOGY +1

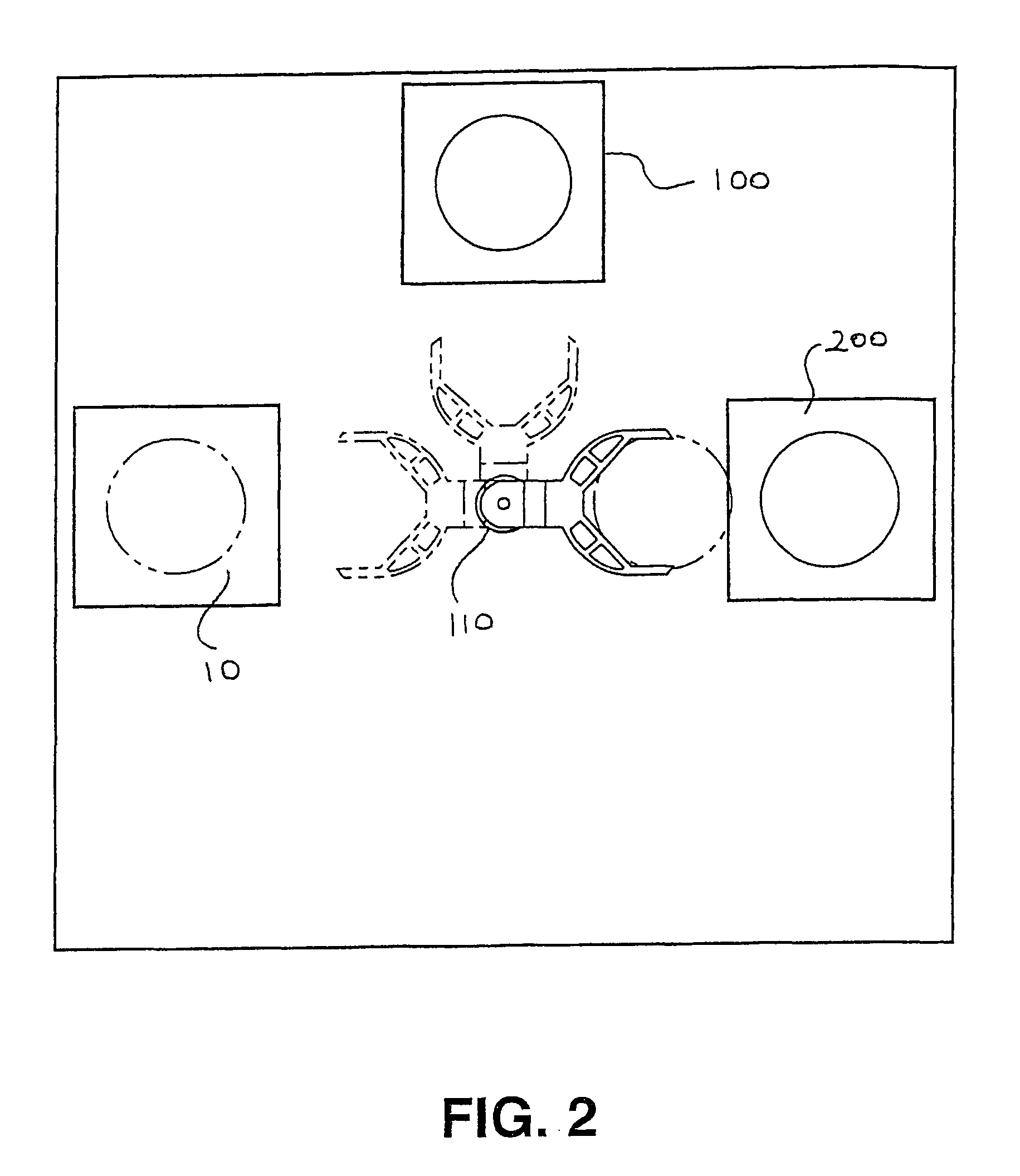

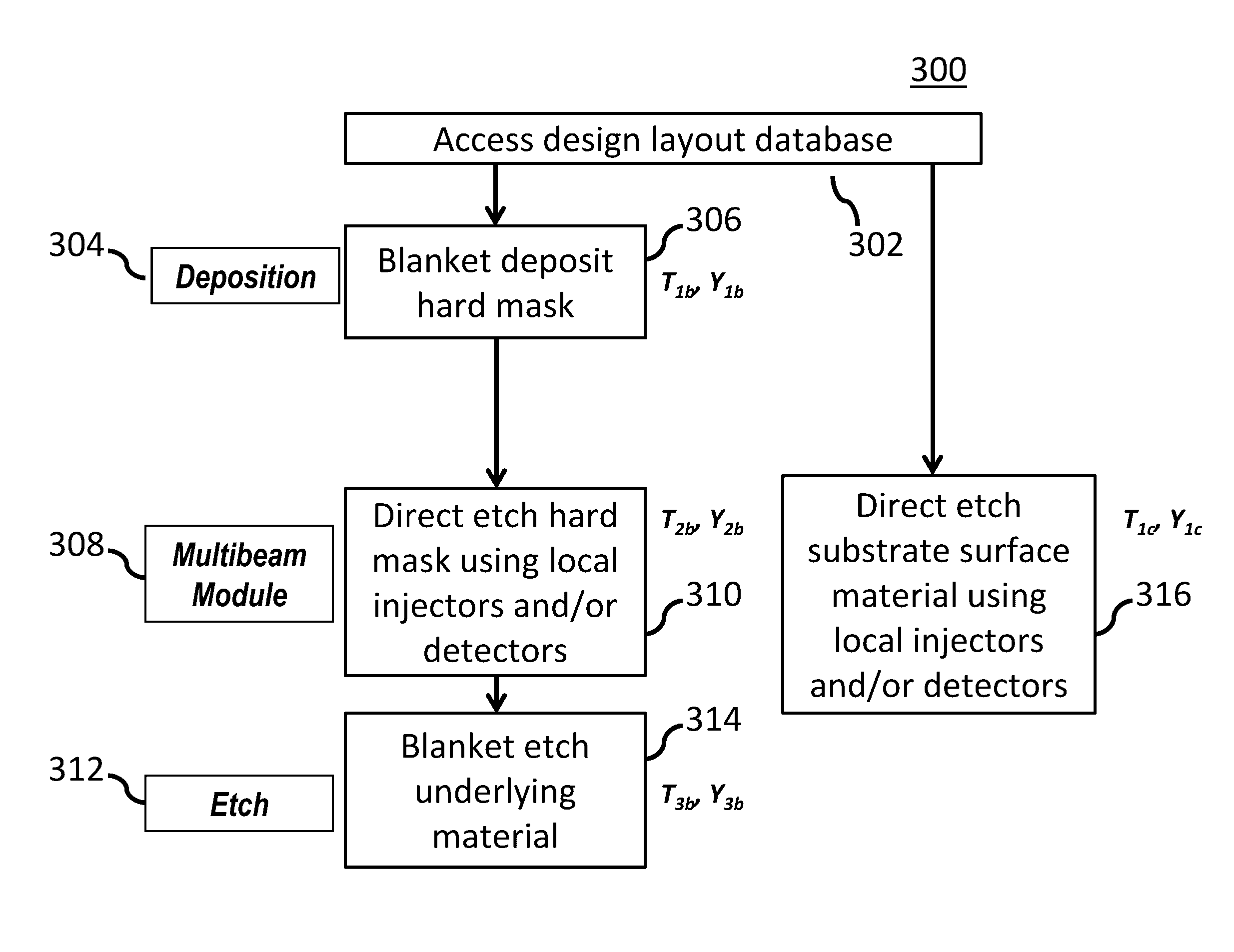

Precision substrate material removal using miniature-column charged particle beam arrays

ActiveUS9466464B1Reaction rate and efficiencyPrecise heatingSemiconductor/solid-state device testing/measurementElectric discharge tubesResistAs Directed

Methods, devices and systems for patterning of substrates using charged particle beams without photomasks and without a resist layer. Material can be removed from a substrate, as directed by a design layout database, localized to positions targeted by multiple, matched charged particle beams. Reducing the number of process steps, and eliminating lithography steps, in localized material removal has the dual benefit of reducing manufacturing cycle time and increasing yield by lowering the probability of defect introduction. Furthermore, highly localized, precision material removal allows for controlled variation of removal rate and enables creation of 3D structures or profiles. Local gas injectors and detectors, and local photon injectors and detectors, are local to corresponding ones of the columns, and can be used to facilitate rapid, accurate, targeted substrate processing.

Owner:MULTIBEAM CORP

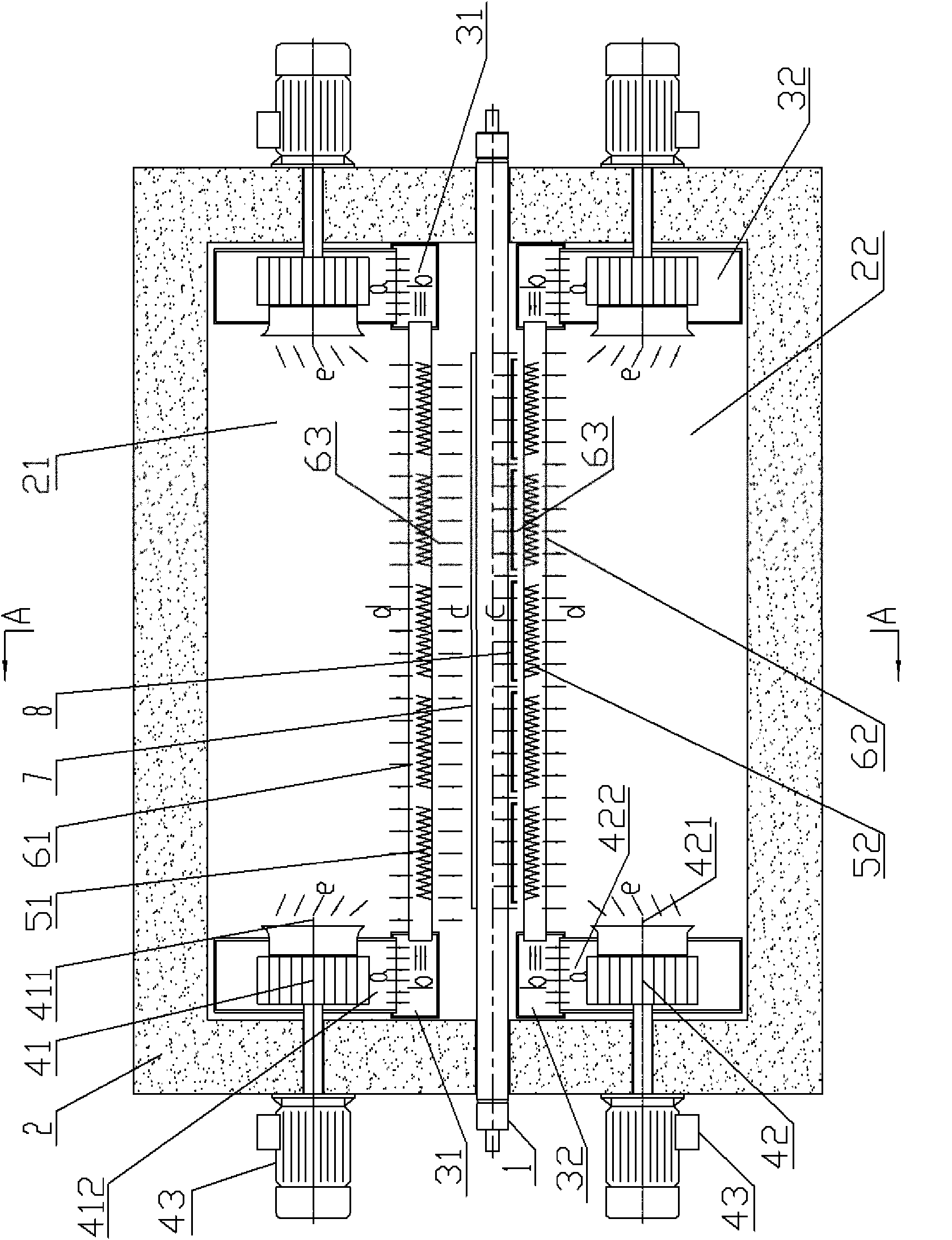

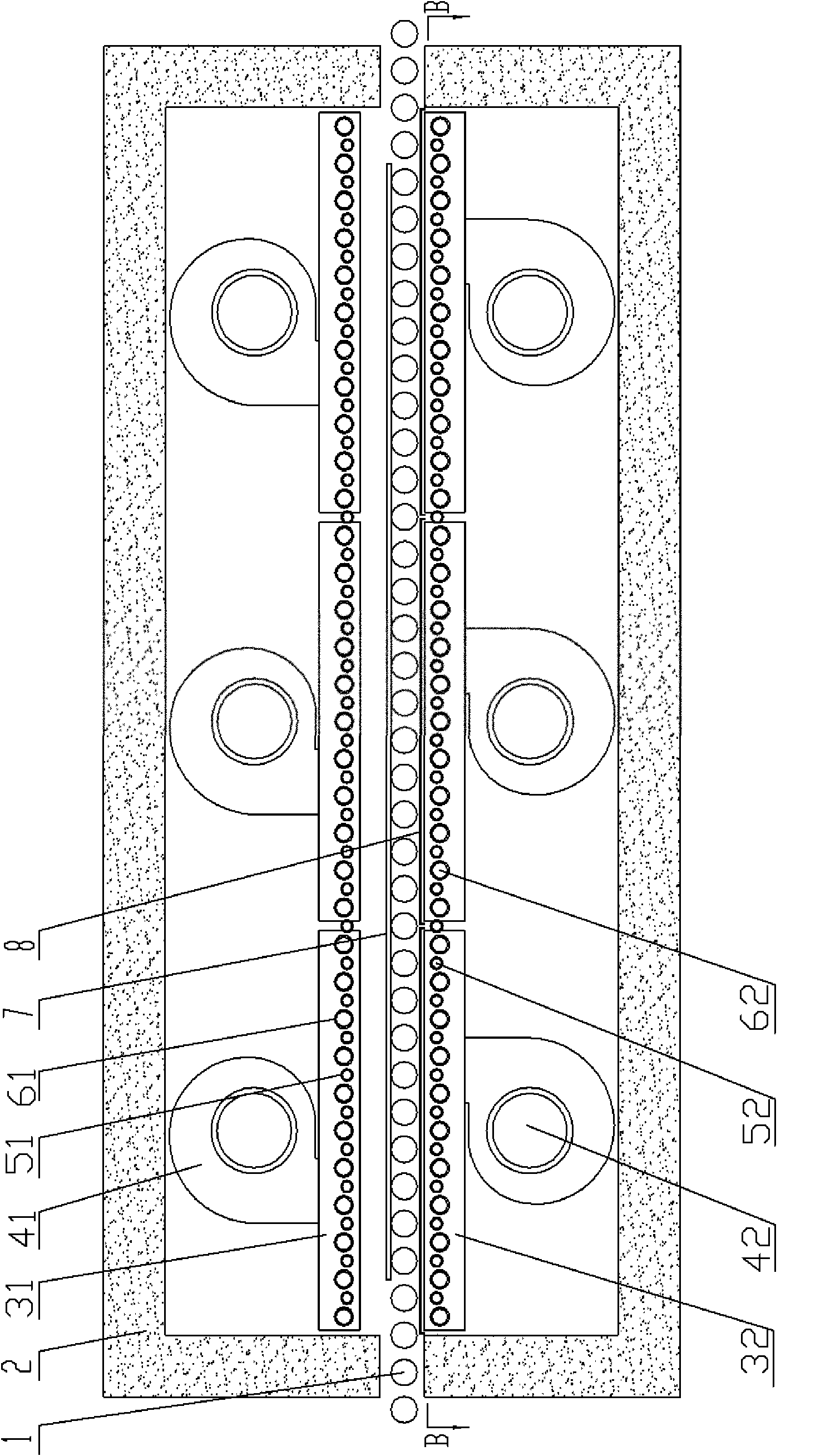

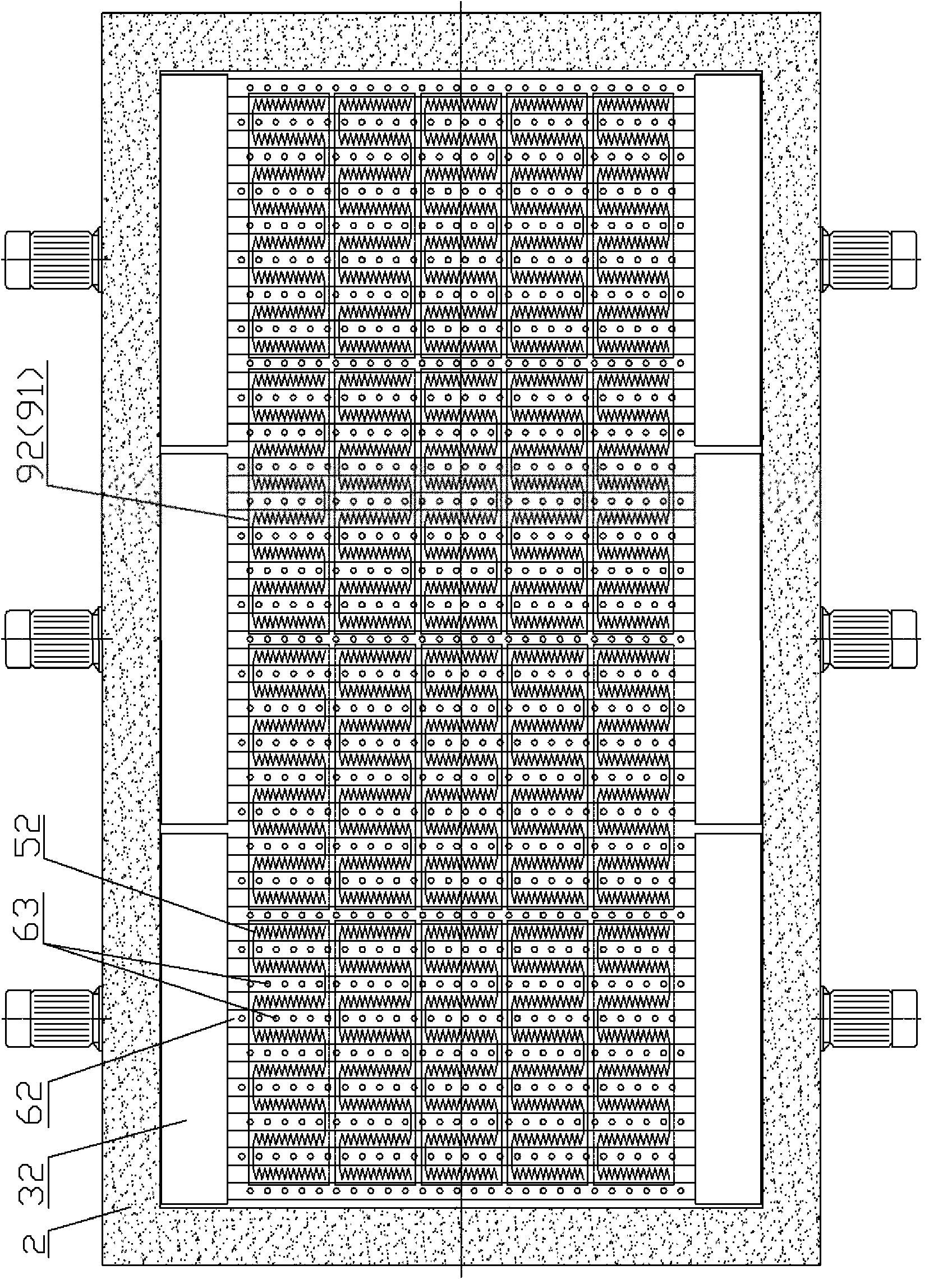

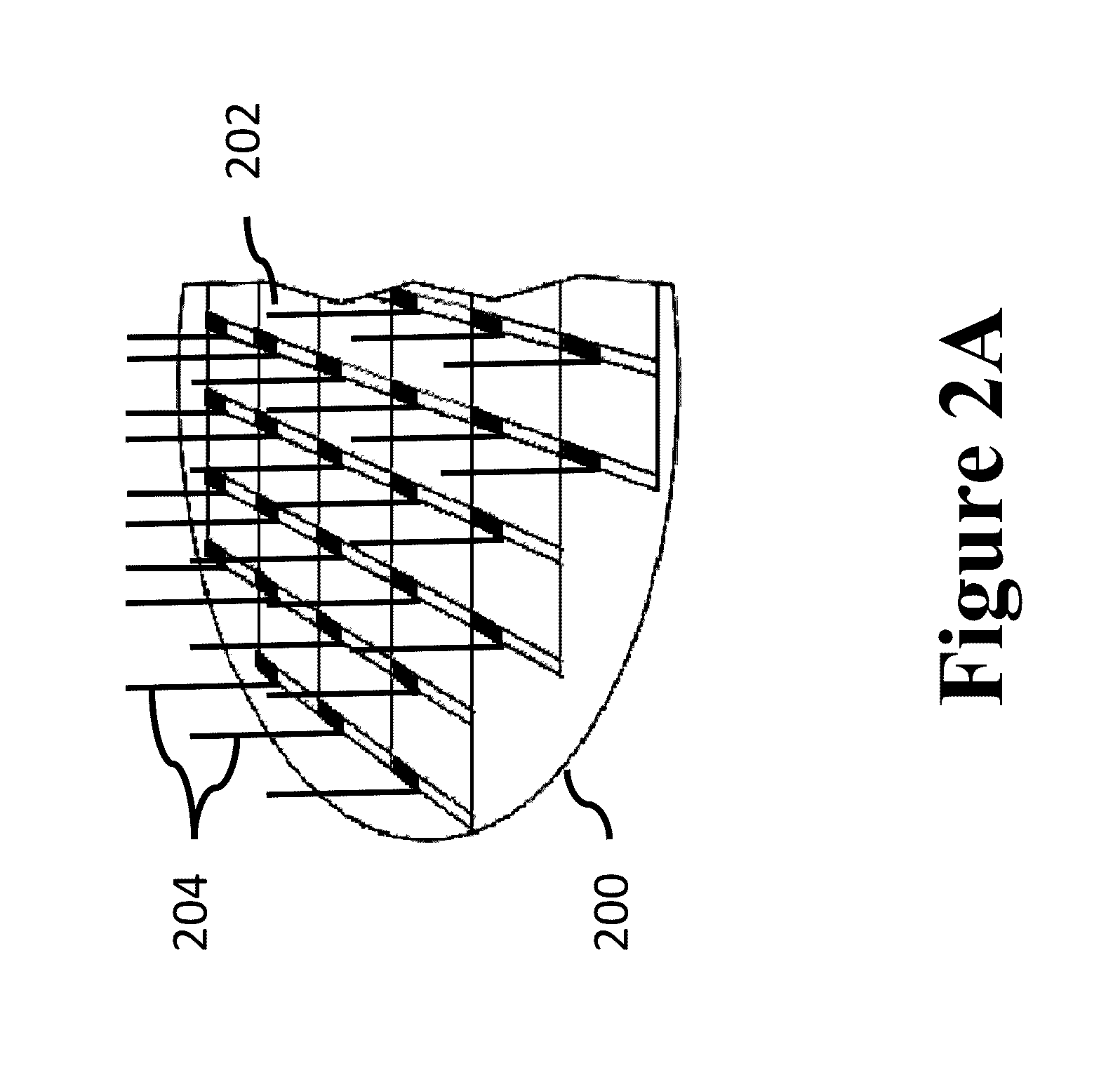

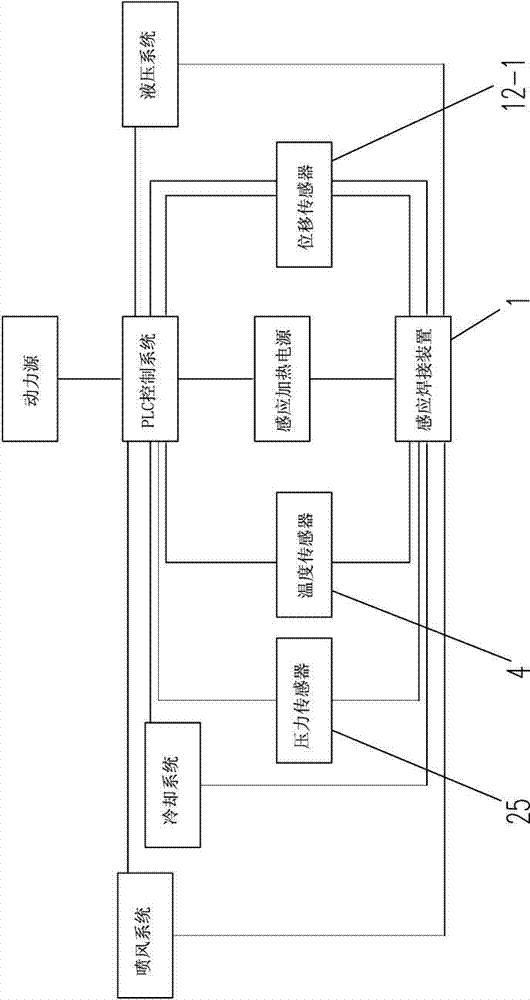

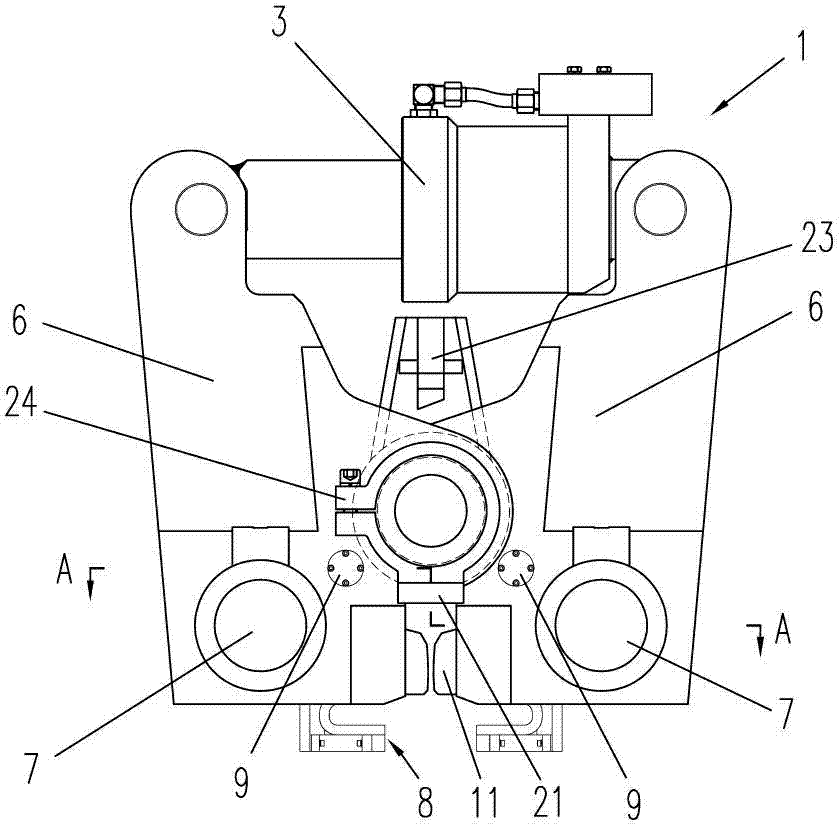

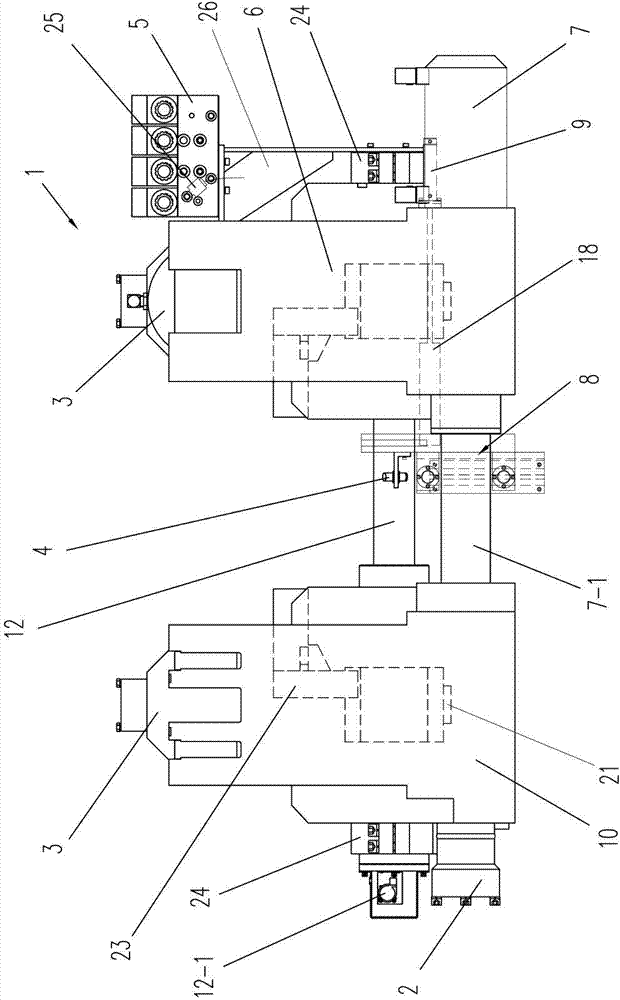

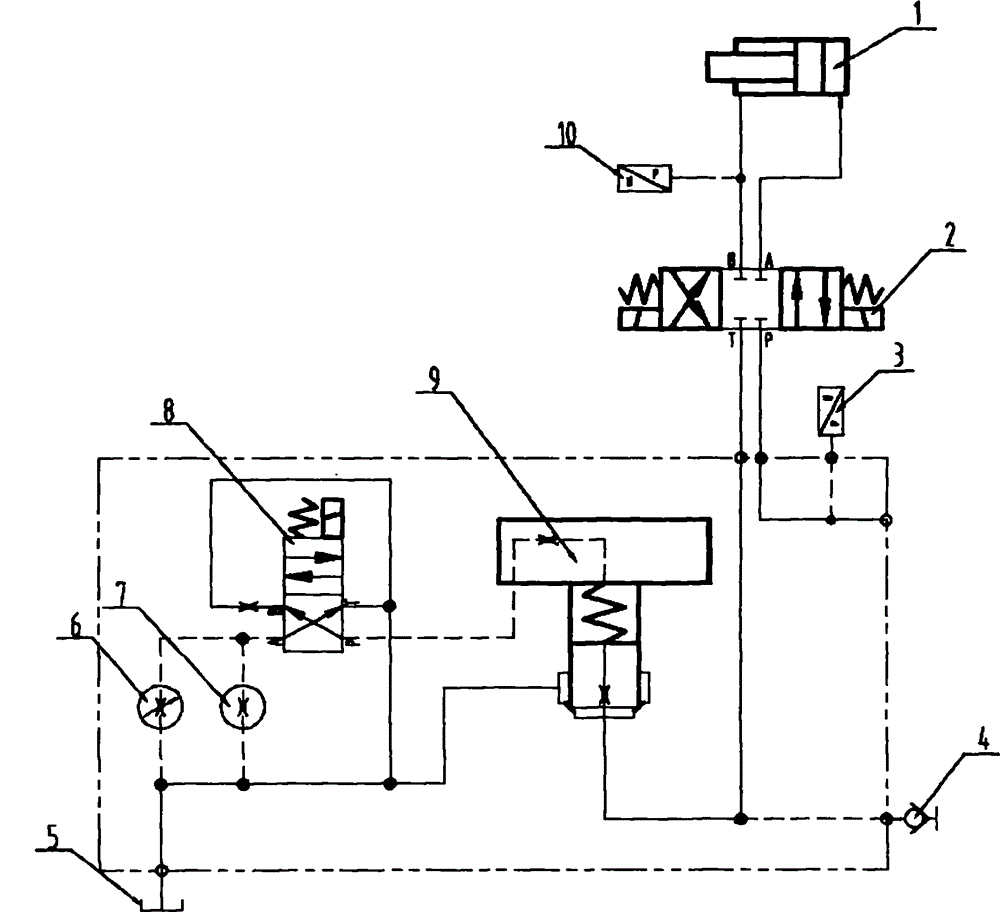

Steel rail induction butt welding and heat treatment device

ActiveCN103495800AFast welding speedImprove welding efficiencyRailsWelding/cutting auxillary devicesButt weldingControl system

A steel rail induction butt welding and heat treatment device comprises an induction welding device, a PLC control system, a hydraulic system, a cooling system, an induction heating power supply and an air spray system. The induction welding device comprises a first group of clip bodies, a second group of clip bodies, a central shaft, a clamping oil cylinder, an upsetting oil cylinder, a protrusion pushing device and a jaw. A left installation plate and a right installation plate are arranged between the first group of clip bodies and the second group of clip bodies, and corresponding locating oil cylinders are arranged on the left installation plate and the right installation plate. The induction welding device further comprises an opening and closing induction heating coil, an electrode structure is fixed on the left installation plate or the right installation plate, auxiliary oil cylinders are arranged on the second group of clip bodies, piston rods of the two auxiliary oil cylinders are respectively connected with nozzles, a locating part is arranged at the lower portion of the central shaft, and a displacement sensor and a temperature sensor are both electrically connected with the PLC control system. The steel rail induction butt welding and heat treatment device is automatic in operation and high in efficiency.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

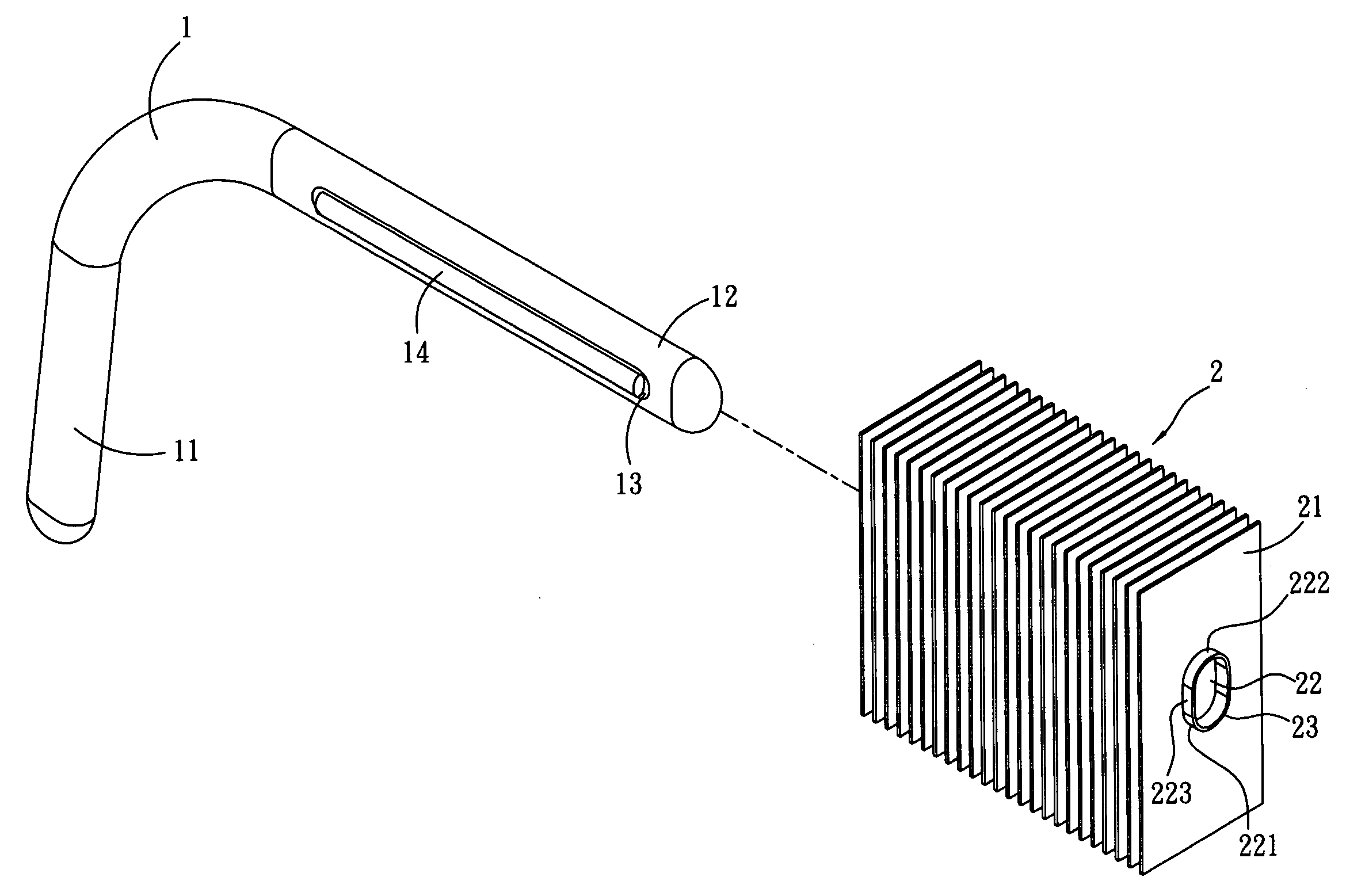

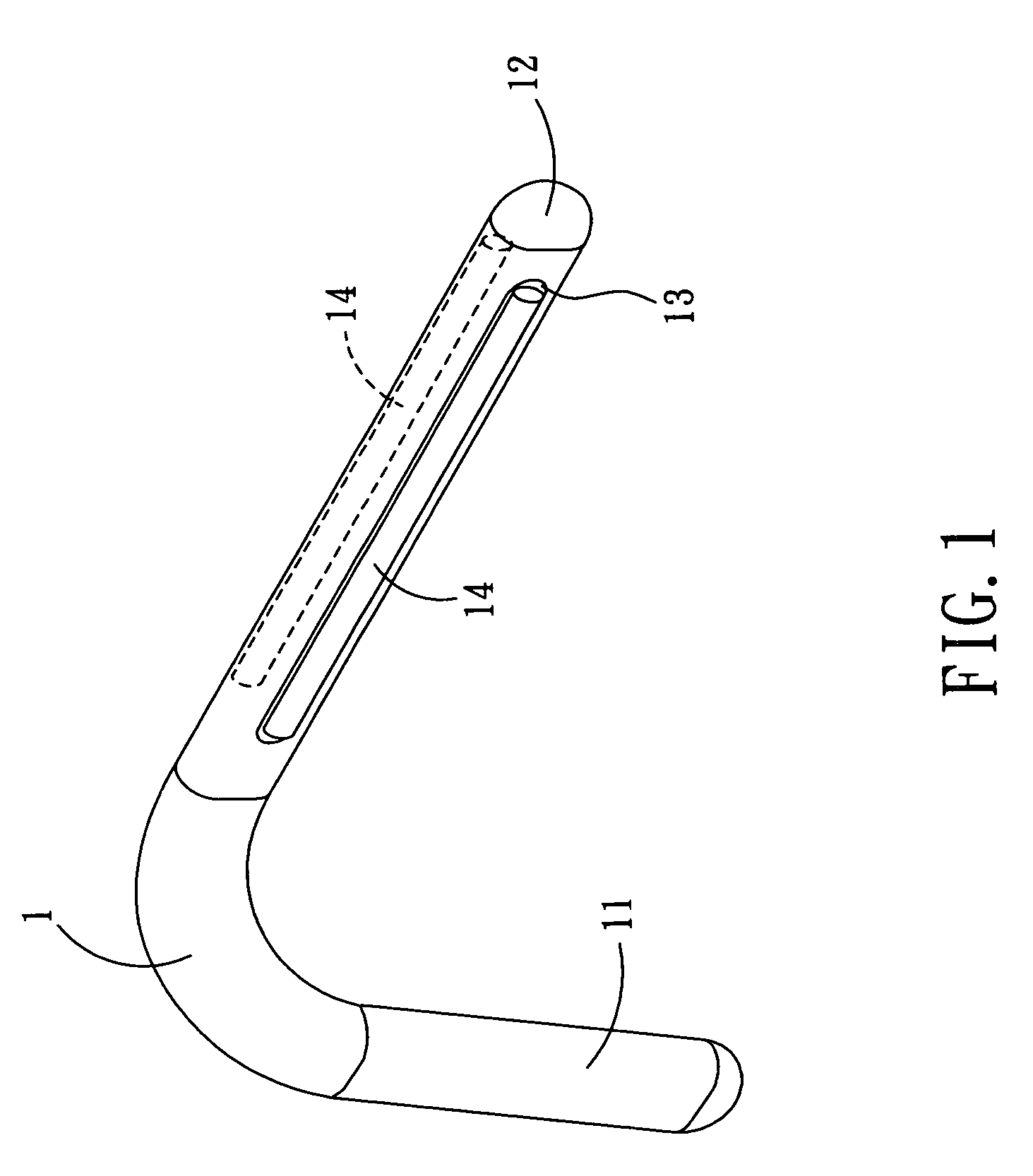

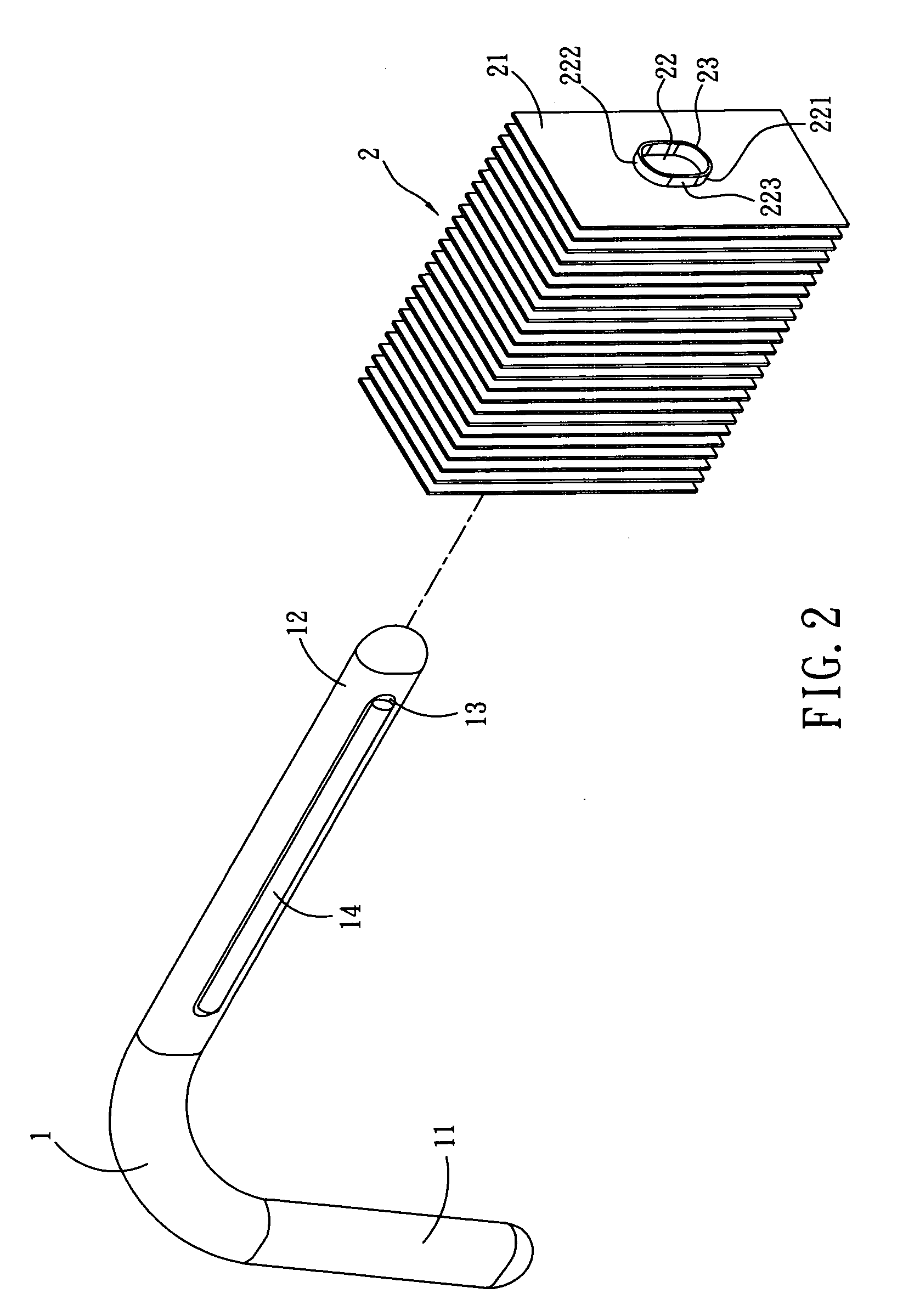

Heat dissipating device

InactiveUS20070284083A1Improve thermal conductivityEffective coolingSemiconductor/solid-state device detailsSolid-state devicesEngineeringTin

A heat dissipating device comprises a heat tube; one end of the heat tube being a heated end and another end thereof being a cooling end; at least one side of the cooling end being formed with a plane; each plane being coated with tin glue; and a fin set being formed by a plurality of fins; each fin being formed with a through hole; each through hole having an upper cambered edge, a lower cambered edge, a left side, and a right side; the left and right edges being as correcting edges; one side of the through hole being formed with a flange. In assembly; the plane of the cooling end of the heat tube is coated with tin glue. The cooling end of the heat tube is inserted into the through holes of the fins of the fin set; and the upper and lower edges of the through holes have the effect of correcting the heat tube.

Owner:SUNG MIN HSIEN

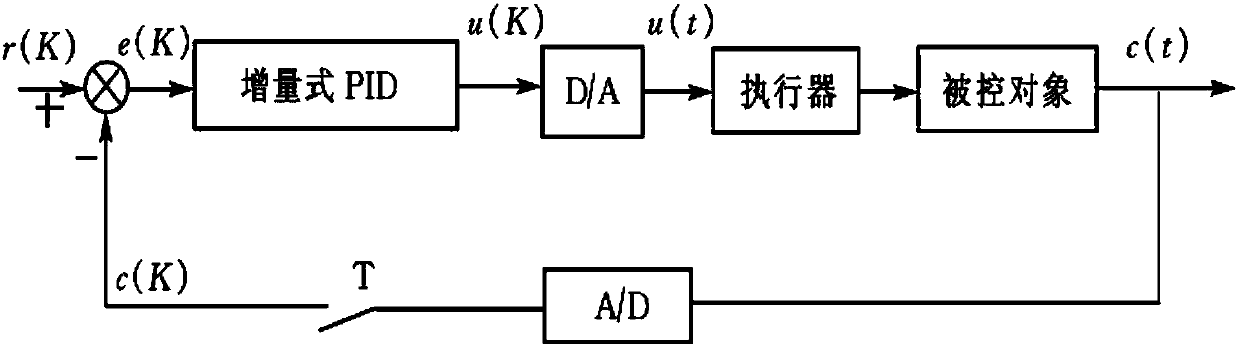

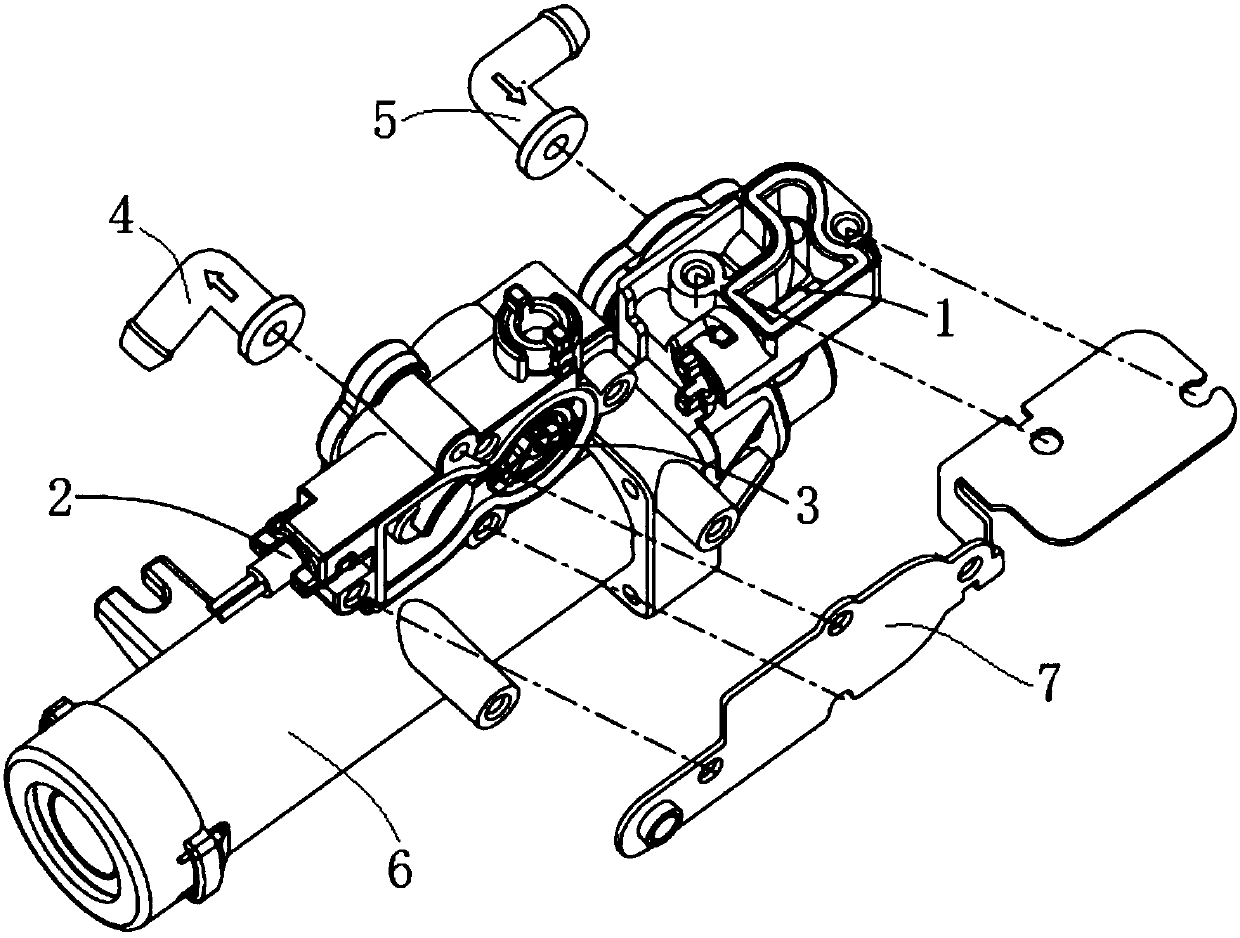

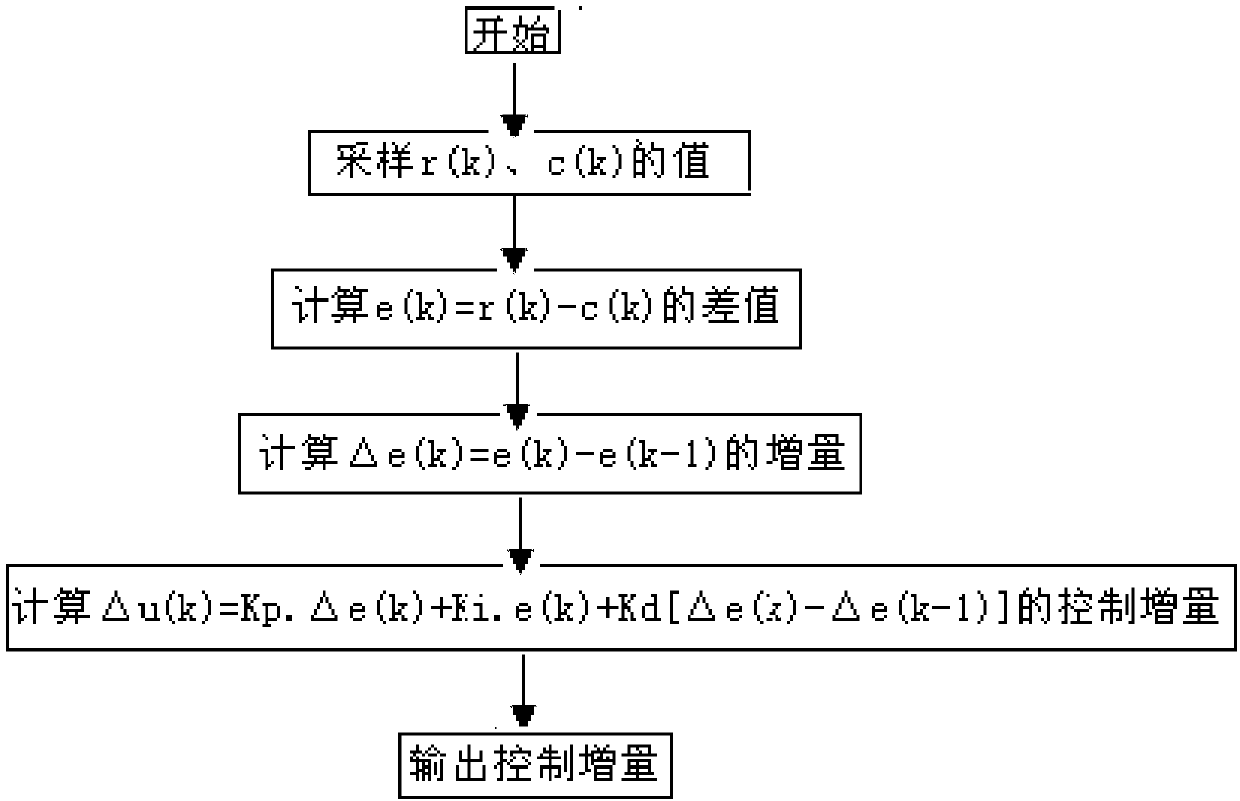

Intelligent toilet bowl instantaneous heating system, device and control method

The invention provides an intelligent toilet bowl instantaneous heating system, device and control method. The intelligent toilet bowl instantaneous heating system comprises a PID regulator, an actuator, an A / D converter, a D / A converter and a temperature sensor; the PID regulator is connected with the actuator through the D / A converter; the actuator is connected with a controlled object; a feedback loop is further arranged between the PID regulator and the controlled object, and the A / D converter is arranged on the feedback loop; and the temperature sensor is used for detecting the temperature of the heating system, the PID regulator is used for regulating heating power of the system according to the temperature, and the actuator is used for heating an intelligent toilet bowl according tothe heating power. With adoption of the technical scheme, the required regulating power is calculated through a PID control algorithm, through controlling assisting of a point speed limit curve, inlet water is heated rapidly and accurately according to the required power so that the heating device can be flexibly applied to the system with the changeable environment.

Owner:厦门沐歌智能技术有限公司

Upper end glue adding device of automatic edge sealing machine

ActiveCN103878864ASmall volumeNot easy to carbonizeDomestic articlesAdhesive application devicesCarbonizationPulp and paper industry

The invention discloses an upper end glue adding device of an automatic edge sealing machine. The upper end glue adding device comprises a glue adding and melting module and a gluing module mounted below the glue adding and melting module, the glue adding and melting module comprises a shell, a piston frame, a hopper and a piston, the shell is provided with a bin, the piston frame is arranged obliquely, the piston is driven by a pushing cylinder to move, a heating block is arranged at an output end of the piston frame, and the gluing module comprises a glue box, a glue door, a gluing roller and a rotating shaft. Split-type up-down design is adopted for glue melting, glue adding and gluing, so that volume of a glue melting box is reduced, hot melting glue time is effectively reduced, energy consumption cost is lowered, production time is increased, production and profit-making capability of a user is improved, hot melting glue is less prone to splitting decomposition and carbonization, product quality of the user is improved, and product competitiveness of the user is improved correspondingly; frequency glue adding is not needed, glue supply quantity is larger, gluing height is higher, the upper end glue adding device is suitable for larger plate thickness and high-speed edge sealing operation, and high-efficiency value is demonstrated.

Owner:NANXING MACHINERY CO LTD

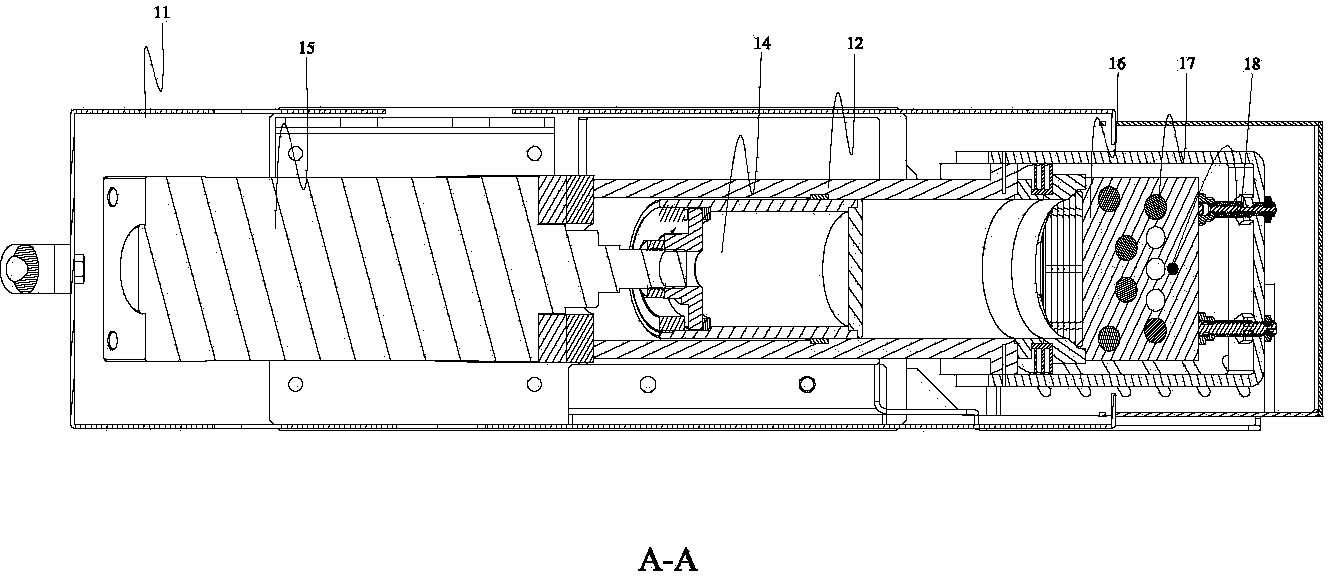

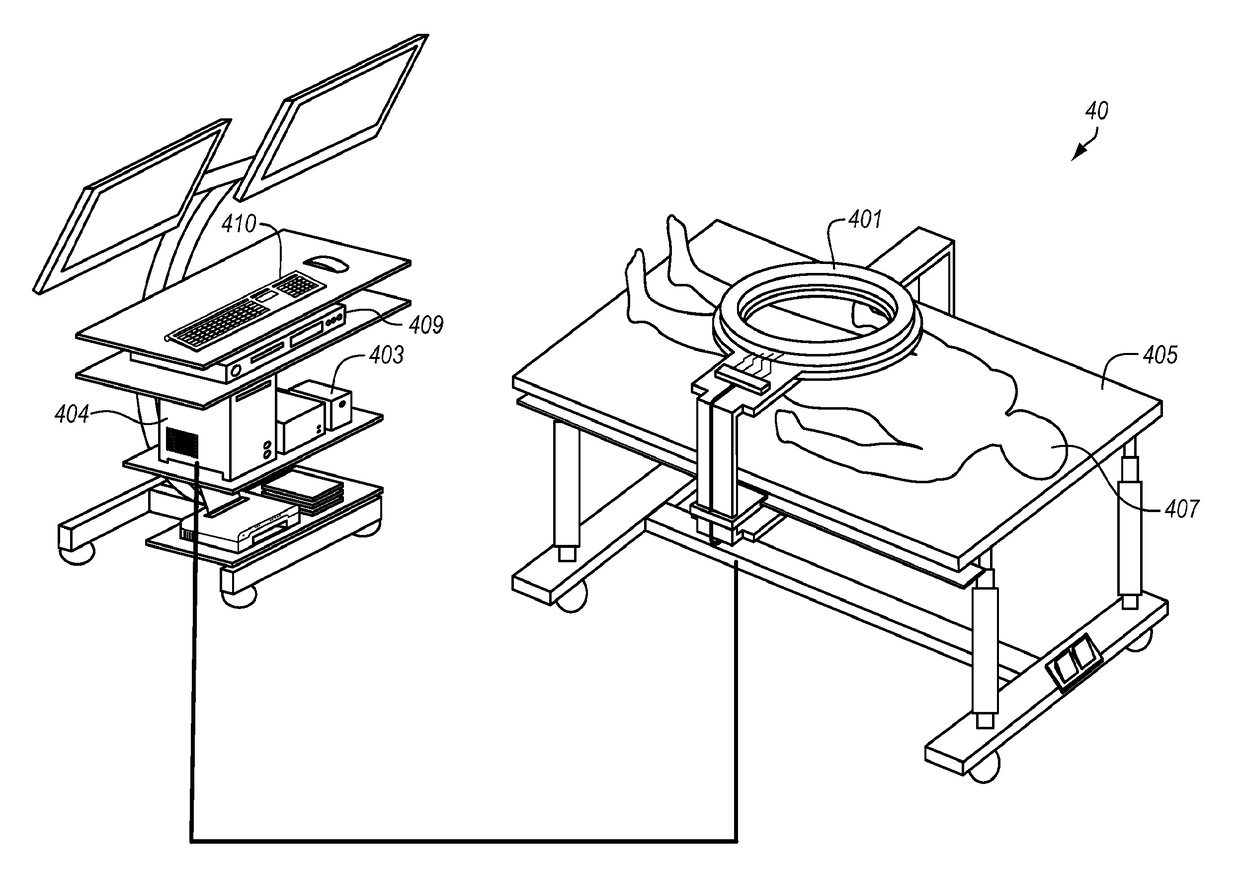

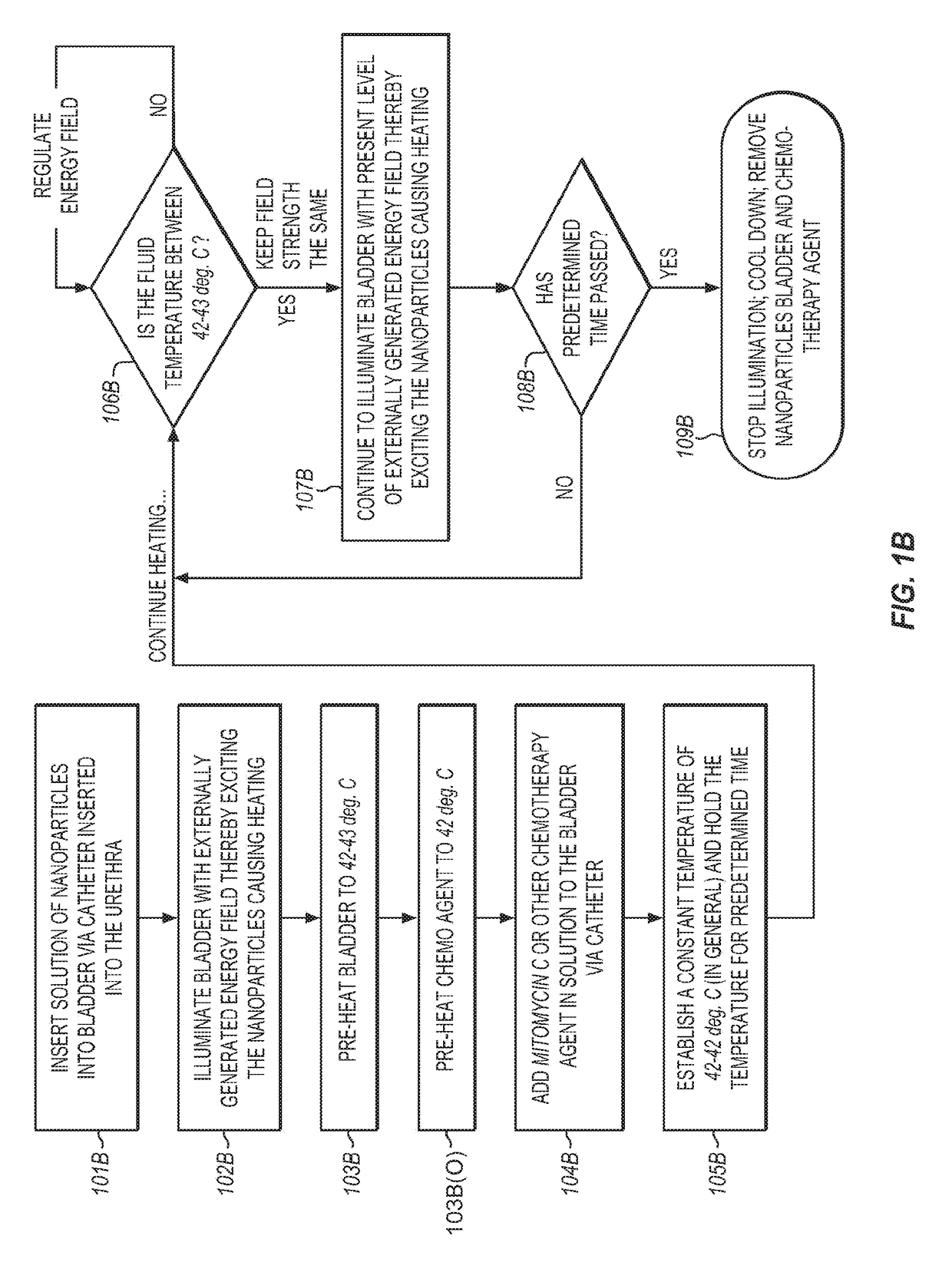

Apparatus for the generation of an energy field for the treatment of cancer in body cavities and parts that are cavity-like

ActiveUS9682247B2Improve effectivenessPrecise heatingElectrotherapyBalloon catheterCancer cellEngineering

The body cavity cancer treatment apparatus generates the magnetic field for use in a combined “low temperature hyperthermia” and ionizing radiation and / or chemotherapy cancer treatment protocol. Unlike other competing systems, the body cavity cancer treatment apparatus does not directly kill or ablate the cancer cells with killing temperatures rather, the body cavity cancer treatment apparatus stresses the cancer and cancer stem cells by keeping them at a nominal 42° C. for some period of time via the heating of nano-particles that have been infused into the bladder, using the generated magnetic field.

Owner:ENDOMAGNETICS LTD

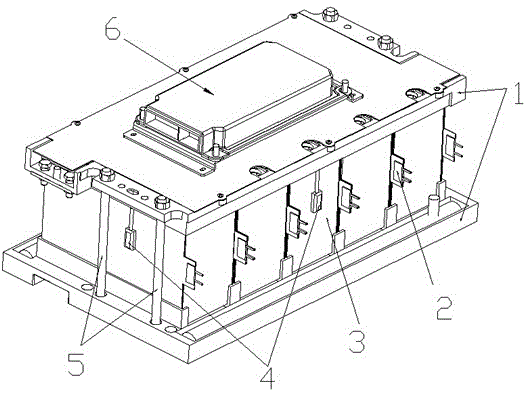

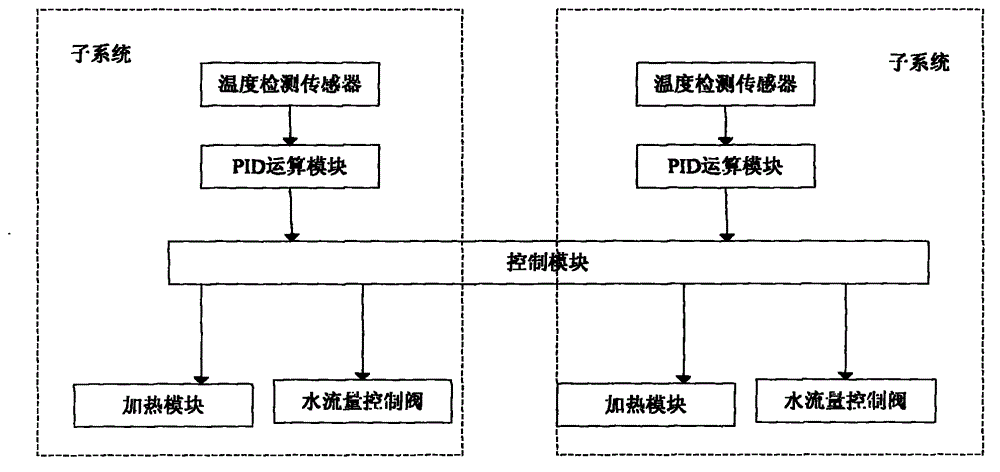

High-precision injection moulding machine for optical-grade transparent product

InactiveCN102744845APrecise heatingImprove precisionTemperature controlProportion integration differentiation

The invention provides a high-precision injection moulding machine for an optical-grade transparent product, belongs to the technical field of injection moulding machines, and solves the problem of being low in precision of the conventional injection moulding machine. The high-precision injection moulding machine for the optical-grade transparent product, disclosed by the invention, comprises a temperature control system; the temperature control system comprises a plurality of sub-systems independently with one another; each sub-system comprises a PID (Proportion Integration Differentiation) operation module, a temperature detection sensor, a control module, a group of heating modules and a water flow control valve; the temperature detection sensor is used for detecting a temperature value at a position where the temperature detection sensor is located and outputting the temperature value to the PID operation module; and the PID operation module is used for carrying out PID calculation according to deviation between the detected temperature value and a preset value so as to output control signals to the control module. The high-precision injection moulding machine disclosed by the invention is used for respectively controlling the heating modules and cooling modules by arranging the heating modules and the cooling modules controlled by water flow valves at different positions in the cavity of the injection moulding machine through the plurality of PID operation modules independently with one another, so that the injection moulding machine can be heated relatively precisely.

Owner:宁波巴斯顿机械科技有限公司

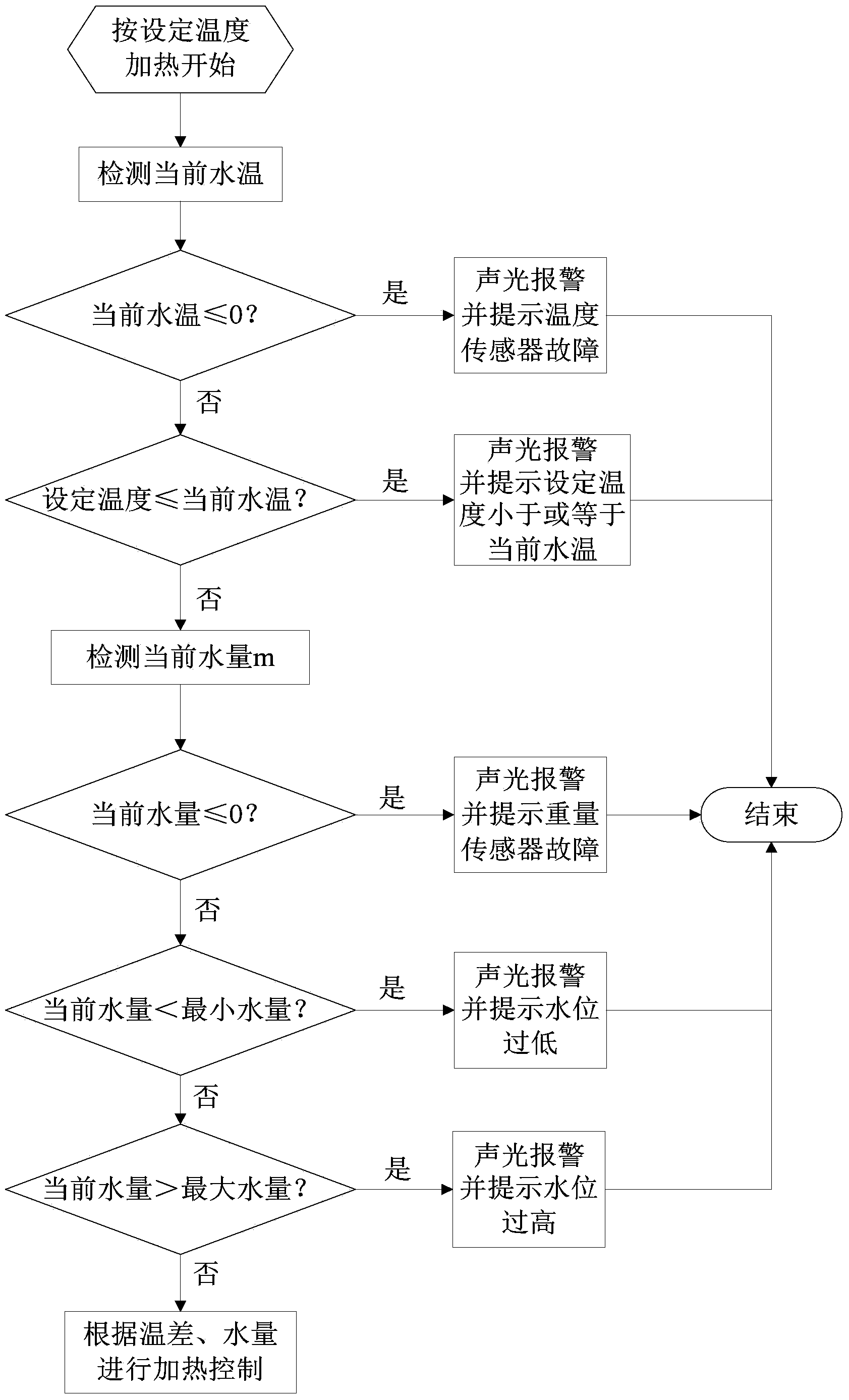

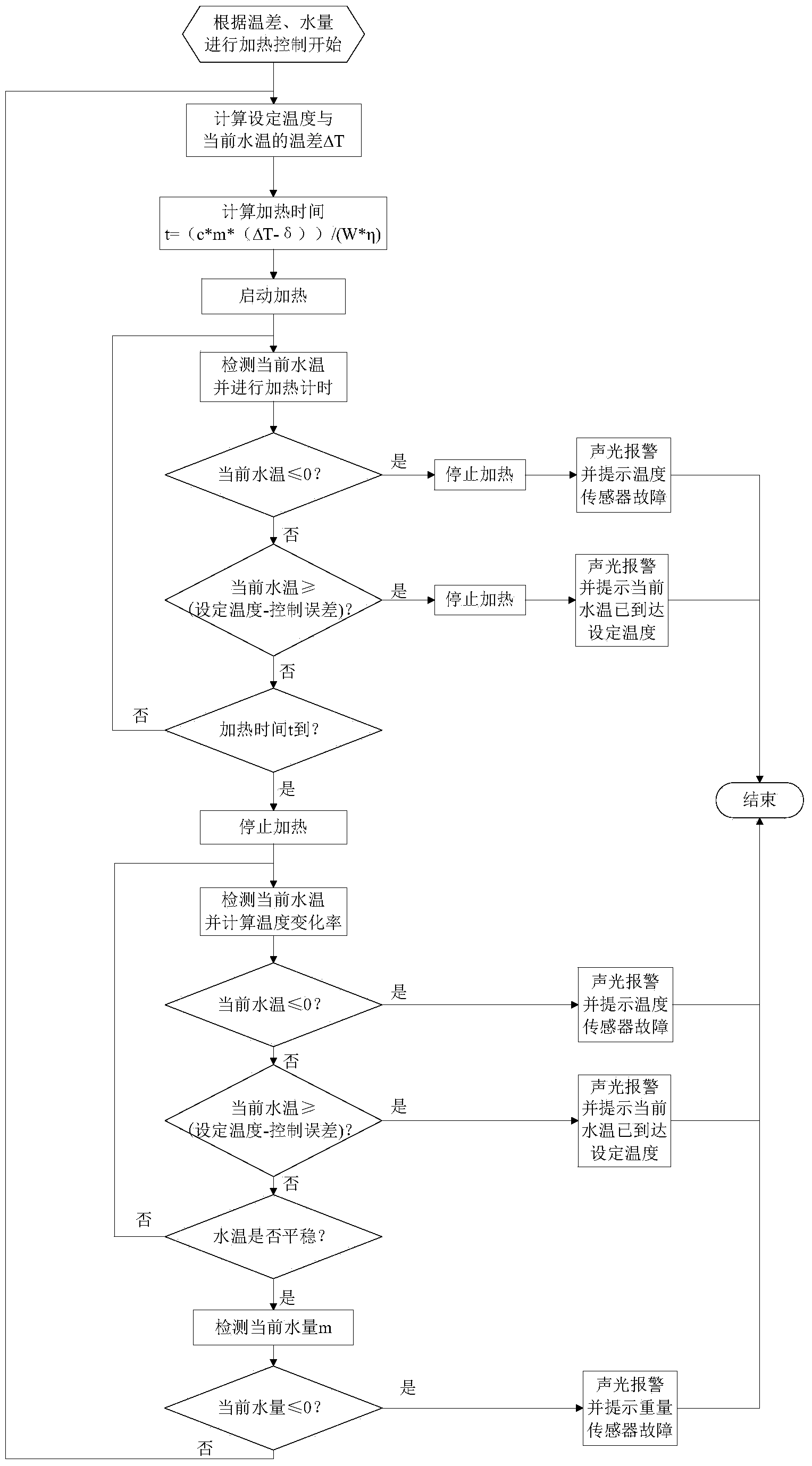

Heating control method of electric kettle and heating control device applying the method

InactiveCN104111676AImprove heating accuracyImplement failsafeAuxillary controllers with auxillary heating devicesElectric heatingHeating time

The invention discloses a heating control method of an electric kettle and a heating control device applying the method. The heating control method includes a water temperature and water volume detection step and a heating control step, through the heating control step, the electric kettle is controlled to perform intermittent heating on a water body that is heated in the cycling way of ''heating within heating intermission heating time, heating pause, heating within recalculated heating intermission heating time, and heating pause'', at each finish moment of heating intermission heating time, the water body that is heated does not reach a target water temperature, and in a period of a heating pause, afterheat released by the electric kettle is utilized to continue to heat the water body that is heated till the water temperature of the water body that is heated reaches the target water temperature, thereby greatly lowering the amplitude of the water temperature of the water body that is heated exceeding the target water temperature due to the afterheat released by the electric kettle, enabling the water body that is heated to be more accurately heated to the target water temperature, and improving heating precision of electrical heating of the kettle.

Owner:GUANGDONG ELECTRONICS TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com