Preparation method of water-soluble nanometer high-temperature super lubricant for wheel belt

A super-lubricant, water-soluble technology, applied in the field of lubricants, can solve problems such as fire, pollution of the environment, difficulty in ensuring continuous and effective lubrication, etc., and achieve good lubrication and heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

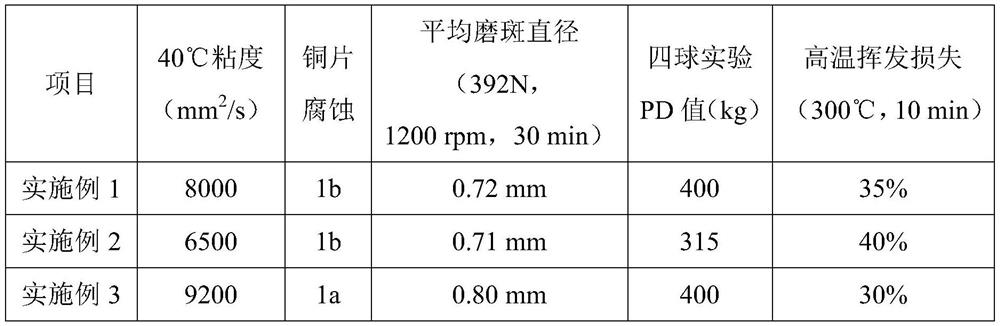

Embodiment 1

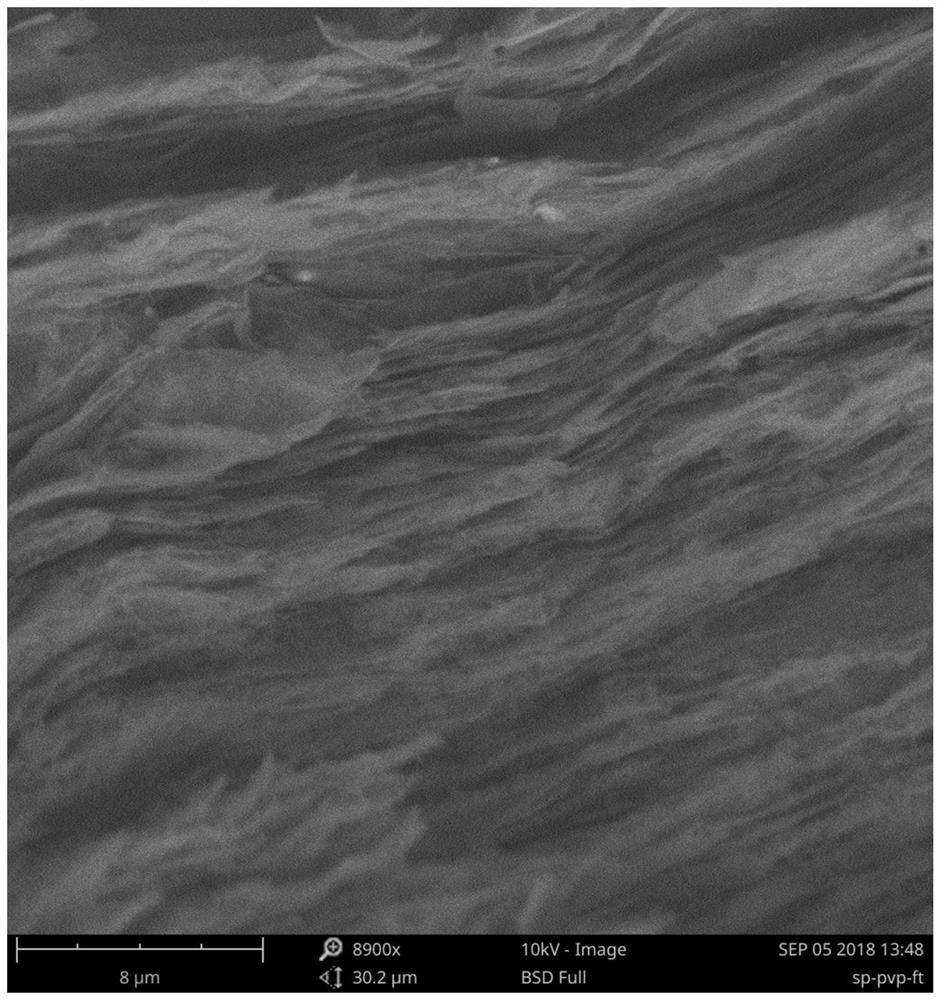

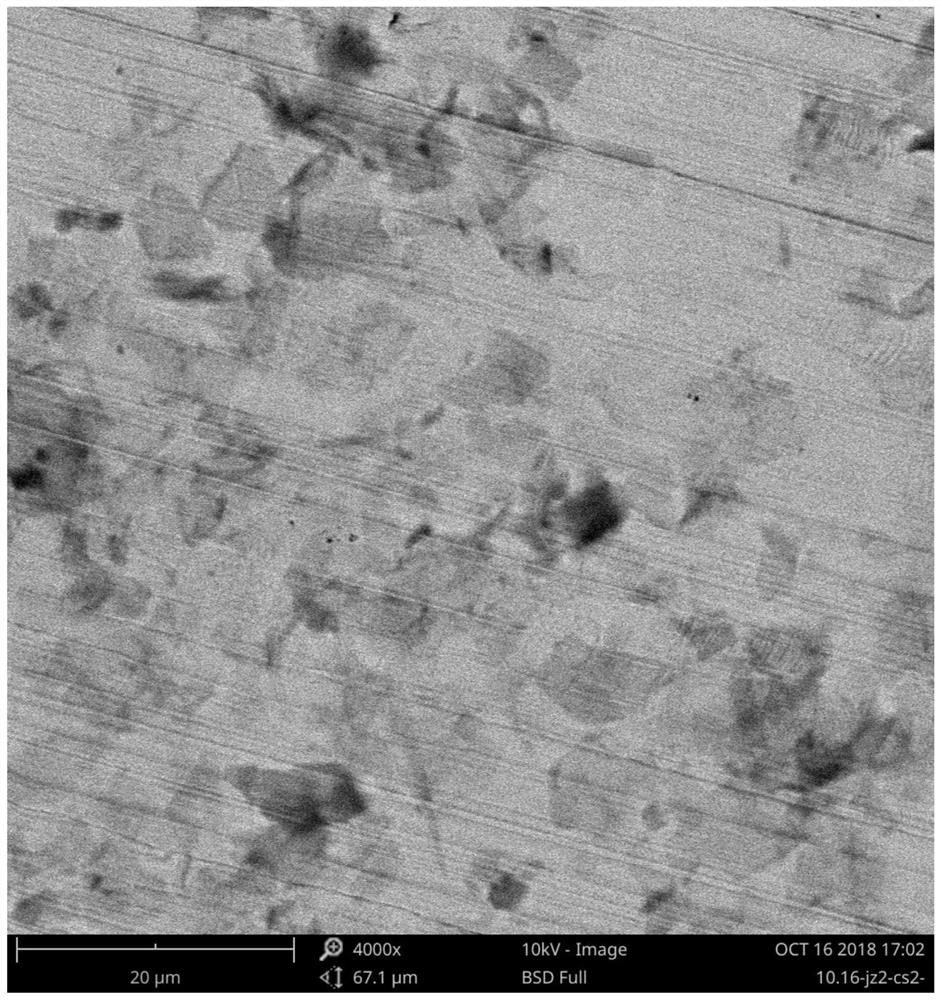

[0025] 1) Solid additive sandwich structure MoS 2 / Graphene / MoS 2 Preparation: Add molybdenum disulfide to the n-pentane solution in n-butyllithium and stir magnetically for 2h, wherein the molar ratio of molybdenum disulfide and n-butyllithium is 1:2; under the condition of inert argon atmosphere at room temperature, The above mixture was stirred for 5 days, washed with n-pentane solvent and dried under reduced pressure to obtain LiMoS 2 ; Then the LiMoS 2 Add deionized water, ultrasonic for 2h, to get LiMoS with exfoliated layers 2 ; CTAB was completely dissolved in deionized water (the mass ratio of the two was 1:5), and it was separated from the layer-exfoliated LiMoS 2 Thoroughly mixed and sonicated for 2h to form exfoliated LiMoS 2 -CTAs + solution; to the above LiMoS 2 -CTAs + Add the dispersion solution of graphene oxide (GO) into the solution, and continue to sonicate for 2h to form LiMoS 2 -CTAs + -GO solution; adding thiourea to the above LiMoS 2 -CTAs +-...

Embodiment 2

[0033] 1) Solid additive sandwich structure MoS 2 / Graphene / MoS 2 Preparation of molybdenum disulfide: add molybdenum disulfide to n-butane solution in lithium lactate and stir magnetically for 3h, wherein the molar ratio of molybdenum disulfide and lithium lactate is 1:2; The solution was stirred for 8 days, washed with n-butane solvent and dried under reduced pressure to obtain LiMoS 2 ; Then the LiMoS 2 Add deionized water, ultrasonic for 3h, to obtain LiMoS with exfoliated layers 2 ; CTAB was completely dissolved in deionized water (the mass ratio of the two was 1:5), and it was separated from the layer-exfoliated LiMoS 2 Thoroughly mixed and sonicated for 2h to form exfoliated LiMoS 2 -CTAs + solution; to the above LiMoS 2 -CTAs + Add the dispersion solution of graphene oxide (GO) into the solution, and continue to sonicate for 2h to form LiMoS 2 -CTAs + -GO solution; adding thiourea to the above LiMoS 2 -CTAs + -GO solution, transferred to the reactor at 180 °...

Embodiment 3

[0041] 1) Solid additive sandwich structure MoS 2 / Graphene / MoS 2 Preparation: Molybdenum disulfide was added to the isopropane solution in isopentyllithium and stirred magnetically for 3h, wherein the molar ratio of molybdenum disulfide and isopentyllithium was 1:2; under the condition of inert argon atmosphere at room temperature, The above mixture was stirred for 5 days, washed with isopropane solvent and dried under reduced pressure to obtain LiMoS 2 ; Then the LiMoS 2 Add deionized water, ultrasonic for 3h, to obtain LiMoS with exfoliated layers 2 ; CTAB was completely dissolved in deionized water (the mass ratio of the two was 1:5), and it was separated from the layer-exfoliated LiMoS 2 Thoroughly mixed and sonicated for 2h to form exfoliated LiMoS 2 -CTAs + solution; to the above LiMoS 2 -CTAs + Add the dispersion solution of graphene oxide (GO) into the solution, and continue to sonicate for 2h to form LiMoS 2 -CTAs + -GO solution; sodium borohydride was added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com