Heating control method of electric kettle and heating control device applying the method

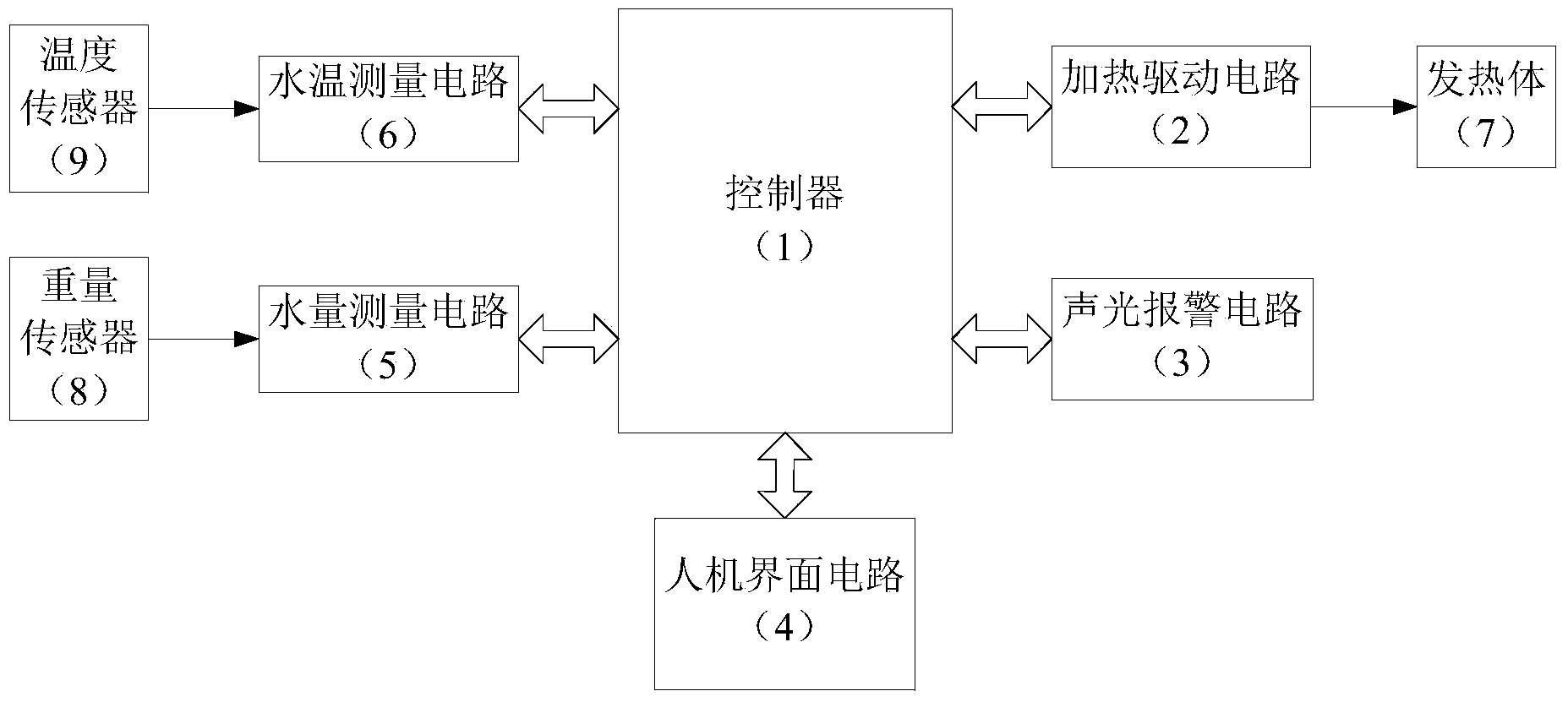

A heating control device and heating control technology are applied to auxiliary controllers with auxiliary heating devices and temperature control using electric methods, which can solve problems such as low heating accuracy, time lag in temperature control, and large inertia, and achieve improved Heating accuracy, to achieve the effect of fault protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

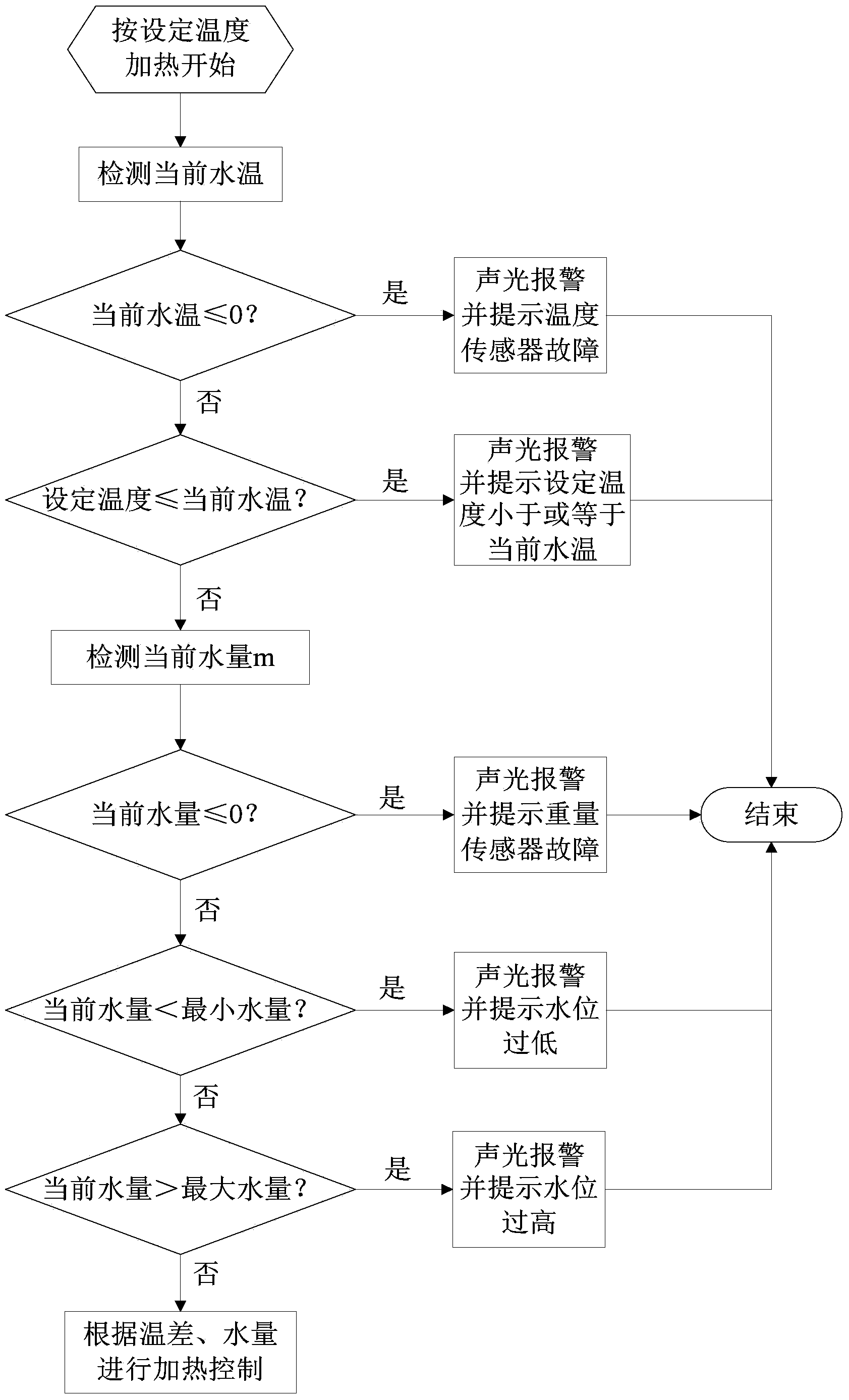

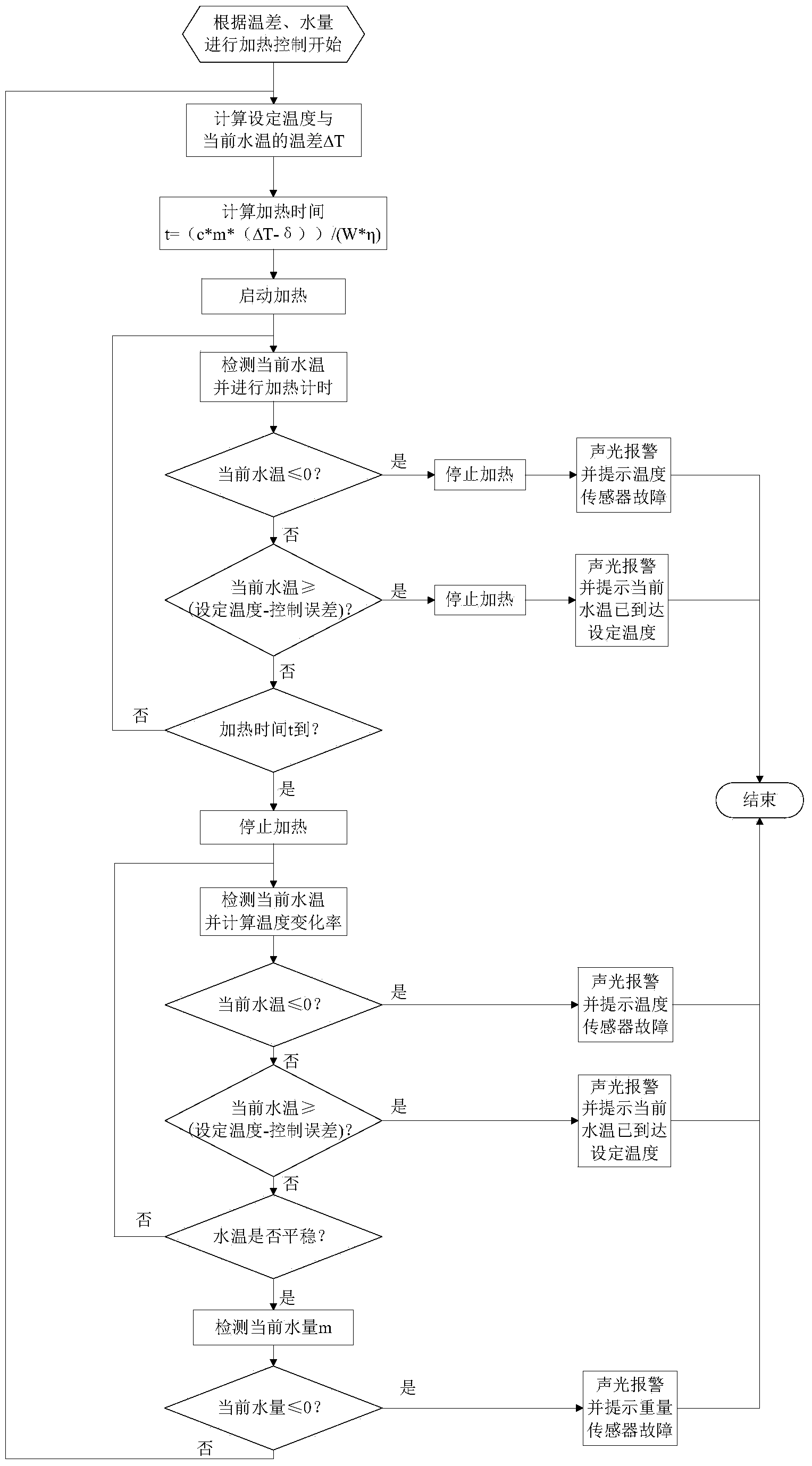

[0036] The heating control method of the electric kettle of the present invention comprises the following steps:

[0037] The water temperature detection step for detecting the water temperature of the heated water body in the electric kettle, the water temperature detected at the initial moment in this step is the initial water temperature of the heated water body;

[0038] A water volume detection step for detecting the mass m of the heated water body in the electric kettle, the quality detected at the initial moment in this step is the initial water volume of the heated water body;

[0039] A heating control step for controlling the heating mode of the electric kettle according to the initial water temperature, initial water volume and target water temperature of the heated water body, the step includes an initial state detection step, a timing heating step, a cycle control step, a water temperature detection fault alarm step and water volume detection Fault alarm steps, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com