BGA chip top heater and heating system

A bottom heater and heater technology, applied in electrical components, printed circuit manufacturing, printed circuit, etc., can solve problems such as inaccurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

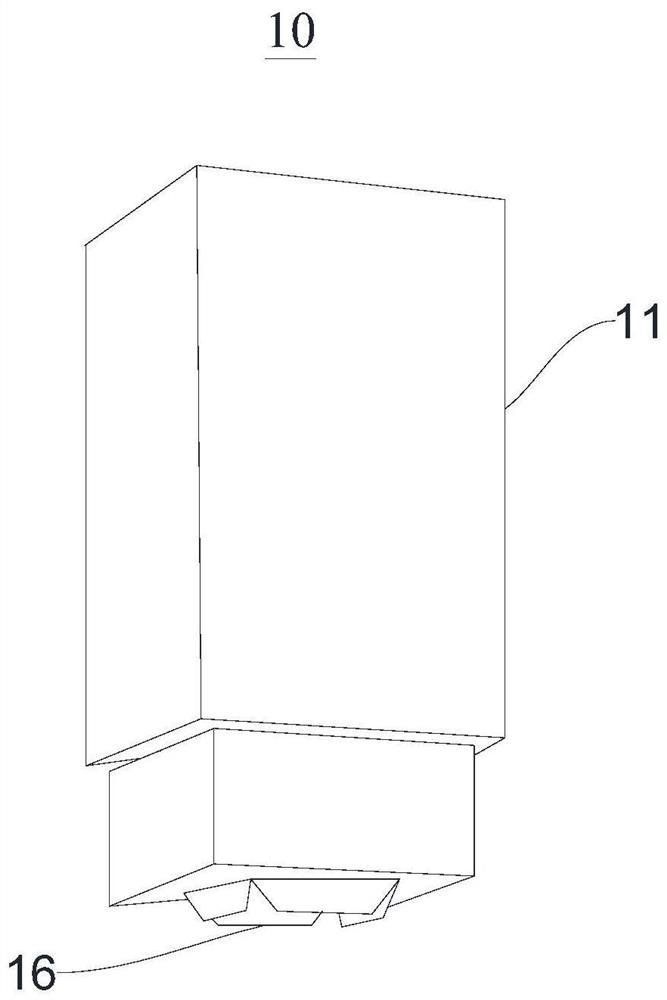

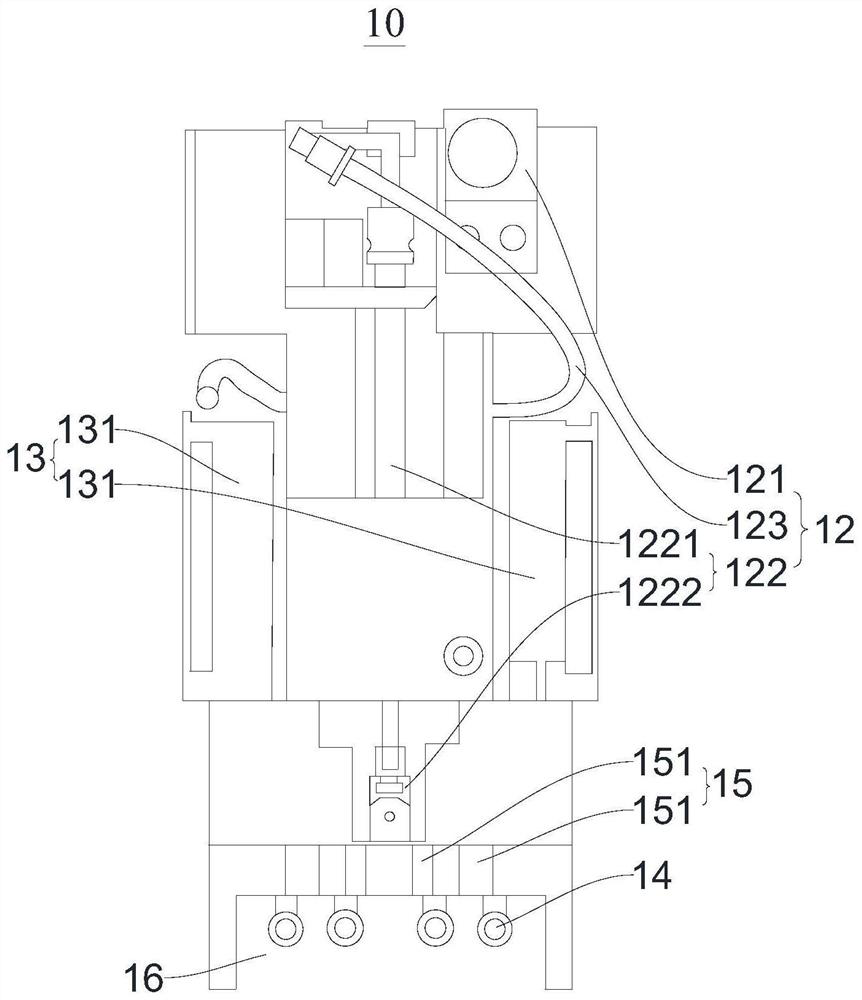

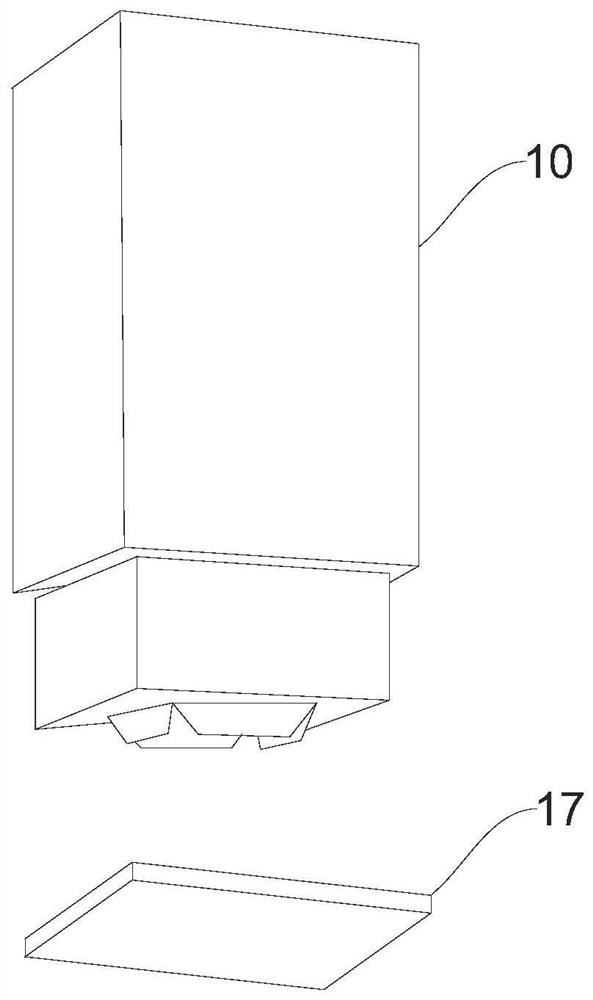

[0031] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0032] According to the applicant's research, the chip heater commonly used in the prior art is usually divided into upper and lower parts, with a board fixture in the middle, and the temperature curve is controlled by a program. Heater power and size vary primarily by design and application. The hot air nozzle on the heater is mainly replaced according to the size of the chip to be repaired. Generally, the temperature range can be set from room temperature to about 320 degrees. The main function is to uniformly heat the device with a hot air nozzle (Nozzle) to cover the device as tightly as possible. The hot air is delivered to the body of the device being repaired through the nozzle, so that the temperature of the device will rise.

[0033] The traditional hot air BGA rework station needs to be h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com