Patents

Literature

44results about How to "Not easy to carbonize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

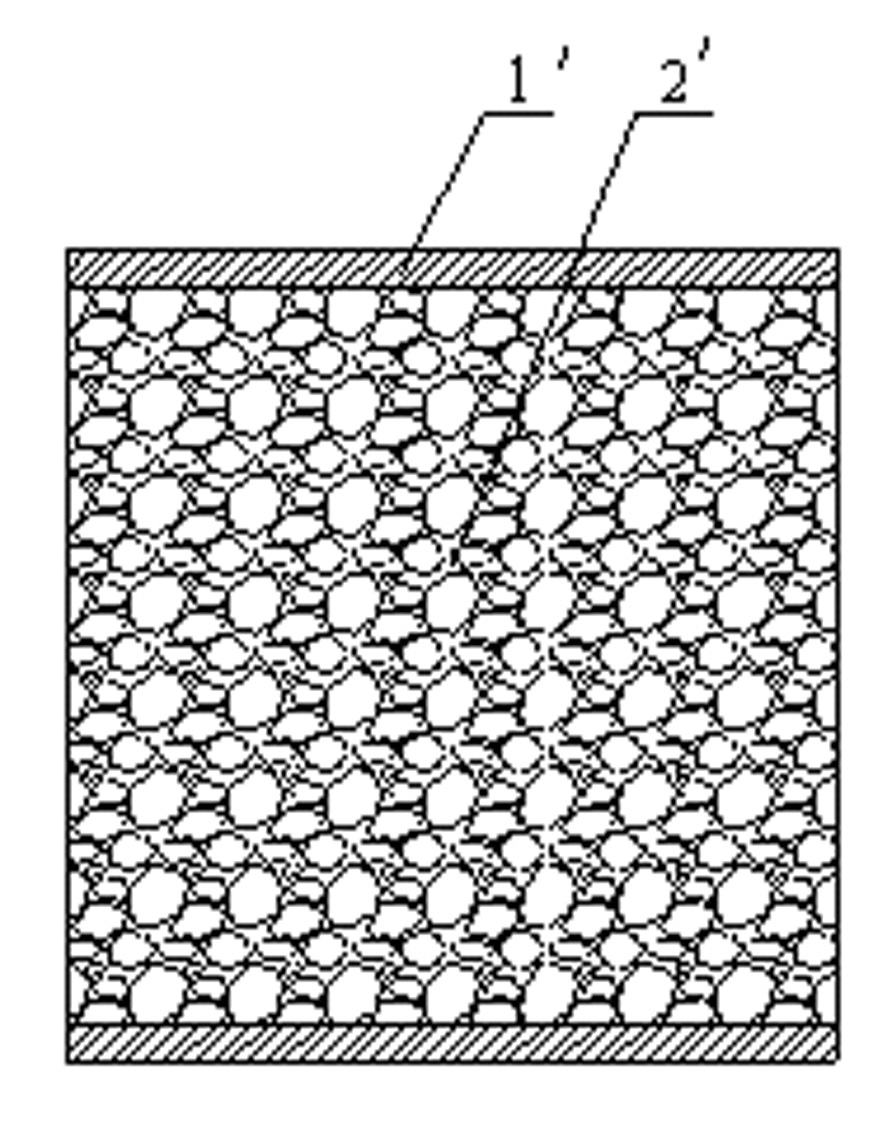

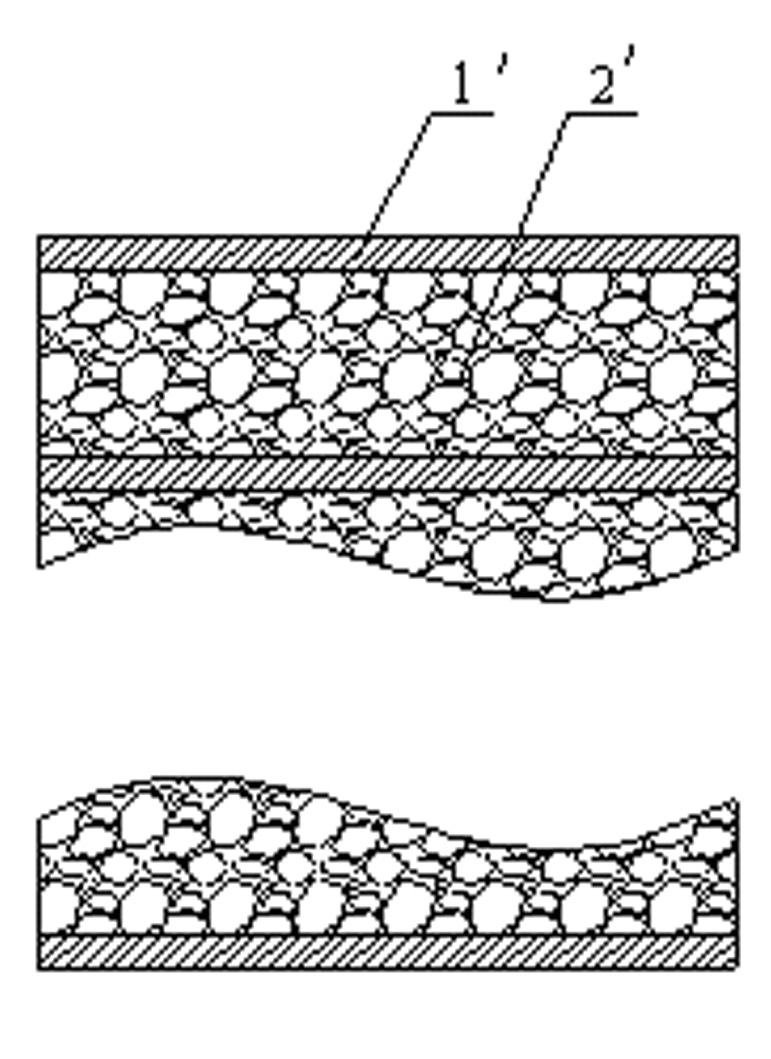

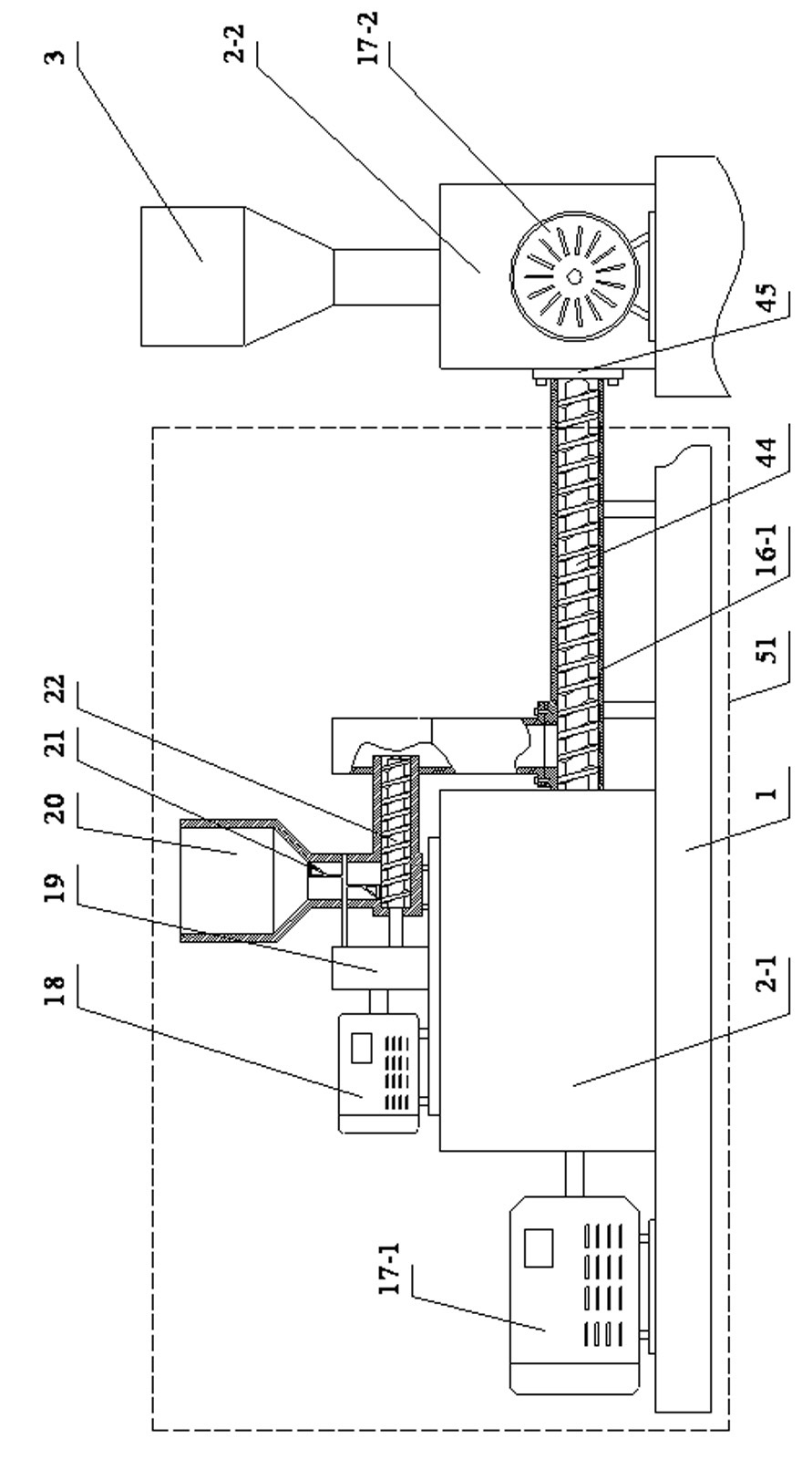

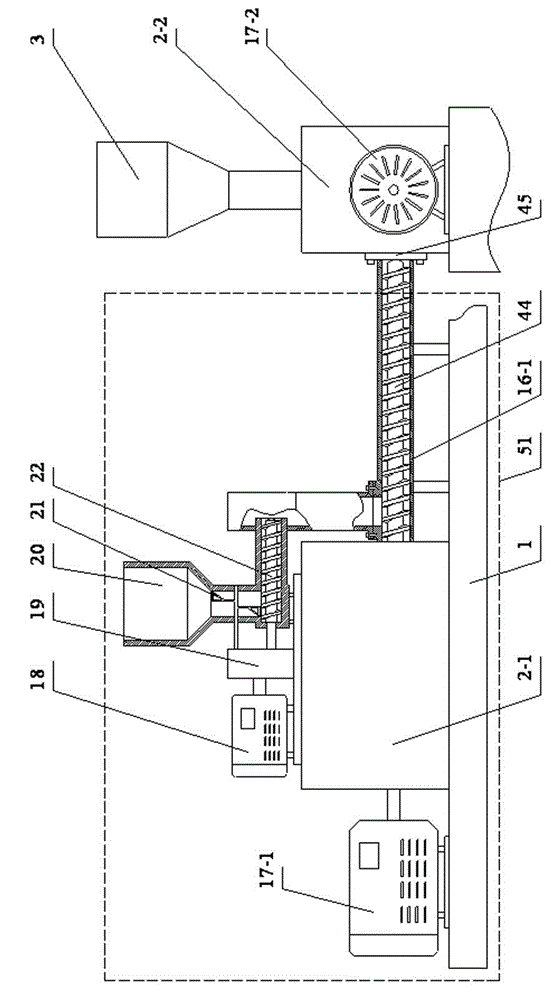

Wood plastic composite foaming material and forming process and equipment thereof

The invention relates to a wood plastic composite foaming material and a forming process and forming equipment thereof. The diameters of foam holes of the wood plastic composite foaming material are 0.01 to 5 millimeters; and the main component of the material is a mixture of thermoplastic plastic and plant fiber powder, or a mixture of thermoplastic plastic, starch and plant fiber powder, or a mixture of thermoplastic plastic, rubber powder and plant fiber powder. The invention also relates to the forming process and the forming equipment for the wood plastic composite foaming material. The wood plastic composite foaming material has the advantages of low density, high strength and low production cost, is suitable to be used as a packing material for various commodities, a buffering member for various devices, an elastic member of a product such as a sofa, a mattress, a sole and the like and a structural component of a household electric appliance, and is used for replacing wood for manufacturing floors, handrails, doors and windows, resting chairs used in gardens and the like.

Owner:佛山市科昌塑料制品有限公司

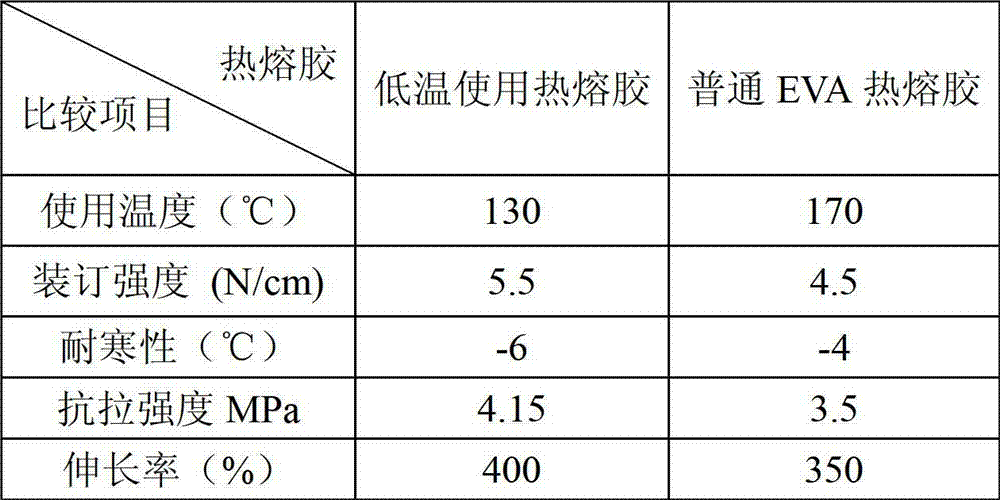

Book thermoplastic binding hot melt glue used at low temperature and preparation method thereof

InactiveCN102925080AImprove performanceNot easy to carbonizeMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention relates to hot melt glue and a preparation method thereof, and belongs to the technical field of preparation of hot melt glue. The preparation method comprises the following steps of: starting stirring and opening a heat-conduction oil heating valve; sequentially filling ethylene-vinyl acetate (EVA) resin, a filler, a wax diluents and an antioxygen according to the proportion into a reaction kettle for heating; totally melting each component; adding tackified resin to heat until the tackified resin is totally melted; vacuumizing a reaction system until the reaction system has no bubbles; adding a filter screen and discharging at a discharging port of the reaction kettle; and cooling and forming the materials to obtain a product. The book thermoplastic binding hot melt glue can be used at about 130 DEG C, and is suitable for linkage line production; compared with the traditional book thermoplastic binding hot melt glue, the using temperature is reduced by 30 DEG C to 50 DEG C, so that the production energy consumption (electric energy, heat energy and the like) is reduced, the maintenance cost of equipment is reduced, and the production efficiency is improved; and the glue performance in a glue groove is stable, energy-saving production is facilitated, and the hot melt glue is environment-friendly.

Owner:WUXI WANLI ADHESION MATERIALS

Cleaning gasoline with alcohol ether base

InactiveCN1597873AMeet power requirementsIncrease oxygen contentLiquid carbonaceous fuelsCleansing AgentsNuclear chemistry

The invention discloses a clean alcohol ether-base gasoline, prepared of alcohol-base fuel mixed solution, naphtana etherified liquid, C-5 and cleaning agent; and its components in weight percent (wt%): alcohol-base fuel mixed solution 40-50, C-5 10-20, naphtana etherified liquid 30-45, cleaning agent 0.1. The alcohol-base fuel mixed solution is composed of methanol, acetone, hydrogen peroxide, ferrocene-benzene solution and camphor powder. The naphtana etherified liquid is prepared by etherifying naphtana, methyl-tert-butyl ether and isopropyl ether. The finished oil has rich HO molecular groups, high oxygen content and can fully burn. After it is used, the indexes of various harmful matters in the discharged tail gas from engines are obviously lower than those of ordinary gasoline and environmental protection.

Owner:于雷

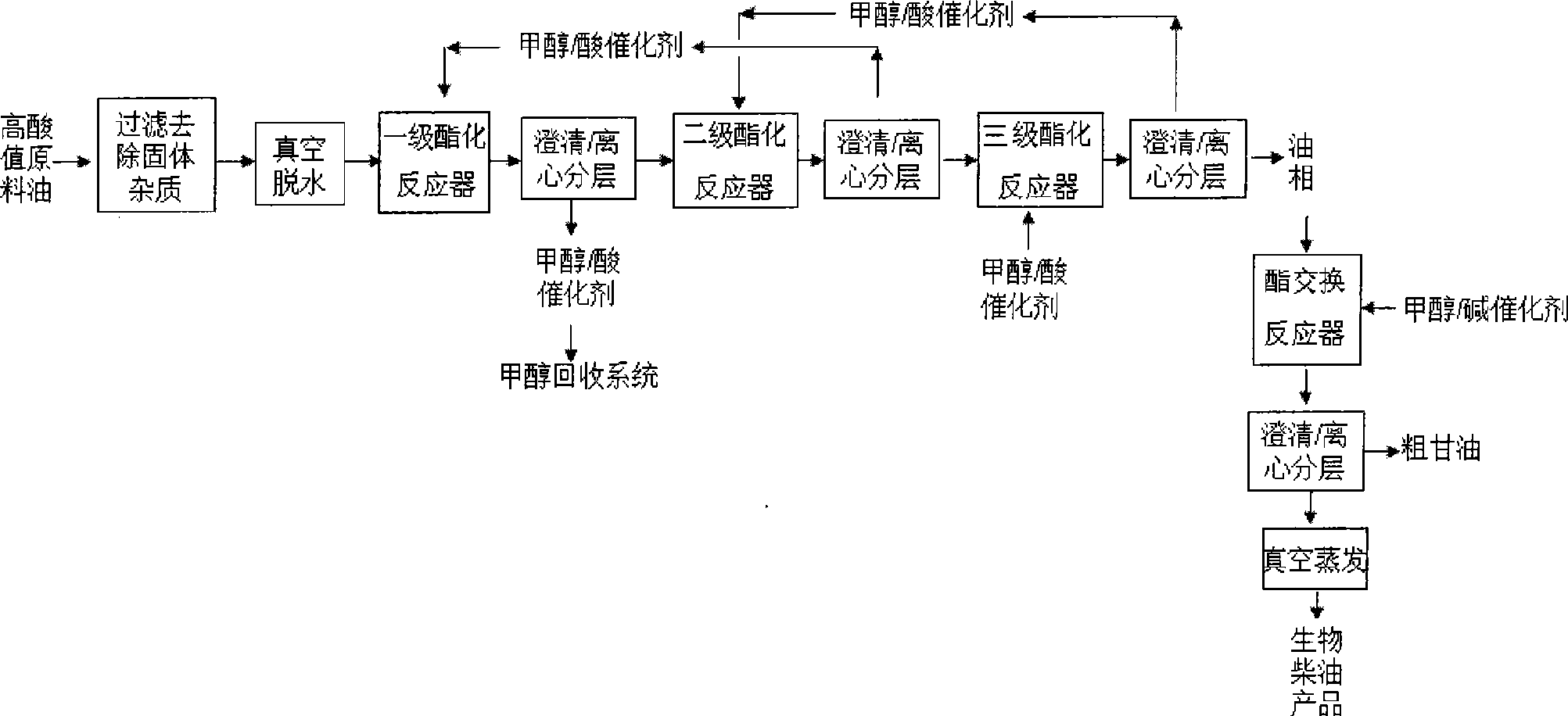

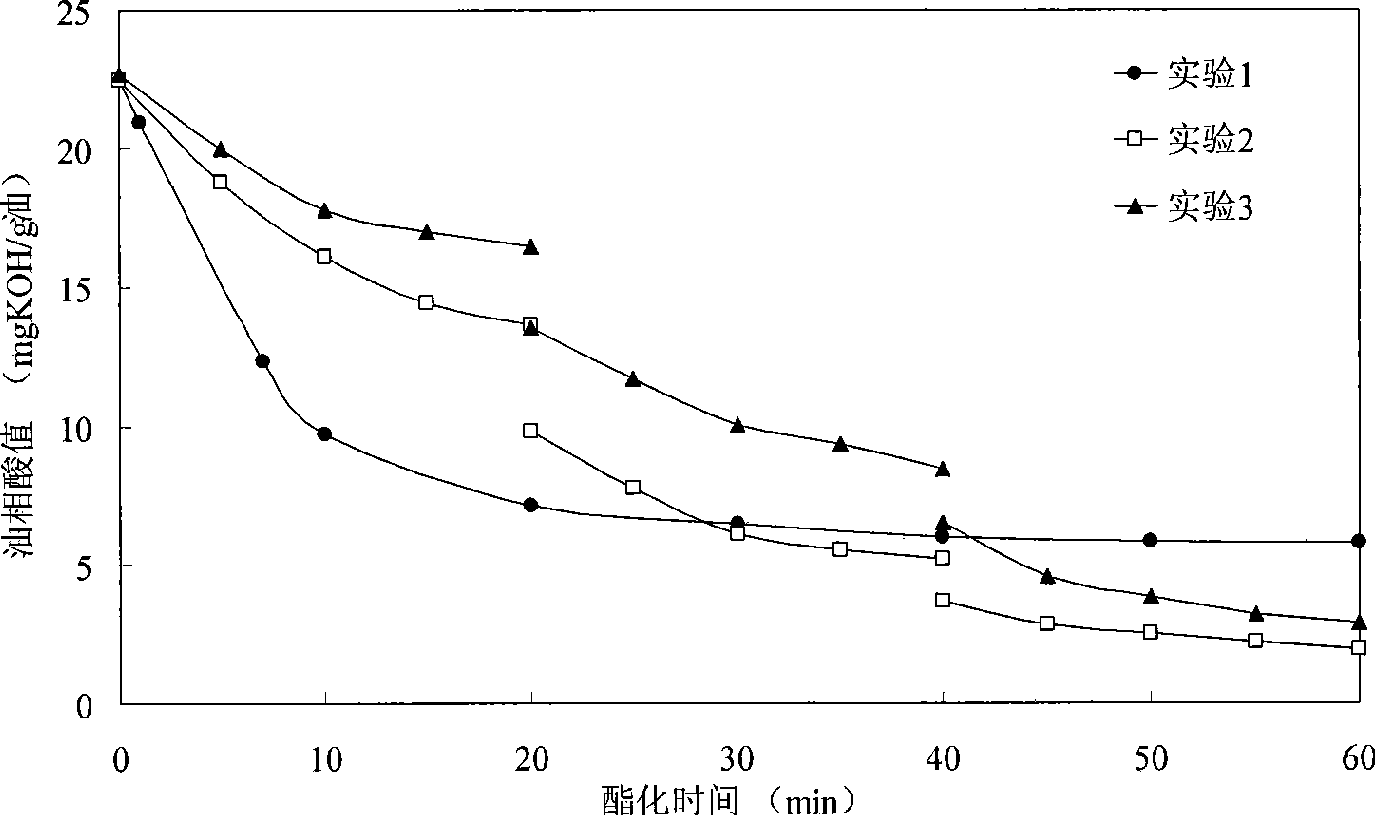

Method for preparing biodiesel by utilizing stratified and graded esterified deacidification of high acid value oil

InactiveCN101445742AHigh reaction conversion rateNot easy to carbonizeBiofuelsLiquid hydrocarbon mixture productionOil and greaseFiltration

The invention provides a method utilizing high acid value oil as raw material for preparing biodiesel. Various animal and vegetable oil, the acid value of which is larger than 3.0mg KOH / g oil, oilstock, soapstock and acidic oil in a vegetable oil refining process, various food waste oil (restaurant waste oil, hogwash oil, trench waste oil, and the like) and various waste animal oil in industrial processing (waste animal oil in leather processing, waste animal oil in slaughtering process, and the like) are used as raw materials to obtain biodiesel products by filtration for removing solid impurities, vacuum dehydration, stratified graded acid catalytic esterification, alkali catalytic transesterification and vacuum distillation. The method utilizing the high acid value oil as the raw material for preparing the biodiesel has the beneficial effect that the production process can be applied to raw materials with different acid values to produce biodiesel products with high purity by changing the operational series of the stratified graded acid catalytic esterification reaction and has the advantages of simple process, low energy consumption, high conversion rate and small device. And continuous production can be realized.

Owner:ZHEJIANG UNIV OF TECH

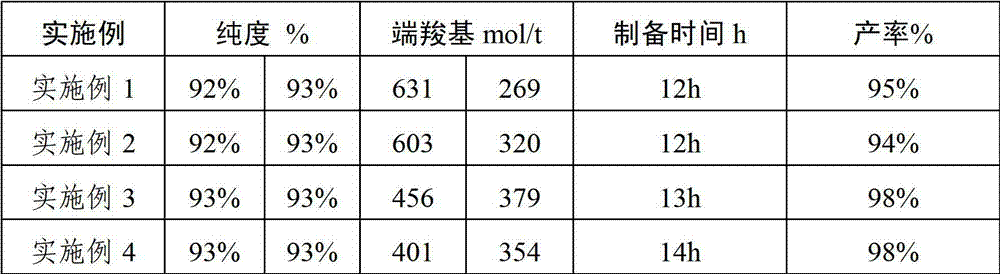

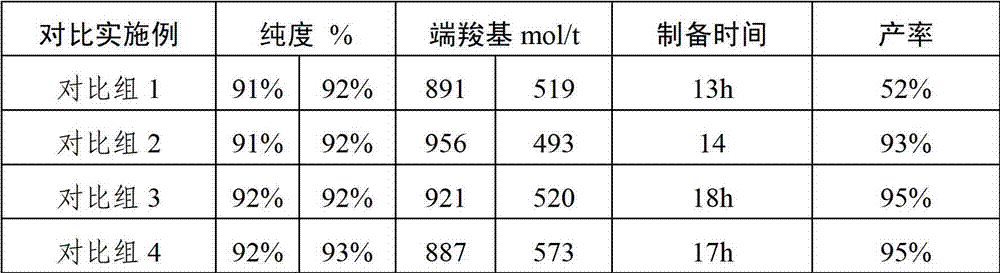

Method for preparing medical lactide

The invention relates to the method for preparing medical lactide. The method includes: adding catalyst and high boiling-point solvent in lactic acid for condensation polymerization to enable the lactic acid to generate lactic-acid oligomer, and adding catalyst in the generated lactic-acid oligomer for depolymerization to obtain the medical lactide. The high boiling-point solvent is added during the condensation polymerization, so that a reaction system during depolymerization cannot become viscous, and is less prone to steam out, carbonize and turn yellow caused by distillation and reduction of lactide, stability of production process, product quality and variability of physical indexes are guaranteed; and the method for preparing medical lactide is high in yield, simple in reaction operation, free of danger, short in production time and beneficial to industrial production, and has quite high economic value.

Owner:上海绿色盛世生态材料有限公司

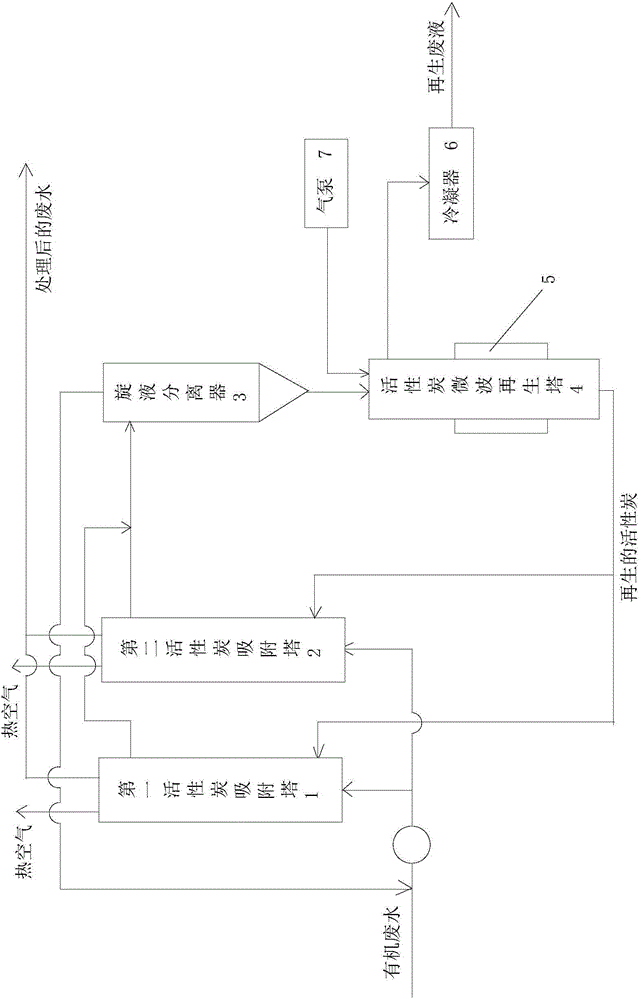

Activated carbon treatment technology for organic wastewater

InactiveCN104609497AFast heatingReduce energy consumptionOther chemical processesWater contaminantsActivated carbonMicrowave

An activated carbon treatment technology for organic wastewater comprises steps such as biochemical treatment, activated charcoal adsorption, suspension separation, microwave regeneration of activated carbon and introduction of generated activated carbon. Two activated charcoal adsorption towers are adopted to perform adsorption alternately and regenerate adsorption-saturated activated carbon alternately so as to realize continuous operation. According to the technology, on-line regeneration of activated carbon is realized by micro-wave heating, the degree of automation is high, the operation is simple and convenient, and the realization of industrialization is facilitated. During micro-wave heating, moisture in activated carbon is vaporized quickly to generate high-temperature vapor, organic substances adsorbed in micro-pores of the activated carbon can be blown out and flaked off quickly by the high-temperature vapor, the organic substances are hard to carbonize and cannot block the micro-pores at a temperature below 650DEG C, and the regeneration efficiency of activated carbon is high.

Owner:上海三夫工程技术有限公司

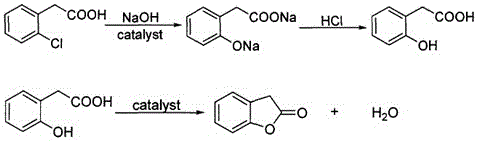

Synthetic method of benzofuran-2(3H)-one

The invention discloses a synthetic method of benzofuran-2(3H)-one. The method comprises the following steps: hydrolyzing o-clorophenylacetic acid by using a sodium hydroxide solution under the catalysis of a catalyst to generate sodium 2-hydroxyphenylacetate, adding hydrochloric acid to acidify the above obtained reaction solution, cooling for crystallizing the above obtained acidification product, filtering obtained crystals to obtain sodium chloride-containing 2-hydroxyphenylacetic acid, and carrying out a lactonization reaction in a water carrying agent under the catalysis of iron sulfate to generate benzofuran-2(3H)-one. The method has the advantages of simplicity, easiness in implementation, good economic property, high yield, realization of operation simplification, 2-hydroxyphenylacetic acid loss avoiding and yield increase due to omission of the 2-hydroxyphenylacetic acid purifying process by carrying out the lactonization reaction on sodium chloride-containing crude 2-hydroxyphenylacetic acid directly used as a raw material, and realization of small corrosion to a reaction device, difficult in product carbonization, small catalysis use amount, no complex post-treatment, production cost saving and reduction of generation of three wastes due to iron sulfate being a neutral substance.

Owner:CHONGQING UNISPLENDOUR CHEM

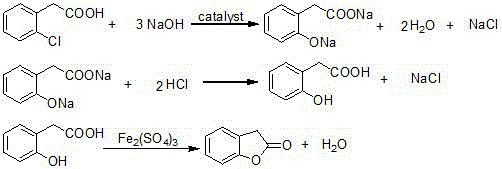

Fresh green pepper edible oil

InactiveCN104255955AEasy to storeFragrant enoughFatty-oils/fats refiningFatty-oils/fats productionSolid massFiltration

The invention discloses a production method of fresh green pepper edible oil. The process comprises the following steps: selecting high-quality fresh green pepper; selecting high-quality colza oil for soaking the high-quality fresh green pepper at normal temperature, wherein the mass ratio of the colza oil to the fresh pepper being (1-2):1, and carrying out vacuum filtration with more than 500 meshes to obtain filter liquor and pepper slag; squeezing the filter liquor again and mixing twice obtained pepper oil; adding 1-2% of saturated salt water to the pepper oil and standing after stirring for 10-20 minutes; centrifugally separating solid from suspended solids by a centrifugal machine; separating oil from water; detecting whether indexes of correlation exceed standard or not; blending to proper hemp taste; and filling. The obtained product is full in flavor, rich in nutrient contents, pure and uniform in color and luster, soft in taste and pure in hemp taste and has full-bodied flavor of green pepper.

Owner:周顺

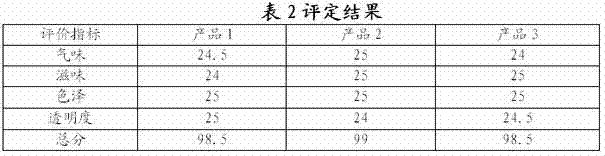

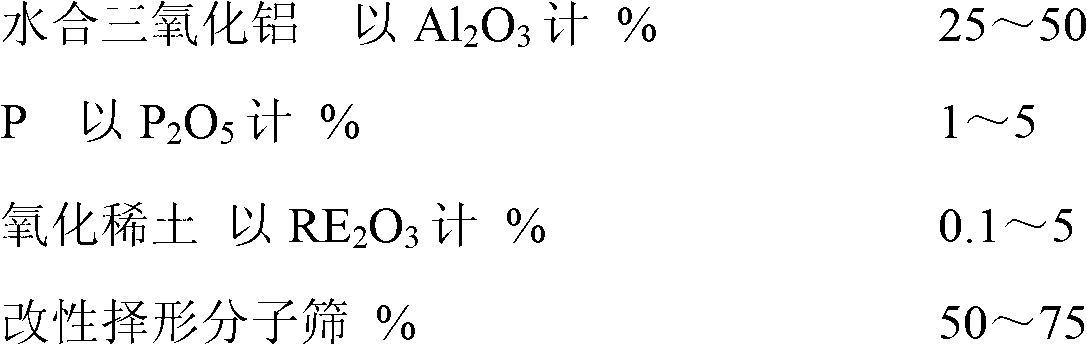

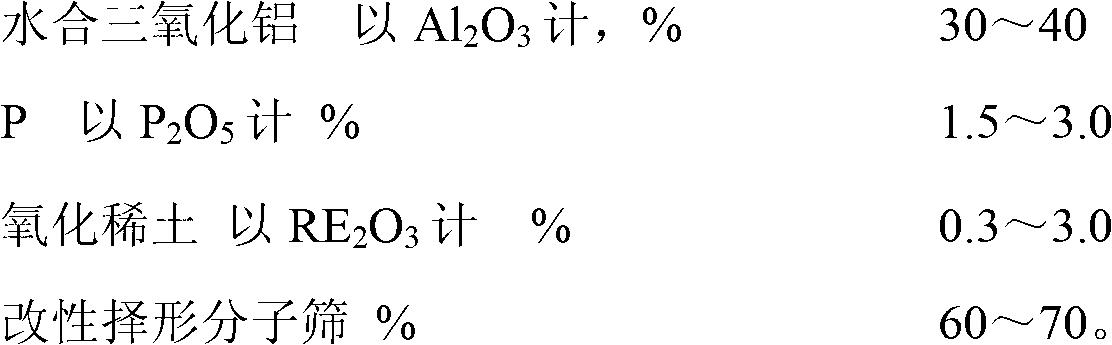

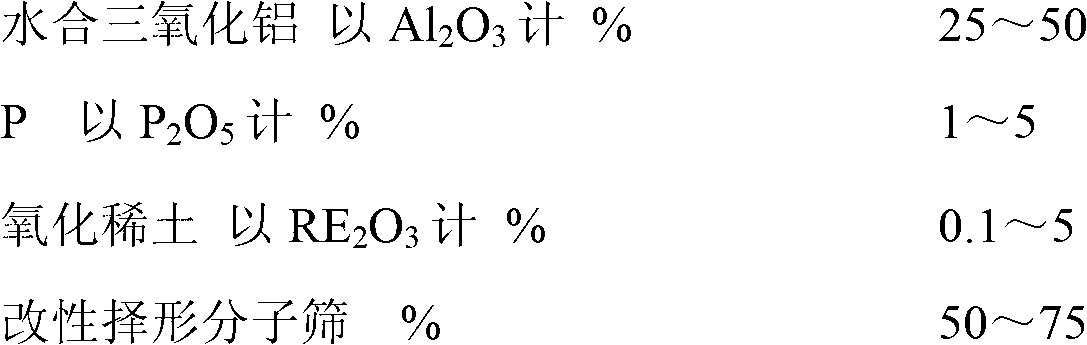

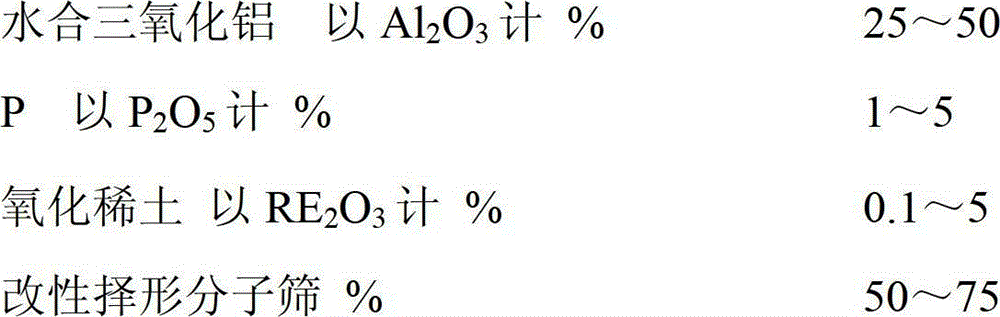

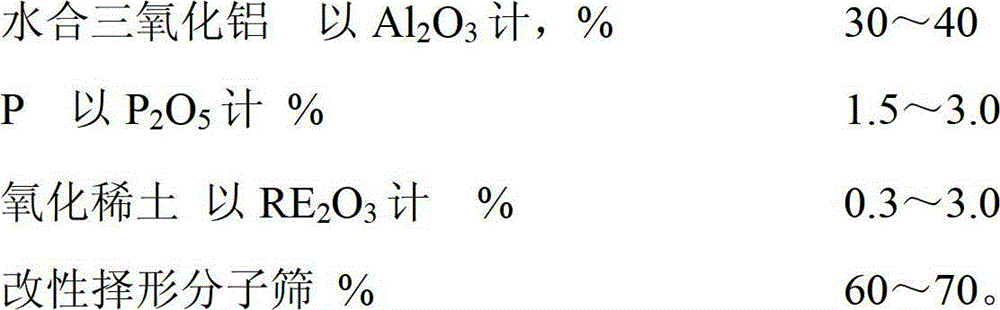

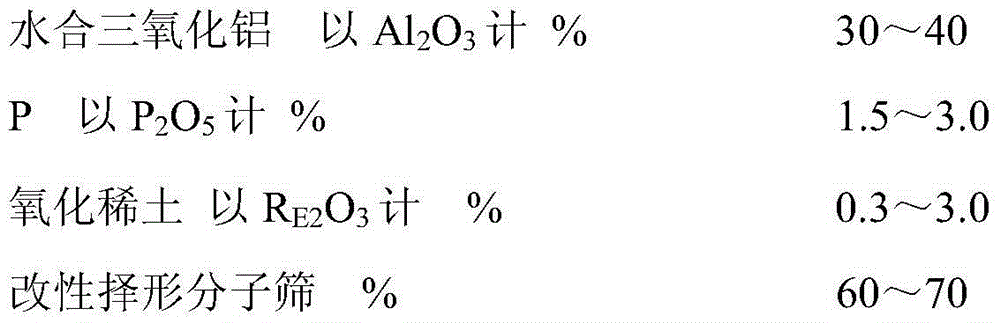

Catalyst suitable for enhancing gasoline octane number of fuel and lowering olefin content and application thereof

ActiveCN102794195AImprove anti-carbon performanceLong life one wayCatalytic crackingMolecular sieve catalystsRare earthRaw material

The invention relates to a catalyst suitable for enhancing gasoline octane number of fuel and lowering olefin content and application thereof, belonging to a catalyst containing a molecular sieve. The catalyst is prepared from the following raw materials in percentage by mass: 25-50% of aluminum trioxide hydrate on the basis of Al2O3, 1-5% of P on the basis of P2O5, 0.1-5% of rare-earth oxide on the basis of RE2O3 and 50-75% of modified shape-selective molecular sieve. The invention provides a catalyst with olefin aromatization function; the fuel treated by the catalyst has the advantages of high gasoline octane number, low olefin content, high gasoline yield and low dry gas yield; and the catalyst has the advantages of low coking tendency and long service life. The catalyst is suitable for aromatization modification of fuel C4 liquefied petroleum gas, and can lower the olefin content of the fuel; and the catalyst enhances the straight-run gasoline octane number, and lowers the catalytically cracked gasoline olefin content. The C4 liquefied petroleum gas and the straight-run gasoline can be used as raw materials to produce modified fuel gasoline; and etherified C4 and straight-run naphtha can be used as raw materials to produce modified fuel gasoline.

Owner:宁夏永全新能源科技有限公司

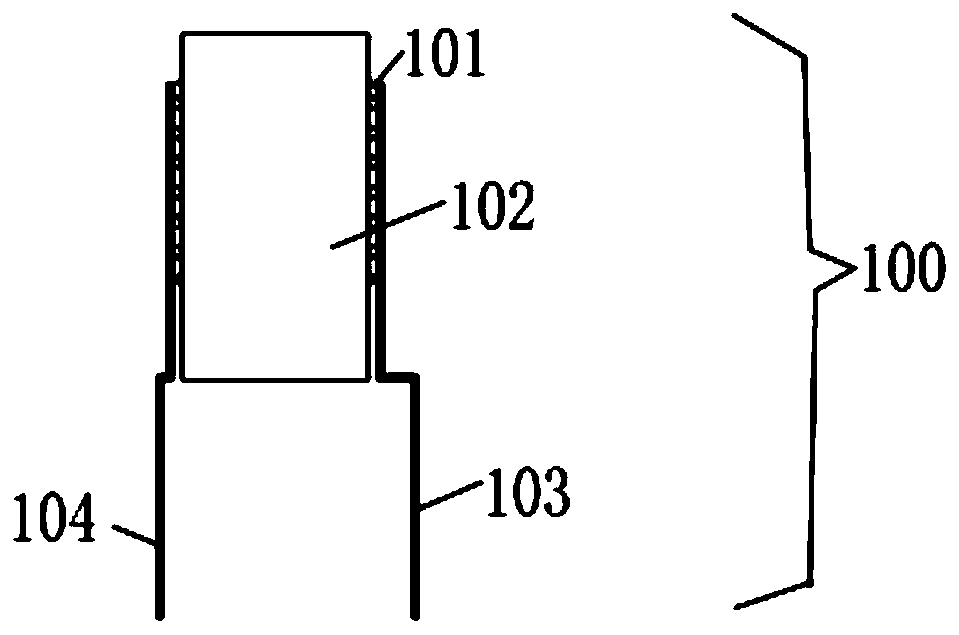

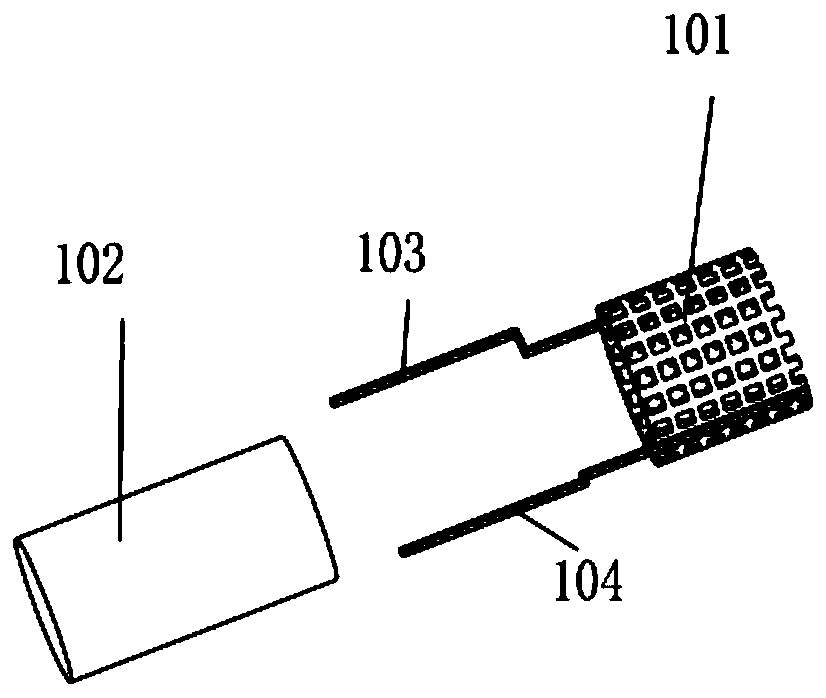

Upper end glue adding device of automatic edge sealing machine

ActiveCN103878864ASmall volumeNot easy to carbonizeDomestic articlesAdhesive application devicesCarbonizationPulp and paper industry

The invention discloses an upper end glue adding device of an automatic edge sealing machine. The upper end glue adding device comprises a glue adding and melting module and a gluing module mounted below the glue adding and melting module, the glue adding and melting module comprises a shell, a piston frame, a hopper and a piston, the shell is provided with a bin, the piston frame is arranged obliquely, the piston is driven by a pushing cylinder to move, a heating block is arranged at an output end of the piston frame, and the gluing module comprises a glue box, a glue door, a gluing roller and a rotating shaft. Split-type up-down design is adopted for glue melting, glue adding and gluing, so that volume of a glue melting box is reduced, hot melting glue time is effectively reduced, energy consumption cost is lowered, production time is increased, production and profit-making capability of a user is improved, hot melting glue is less prone to splitting decomposition and carbonization, product quality of the user is improved, and product competitiveness of the user is improved correspondingly; frequency glue adding is not needed, glue supply quantity is larger, gluing height is higher, the upper end glue adding device is suitable for larger plate thickness and high-speed edge sealing operation, and high-efficiency value is demonstrated.

Owner:NANXING MACHINERY CO LTD

Method for preparing epoxy fatty acid methyl ester

The invention relates to an improved method for preparing epoxy fatty acid methyl ester, which is characterized in that a solid catalyst or a sodium bisulfate solid catalyst obtained by mixing 30-90 parts of sodium bisulfate, 10-50 parts of ferric sulfate and 0-20 parts of calcium sulfate is adopted in an epoxidation reaction. By using the solid catalyst, when catalytic activity of the solid catalyst corresponds to that of sulfuric acid, the reaction condition is temperate; the production safety is good; the obtained product has high epoxy value which can reach more than 3.5; the epoxidation temperature is reduced to a certain degree, for example, the reaction temperature can be reduced by about 10 DEG C; and because too high temperature is needless, the fatty acid eater is not easy to be carbonized; the obtained product has light and bright color and luster and can be directly used for a light-color product without a decolorization process; the yield is also enhanced; and particularly the corrosivity to equipment is greatly reduced, thereby reducing equipment investment, maintainance and replacement. Meanwhile, the solid catalyst is simpler than a liquid catalyst in use and recovery aspects and is friendly to environment.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

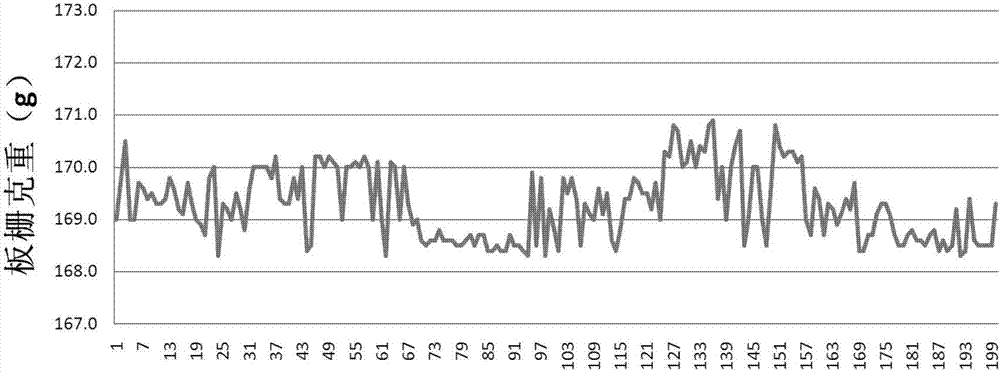

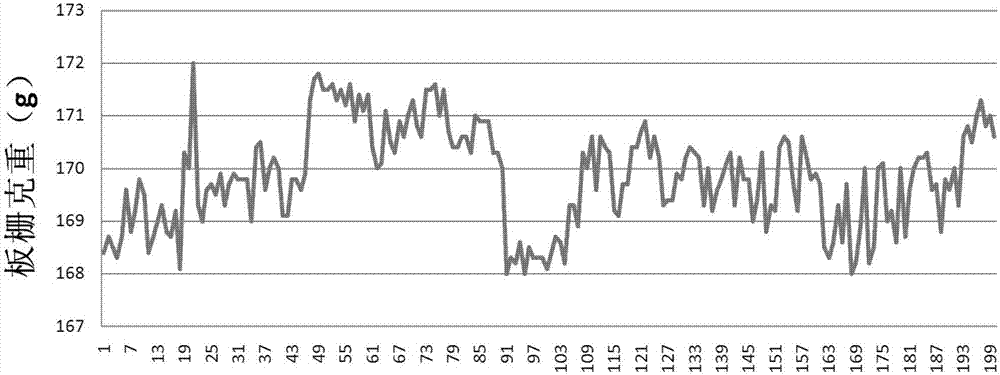

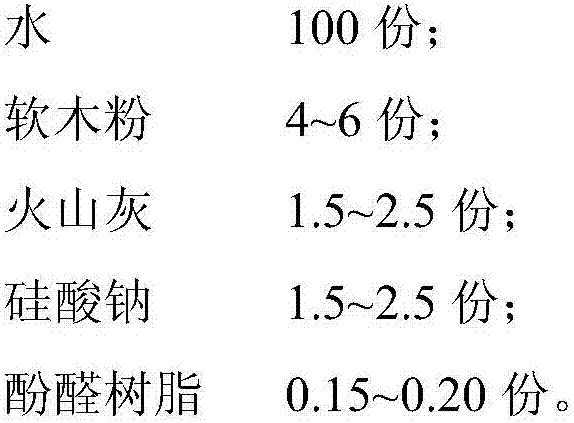

Release agent for lead storage battery grid casting and preparing method thereof

ActiveCN107511448AReduce excessive sheddingIncreased durabilityFoundry mouldsFoundry coresVolcanic ashCorrosion

The invention discloses a release agent for lead storage battery grid casting and a preparing method thereof. The release agent for lead storage battery grid casting comprises the following raw materials of, by mass, 100 parts of water, 4-6 parts of cork powder, 1.5-2.5 parts of volcanic ash, 1.5-2.5 parts of sodium silicate and 0.15-0.20 parts of phenolic resin. According to the release agent for lead storage battery grid casting, the volcanic ash of being high-temperature-resistant, high in viscosity, not easy to carbonize and small in particles is added, the fact that the release agent falls off too fast is reduced, the durability of the release agent is increased, the time interval of mould jetting during grid casting is extended, the work efficiency is improved, and the stability of plate grid gram weight is improved; and the water-soluble phenolic resin is added, the release agent has the advantages of heat resistance, flame resistance and water resistance and insulativity, the acid resistance is good, the alkali resistance is poor, the mechanical and electrical performances are good, demoulding is easy, the transfer rate is low, during synthesis, different components are added, the modified phenolic resin of different functions can be obtained, and the release agent has a variety of excellent characteristics such as alkali resistance, abrasion resistance, oil resistance and corrosion resistance.

Owner:TIANNENG BATTERY GROUP

Method for preparing vacuum glass

ActiveCN104030557AShort heating timeQuality assuranceClimate change adaptationWindows/door improvementEnergy consumptionKiln

The invention relates to the field of vacuum glass and in particular relates to a method for preparing vacuum glass. The method comprises the following steps: (1) heating glass, gluing and curing; (2) arranging the glass; (3) heating the glass in a kiln; and (4) taking out the vacuum glass. The method is short in preparation time and high in sealing property, the energy consumption is reduced, and the vacuum glass manufactured by the method is uniform in bearing capacity.

Owner:青岛中腾志远真空玻璃科技发展有限公司

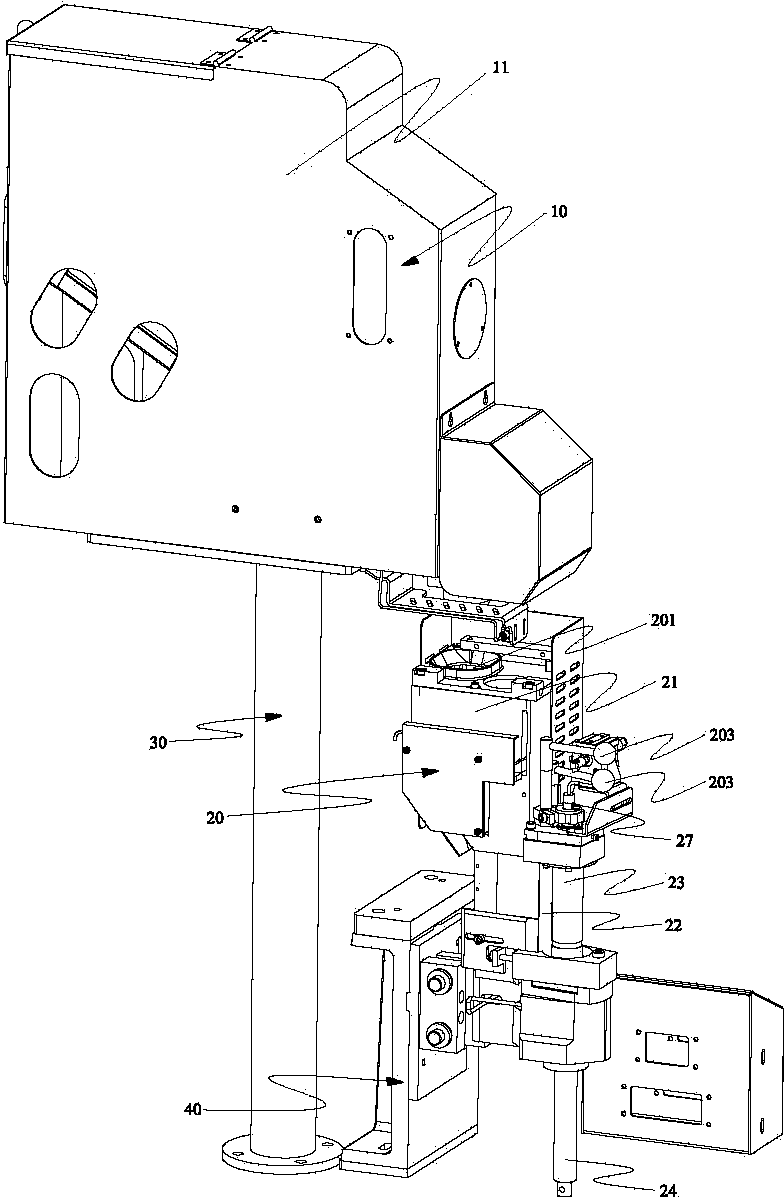

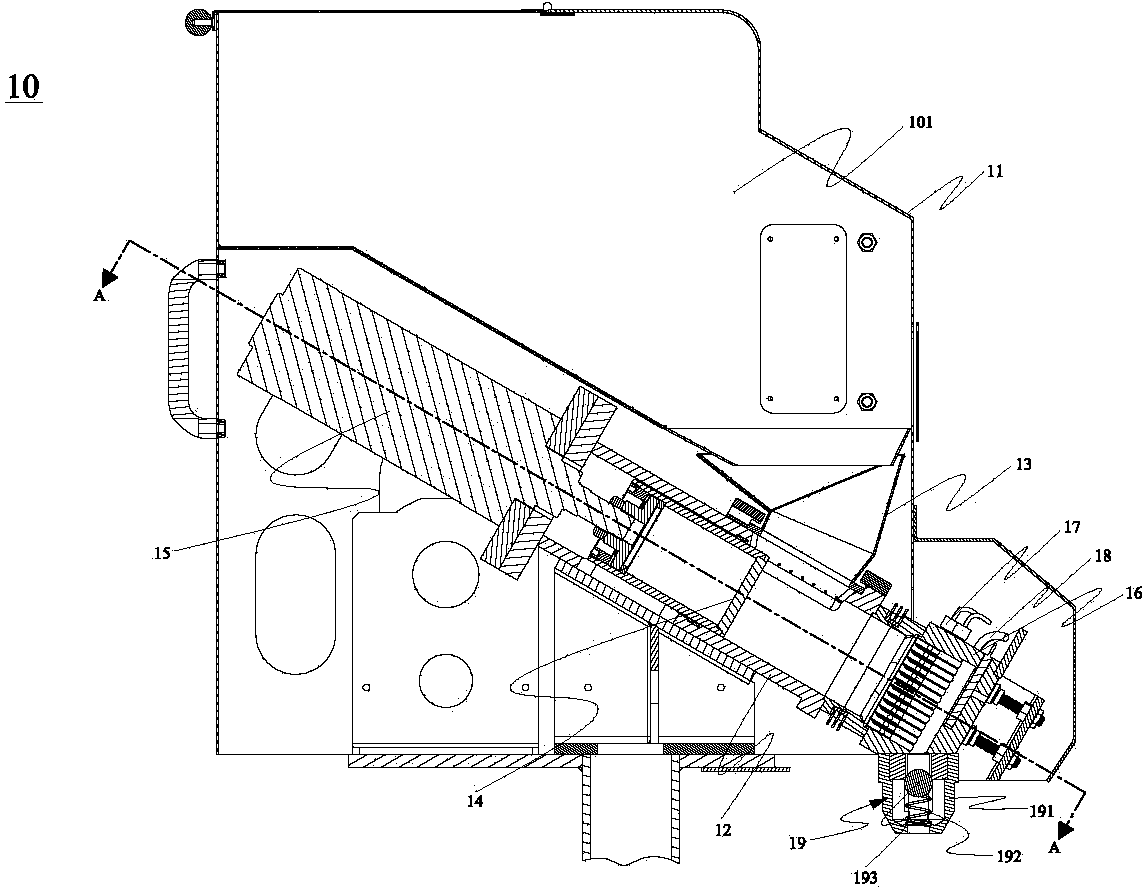

Single-head swing type striking-off machine

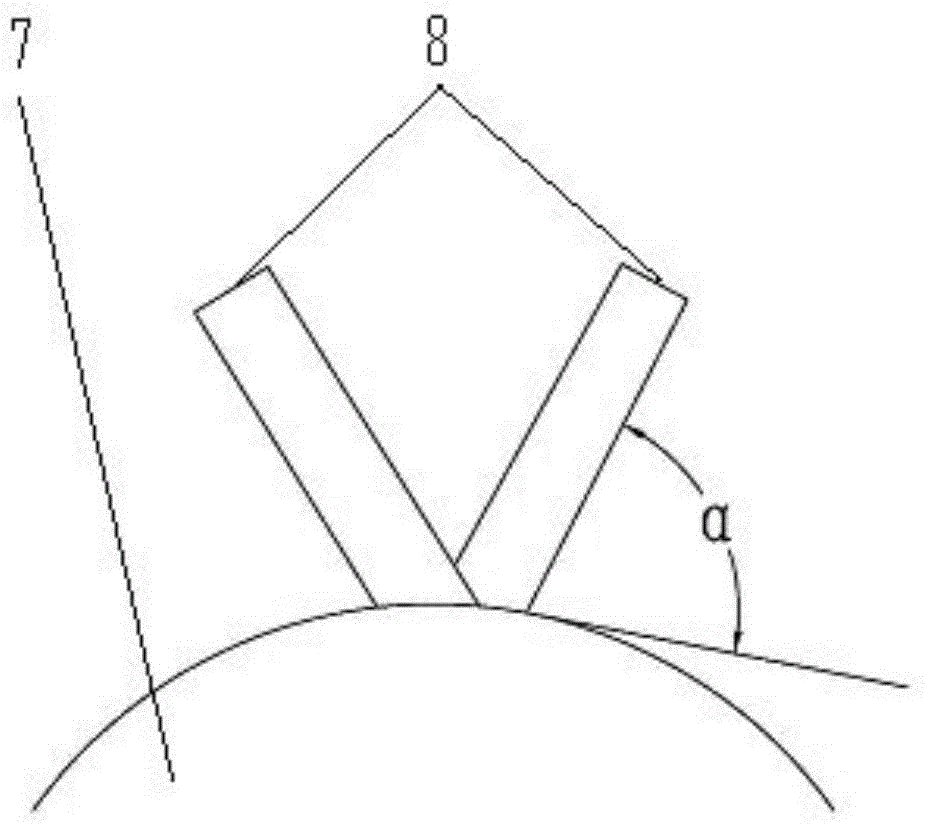

InactiveCN105773812AIncrease cooling areaImprove wear resistanceCeramic shaping apparatusAcute angleEngineering

Owner:FOSHAN BAOHANG MACHINERY EQUIP IND INTPROP SERVICES

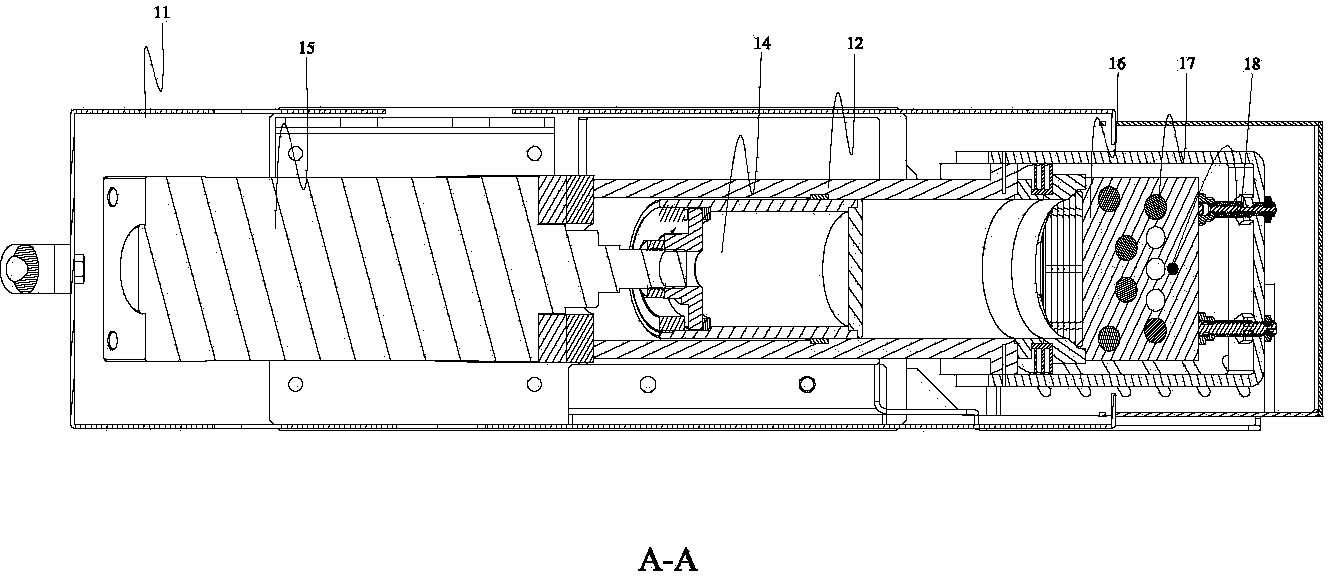

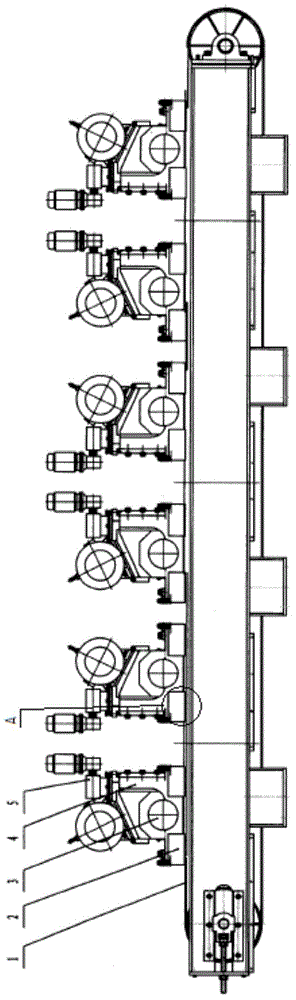

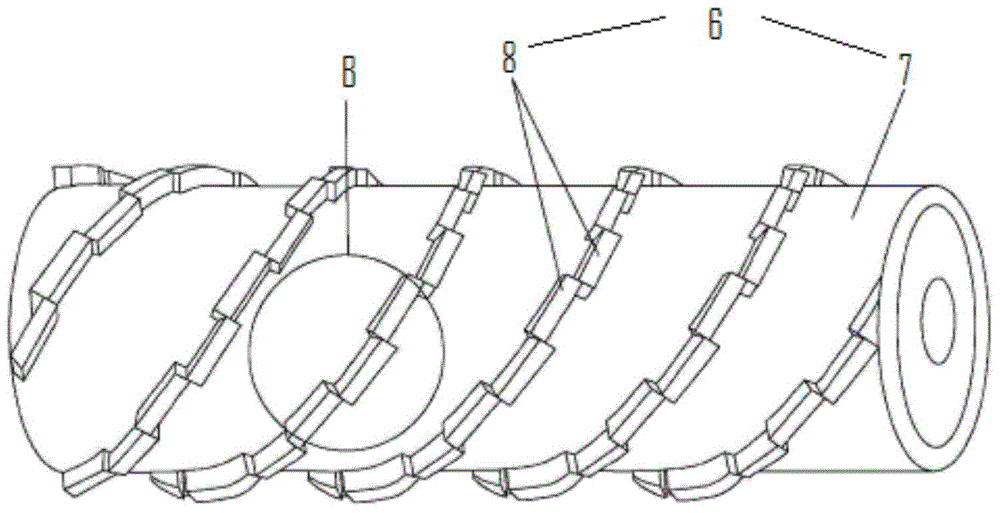

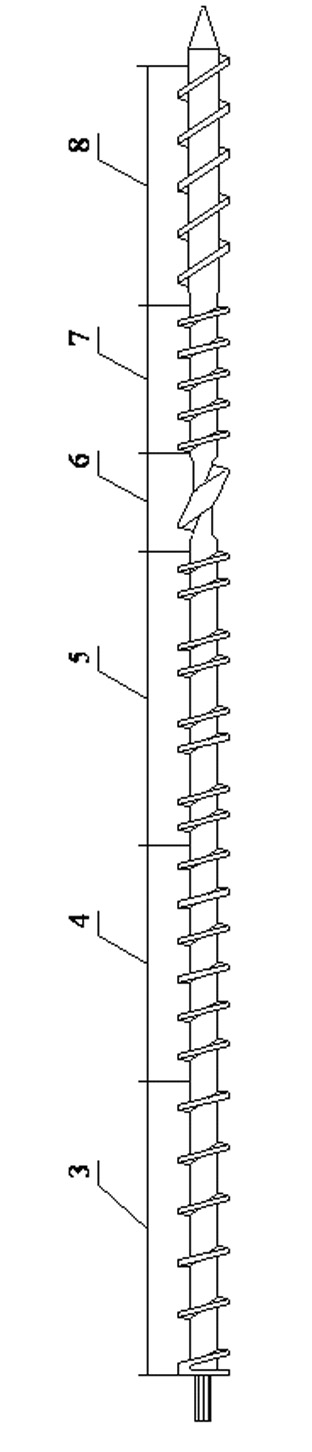

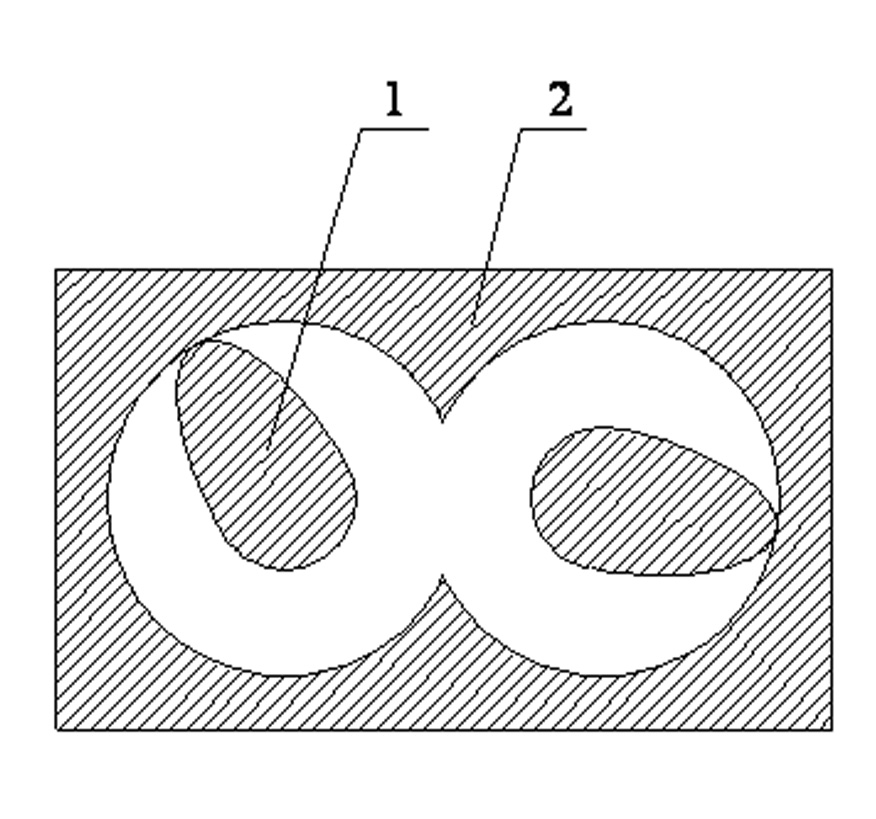

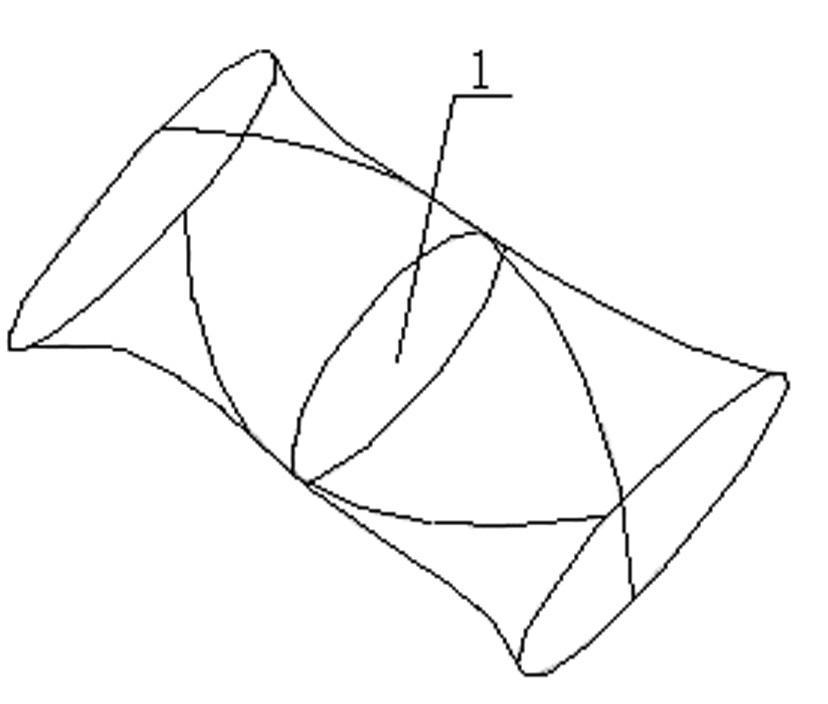

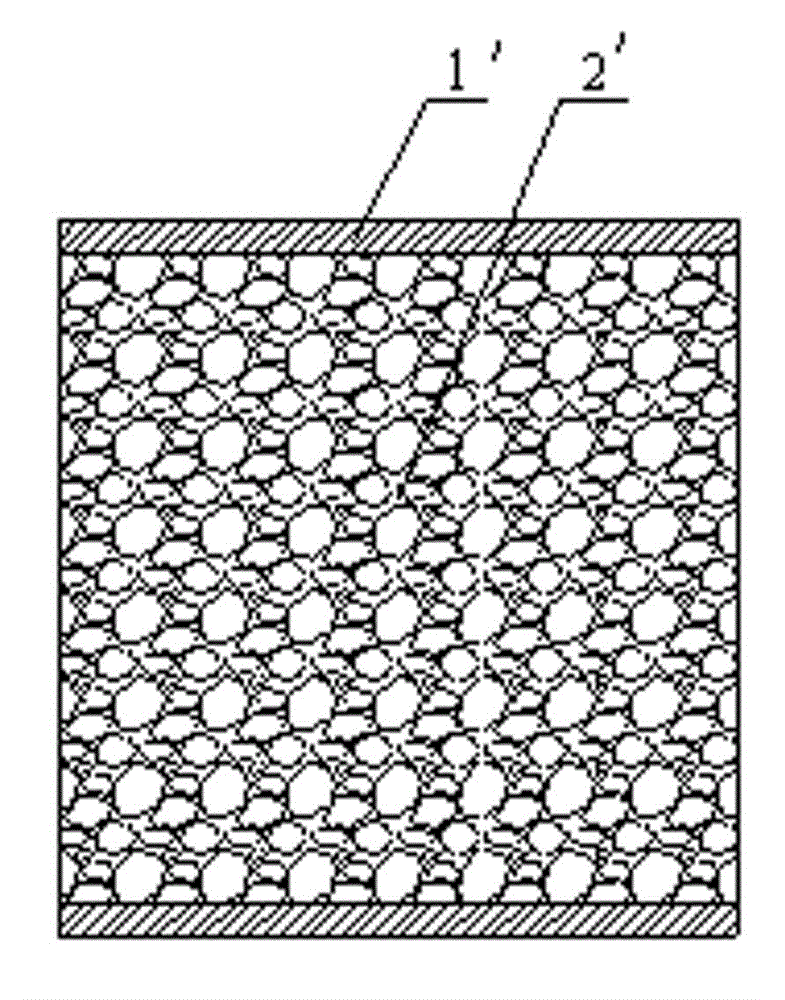

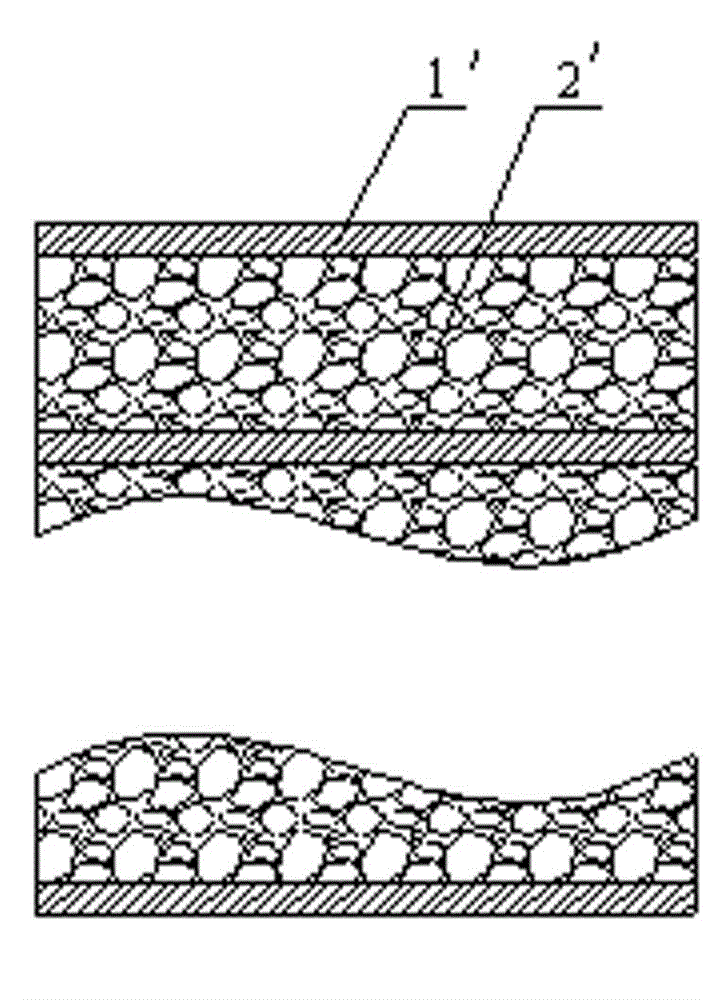

Wood-plastic composite reinforced blending plasticization device

The invention discloses a wood-plastic composite reinforced blending plasticization device. The device comprises a blending plasticization screw I and a blending plasticization screw II with the same structure; both the blending plasticization screw I and the blending plasticization screw II are sequentially divided into a plastic granule conveying section, a plastic melting plasticization section, a fiber / plastic blending section, a reinforced blending plasticization section, a homogenization section and a metering section; and the reinforced blending plasticization section consists of 1 to 6 single-helix mixing rotors. The device has compact structure, small volume and good mixing effect, is convenient to operate, solves the problem of difficult blanking of fibers, realizes uniform dispersion of fibers and polymer resin in a submicroscopic scale range, is favorable for improving the two-phase structure and the perform uniformity of the composite materials, and improves the integral physical and mechanical properties of the materials; and the residence time of the fibers in the device is short, the temperature is appropriate, the fibers are not easy to carbonize, and the device is environmentally-friendly.

Owner:曾广胜

Copper and aluminum connection structure with flame retardant insulation bush

InactiveCN102025031AIncrease contactHigh strengthConnections effected by permanent deformationConnection contact member materialCopper conductorUltimate tensile strength

The invention relates to a copper and aluminum connection structure with a flame retardant insulation bush. In the connection structure, cold welding and pressure welding manners are simultaneously adopted for fixedly connecting a copper conductor joint section of a copper conductor and an aluminum conductor joint section of an aluminum conductor into a copper and aluminum conductor joint section; the copper and aluminum conductor joint section and the peripheries of the copper conductor joint section and the aluminum conductor joint section which are adjacent to the copper and aluminum conductor joint section are coated by heat-shrinkable insulation bushes with a good flame retardant property; and the tension resistance strength of the copper and aluminum conductor joint section is not less that 200 N. The copper and aluminum connection structure with the flame retardant insulation bush can ensure that the two different metal conductors can well contact, have the characteristics of good strength and good insulation property, and can not be broken, carbonized and burnt easily in operation for a long time.

Owner:JIANGSUSNGSHANG CABLE GROUP

Production method of insulating bamboo ball

ActiveCN108995006AEasy to fillIncrease insulation functionWood treatment detailsCane mechanical workingFilling materialsForest product

The invention relates to the technical field of forest product machining, in particular to a production method of an insulating bamboo ball. Old moso bamboos are adopted as raw materials, the machining method comprises the following steps of primary machining, ball blank making, fermentation, high-temperature cooking, drying, insulating paint applying, secondary drying, ball blank grinding and secondary paint spraying, hot air vibration drying and the like. Eggs and microorganisms in the bamboo balls are completely eradicated, the high-temperature-resistant insulating paint is impregnated, aninsulation function of the bamboo ball is enhanced, so that mobility is good when the post-filling is carried out on the prepared insulation bamboo ball, various irregular non-standard gaps are proneto be filled, the insulation bamboo ball is resistant to high temperature and high pressure, and is not easy to carbonize; and light weight, corrosion resistance, high strength and impact resistance are achieved, the insulation bamboo ball is an ideal insulation post-filling material, can be applied to the field of aerospace and large-scale mechanical equipment for long-time fatigue operation.

Owner:吴青平

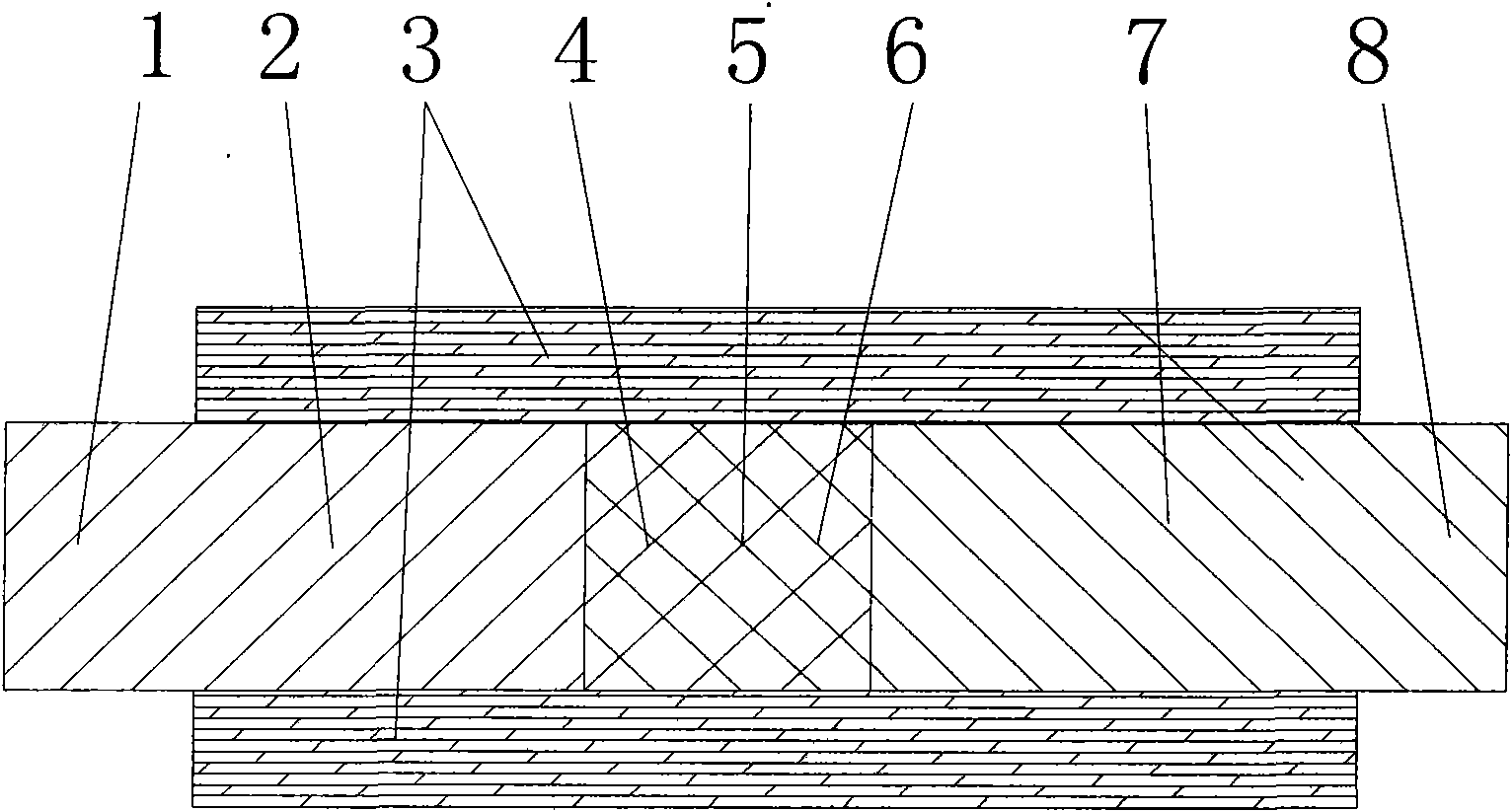

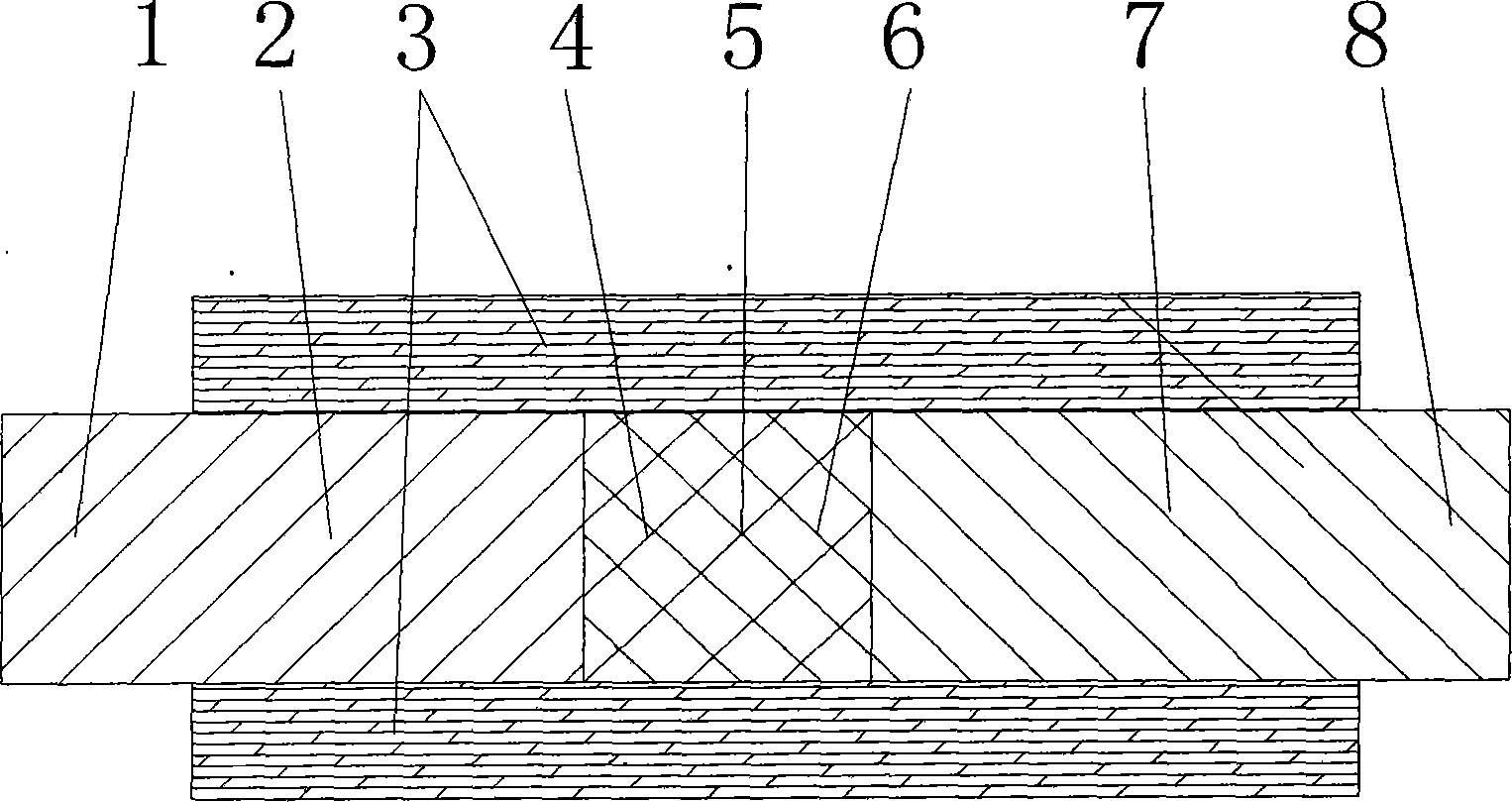

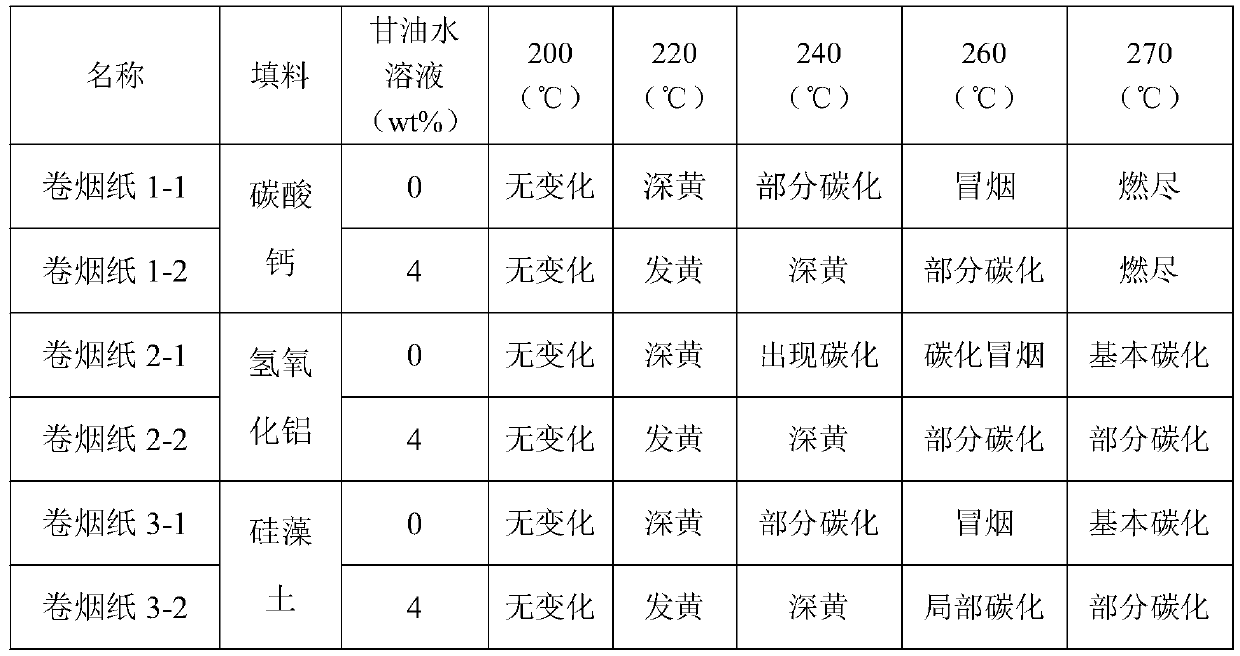

Method for improving temperature resistance of cigarette paper

InactiveCN110295512AImprove corrosion resistanceAccelerated corrosionFlexible coversWrappersGlycerolProcess engineering

The invention belongs to the technical field of cigarette paper, and particularly relates to a method for improving the temperature resistance of cigarette paper. The method comprises adding glycerolin the production process of the cigarette paper. According to the invention, a 3-5 wt% glycerol aqueous solution as a sizing agent is applied to common cigarette paper, the phase change heat absorption property of glycerol is utilized to improve the temperature resistance of the cigarette paper, and compared with the cigarette paper without glycerol, the temperature resistance is improved by 15-25 DEG C.

Owner:CHINA TOBACCO YUNNAN IND

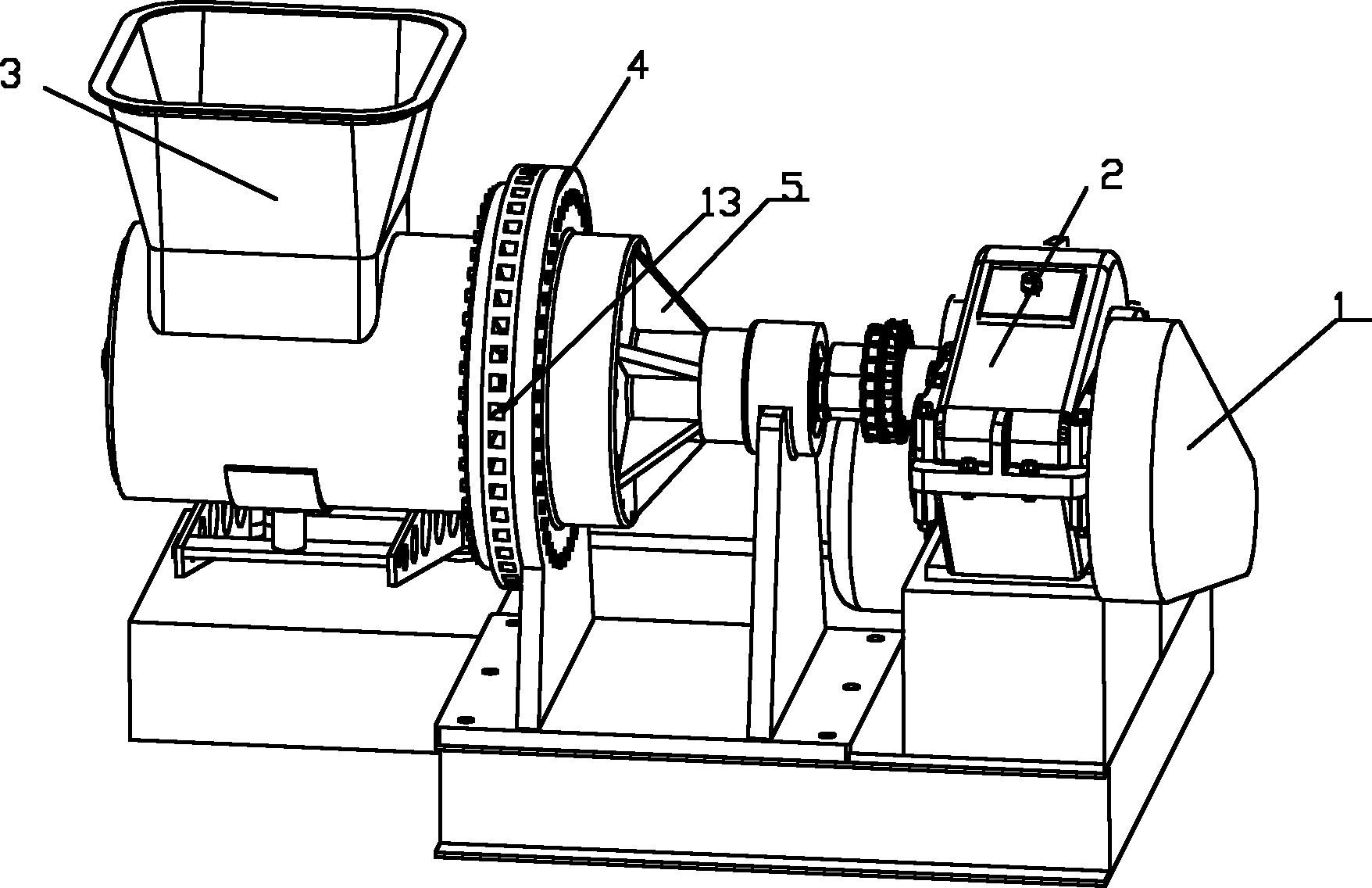

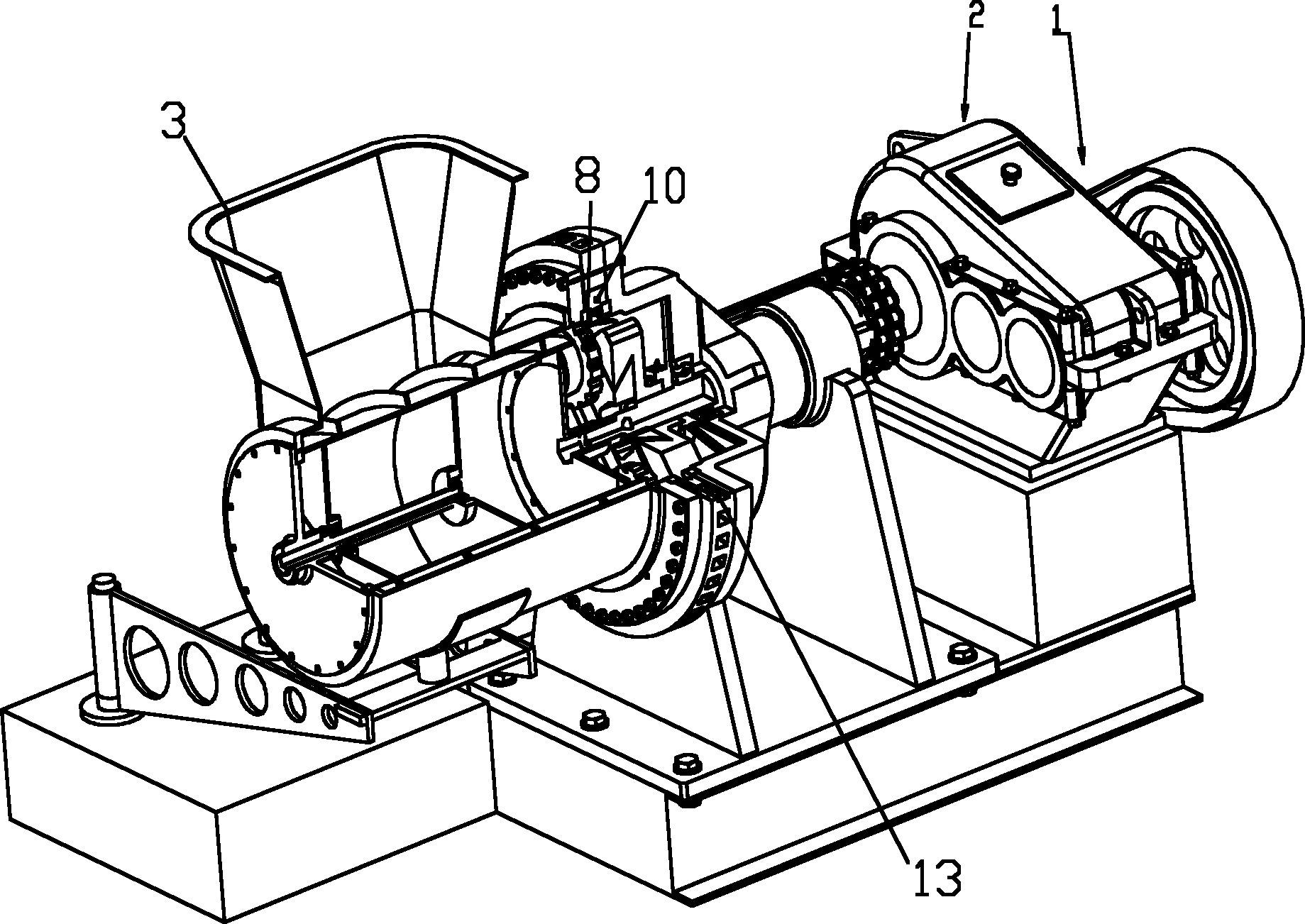

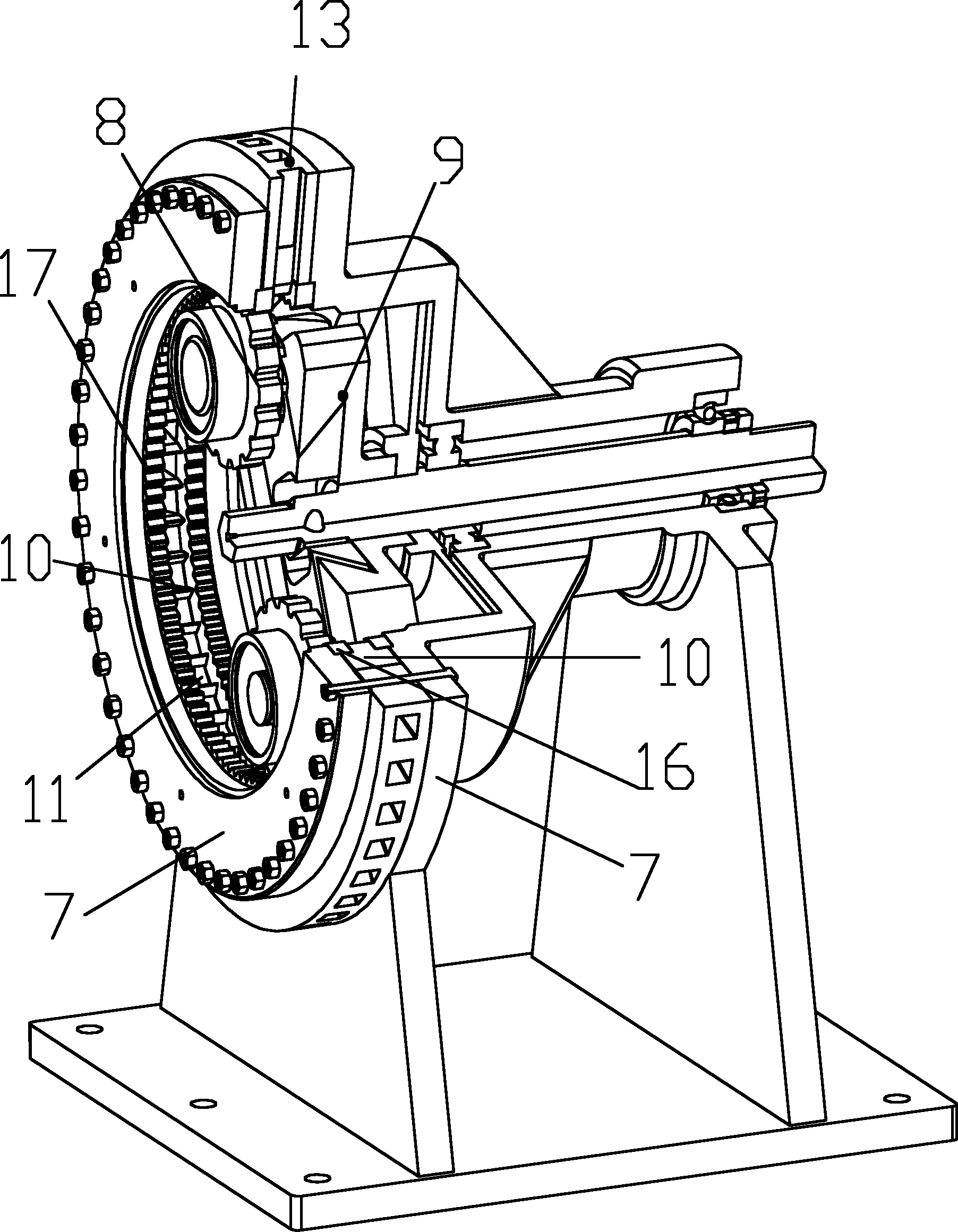

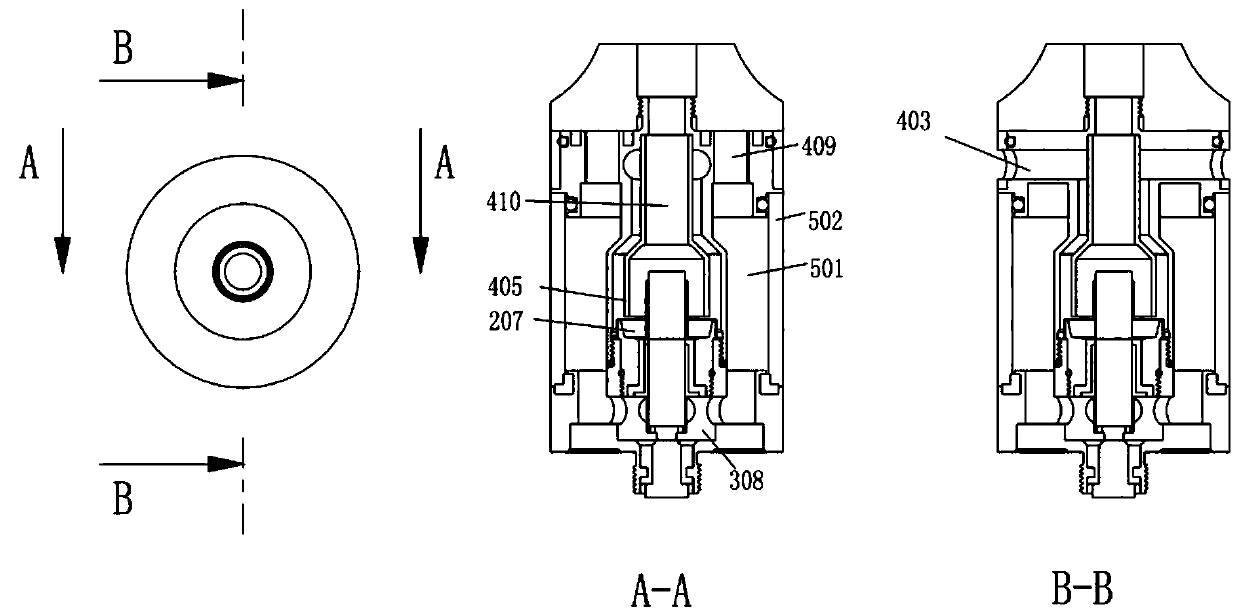

Rolling shear type straw briquetting machine

The invention discloses a rolling shear type straw briquetting machine which comprises a power device, a transmission device, a feeding device and a straw briquetting device, wherein the power device is connected with the transmission device, the transmission device is connected with a frame, the frame is provided with the straw briquetting device, and the feeding device is connected with the straw briquetting device. The rolling shear type straw briquetting machine is characterized in that the straw briquetting device comprises a cutter main body, round blades, hobbing cutters and a hobbing cutter rest, wherein the inside of the cutter main body is provided with cutter teeth, a tapered feed inlet is formed between two adjacent cutter teeth, the two sides of the cutter main body are respectively provided with a round blade, the inside of each round blade is provided with cutter teeth, the hobbing cutter rest is connected with the frame, at least two hobbing cutters are arranged on the hobbing cutter rest, the blade of each hobbing cutter is arranged in an annular cutter groove formed between the round blades and the cutter main body, and the hobbing cutters are driven by the hobbing cutter rest so as to rotate along the annular cutter groove. By using the rolling shear type straw briquetting machine disclosed by the invention, the production efficiency is greatly improved, the machine is not easy to crash, and the straws are not easy to carbonize, therefore, the machine complies with the orientation of national environmental protection policies.

Owner:潘留华 +1

Environment-friendly simple electronic cigarette atomizer

The invention discloses an environment-friendly simple electronic cigarette atomizer which comprises a heating component, an atomizing core component, an atomizing seat component and a top seat component. Parallel central lines of the outer wall of a heat generating net are welded with a positive electrode pin and a negative electrode pin, a core, the lower-end surface of a silica gel pipe, the lower-end outer surface of a position electrode pipe, the middle inner wall of an atomizing seat, a silica gel sleeve and a positive electrode surround to form an oil incoming cavity, an inwards-concaveface, the upper end face of the silica gel pipe, the outer surface of an upper oil absorbing core and the inner surface of a connection cover surround to form a seeping oil collection cavity, and thelower-end outer surface of a top seat, the inner wall of a glass pipe, the inner wall of a base and the upper-end outer surface of the atomizing seat surround to form an oil storage bin. The heatingcomponent generates heat on the outer surface for atomization, so that convenience is brought to heat radiation, and the surface is less prone to carbonization; when the surface of a heating net carbonizes, replacement of the atomizing core component is not needed, and only the heating component needs to be replaced, so that waste is reduced, and using cost of users is lowered; seeping tobacco taris recycled, so that pollution and waste caused by direction emission are avoided, and user experience is improved.

Owner:东莞市轩策五金制品有限公司

Method for preparing medical lactide

The invention relates to a method for preparing medical lactide, comprising: adding a catalyst and a high boiling point solvent to lactic acid to carry out polycondensation reaction, so that the lactic acid generates oligomeric lactic acid; adding a catalyst to the generated oligomeric lactic acid to perform depolymerization reaction, Obtain medical lactide. In the method provided by the invention, a high-boiling solvent is added in the polycondensation process, so that the reaction system will not become viscous, difficult to evaporate, carbonized, and yellow due to the reduction of lactide distillation during depolymerization, ensuring the production process The stability and product quality, as well as the variability of physical indicators; and the yield is high, the reaction operation is simple, there is no danger, the production time is short, it is beneficial to industrial production, and it has high economic value.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

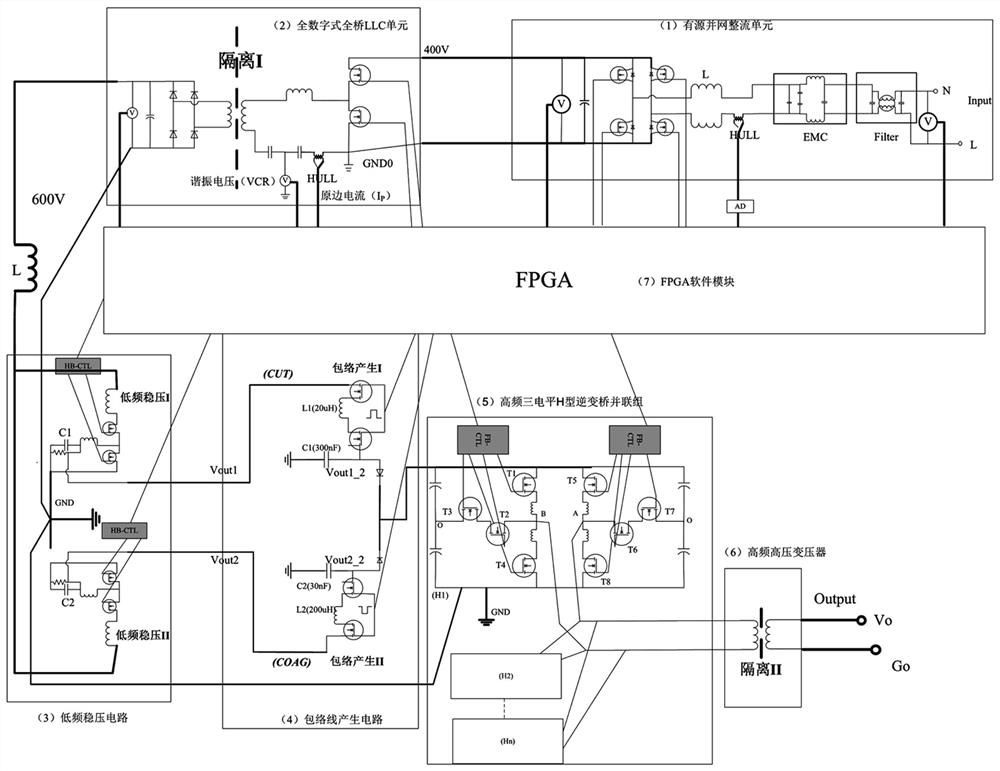

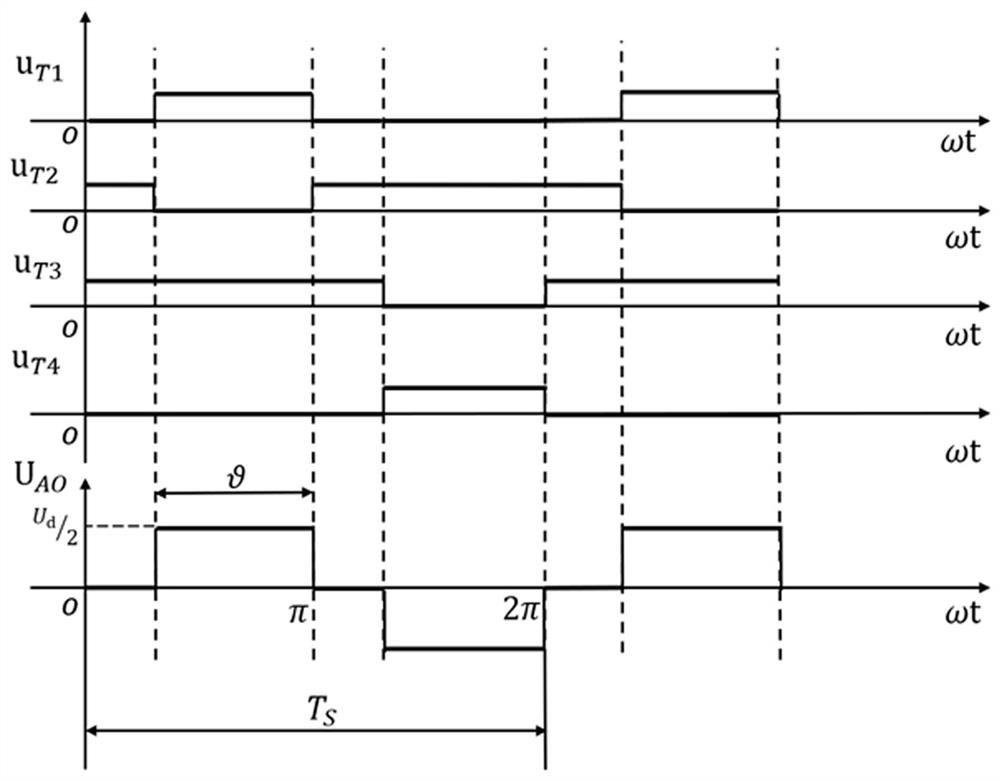

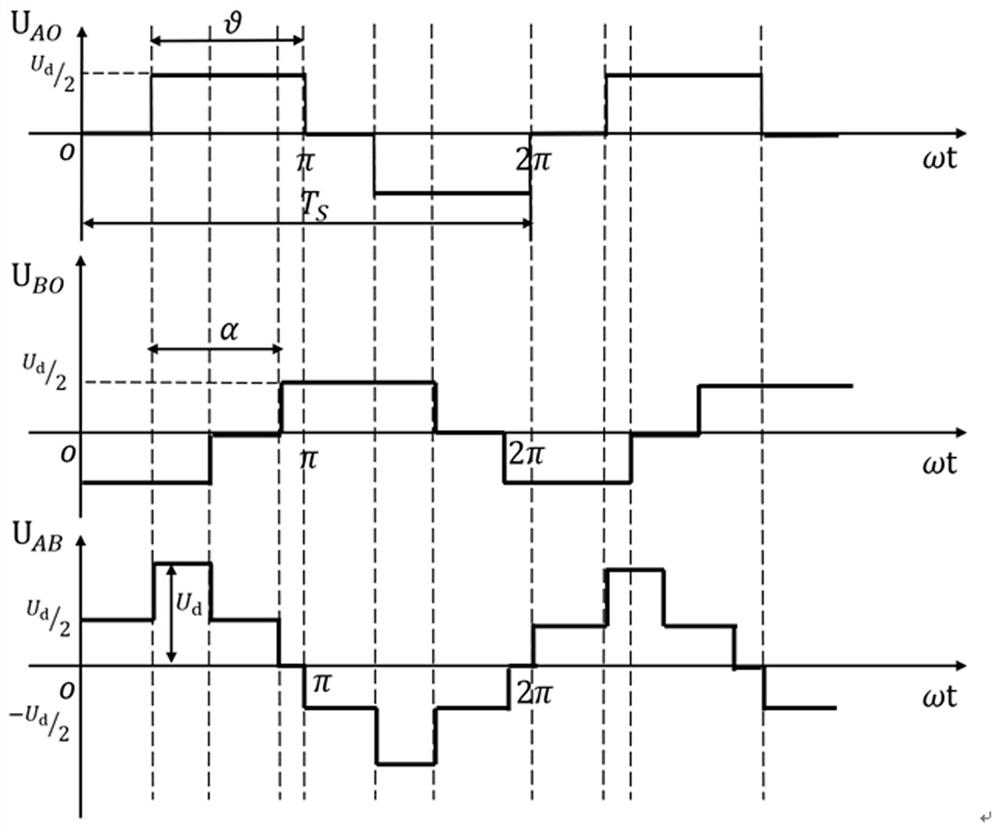

Plasma scalpel power supply control system

PendingCN113262038AStable output waveformRelieve pressureProgramme controlComputer controlCapacitancePower control system

The plasma scalpel power supply control system comprises an active grid-connected rectifying unit, a full-digital full-bridge LLC unit, a low-frequency voltage stabilizing circuit, an envelope line generating circuit, a high-frequency three-level H-type inverter bridge parallel group, a high-frequency high-voltage transformer and an FPGA software module which are connected in sequence. The FPGA software module is respectively connected with the active grid-connected rectifying unit, the full-digital full-bridge LLC unit, the low-frequency voltage stabilizing circuit, the envelope line generating circuit, the high-frequency three-level H-type inverter bridge parallel group and the high-frequency high-voltage transformer. Compared with a traditional power supply, isolation and safety are fully considered, and particularly, the absolute safety of a human body is fully ensured due to the addition of a capacitor charging and discharging link; besides, the working frequency can be improved from 10k level to million level, the wound is not easy to carbonize and heal during cutting, and the blood flow amount in the operation process is smaller.

Owner:ANHUI AOFO MEDICAL EQUIP TECH

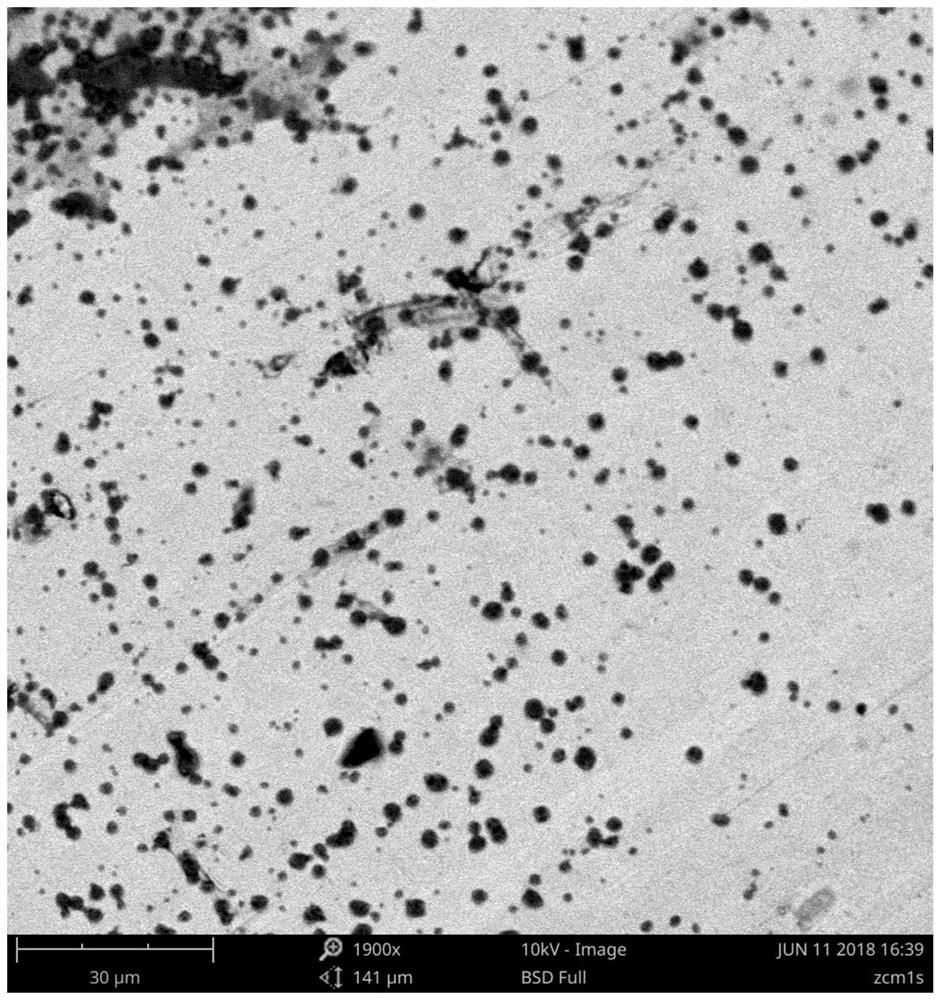

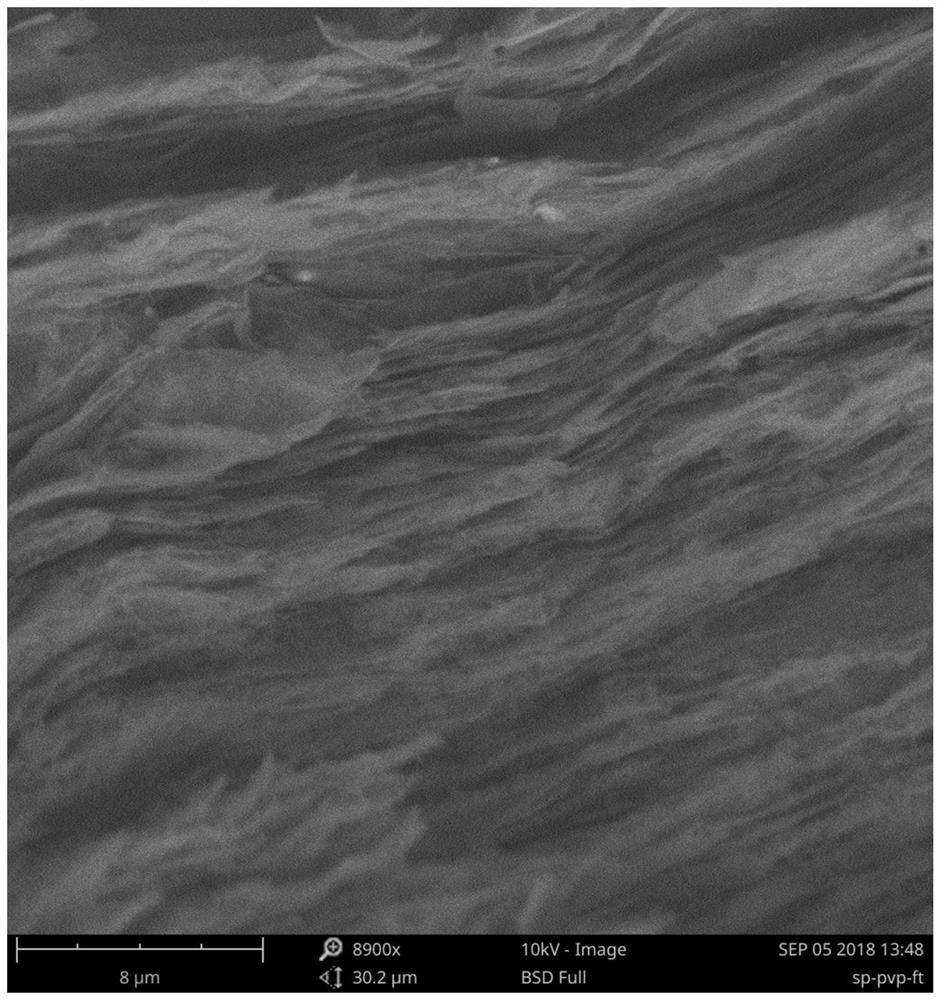

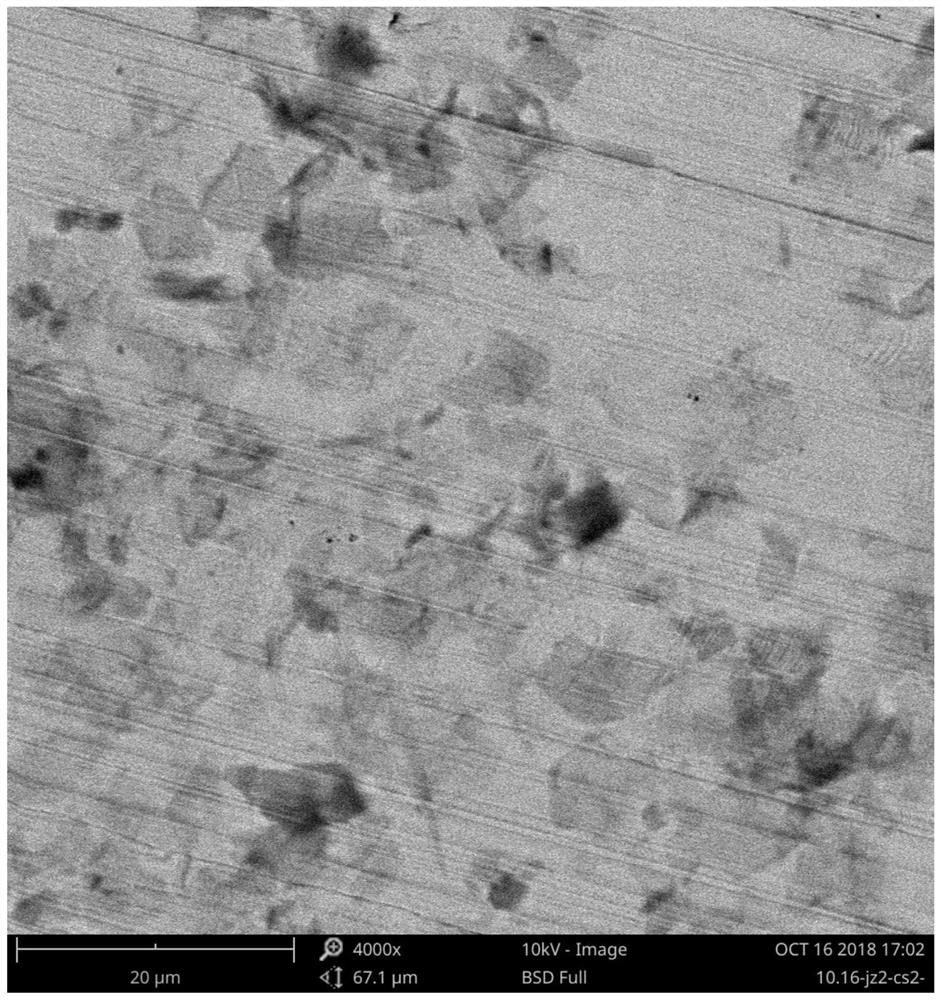

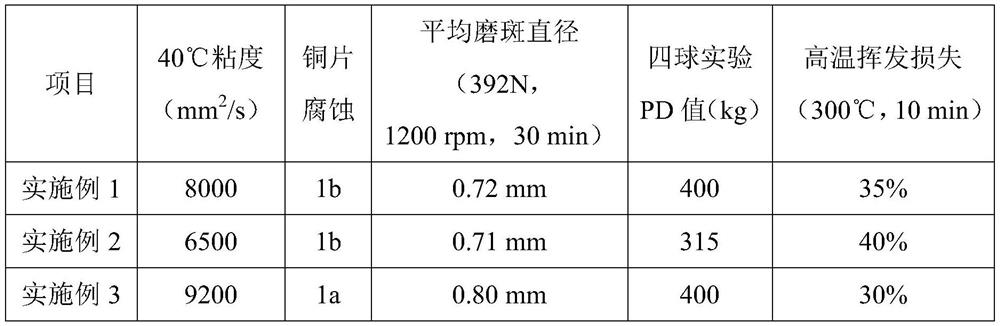

Preparation method of micro-emulsified cutting fluid for aero-engine aluminum alloy processing

InactiveCN113652292AImprove the lubrication effectImprove cooling effectLubricant compositionActive agentFreeze-drying

The invention provides a preparation method of a micro-emulsified cutting fluid for aero-engine aluminum alloy processing. The preparation method comprises the following steps of: pre-reducing graphene oxide, sulfonating, and reducing residual oxygen functional groups by hydrazine hydrate to obtain sulfonated graphene; preparing dispersion liquid from the sulfonated graphene; adding molybdenum salt and powdered sulfur into a mixed solution of hydrazine hydrate and N, N-dimethylformamide, adding the mixed solution into the sulfonated graphene dispersion liquid, adding hydrogen peroxide, centrifuging, washing, and freeze-drying to obtain sulfonated graphene / MoS2 nanocages; ball-milling the nanocages, putting the ball-milled nanocages into ethylene glycol, then adding dimethyl sulfate and sodium dodecyl sulfate, and carrying out stirring and ultrasonic treatment; taking biodegradable base oil, and adding an emulsifier, triethanolamine, polyethylene wax, a compound surfactant, an anti-rust agent and a defoaming agent into the biodegradable base oil to obtain an oil-based mixed solution; taking deionized water, and adding the sulfonated graphene / MoS2 nanocages, glycerol and propylene glycol into the deionized water to obtain a water-based mixed solution; and mixing the oil-based mixed solution with the water-based mixed solution, and stirring until the liquid is uniform and transparent, thereby obtaining micro-emulsified cutting fluid for aero-engine aluminum alloy processing.

Owner:四川欧力泰尔新材料有限公司

Wood plastic composite foaming material and forming process and equipment thereof

The invention relates to a wood plastic composite foaming material and a forming process and forming equipment thereof. The diameters of foam holes of the wood plastic composite foaming material are 0.01 to 5 millimeters; and the main component of the material is a mixture of thermoplastic plastic and plant fiber powder, or a mixture of thermoplastic plastic, starch and plant fiber powder, or a mixture of thermoplastic plastic, rubber powder and plant fiber powder. The invention also relates to the forming process and the forming equipment for the wood plastic composite foaming material. The wood plastic composite foaming material has the advantages of low density, high strength and low production cost, is suitable to be used as a packing material for various commodities, a buffering member for various devices, an elastic member of a product such as a sofa, a mattress, a sole and the like and a structural component of a household electric appliance, and is used for replacing wood for manufacturing floors, handrails, doors and windows, resting chairs used in gardens and the like.

Owner:佛山市科昌塑料制品有限公司

Preparation method of water-soluble nanometer high-temperature super lubricant for wheel belt

The invention provides a preparation method of a water-soluble nanometer high-temperature super lubricant for a wheel belt. The preparation method comprises the following steps: firstly, preparing a sandwich-structure solid additive MoS2 / graphene / MoS2 and a water-based bio-based bactericide carbon nanotube / lysozyme; preparing an oil-phase mixed solution and a water-phase solution, namely sequentially adding a lubricant, an emulsifier and an oily bactericide into base oil, conducting full stirring at 50-60 DEG C to obtain the oil-phase mixed solution, sequentially adding an anti-corrosion and anti-rust agent and a waterborne bio-based bactericide carbon nanotube / lysozyme into water, and conducting full dissolving to obtain a water-phase solution; then, adding the water-phase solution into the oil-phase mixed solution, and carrying out uniform stirring to obtain an emulsion; then, adding the sandwich-structure solid additive MoS2 / graphene / MoS2 into the emulsion, and performing stirring to obtain a colloid mixture; and finally, homogenizing the colloid mixture in a three-roller ball mill 2-3 times to obtain the water-soluble nanometer high-temperature super lubricant for the wheel belt. With the water-soluble nanometer high-temperature super lubricant, relative friction between the wheel belt and a base plate can be reduced, the service life of equipment is prolonged, and energy consumption is reduced.

Owner:四川欧力泰尔新材料有限公司

Cleaning gasoline with alcohol ether base

InactiveCN1236023CMeet power requirementsIncrease oxygen contentLiquid carbonaceous fuelsCleansing AgentsNuclear chemistry

The invention discloses a clean alcohol ether-base gasoline, prepared of alcohol-base fuel mixed solution, naphtana etherified liquid, C-5 and cleaning agent; and its components in weight percent (wt%): alcohol-base fuel mixed solution 40-50, C-5 10-20, naphtana etherified liquid 30-45, cleaning agent 0.1. The alcohol-base fuel mixed solution is composed of methanol, acetone, hydrogen peroxide, ferrocene-benzene solution and camphor powder. The naphtana etherified liquid is prepared by etherifying naphtana, methyl-tert-butyl ether and isopropyl ether. The finished oil has rich HO molecular groups, high oxygen content and can fully burn. After it is used, the indexes of various harmful matters in the discharged tail gas from engines are obviously lower than those of ordinary gasoline and environmental protection.

Owner:于雷

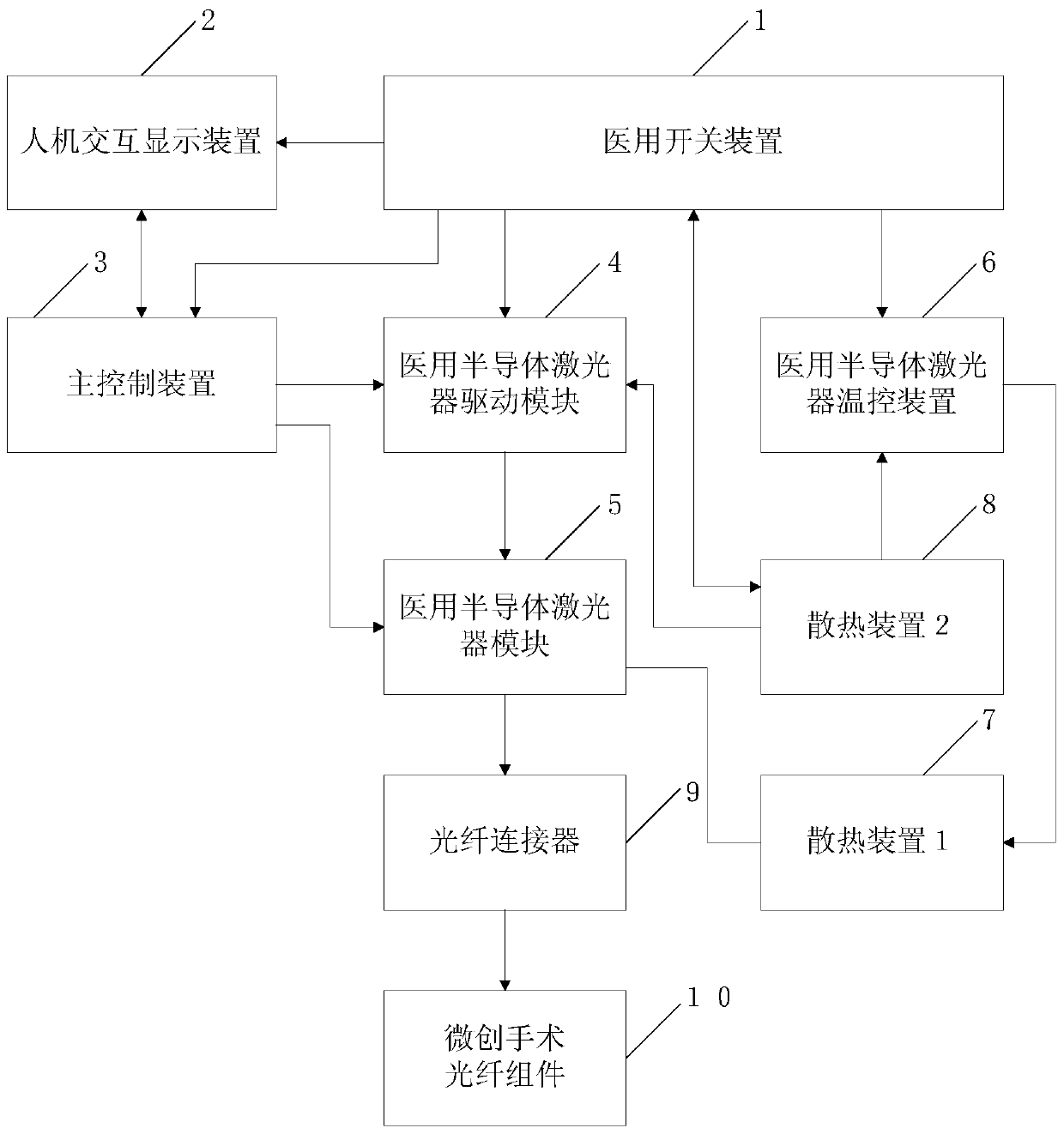

A laser therapy system for tissue ablation

ActiveCN104688337BSpherical light is easy to controlUniform light and heat temperatureSurgical instrument detailsHigh absorptionEngineering

The invention discloses a laser treatment system for tissue ablation, which includes a medical switch device, a human-computer interaction display device, a main control device, a medical semiconductor laser drive module, a medical semiconductor laser module, a medical semiconductor laser temperature control device, and a cooling device 1 , cooling device 2, optical fiber connectors and optical fiber components for minimally invasive surgery. The medical semiconductor laser module includes a first laser component and a second laser component; the wavelengths of the first laser and the second laser are different; the first laser is a visible wavelength laser used to indicate the irradiation area, and the The second laser is an eye-safe infrared wavelength laser for fat melting, which has a higher absorption rate of water and fat.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Catalyst suitable for enhancing gasoline octane number of fuel and lowering olefin content and application thereof

ActiveCN102794195BBoost octaneImprove conversion rateCatalytic crackingMolecular sieve catalystsMolecular sieveNaphtha

The invention relates to a catalyst suitable for enhancing gasoline octane number of fuel and lowering olefin content and application thereof, belonging to a catalyst containing a molecular sieve. The catalyst is prepared from the following raw materials in percentage by mass: 25-50% of aluminum trioxide hydrate on the basis of Al2O3, 1-5% of P on the basis of P2O5, 0.1-5% of rare-earth oxide on the basis of RE2O3 and 50-75% of modified shape-selective molecular sieve. The invention provides a catalyst with olefin aromatization function; the fuel treated by the catalyst has the advantages of high gasoline octane number, low olefin content, high gasoline yield and low dry gas yield; and the catalyst has the advantages of low coking tendency and long service life. The catalyst is suitable for aromatization modification of fuel C4 liquefied petroleum gas, and can lower the olefin content of the fuel; and the catalyst enhances the straight-run gasoline octane number, and lowers the catalytically cracked gasoline olefin content. The C4 liquefied petroleum gas and the straight-run gasoline can be used as raw materials to produce modified fuel gasoline; and etherified C4 and straight-run naphtha can be used as raw materials to produce modified fuel gasoline.

Owner:宁夏永全新能源科技有限公司

Method for increasing synthetic ratio in hair hydrolyzation for preparing aquatic ecological protecting agent

ActiveCN105293599AShorten the hydrolysis timeHigh extraction rateWater/sewage treatmentChemistrySalicylic acid

The invention discloses a method for increasing a synthetic ratio in hair hydrolyzation for preparing an aquatic ecological protecting agent. The method comprises the following steps: 1) cleaning, drying and crushing hair, adding keratinase and deionized water and reacting to obtain a solution A under the pressure of 20 to 30 Mpa and normal temperature; 2) selecting one or more of salicylic acid, adipic acid, malonic acid, succinic acid and palmic acid and uniformly mixing with the deionized water to prepare a solution, reacting the obtained solution with the solution A at 10 to 20Mpa and at 30 to 40 DEG C, and filtering to obtain a solution B; 3) selecting one or more of ethylene diamine tetra (methylene phosphonic acid) sodium, diethylenetriaminepenta(methylenephosphonic) acid, amino trimethylene phosphonic acid, tartaric acid, heptonate, sodium gluconate and sodium alginate and uniformly mixing with the deionized water, and then uniformly mixing with the solution B to obtain a finished product. According to the method disclosed by the invention, the time of hair hydrolyzation is shortened, the extraction rate of hair hydrolyzation into amino acids is increased, and therefore the synthetic rate of synthesizing the aquatic ecological protecting agent is increased.

Owner:临沭县益兴供汽维修服务有限公司

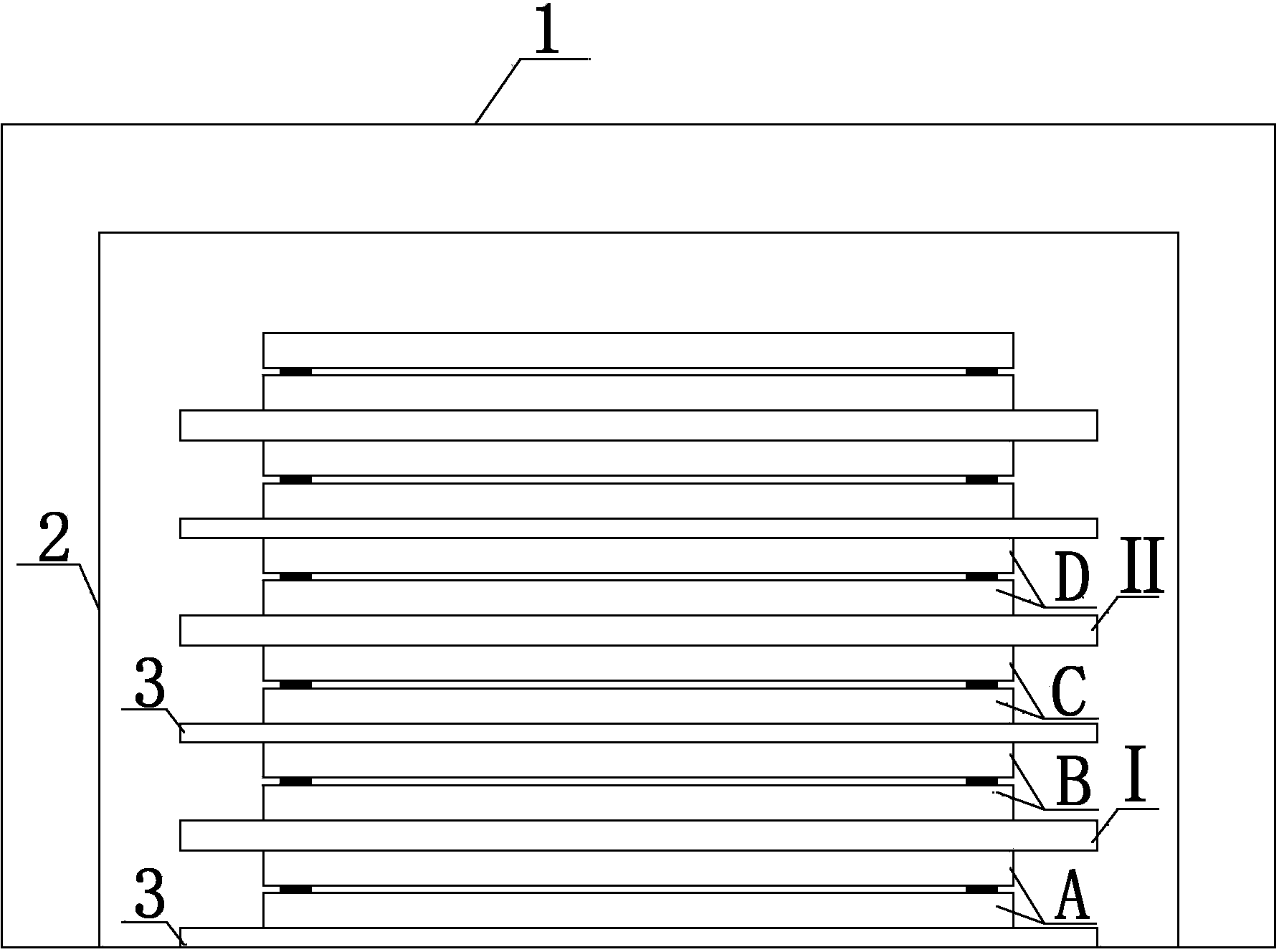

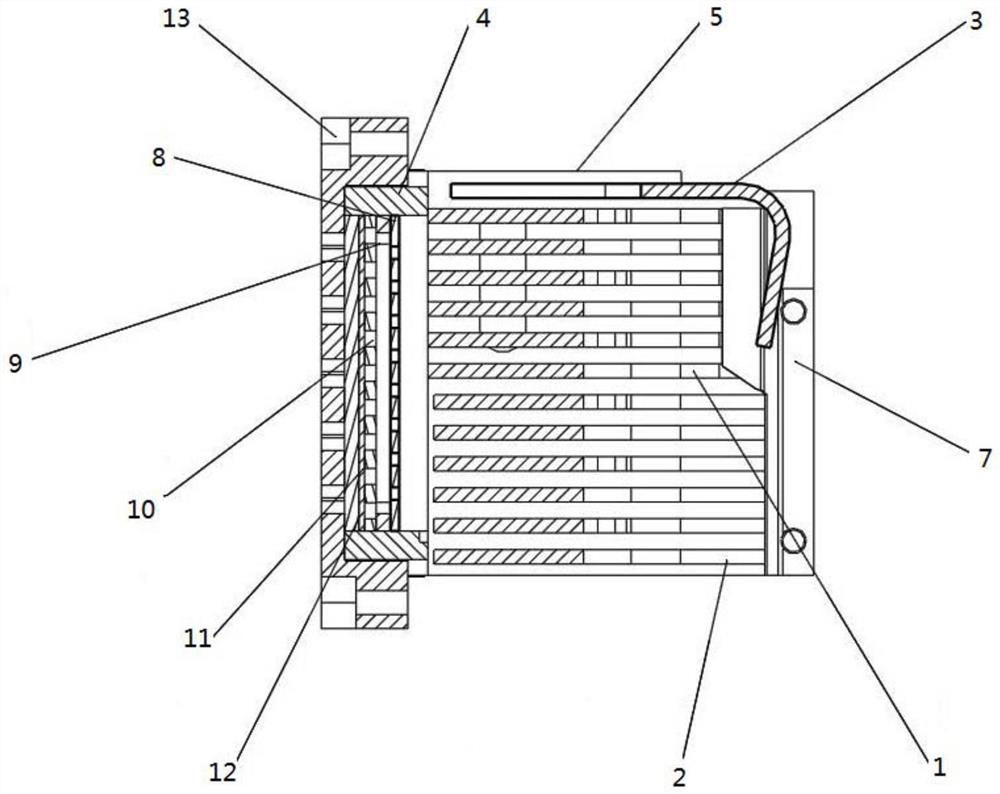

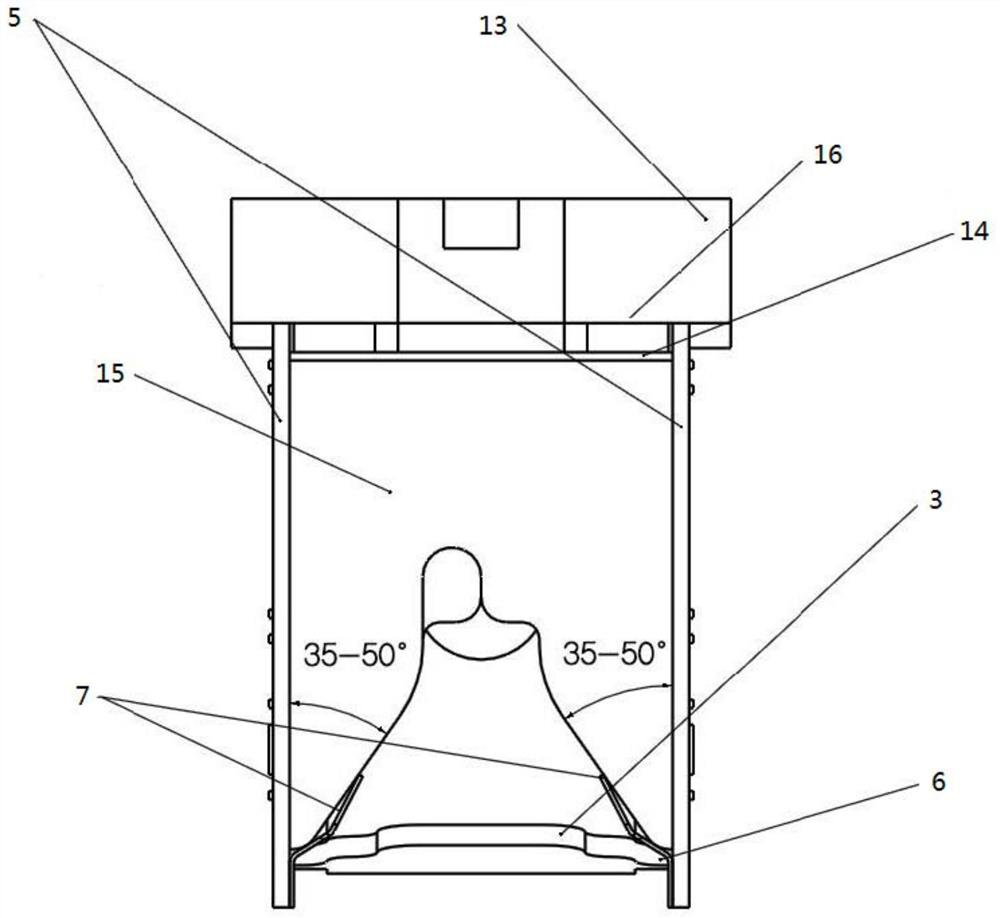

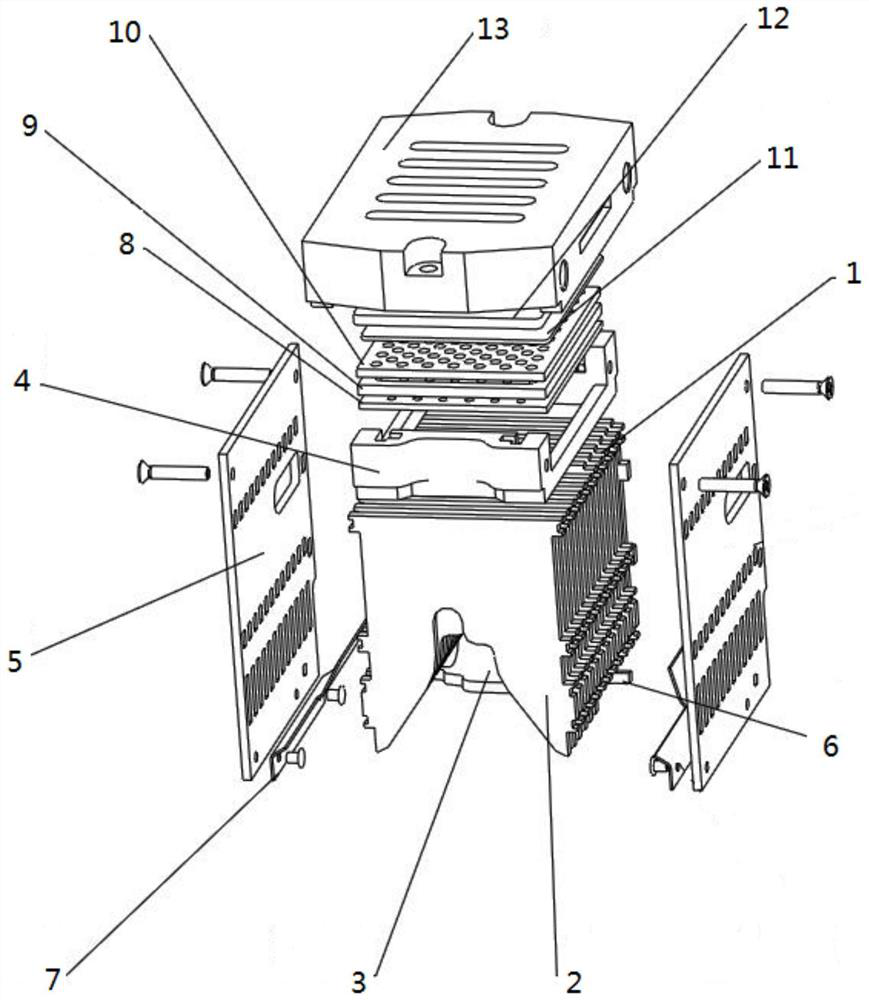

Arc extinguish chamber for low-voltage circuit breaker

PendingCN114141592AGood arc extinguishing performanceIncrease the areaCircuit-breaking switch detailsEngineeringBreaking capacity

The invention relates to an arc extinguish chamber for a low-voltage circuit breaker, the arc extinguish chamber comprises an arc extinguish grid group (15), an arc striking sheet (3), a side plate (5), a base (4), a flame extinguish sheet (16) and a top cover (13), the arc extinguish grid group (15) is composed of an upper arc extinguish grid group (1) and a lower arc extinguish grid group (2) which are parallel to each other, and the lower arc extinguish grid group (2) is close to a static contact area, namely an arc generation area. The upper arc-extinguishing grid plate group (1) is arranged above the lower arc-extinguishing grid plate group (2), and an included angle between a pin of the lower arc-extinguishing grid plate group (2) and the horizontal direction is 35-50 degrees; the area of the lower arc-extinguishing grid sheet group (2) is larger than that of the upper arc-extinguishing grid sheet group (1), the distance between the lower arc-extinguishing grid sheet group (2) and a contact area is smaller, and the area of each grid sheet in the lower arc-extinguishing grid sheet group (2) is larger than that of each grid sheet in the upper arc-extinguishing grid sheet group (1) by 2-3 cm < 2 >. Compared with the prior art, the invention has the advantages of excellent arc extinguishing performance, long service life, high breaking capacity and the like.

Owner:SHANGHAI RENMIN ELECTRICAL APP WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com