Method for recycling liquid SF6 purification device

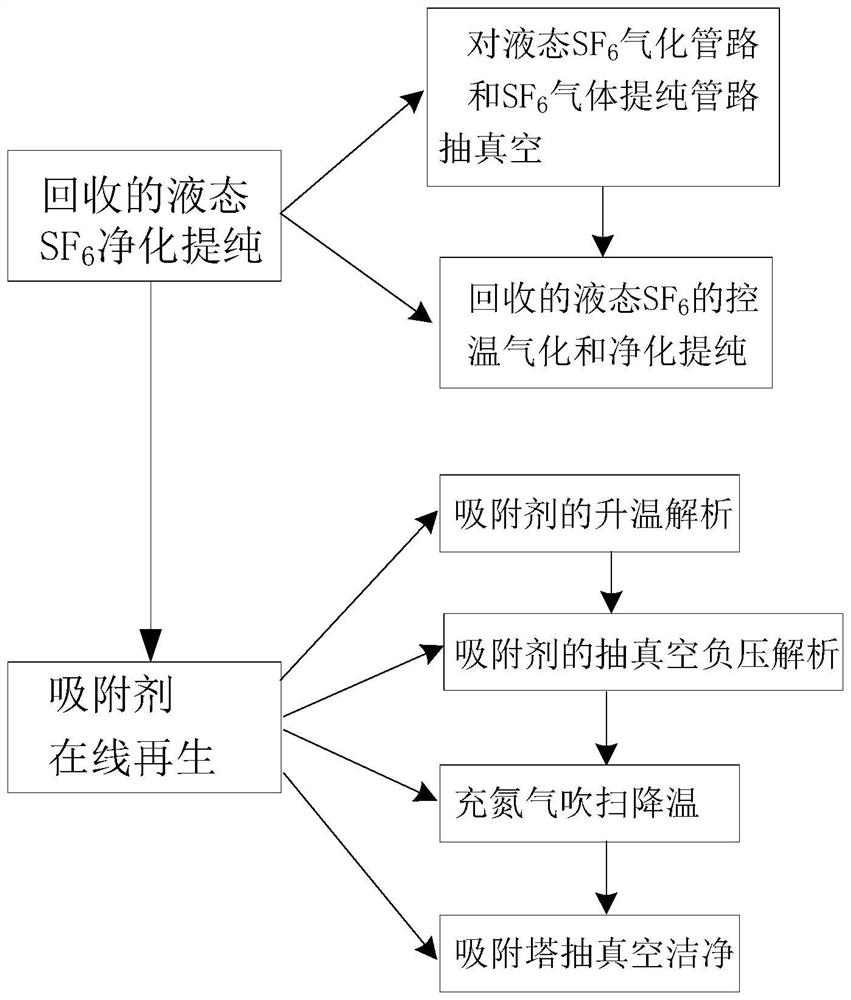

A purification device and SF6 technology, applied in the field of SF6 purification treatment in substations, can solve the problems of low purification and purification efficiency, can not guarantee the complete gasification of liquid SF6, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

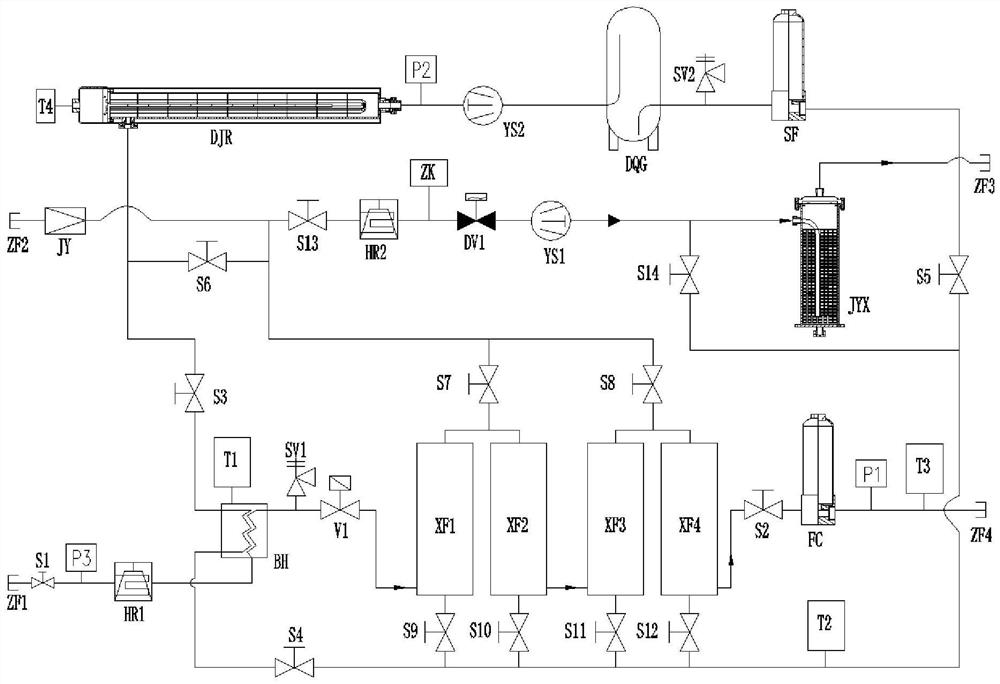

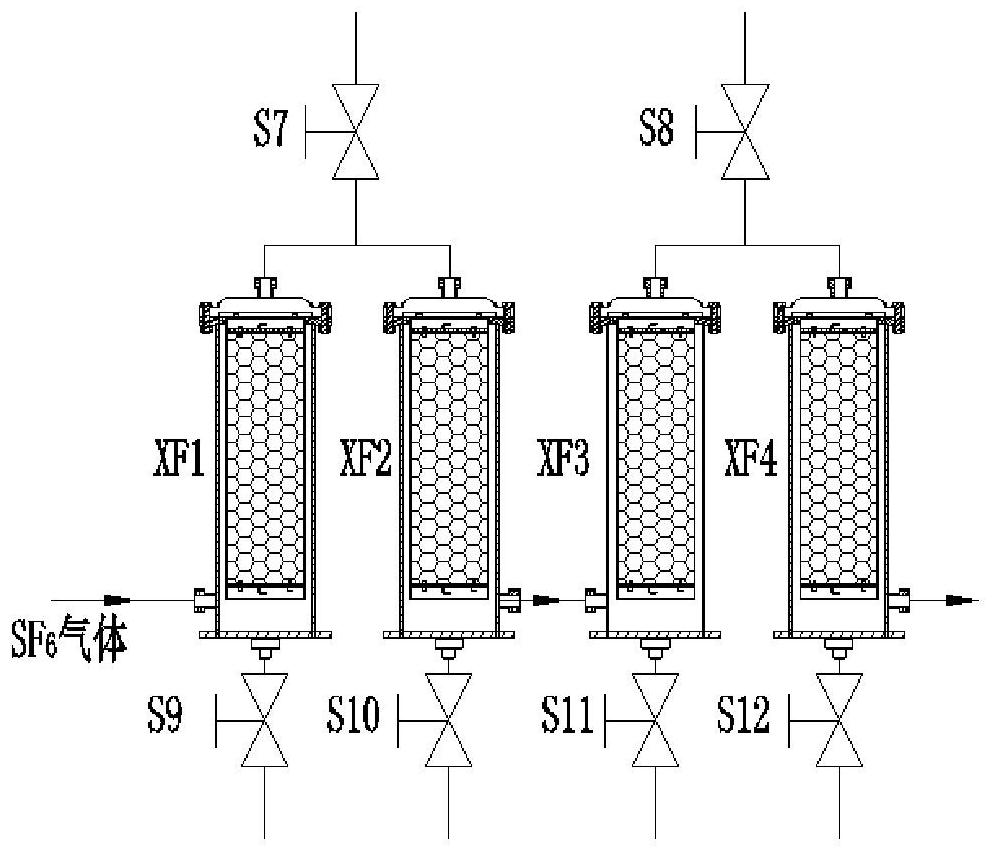

[0031] like figure 1 shown, a recovered liquid SF 6 The purification device includes: the first self-sealing interface ZF1, the first manual ball valve S1, the third pressure sensor P3, the first air heat exchanger HR1, the plate heat exchanger BH, the first safety valve SV1, the first electric ball valve V1; the first Adsorption tower XF1, second adsorption tower XF2, third adsorption tower XF3, fourth adsorption tower XF4, seventh manual ball valve S7, eighth manual ball valve S8, ninth manual ball valve S9, tenth manual ball valve S10, eleventh manual ball valve Ball valve S11, the twelfth manual ball valve S12, the second manual ball valve S2, the dust filter FC, the first pressure sensor P1, the first temperature sensor T1, the third temperature sensor T3, the fourth self-sealing interface ZF4; the thirteenth Manual ball valve S13, second air heat exchanger HR2, vacuum gauge ZK, solenoid valve DV1, vacuum compressor YS1; lye tank JYX, third self-sealing interface ZF3, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com