Patents

Literature

51results about How to "Realize online regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Online regeneration method of filter element of dust remover for filtering high-temperature combustible dust

InactiveCN103961954ARealize online regenerationImprove filtration efficiencyDispersed particle filtrationThermodynamicsProcess engineering

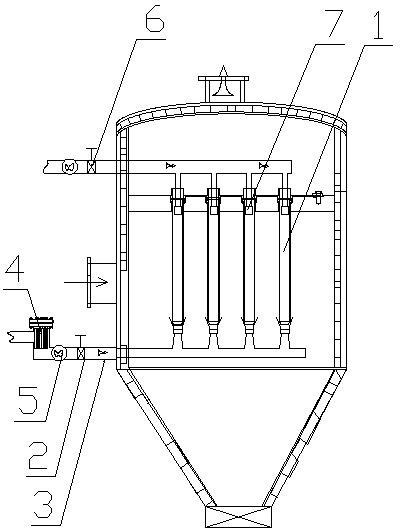

The invention discloses an online regeneration method of a filter element of a dust remover for filtering high-temperature combustible dust. The online regeneration method comprises a step of poor oxygen combustion of oxygen-poor gas sent to the outside of the filter element of the dust remover and combustible dust on the filter element of the dust remover. The oxygen content of the oxygen-poor gas is 2-17 percent, and the poor oxygen combustion step and a step of back-blow dedusting of the filter element of the dust remover are alternated. The method breaks through the limit of a traditional back-blow dedusting process, realizes online regeneration of the filter element by combination of a poor oxygen combustion technology and a back-blow dedusting measure, and can thoroughly clear blind angles of dust accumulation on the surface of the filter element so as to improve the filtering efficiency of the filter element and prolong the service life of the filter element. The online regeneration method has the advantages of being reasonable in design, low in cost and long in operation cycle, the filter element is high in regenerability and high in filtering efficiency and has good promotion and use values, equipment is safe and reliable, and the operation cost is reduced.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

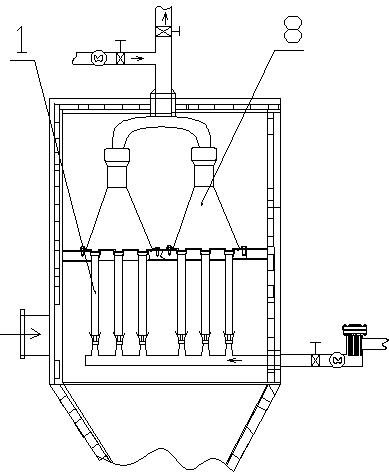

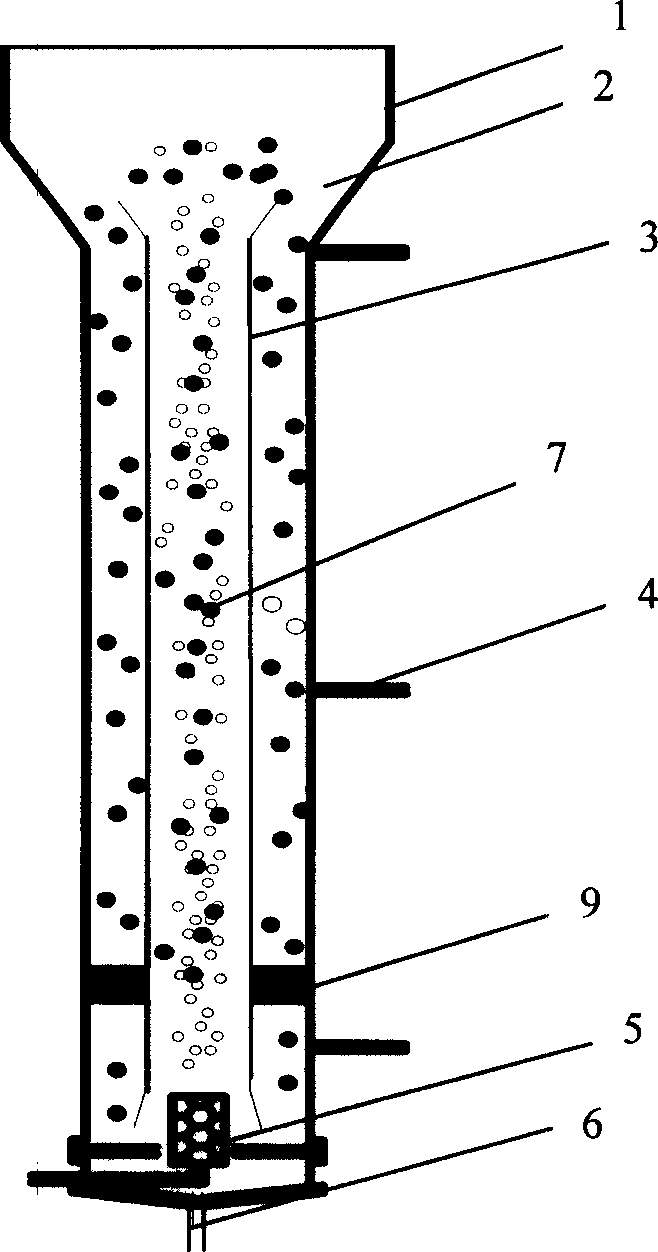

Device for treating organic wastewater by ozone and active carbon and method therefor

InactiveCN1884125ASimple methodSimple and efficient operationWater/sewage treatment by sorptionWater/sewage treatment by oxidationPollutantGrain shape

The invention discloses an organic waste water disposing device through ozone or activated carbon, which comprises the following parts: outer cylinder, circulating cylinder with the same shaft of outer cylinder, inlet on the bottom of outer cylinder, aerating device on the bottom of inner cylinder. The disposing method comprises the following steps: pumping organic waste water in the device from inlet; putting grain-shaped activated carbon in the device; inputting ozone gas; circulating to flow the activated carbon in the space of inner cylinder and outer cylinder pushed by ozone gas.

Owner:ZHEJIANG UNIV

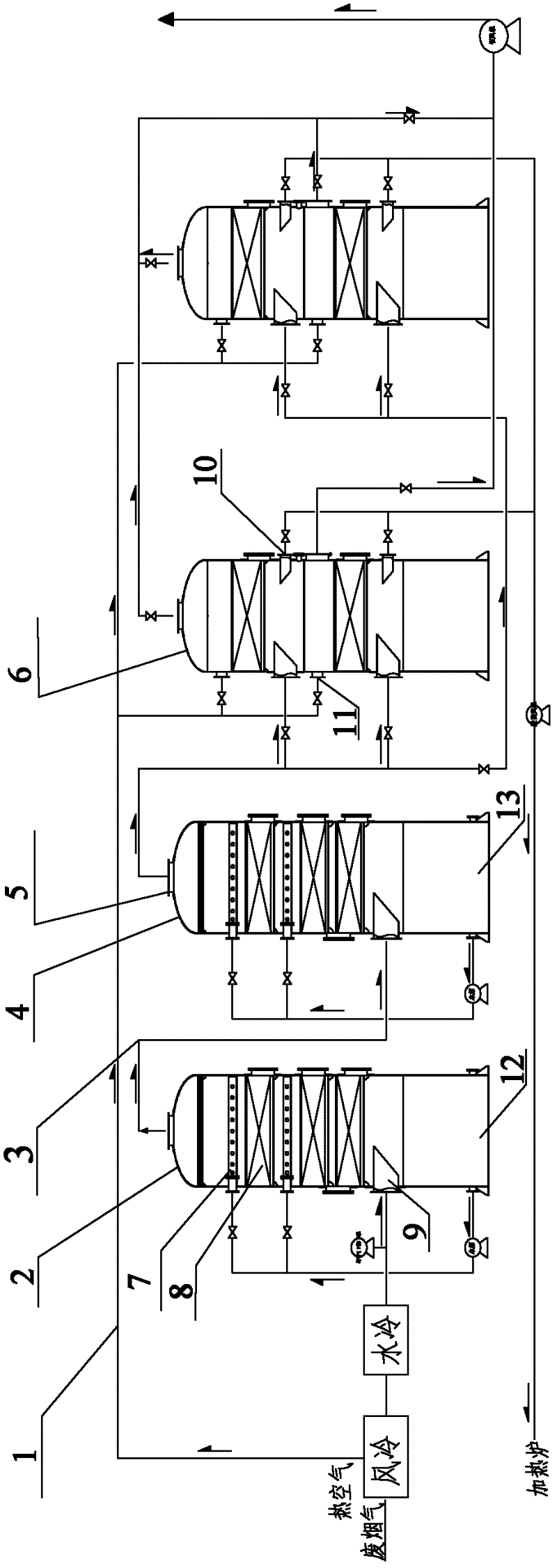

Waste rubber cracking gas purifying process and equipment thereof

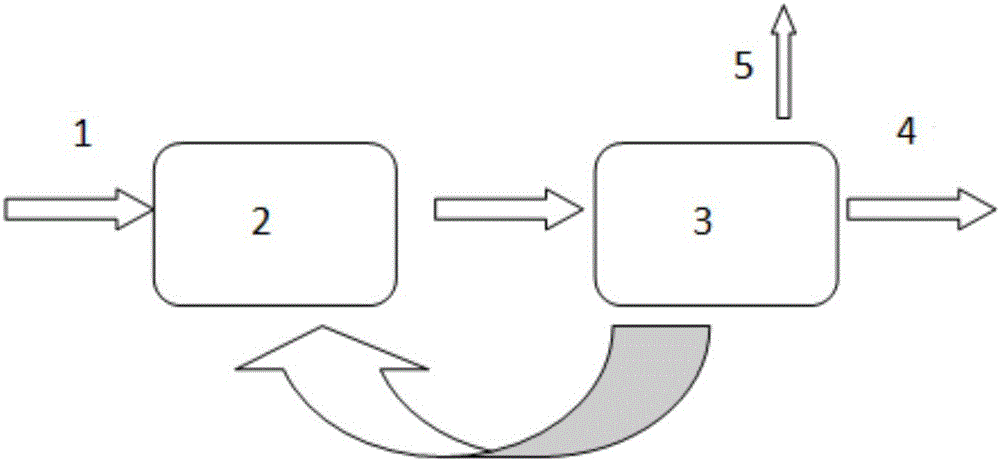

InactiveCN102380295AGuaranteed regenerationDoes not affect productionDispersed particle separationAcid washingWaste rubber

The invention belongs to the technical field of environmental protection, and in particular relates to a waste rubber cracking gas purifying process and equipment thereof. In the invention, a method combining acid washing, alkaline washing and physical adsorption is adopted so that the gas sequentially passes through a condenser, an acid washing tower, an alkaline washing tower and a physical adsorption tower through a pipeline to be purified, and online regeneration of a filler is realized. Through the invention, the purifying efficiency is high, the filler can be recycled, and efficient continuous purification is realized.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

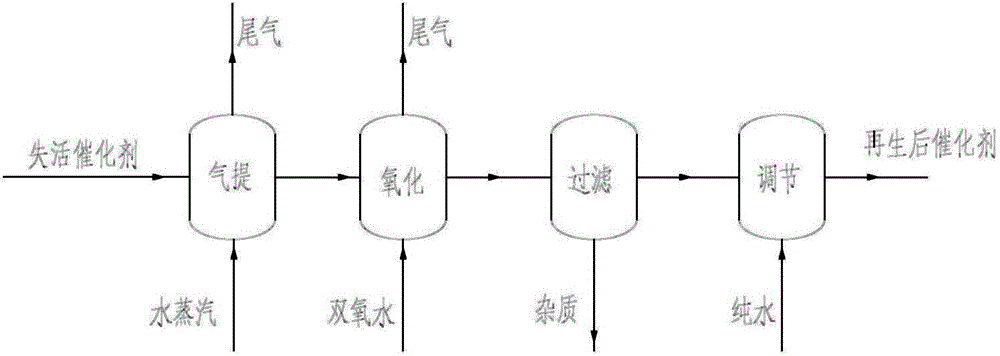

Regeneration method of cyclohexene hydration catalyst

ActiveCN102872910AAchieve regenerationRealize online regenerationMolecular sieve catalystsPreparation by hydroxy group additionChemistryMolecular sieve

The invention relates to a regeneration method of a cyclohexene hydration catalyst. The regeneration method includes steps that: molecular sieve catalyst water solution with activity reduced in a cyclohexene hydration reaction is subjected to gas stripping so as to remove entrained organics, the catalyst solution is subjected to oxidization for further oil removing, and the catalyst with oil removed is subjected to filtering for impurity removing and harmonious stabilizing. The activity of the catalyst obtained after the steps is restored in the maximum limit, and the catalyst is directly sent back to a hydration reaction system by a pump for cycle use. The regeneration method of the cyclohexene hydration catalyst enables the catalyst activity to restore to be above 95% of the initial activity, and achieves online regeneration of the catalyst when the catalyst is in the slurry state same as that in a reactor.

Owner:CHINA TIANCHEN ENG +3

Catalyst for removing low-concentration formaldehyde in gases and application thereof

InactiveCN102000603AReduce energy consumptionIncrease storage capacityMolecular sieve catalystsDispersed particle separationMolecular sieveCarbon dioxide

The invention belongs to the technical field of gas purification treatment, relating to a catalyst for removing low-concentration formaldehyde in gases and the application thereof. The catalyst is characterized by using at least two of Ag, Co, Fe and Cu as main active components which are loaded on an HZSM-5 type molecular sieve carrier and are 1-20 percent by weight of the catalyst. The catalyst is filled in a reactor and applied to two alternately operating stages, i.e. a storage stage and a regeneration stage, wherein the reactor can be inflated with ozone, can be used for heating at a controlled temperature and can carry out DBD (Dielectric Barrier Discharges). At the storage stage, low-concentration formaldehyde in the gases is firstly stored on the catalyst; and at the regeneration stage, ozone or oxygen-contained gas is introduced for heating or carrying out the DBD so that the formaldehyde stored on the catalyst is fully oxidized into carbon dioxide and water, wherein the oxygen content in the introduced oxygen-contained gas at the regeneration stage is 20-100 percent, and air can be directly used as the oxygen-contained gas at the regeneration stage. In the invention, the provided catalyst with the function of selective storing and catalytic oxidation on the formaldehyde has the advantages of low energy consumption and no secondary pollution, is extremely suitable for removing low-concentration formaldehyde in gases and is particularly suitable for removing formaldehyde pollutants in indoor air.

Owner:DALIAN UNIV OF TECH

SCR flue gas denitration device with various adjustment functions

PendingCN108854531ALower inlet flue gas temperatureImprove adaptabilityGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses an SCR flue gas denitration device with various adjustment functions, comprising a denitration inlet flue having a plurality of sub-flues separated by flue partition boards, each sub-flue being provided with an independent flue baffle; a denitration reactor, arranged after the denitration inlet flue, provided with a plurality of layers of denitration catalysts, and having aplurality of parallel sub-zones separated by reactor partition boards, the number of the sub-zones being the same as the number of the sub-flues and the sub-zones correspondingly being connected to the sub-flues; an ammonia-spraying unit having a plurality of sub-ammonia-spraying units for respectively spraying ammonia to the plurality of sub-flues, the sub-ammonia-spraying units being located before the flue baffle; and a flue gas temperature regulation unit having a plurality of sub-air-distribution units for air distribution and temperature adjustment to the plurality of sub-flues, respectively, the sub-air-distribution units being located after the flue baffle. The inlet flue gas temperature of the denitration device provided by the invention can be flexibly adjusted, so as to realizeon-line regeneration and replacement of a catalyst and perform zoned adjustment and control on the denitration device.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Immobilized cultivation method for 'microbiological straw additive'

InactiveCN101659951AFully activeImprove operational stabilityOn/in organic carrierMicroorganismPolyvinyl alcohol

The invention discloses an immobilized cultivation method for 'microbiological straw additive', which comprises the following steps: mixing an activated 'microbiological straw additive' bacterial agent with an immobilized embedded carrier (mixture of 8 percent polyvinyl alcohol and 2 percent sodium alginate in a volume ratio of 0.6 to 1.4) in a volume ratio of 1 to 1, then dropping an embedding agent mixed with bacteria into the sterilized 0.2M CaCl2 solution in a super clean bench by using a medical injector of 10 milliliters and a matched needle, controlling the dropping speed, forming granules to embed the mixed bacterial agent therein, soaking the granules in the CaCl2 solution, flushing the granules by sterile water, and adding a proliferation culture medium into the solution to carryout timing cultivation. The method can fully exert the activity of strains, improve the tolerance of the strains, improve the operation stability of the bacterial agent production, simplify the operation process, simplify the reclamation problem of microbe at the later stage of the reaction, reduce the production cost and labor intensity, fully exert the advantages of microbe reaction, realize on-line regeneration of the microbe, and ensure the feasibility of the process.

Owner:天津市农业科学院

Waste-gas denitration device and method

ActiveCN105854527AImprove removal effectLow equipment requirementsNitrous oxide captureGas treatmentNitrogen gasReduced nitrogen

The invention discloses a waste-gas denitration device. The waste-gas denitration device comprises a waste-gas absorption device and a waste-gas removing device. The waste-gas absorption device is a spraying tower or a bubble tower. The waste-gas removing device is an electrochemistry device which is of an integrated structure, and comprises negative poles, positive poles and a reaction channel; the negative poles are negative-pole three-dimensional electrodes, and the negative poles and the positive poles are arranged in scroll shapes; a water inlet channel is formed in one side of the electrochemistry device, a water outlet channel is formed in the other corresponding side of the electrochemistry device, a gas exhausting hole is formed in the upper portion of the electrochemistry device, electric fields are externally added on the negative poles and the positive poles, absorption liquid in the electrochemistry device is regenerated, and meanwhile nitrogen oxide in waste gas is reduced nitrogen. According to the waste-gas denitration device, nitrogen oxide in the waste gas is absorbed and removed through the absorption liquid, the absorption liquid can be efficiently regenerated, and is continuously cycled in a waste-gas denitration system, and the stable and efficient effect on removing NO in the waste gas is achieved; the high temperature, the mild reaction condition and the like are not required, cost is saved, the storage volume of the absorption liquid is reduced, the device space is saved, and zero pollution to the environment is achieved.

Owner:QINGDAO HEADWAY TECH

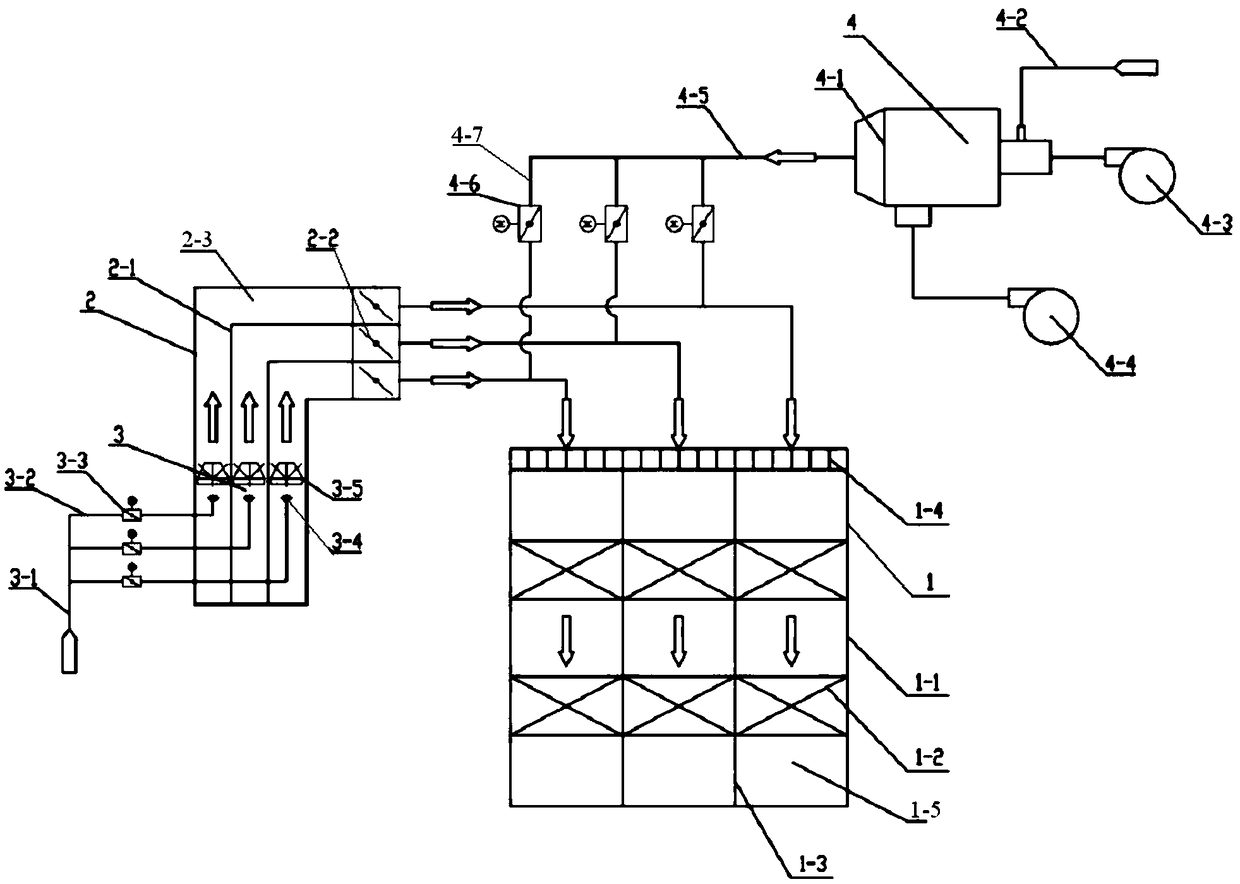

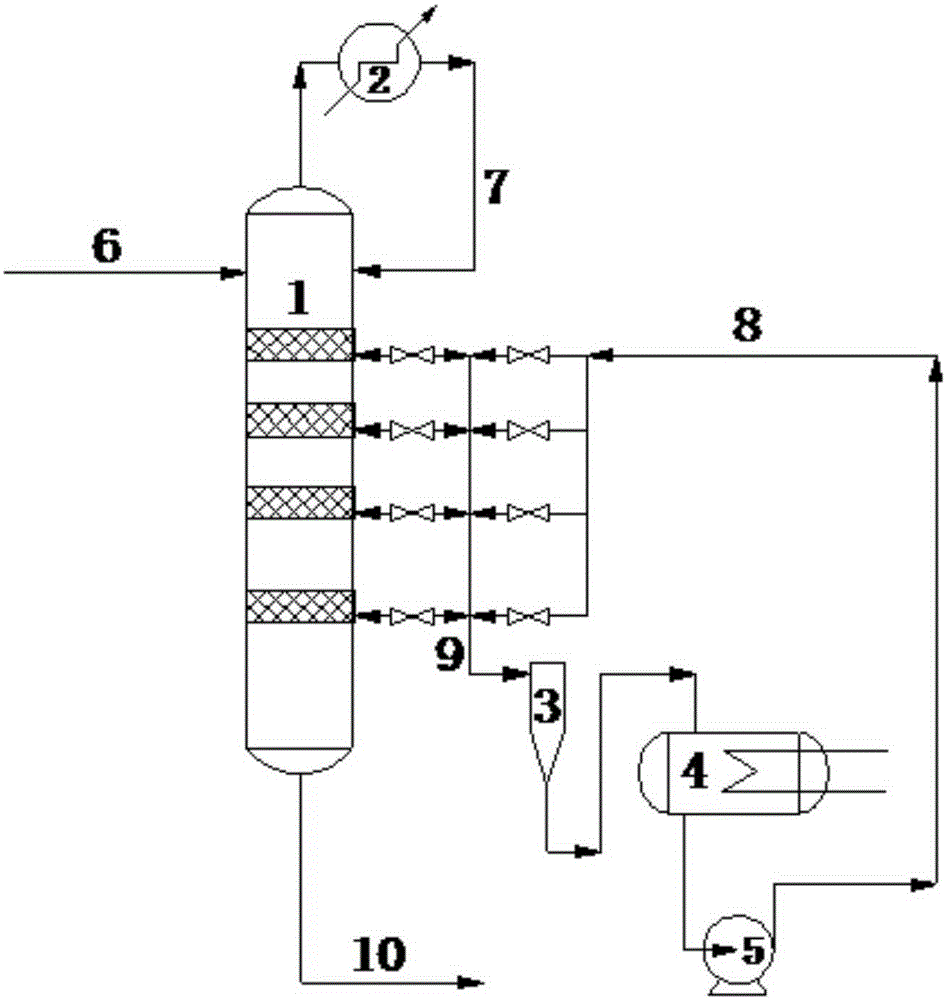

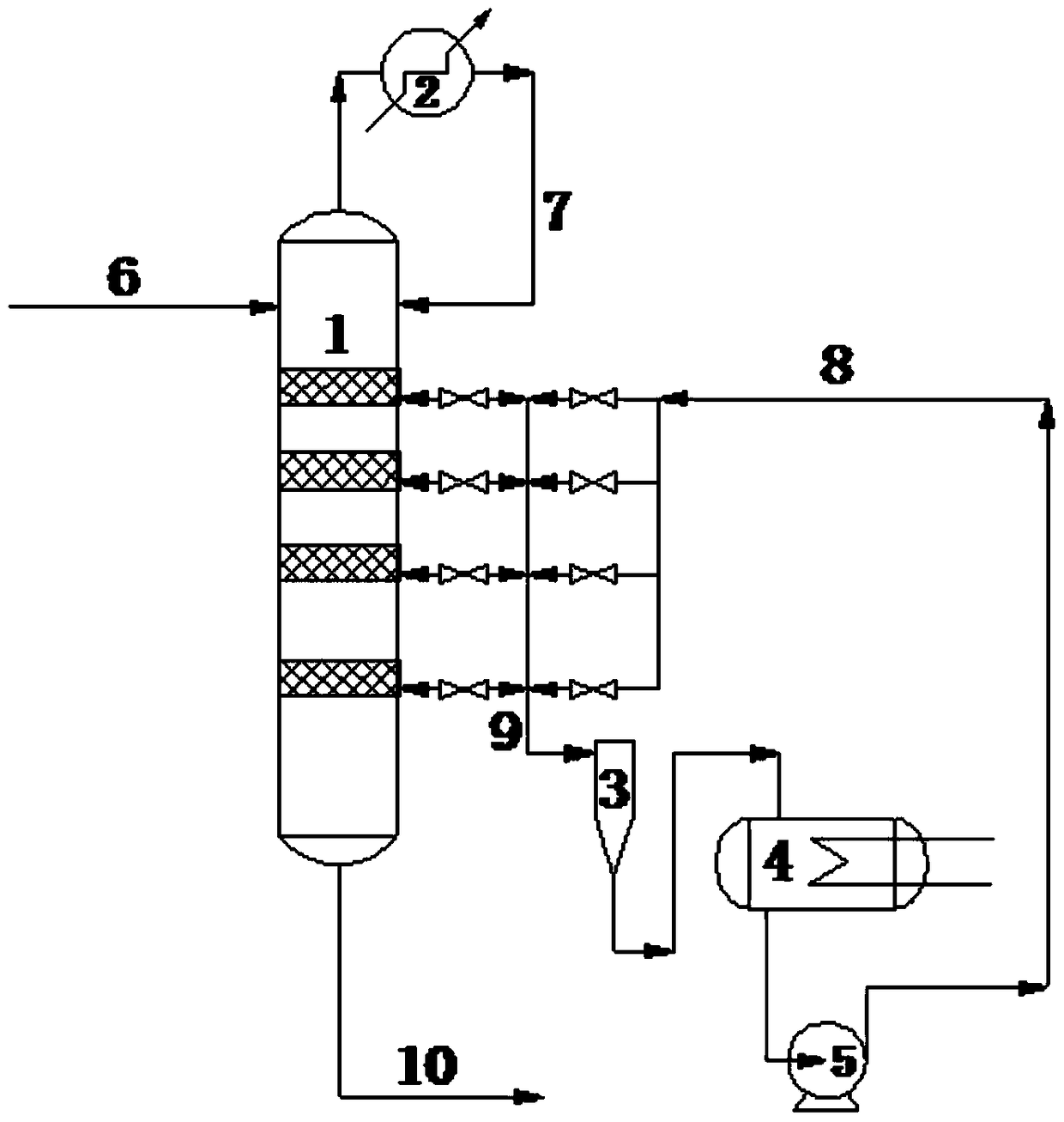

Method for preparing phenol-acetone through movable bed reactor

ActiveCN105218304ARealize online regenerationRealize online replacementOxygen-containing compound preparationOrganic compound preparationChemistryChemical decomposition

The invention relates to a method for preparing phenol-acetone through a movable bed reactor. The method mainly solves the problem that in the prior art, selectivity of phenol and acetone is low. According to the technical scheme, a CHP raw material (6) enters the top of the movable bed reactor (1) to make contact with a solid catalyst, a decomposition reaction is conducted, a large amount of heat is dissipated, liquid-phase acetone is evaporated into gas-phase acetone (7) to be discharged out of the top of the movable bed reactor (1), the discharged gas-phase acetone (7) is condensed into the liquid-phase acetone in a condenser (2) on the top of the reactor, the liquid-phase acetone is returned to the inner portion of the movable bed reactor (1), a reaction product (10) containing phenol and acetone is discharged out of the bottom of the movable bed reactor (1), and therefore the problems are solved, and the method can be used for preparing phenol-acetone.

Owner:SINOPEC SHANGHAI ENG +1

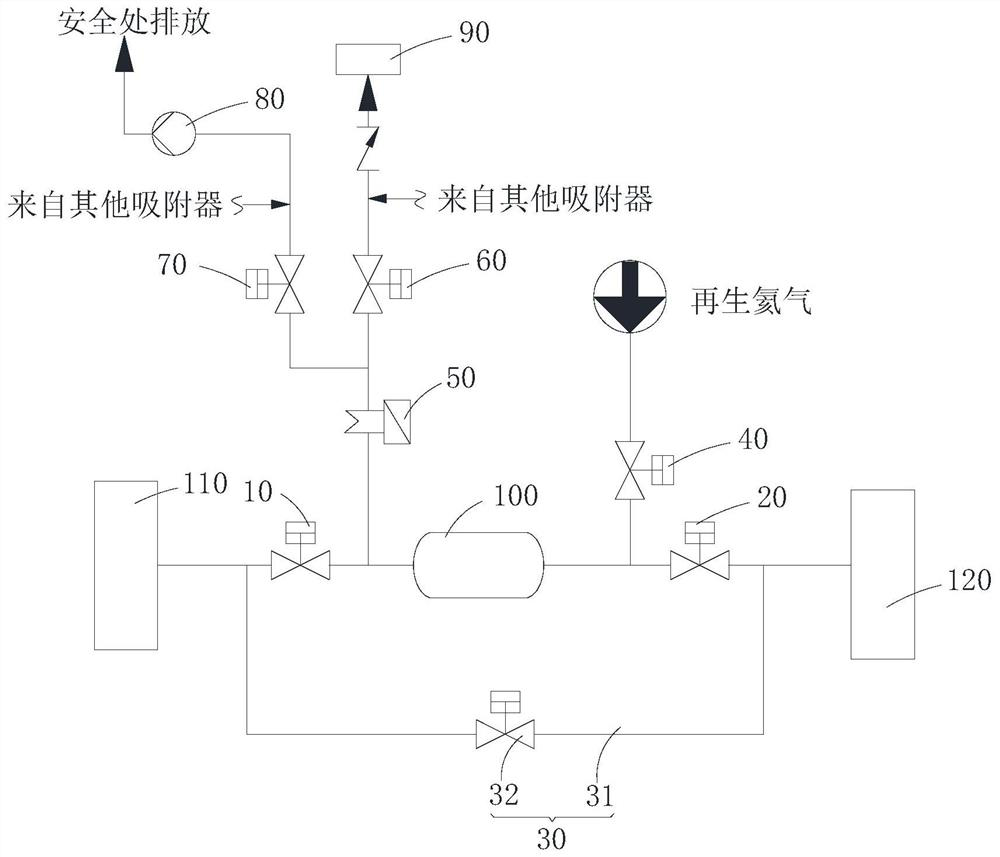

Online regeneration system

ActiveCN113731107ARealize online regenerationReduce complexityDispersed particle separationInlet valveEngineering

The invention is suitable for the field of helium refrigeration, and discloses an online regeneration system. The online regeneration system comprises an adsorber bypass used for being connected with an adsorber in parallel, an adsorber gas inlet valve, an adsorber gas outlet valve, a regenerated gas inlet valve arranged between the adsorber and the adsorber gas outlet valve, a rewarming heater arranged between the adsorber gas inlet valve and the adsorber, a vacuum pump and a tail gas recovery device which are respectively connected with a gas outlet of the rewarming heater, a regenerated gas discharge valve, a tail gas recovery valve, a first pressure sensor which is used for measuring the internal pressure of the adsorber, a second pressure sensor is used for measuring the pressure at the inlet side of the vacuum pump; a first temperature sensor which is used for measuring the temperature of the adsorber, a second temperature sensor which is used for measuring the temperature of the tail gas at the outlet side of the rewarming heater; wherein the adsorber gas inlet valve, the adsorber gas outlet valve and the adsorber bypass are arranged in a cold box, and other parts are arranged outside the cold box, so that the number of equipment in the cold box and the complexity of a pipeline system are reduced.

Owner:北京中科富海低温科技有限公司

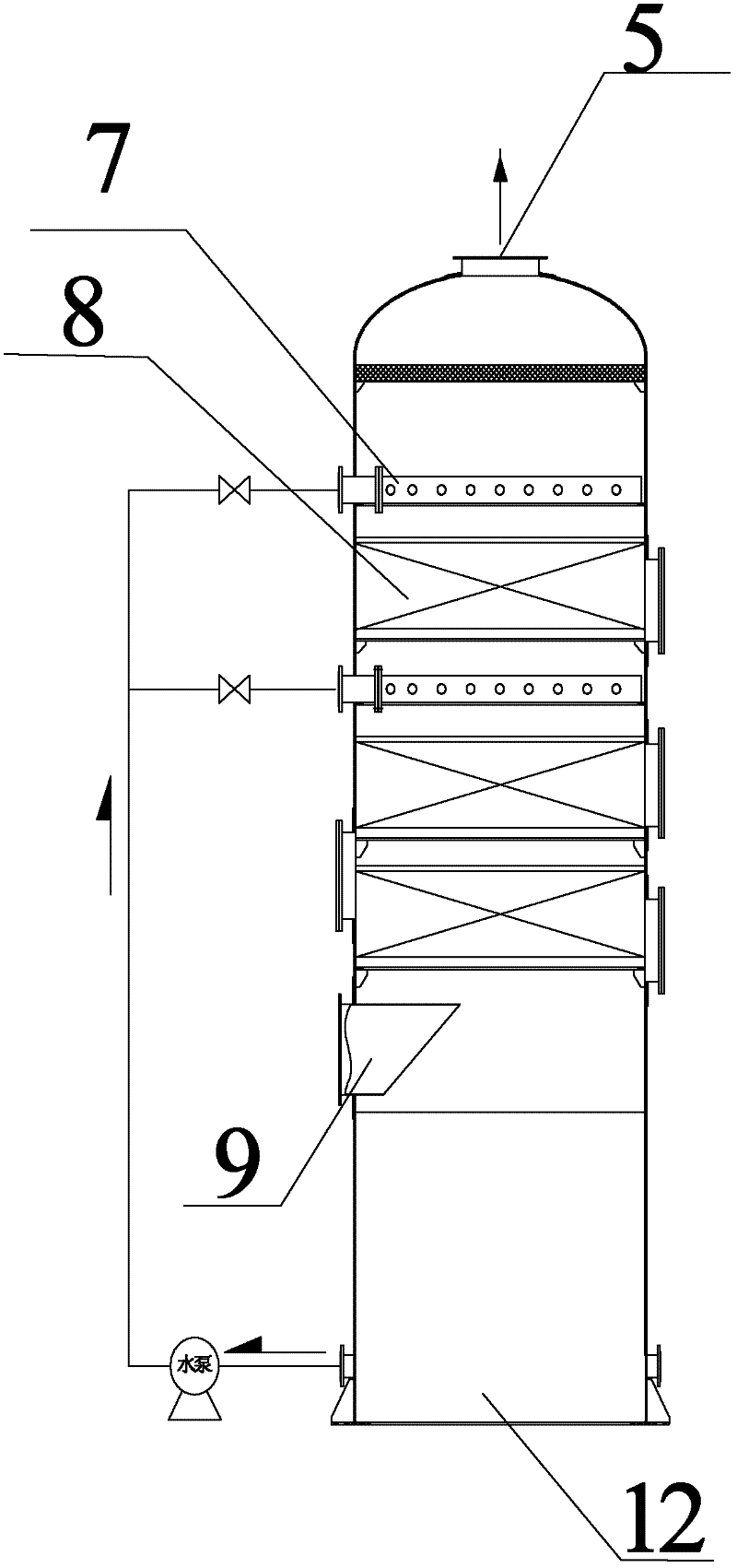

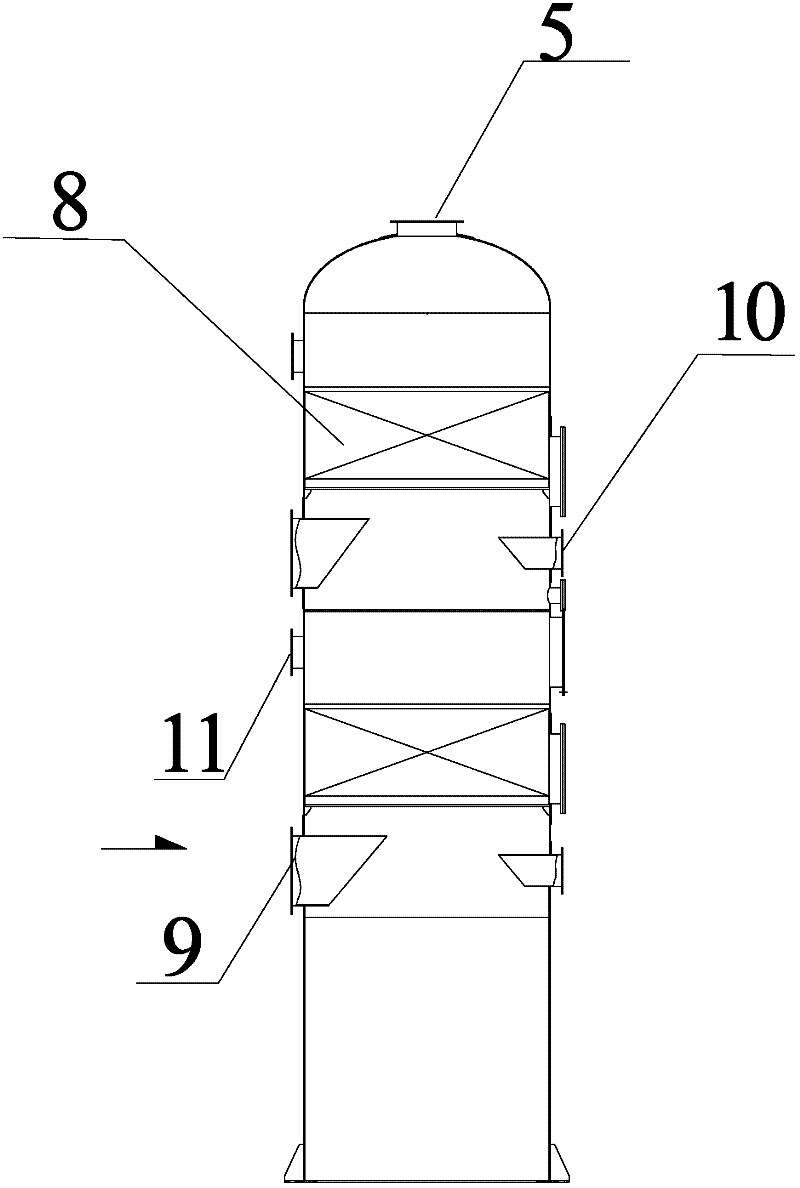

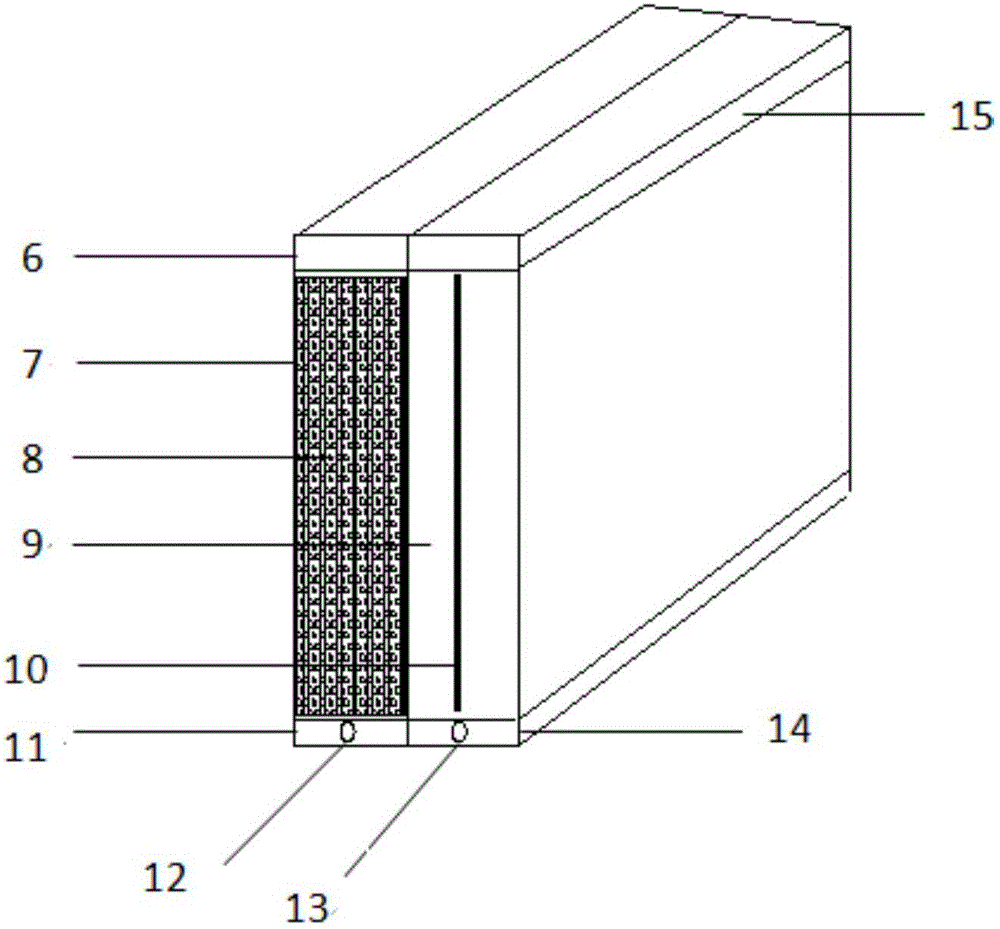

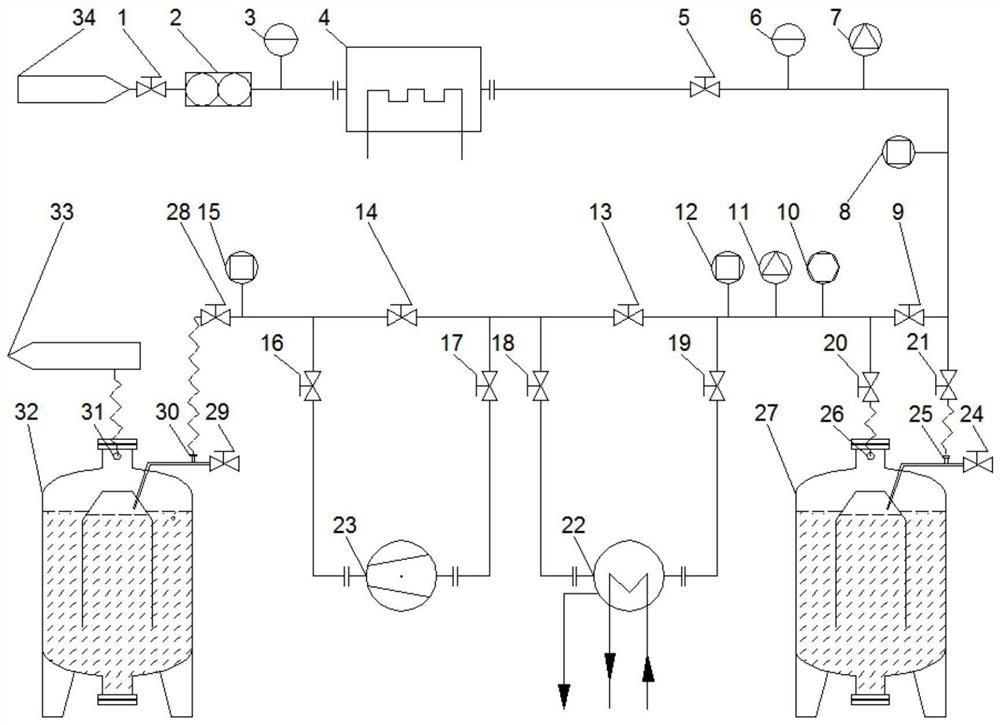

Online-renewable biogas dry-process desulfurizing device and method

ActiveCN108421400AExtend the lifespanSave desulfurizer costDispersed particle separationGaseous fuelsBiogasAir flow meter

The invention relates to an online-renewable biogas dry-process desulfurizing device which comprises a dry-type desulfurizing tower body, an online regeneration device and a PLC. The online regeneration device comprises an air incoming pipe communicated with a biogas incoming pipe and a plurality of electronic thermometers, the inlet end of the air incoming pipe is connected with an air compressor, an air flowmeter, an electric adjusting valve and an air one-way valve are sequentially arranged on the air incoming pipe, the electronic thermometers are arranged at different positions of a desulfurizing agent filling area, and a biogas flowmeter, a gas detector, the air flowmeter, the electric adjusting valve, the electronic thermometers and the air compressor are connected with the PLC. Thebiogas dry-process desulfurizing device realizes online regeneration of a ferric oxide desulfurizing agent therein, prolongs service life of the desulfurizing agent for 3-4 times, saves expense of thedesulfurizing agent, realizes automatic running, avoids safety risk caused by improper operation and adds a guarantee for biogas utilization.

Owner:华夏碧水环保科技股份有限公司

Regeneration method of inactivated COS hydrolytic agent

ActiveCN111729692ARealize online regenerationAchieve recyclingCatalyst regeneration/reactivationPtru catalystEnvironmental engineering

The invention relates to the technical field of regeneration of deactivated catalysts, in particular to a regeneration method of a deactivated COS hydrolytic agent. The regeneration method of the inactivated COS hydrolytic agent comprises the following steps: under the atmosphere of reducing gas, carrying out primary heating and heat preservation on the inactivated COS hydrolytic agent to obtain afirst regenerated COS hydrolytic agent; and maintaining the atmosphere of the reducing gas, carrying out secondary heating on the first regenerated COS hydrolytic agent, introducing carbon dioxide gas containing saturated steam into the atmosphere of the reducing gas, and carrying out heat preservation at a secondary heating temperature to obtain the regenerated COS hydrolytic agent. The regeneration method of the inactivated COS hydrolytic agent provided by the invention is a green regeneration method which does not need to be washed by a solution, does not add an active component additive and can effectively save the regeneration period.

Owner:中琉科技有限公司

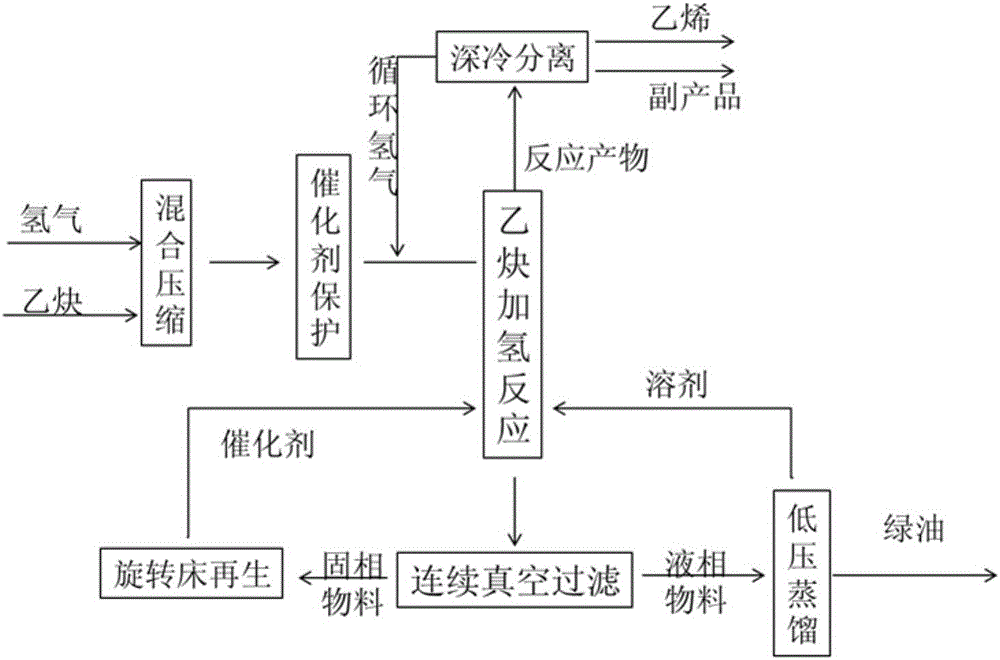

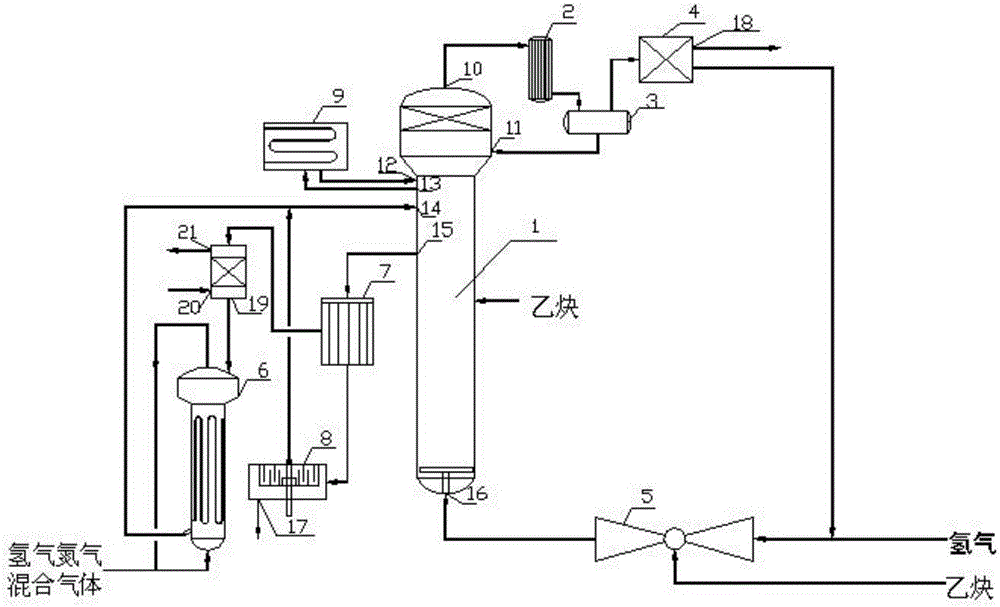

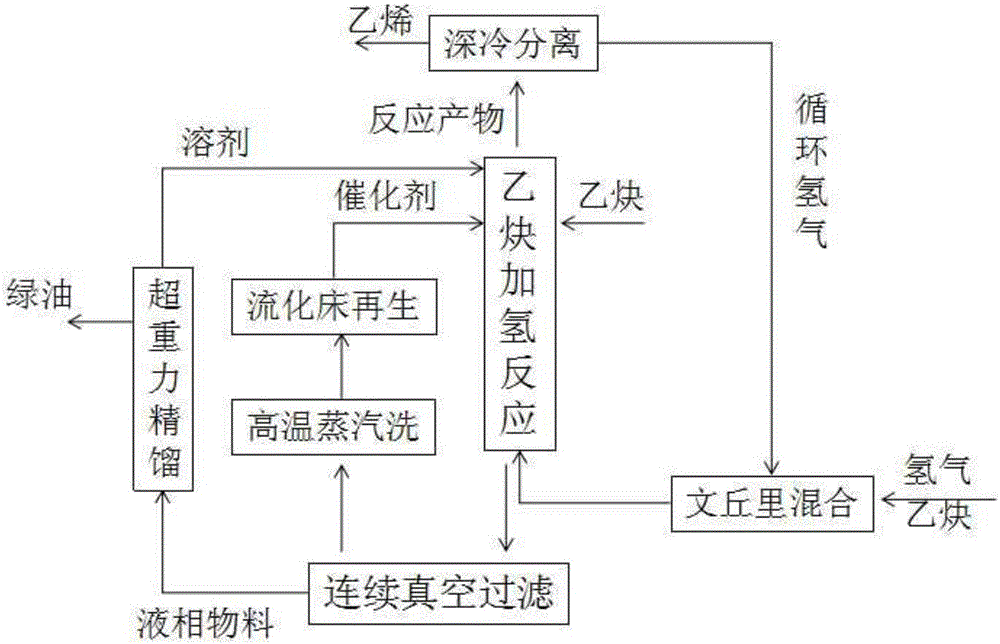

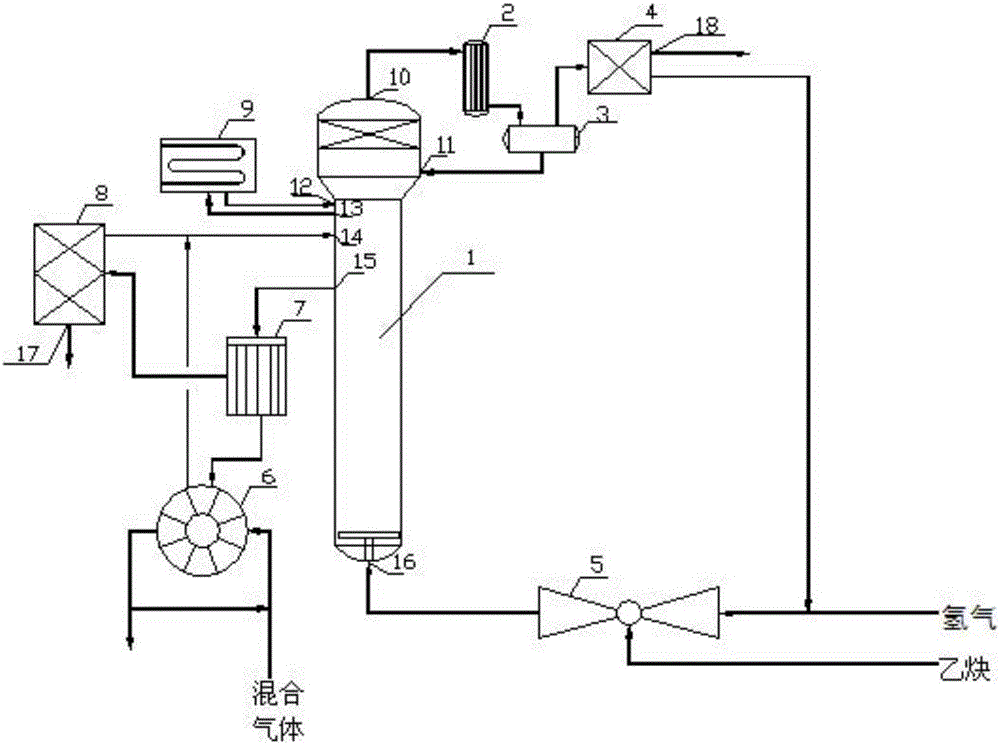

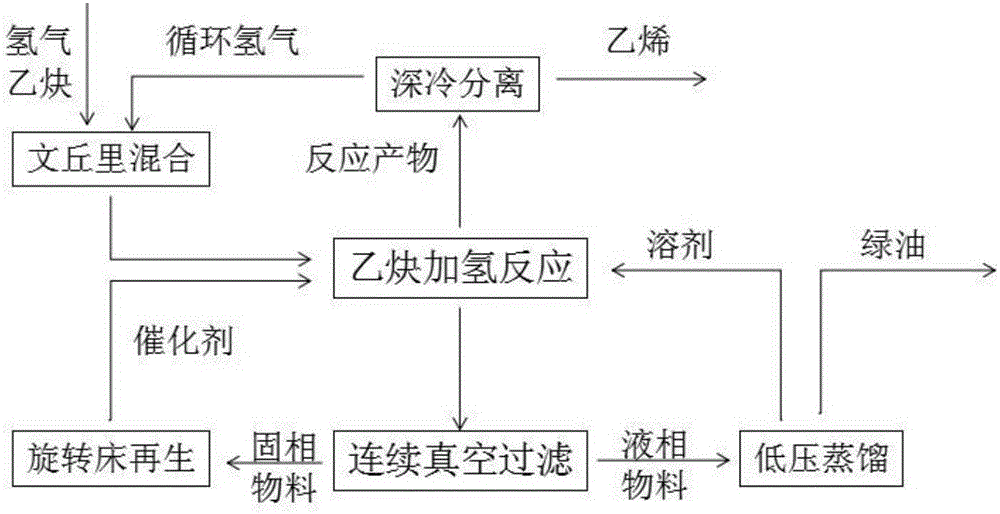

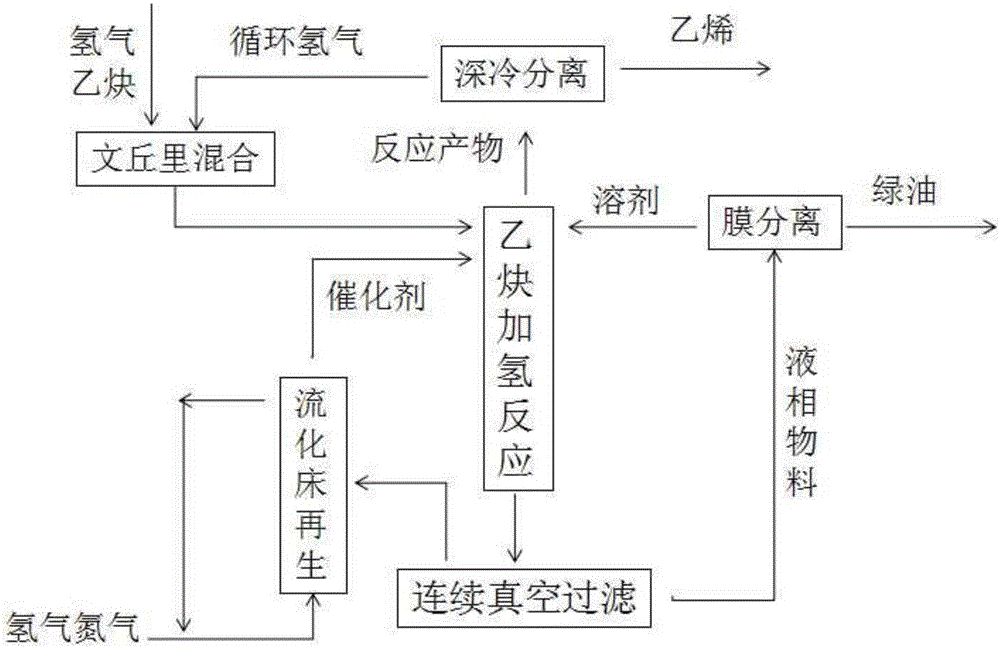

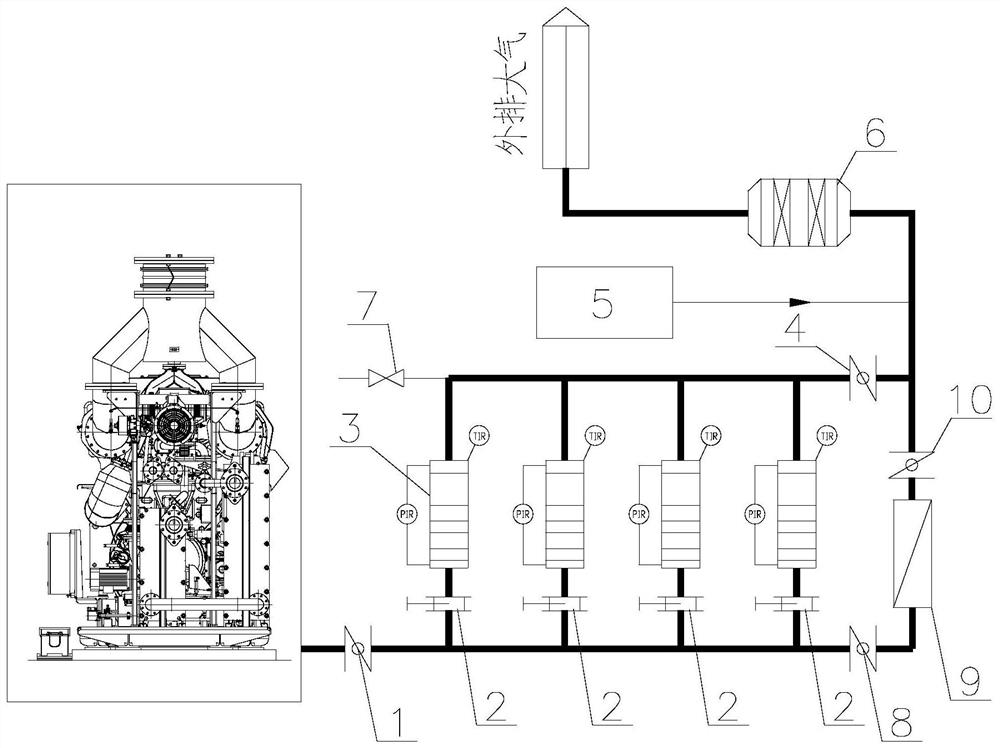

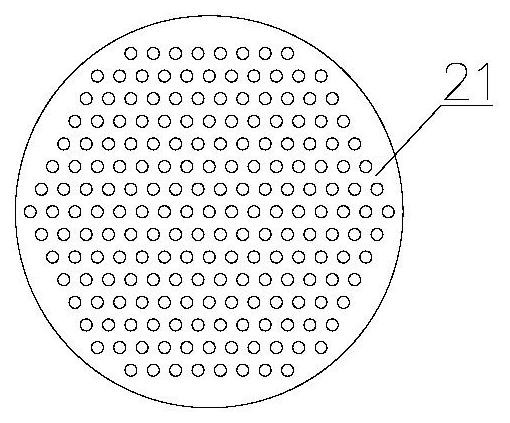

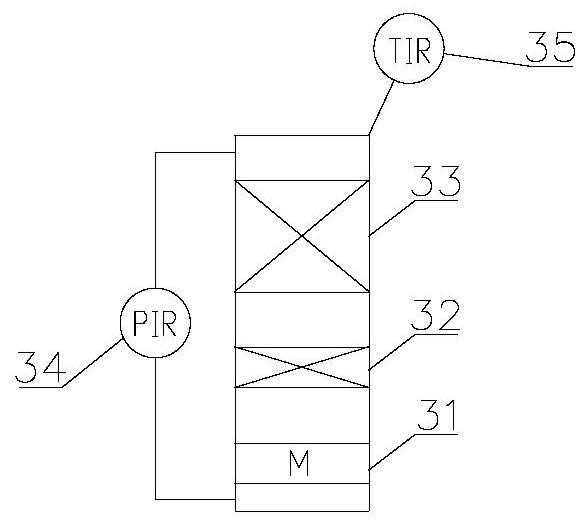

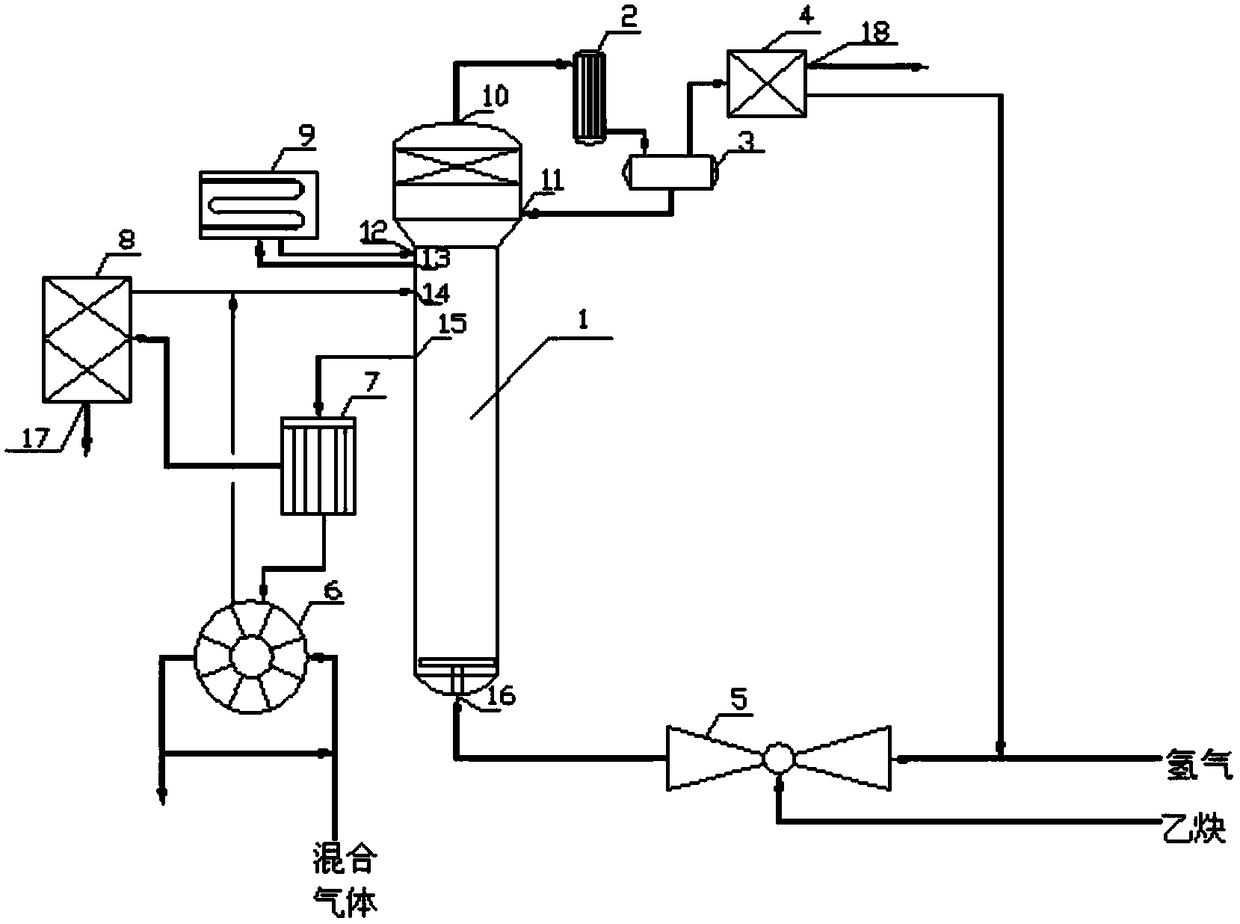

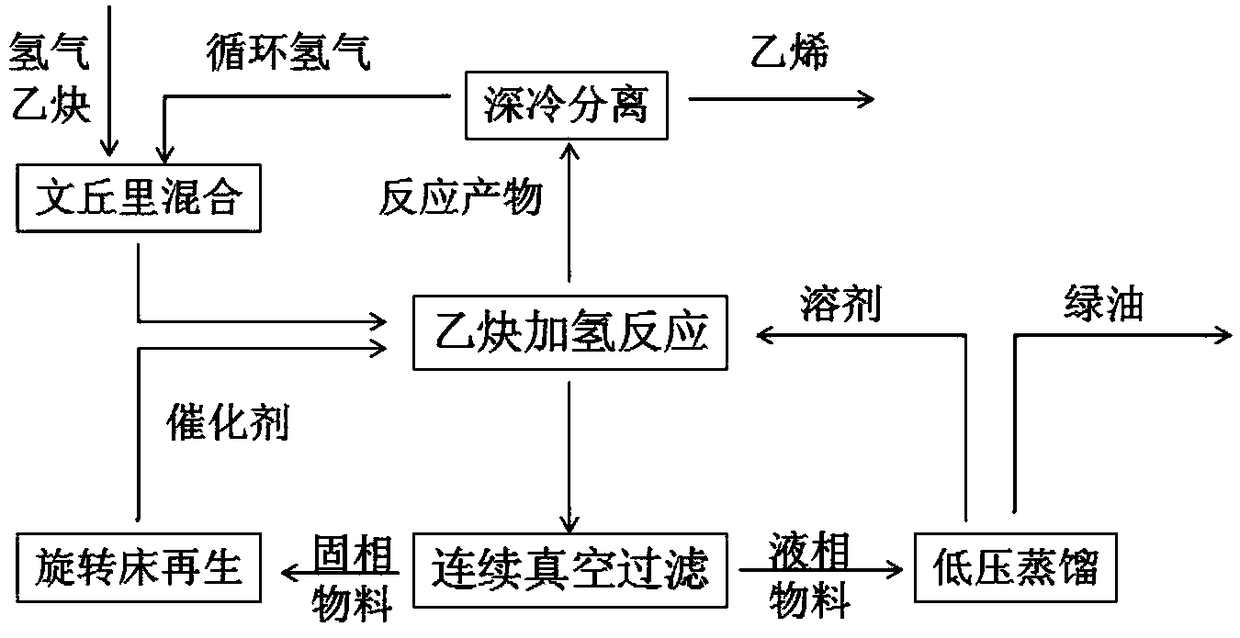

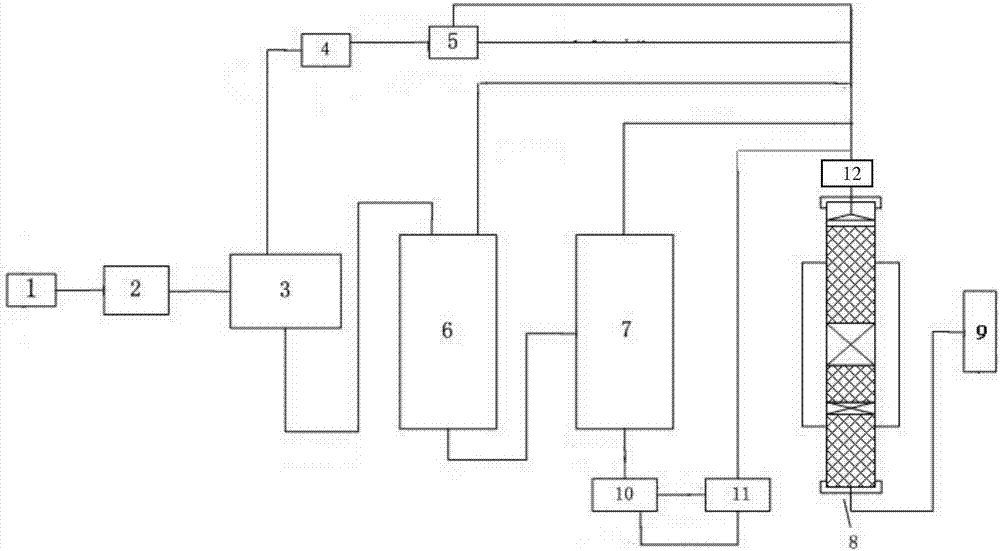

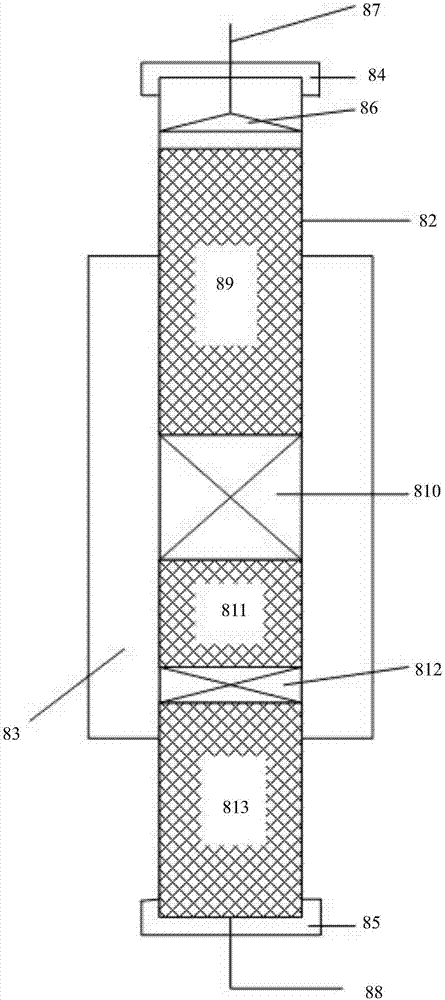

System and method for preparing ethylene through acetylene hydrogenation

PendingCN106631674AAvoid overheatingOvercoming VulnerabilityHydrocarbon by hydrogenationChemical recyclingSlurry reactorDistillation

The invention relates to a system and a method for preparing ethylene through acetylene hydrogenation. The system comprises a mixed pressure increasing unit, a catalyst protection unit, a hydrogenation reaction unit, a cryogenic separation unit, a vacuum filtration unit, a revolving bed generation unit and a vacuum low-pressure distillation unit. The method comprises steps as follows: acetylene and hydrogen are mixed under increased pressure; feed gases obtained after mixing are sequentially introduced into the catalyst protection unit and the hydrogenation reaction unit for a reaction; gaseous products obtained after the reaction are separated, a product ethylene, byproducts and surplus hydrogen are obtained, and the surplus hydrogen is sent to the reaction unit; slurry in a slurry reactor is led out and separated by the vacuum filtration unit, and a solid-phase material and a liquid-phase material are obtained; the solid-phase material is treated by the revolving bed generation unit, and a regenerated catalyst is obtained; the liquid-phase material is treated by the vacuum low-pressure distillation unit, and a solvent is recovered. The system and the method have the advantages as follows: operating flexibility is high, energy consumption of a compressor is low, the service life of the catalyst is long and the adaptive capacity is high.

Owner:SHENWU TECH GRP CO LTD

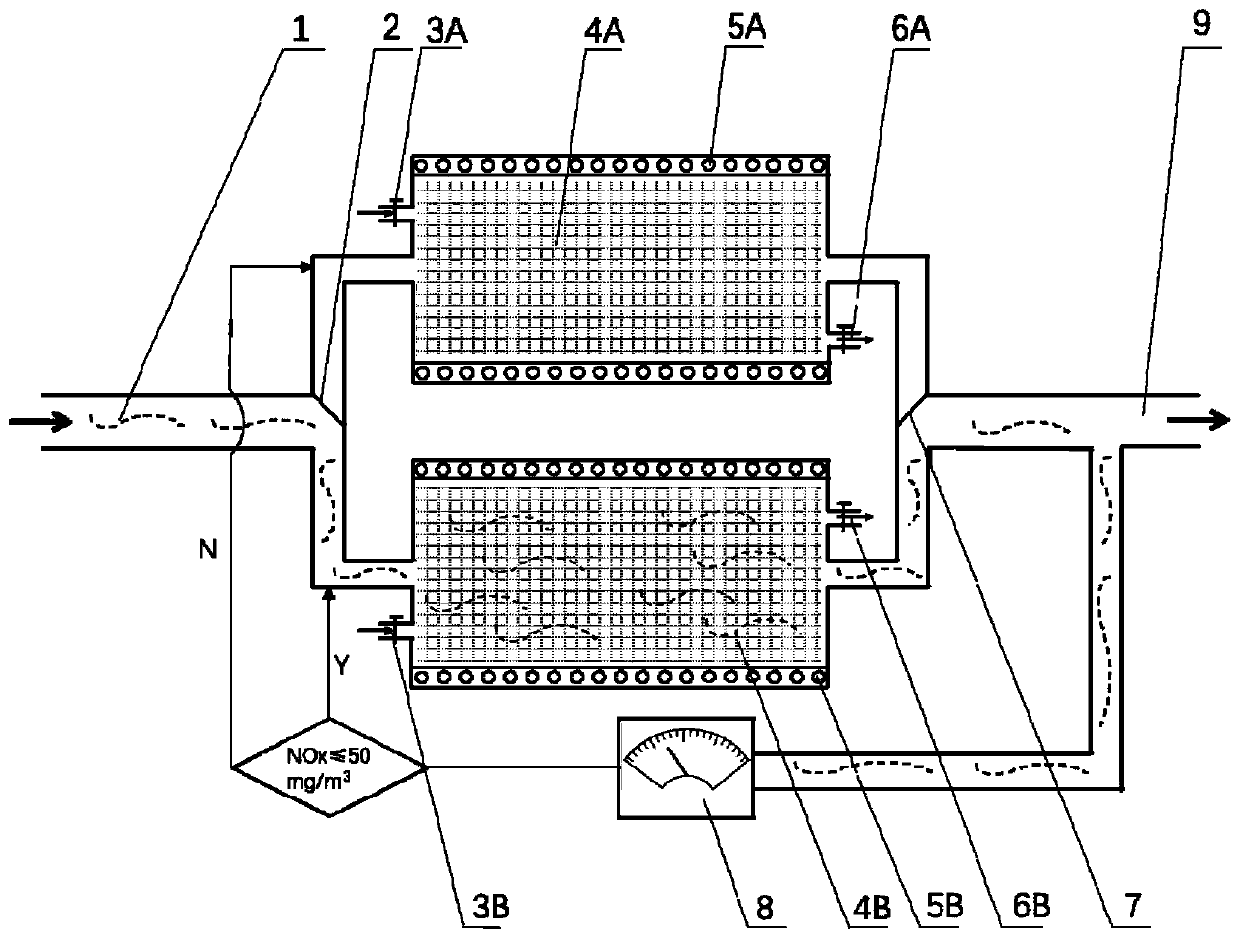

Online regeneration system of denitrification catalyst

InactiveCN109908972ARealize online regenerationReduce manufacturing costDispersed particle separationCatalyst regeneration/reactivationFlue gasRegenerative system

The invention relates to an online regeneration system of a denitrification catalyst, and belongs to the field of flue gas treatment. The online regeneration system of the denitrification catalyst comprises a flue gas inlet, a flue gas inlet three-way valve, a cleaning fluid and replenishing fluid inlet, a group A denitrification catalytic unit, a group B denitrification catalytic unit, a heatingelement, a pollutant outlet, a flue gas outlet three-way valve, a flue gas analyzer and a flue gas outlet. Flue gas enters the group A denitrification catalytic unit or the group B denitrification catalytic unit to be subjected to denitrification through the flue gas inlet three-way valve, and the flue gas subjected to the denitrification is monitored online through the flue gas analyzer. When theconcentration of NOx in the flue gas is greater than 50mg / m<3>, the flue gas inlet three-way valve and the flue gas outlet three-way valve are simultaneously switched, and the working states of the group A denitrification catalytic unit or the B group denitrification catalytic unit are switched, the denitrification catalytic unit which does not work is cleaned to remove salts and dust on the surface of the catalyst, and replenishing fluid is supplemented and heated and dried to remove water, and temperature rise is performed continuously to activate the denitrification catalyst; online regeneration of the denitrification catalyst is realized, the service life of the catalyst is prolonged and the operation cost of a denitrification device is lowered.

Owner:UNIV OF SCI & TECH BEIJING

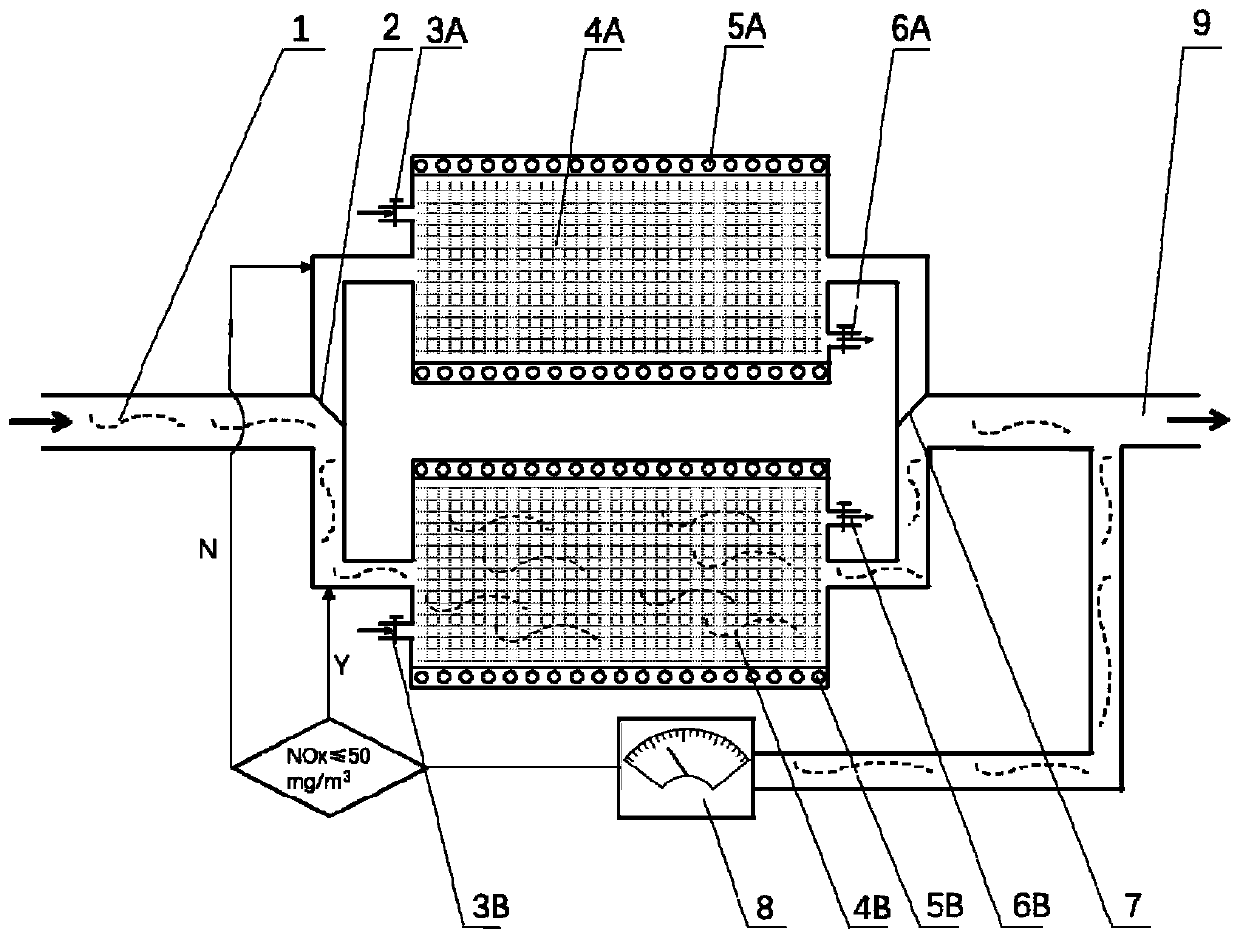

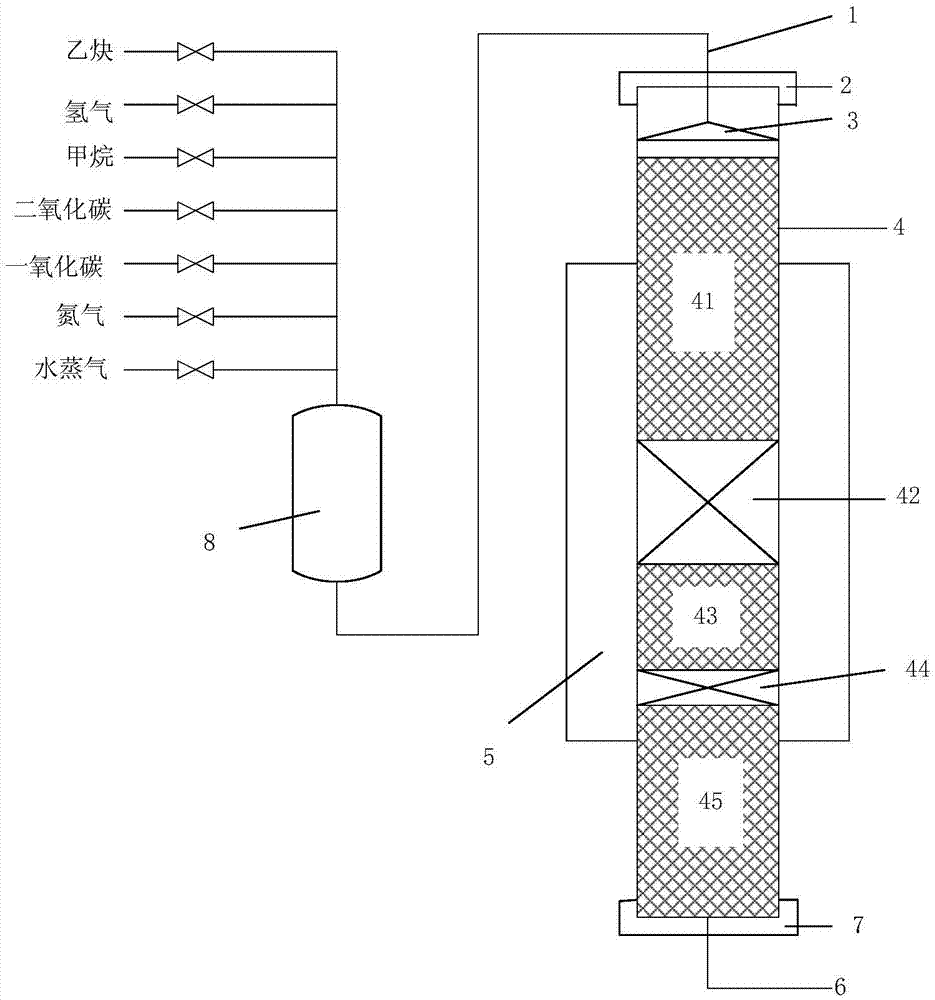

Apparatus and method for producing lightweight aromatic hydrocarbons from acetylene in order to realize reaction regeneration

PendingCN107213854ASolve the problem of carbon depositionRealize online regenerationLiquid hydrocarbon mixtures productionCatalystsHydrogenWater vapor

The present invention relates to a method and device for producing light aromatics from acetylene to realize reaction regeneration. The method includes a light aromatics production process and a catalyst regeneration process. The latter is carried out after the former is carried out continuously for a period of time, and the former is repeated after the latter is finished. , where the former includes passing the reaction gas into the reaction sleeve, passing through the preheating zone, thermal reaction zone, heat storage zone, catalytic reaction zone and cooling zone in sequence, the reaction gas is heated up to the thermal reaction temperature in the preheating zone, and then The thermal reaction occurs in the thermal reaction zone, and the product after the thermal reaction cools down to the catalytic reaction temperature in the heat storage zone, and the catalytic reaction takes place in the catalytic reaction zone to obtain light aromatics, which are cooled in the cooling zone; Nitrogen is introduced into the casing for purging, then water vapor is introduced to react with carbon deposition, and finally hydrogen is introduced to reduce the catalyst. The device implements the method described above. The invention solves the problem of carbon deposition in the acetylene reaction process, and realizes on-line regeneration without shutting down the device when there is too much carbon deposition.

Owner:BEIJING HUAFU ENG

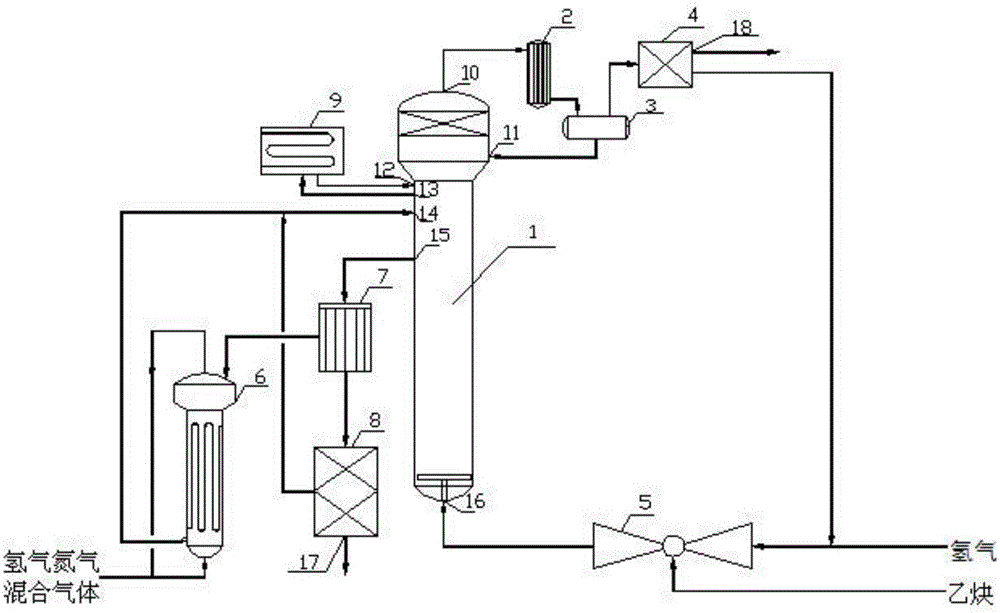

Reaction system and method for preparing ethylene through regeneration of super gravity solvent

InactiveCN105906468AAvoid fixationAvoid reactionHydrocarbon by hydrogenationDistillation purification/separationGas phaseHydrogenation reaction

The invention relates to a reaction system and method for preparing ethylene through regeneration of super gravity solvent. The system comprises a hydrogen and acetylene mixing equalizing unit, a hydrogen adding reaction unit, a deep cold separation unit, a vacuum filtering unit, a high-temperature steam and fluidized bed regenerating unit and a super gravity rectifying unit. The method includes the steps of mixing acetylene and hydrogen in an equalizing mode through the hydrogen and acetylene mixing equalizing unit, introducing mixed acetylene and hydrogen into the hydrogen adding reaction unit for reaction, conducting deep cold separation on gas-phase products obtained through acetylene and hydrogen reaction through the deep cold separation unit to obtain products, namely ethylene and abundant hydrogen, sending the abundant hydrogen into the hydrogen and acetylene mixing equalizing unit, leading out slurry in a slurry state bed, conducting separation through the vacuum filtering unit to obtain a solid-phase material and a liquid-phase material, processing the solid-phase material through the high-temperature steam and fluidizing bed regenerating unit to obtain a regeneration catalyst, and processing the liquid-phase material through the super gravity rectifying unit to recover solvent. The reaction system and method have the advantages of being large in operation elasticity and high in adaptability to catalyst.

Owner:霍尔果斯道科特环能科技有限公司

Method for preparing phenol acetone using moving bed reactor

ActiveCN105218304BRealize online regenerationRealize online replacementOxygen-containing compound preparationOrganic compound preparationGas phasePhenol

The invention relates to a method for preparing phenol-acetone by using a moving bed reactor, which mainly solves the problem of low selectivity between phenol and acetone in the prior art. The present invention adopts a method for preparing phenol-acetone using a moving bed reactor. The CHP raw material (6) enters the top of the moving bed reactor (1), contacts with a solid catalyst, undergoes a decomposition reaction and releases a large amount of heat, and evaporates the liquid-phase acetone. Be gaseous phase acetone (7) and discharge from moving bed reactor (1) top, the gaseous phase acetone (7) of discharge is condensed into liquid phase acetone in reactor top condenser (2) and return to moving bed reactor (1) Inside, the technical scheme that the reaction product (10) containing phenol and acetone is discharged from the bottom of the moving bed reactor (1) solves the above problems better, and can be used in the preparation of phenol acetone.

Owner:SINOPEC SHANGHAI ENG +1

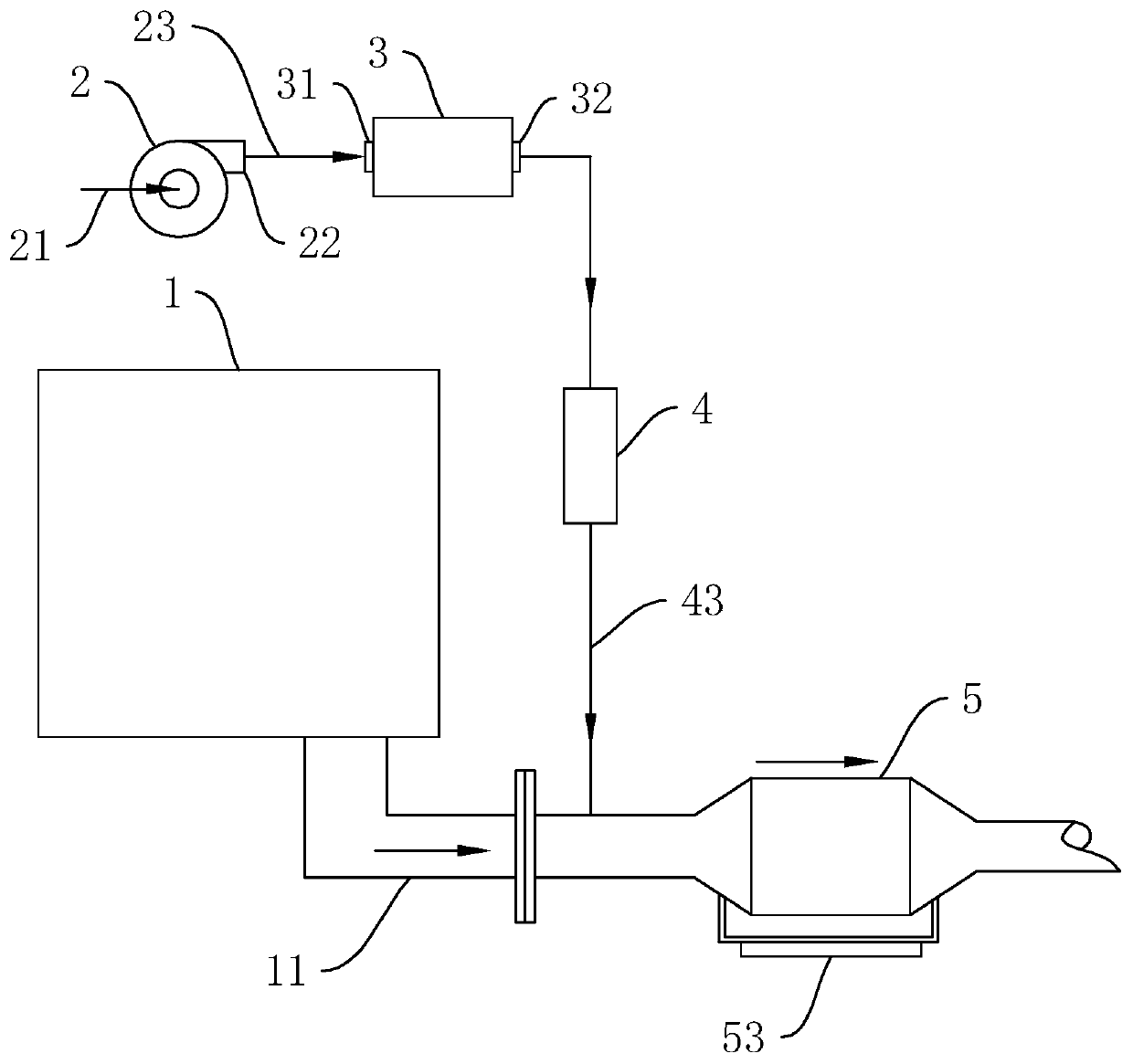

Low-temperature plasma regeneration DPF system

PendingCN109966809AHigh concentration of active ingredientsImprove oxidation efficiencyCombination devicesGas treatmentProduct gasFirst generation

The invention relates to a particle capturing system, and discloses a low-temperature plasma regeneration DPF system which comprises an air supply machine, a first air supply pipe, a first NTP generator, a DPF and an ultrasonic converter. The outlet of the air supply machine is connected with the inlet of a first NTP generator through the first air supply pipe. The ultrasonic converter is internally provided with a conversion channel and an ultrasonic generation module which generates and irradiates ultrasonic light to the conversion channel. The light generated by the ultrasonic generation module has the wavelength of 180-262 nm. The outlet of a first generation module is connected with the inlet of the conversion channel. A nozzle facing the downstream side is fixed to the inner wall ofa DPF upstream pipeline. The outlet of the conversion channel is communicated with the nozzle. NO is converted into NO2 in the ultrasonic conversion process with the sacrifice of O3, the concentrationof NO2 is increased, the amount of PM capable of being degraded by converted gas flow under the unit volume is increased, the regeneration efficiency of the DPF under the same flow velocity of the converted gas is improved, and the regeneration efficiency of the system is improved.

Owner:NINGBO UNIV

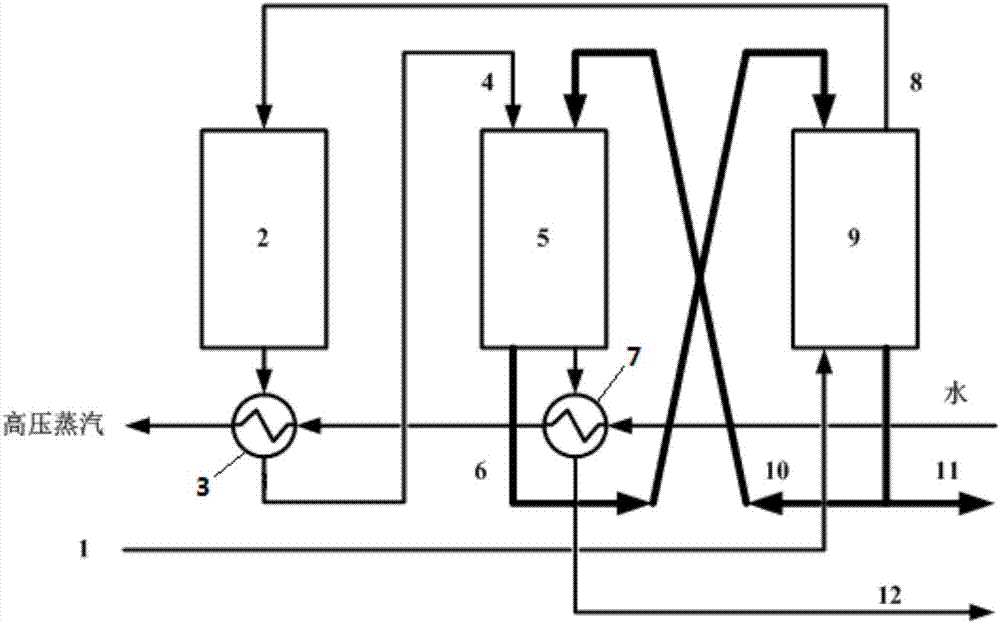

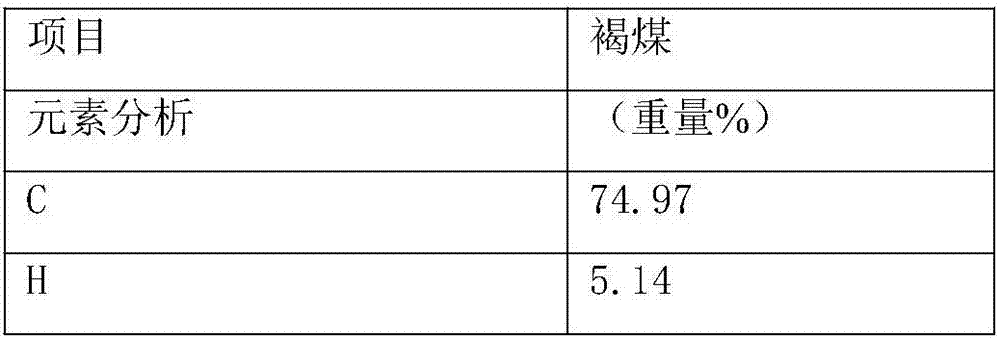

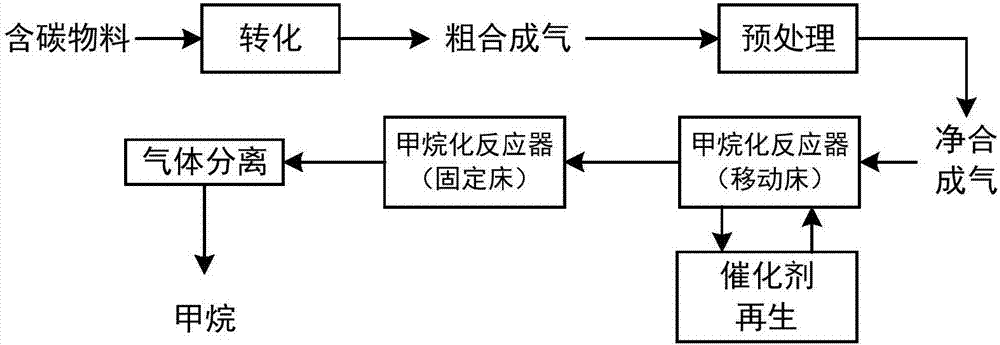

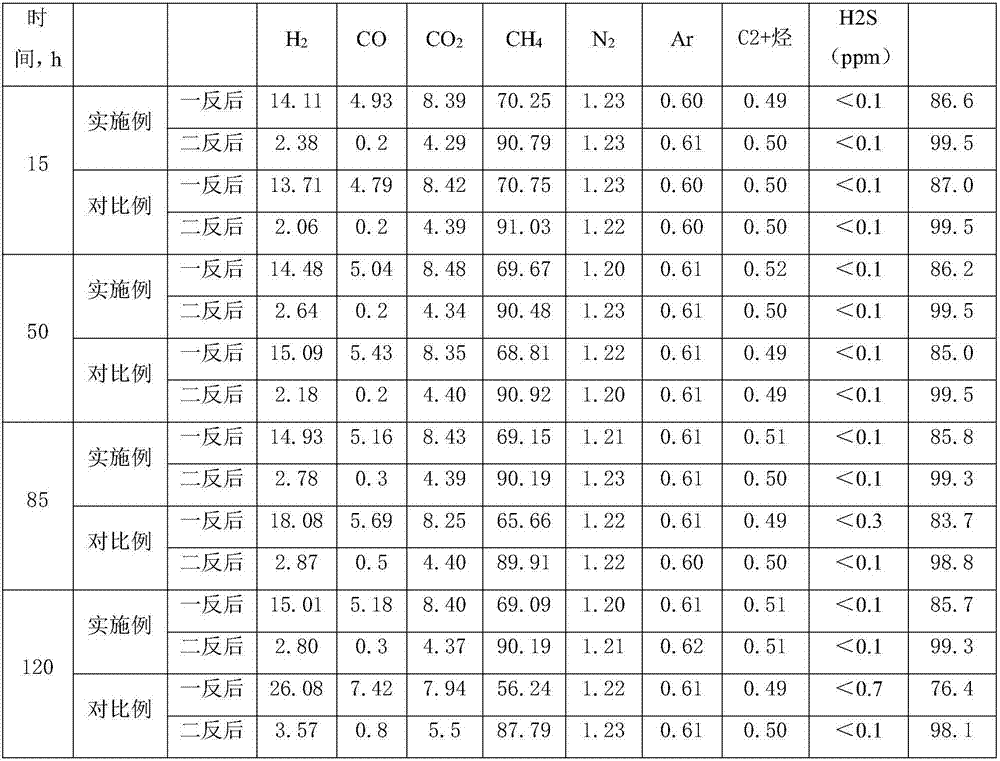

Method for preparing methane-rich gas from synthesis gas

ActiveCN107987907AReduced single-shot service life requirementsEfficient recyclingGaseous fuelsChemical/physical processesHeat carrierMethanation

The invention provides a method for preparing methane-rich gas from synthesis gas. The method comprises steps as follows: purified synthesis gas and a first methanation catalyst are subjected to contact reaction in a first methanation reactor, and methanated feed gas is obtained; the methanated feed gas and a second methanation catalyst are subjected to the contact reaction in a second methanationreactor, and gas material flow I is obtained; the first methanation catalyst is led out from the first methanation reactor and divided into three parts; the gas material flow I is subjected to the contact reaction with a third-part catalyst and / or a regenerated first methanation catalyst in a third methanation reactor, and a methane-rich gas product is obtained. The methanation catalysts undertake the function of a heat carrier in a moving bed and can be regenerated and recycled online, and reaction heat is effectively recycled.

Owner:PETROCHINA CO LTD

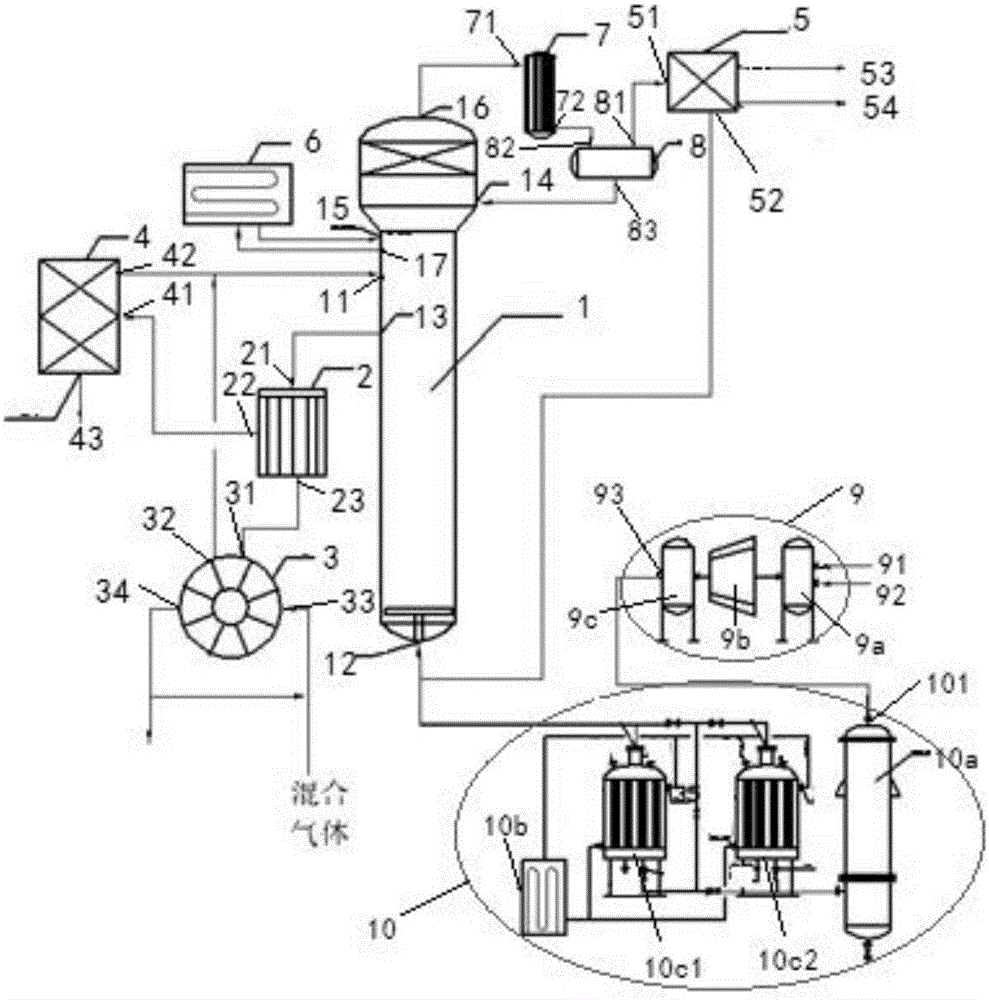

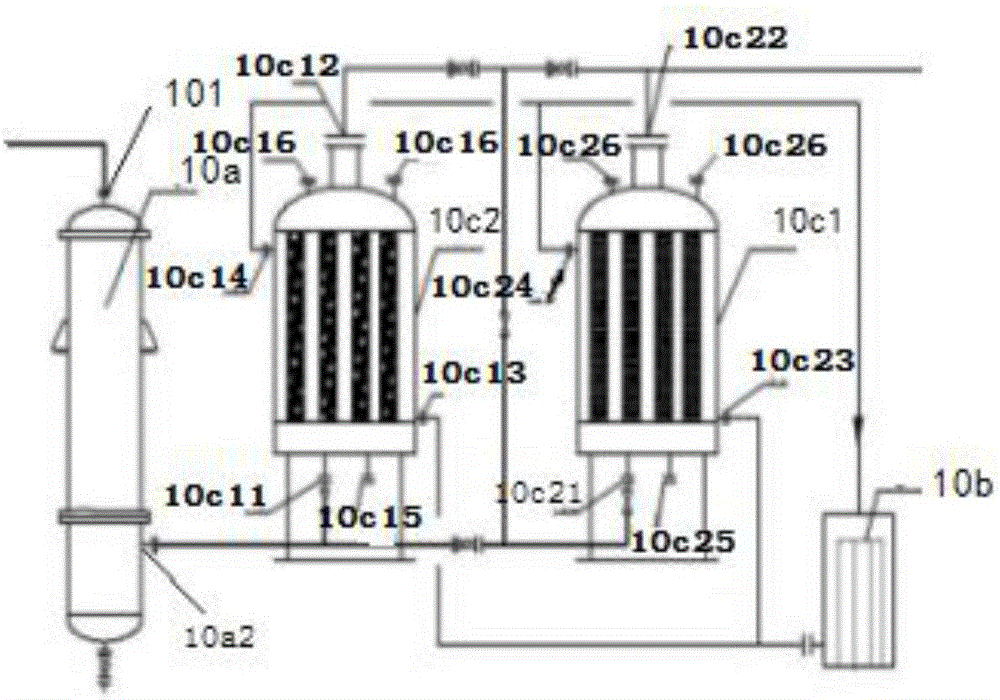

Reaction system and method for preparing ethylene through hydrogenation of acetylene

InactiveCN105859499AAdaptableGreat operating flexibilityHydrocarbon by hydrogenationChemical recyclingSlurry reactorDistillation

The invention relates to a reaction system and method for preparing ethylene through hydrogenation of acetylene. The system comprises a hydrogen and acetylene mixing and pressure equalizing unit, a hydrogenation reaction unit, a cryogenic separation unit, a vacuum filtering unit, a revolving bed regeneration unit and a vacuum low-pressure distillation unit. The method comprises the steps that acetylene and hydrogen are mixed in a pressure equalizing mode through the hydrogen and acetylene mixing and pressure equalizing unit; mixed acetylene and hydrogen are introduced into the hydrogenation reaction unit for a reaction; a gas-phase product generated in the hydrogen and acetylene reaction is subjected to cryogenic separation through the cryogenic separation unit, the product ethylene and excessive hydrogen are obtained, and excessive hydrogen is fed into the hydrogen and acetylene mixing and pressure equalizing unit; slurry in a slurry reactor is led out and separated through the vacuum filtering unit, and a solid phase material and a liquid phase material are obtained; the solid phase material is treated through the revolving bed regeneration unit, and a generation catalyst is obtained; the liquid phase material is treated through the vacuum low-pressure distillation unit for solvent recycling. The reaction system and method for preparing ethylene through hydrogenation of acetylene have the advantages that operation flexibility is high, and the adaptability to the catalyst is high.

Owner:霍尔果斯道科特环能科技有限公司

Reaction system and method for producing ethylene through catalyst regeneration

InactiveCN105859498AAdaptableGreat operating flexibilityHydrocarbon by hydrogenationCatalyst regeneration/reactivationGas phaseFiltration

The invention relates to a reaction system and method for producing ethylene through catalyst regeneration. The system comprises a hydrogen-ethyne mixing and pressure-equalizing unit, a hydrogenation reaction unit, a cryogenic separation unit, a vacuum filtration unit, a fluidized bed regeneration unit and a membrane separation unit. The method comprises the steps of conducting pressure-equalizing and mixing on ethyne and hydrogen through the hydrogen-ethyne mixing and pressure-equalizing unit; introducing the mixed ethyne and hydrogen into the hydrogenation reaction unit for a reaction; conducting cryogenic separation on a gaseous product obtained after the ethyne-hydrogen reaction through the cryogenic separation unit, so that products ethylene and surplus hydrogen are obtained, and sending the surplus hydrogen into the hydrogen-ethyne mixing and pressure-equalizing unit; guiding slurry in a slurry bed out, and conducing separation through the vacuum filtering unit, so that a solid phase material and a liquid phase material are obtained; treating the solid phase material through the fluidized bed regeneration unit, so that a regenerated catalyst is obtained; treating the liquid phase material through the membrane separation unit, and recycling solvent. The reaction system and method have the advantages of being high in operation flexibility and great in catalyst adaptive capacity.

Owner:霍尔果斯道科特环能科技有限公司

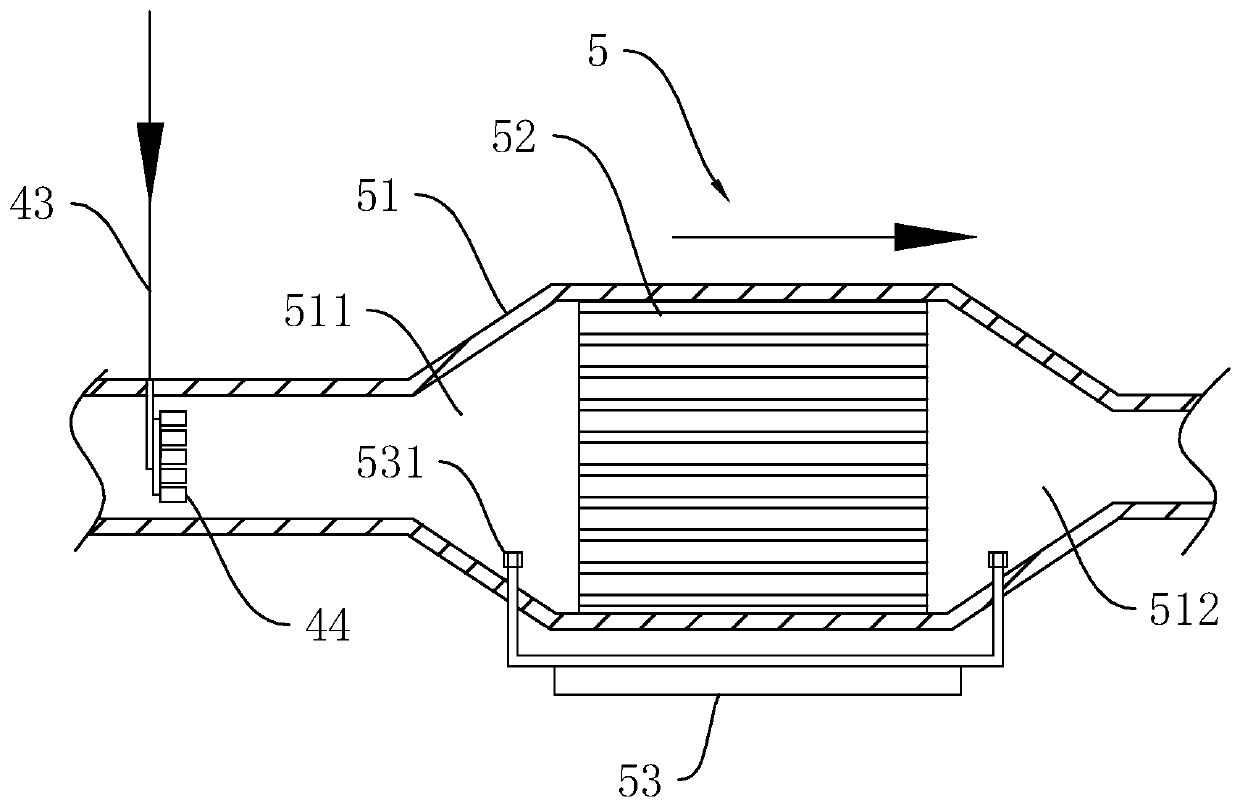

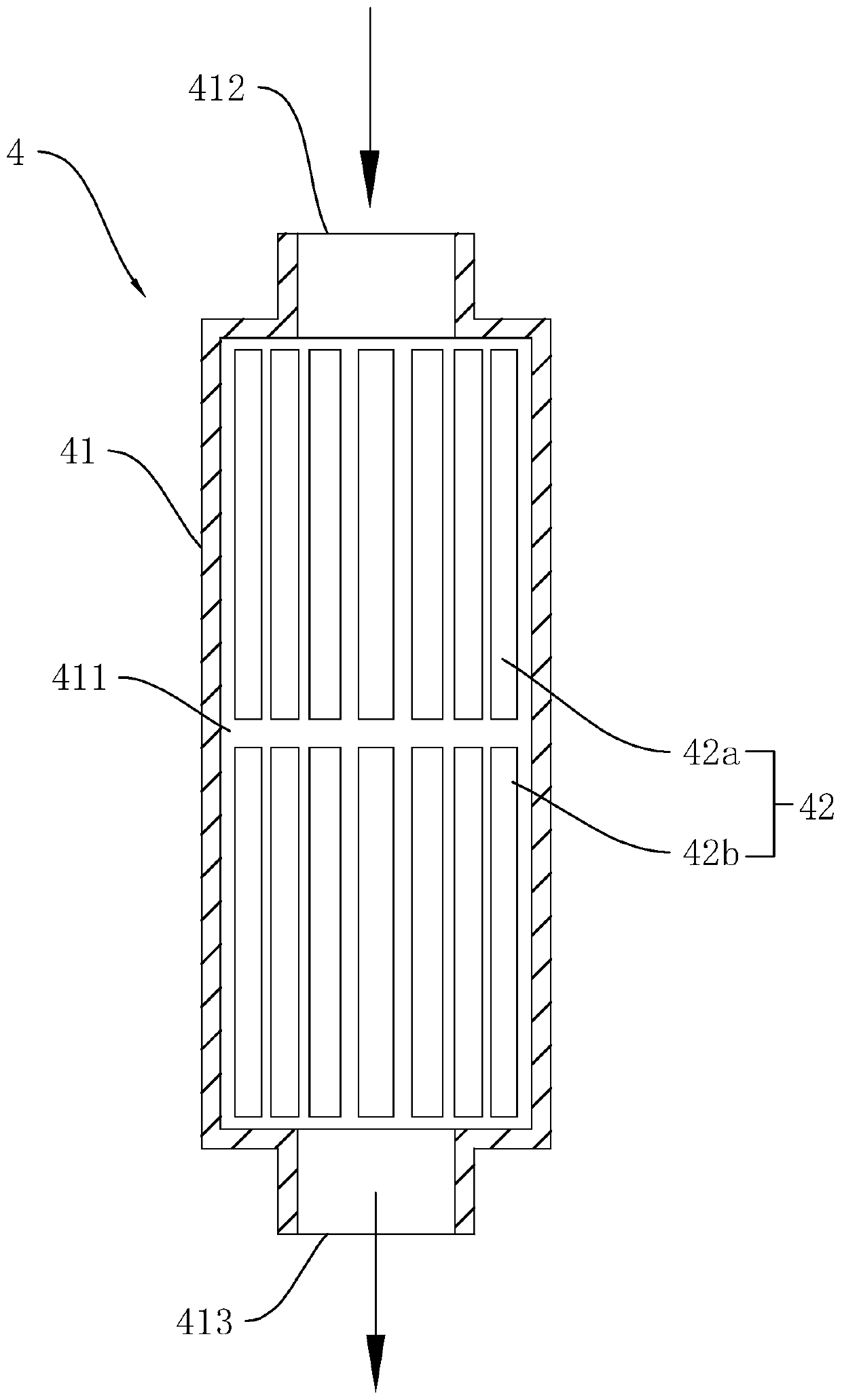

Ship off-gas treatment system and method with on-line regeneration and off-line ash removal

PendingCN111852618ARealize online regenerationRealize the purpose of off-line cleaningExhaust apparatusSilencing apparatusParticulatesPtru catalyst

The invention relates to a ship off-gas treatment system with on-line regeneration and off-line ash removal. The ship off-gas treatment system comprises an inlet valve, a throttle valve, a combustiblegas and particulate matter treatment combined device, an outlet valve, a reducing agent metering and injection device, an SCR device, a compressed air valve and a filter; the inlet valve and the outlet valve are correspondingly arranged on an inlet main pipe and an outlet main pipe of the combustible gas and particulate matter treatment combined device; and the combustible gas and particulate matter treatment combined device is composed of a plurality of combined device units, an electric heater, a DOC catalyst and a DPF catalyst are sequentially installed on each combined device unit from bottom to top, a differential pressure transmitter is installed on each combined device unit body, and a temperature switch is installed at an outlet of each combined device unit. The ship off-gas treatment system has the beneficial effects that through the combustible gas and particulate matter treatment combine device, the compressed air valve and a particulate matter filter, the purposes of on-line regeneration and off-line ash removal are achieved, the gaseous and solid pollutants in the off-gas are removed, the energy consumption is low, and the regeneration is convenient.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

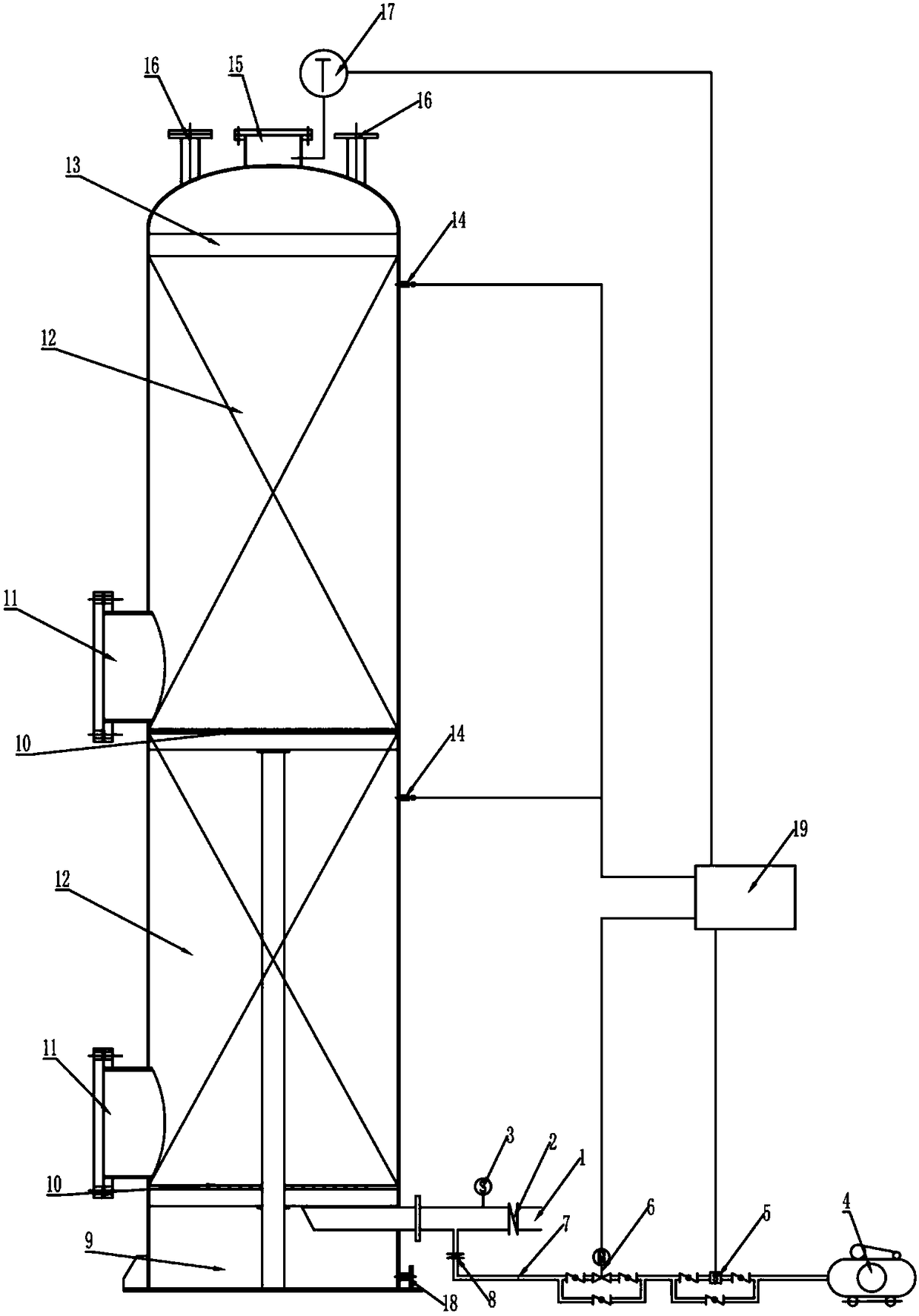

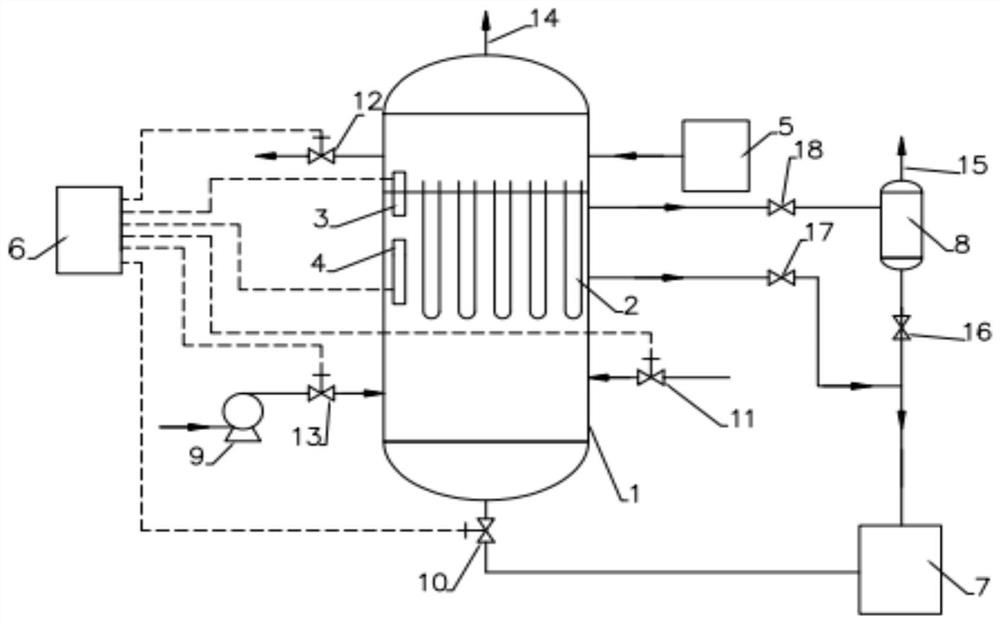

Filter automatic backwashing equipment and backwashing method thereof

PendingCN111632425AShort rinse timeEasy to operateFiltration separationProcess engineeringCoal chemical industry

The invention relates to the field of manufacturing of filtering equipment in coal chemical industry, and discloses a filter automatic backwashing equipment and a backwashing method thereof. The equipment comprises a filter body (1) with a filter element (2), the filter body is respectively connected with a pulse gas generator (5) and a backwashing pump (9), and the pulse gas generator inputs pulse gas into the filter body and forms pulse vortexes in the filter body; the backwashing pump is used for pumping the filtrate into the filter body to form backwashing liquid and soaking the filter element in the backwashing liquid for backwashing; and the filter body is provided with an output pipeline for discharging a gas-liquid mixture of the pulse gas and the backwashing liquid. According to the invention, under the condition that the top end cover of the filter is not disassembled and the filter element does not need to be taken out, the filtrate is directly used as the backwashing liquidto backwash the filter element in the filter body so that online regeneration of the filter system is realized; flushing time is short, operation is easy, cleaning is thorough, the service life of the filter element is prolonged, and equipment operation cost is reduced.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

Device for online vacuum drying and regeneration of activated carbon of retention bed of nuclear power unit

PendingCN112755987AImprove adsorption capacityDesign optimization referenceOther chemical processesCombustible gas purificationActivated carbonNuclear power

The invention belongs to a nuclear power station waste gas treatment technology, and particularly relates to a device for online vacuum drying and regeneration of activated carbon of a retention bed of a nuclear power unit. The device comprises a compressed air source for introducing compressed air, an electric heater for heating an output pipeline of the compressed air source, and a test retention bed, a refrigerated air dryer, a vacuum pump and an emptying retention bed which are sequentially connected with the heated output pipeline through valves. Under the condition that the retention bed activated carbon is not discharged, the adsorption performance of the activated carbon can be improved through an online vacuum drying regeneration technology and a zero emission mode, a new mode can be provided for retention bed activated carbon treatment, and an optimization reference is provided for subsequent design and operation of a nuclear power unit inert gas retention system.

Owner:JIANGSU NUCLEAR POWER CORP +1

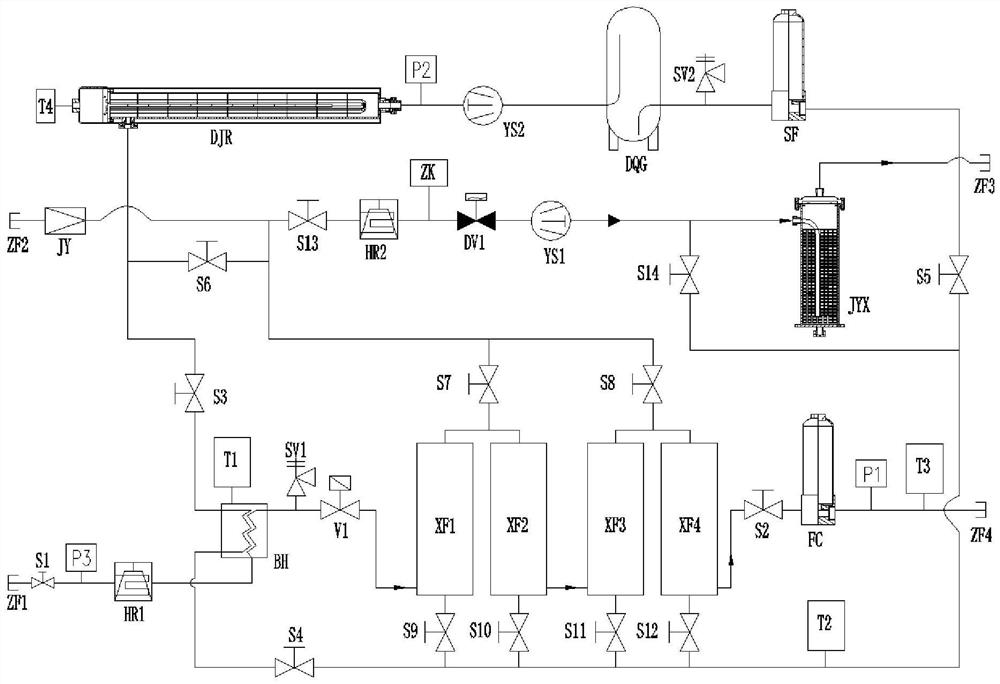

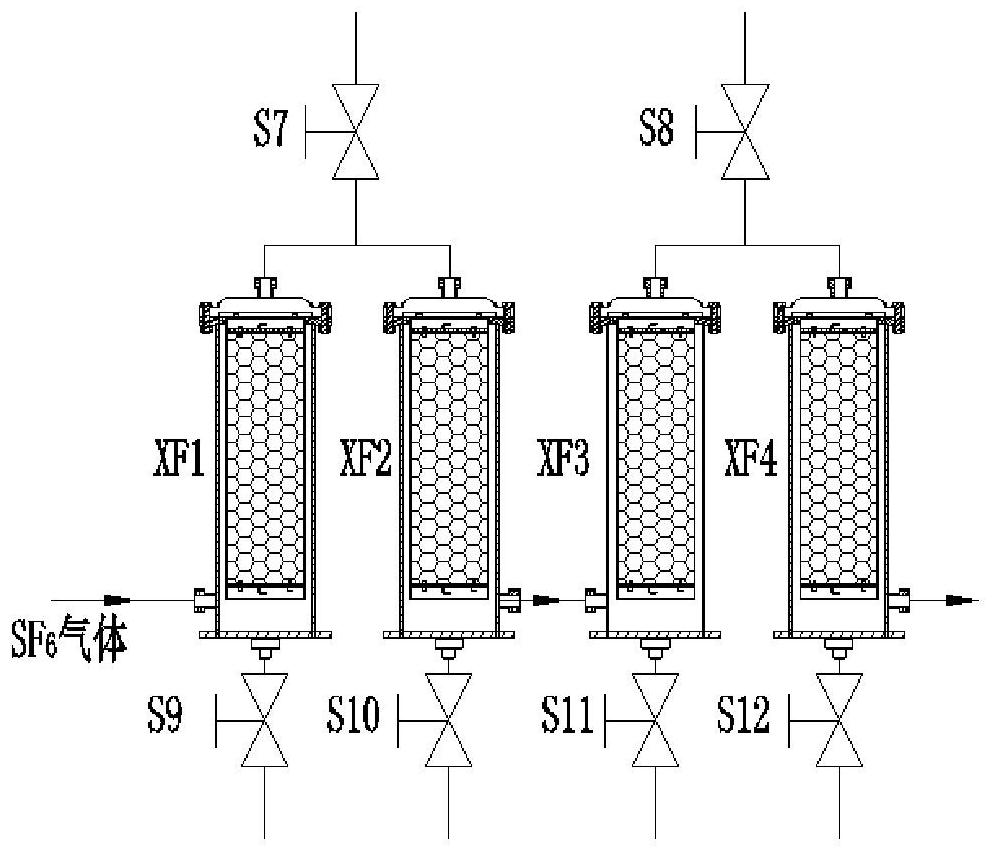

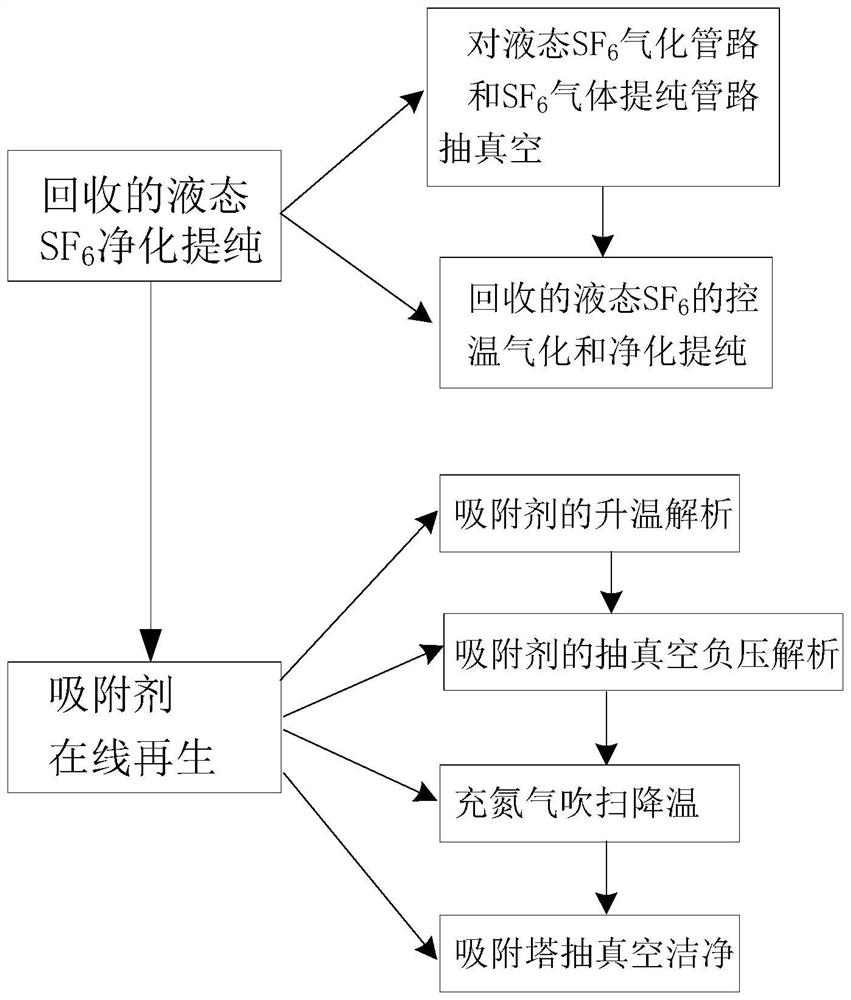

Method for recycling liquid SF6 purification device

PendingCN114849414AImprove the efficiency of purification and purification operationsRealize online regenerationProductsGas treatmentPlate heat exchangerLiquid state

The invention discloses a method of a liquid SF6 purification device for recovery, belongs to the technical field of SF6 purification treatment, and solves the problem that the existing device cannot ensure complete gasification of liquid SF6. The input end of the first air heat exchanger is connected with the first manual ball valve, the output end of the first air heat exchanger is connected with the first input end of the plate heat exchanger, the first output end of the plate heat exchanger is connected with one end of the first electric ball valve, and the other end of the first electric ball valve is connected with the input end of the multi-stage adsorption tower. The output end of the multi-stage adsorption tower is connected with one end of a second manual ball valve, the other end of the second manual ball valve is connected with the input end of a dust filter, the output end of the dust filter is connected with a fourth self-sealing connector, and a nitrogen circulation heating pipeline is connected between the second input end and the second output end of the plate heat exchanger. The first safety valve is mounted between the plate heat exchanger and the first electric ball valve; and liquid SF6 is completely gasified after being heated twice by the first air heat exchanger and the plate heat exchanger, so that the purification efficiency is greatly improved.

Owner:ANHUI XINLT POWER TECH CONSULTING

Method for producing methane

InactiveCN107987906AShorten the time periodReduce development difficultyGaseous fuelsMethanationMoving bed

The invention provides a method for producing methane. The method comprises steps as follows: methanation feed gas and a high-temperature methanation catalyst are subjected to a contacting reaction ina moving bed methanation reactor, and a gas flow I containing rich methane and the high-temperature methanation catalyst with reduced catalytic activity are obtained; the gas flow I and the methanation catalyst are subjected to a contacting reaction in a fixed bed methanation reactor, and a gas flow II containing rich methane is obtained; the high-temperature methanation catalyst with reduced catalytic activity is divided into three parts, the first part of the catalyst is sent into a regeneration reactor for regeneration treatment, and the regenerated high-temperature methanation catalyst issent into the moving bed methanation reactor to be recycled; the second part of the catalyst is discharged out of a reaction system as a waste catalyst; the third part of the catalyst is directly send into the moving bed methanation reactor to be recycled. The strict requirements for raw gas pretreatment procedures are effectively reduced, the pressure drop of the reactor is reduced, and energy consumption required for gas circulation is reduced.

Owner:PETROCHINA CO LTD

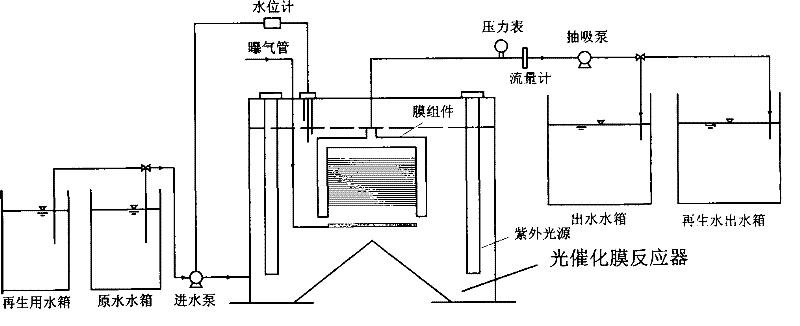

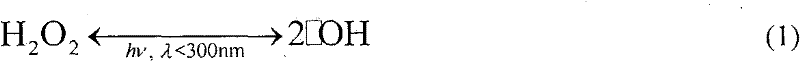

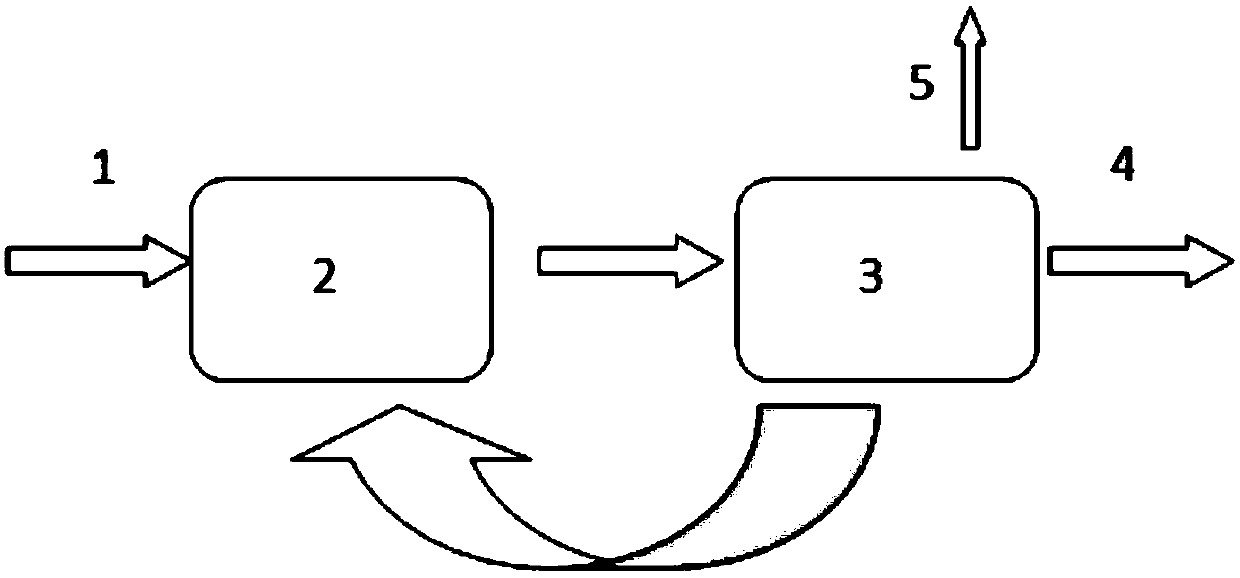

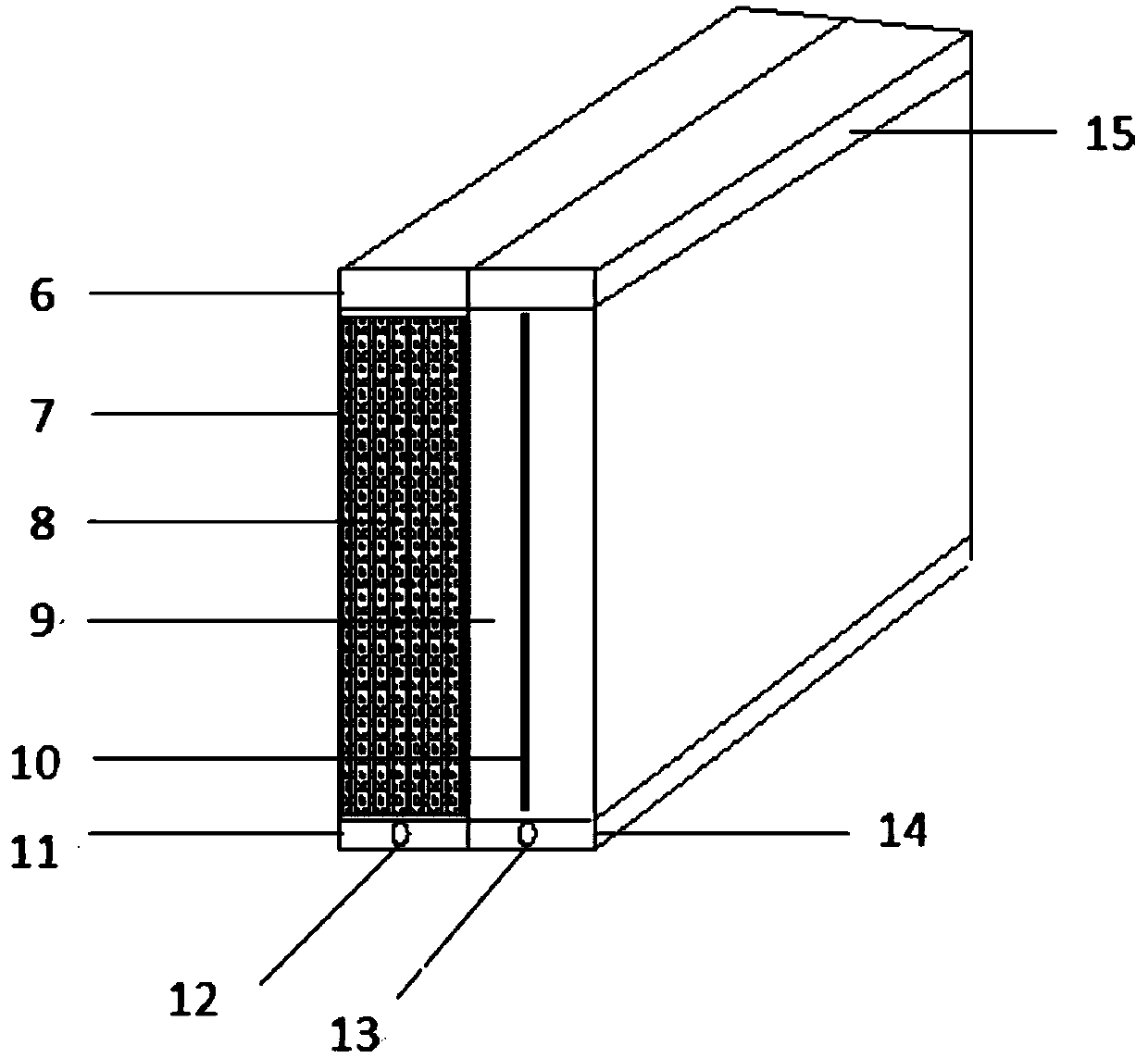

On-line regeneration method of spent photocatalyst

InactiveCN101579645BAchieve regenerationRealize online regenerationCatalyst regeneration/reactivationNatural organic matterPhotocatalytic reaction

The invention discloses an on-line regeneration method of spent TiO2 powder photocatalyst after degradation of natural organic matter, relating to a regeneration method of spent photocatalyst. The invention solves the problems that the existing regeneration method of spent suspending type TiO2 photocatalyst has complicated technique, and photocatalyst needs to be extracted from a photocatalytic reactor. The regeneration method of the invention comprises the steps: 1. after photocatalyst loses effectiveness in the process of using photocatalytic membrane combined technique, stopping feeding raw water, discharging parts of solution in a photocatalytic membrane reactor by using a membrane module; the photocatalyst being TiO2 powder; 2. feeding regeneration liquid into the photocatalytic membrane reactor to remove substance absorbed on the surface of photocatalyst, the regeneration liquid being H2O2 solution, and the concentration of the H2O2 solution being 0.05mM; 3. controlling the intensity of ultraviolet light source 0.1-20mW / cm<2> so as to perform ultra-vioket radiation regeneration. The invention has high regeneration efficiency, does not need to extract photocatalyst from a photocatalytic reactor, can realize on-line regeneration of photocatalyst and has simple operation.

Owner:HARBIN INST OF TECH

An exhaust gas denitrification device and method

ActiveCN105854527BImprove removal effectFast regenerationNitrous oxide captureGas treatmentEngineeringNitrogen gas

The invention discloses a waste-gas denitration device. The waste-gas denitration device comprises a waste-gas absorption device and a waste-gas removing device. The waste-gas absorption device is a spraying tower or a bubble tower. The waste-gas removing device is an electrochemistry device which is of an integrated structure, and comprises negative poles, positive poles and a reaction channel; the negative poles are negative-pole three-dimensional electrodes, and the negative poles and the positive poles are arranged in scroll shapes; a water inlet channel is formed in one side of the electrochemistry device, a water outlet channel is formed in the other corresponding side of the electrochemistry device, a gas exhausting hole is formed in the upper portion of the electrochemistry device, electric fields are externally added on the negative poles and the positive poles, absorption liquid in the electrochemistry device is regenerated, and meanwhile nitrogen oxide in waste gas is reduced nitrogen. According to the waste-gas denitration device, nitrogen oxide in the waste gas is absorbed and removed through the absorption liquid, the absorption liquid can be efficiently regenerated, and is continuously cycled in a waste-gas denitration system, and the stable and efficient effect on removing NO in the waste gas is achieved; the high temperature, the mild reaction condition and the like are not required, cost is saved, the storage volume of the absorption liquid is reduced, the device space is saved, and zero pollution to the environment is achieved.

Owner:QINGDAO HEADWAY TECH

A reaction system and method for producing ethylene by hydrogenation of acetylene

InactiveCN105859499BAdaptableGreat operating flexibilityHydrocarbon by hydrogenationChemical recyclingSlurry reactorDistillation

The invention relates to a reaction system and method for preparing ethylene through hydrogenation of acetylene. The system comprises a hydrogen and acetylene mixing and pressure equalizing unit, a hydrogenation reaction unit, a cryogenic separation unit, a vacuum filtering unit, a revolving bed regeneration unit and a vacuum low-pressure distillation unit. The method comprises the steps that acetylene and hydrogen are mixed in a pressure equalizing mode through the hydrogen and acetylene mixing and pressure equalizing unit; mixed acetylene and hydrogen are introduced into the hydrogenation reaction unit for a reaction; a gas-phase product generated in the hydrogen and acetylene reaction is subjected to cryogenic separation through the cryogenic separation unit, the product ethylene and excessive hydrogen are obtained, and excessive hydrogen is fed into the hydrogen and acetylene mixing and pressure equalizing unit; slurry in a slurry reactor is led out and separated through the vacuum filtering unit, and a solid phase material and a liquid phase material are obtained; the solid phase material is treated through the revolving bed regeneration unit, and a generation catalyst is obtained; the liquid phase material is treated through the vacuum low-pressure distillation unit for solvent recycling. The reaction system and method for preparing ethylene through hydrogenation of acetylene have the advantages that operation flexibility is high, and the adaptability to the catalyst is high.

Owner:霍尔果斯道科特环能科技有限公司

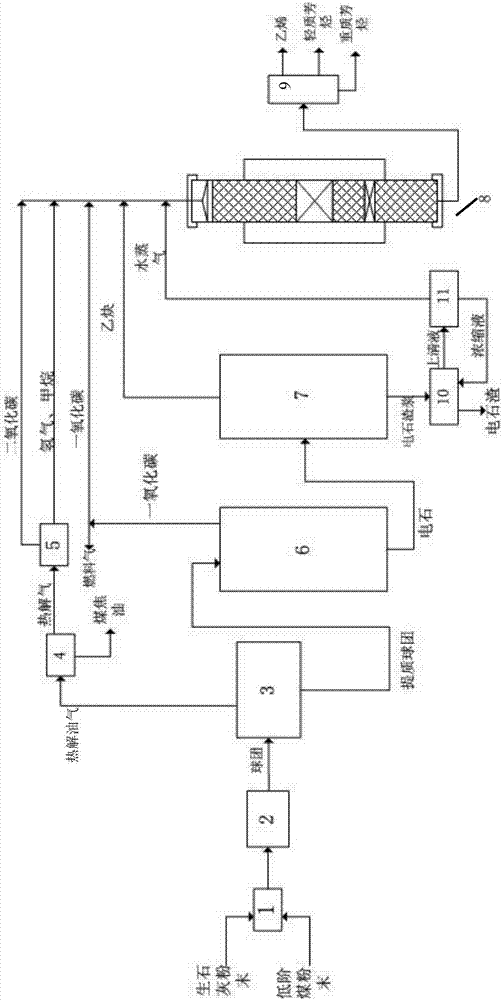

System used for producing lightweight aromatic hydrocarbons from low grade coal and having water recovering system, and method thereof

PendingCN107216895ASolve the problem of production constraintsClean and efficient useAcetylene gas generator detailsCalcium carbideEngineeringPetroleum

The invention relates to a system for producing light aromatics from low-rank coal. The system includes a mixer, a briquetting machine, a rotary bed pyrolysis device, a calcium carbide furnace, an acetylene generator, an oil-gas separator, a purification device, and a reaction for producing aromatics from acetylene devices, separation systems, natural settlers, evaporative concentrators and mixing tanks. The invention also relates to a method of producing light aromatics using the system. The invention prepares aromatics from coal, solves the problem of limited output of aromatics due to limited petroleum resources, and realizes the conversion process from low-value low-rank coal to high value-added aromatics.

Owner:BEIJING HUAFU ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com