Optimizing method for setting temperature of walking beam billet heating furnace

A billet heating and optimization method technology, applied to lighting and heating equipment, furnace control devices, furnaces, etc., can solve the problems of high energy consumption, low heating precision, low energy utilization rate, etc., and achieve low energy consumption and high heating precision , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

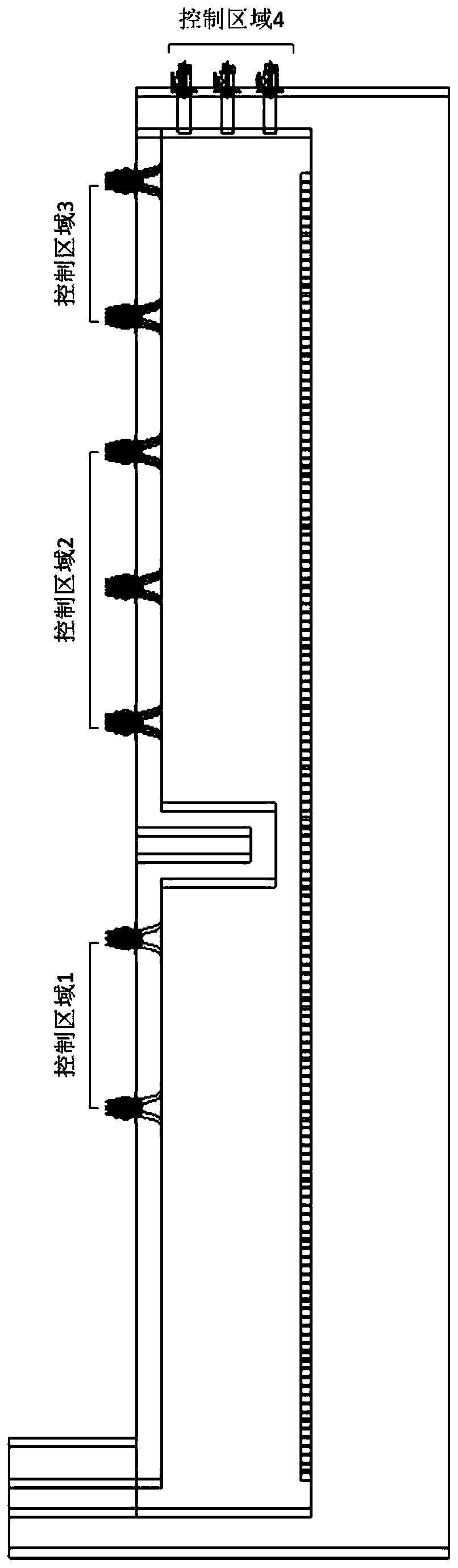

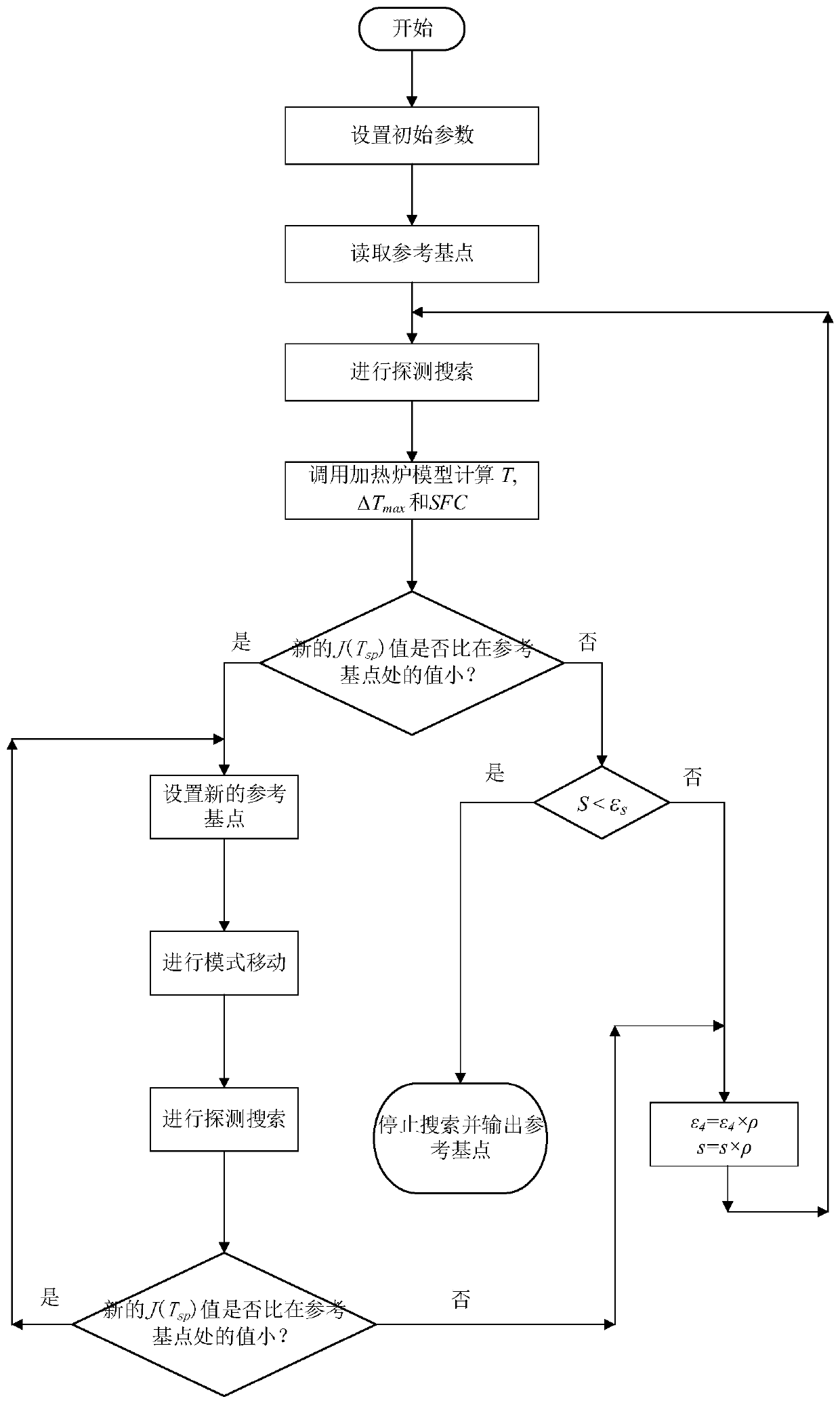

[0030] Utilize the present invention for such as figure 1 The method for optimizing the setting temperature of the walking beam type billet heating furnace includes the following steps:

[0031] Step A. Construct the multi-objective optimization function J:

[0032]

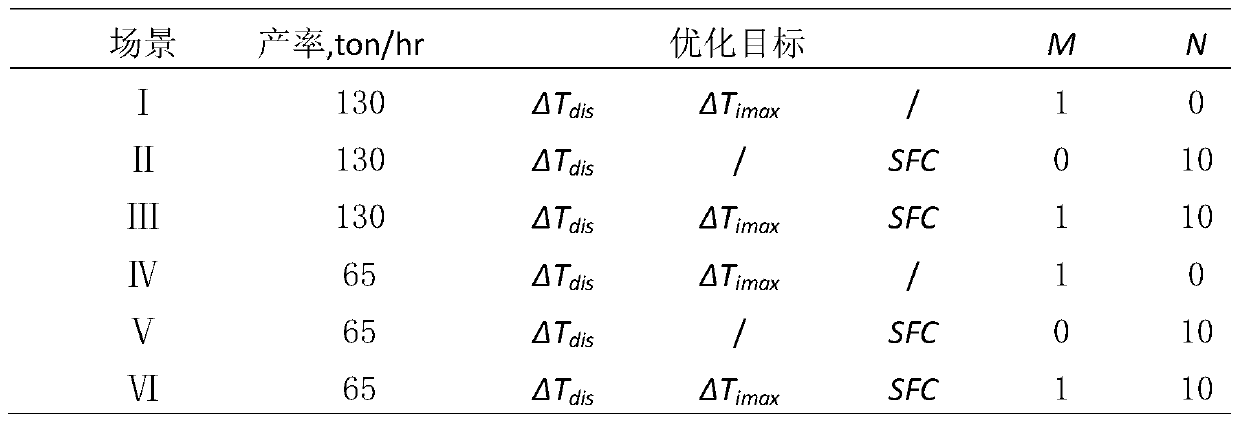

[0033] Among them, T i is the exit temperature of the i-th billet, T A is the target temperature of billet out of the furnace, ΔT imax is the maximum temperature difference of the i-th billet out of the furnace, SFC i is the fuel consumption rate of the heating furnace when the i-th billet comes out of the furnace, M and N are the weight coefficients set according to the optimization scenario, and n is the number of billets.

[0034] Step B. Equivalently transform the multi-objective optimization function J to include the set temperature T of each control area spj The multi-objective optimization function; where T spj is the set temperature for the jth control zone. In this embodiment, the number of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com