Cookware heating controlling method and heating-state examination method

A technology for heating control and cooking utensils, which is applied in gaseous heating fuel, lighting and heating equipment, household heating, etc. It can solve the problems of soil-breaking food appearance, fire, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the present invention more clearly, preferred embodiments are given and described in detail in conjunction with the accompanying drawings as follows.

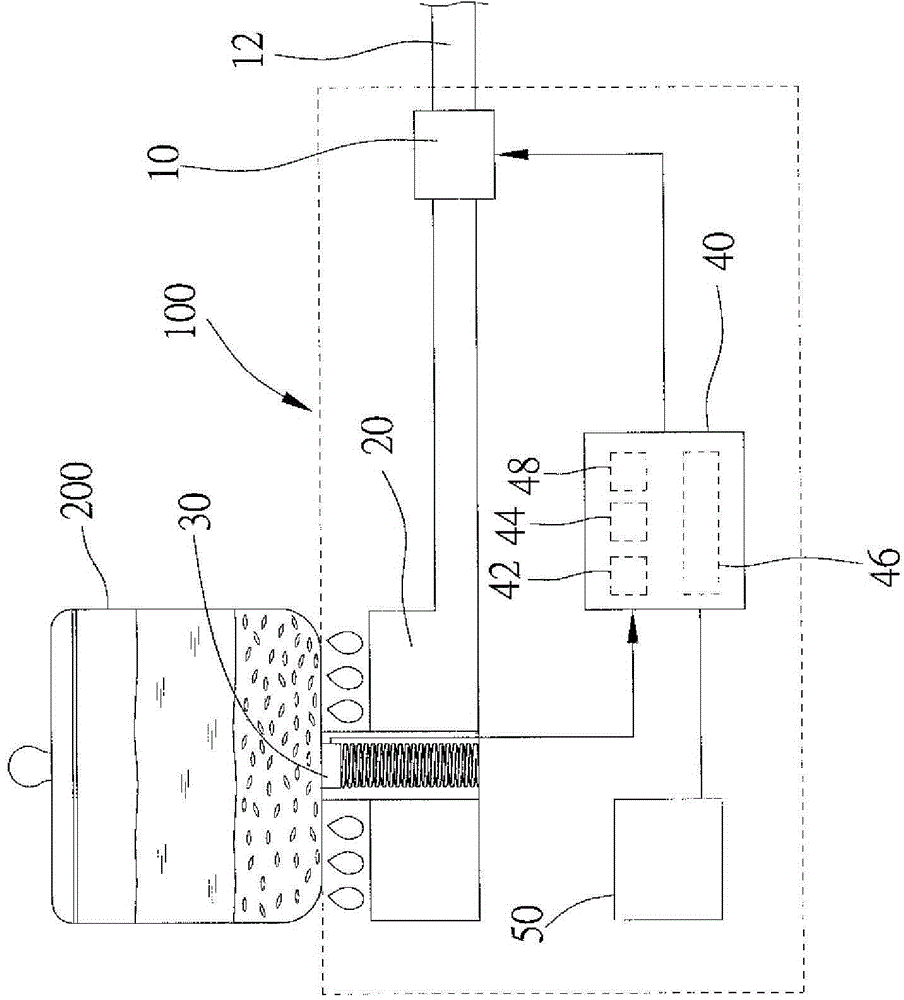

[0022] see figure 1 , is to apply the gas appliance 100 of the heating control method of the first preferred embodiment of the present invention, for heating a pot 200, the gas appliance 100 includes a gas valve 10, a heating device 20, a temperature sensor 30, a control The unit 40 and a display unit 50 . in:

[0023] The gas valve 10 is disposed on a gas pipeline 12 connected to the heating device 20 , and the gas valve 10 is controlled to regulate the flow of gas supplied to the heating device 20 . In practice, the gas valve 10 can be designed in such a way that a gas proportional valve, a step valve, etc. are driven by a control signal to change the flow rate of the passing gas. The heating device 20 receives the gas from the gas valve 10 and burns it to heat the pot 200 placed above it.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com