Method for preparing vacuum glass

A vacuum glass and glass technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems affecting the gelling property of low melting point sealing glass powder, the different pressure bearing capacity of vacuum glass surface, and the impact of vacuum glass Sealing and other issues, to achieve the effect of short heating time, uniform temperature change, and reduce production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

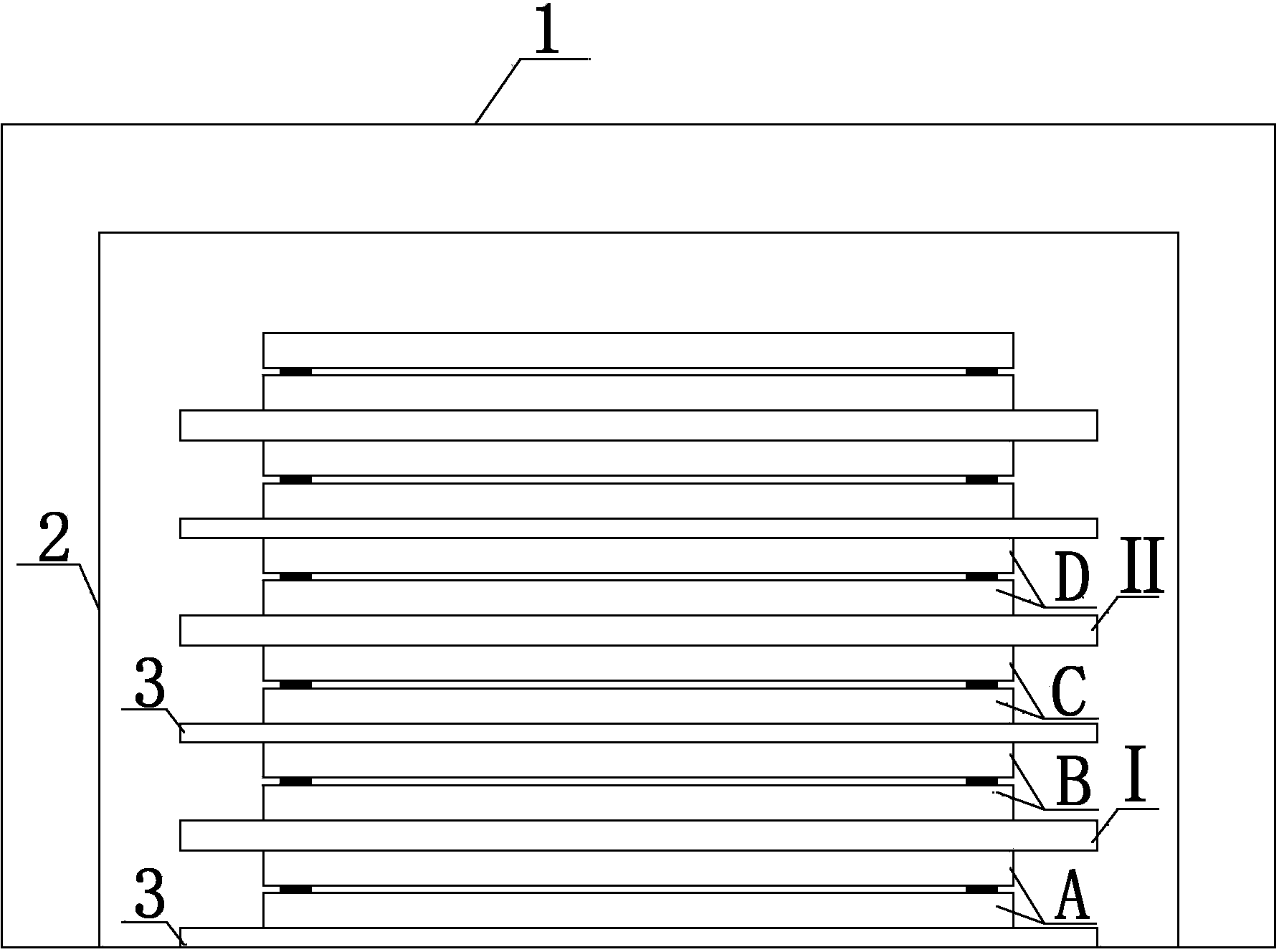

[0022] The method for preparing vacuum glass of the present invention includes the following steps:

[0023] The first step is to heat the glass to solidify the low melting point sealing glass powder: apply the low melting point sealing glass powder to the four edges of the glass sheet. The melting point of the low melting point sealing glass powder is 420~440℃; The glued glass sheet with melting point sealing glass powder is placed in a tempering furnace and heated to 650~750℃, and then heated continuously for 2~3min to melt the low melting point sealing glass powder into a gel shape, and then blow it to cool down. The melting point sealing glass powder is solidified on the glass. At the same time, during the blowing process, the upper surface of the solidified low-melting sealing glass glue forms concave and convex points that can play a supporting role. At the same time, the tempered glass becomes tempered glass . The glass after the above-mentioned treatment finally forms a ...

Embodiment 2

[0034] The difference from Example 1 is that in the first step of heating the glass, during the curing of the low-melting sealing glass powder, the low-melting sealing glass powder is applied to the four edges of the glass sheet, and at the same time along the already coated low-melting sealing glass The upper surface of the glass powder is then coated with low-melting sealing glass powder at intervals. The height of the low-melting sealing glass powder applied at intervals is higher than the upper surface of the low-melting sealing glass powder, and the glass sheet coated with the low-melting sealing glass powder is heated Heat to 420-480°C and heat for 20-30 minutes until the low melting point sealing glass powder is gelatinous, and then cooling to room temperature to solidify the low melting point sealing glass powder on the glass sheet. At this time, the low-melting-point sealing glass powder applied at intervals is cooled and solidified into a suction port between the two g...

Embodiment 3

[0037] The difference from Example 1 is that the non-glue glass sheet is replaced by a low-glue glass sheet, that is, there are a small amount of glue formed by low-melting sealing glass powder heated to a gel shape and then cooled and solidified at the four edges of the glass, which is heated and solidified The way is realized through the first step in Example 1. Compared with the glueless glass sheet, the adhesion between the less glued glass sheet and the glued glass sheet is better.

[0038] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com