Activated carbon treatment technology for organic wastewater

A technology of organic wastewater and treatment process, applied in the direction of adsorption water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve environmental pollution, waste of resources and other problems, achieve high degree of automation and fast heating speed , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

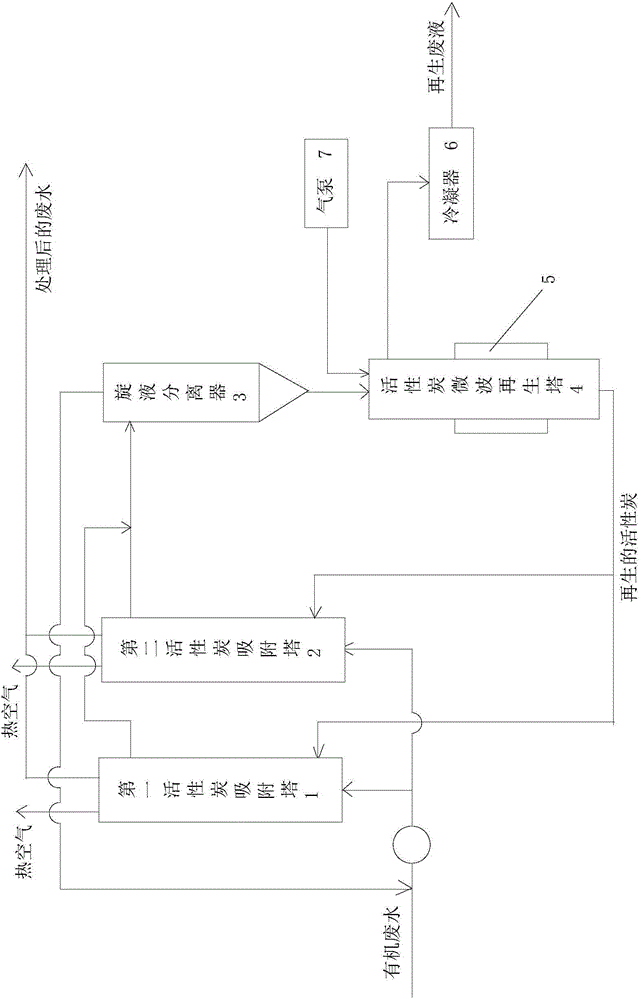

Image

Examples

Embodiment 1

[0023] The water output from the secondary settling tank of a domestic sewage treatment station, the water volume is 100m 3 / h, COD: 80~100mg / L, pumped into the first activated carbon adsorption tower 1 through the wastewater lifting pump, the contact time of the wastewater in the activated carbon tower is 5~7min, fully contact with the activated carbon so that the organic matter in it is loose and porous activated carbon Further adsorption and removal. The treated wastewater COD<50mg / L is discharged from the top of the adsorption tower and directly reused in the circulating cooling water system.

[0024] After 72 hours of adsorption, the activated carbon reached adsorption saturation and lost its adsorption function. Now, switch to the second activated carbon adsorption tower 2, and simultaneously the activated carbon adsorbed and saturated in the first activated carbon adsorption tower 1 is introduced into the hydrocyclone 3, and the dilute phase therein, that is, the organ...

Embodiment 2

[0028] A coking wastewater biochemical + MBR water production, water volume 50m 3 / h, COD: 200~350mg / L, TDS: about 3500mg / L, pumped into the first activated carbon adsorption tower 1 through the wastewater lift pump, the contact time of the wastewater in the activated carbon tower is 12~15min, fully contact with the activated carbon to make it The organic matter is further adsorbed and removed by the loose and porous activated carbon. The treated wastewater COD<60mg / L is discharged from the top of the adsorption tower and enters the subsequent advanced treatment unit.

[0029] After 36 hours of adsorption, the activated carbon reached adsorption saturation and lost its adsorption function. Now, switch to the second activated carbon adsorption tower 2, and simultaneously the activated carbon absorbed and saturated in the first activated carbon adsorption tower 1 is introduced into the hydrocyclone 3, and the dilute phase therein, that is, the organic waste water is refluxed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com